V-shaped arranged double-acting type Stirling engine

A Stirling engine, double-acting technology, used in hot gas variable capacity engine devices, machines/engines, mechanical equipment, etc., can solve the problems of excessive size and weight of the whole machine, low output power, complex structure, etc. Light weight, increased power, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

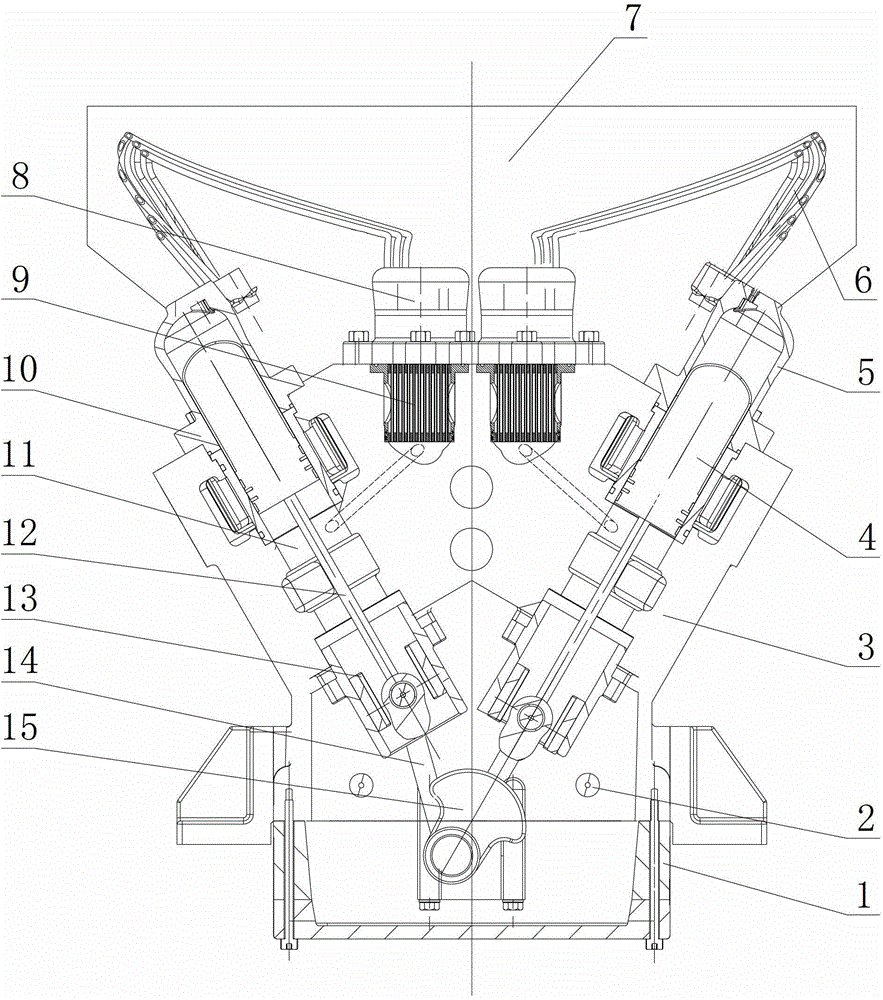

[0032] The specific embodiment of the present invention is shown in accompanying drawing, is made up of machine base 1, machine body 3, cylinder liner 10, crankshaft 15 and hot chamber cylinder 5; There are two rows of cavities arranged in a V shape, and the center line intersects on the crankshaft axis of the crankshaft 15 installed at the bottom of the body 3; the moving device is installed on the upper part of the cavity of the body 3 through the cylinder liner 10, and the lower part of the moving device is connected to the crankshaft. 15 are connected; on the upper part of the body 3, a hot chamber cylinder 5 is installed on the moving device, and a heating device is installed on the hot chamber cylinder 5 and the body 3; a working fluid system is also installed between the heating device and the moving device.

[0033] The heating device includes a heating tube 6 and a heating head 7; the heating tube 6 is integrally arranged in the heating head 7 installed on the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com