Patents

Literature

63results about How to "Constant diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

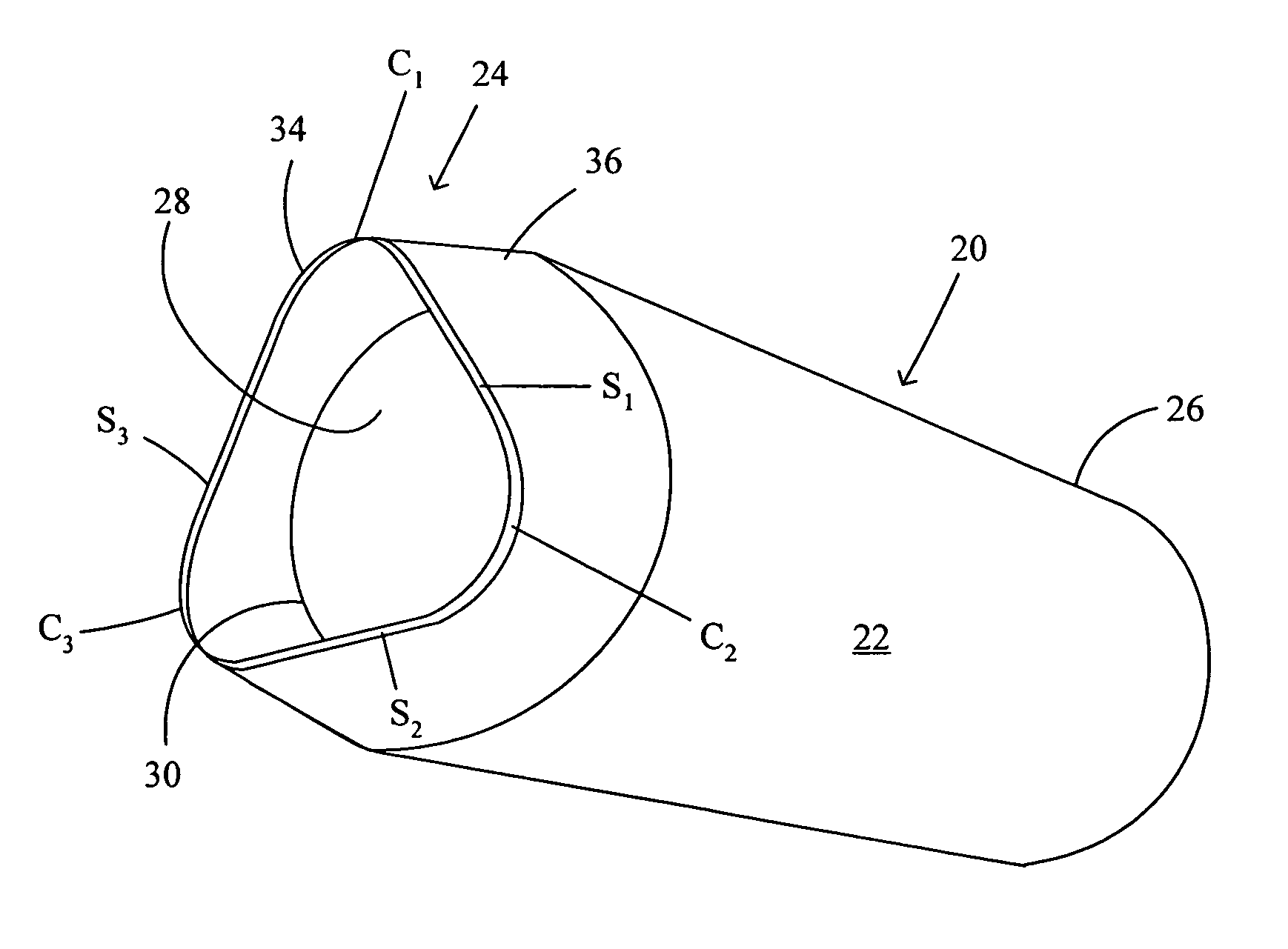

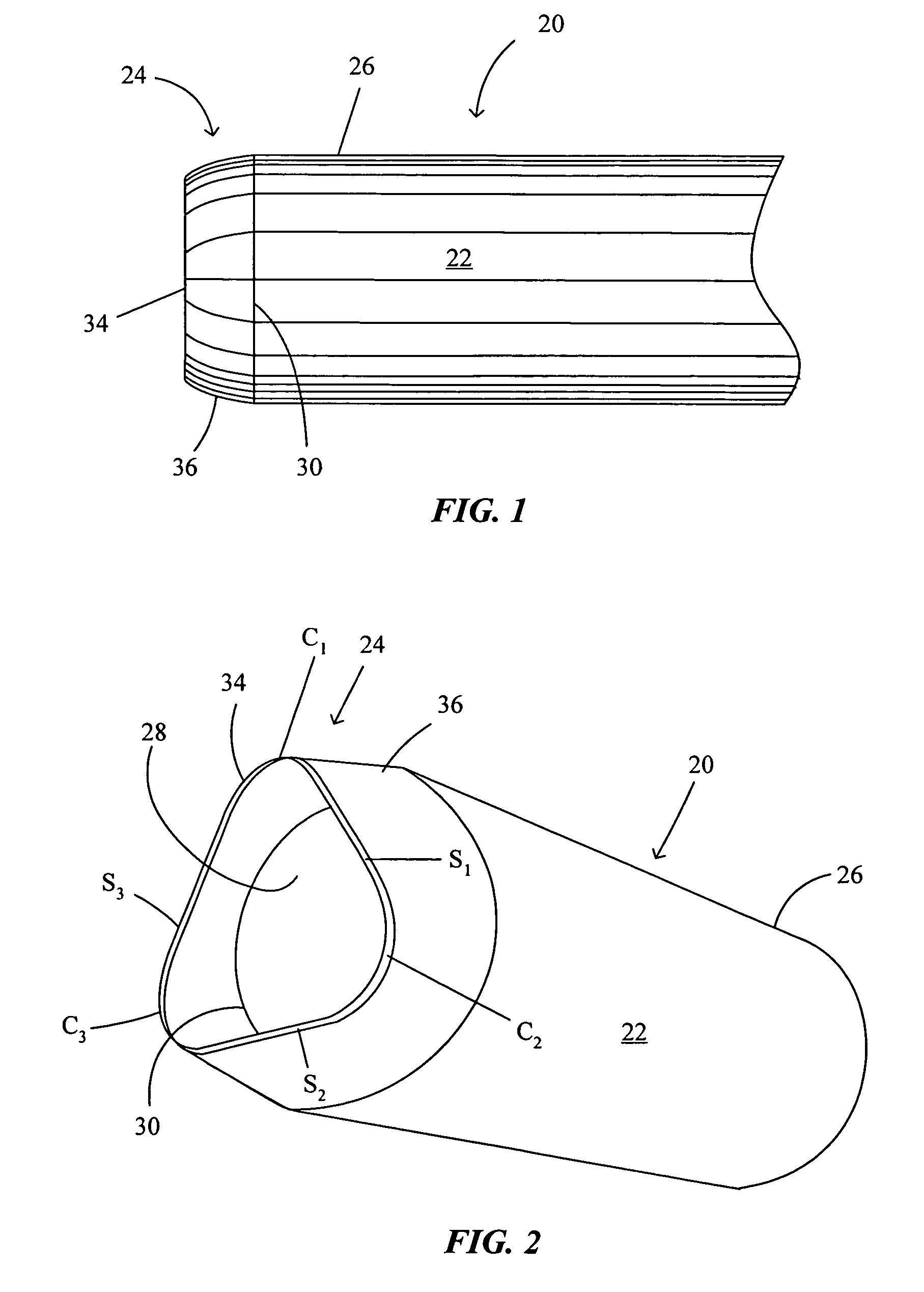

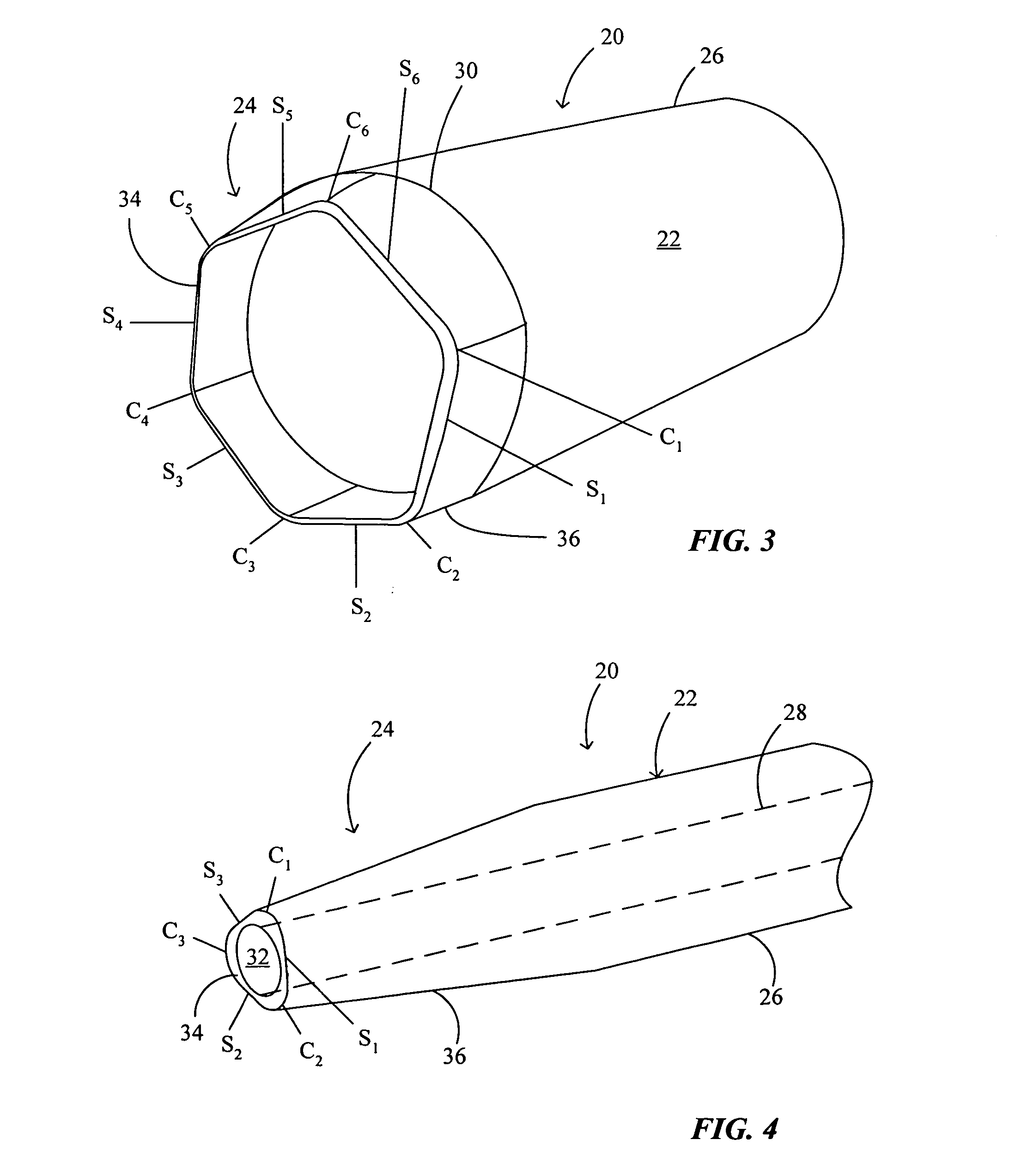

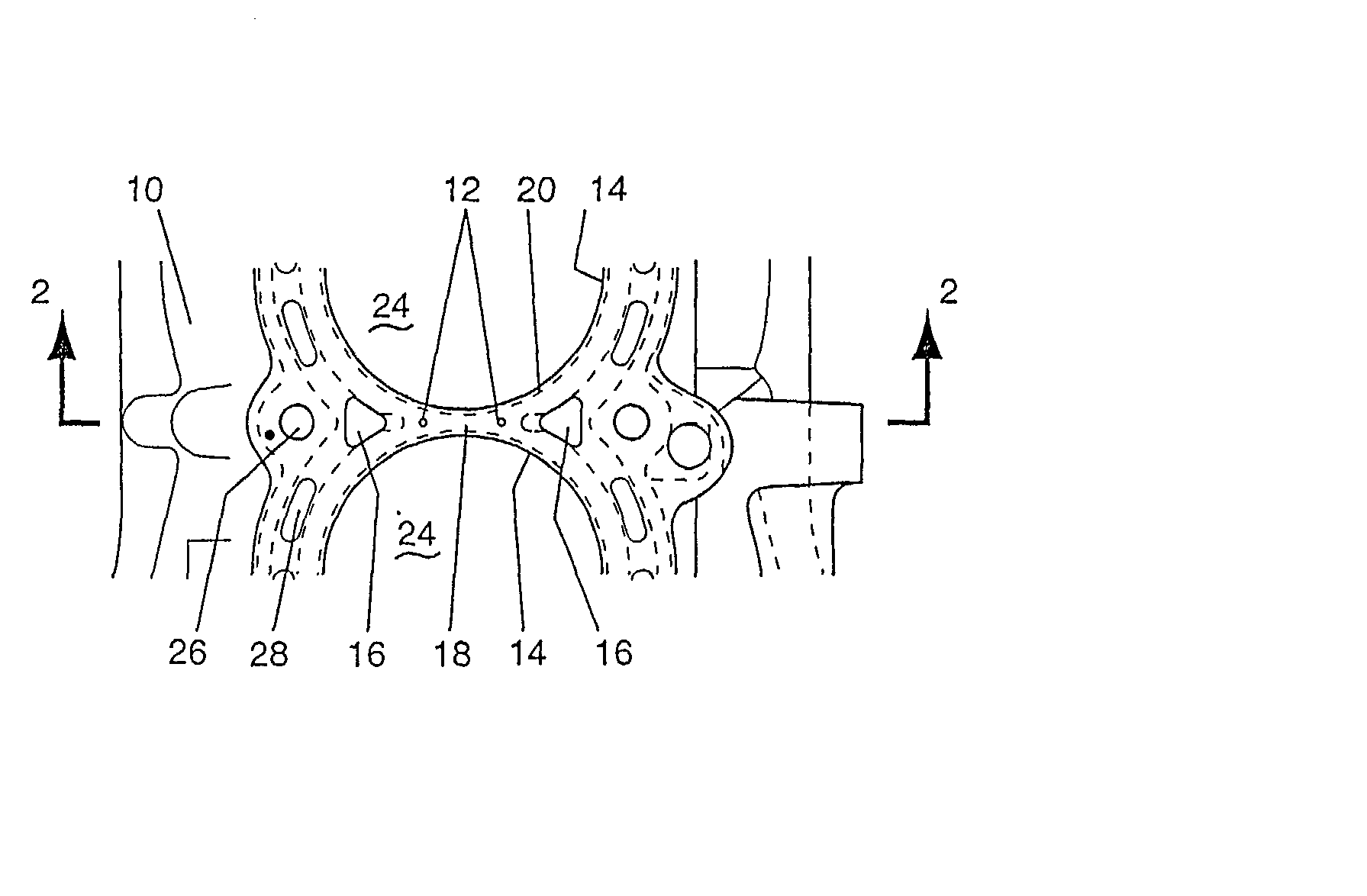

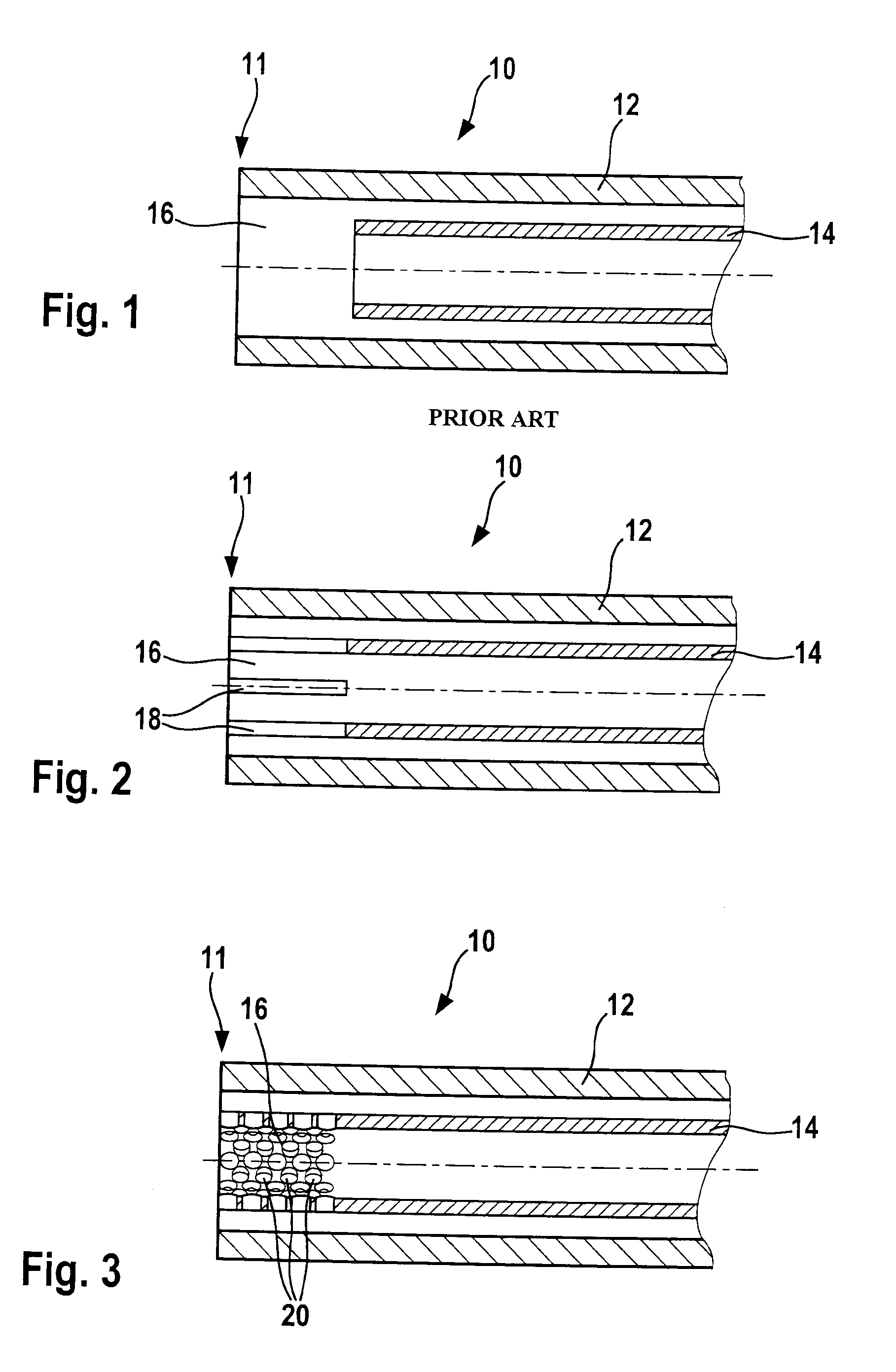

Improved Catheters

Catheters having a tapered, atraumatic distal tip are provided. In one embodiment, the outer surface of the distal portion of the catheter has a generally non-cylindrical and substantially triangular cross-sectional configuration. The inner surface cross-sectional configuration of the distal portion of the catheter may match the outer surface, or it may have a cylindrical or oval configuration. The terminal orthogonal surface of the distal catheter tip is chamfered or rounded or contoured. In another embodiment, inner and / or outer catheter surfaces have a three dimensional surface conformation and may be dimpled or grooved. The grooves may be generally liner or curved or helical or in a spiral configuration. Dimpled and / or grooved surface discontinuities may be provided in connection with and in addition to lubricious coatings, surfaces, and the like.

Owner:PULSAR VASCULAR

Apparatus for providing optical radiation

ActiveUS20070104438A1Enhanced couplingConstant diameterLaser using scattering effectsOptical fibre with multilayer core/claddingOptical radiationEngineering

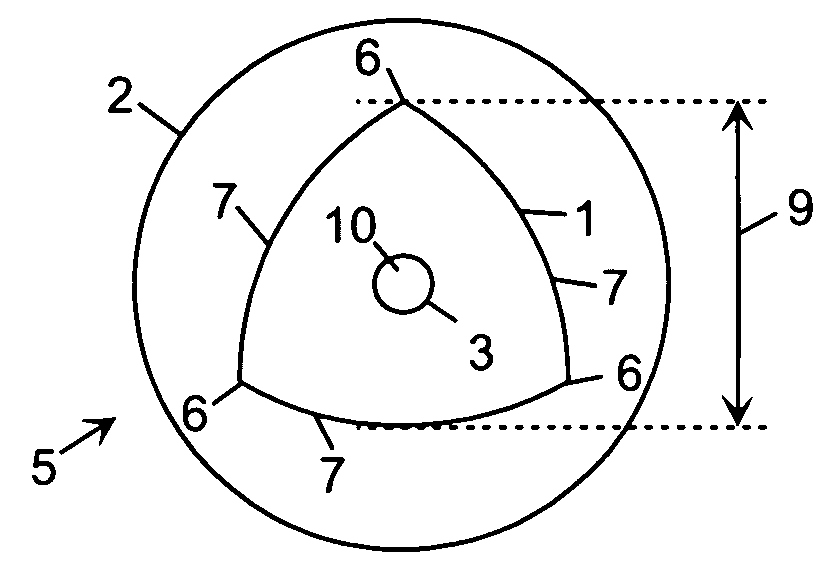

Apparatus for providing optical radiation, which apparatus comprises an optical fibre (5) having a core (3), a first cladding (1) and a second cladding (2), in which the first cladding (1) has a substantially constant diameter (9) in its cross-section. The first cladding (1) can be non-circular. Advantages include more reliable cleaving, joining and splicing.

