Band clamp for elongated member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

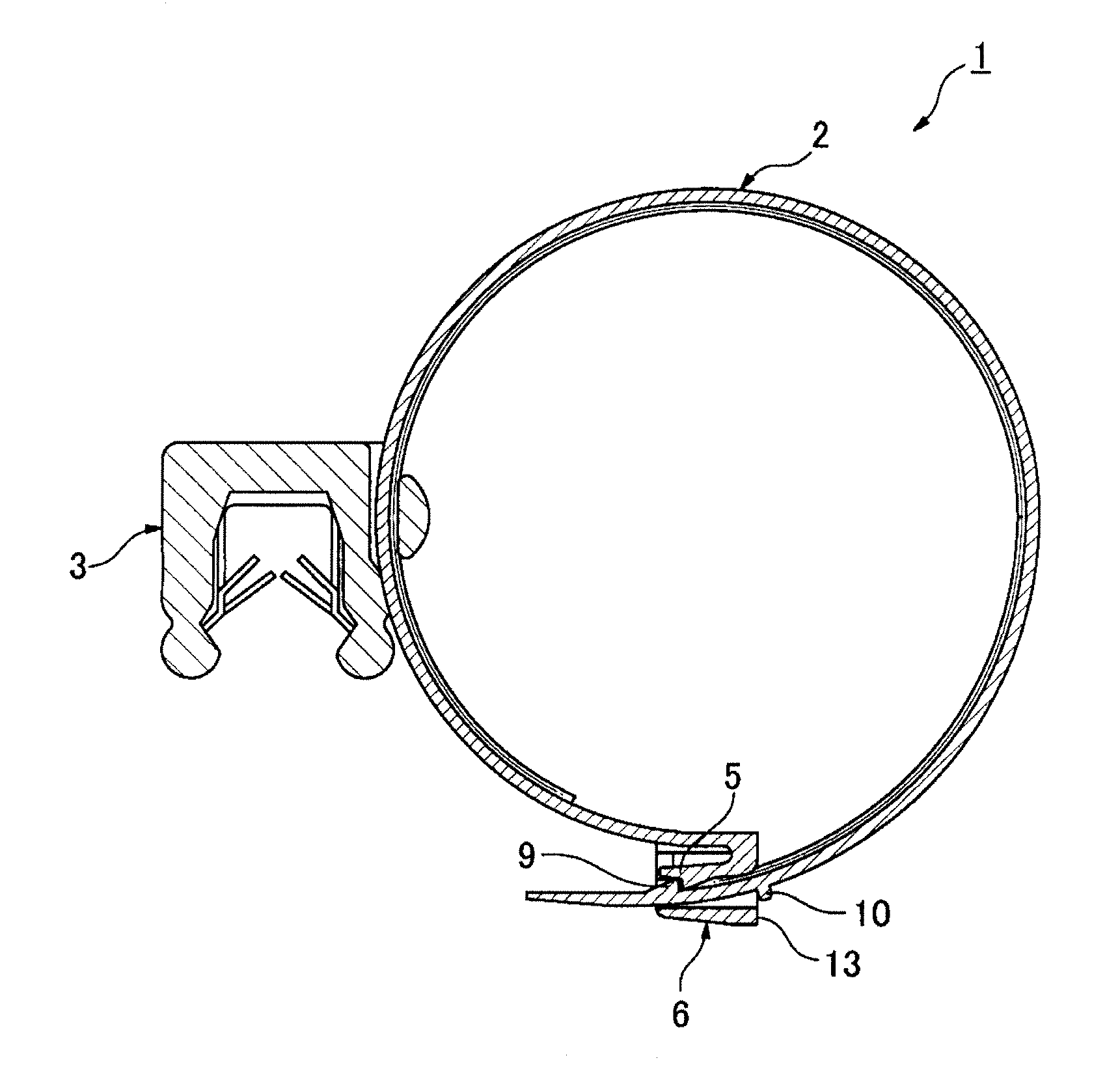

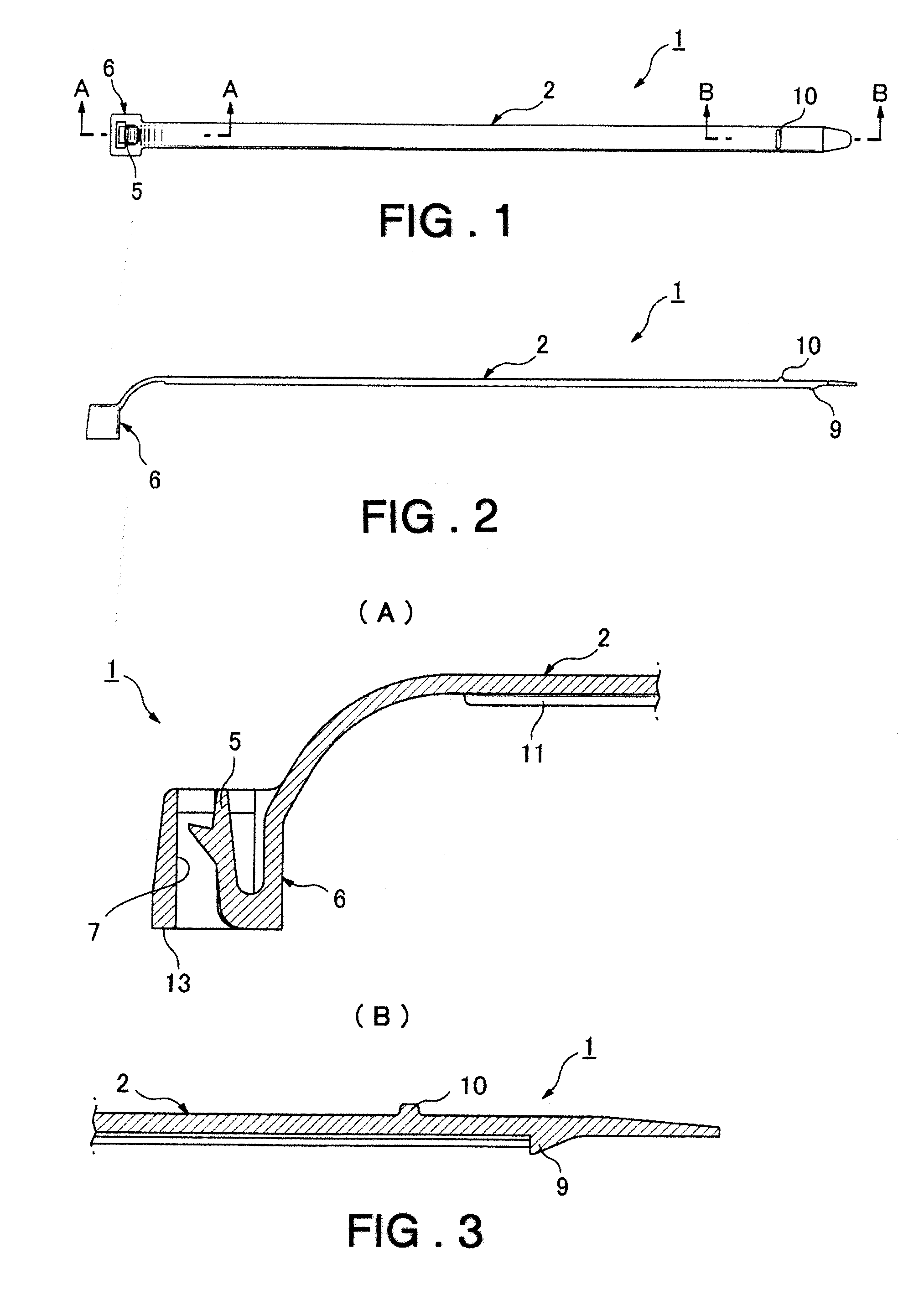

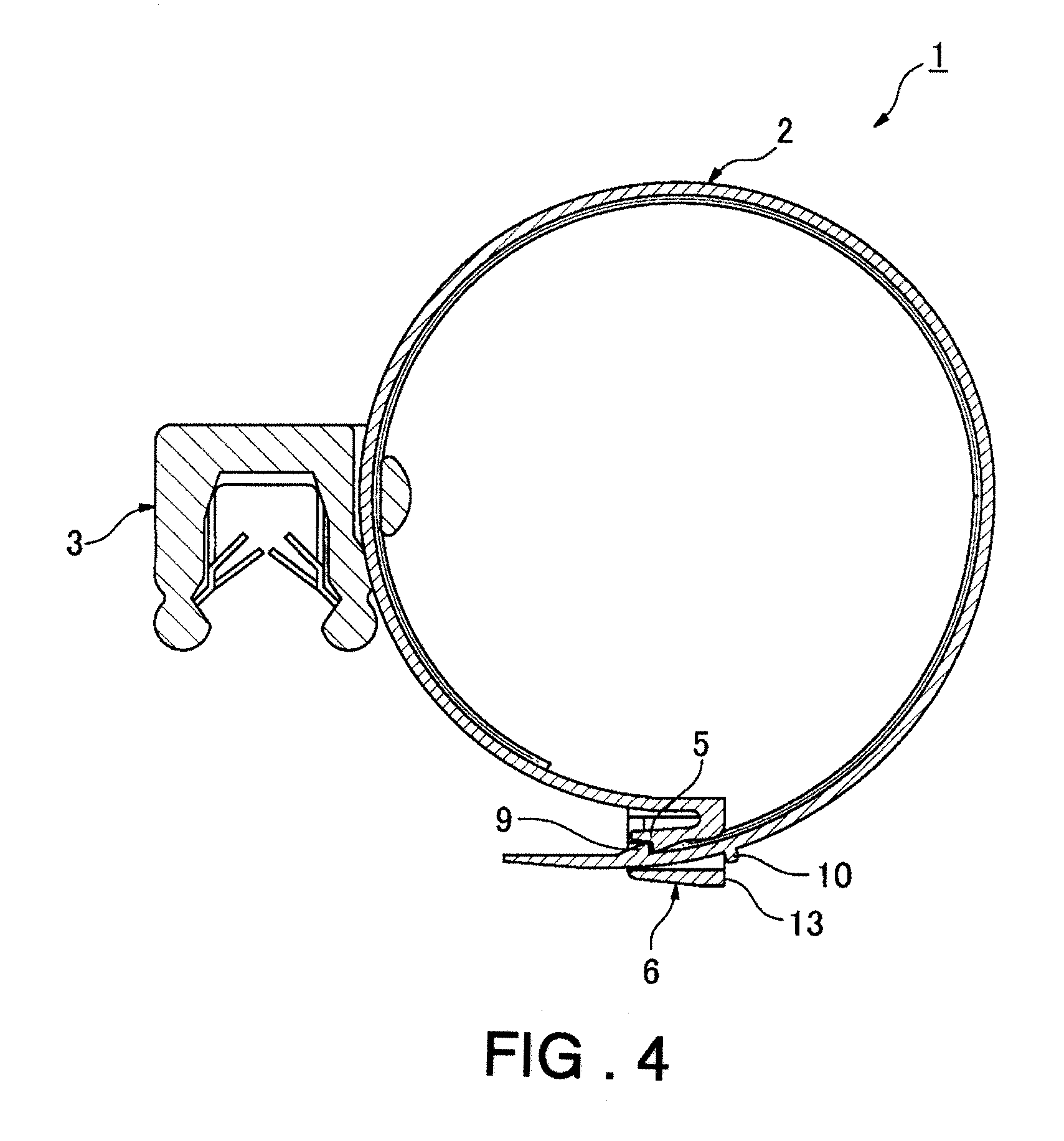

[0018]A band clamp 1 relating to one embodiment of the present invention is now described with reference to the drawings. In FIGS. 1 to 3, the band clamp 1 is diagrammed in its prior-to-use condition. In FIG. 4, how the band clamp 1 is wound about a long member such as a wire harness (not shown) to effect holding is diagrammed, with a clip 3 connected to a band 2 for connecting the long member to the member being attached to such as an automobile body panel.

[0019]In FIGS. 1 to 3, the band clamp 1 is a product that is integrally molded of a hard plastic. The band clamp 1 has a band 2 formed as a narrow, flat, belt-shaped member, and a lock 6, formed at one end of the band 2, having a latching pawl 5, for locking the condition wherein the band 2 is wound about the outer circumference of the long member such as a wire harness.

[0020]The lock 6 has a tubular band receptacle 7 through which the band 2 is passed, and a latching pawl 5 for latching the band 2, that has been accepted by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com