Owner:SPI LASERS UK

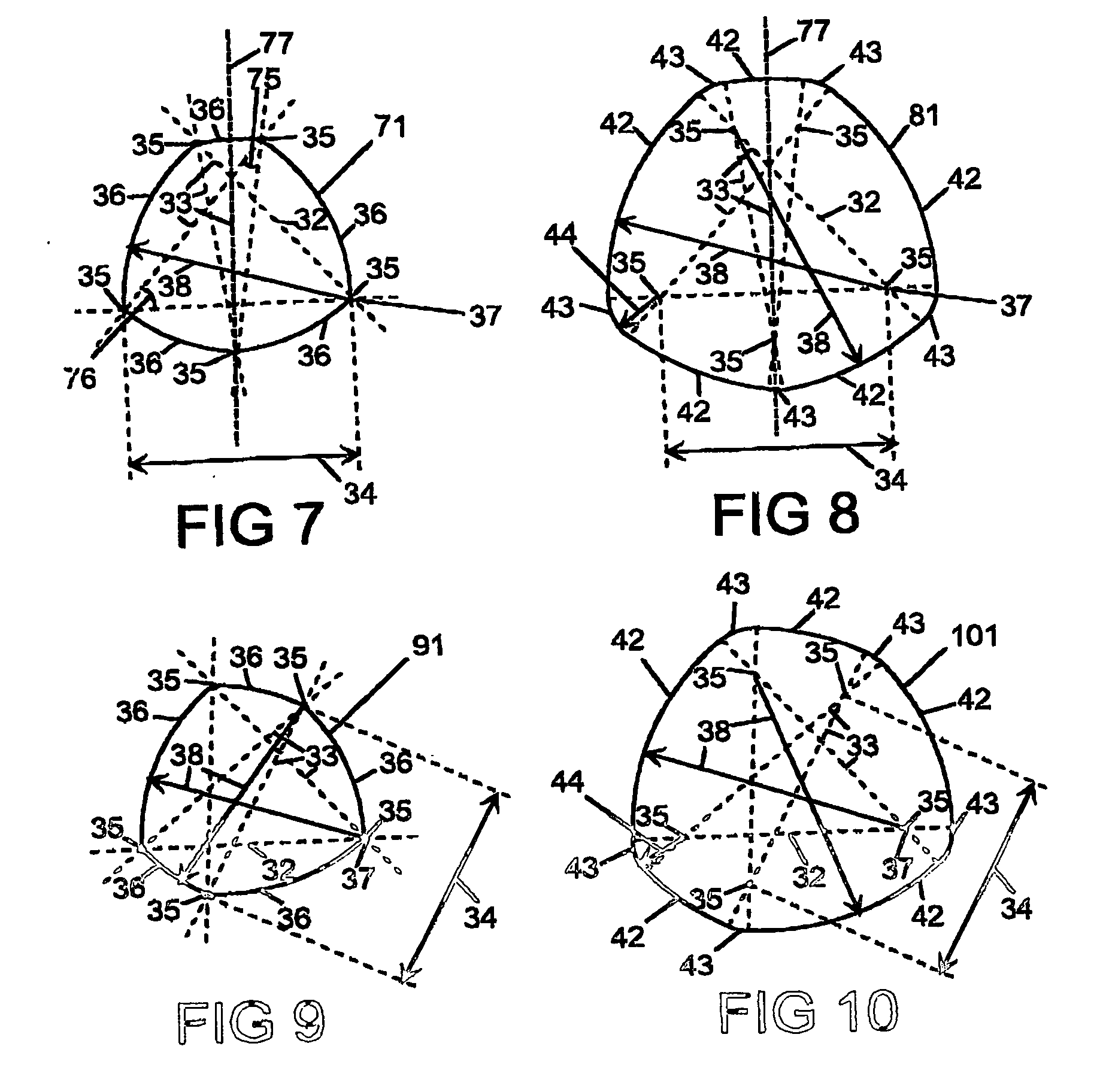

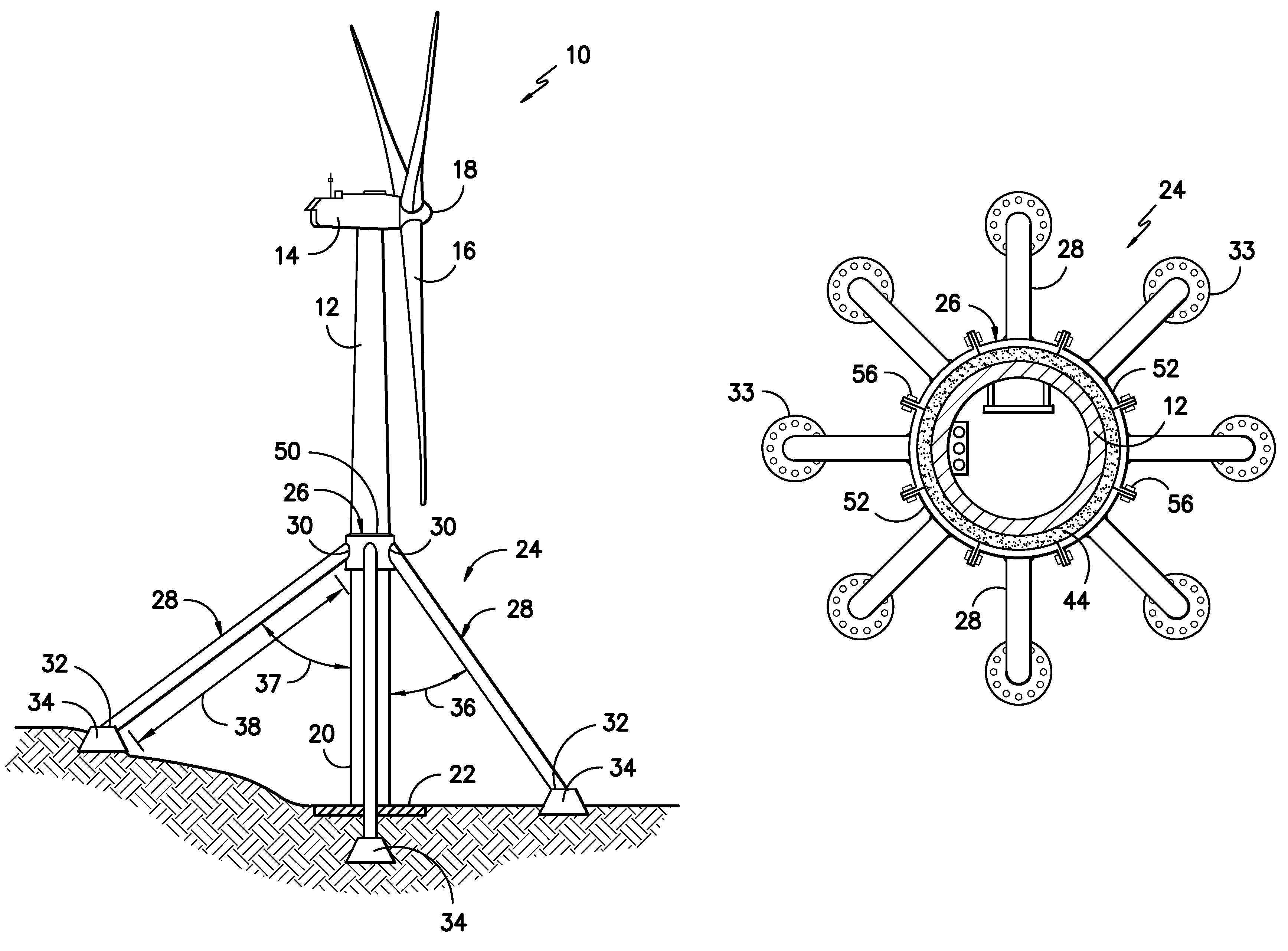

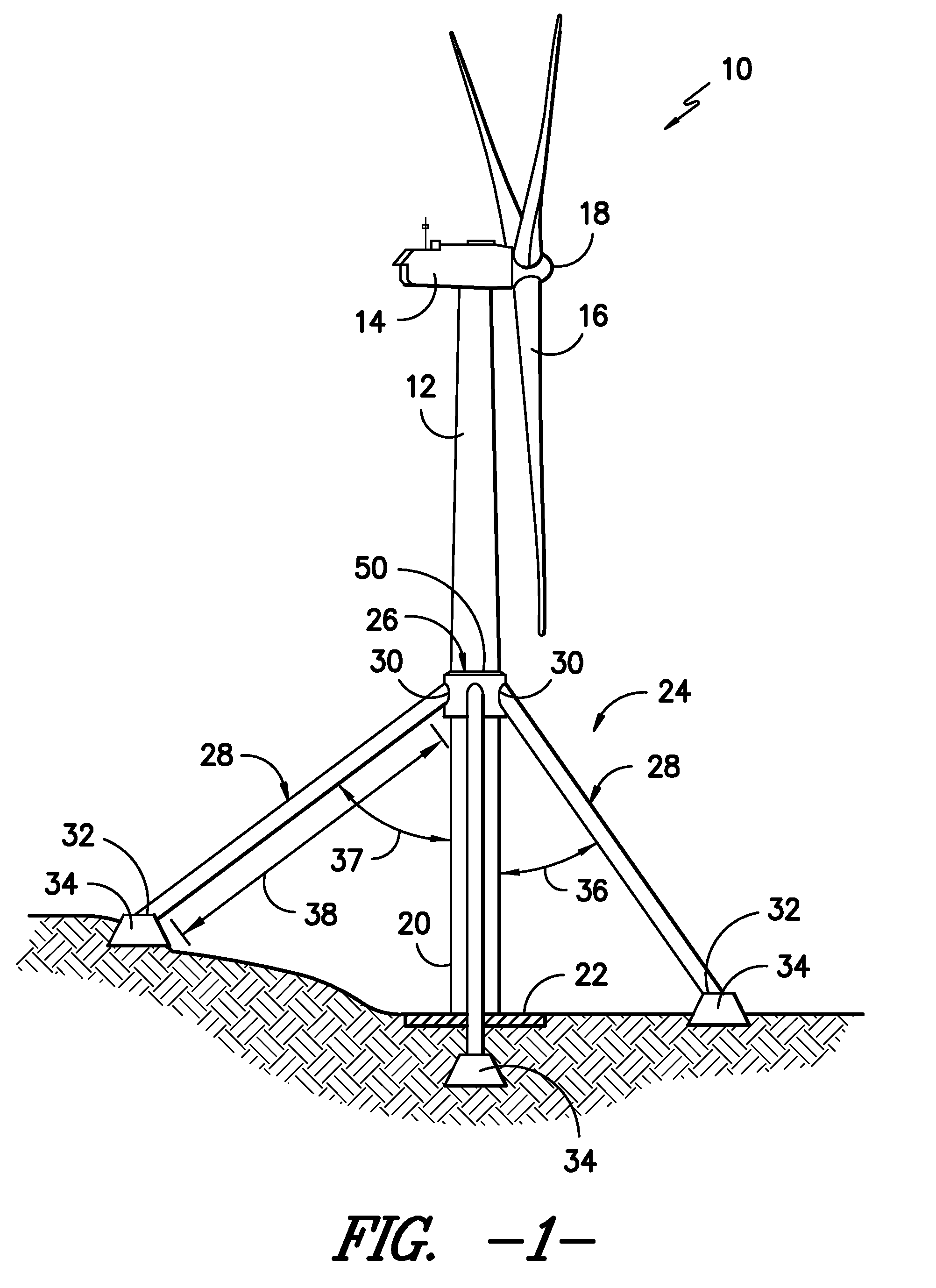

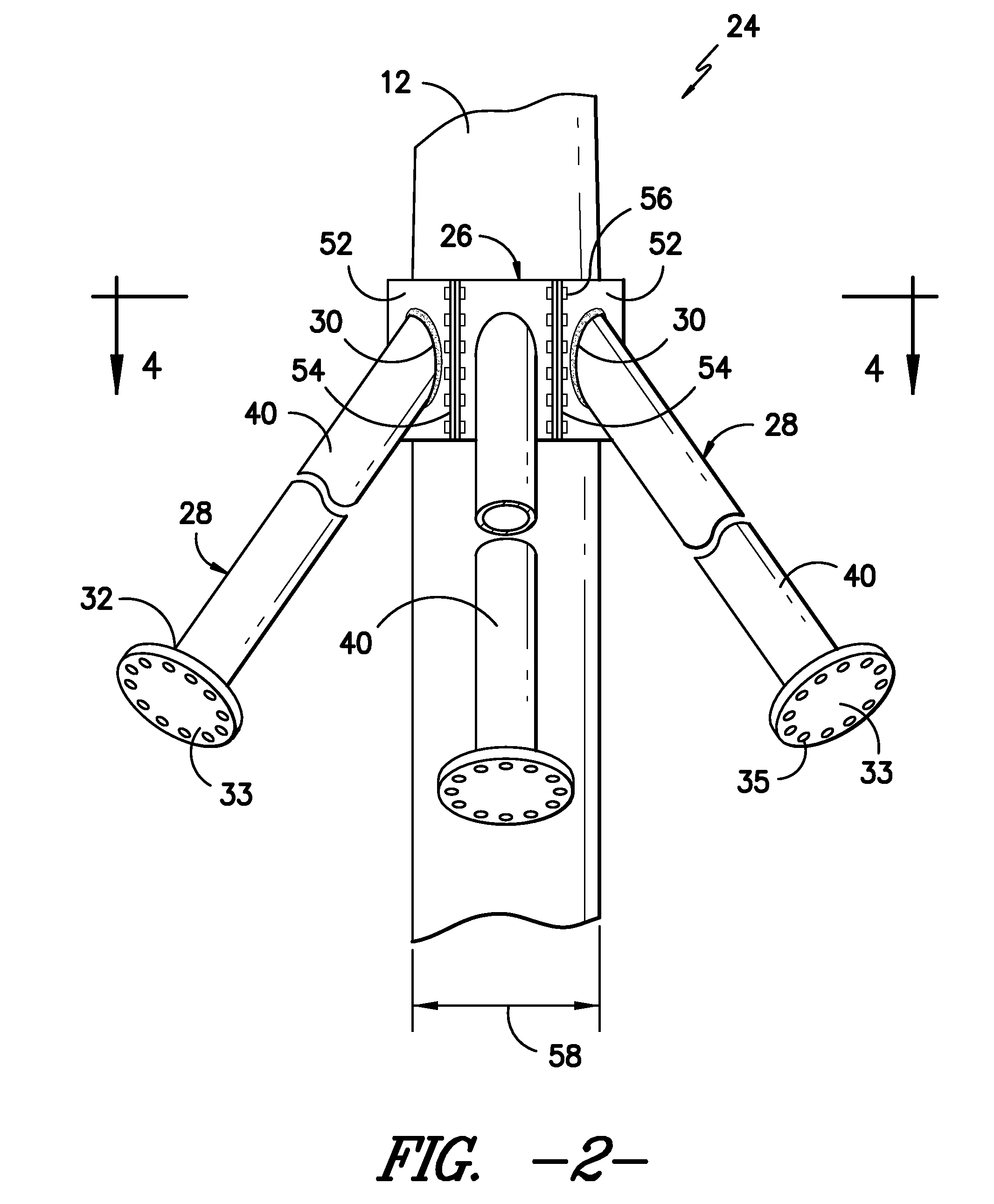

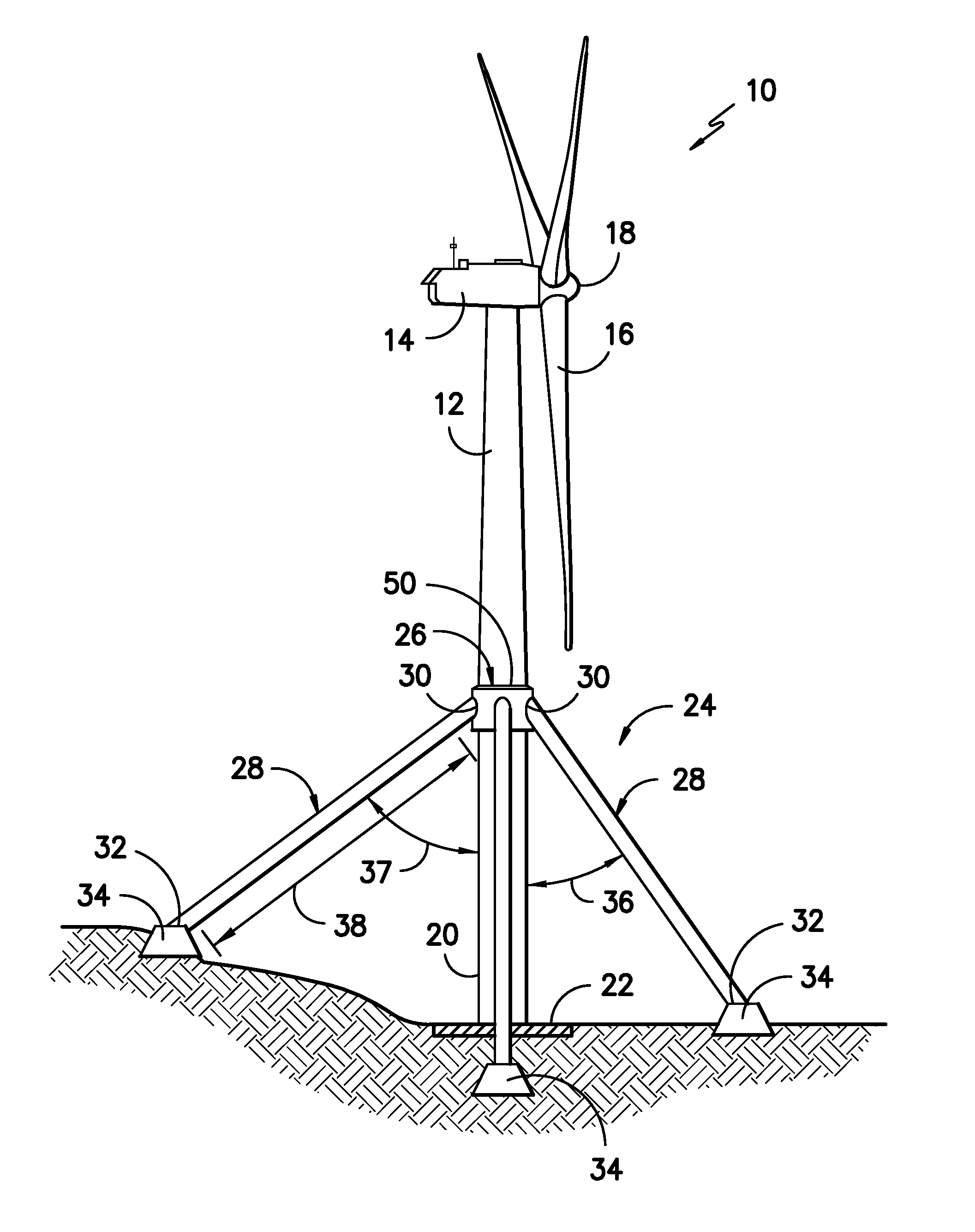

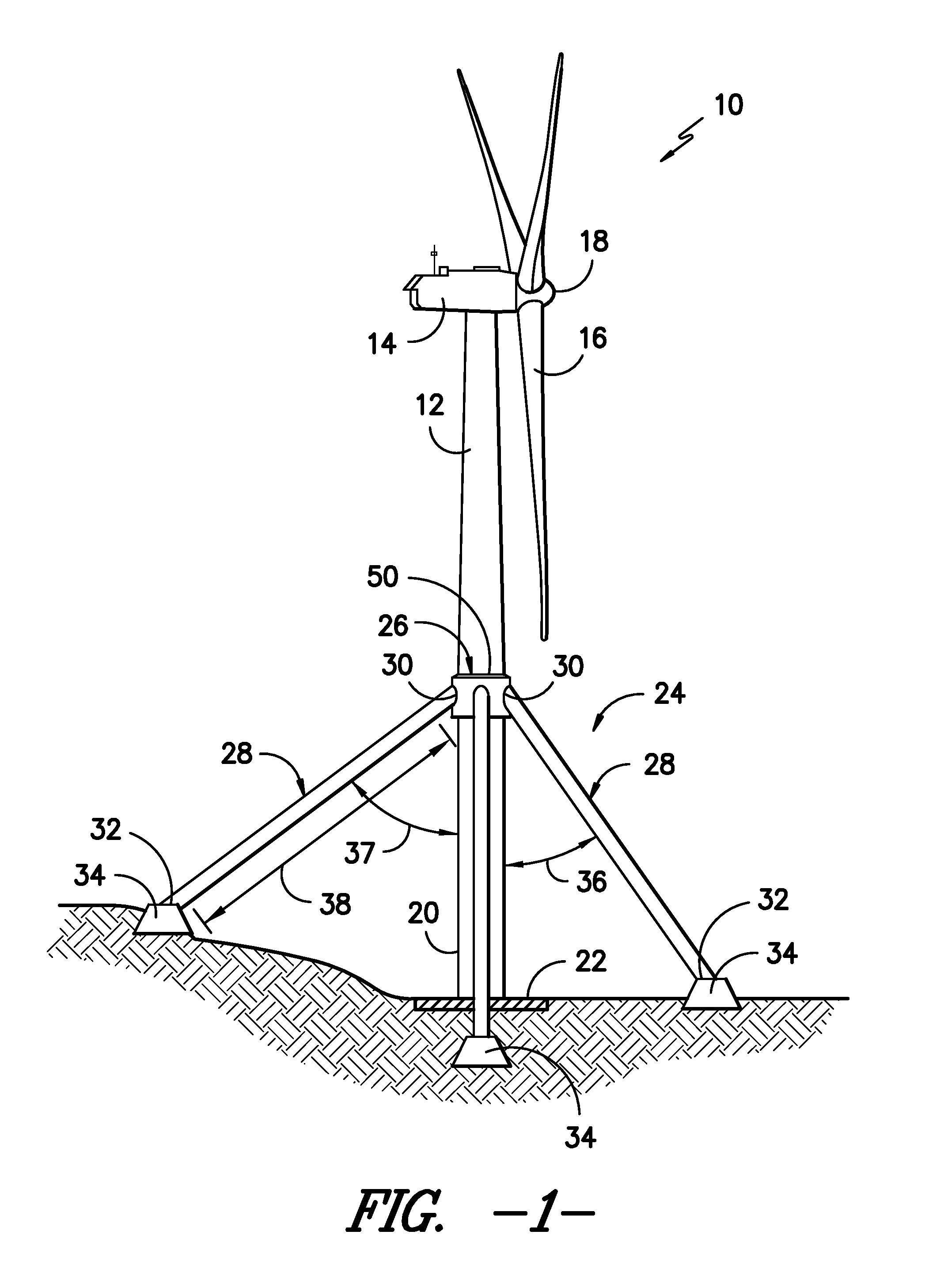

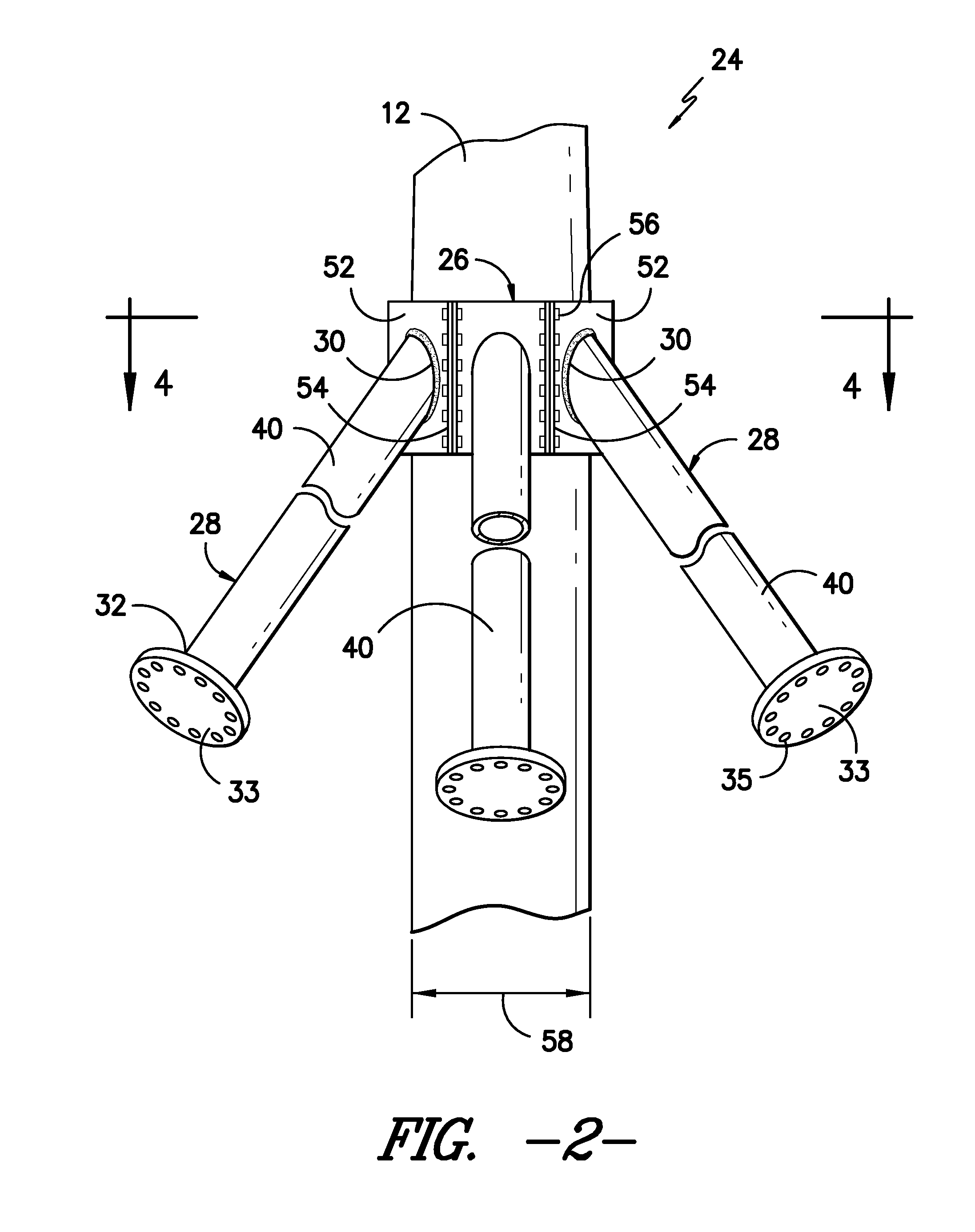

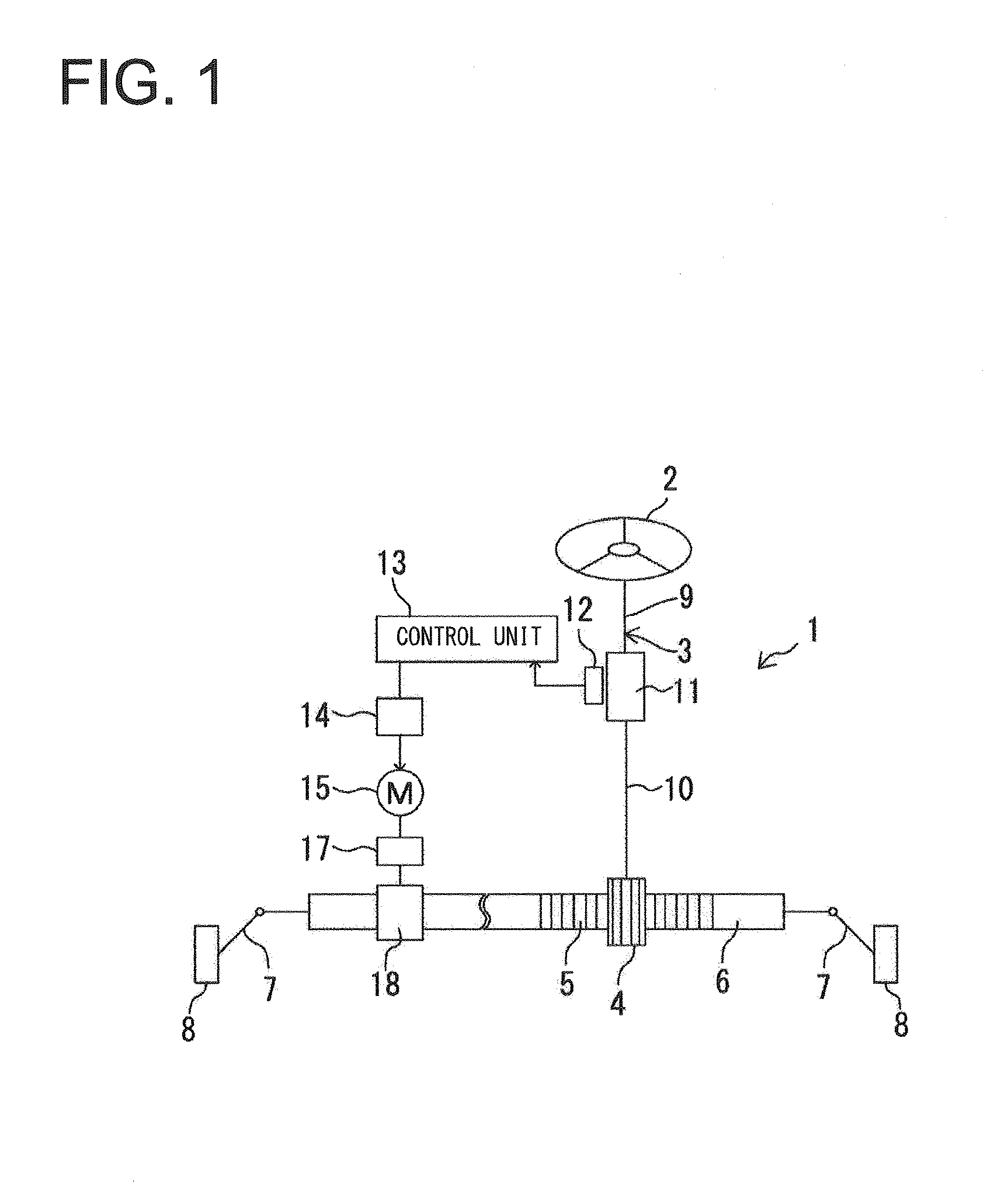

Onshore wind turbine with tower support system

ActiveUS7993107B2Reduction in weight and diameterReduction in weight and footprintWind motor assemblyWind motor supports/mountsNacelleTower

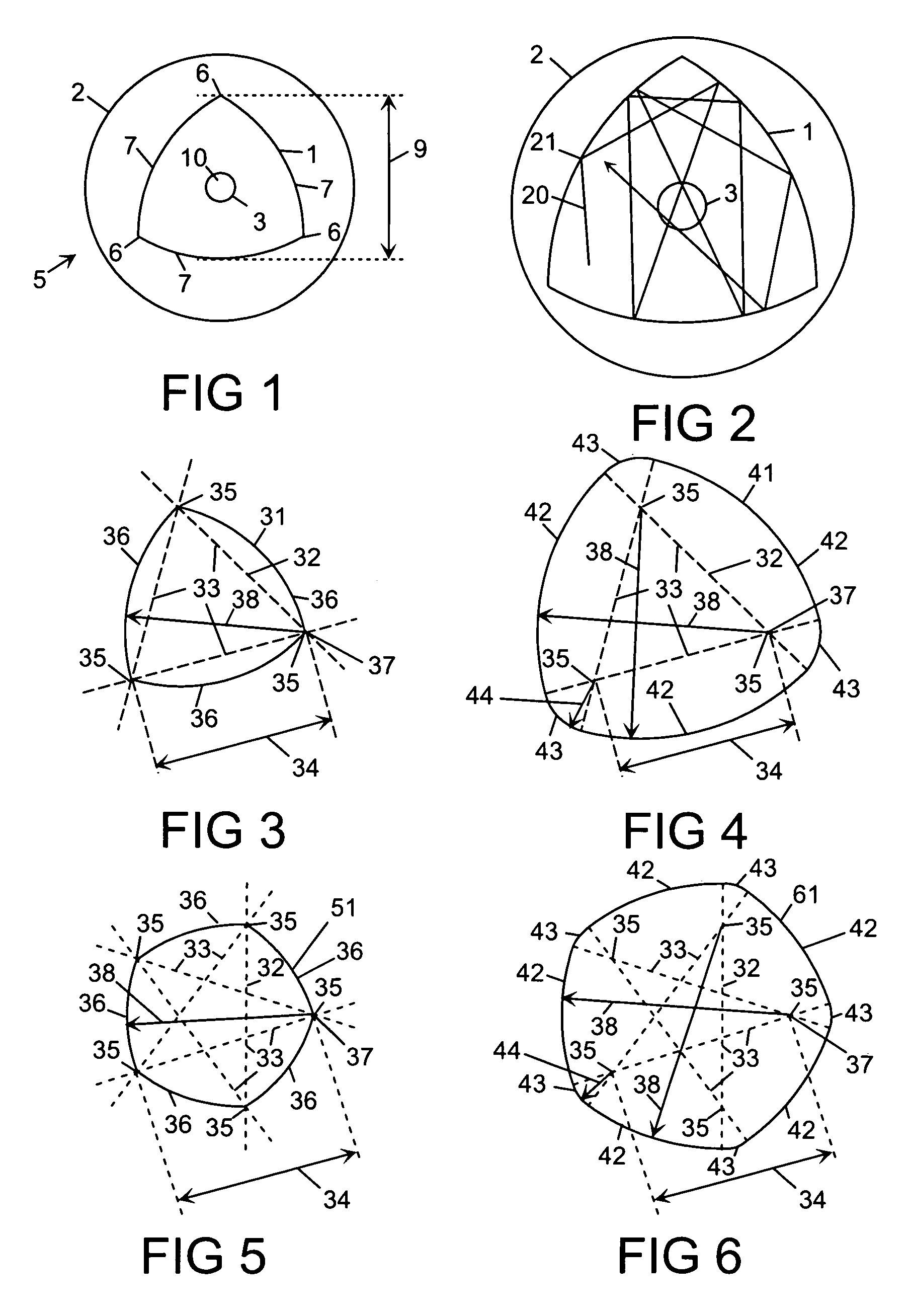

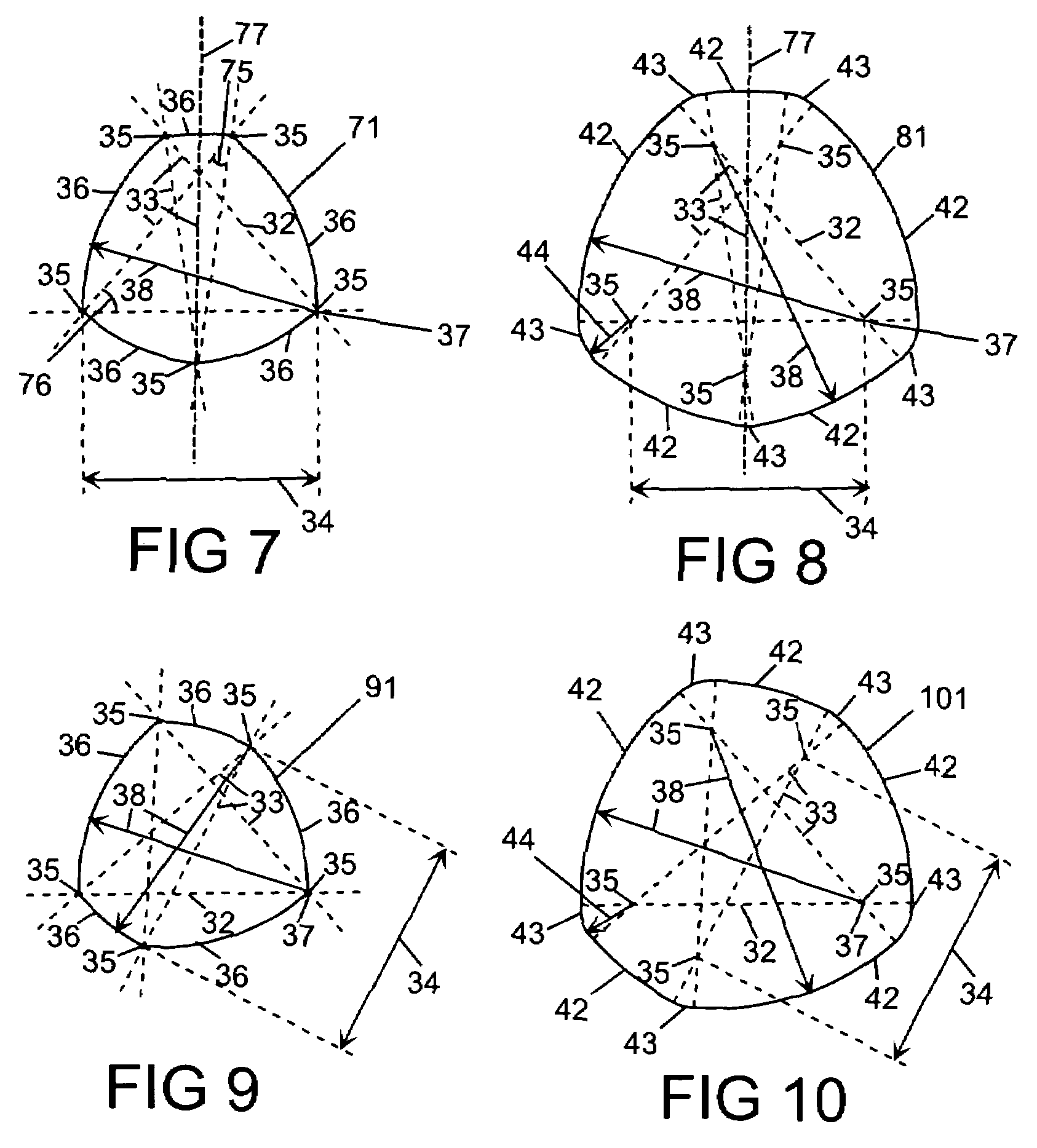

A wind turbine includes a nacelle with any manner of associated power generation equipment. The nacelle is mounted atop a tower having a base end configured for support on a ground level foundation. A tower support system provides support to the tower and includes an axially extending circumferential sleeve mounted around the tower at a location between the base end and the nacelle. A plurality of support legs are disposed around the sleeve, with each support leg having a first end rigidly affixed to the sleeve and an opposite foot end configured for mounting to a ground level footing. The support legs extend from the sleeve with a length and at an acute extension angle relative to a longitudinal axis of the tower so as to provide a designed degree of vertical and lateral support around the circumference of the tower.

Owner:GENERAL ELECTRIC CO

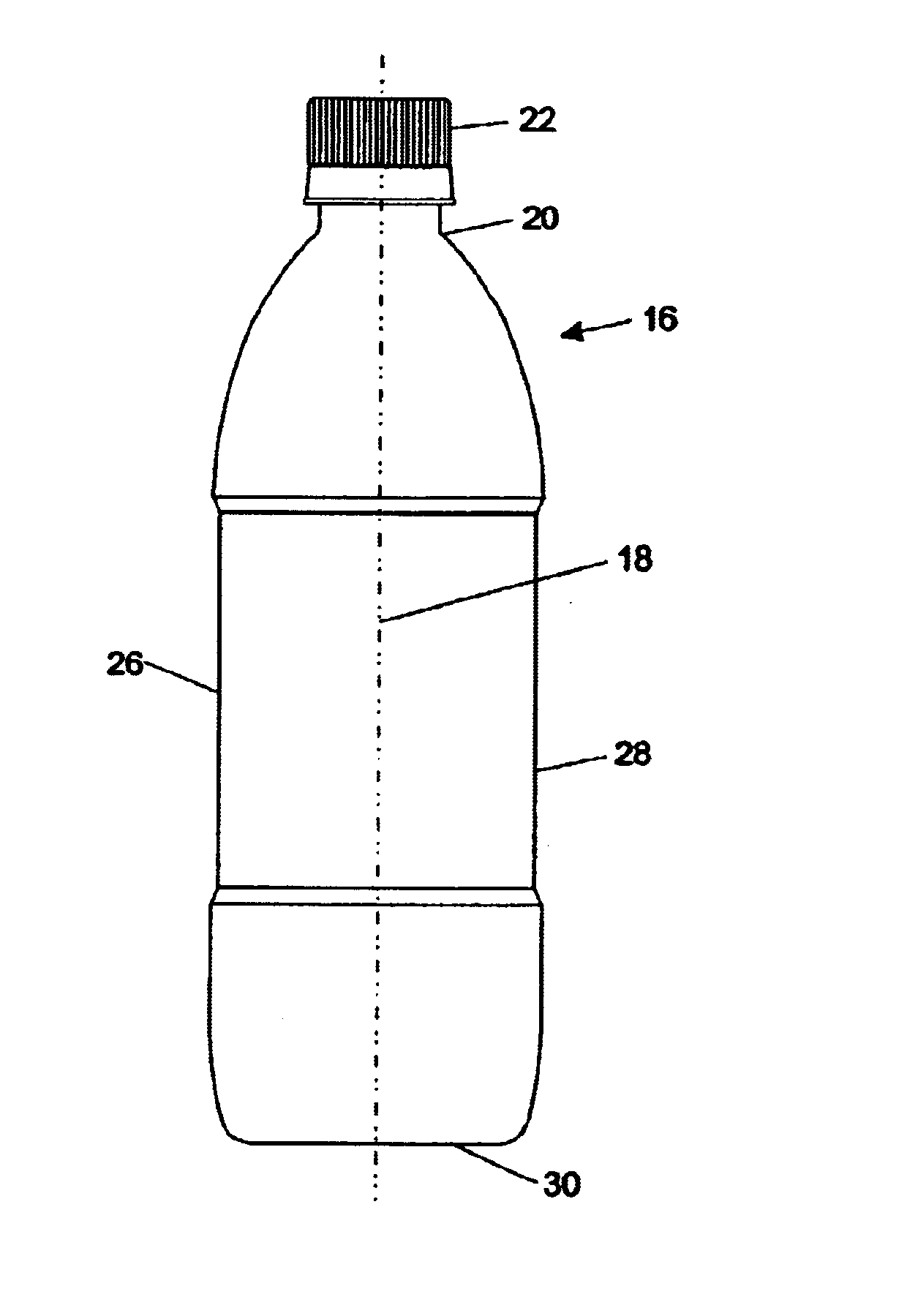

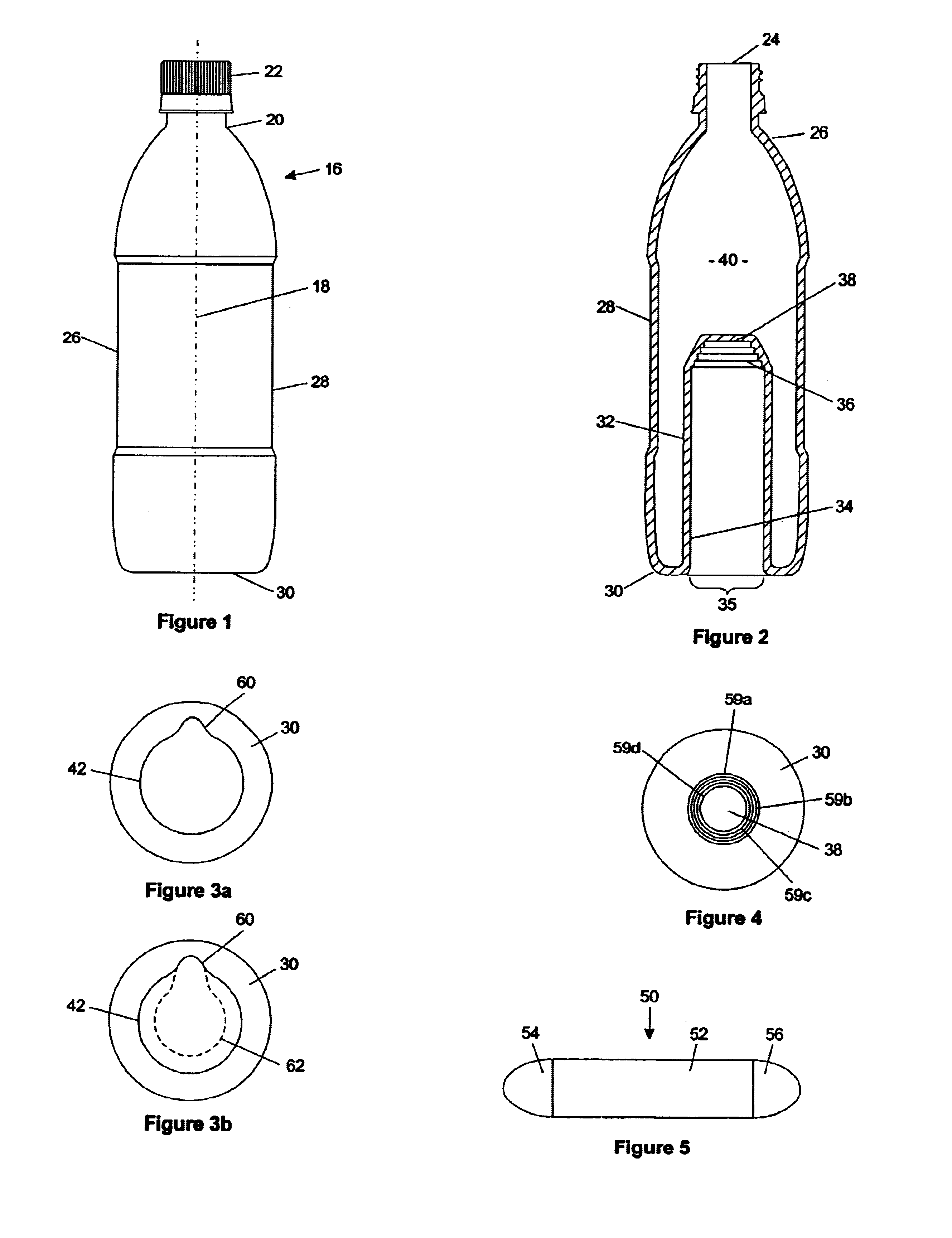

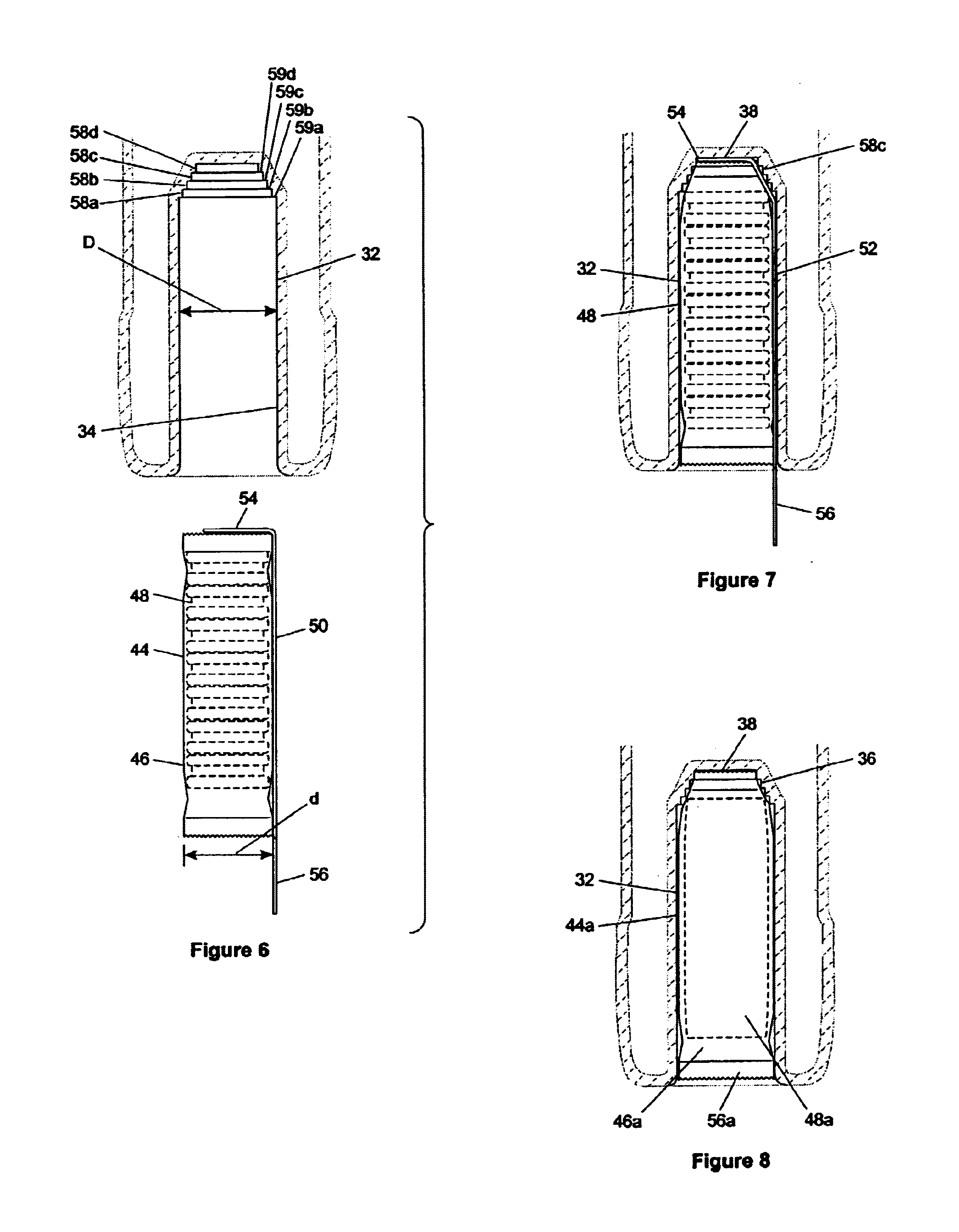

Dual compartment beverage container

InactiveUS6989168B2Reduced dimensionReduce consumptionReady-for-oven doughsBottlesLeading edgeSnack food

A container for vending single servings of beverages and snack foods, includes a liquid-impermeable wall providing a compartment for the beverage. An inside section of the wall defines a recess isolated from the compartment and open to the container exterior at the bottom. Near the upper end of the recess, the inside wall diameter is decreased in steps, to frictionally engage a leading edge region of a snack-food cartridge or other product inserted into the recess. A pull tab between the cartridge and the recess is accessible to remove the cartridge. Alternatively, a cartridge wrapper can be shaped to provide a pull tab component. The preferred snack-food cartridge includes a compliant thin film or foil wrapping surrounding a stack of cookies, a bar, or other snack food. In alternative arrangements, the container has a vertical slot for viewing a cartridge inserted into the recess, or is formed with horizontal top and bottom wall sections. Further alternatives involve a refrigeration package or chilled cartridge insertable into the recess to cool the beverage.

Owner:EMERGENT TECH

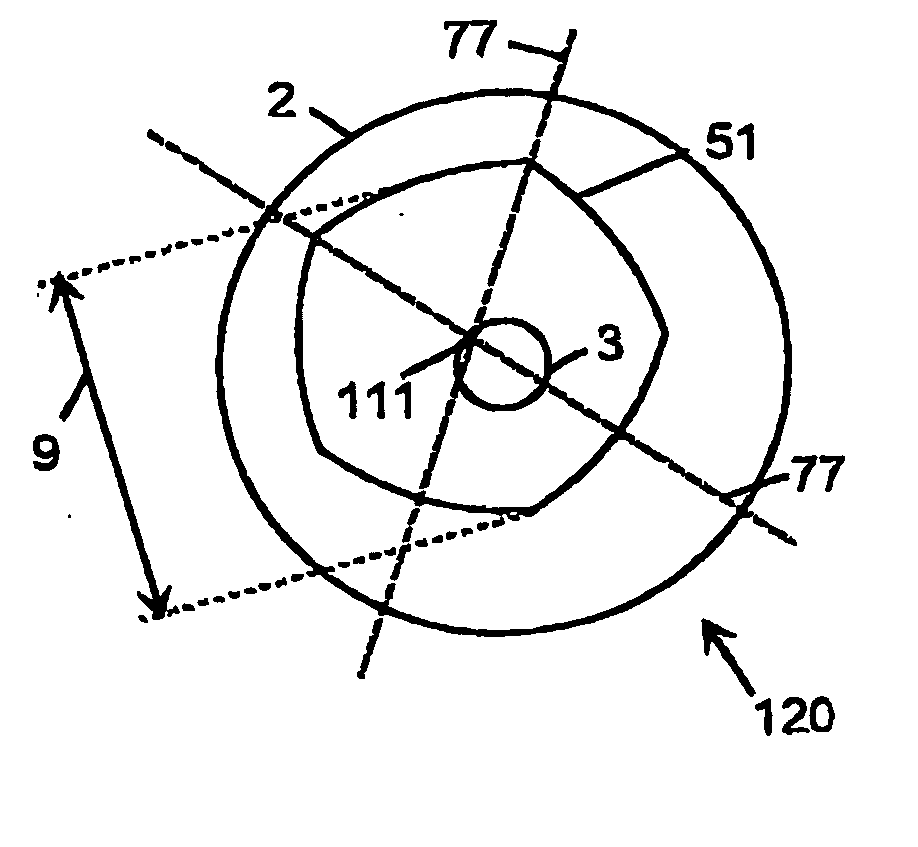

Apparatus for providing optical radiation

ActiveUS7421175B2Constant diameterEnhanced couplingLaser using scattering effectsOptical fibre with multilayer core/claddingOptical radiationOptoelectronics

Apparatus for providing optical radiation, which apparatus comprises an optical fibre (5) having a core (3), a first cladding (1) and a second cladding (2), in which the first cladding (1) has a substantially constant diameter (9) in its cross-section. The first cladding (1) can be non-circular. Advantages include more reliable cleaving, joining and splicing.

Owner:SPI LASERS UK

Onshore wind turbine with tower support system

ActiveUS20110142682A1Reduce weightReduce the overall diameterOther chemical processesWind motor assemblySupporting systemNacelle

A wind turbine includes a nacelle with any manner of associated power generation equipment. The nacelle is mounted atop a tower having a base end configured for support on a ground level foundation. A tower support system provides support to the tower and includes an axially extending circumferential sleeve mounted around the tower at a location between the base end and the nacelle. A plurality of support legs are disposed around the sleeve, with each support leg having a first end rigidly affixed to the sleeve and an opposite foot end configured for mounting to a ground level footing. The support legs extend from the sleeve with a length and at an acute extension angle relative to a longitudinal axis of the tower so as to provide a designed degree of vertical and lateral support around the circumference of the tower.

Owner:GENERAL ELECTRIC CO

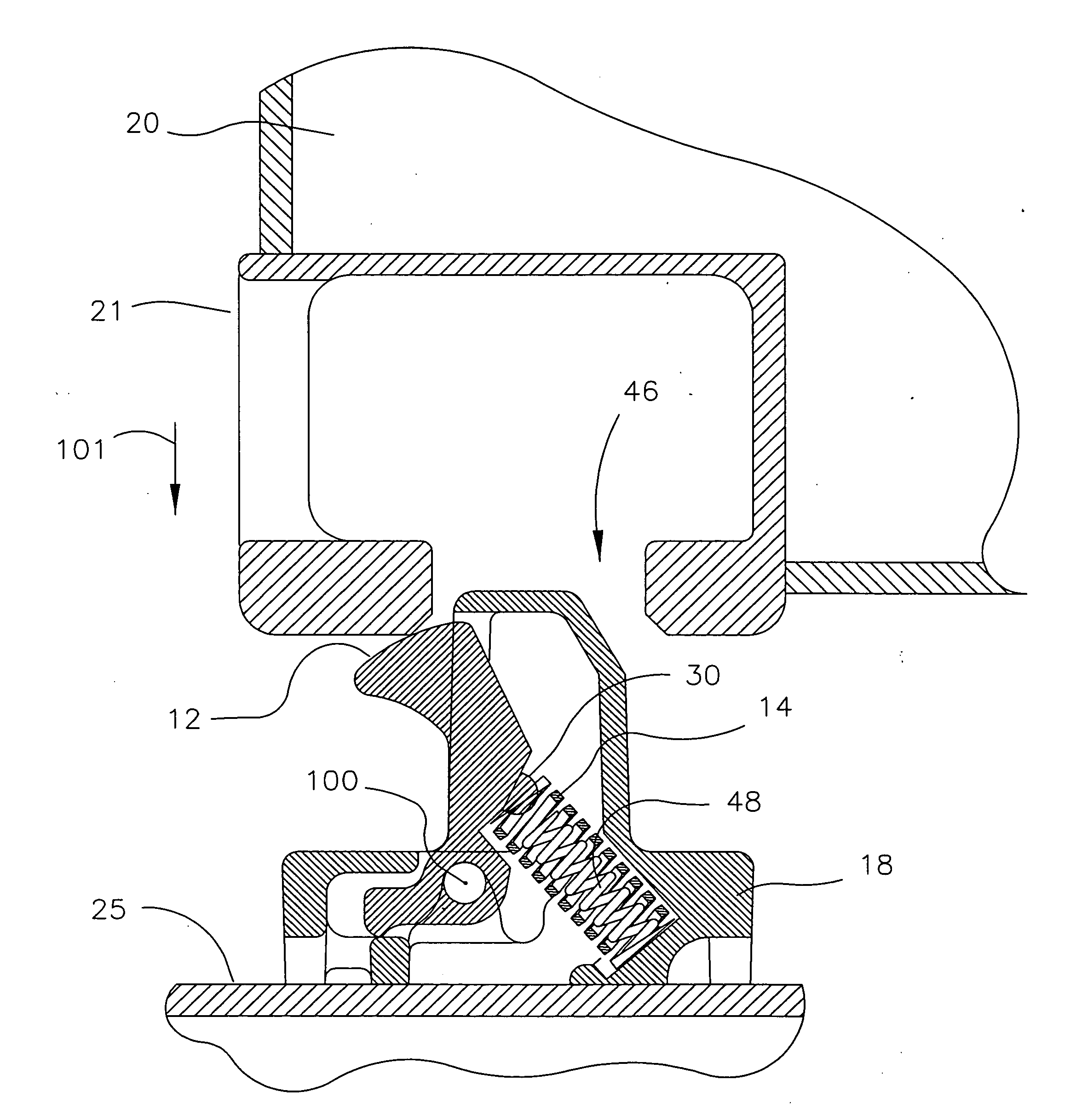

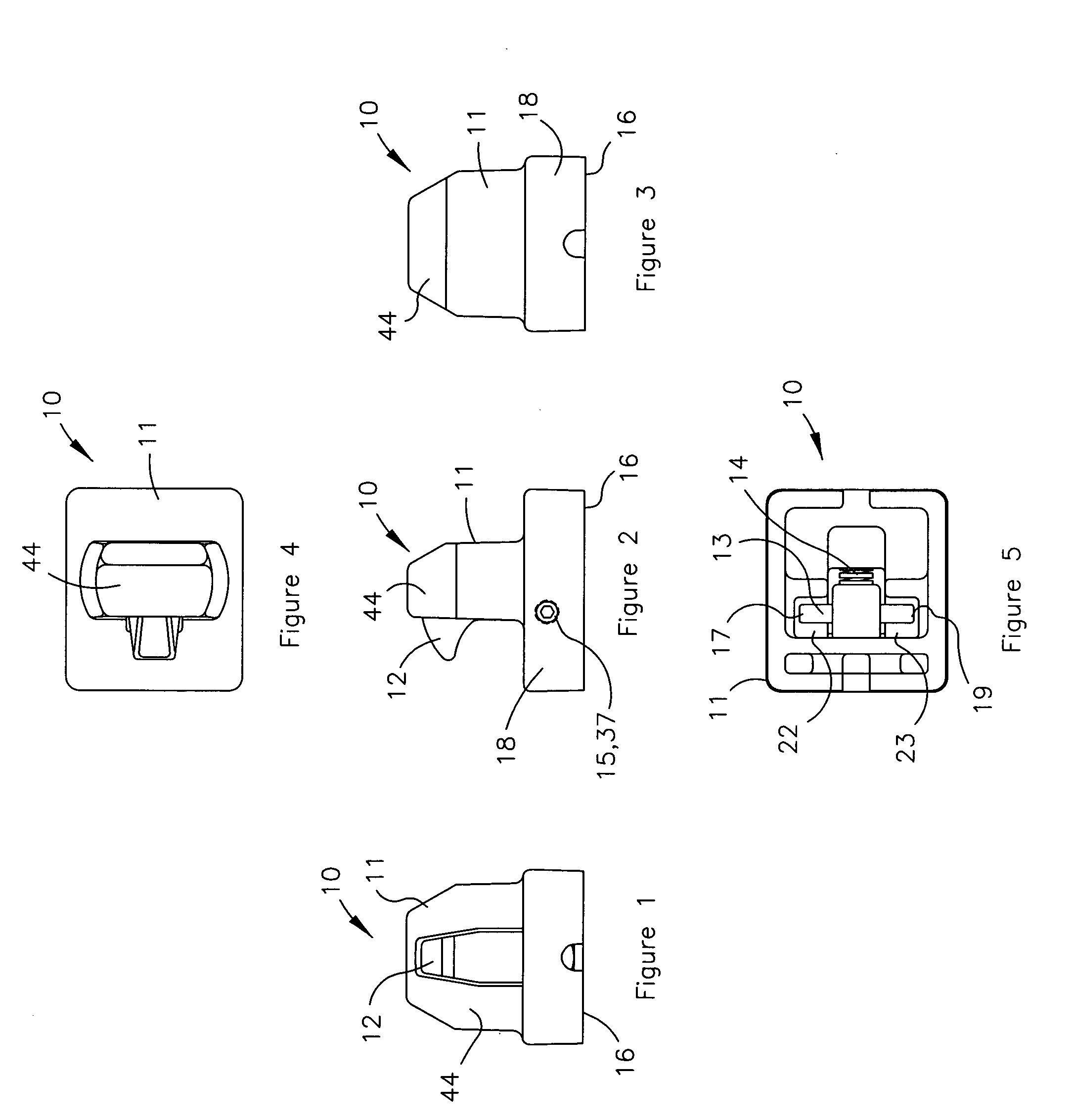

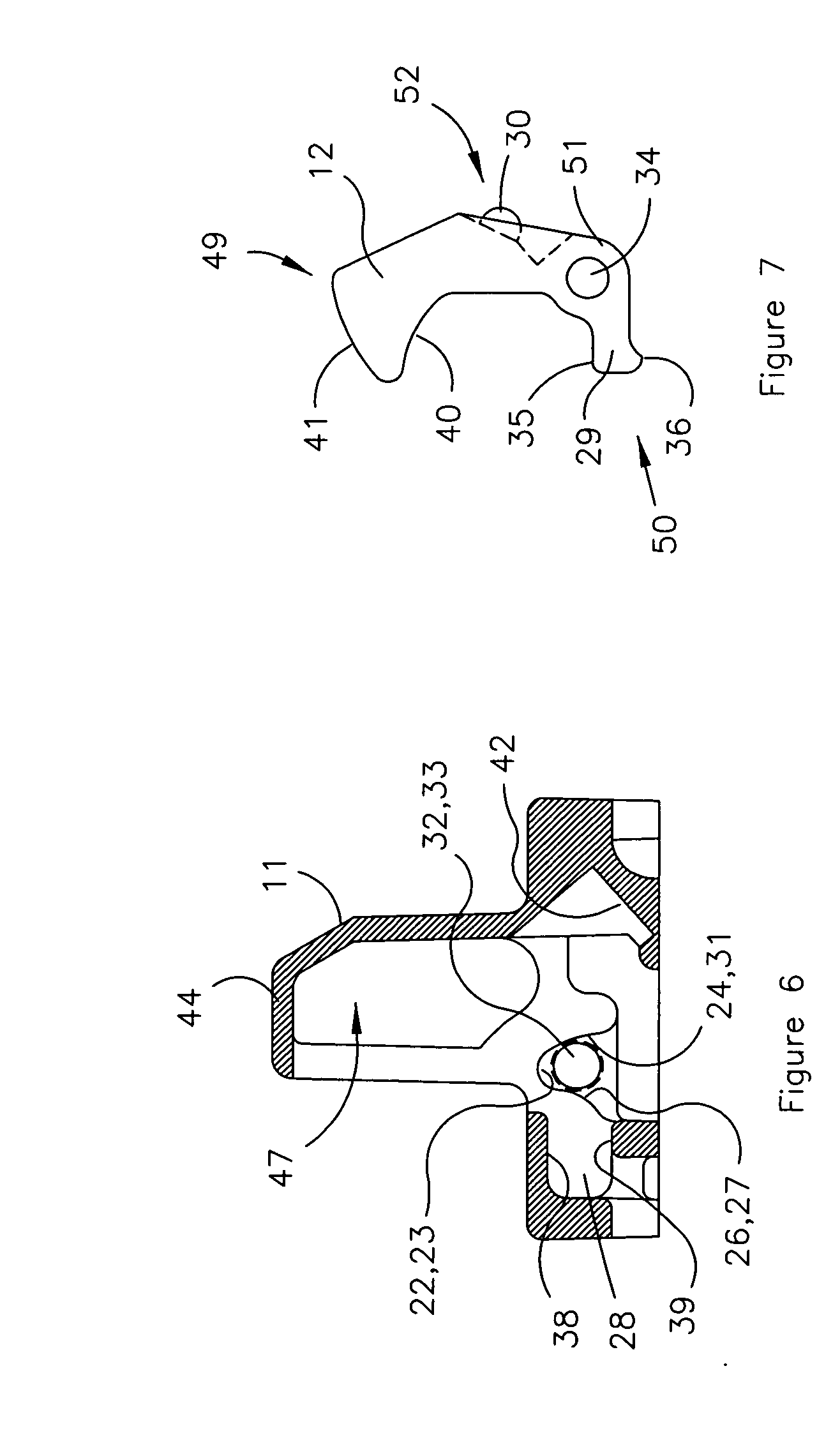

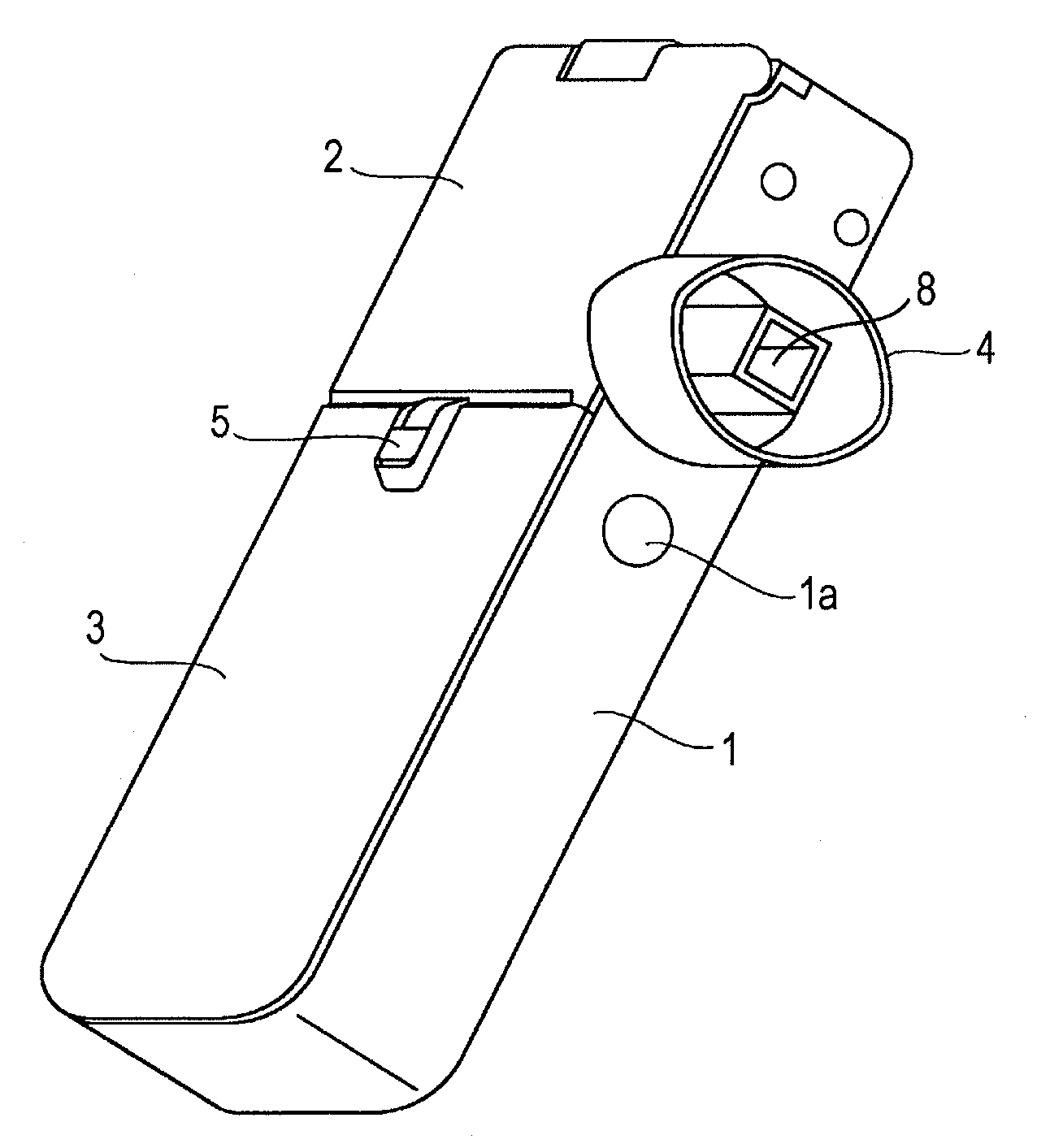

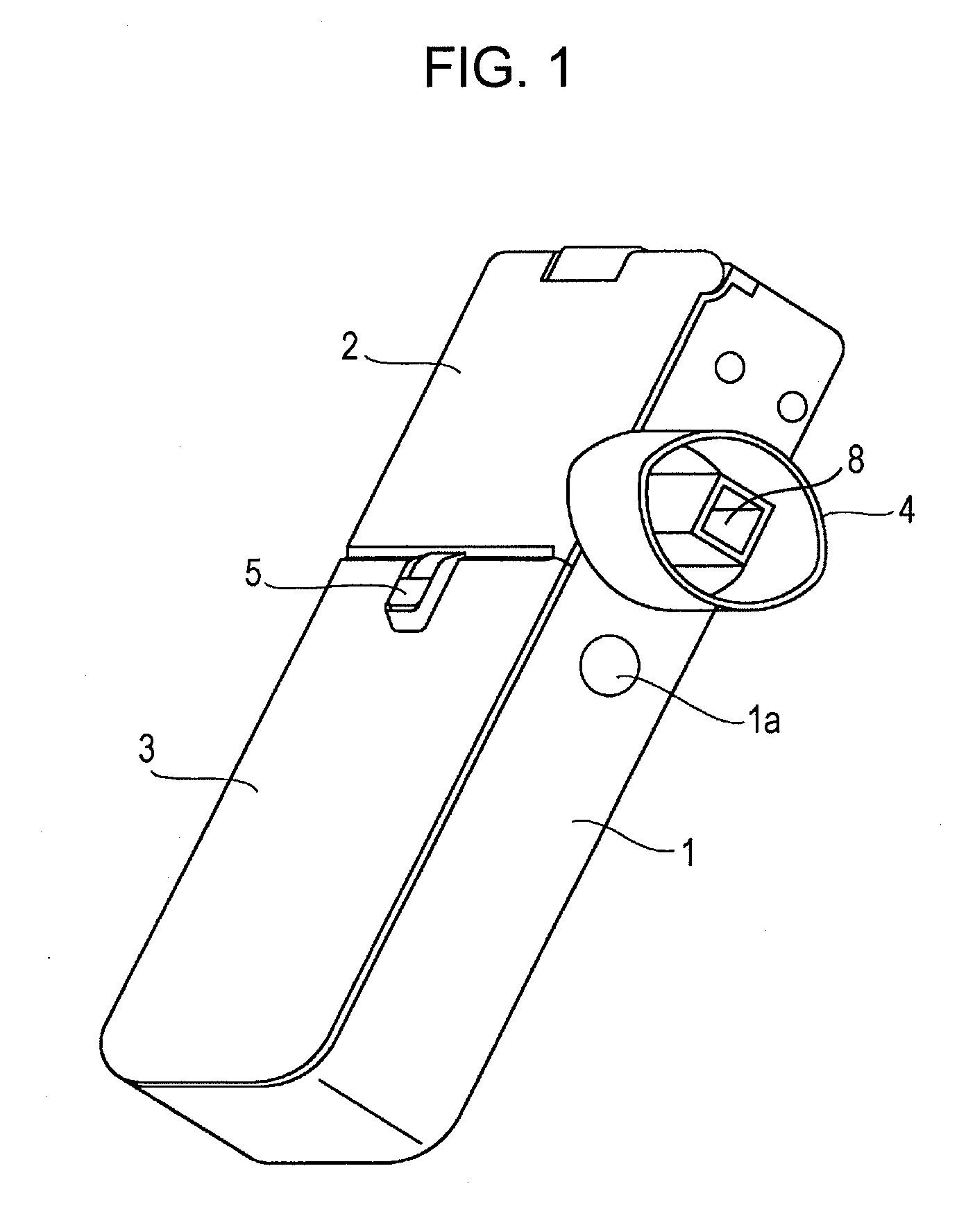

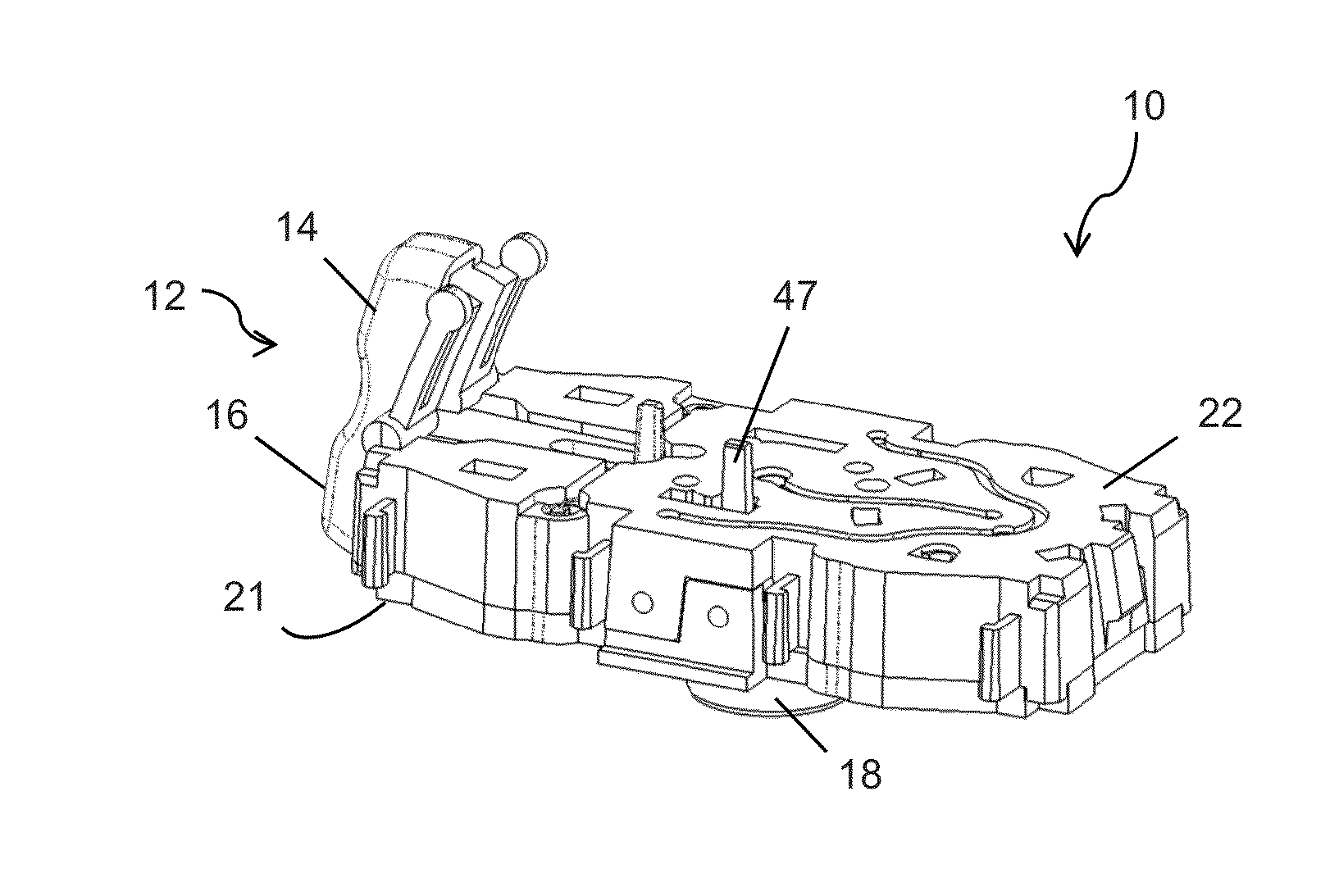

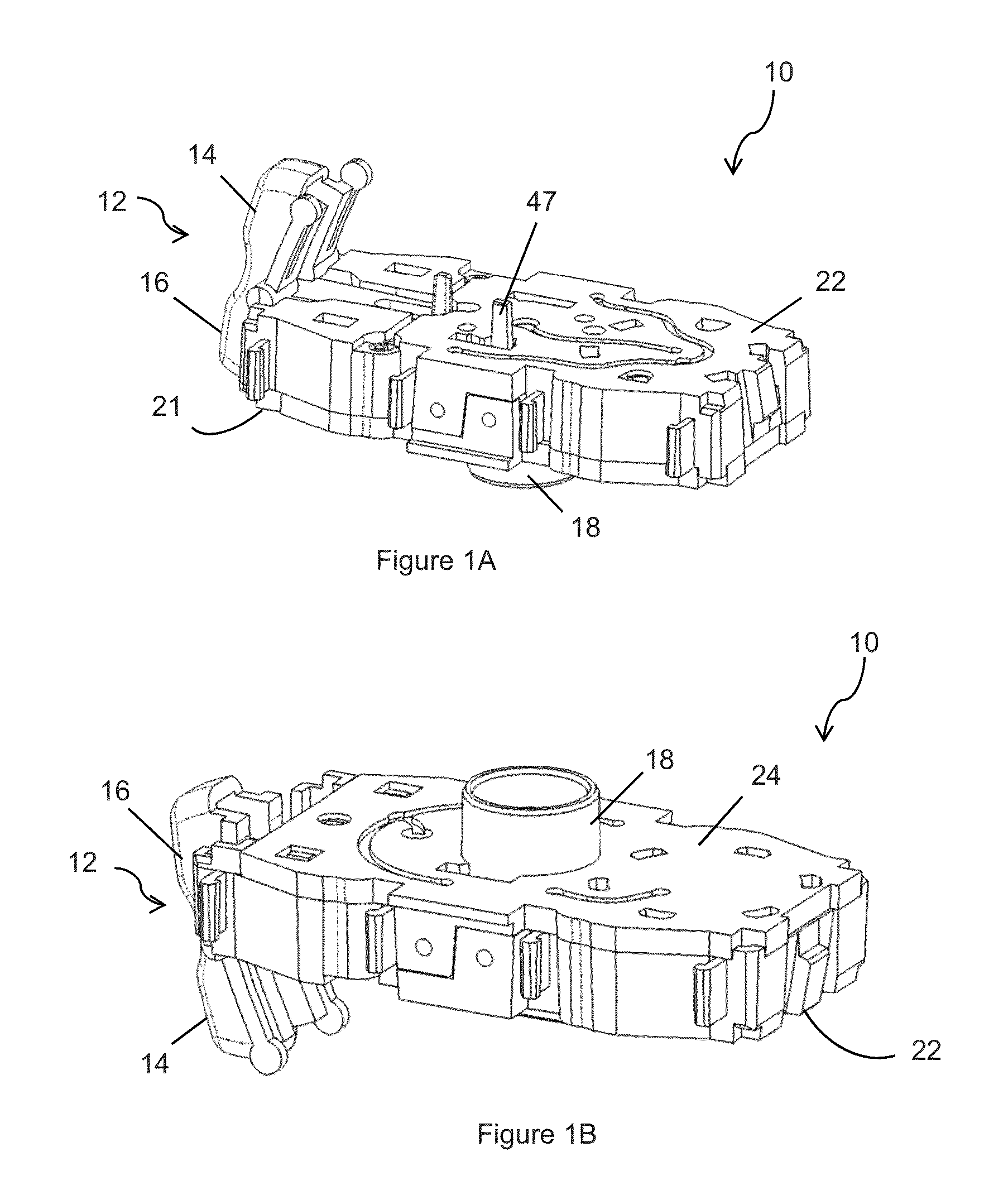

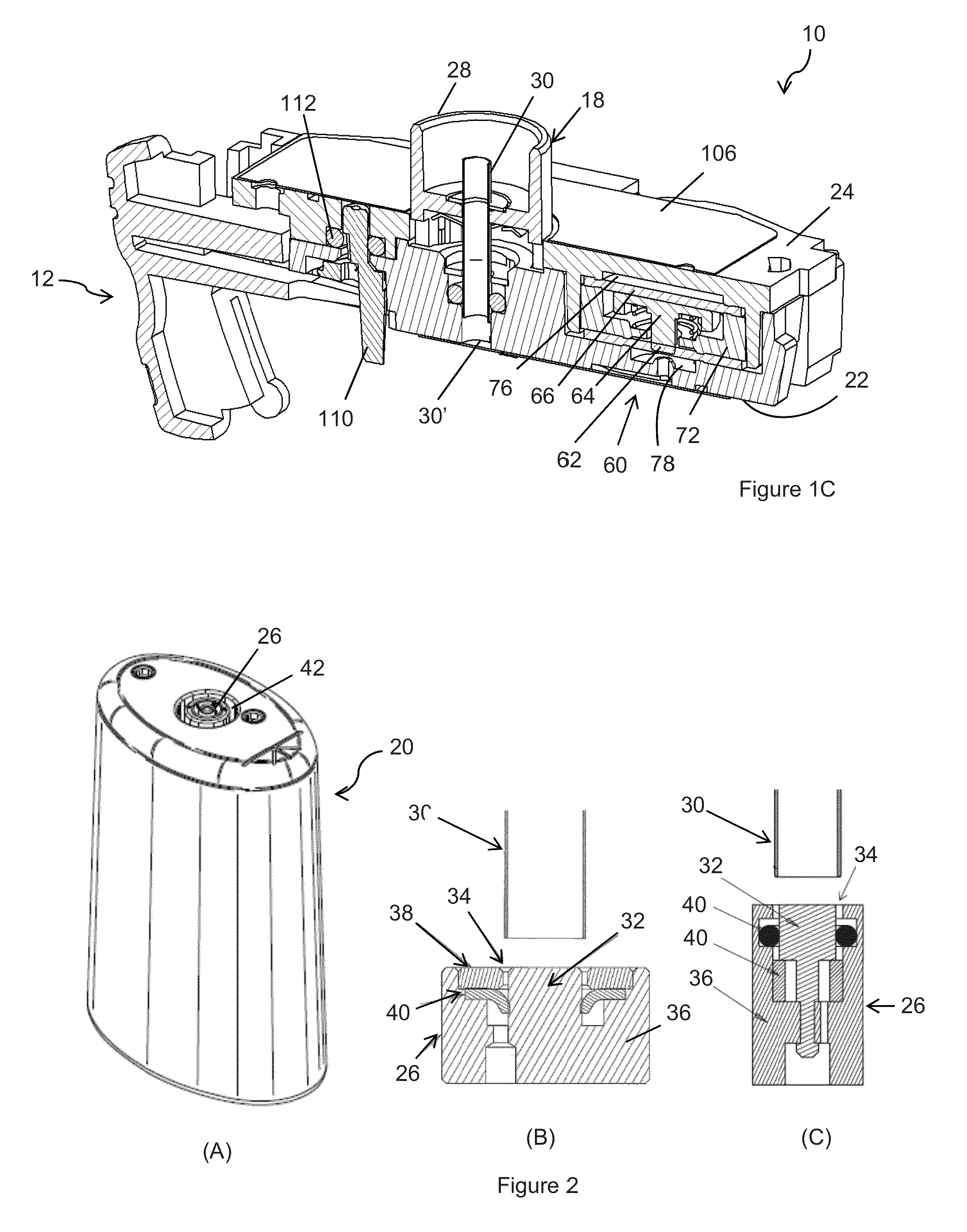

Latch device with variable latching resistance and method

InactiveUS20100303573A1Provide resistanceLow costVehicle with removable loadingLoad accommodationEngineeringSupport surface

A latch device releasably secures a container to a support surface. The device comprises a housing, a latch, interchangeable spring sets, and a pin. The housing comprises an upper shell and an inner coil-receiving cavity. The shell defines a latch-receiving cavity. The latch comprises an upper latch end and a coil-engaging portion. The coil-engaging portion comprises coil-aligning structure. At least one compression coil is received within the coil-receiving cavity and placed into engagement with the coil-engaging portion so as to bias the upper latch end exterior to shell via the latch-receiving cavity. The coil-aligning structure enhances axial alignment of each coil during coil compression. The pin pivotally connects the latch to the housing for enabling pivotal movement of the latch under selectively varied spring resistance for targeted applications. The coil(s) thus enable the user to vary latching forces during latching securement and release depending to the targeted loads and conditions.

Owner:HOLLAND CO

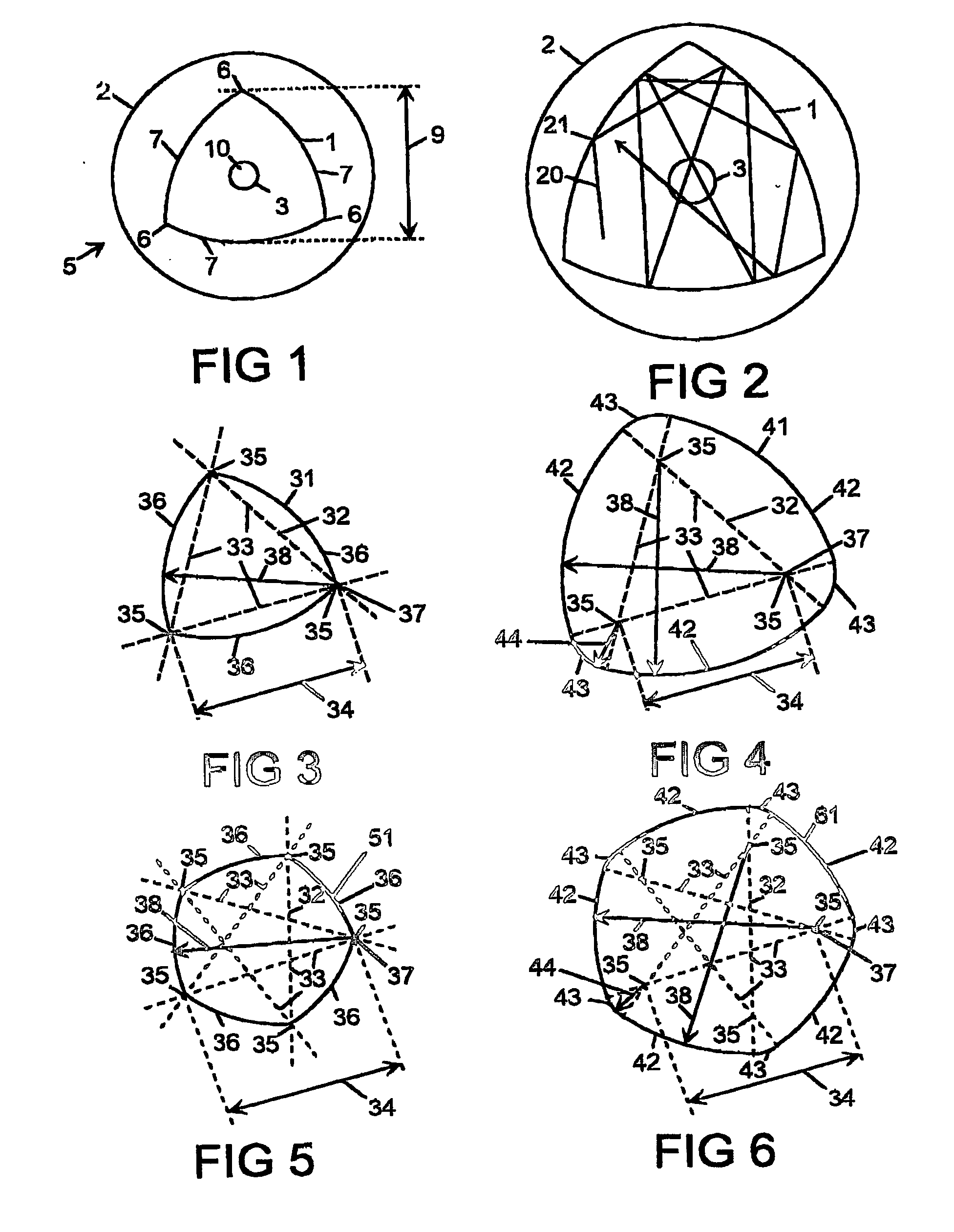

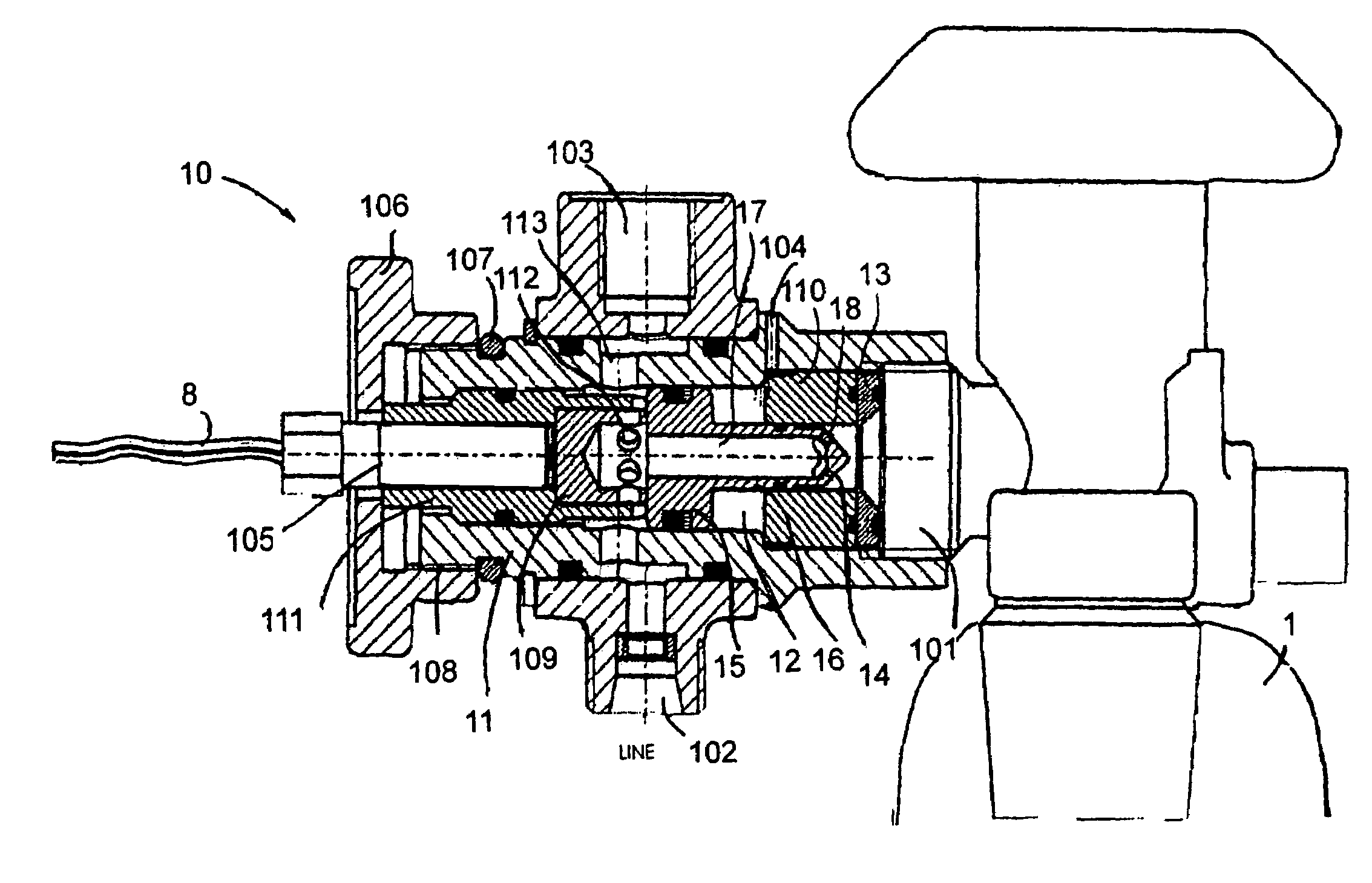

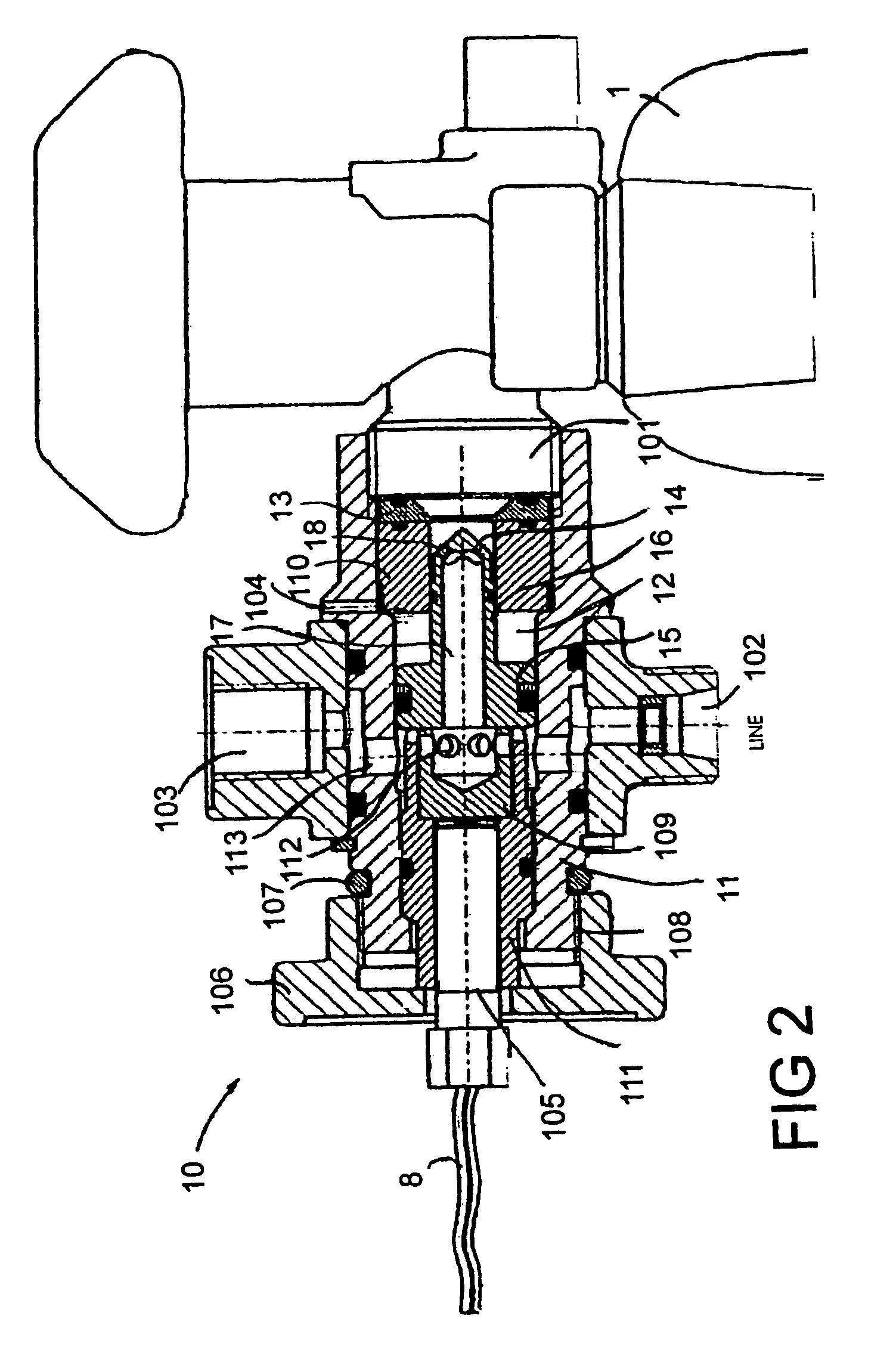

Valve element

InactiveUS7143775B2Efficient pressingConstant diameterEqualizing valvesFire rescueMechanical engineeringPiston

Valve element (3, 6, 10), comprising a frame, at least one inlet and at least one outlet, a passage connecting the inlet and outlet, at least one burst disk (13, 35, 63) or equivalent, which, when unbroken, closes the passage from inlet to outlet, and a piston element (15, 36, 65) provided with a piercing element or the like for piercing the burst disk. The piston element (15, 36, 65) is provided with a passage (17, 39, 67) for a pressure medium, said passage extending axially through the piston element from one first side to one second side, which passage leading through the piston forms a part of the passage of the pressure medium after the burst disk (13, 35, 63) has been pierced.

Owner:MARIOFF CORP OY

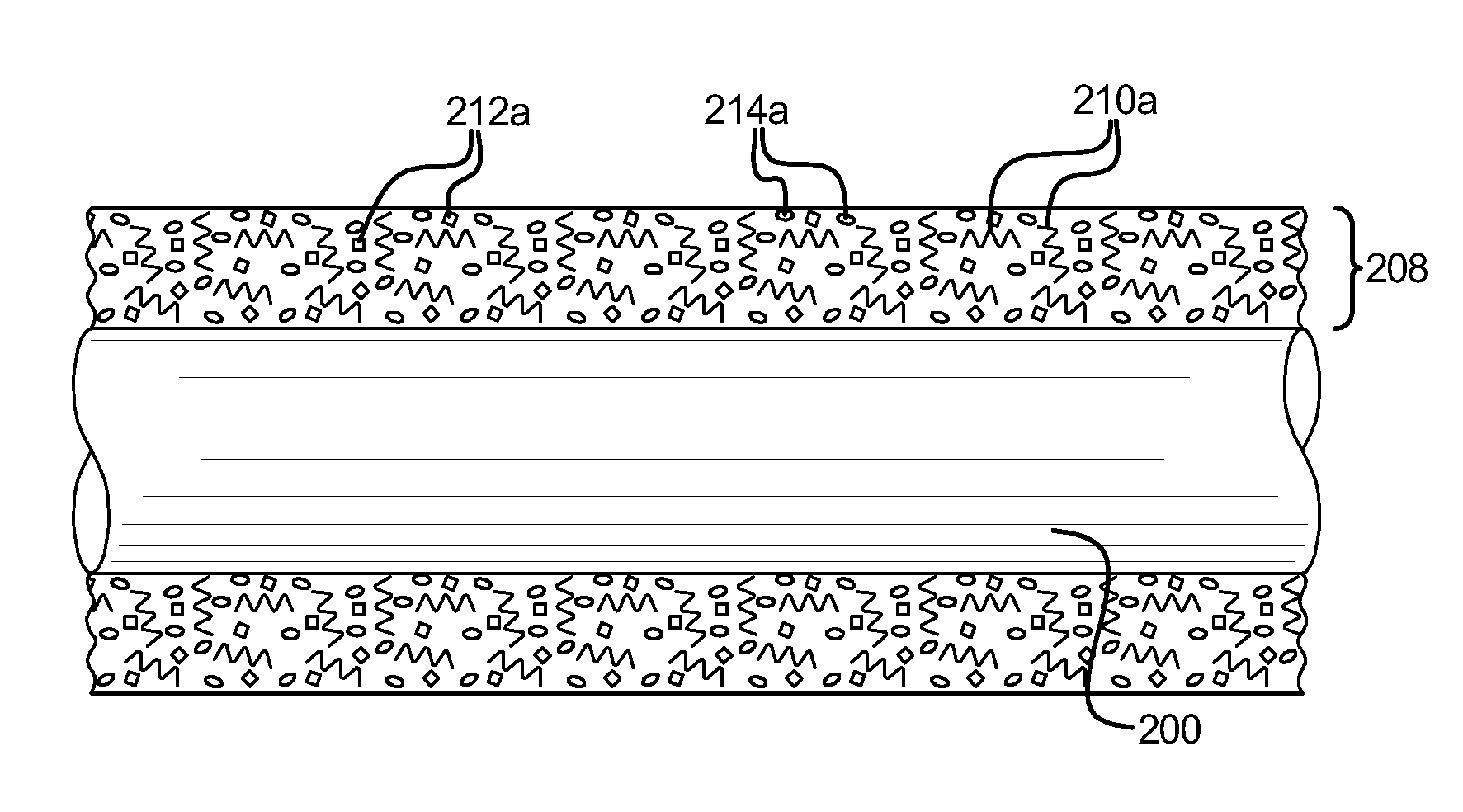

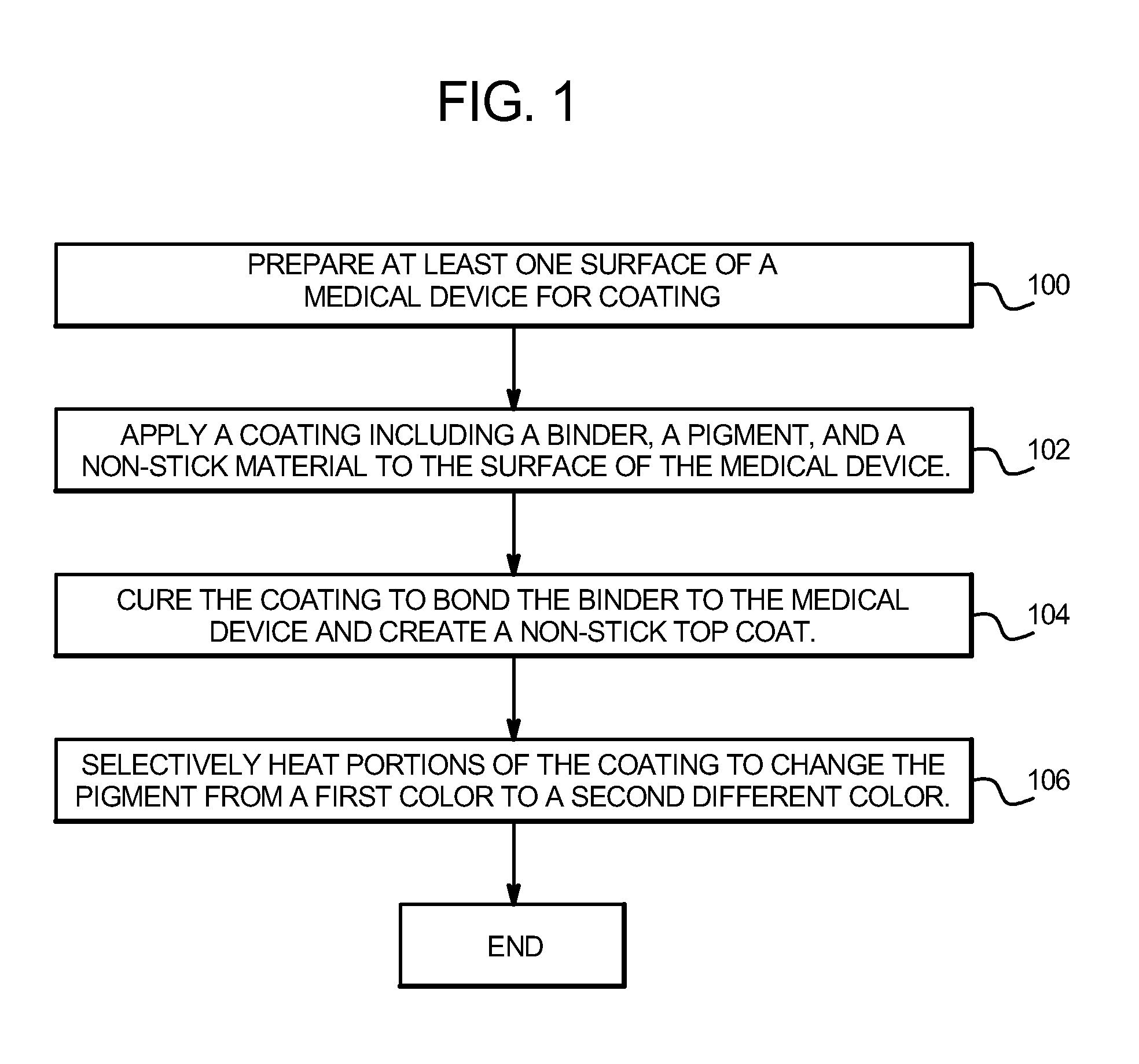

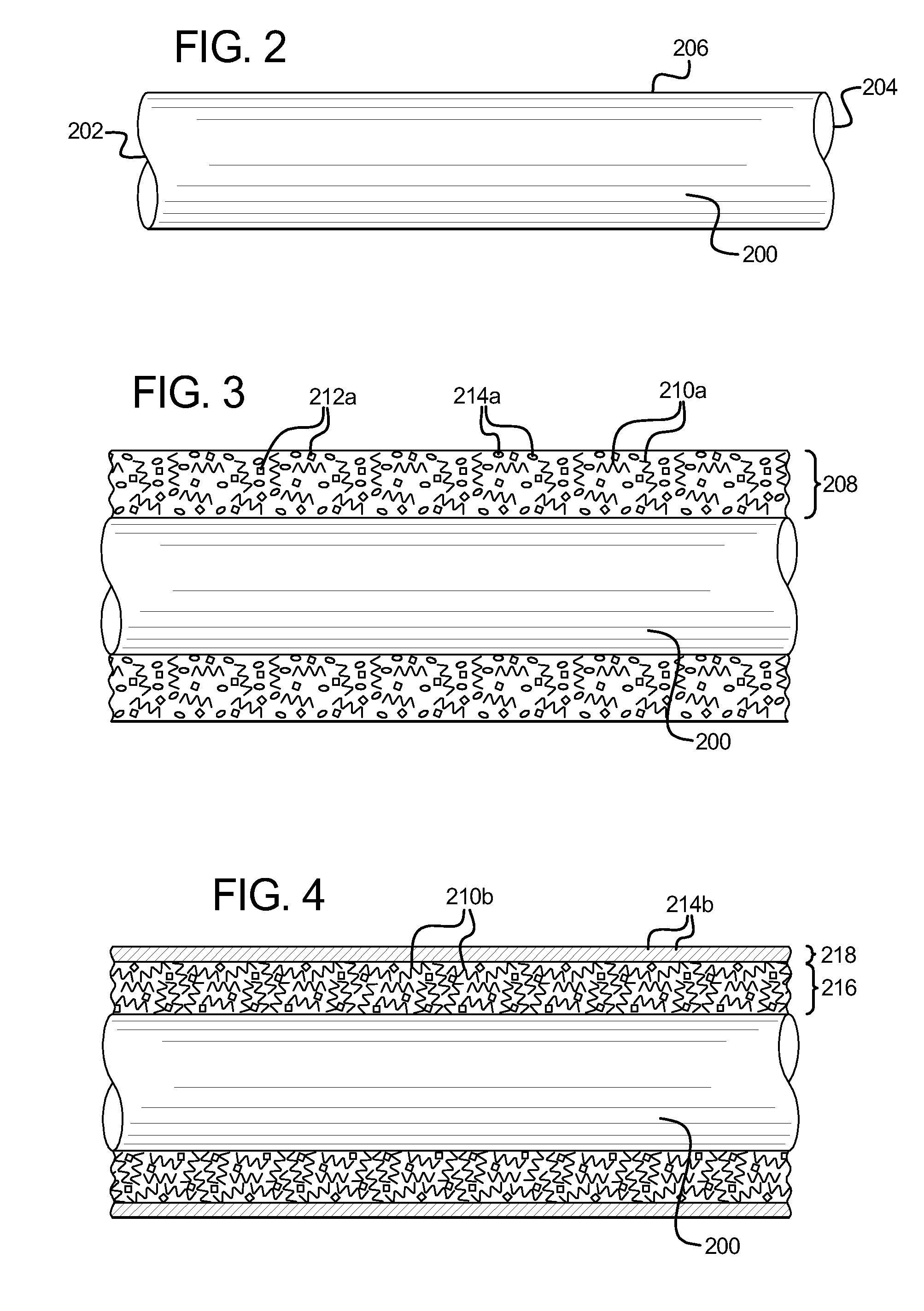

Marked precoated medical device and method of manufacturing same

InactiveUS20120271248A1Fully dryConstant diameterSurgeryPretreated surfacesCoated surfaceGuide wires

A method of manufacturing a coated medical device, such as a medical guide wire, including at least applying a first colored coating to at least a first portion of an outer surface of a medical guide wire, securing a first end of the medical guide wire, and for each a designated quantity of turns, turn a second end of the medical guide wire upon a longitudinal axis of the medical guide wire. The method of manufacturing also includes securing the second end of the medical guide wire, blocking at least a first portion of the coated surface of the medical guide wire, applying a second contrasting colored coating to at least a second, unblocked portion of the outer surface of the medical guide wire and releasing the first end and the second end of the medical guide wire to display at least one spiral marking formed along a length of the medical guide wire.

Owner:INNOVATECH

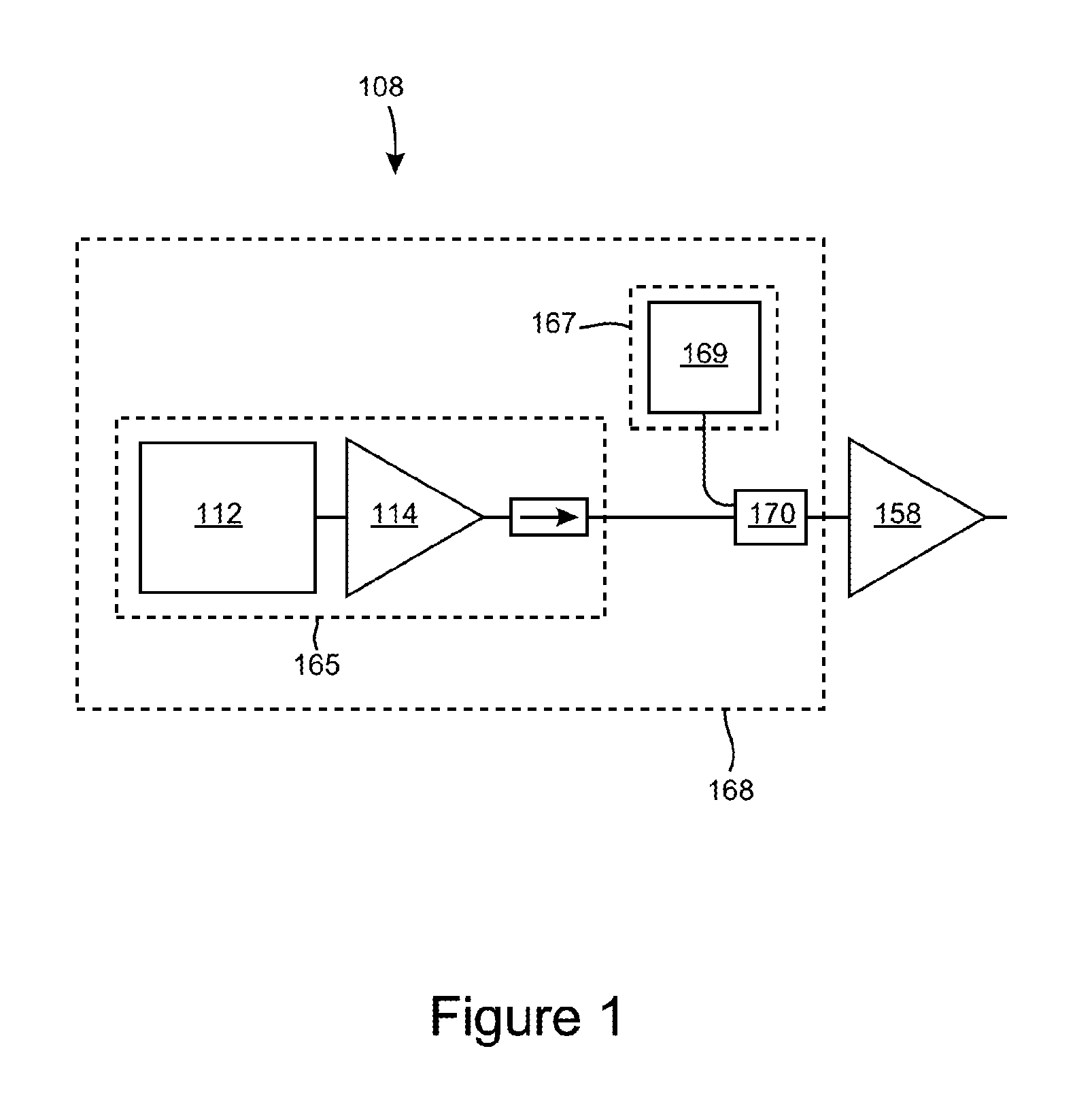

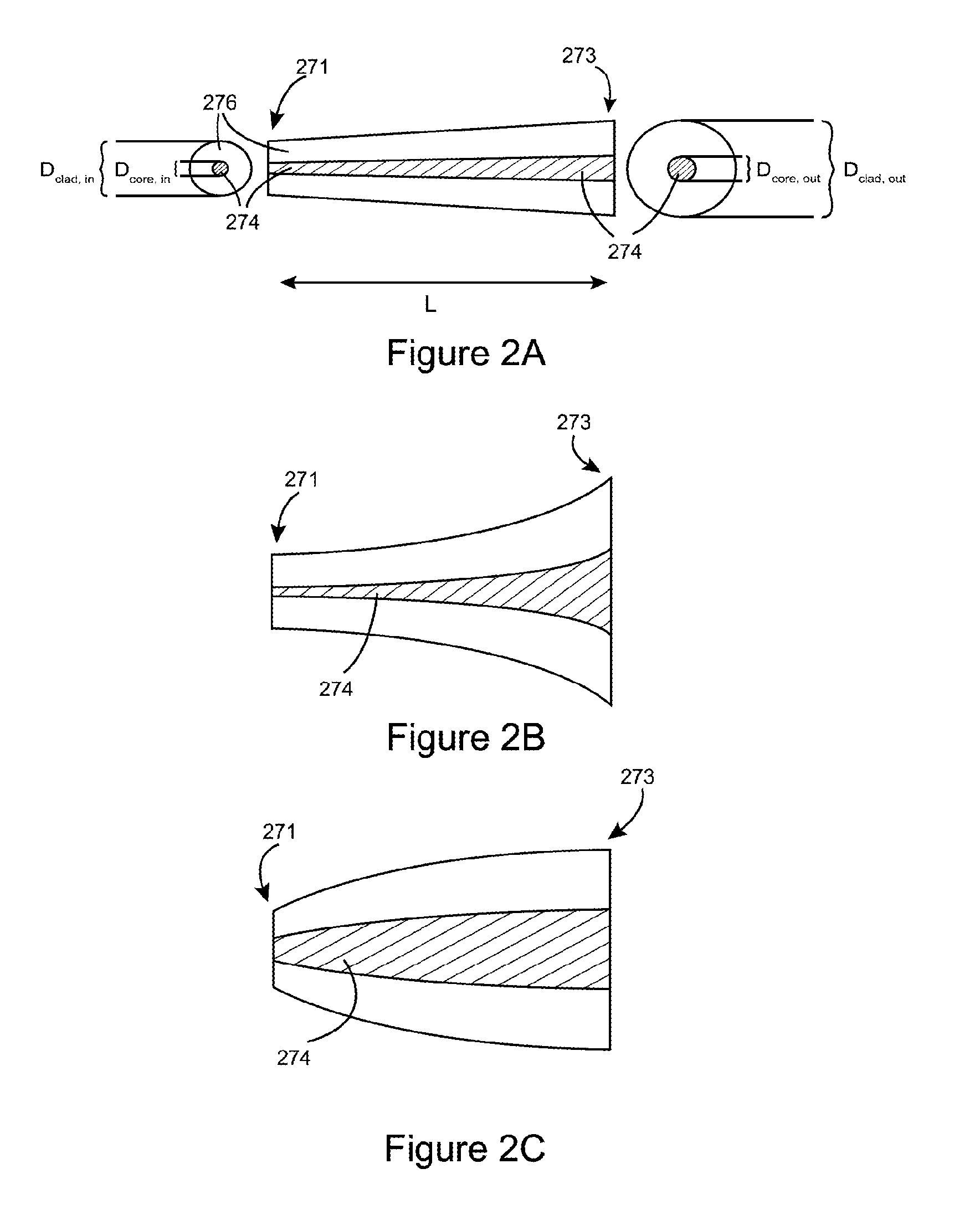

Lasers and Amplifiers Having Tapered Elements

InactiveUS20130301663A1Constant diameterUniform refractive index distributionLaser using scattering effectsOptical resonator shape and constructionAudio power amplifierMultiple modes

A laser system for generating optical pulses at an operating wavelength of the laser system. The system has an optical resonator comprising first and second reflectors, and a tapered optical fiber disposed between the first and second reflectors. The tapered optical fiber has a core which has a tapered input section which tapers from single mode to multimode at the laser operating wavelength, an inner section of substantially constant diameter capable of supporting multiple modes at the laser operating wavelength and a tapered output section which tapers from a first diameter to a second diameter that is smaller than the first diameter.

Owner:NKT PHOTONICS

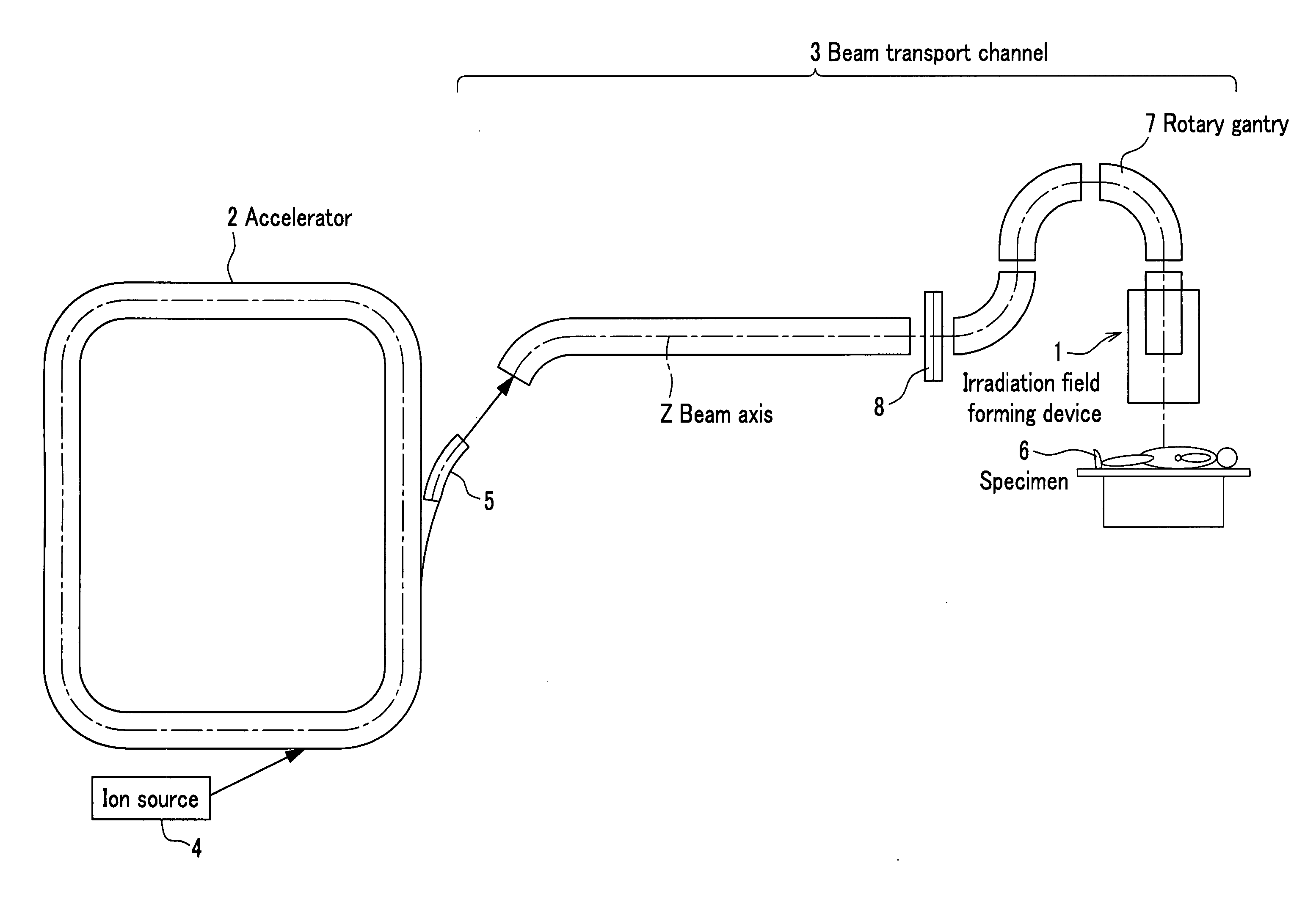

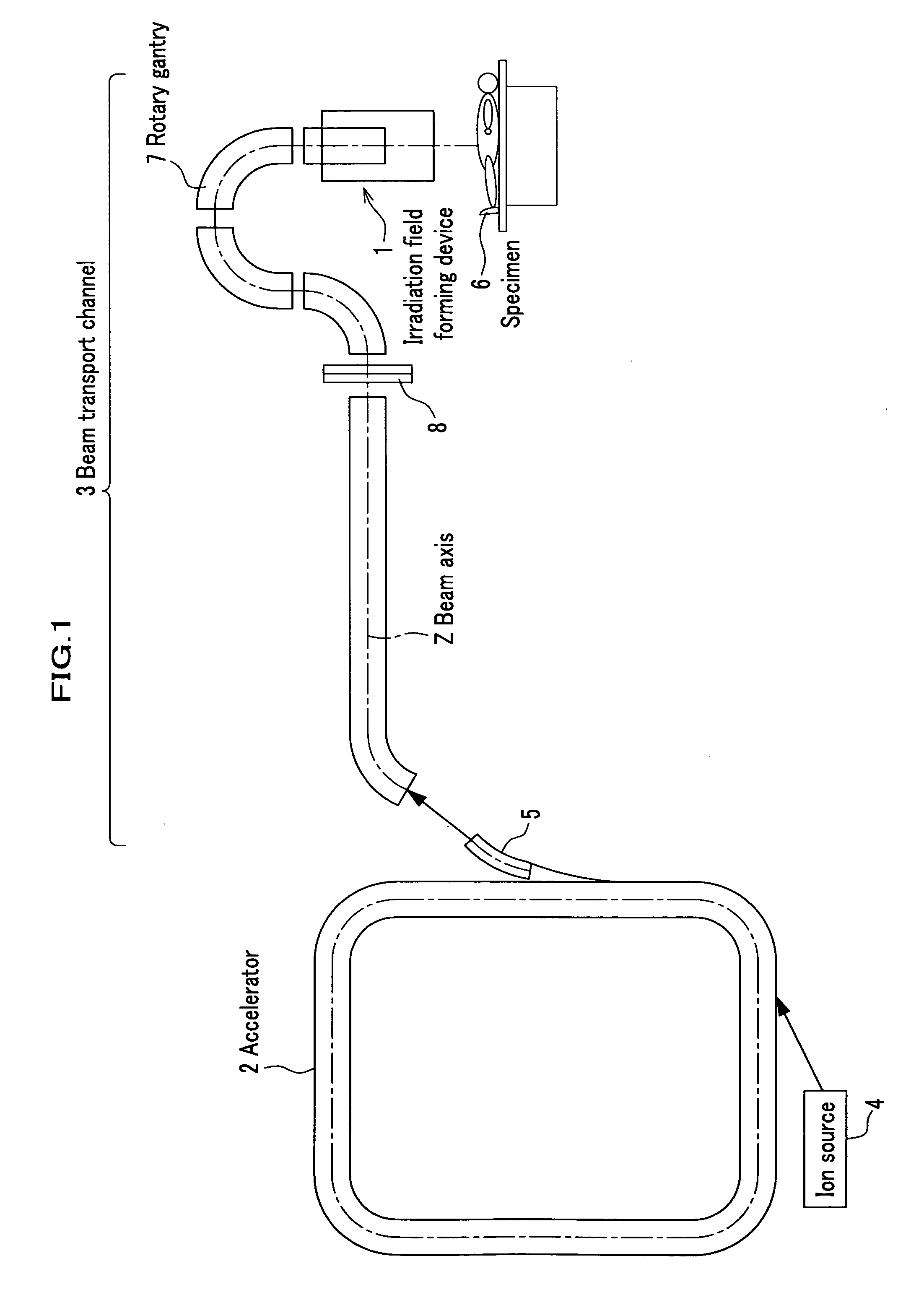

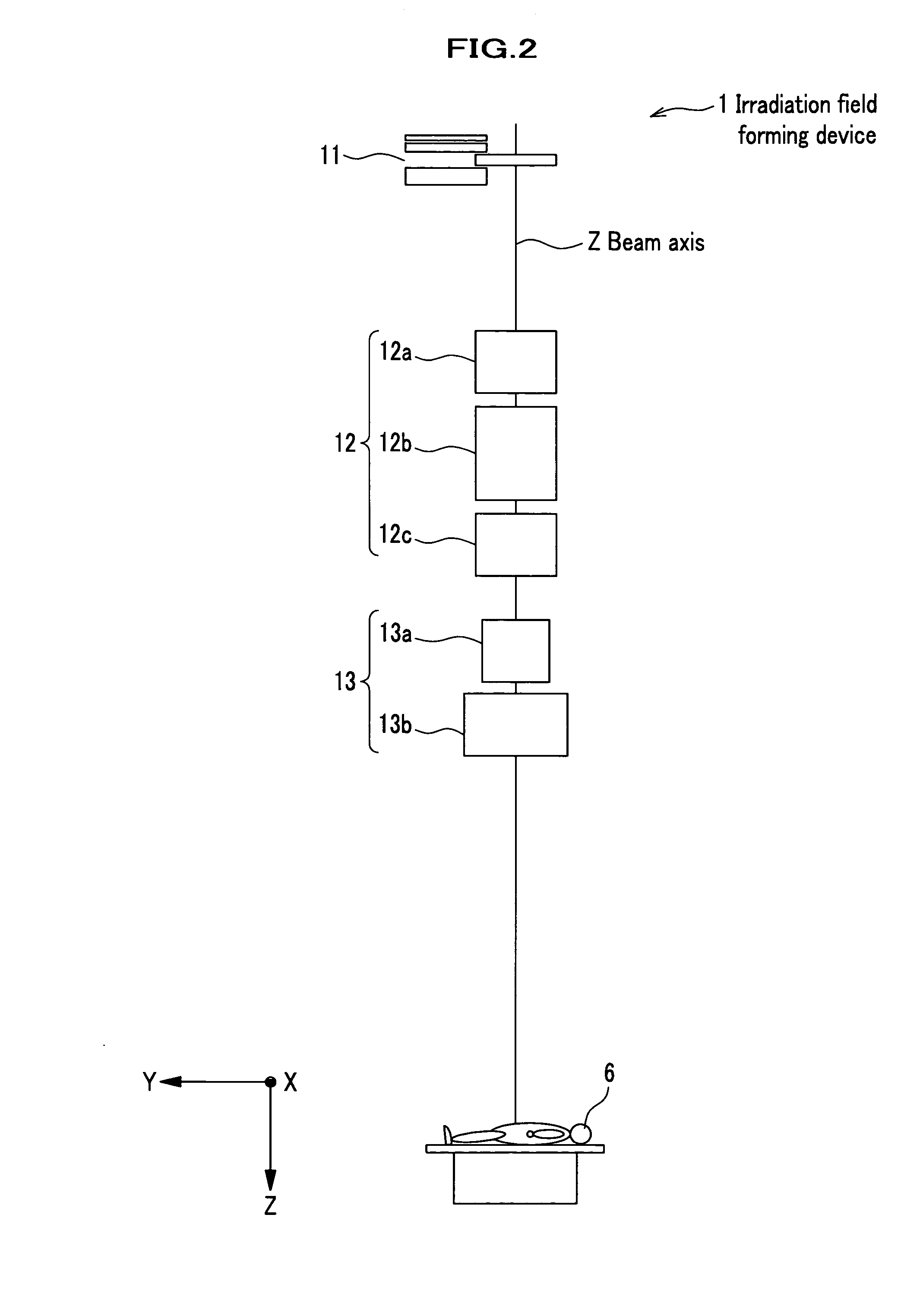

Irradiation Field Forming Device

InactiveUS20100213384A1Constant diameterThermometer detailsBeam/ray focussing/reflecting arrangementsBeam diameterLight beam

An irradiation field forming device for forming an irradiation field when a specimen is irradiated with a charged particle beam generated by an accelerator, the irradiation field forming device includes: a range shifter arranged on a beam axis of the charged particle beam for regulating an irradiation depth of the charged particle beam; and two or more than two converging electromagnets arranged in the downstream of the range shifter for regulating a beam diameter of the charged particle beam which is enlarged by the range shifter to a constant value.

Owner:NAT INST OF RADIOLOGICAL SCI

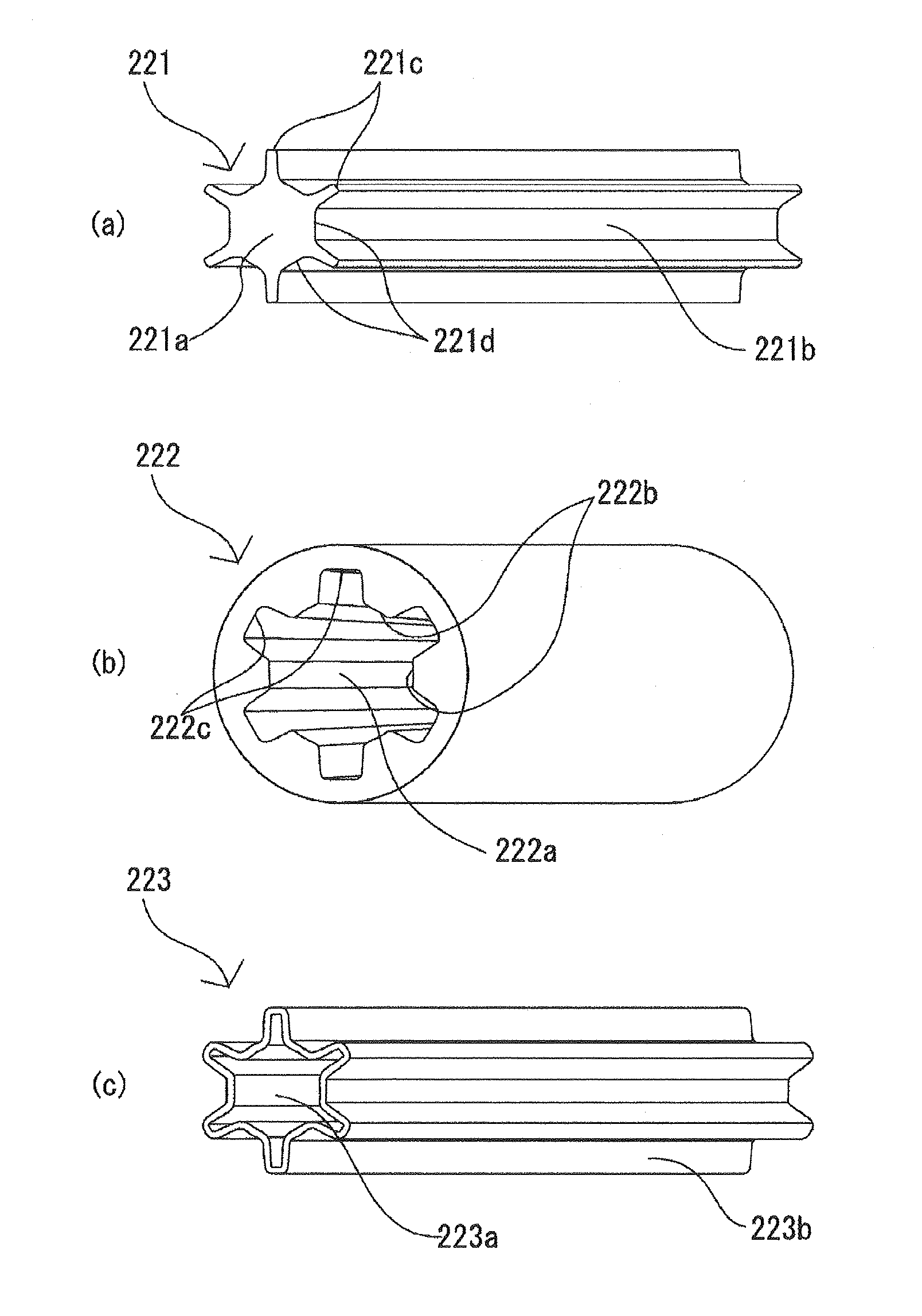

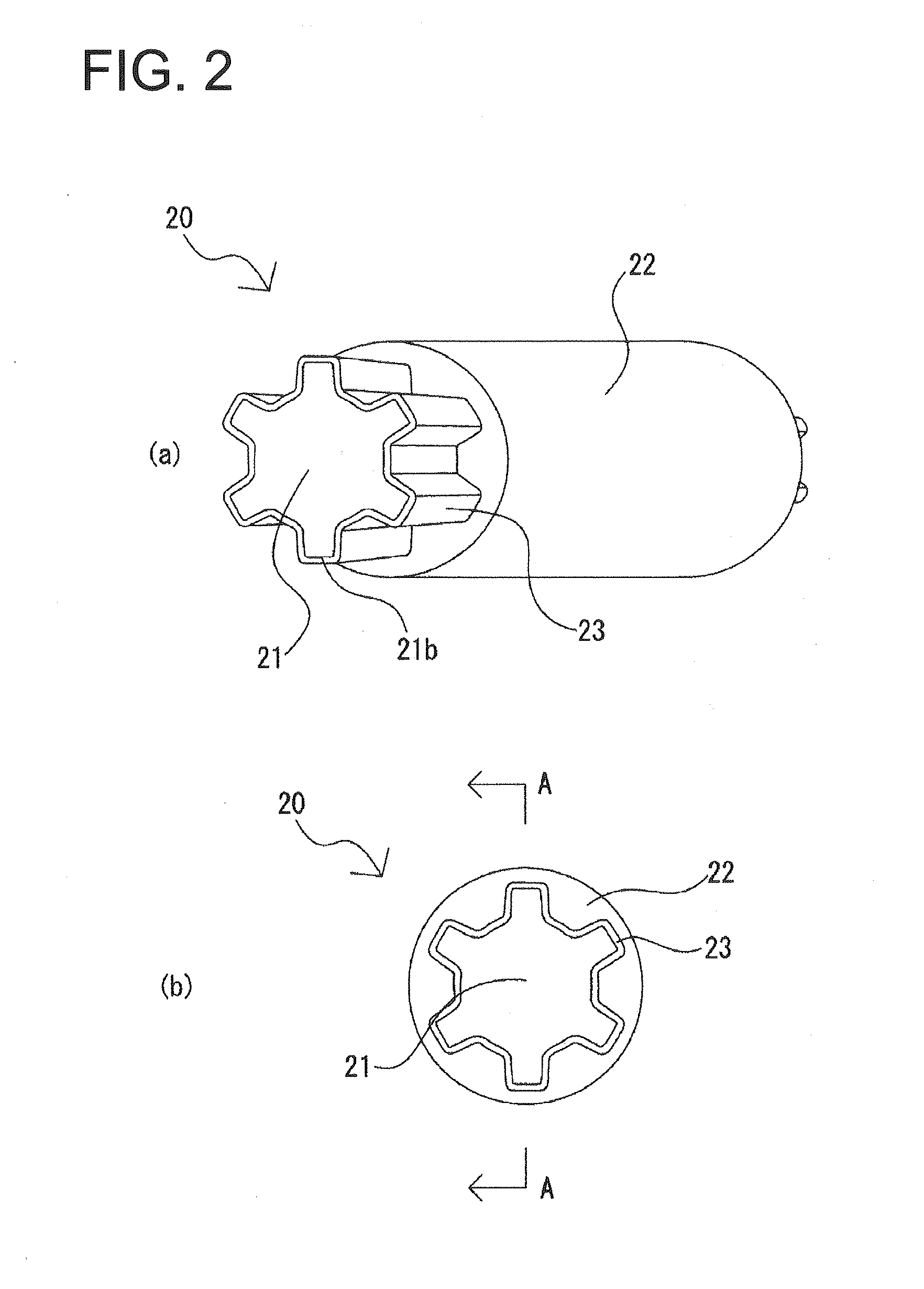

Structure for shaft, male member, and female member

InactiveUS20150275946A1Constant diameterReduced durabilityYielding couplingRod connectionsEngineeringTime difference

A shaft structure including: a male component having male spline parts and male spline bottom parts on an outer peripheral part; a female component having female spline parts and female spline bottom parts on an inner peripheral part configured to allow the male component to be slidably inserted in an axial direction; and an elastic member arranged on the male component covering a surface of the outer peripheral part of the male component, wherein, in an initial state where the male component is inserted into the female component, the female and male components have first gaps between: sides of the female spline parts; and sides-facing portions of the elastic member, and when the male component is rotated, a time from the initial state to a state where the sides of the female spline parts abut on the portions of the elastic member, has predetermined time differences along the axial direction.

Owner:NITTA CORP

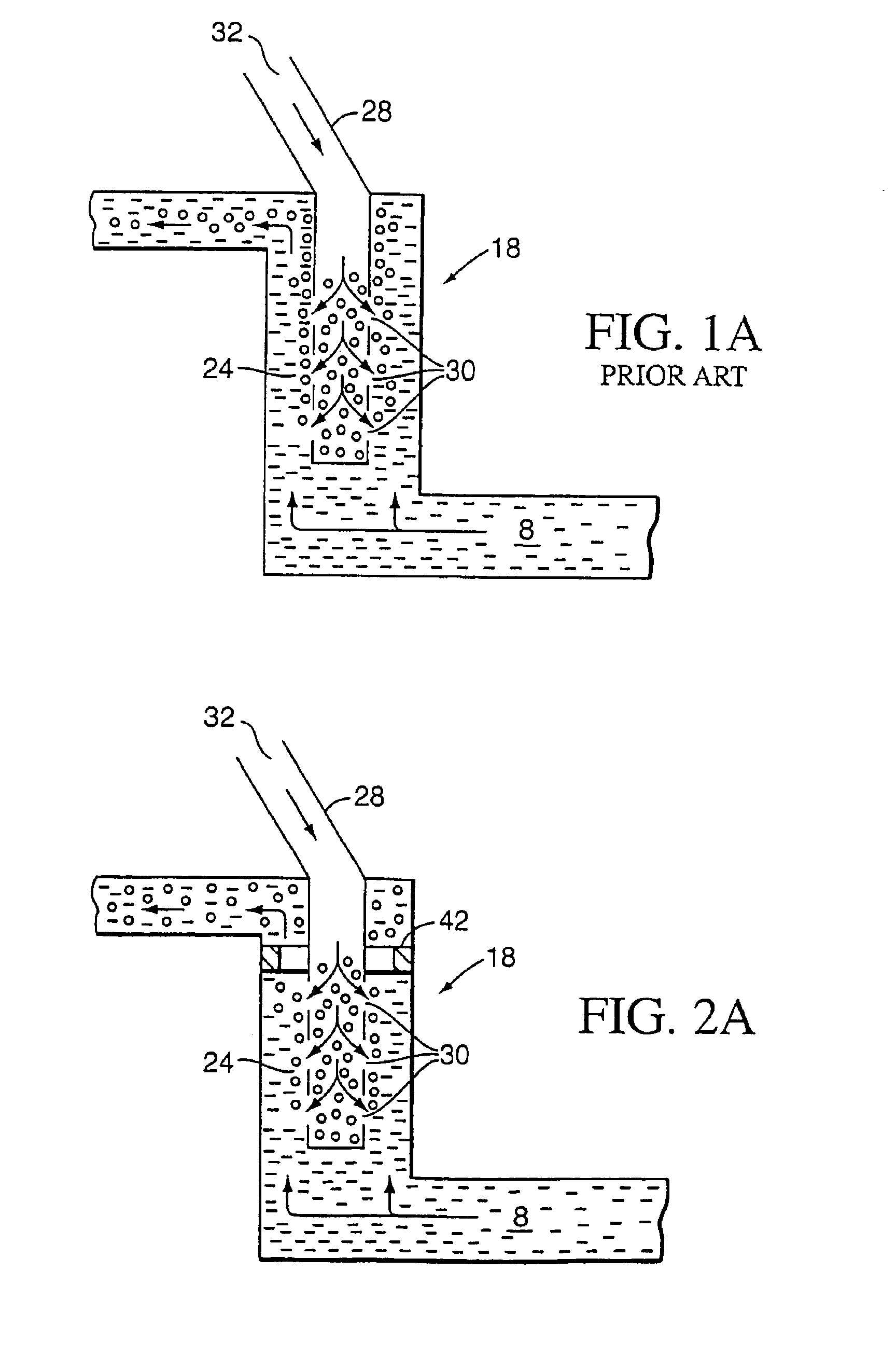

Interbore cooling system

A cooling system for cooling an interbore bridge of a cylinder block of a water cooled engine, the interbore bridge having a top surface and a central region of minimum width; the cylinder block having a water jacket; the cooling system including at lest one water passage extending from the top of the interbore bridge adjacent the central region to the water jacket. A method of forming the cooling system, and a cylinder block so formed, are also disclosed.

Owner:GASOLINEIAM NASIONAL BERHAD

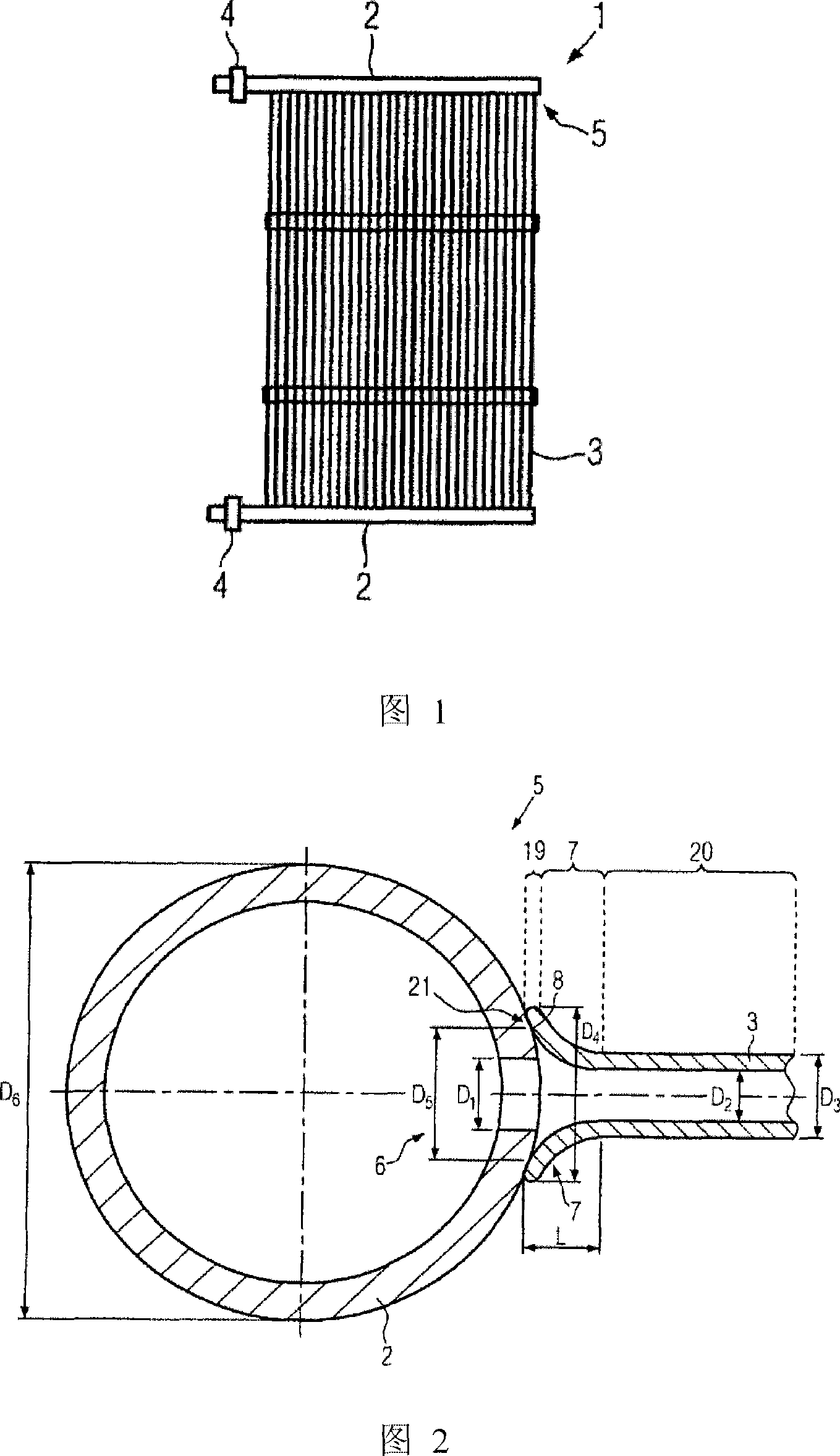

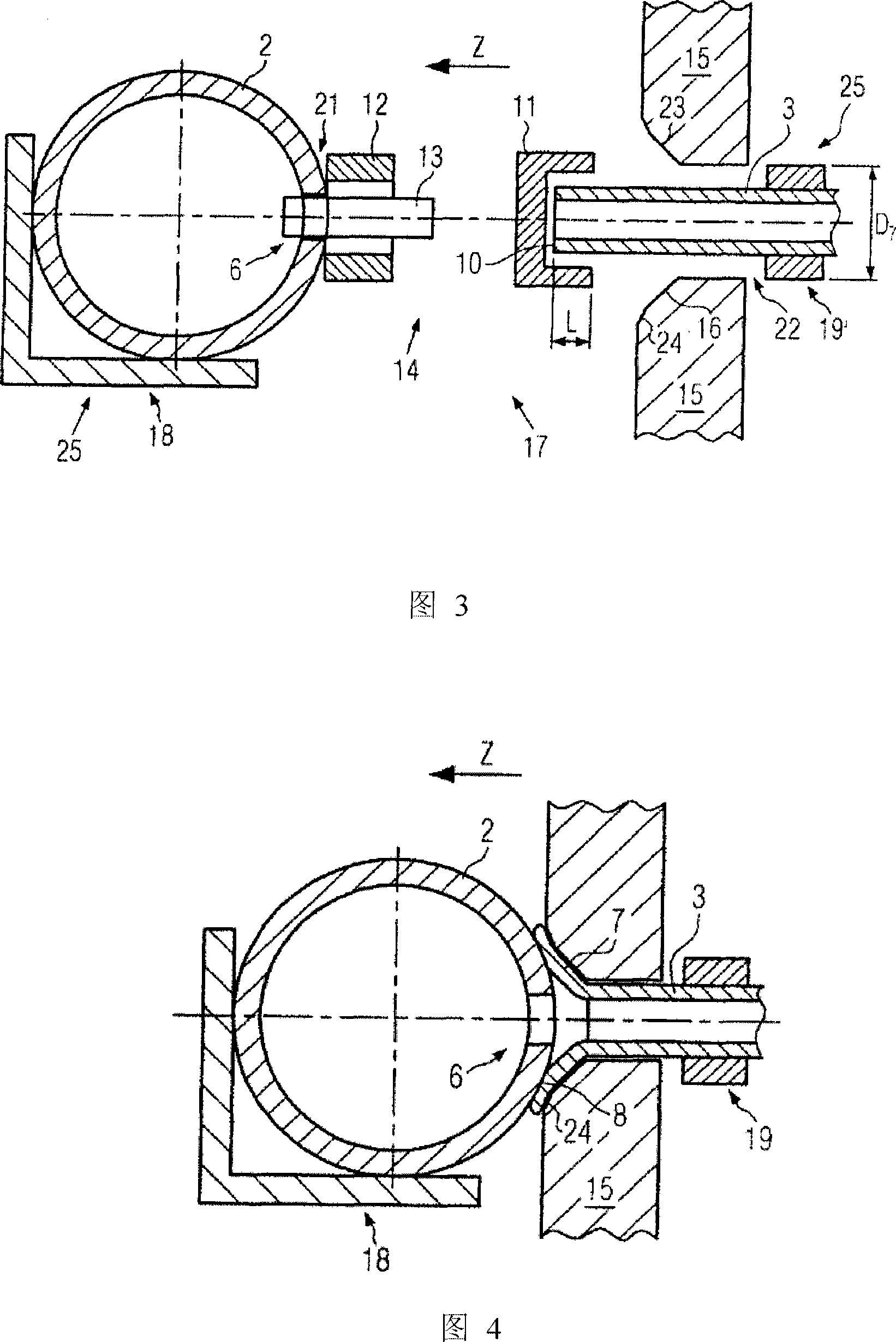

Plastic capillary pad, method and apparatus for producing the same

InactiveCN101219577AGood mechanical stressStrengthen connectionHeat exchanger casingsDomestic articlesBiomedical engineeringMechanical load

The invention relates to a method for producing a plastic capillary mat (1), in which a welding zone (19) at the axial end of a capillary (3) is radially welded to a manifold (2), wherein first Heating the weld zone (19) of the capillary (3) and the transition zone (7) adjacent to the weld zone (19) while increasing the outer diameter (D4) of the transition zone (7) and then removing the weld zone (19) Press onto the manifold (2). In order to improve the mechanical load-bearing properties of the capillary mat, the invention proposes to form a predetermined outer contour in the transition region ( 7 ) during the mutual pressing.

Owner:BEKA HEIZ & KUEHLMATTEN

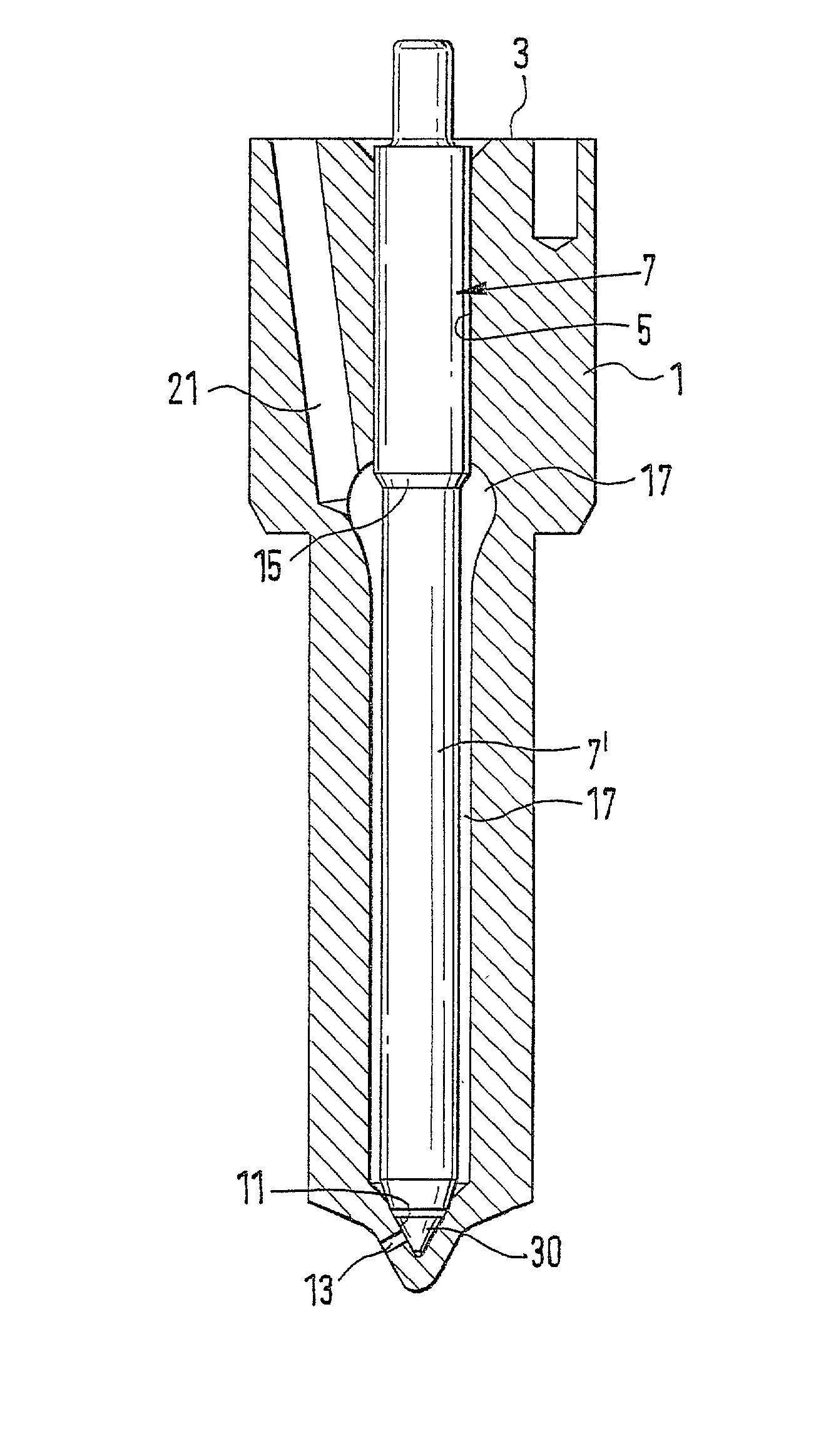

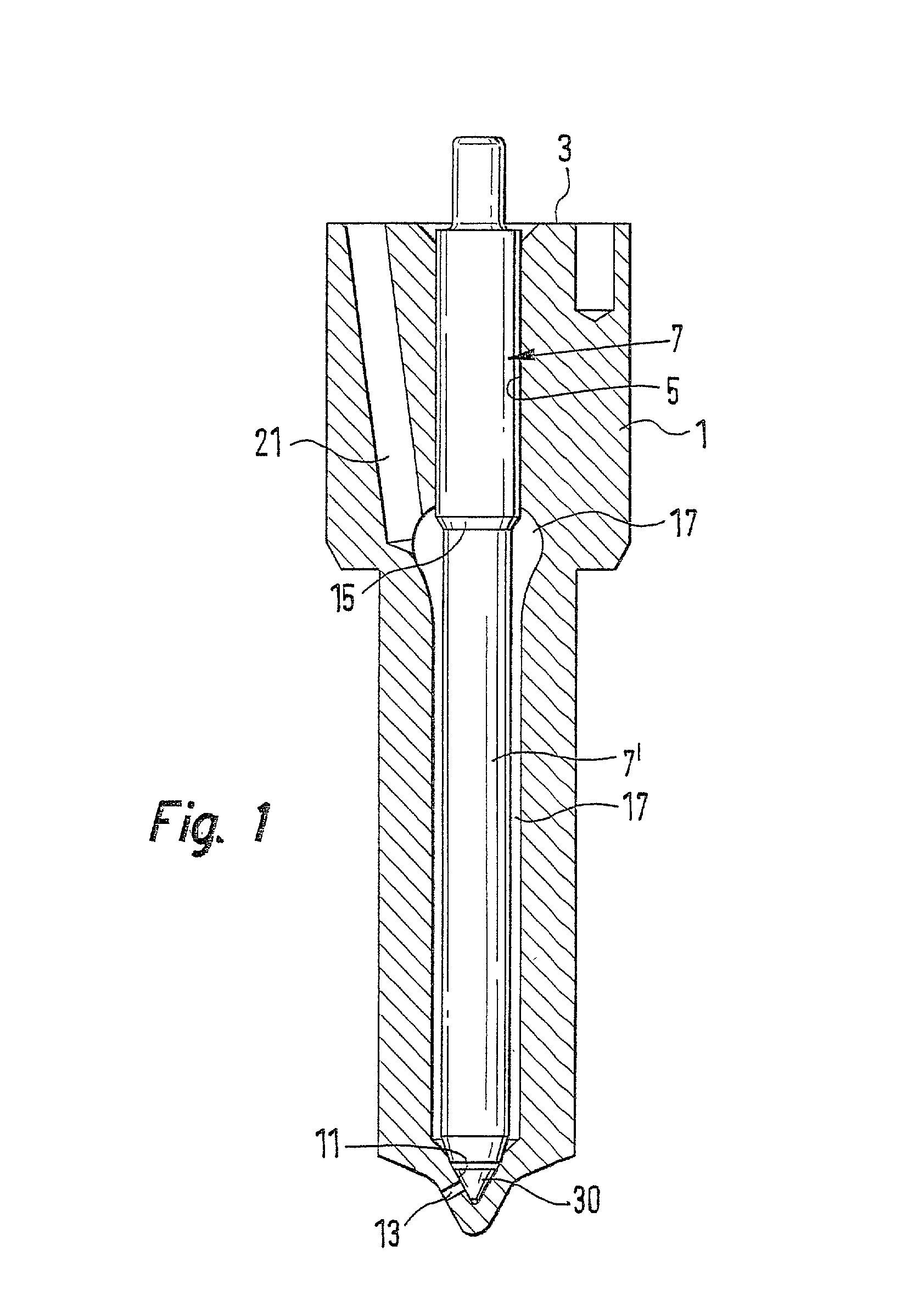

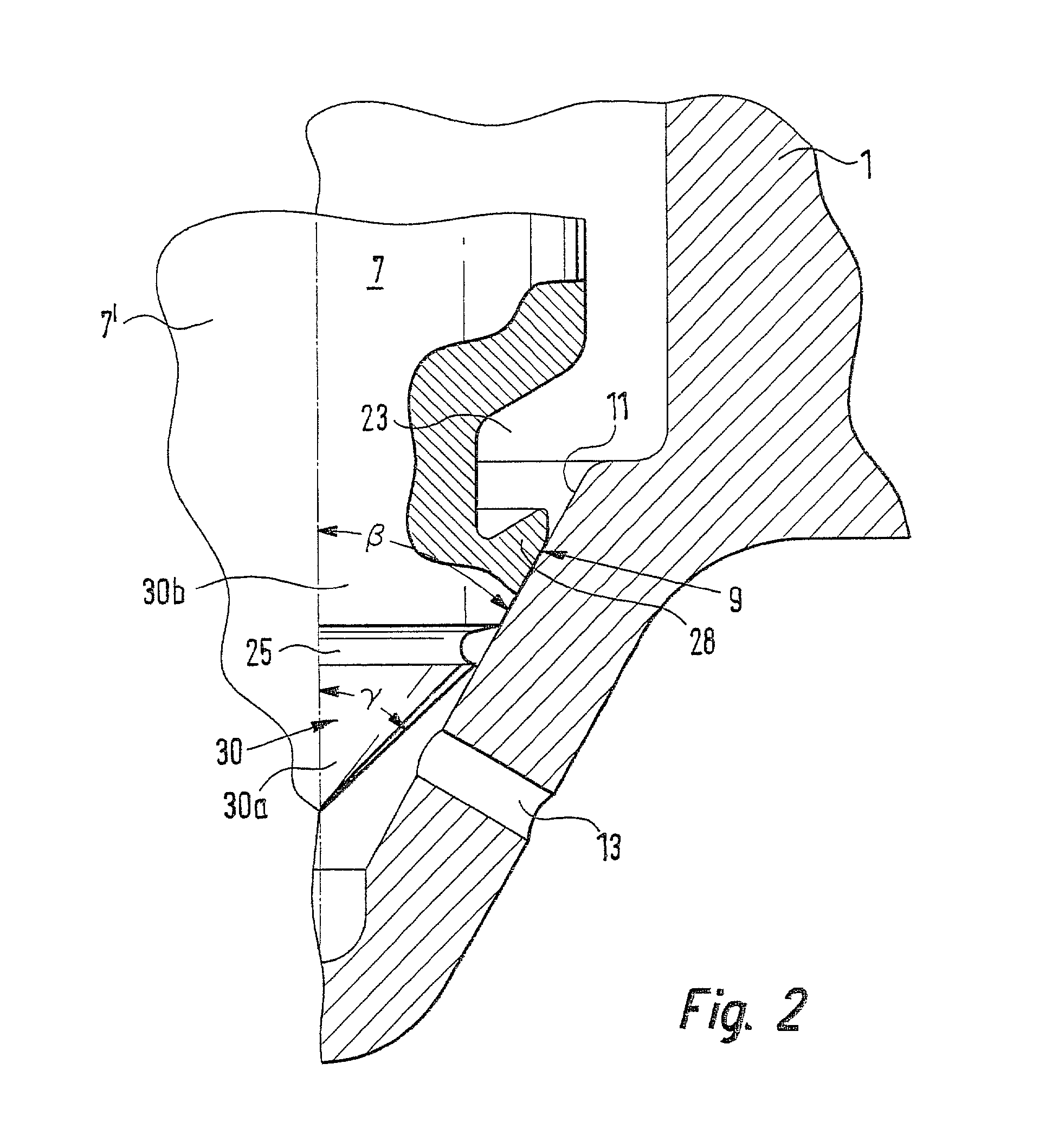

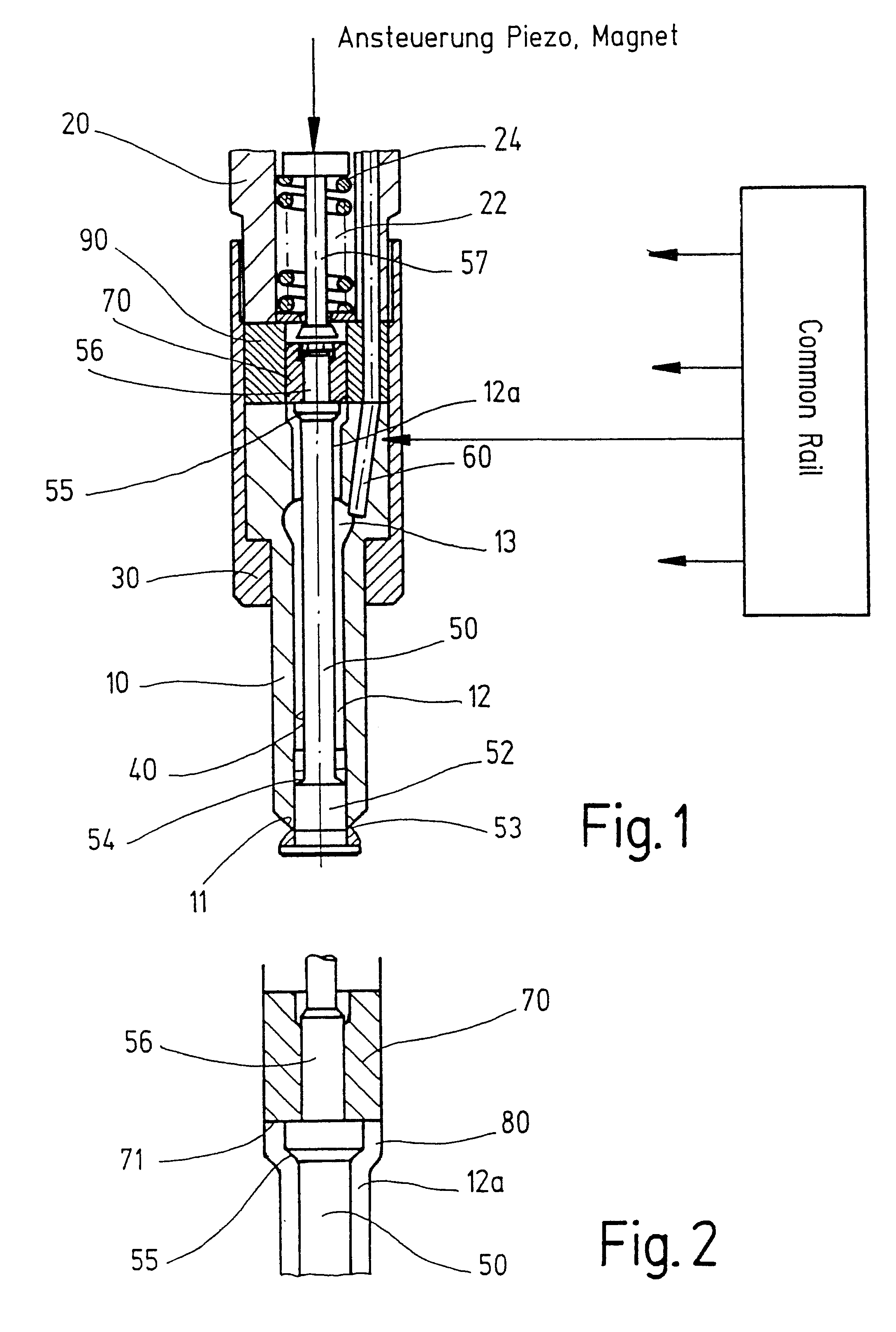

Fuel injection valve for internal combustion engines

InactiveUS20030057298A1Avoid excessive wearReduce deformationSpray nozzlesMachines/enginesCombustion chamberEngineering

A fuel injection valve for internal combustion engines, having a valve body (1) in which in a bore (5), a valve member (7) is disposed to be axially movable counter to a closing force. On its end, the valve member (7) has a substantially conical valve member tip (30), which with a part of its jacket face that serves as a valve sealing face (9) comes to rest on a valve seat (11), embodied on the end toward the combustion chamber of the bore (5). At the transition from the valve member (7) to the valve member tip (30), an annular groove (23) is embodied, which undercuts the valve sealing face (11) in part and thereby forms an annular collar (28), which is resiliently yielding. The cone angle (beta) of the valve sealing face (9), in the open position of the valve member (7), is somewhat larger than the cone angle (alpha) of the valve seat (11), so that in the closing motion of the valve member (7) toward the valve seat (11), the annular collar (28) is first seated with the outer edge, embodied as a sealing edge (34) and is deformed inward by the further closing motion. The sealing edge (34) is thus not press-fitted into the valve seat (11), and as a result the seat diameter remains unchanged over the service life of the fuel injection valve (FIG. 2).

Owner:ROBERT BOSCH GMBH

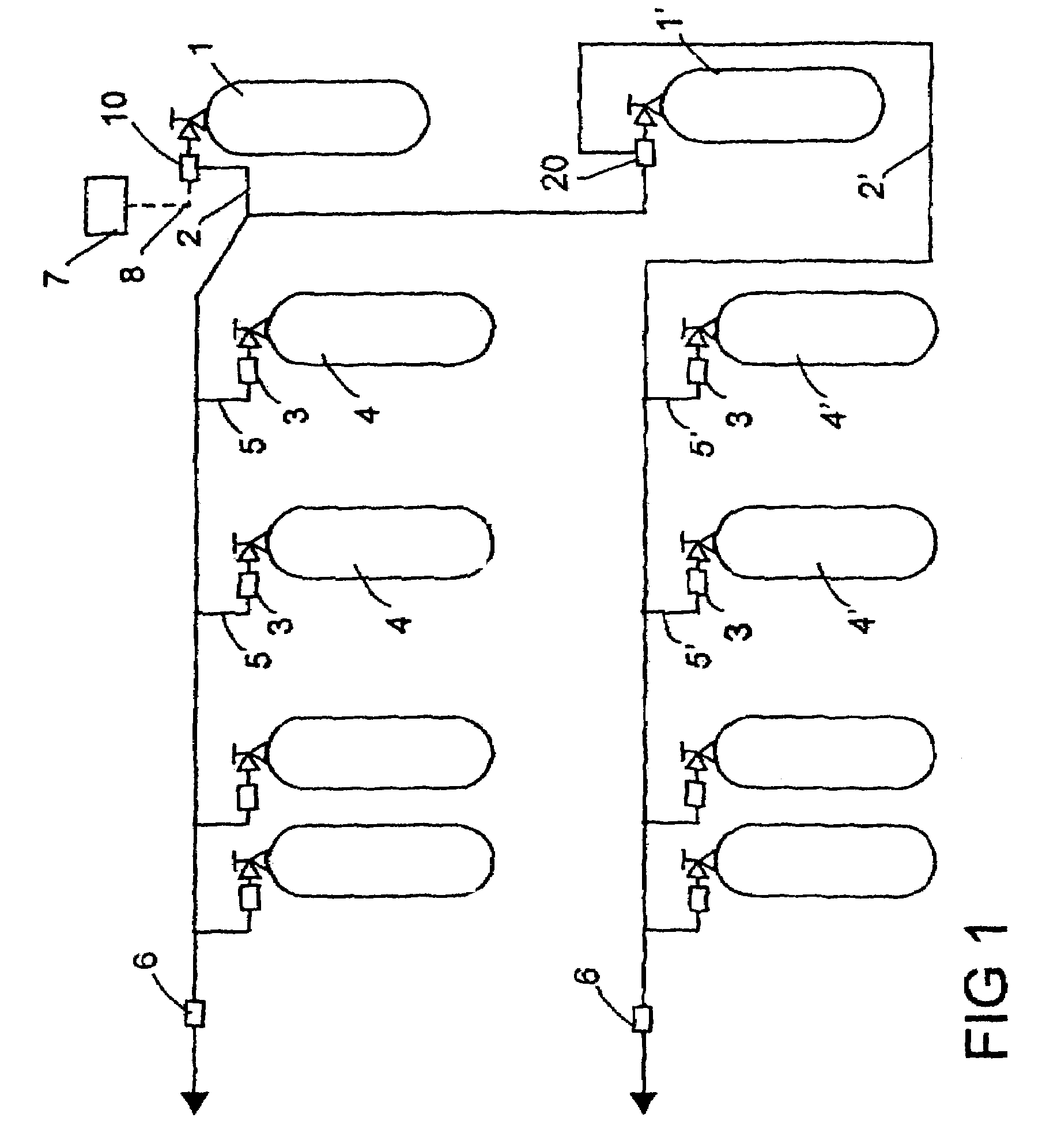

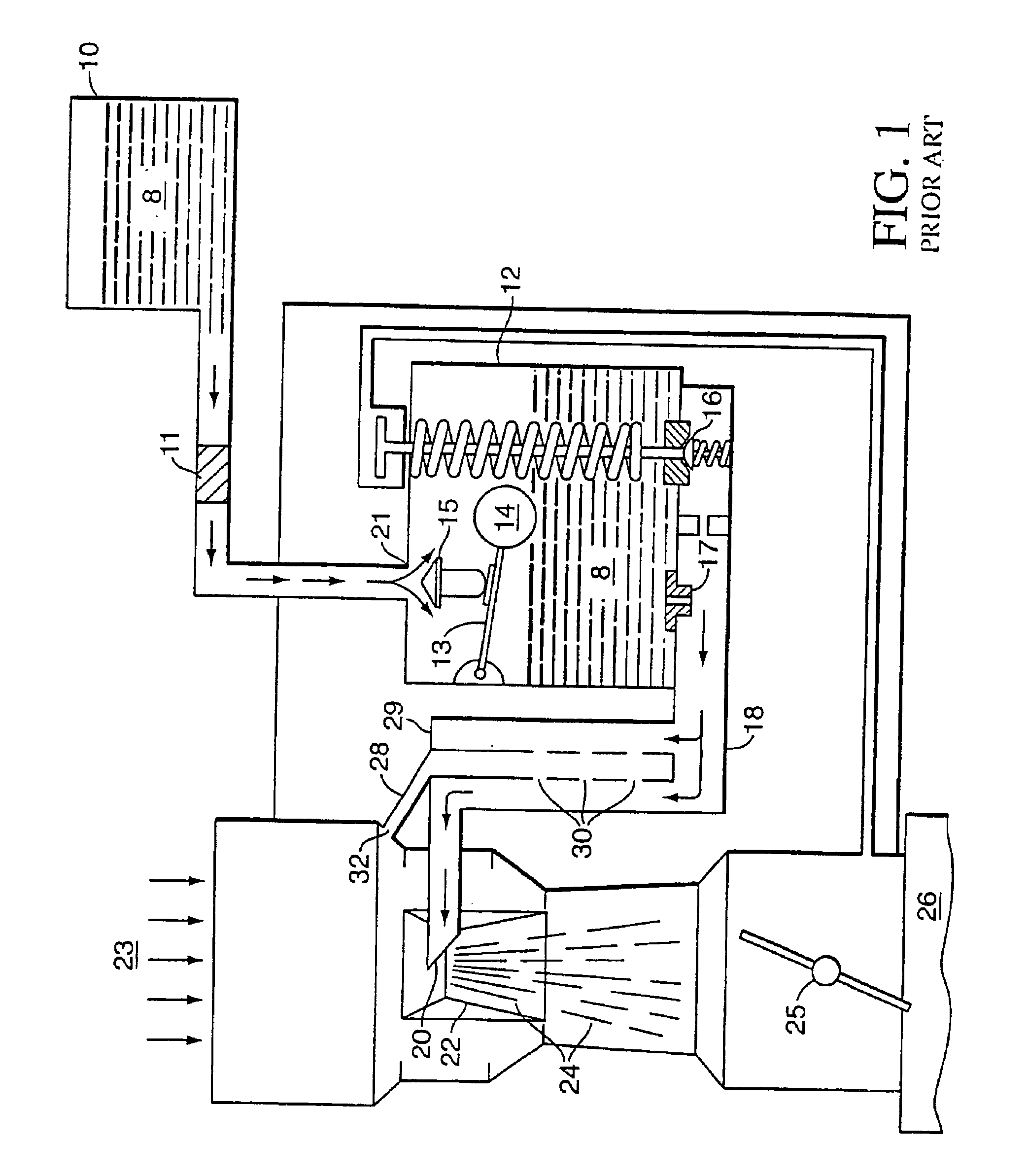

Fluid emulsification systems and methods

This invention describes systems and methods for mixing two fluids. A first fluid, usually fuel, can be passed through a primary passage that typically leads to a carburetor or other inlet to a combustion engine. A second fluid, usually air, can be mixed with the first by introducing it to the primary passage through an inlet located upstream in the primary passage. The mixture of fluids can then be further emulsified by passing it over a plurality of obstructions, such as a threaded interior surface of the primary passage, located within the primary passage downstream of the inlet.

Owner:SATTERFIELD JOHN R

Inhalation apparatus

InactiveUS20080092880A1Constant diameterEfficient dosingRespiratorsBreathing filtersInhalationEvaporation

In order to control the amount of evaporation of discharged agent droplets and so that a user can inhale agent droplets having a constant diameter regardless of use environment, an inhalation apparatus includes an airflow path communicating with a suction port through which the user inhales an agent, an agent discharging portion configured to discharge an agent supplied to the airflow path, and a humidifier located outside the airflow path and configured to humidify an airflow in the airflow path generated by an inhalation of the user.

Owner:CANON KK

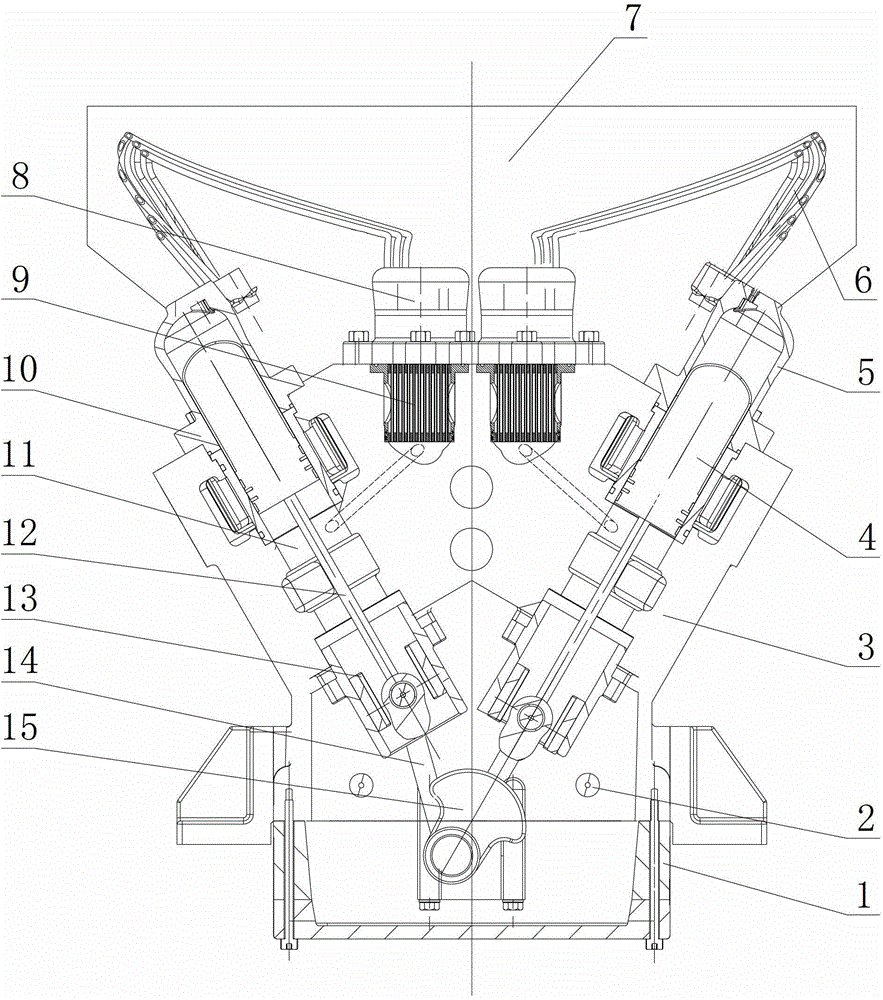

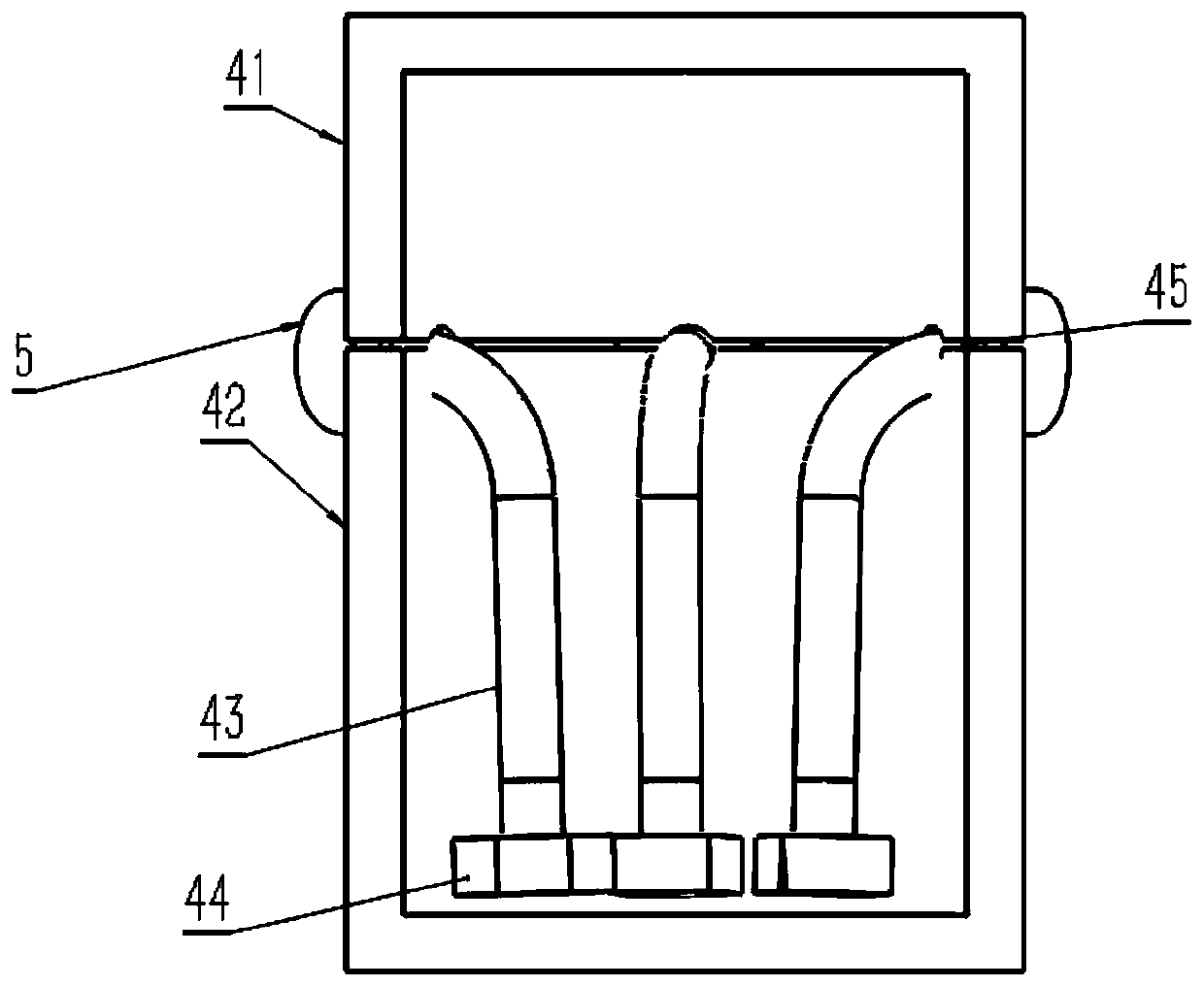

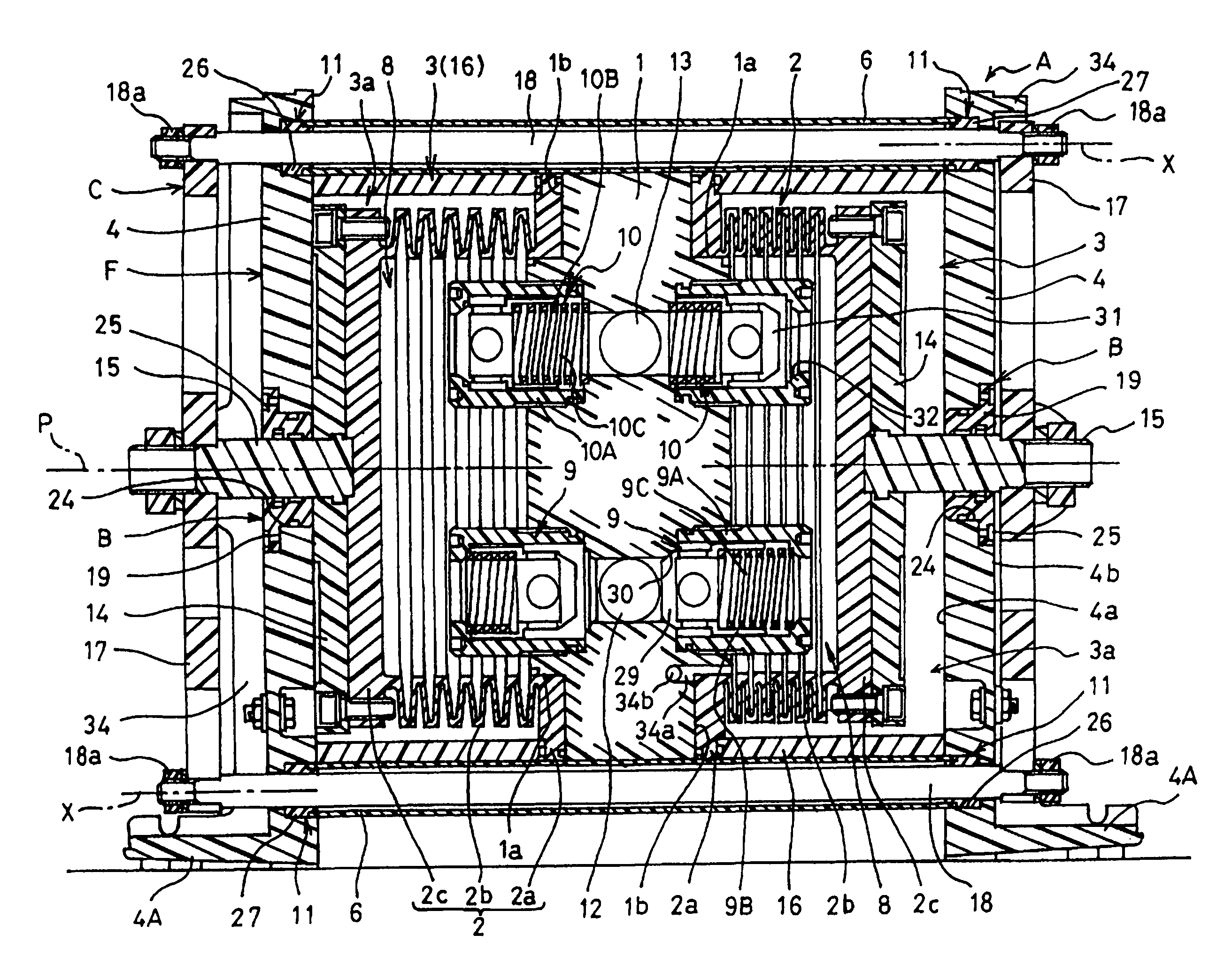

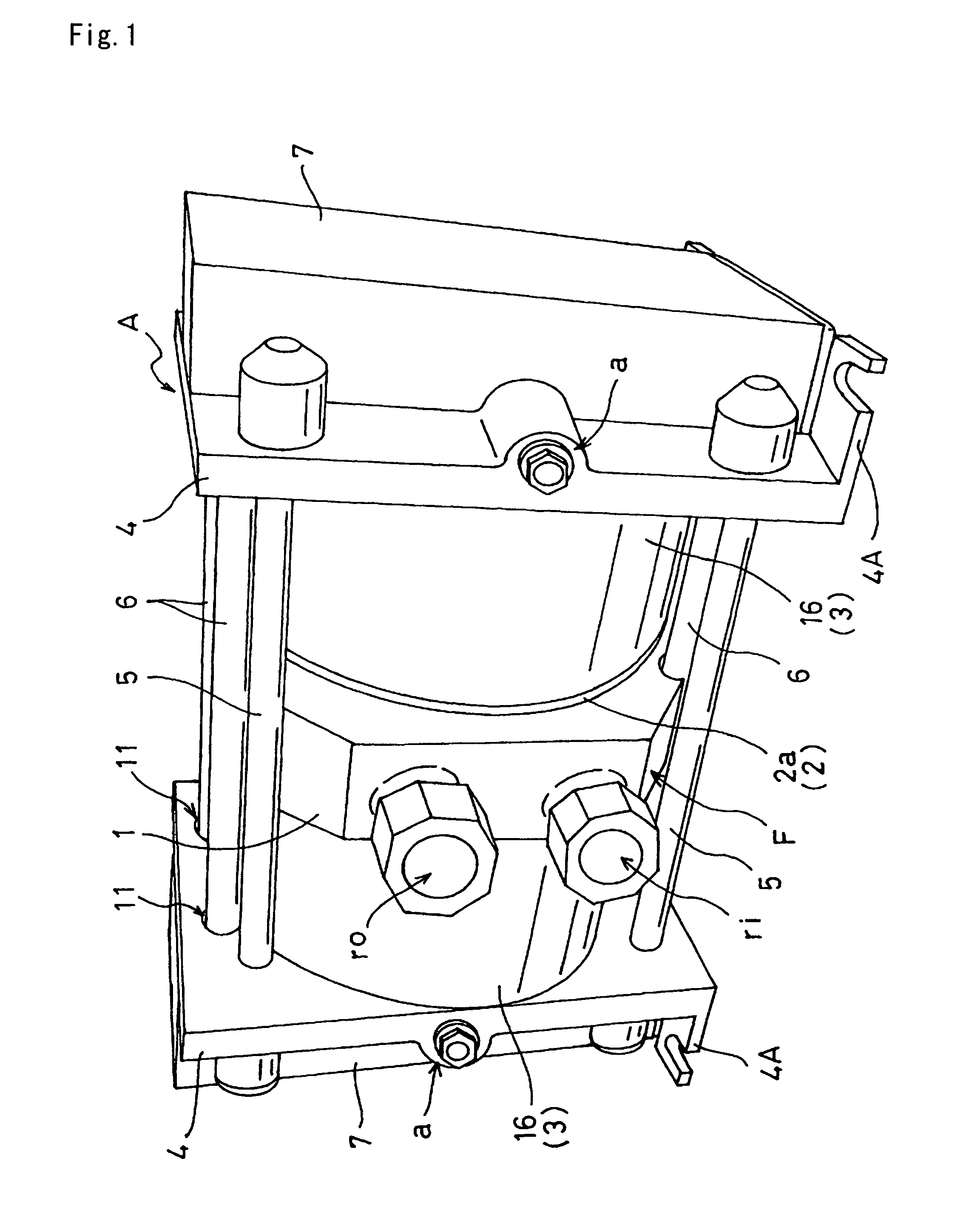

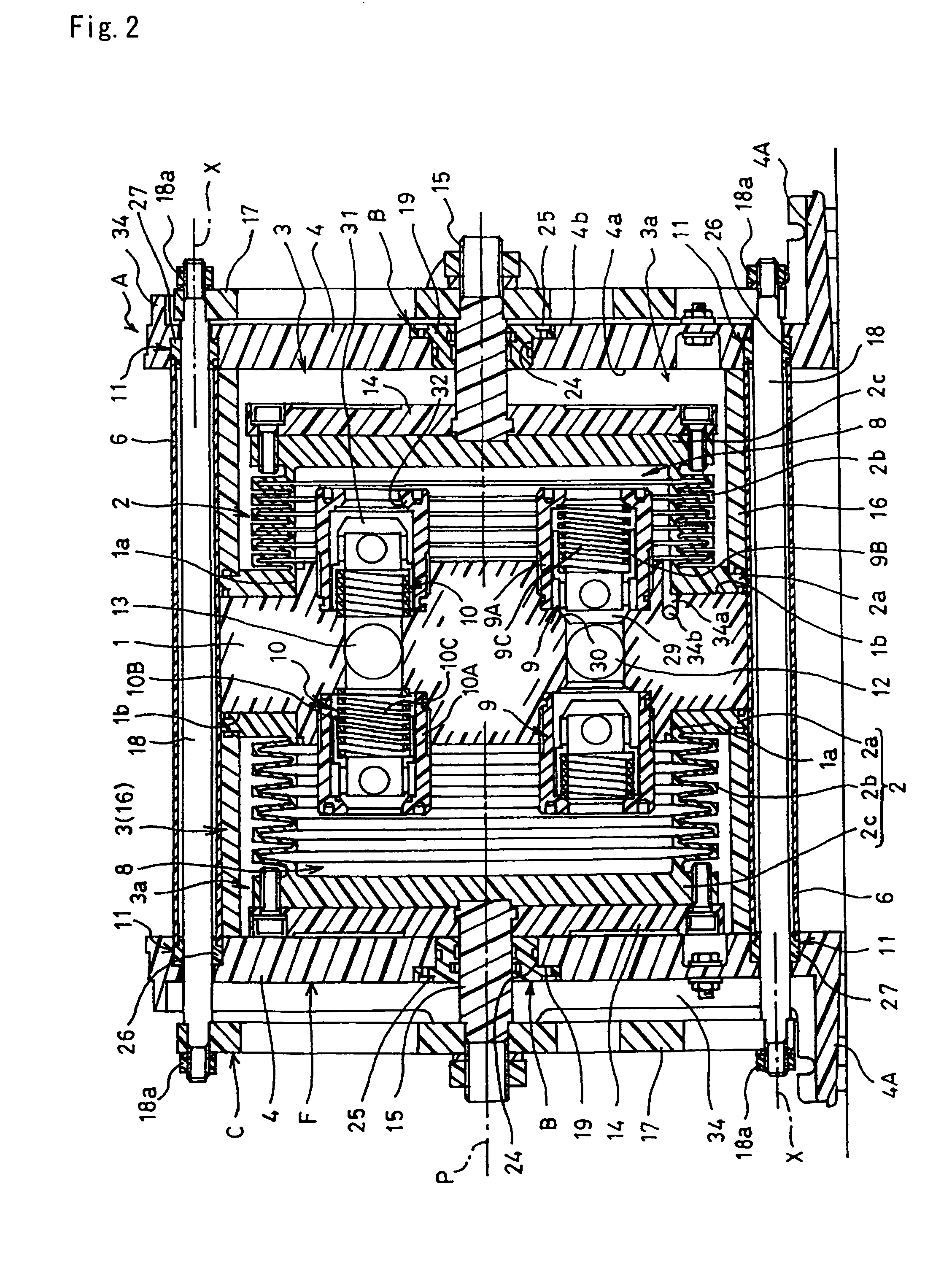

V-shaped arranged double-acting type Stirling engine

InactiveCN102913340ASimple structureIncrease the number of cylindersHot gas positive displacement engine plantsStirling engineEngineering

The invention provides a V-shaped arranged double-acting type Stirling engine, relates to a Stirling engine and particularly relates to a V-shaped arranged optical energy and heat energy engine. The V-shaped arranged double-acting type Stirling engine is formed by an engine base, a machine body, a cylinder sleeve, a crank shaft and a heat cavity air cylinder, and is characterized in that the machine body is arranged on the engine base; two rows of cavity bodies are machined on the machine body to be arranged in a V shape; the central line is crossed to a crank throw axial center of the crank shaft mounted at the lower part of the machine body; a moving device is arranged at the upper parts of the cavity bodies of the machine body through the cylinder sleeve; the lower part of the moving device is connected with the crank shaft; the heat cavity air cylinder is arranged on the moving device at the upper part of the machine body; a heating device is arranged on the heat cavity air cylinder and the machine body; and a work medium system is further arranged between the heating device and the moving device. The V-shaped arranged double-acting type Stirling engine has the characteristics of novel structure, simple structure, simplicity in machining, small volume, light weight, increased power and the like, so that the novel V-shaped arranged double-acting type Stirling engine which integrates the economical efficiency and the economical efficiency is provided.

Owner:DALIAN GREAT OCEAN NEW ENERGY DEV

Fluidic Interface Module for a Fuel Cell System

InactiveUS20140272647A1Constant diameterOperating means/releasing devices for valvesReactant parameters controlAutomotive engineeringElectricity

Purge valves that are manually turned ON but are automatically or electrically turned OFF as the fuel cell's production of electricity reaches a predetermined level, e.g., steady state or thereabout are disclosed. The purge valve may be opened at system start-up, or may be opened at system shut-down so that the purge valve is armed and the fuel cell system is purged at the next start-up. Also disclosed is an integrated fluidic interface module that contains various fluidic components including one of these purge valves. The integrated fluidic interface module can operate passively or without being actively controlled by a processor. Methods of operating a fuel cell system, wherein the fuel cell system is purged at system start-up, are also disclosed. The purging automatically stops when the anode plenum is fully purged and replaced with fuel.

Owner:INTELLIGENT ENERGY LTD

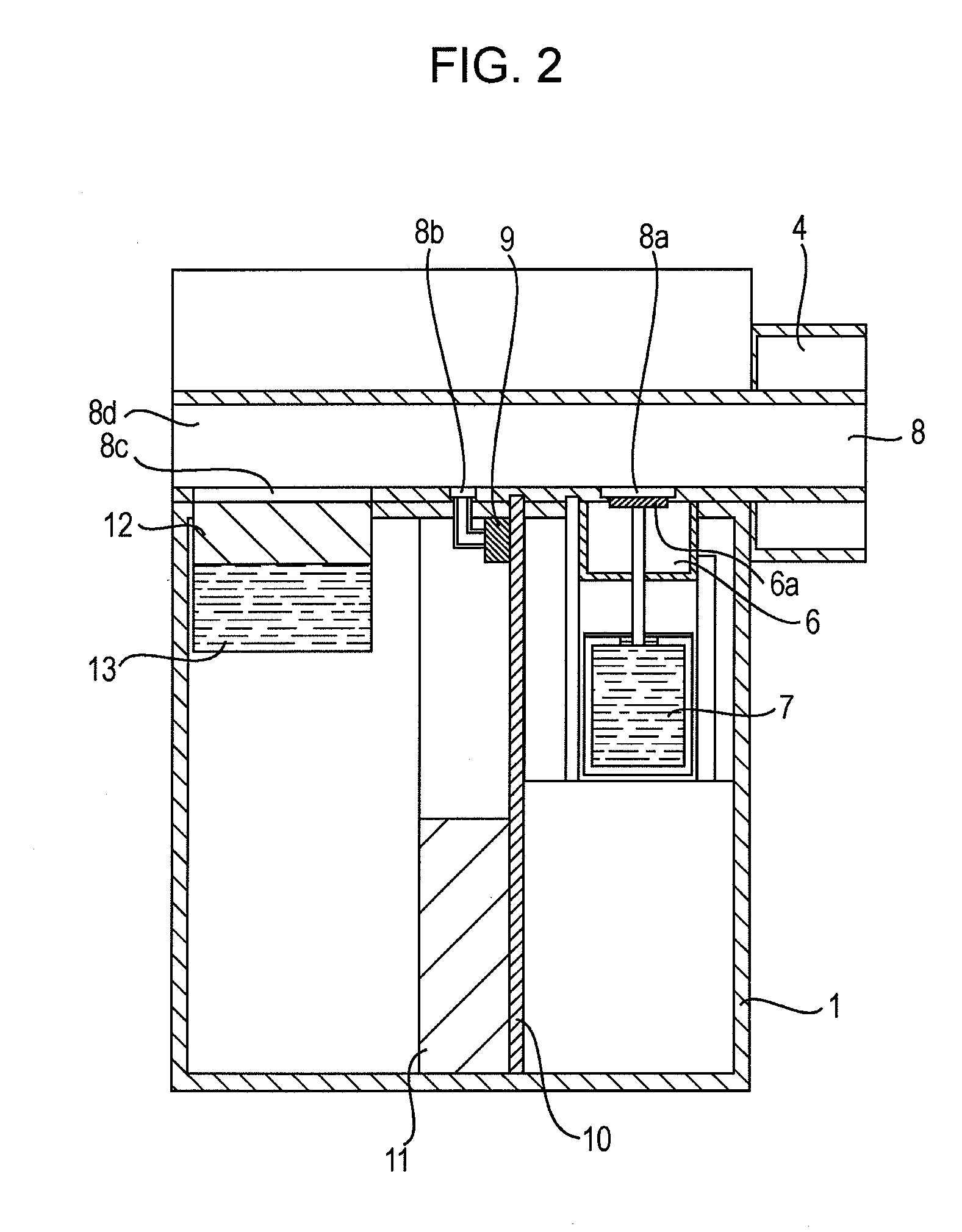

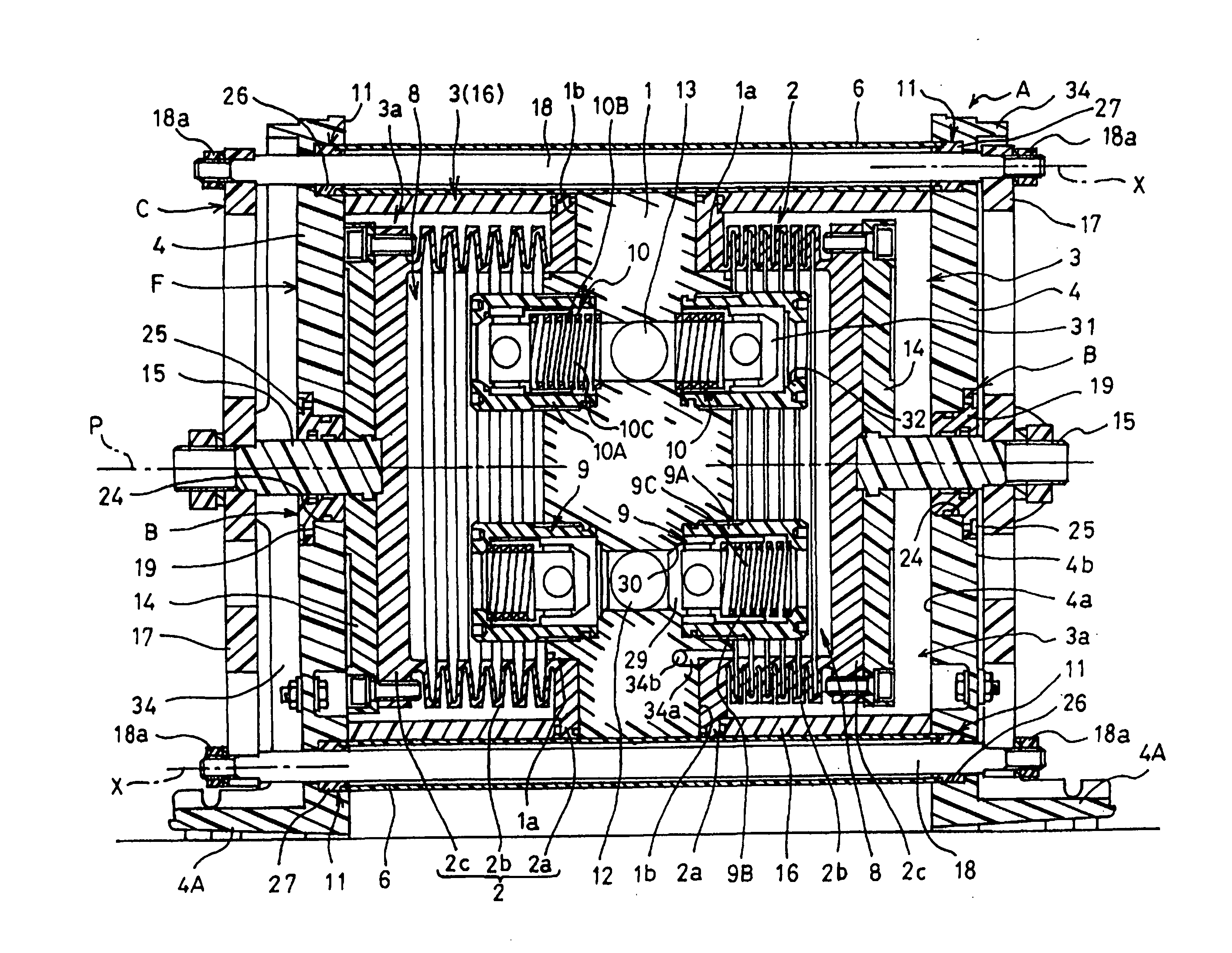

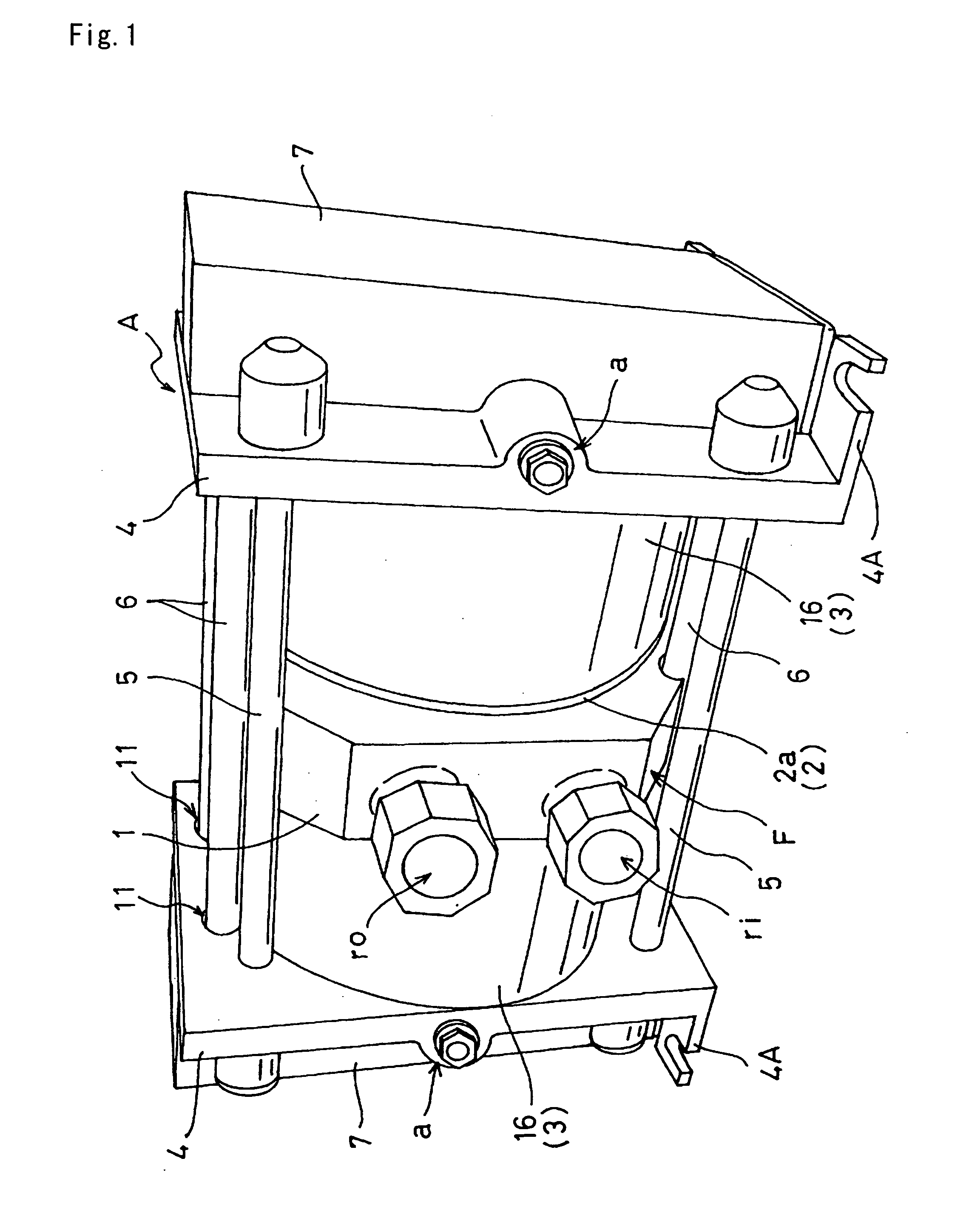

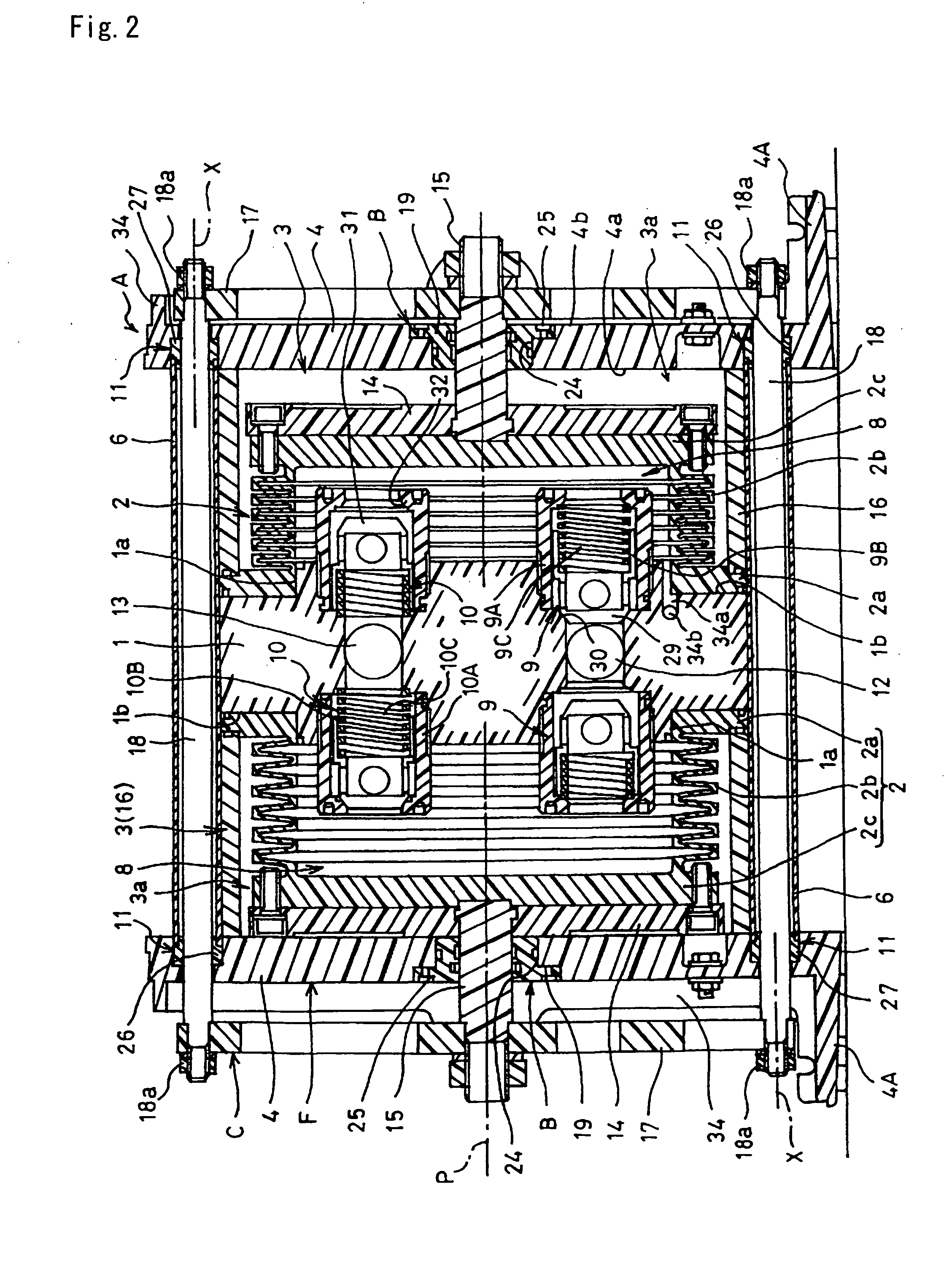

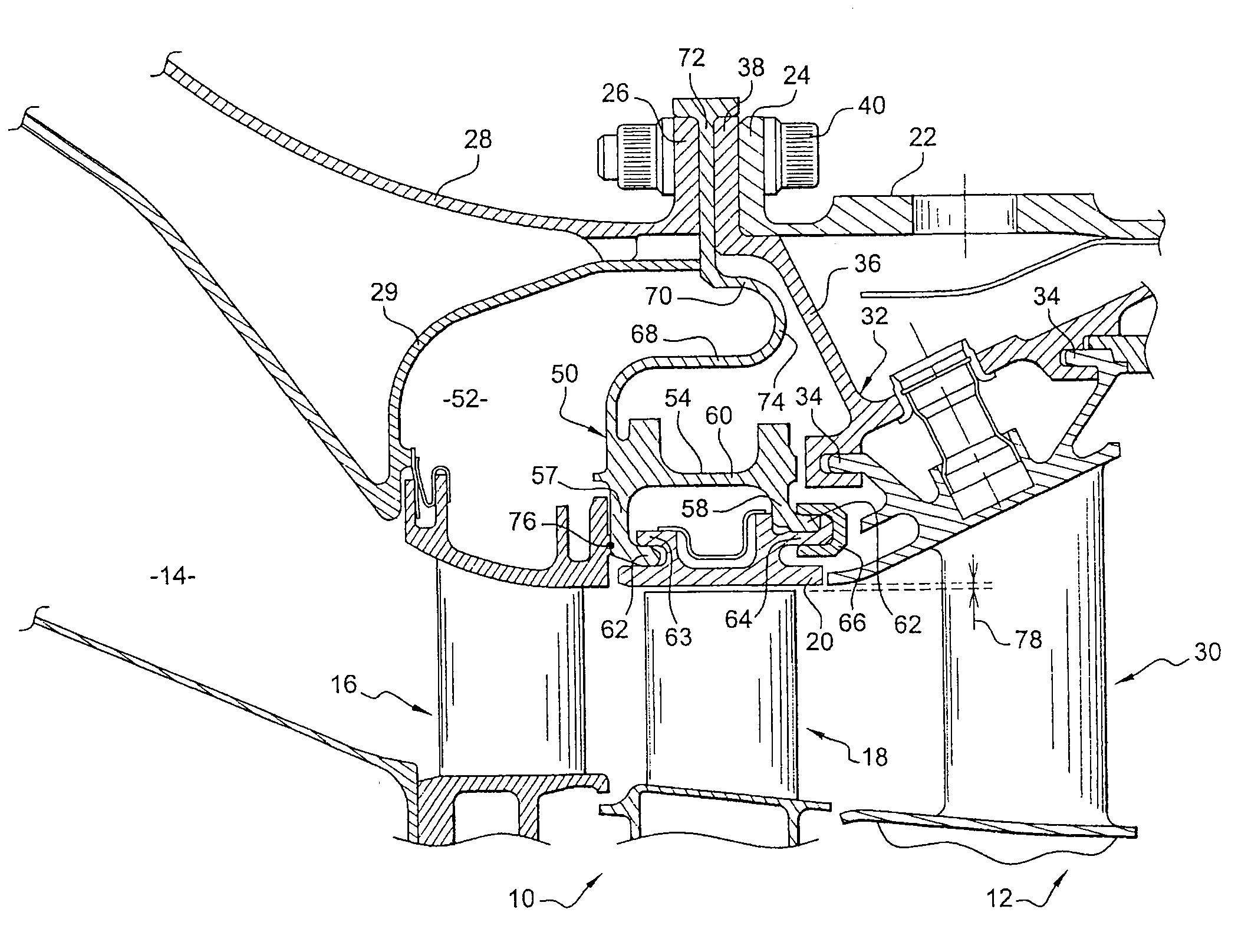

Reciprocating pump

ActiveUS20100119392A1Extended maintenance periodImprove flatnessPositive displacement pump componentsFlexible member pumpsEngineeringFlange

The structure is improved so that a bearing is disposed in a place other than pump shafts, thereby improving the smoothness of the slide movement of a moving body which is a large structure, and the durability of slide supporting means (bearings or the like) for it. In a reciprocating pump having: a pump body 1 including a suction path 12 and discharge path 13 for a fluid; a pair of diaphragms 2 which are airtightly fixed to both end portions of the pump body; pump shafts 15 which are attached to tip end portions of the diaphragms 2; a pair of pump flanges 4 which slidably support the pump shafts 15, and which are integrated with the pump body 1 through connection bodies 16 that are placed outside the diaphragms 2; connecting rods 18 which connect connecting plates 17 attached to projecting tip-end portions 15B that are projected from the pump flanges 4 in the pump shafts 15, to each other in a state where the connecting rods are passed through the pump flanges 4 to be placed outside the diaphragms 2; and a cover cylinder 6 which is disposed between the pair of pump flanges 4, and which surrounds the connecting rods 18, the connecting rods 18 are slidably supported through slide bearings 27 which are supported by the pump flanges 4.

Owner:NIPPON PILLAR PACKING CO LTD

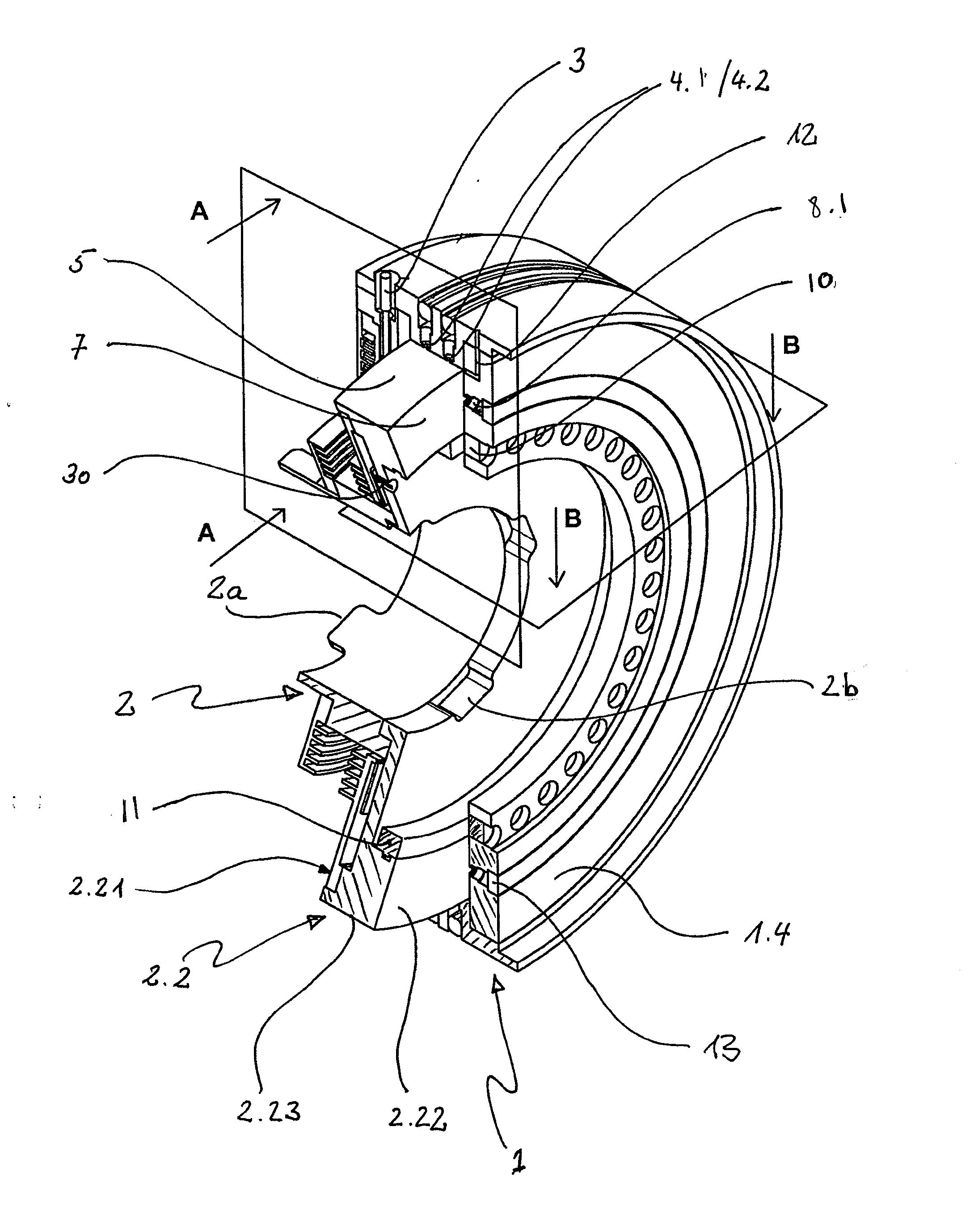

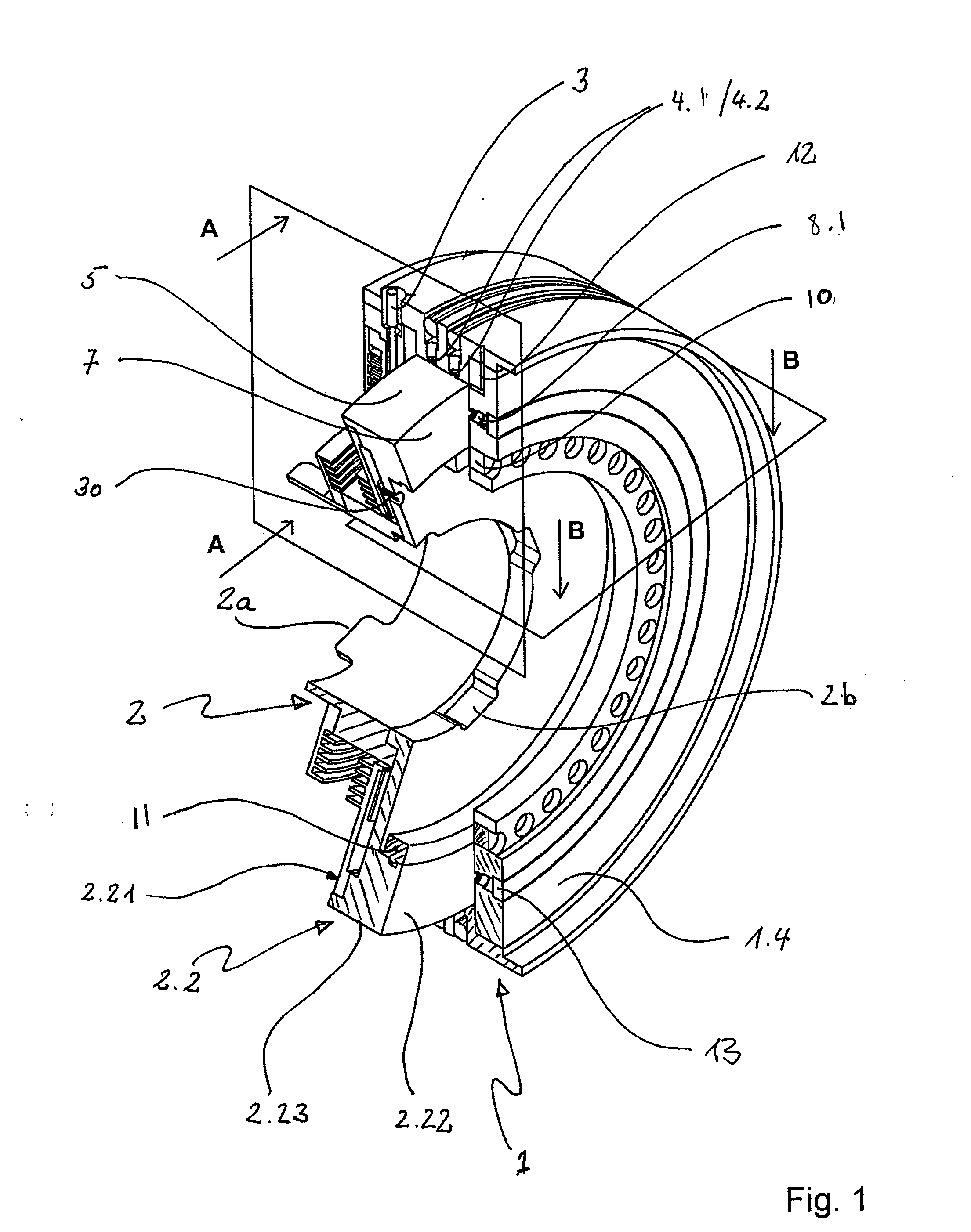

Rotary Joint

InactiveUS20080303614A1Constant diameterAvoid contactRotary current collectorGas cushion bearingsEngineeringRotational joint

A high frequency (HF) rotary joint including a rotor and a stator is disclosed. The rotor is connected to the stator by a high frequency connection via a λ / 4 line. The rotor, moreover, is mounted in the stator utilizing at least one radial aircushion bearing and at least one axial aircushion bearing. The bearings prevent contact between the rotor and the stator.

Owner:SPINNER

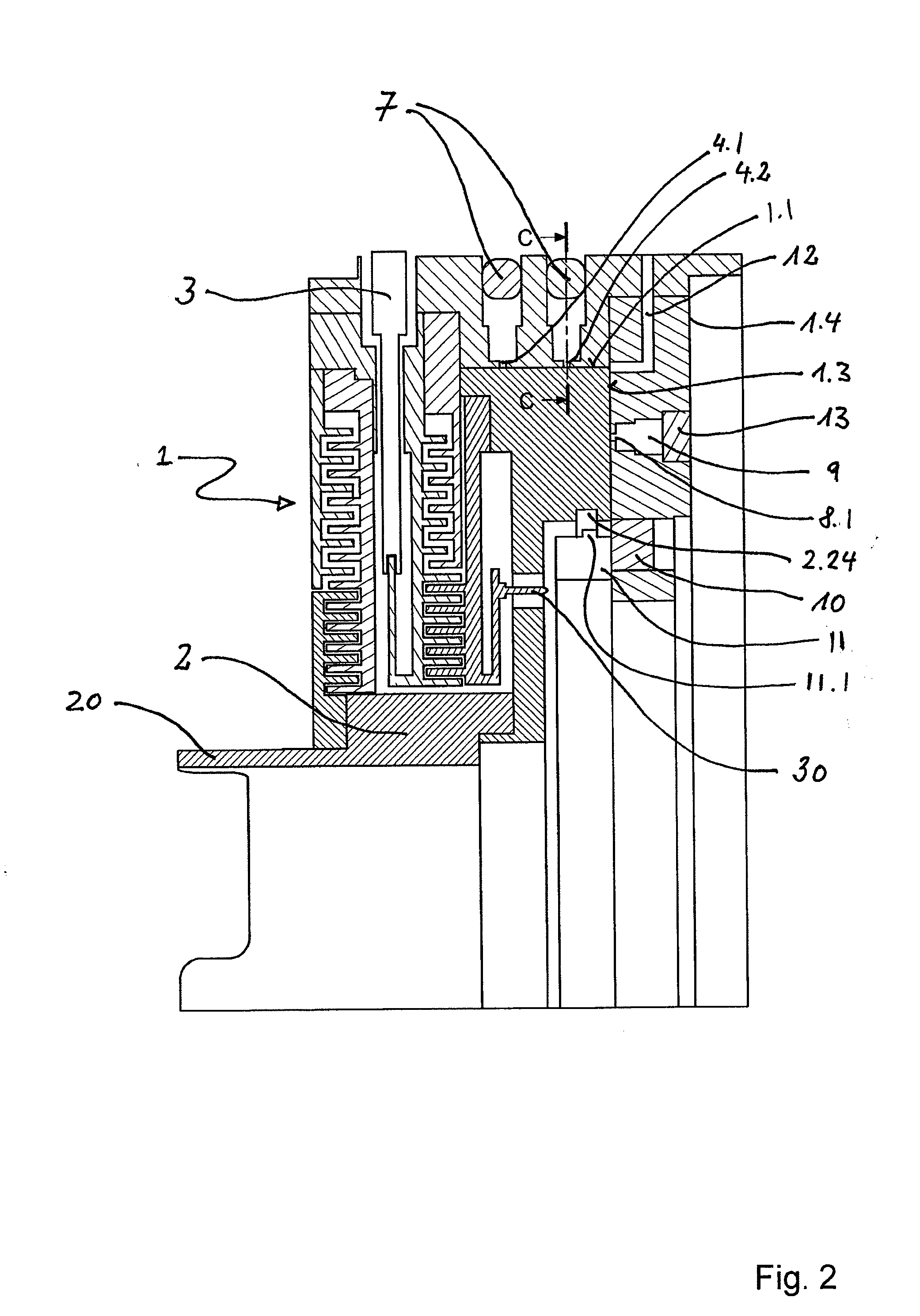

Needleless electrostatic spinning device

ActiveCN110129899AAchieve recyclingStable concentrationFilament/thread formingFiberLiquid storage tank

The invention discloses a needleless electrostatic spinning device. The device comprises a receiving ball, spinneret orifice pipes, an umbrella cover recovery device, a liquid storage tank, a tank cover, liquid supply pipes and liquid supply pumps, wherein the concave surface of the umbrella cover recovery device faces the receiving ball, the receiving ball is located at the upper part of the umbrella cover recovery device, the spinneret orifice pipes are arranged on the inner side of the concave surface of the umbrella cover recovery device, a plurality of spinneret orifices are densely distributed on pipe bodies of the spinneret orifice pipes, the liquid supply pumps are connected with the spinneret orifice pipes through the liquid supply pipes, and the tail ends of the spinneret orificepipes are closed; a backflow gap is formed between the liquid storage tank and the tank cover and used for allowing a solution recovered by the umbrella cover recovery device to flow into the liquidstorage tank. In the specific working process, the surplus solution flows back to the liquid storage tank from the backflow gap through the umbrella cover recovery device and continues to be input into the liquid supply pipes by the liquid supply pumps, so that recycling of the spinning solution is achieved. In the whole process, the spinning solution cannot make contact with air, and accordingly,stable concentration of the spinning solution is maintained, and the diameter of a spinning fiber remains unchanged.

Owner:GUANGDONG UNIV OF TECH

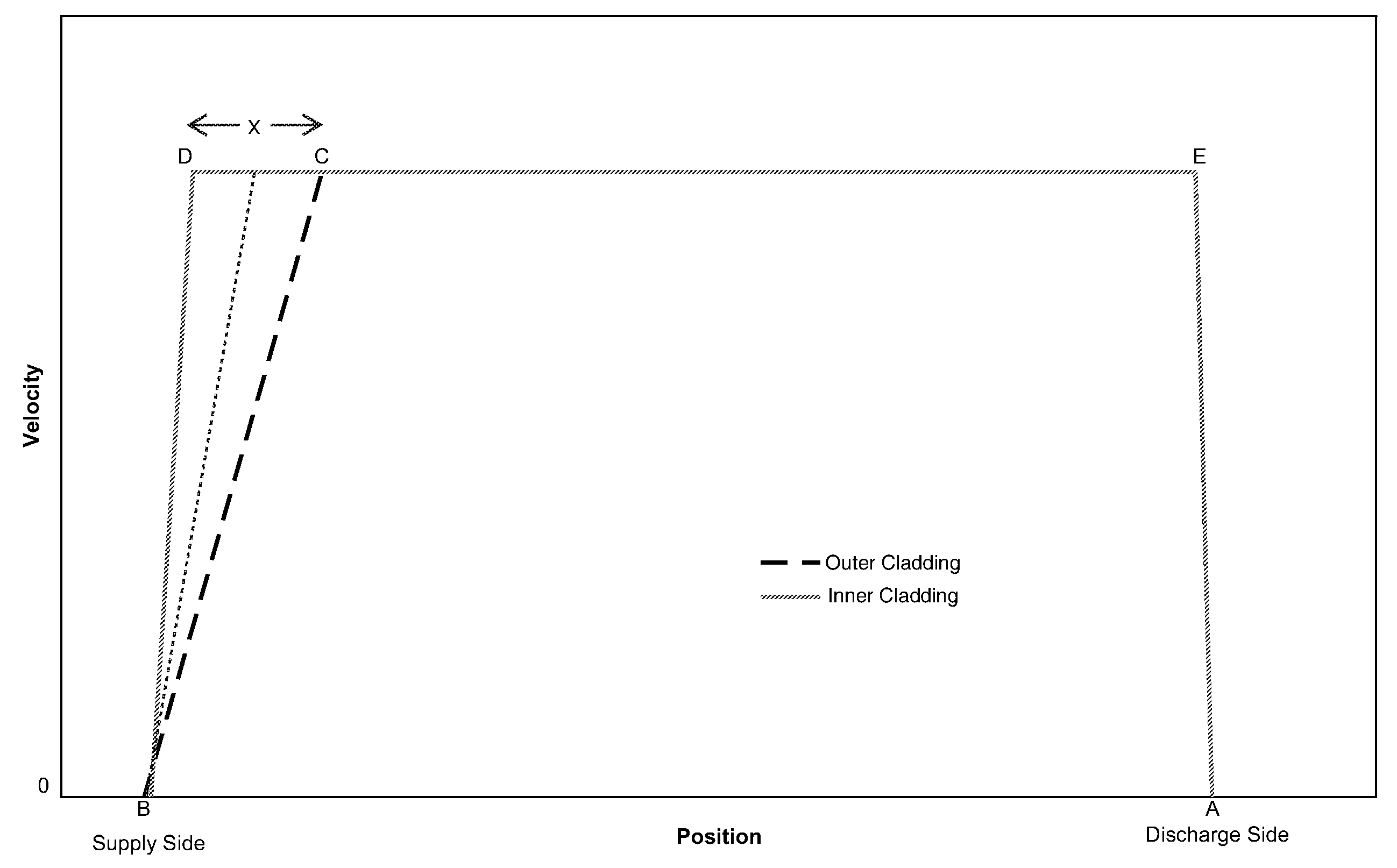

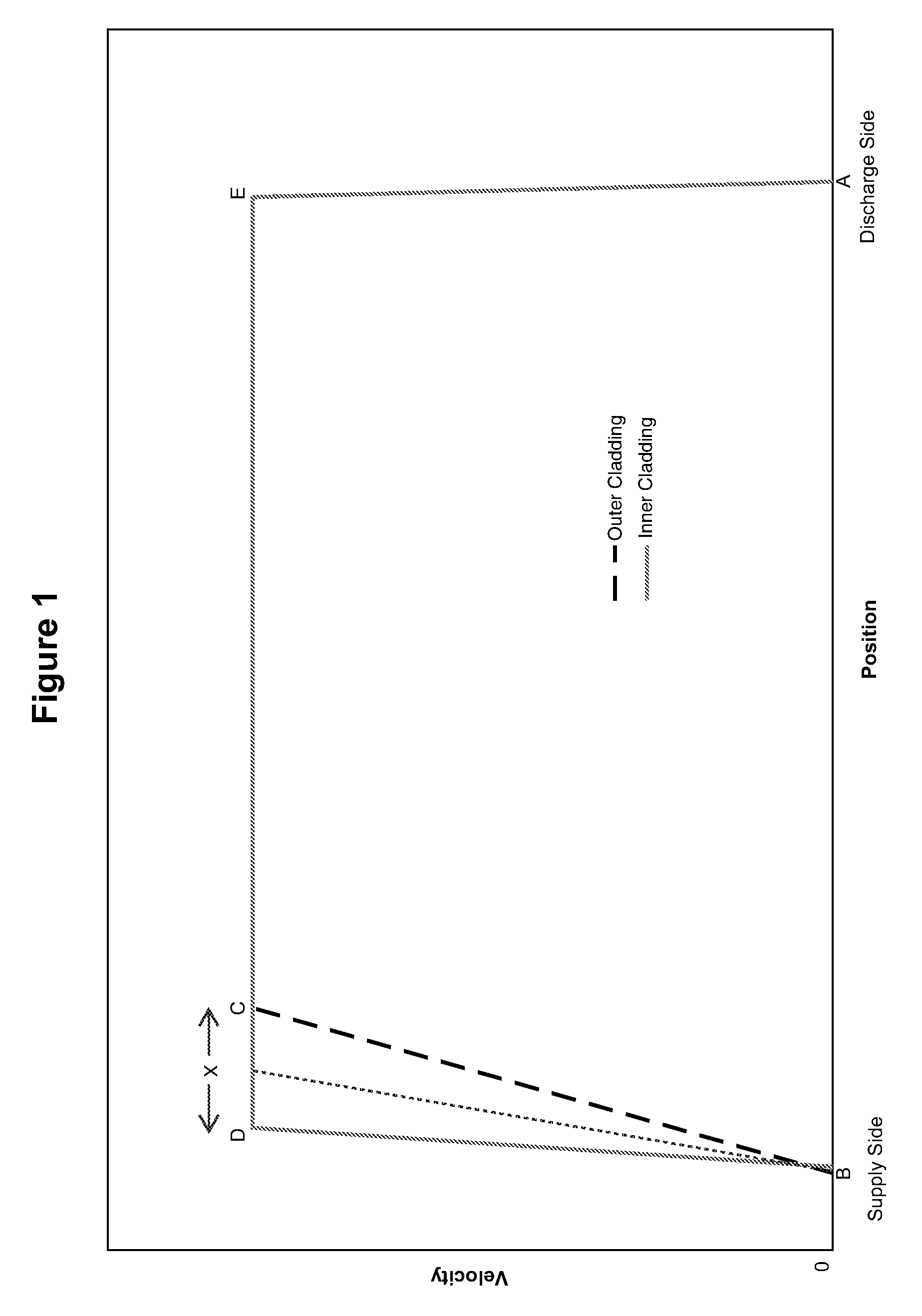

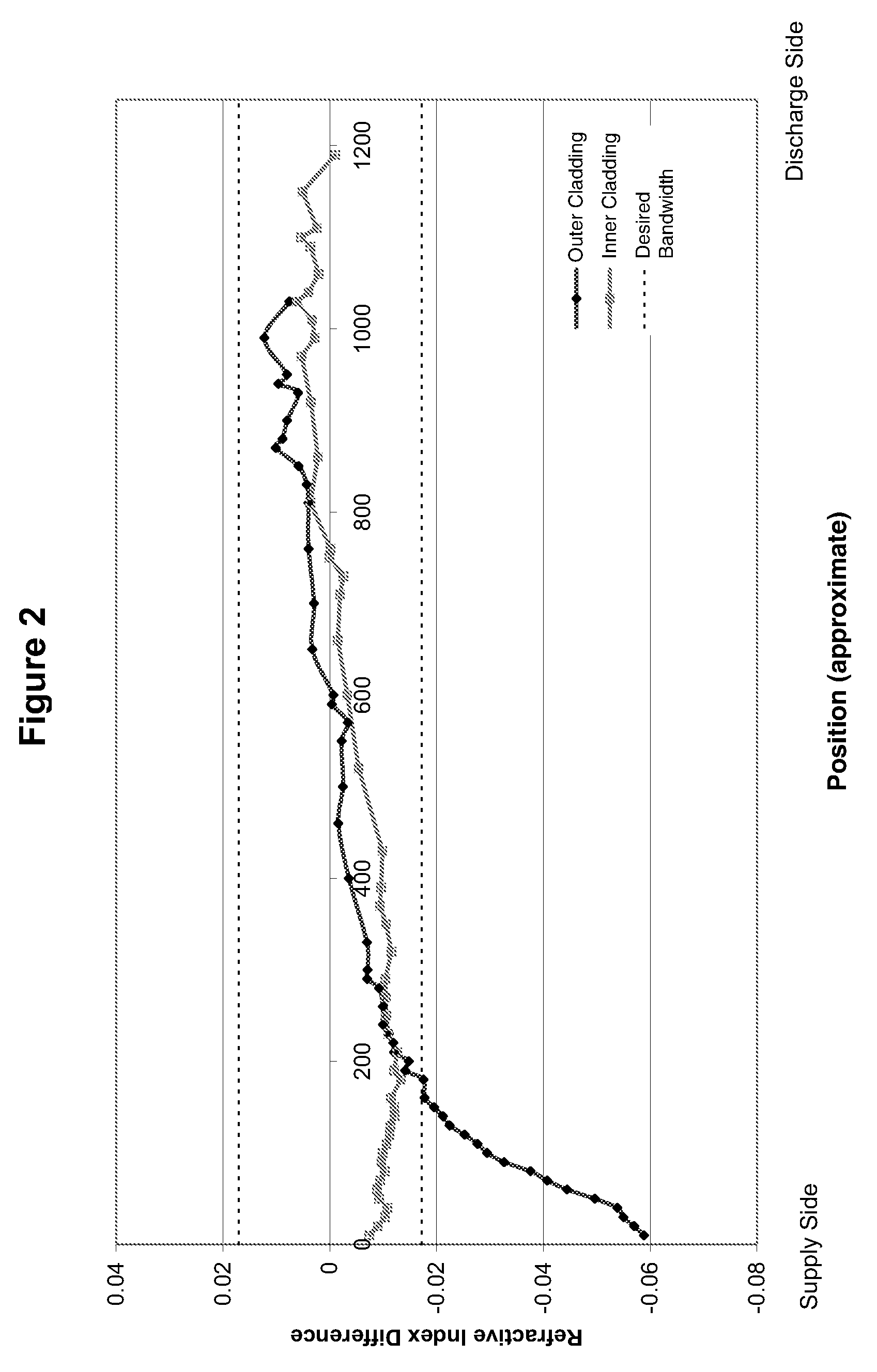

Method for making an optical fiber preform via internal vapor deposition

ActiveUS7519256B2Stable cut-off wavelengthMinimization is negatively influencedGlass making apparatusOptical fibre with graded refractive index core/claddingGas phaseEngineering

The present invention relates to a method for manufacturing an optical preform by employing an internal vapor deposition process. The method uses an energy source and a substrate tube, wherein the energy source is movable over the length of the substrate tube between a point of a reversal at the supply side and a point of a reversal at the discharge side.

Owner:DRAKA COMTEQ BV

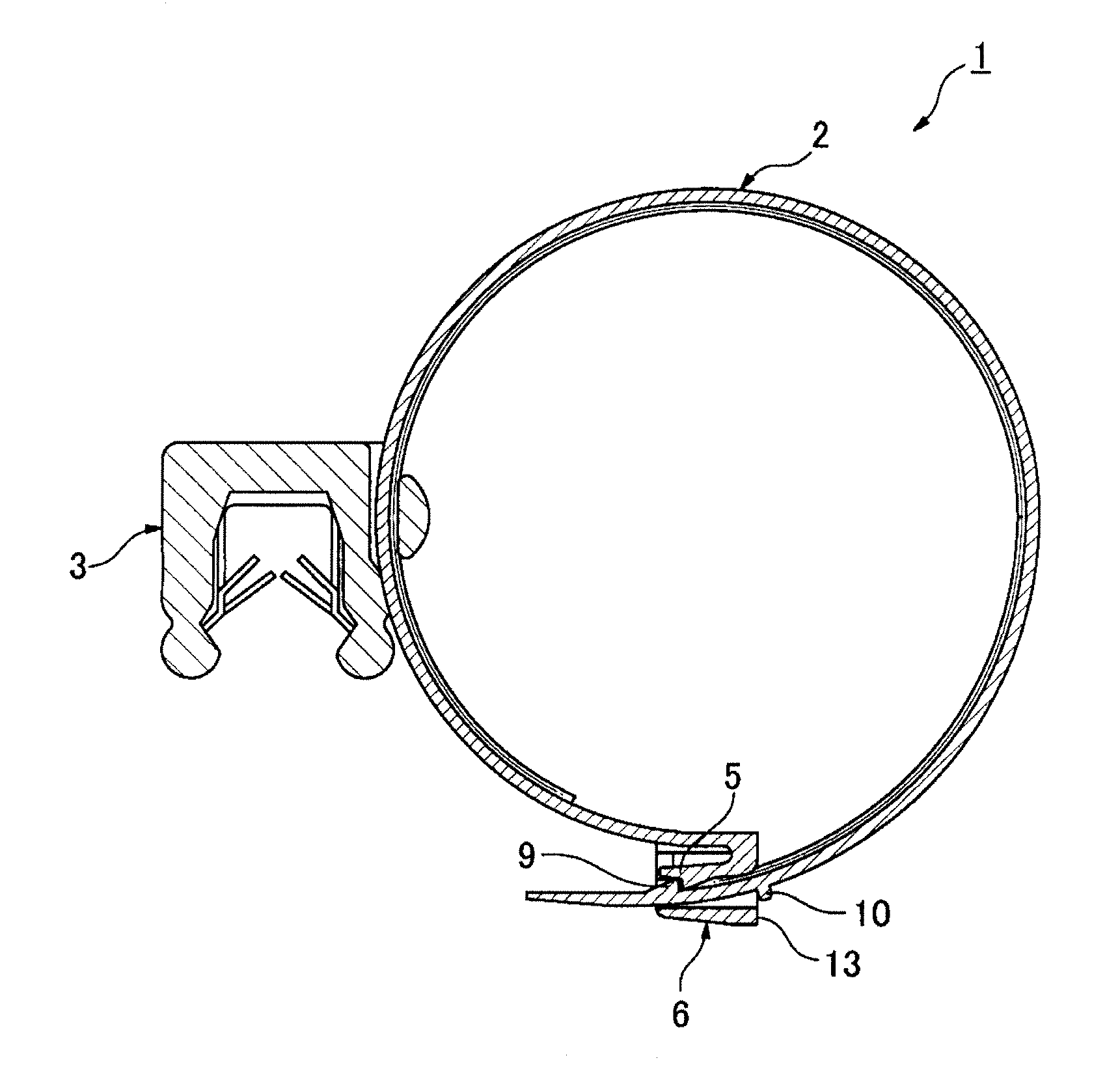

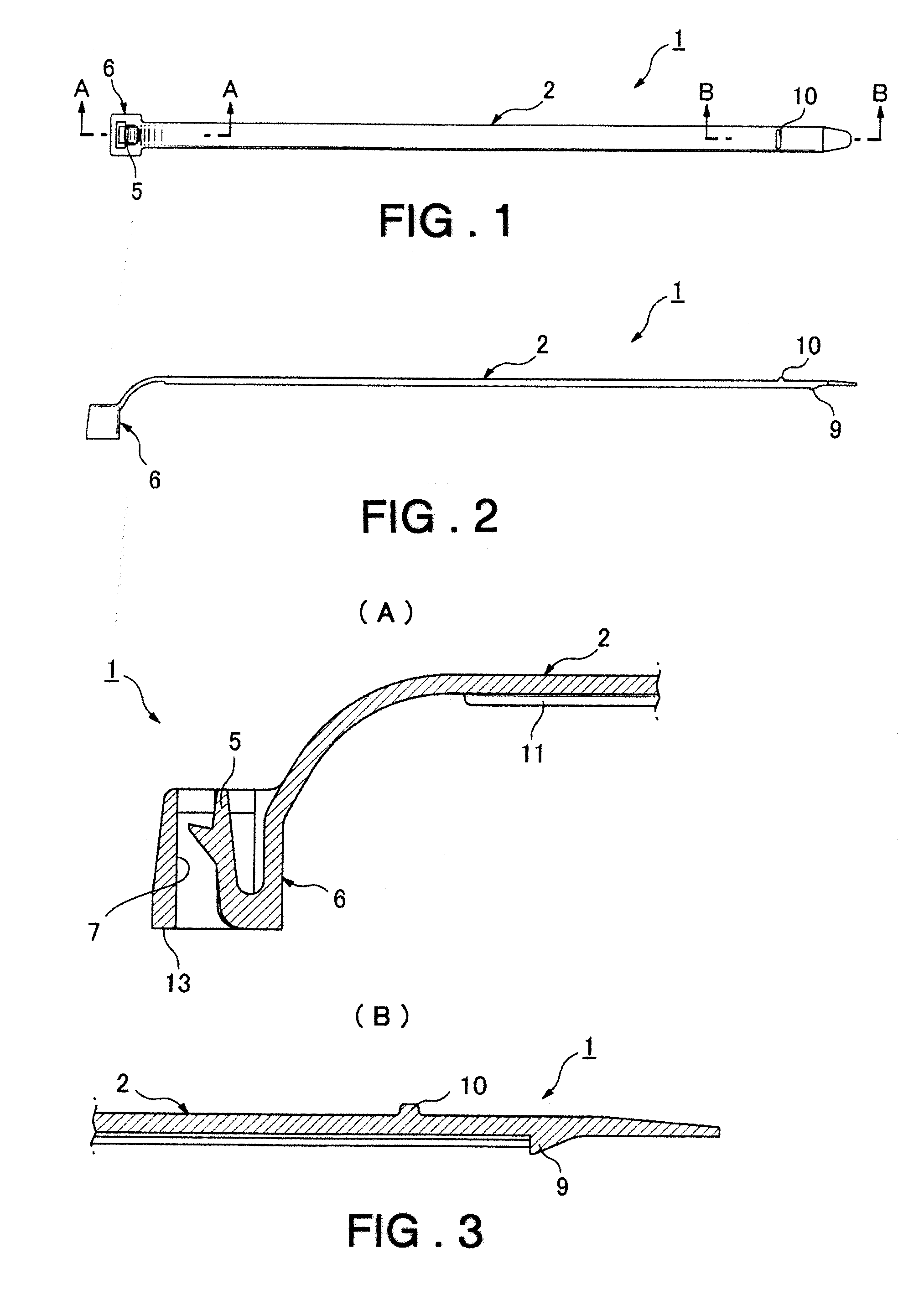

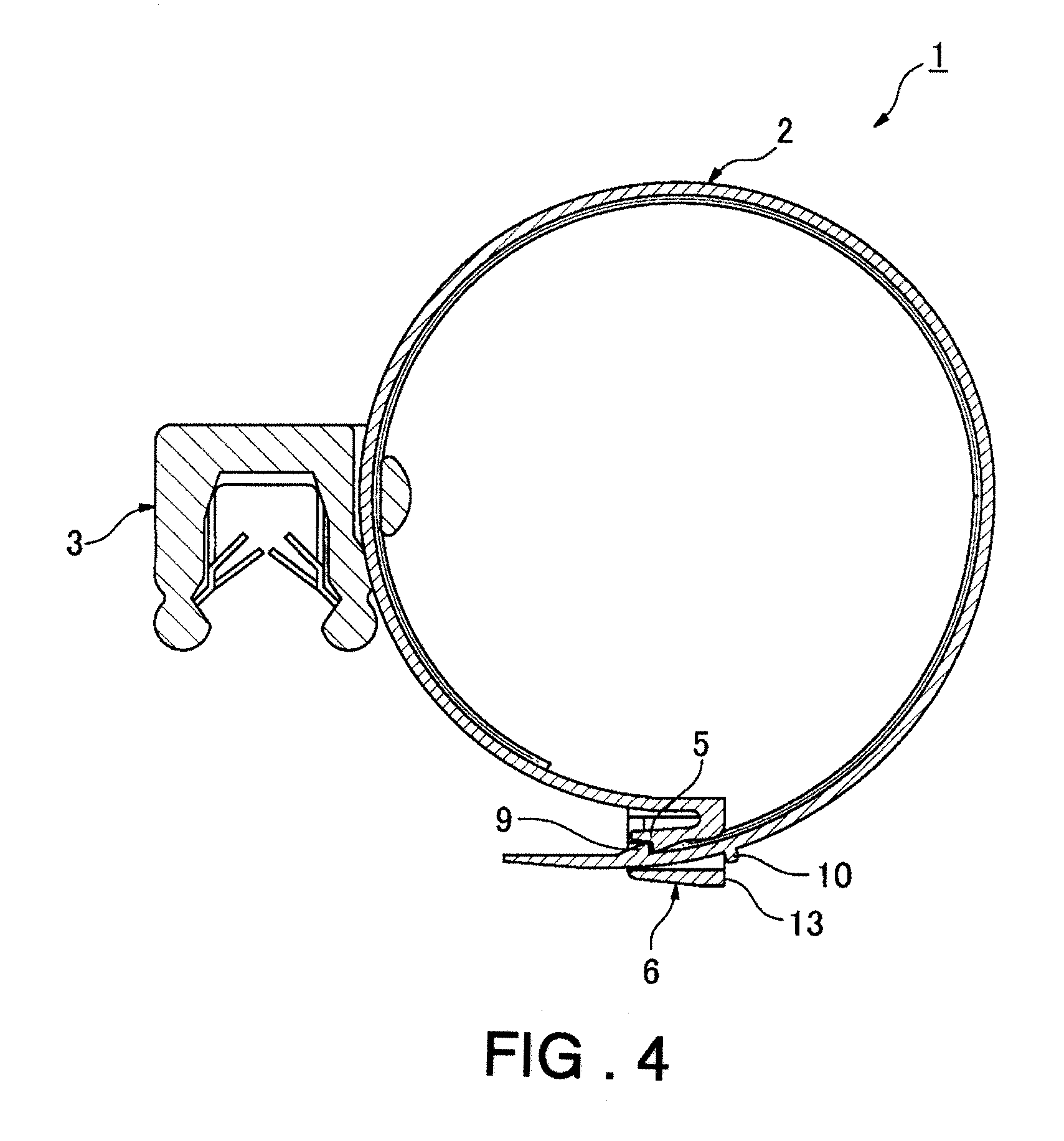

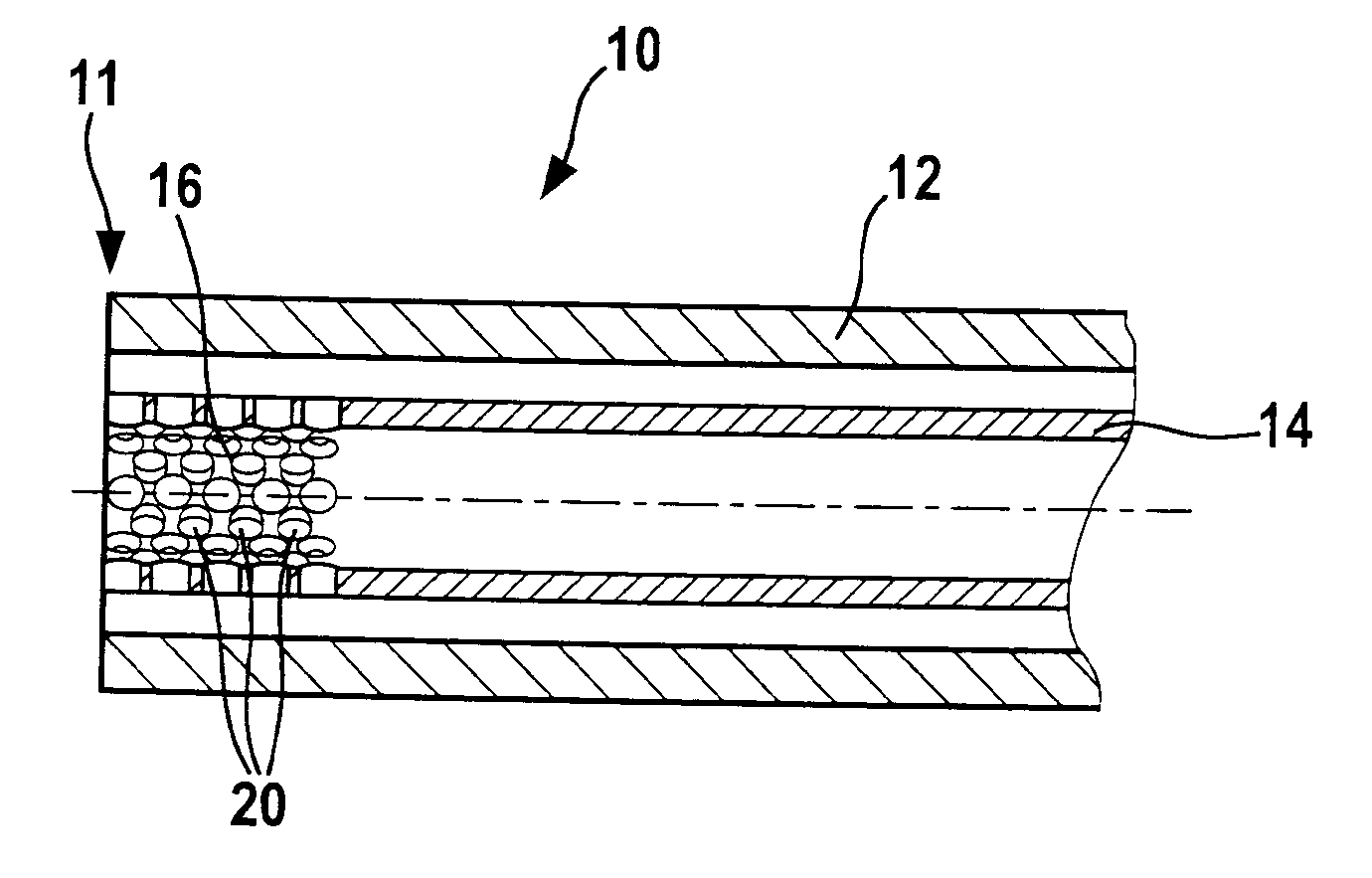

Band clamp for elongated member

InactiveUS20100199463A1Constant diameterLength differencePipe supportsFlexible elementsEngineeringConductor Coil

Owner:NEWFREY

Pulverized coal injection lance

The present invention proposes a pulverized coal injection lance (10) for feeding pulverized coal from a rear end of the lance (10) to a front end (11) of the lance (10). The lance (10) comprises an outer pipe (12) for conveying combustive gas, and an inner pipe (14), coaxially arranged within the outer pipe (12), for conveying pulverized coal. The inner pipe (14) forms a separation wall for separating the pulverized coal from the combustive gas. The separation wall is at least partially discontinued in a region near the front end (11) of the lance (10), thereby forming a mixing region (16) within the pulverized coal injection lance (10). According to an important aspect of the invention, the outer pipe (12) and the inner pipe (14) have substantially the same length and wherein the inner pipe (14) comprises at least one lateral opening (18, 20) for allowing pulverized coal and combustive gas to come into contact within the pulverized coal injection lance (10) near the front end (11).

Owner:PAUL WURTH SA

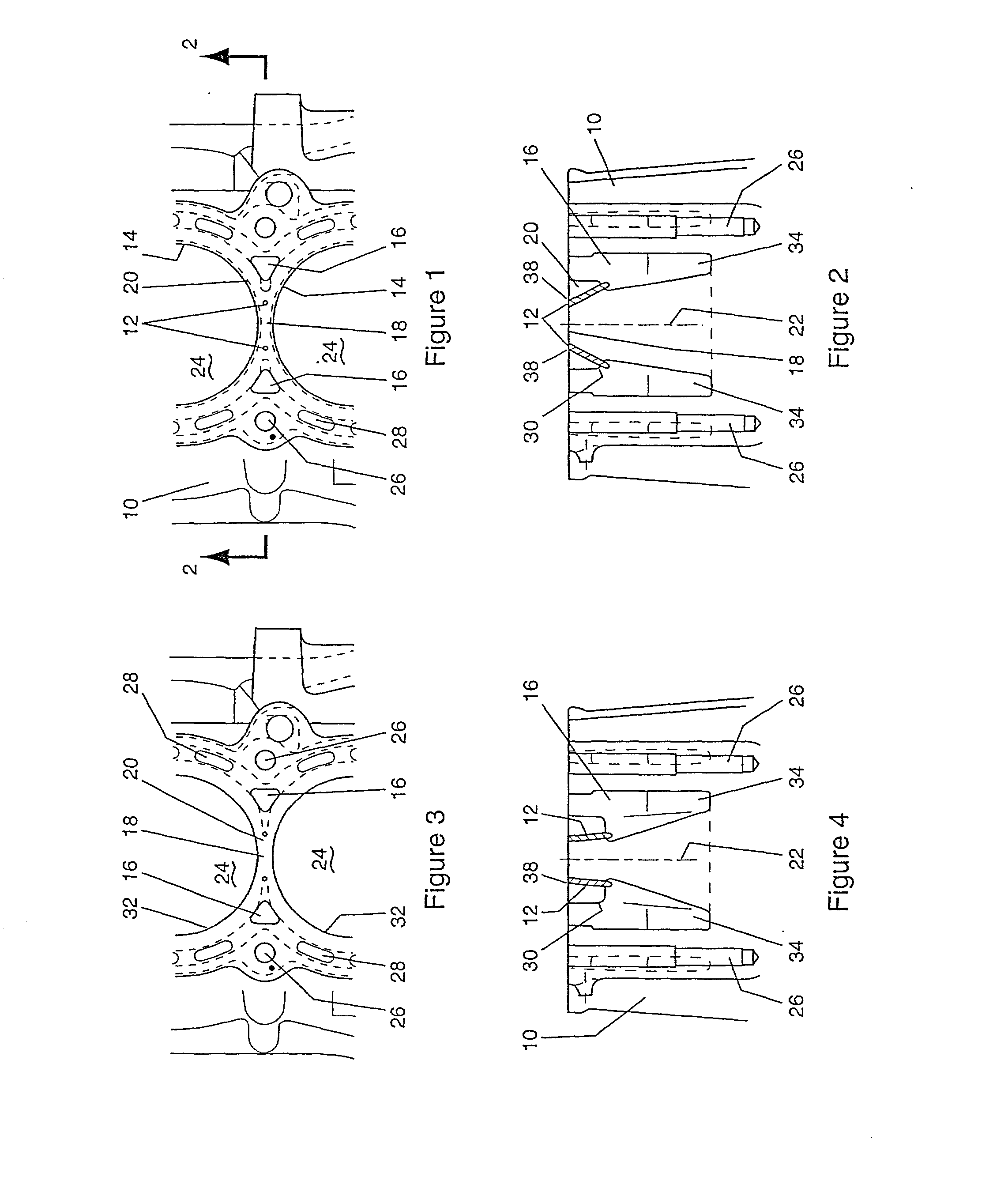

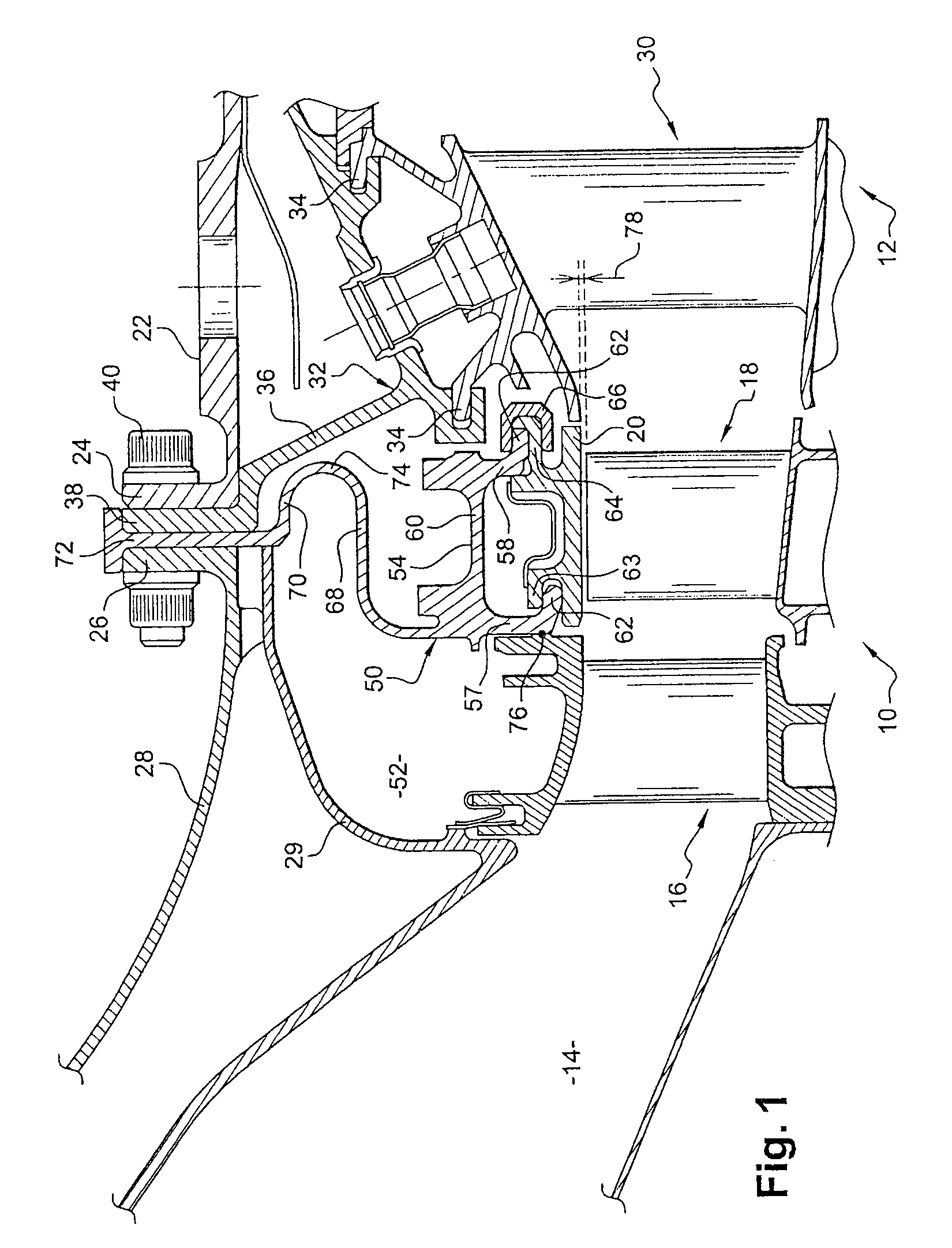

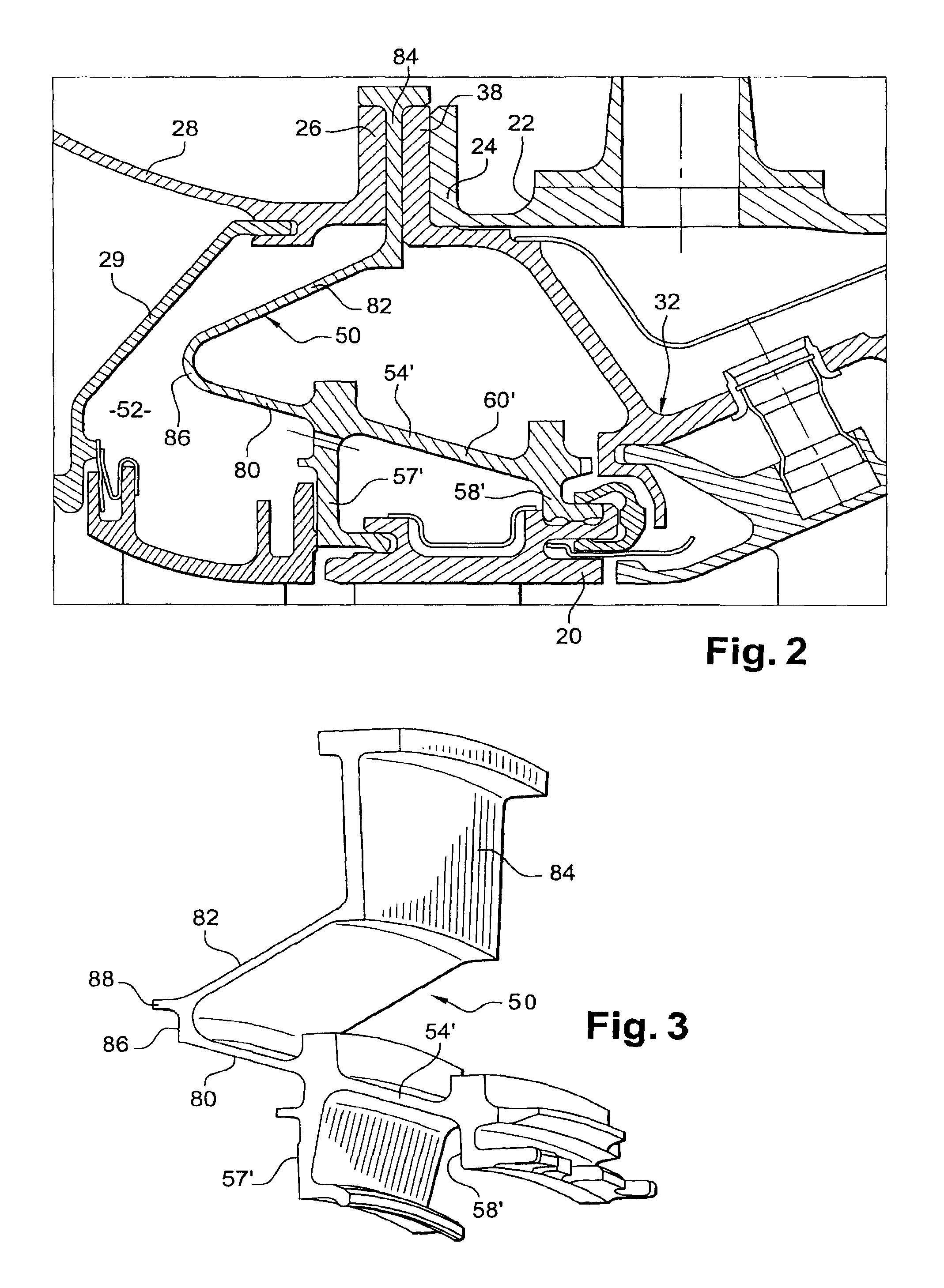

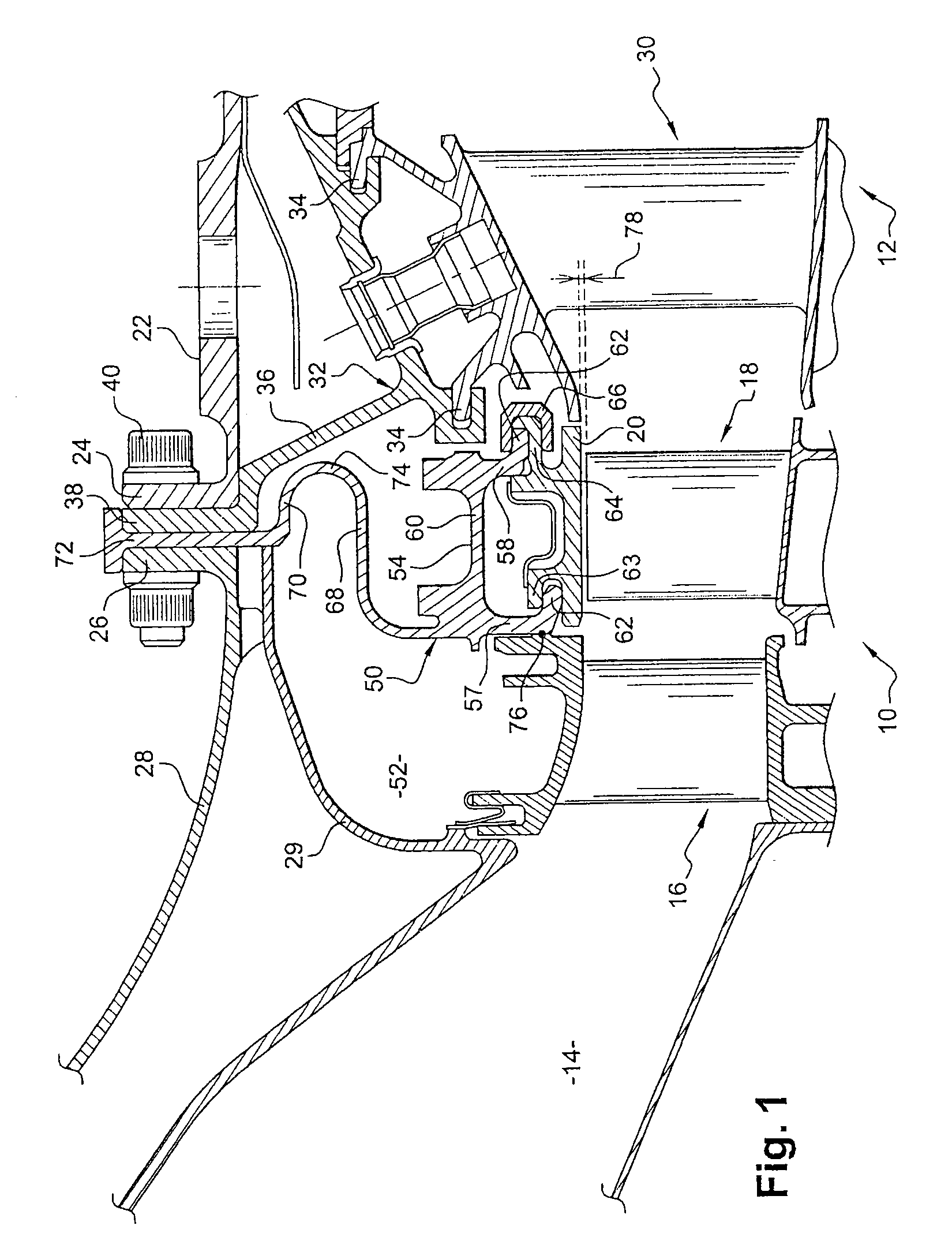

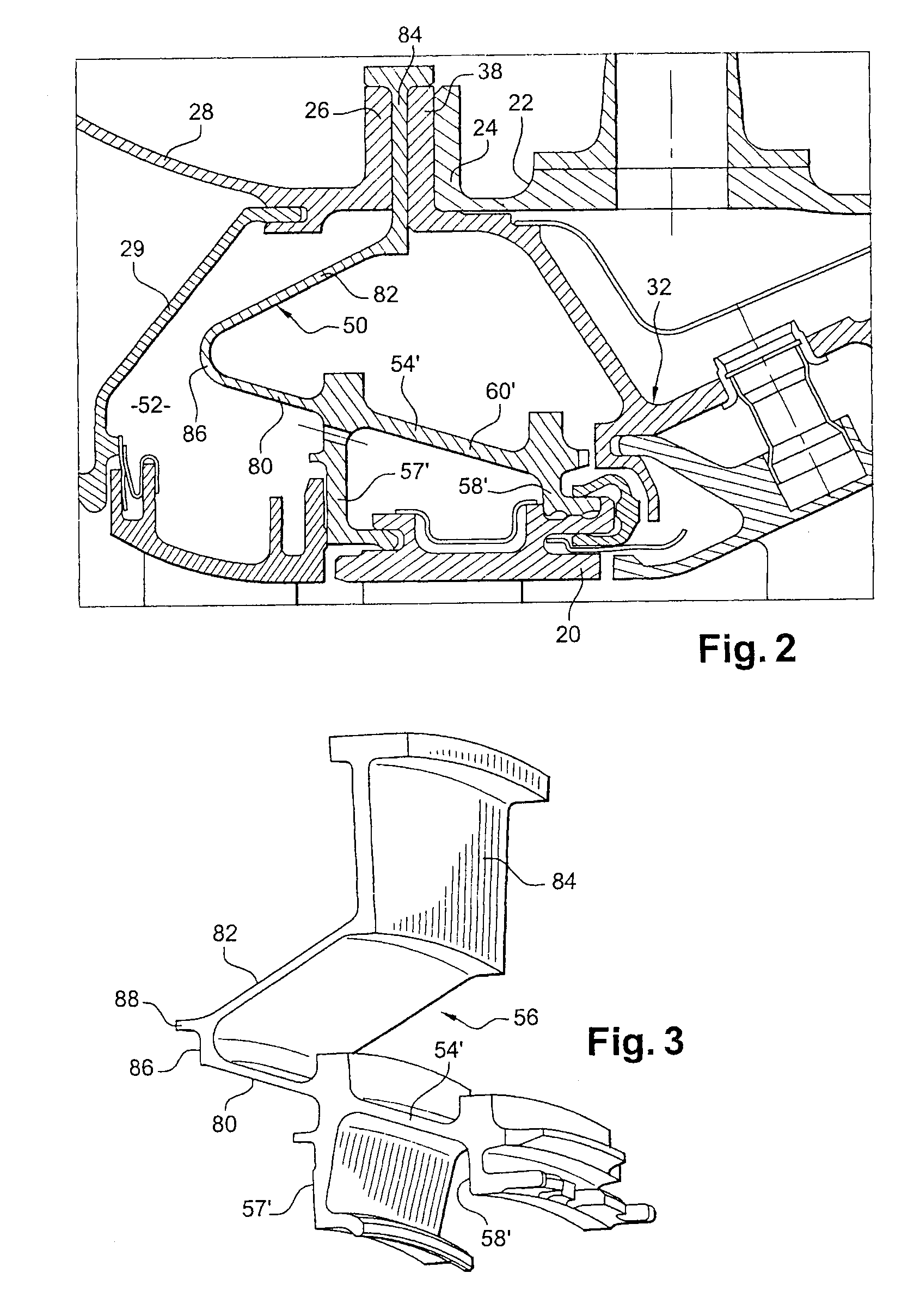

Turbine stage in a turbomachine

ActiveUS8403636B2Improve rigidityConstant diameterPump componentsRotary non-positive displacement pumpsImpellerTurbine wheel

A turbine stage in a turbomachine including ring sectors arranged about a turbine impeller, and an annular support supporting the ring sectors and attached to a turbine casing is disclosed. The annular support is able to be deformed elastically in the radial direction to cushion at least a portion of the deformations of the turbine casing in operation.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Reciprocating pump

ActiveUS8568114B2Extended maintenance periodPortions of slide bearings are remarkably increasedPositive displacement pump componentsFlexible member pumpsEngineeringExtremity Part

A reciprocating pump having: a pump body including a suction path and a discharge path for a fluid; a pair of diaphragms; pump shafts which are attached to tip end portions of the diaphragms; a pair of pump flanges which slidably support the pump shafts, and which are integrated with the pump body through connection bodies that are placed outside the diaphragms; connecting rods which connect connecting plates attached to projecting tip-end portions that are projected from the pump flanges in the pump shafts, to each other in a state where the connecting rods are passed through the pump flanges to be placed outside the diaphragms; and a cover cylinder. The connecting rods are slidably supported through slide bearings which are supported by the pump flanges.

Owner:NIPPON PILLAR PACKING CO LTD

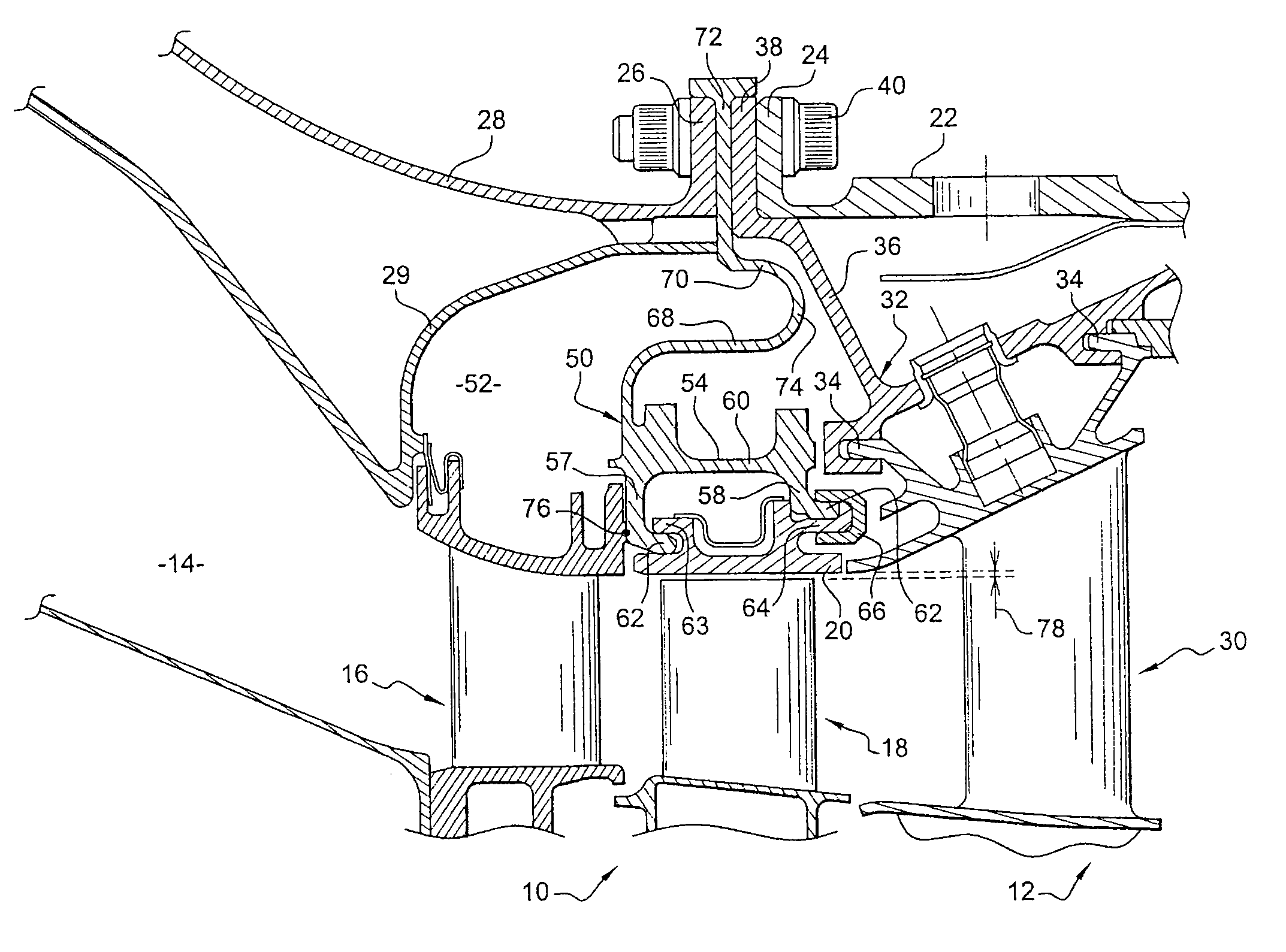

Turbine stage in a turbomachine

ActiveUS20080206047A1Simple and effective and economicalImprove rigidityPump componentsRotary non-positive displacement pumpsImpellerTurbine wheel

A turbine stage in a turbomachine comprising ring sectors (20) arranged about a turbine impeller (18), and an annular support (50) supporting the ring sectors and attached to a turbine casing (22), this annular support being able to be deformed elastically in the radial direction to cushion at least a portion of the deformations of the turbine casing in operation.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

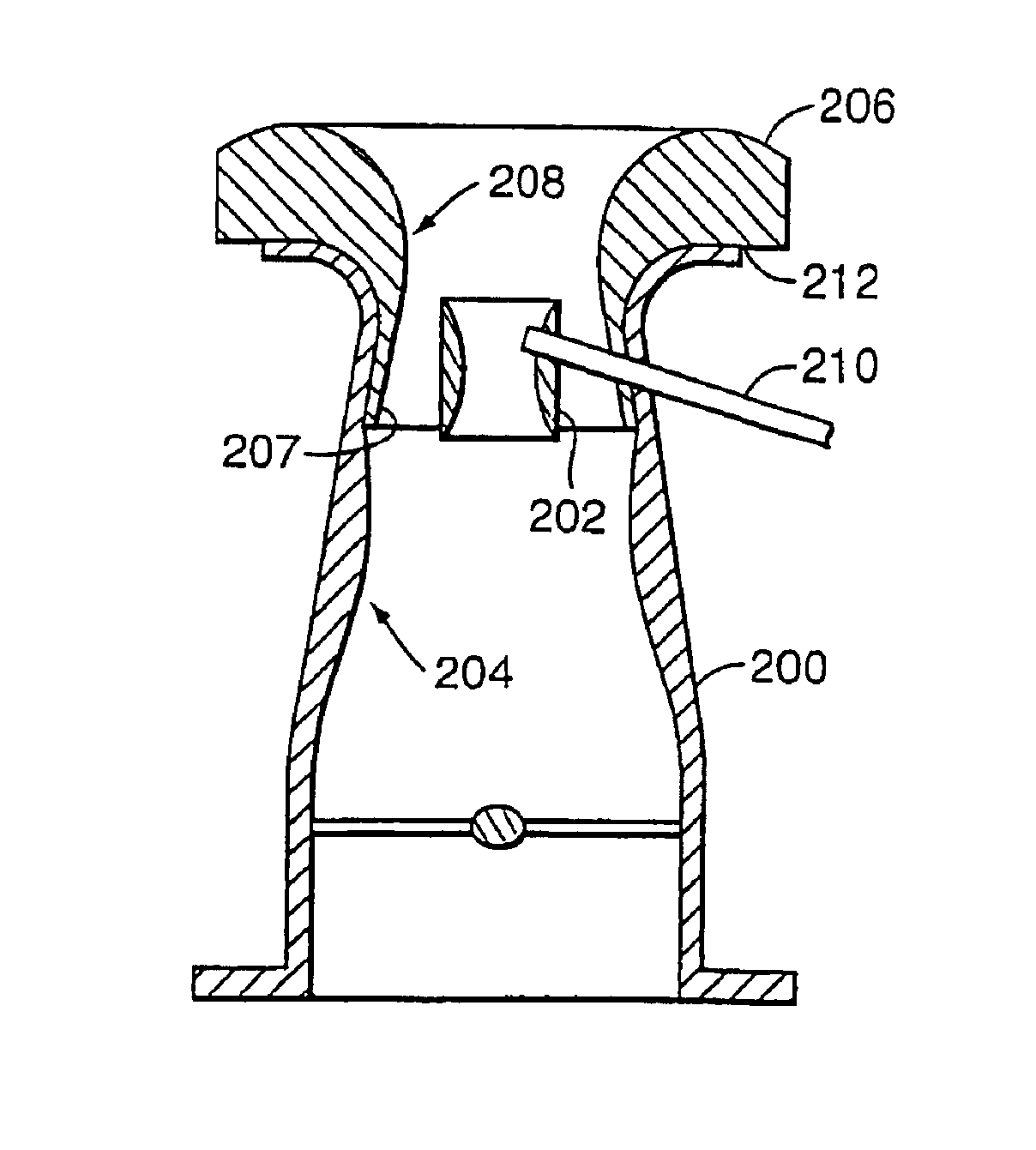

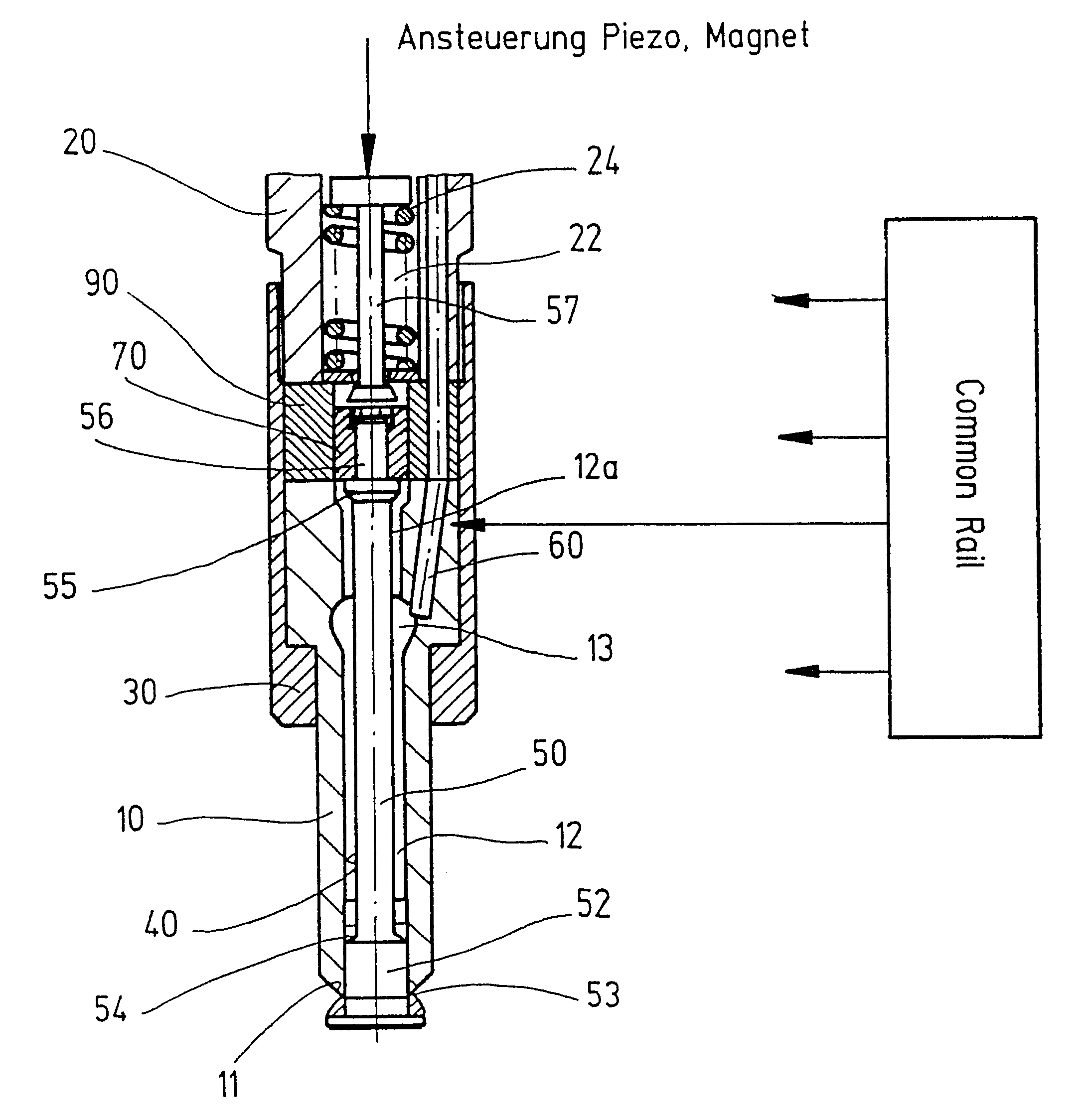

Fuel injection valve for internal combustion engines

InactiveUS6247453B1Constant diameterSpray nozzlesFuel injection apparatusCombustion chamberInternal combustion engine

A fuel injection valve for internal combustion engines, having a valve member which is axially displaceable in a bore of a valve body and which on an end toward the combustion chamber has a valve member head. The head forms a valve closing member, which on one side toward the valve body has a sealing face, with which the sealing face cooperates with a valve seat face provided on the face end of the valve body toward the combustion chamber. An injection opening in the valve member head, which emerges from a pressure chamber, formed between the valve member and the wall of the bore, and leads away along the circumferential wall of the valve member head. The injection opening is closed by the wall of the bore when the valve member is resting on the valve seat and is opened by an outward-oriented opening stroke motion of the valve member. The valve member is actuatable by an externally controllable actuator independently of the high fuel pressure in the pressure chamber, and two pressure shoulders, facing one another and axially defining the pressure chamber, are provided on the needle-like valve member and each have substantially equal pressure engagement surface area. The pressure chamber is characterized in that one of the pressure shoulders is disposed on an end remote from the combustion chamber of the valve body, in a compensation chamber which communicates fluidically with the pressure chamber and is closed off on a face end by an axially displaceably guided pressure sleeve.

Owner:ROBERT BOSCH GMBH

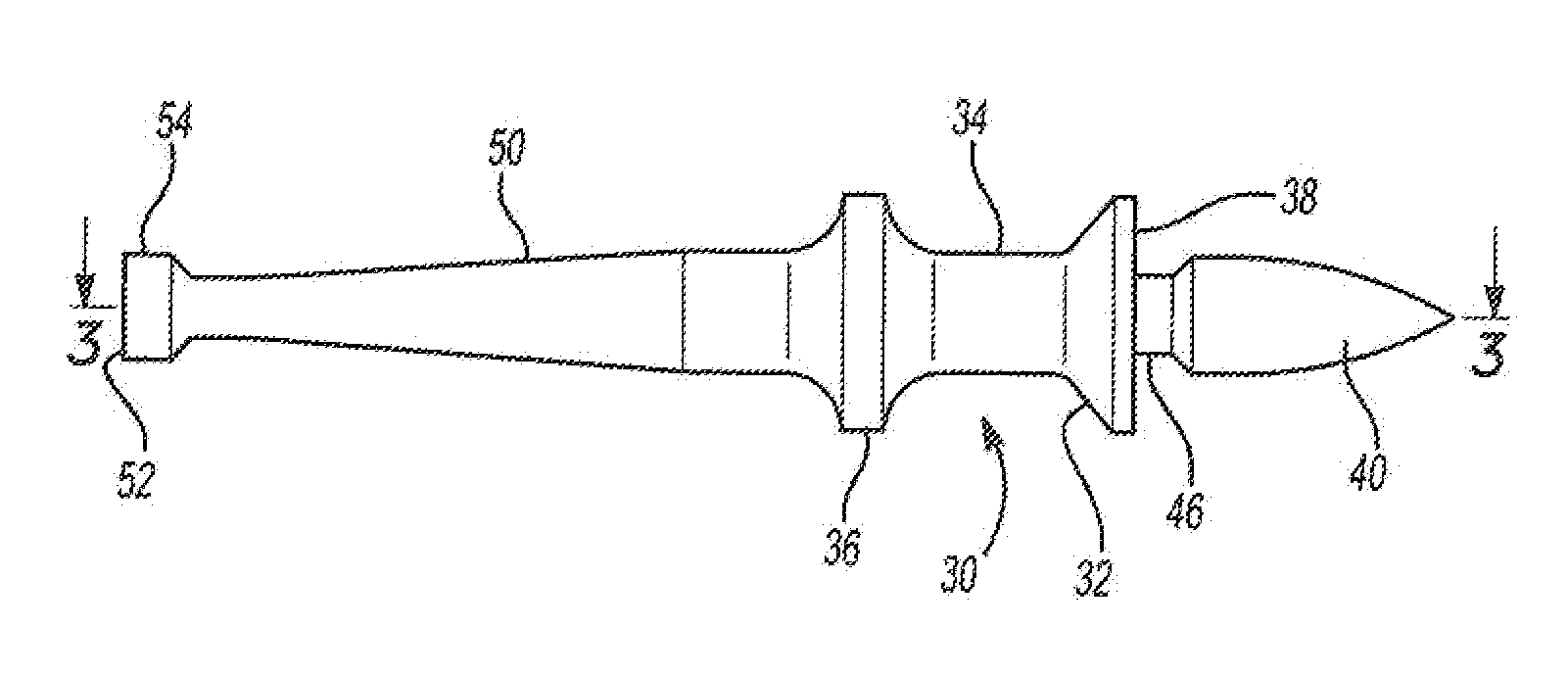

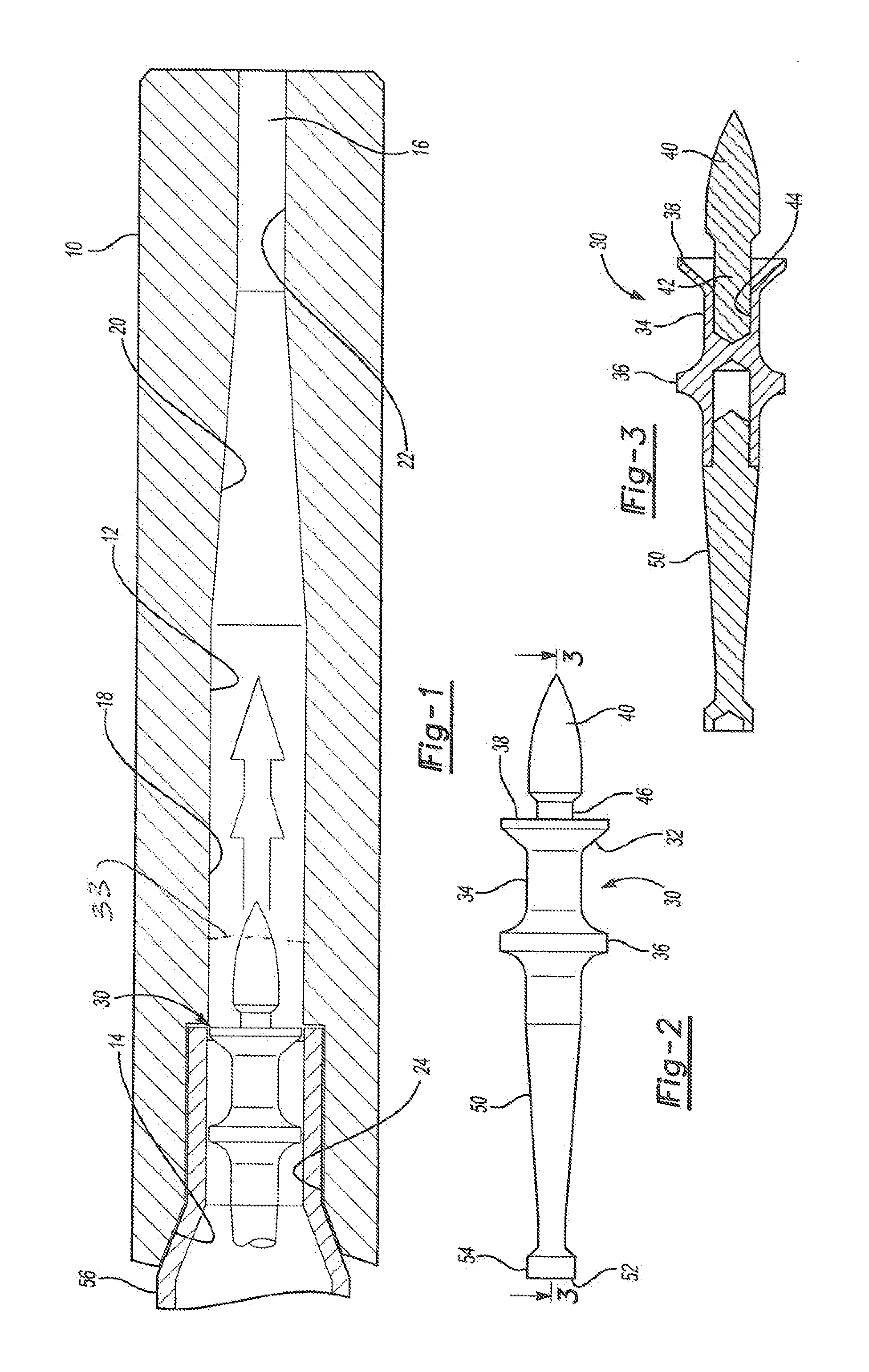

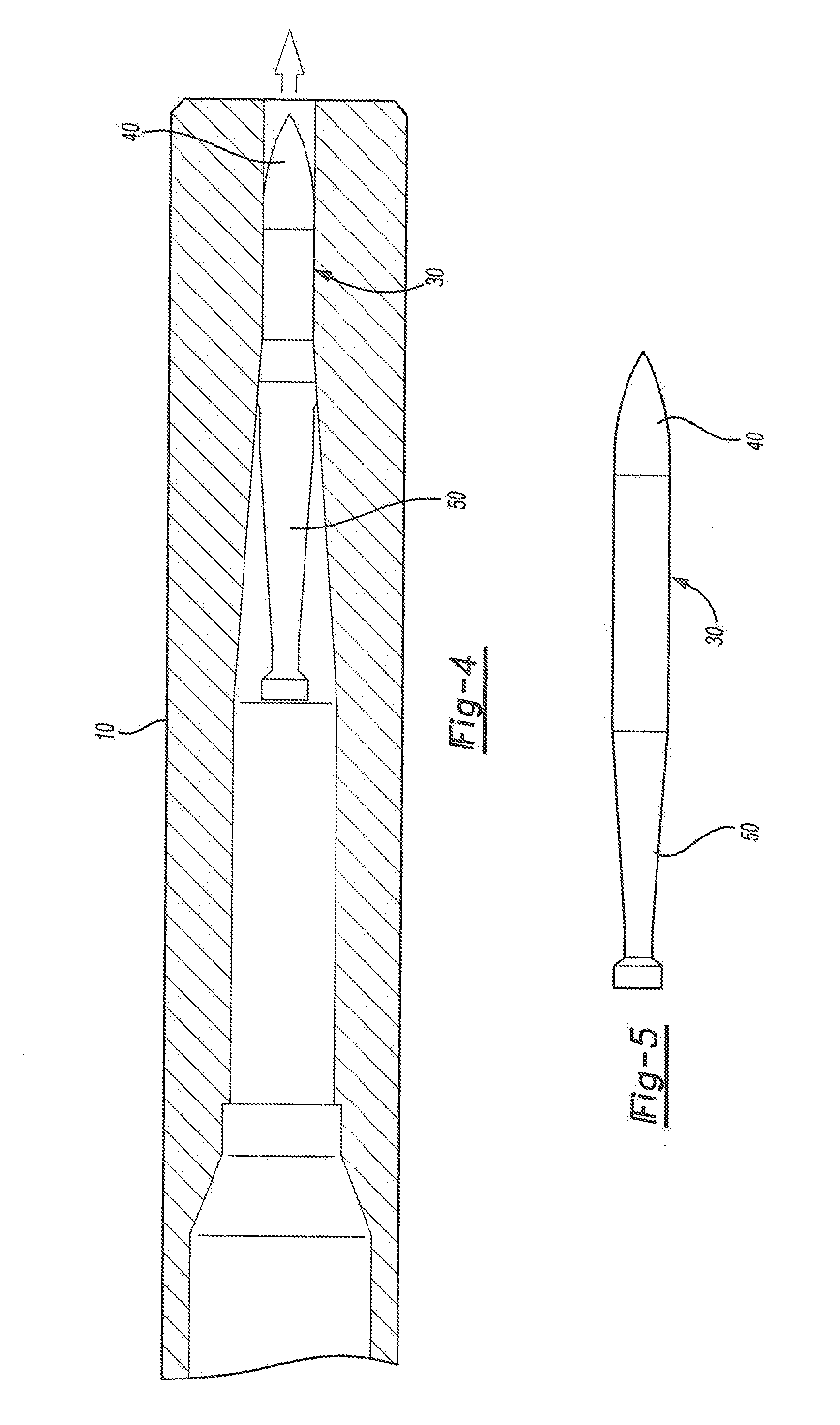

Flechette for direct fire weapons

ActiveUS20160363425A1Improve flight stabilityIncrease launch speedAmmunition projectilesBarrelsEngineeringCantilever

A flechette for use with a gun barrel having a tapered bore with a diameter at the initial bore section greater than the diameter at the emergent bore. The flechette includes a body constructed of a ductile material and having an elongated axis aligned with the axis of the tapered bore when positioned in the load end of the bore. The body also includes a cylindrical bulkhead as well as a bourrelet that are axially spaced from each other along the flechette and have an outside diameter substantially the same as the diameter at the initial bore section of the tapered bore. An elongated boom is attached at the tail end of the body while a penetrator is attached at the forward end of the body. Upon launch, both the bulkhead and bourrelet are compressed radially inward by the bore reduction so that the body is substantially cylindrical upon exit from the discharge end of the bore.

Owner:US SEC THE ARMY THE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com