Ultrathin hard alloy with high hardness and preparation method thereof

A kind of cemented carbide, a technology of manufacturing method, applied in the field of high-hardness ultrafine cemented carbide and its manufacturing, to achieve the effects of improving service life, reducing porosity, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

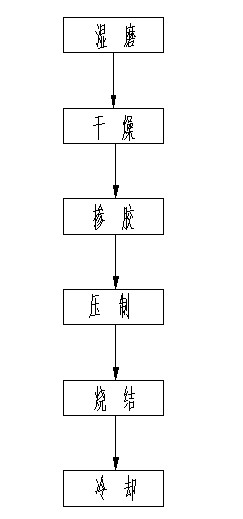

[0026] Such as figure 1 As shown, a high-hardness ultra-fine cemented carbide, the alloy uses ultra-fine carbide WC as the hard phase, Co as the binder phase, VC, NbC and TaC as inhibitors, the composition and weight of the alloy The content is as follows: WC: 90%, Co: 8%, VC: 0.6%, NbC: 0.6%, TaC: 0.8%; wherein the grain size of WC is 0.4 μm, and the grain size of Co is 1.42 μm .

[0027] The above-mentioned high-hardness ultra-fine cemented carbide is prepared by the following steps:

[0028] (1) Wet milling: Add WC, VC, NbC and TaC to the ball mill barrel in proportion, and at the same time add 300ml / kg of absolute ethanol with a purity of 99.99% as the ball mill medium, and add WC, VC, NbC and TaC in the ball mill barrel in proportion At TaC, the ratio of ball to material is 3:1, first ball mill for 20 hours, then add the binder phase Co, and then ball mill for 60 hours, and turn the ball mill cylinder once every 12 hours during the ball milling process;

[0029] (2) D...

Embodiment 2

[0036] Such as figure 1 As shown, a high-hardness ultra-fine cemented carbide, the alloy uses ultra-fine carbide WC as the hard phase, Co as the binder phase, VC, NbC and TaC as inhibitors, the composition and weight of the alloy The content is as follows: WC: 90.2%, Co: 8%, VC: 0.4%, NbC: 0.6%, TaC: 0.8%; wherein the grain size of WC is 0.4 μm, and the grain size of Co is 1.42 μm .

[0037] The above-mentioned high-hardness ultra-fine cemented carbide is prepared by the following steps:

[0038] (1) Wet milling: Add WC, VC, NbC and TaC to the ball mill barrel in proportion, and at the same time add 350ml / kg of absolute ethanol with a purity of 99.99% as the ball mill medium, and add WC, VC, NbC and TaC to the ball mill barrel in proportion At TaC, the ball-to-material ratio is 4.7:1, first ball mill for 34 hours, then add the binder phase Co, and then ball mill for 72 hours, and turn the ball mill cylinder once every 12 hours during the ball milling process;

[0039] (2) ...

Embodiment 3

[0047] Such as figure 1 As shown, a high-hardness ultra-fine cemented carbide, the alloy uses ultra-fine carbide WC as the hard phase, Co as the binder phase, VC, NbC and TaC as inhibitors, the composition and weight of the alloy The contents are as follows: WC: 90.4%, Co: 8%, VC: 0.2%, NbC: 0.6%, TaC: 0.8%; wherein the grain size of WC is 0.4 μm, and the grain size of Co is 1.42 μm .

[0048] The above-mentioned high-hardness ultra-fine cemented carbide is prepared by the following steps:

[0049] (1) Wet milling: Add WC, VC, NbC and TaC to the ball mill barrel in proportion, and at the same time add 400ml / kg of absolute ethanol with a purity of 99.99% as the ball mill medium, and add WC, VC, NbC and TaC in the ball mill barrel in proportion At TaC, the ball-to-material ratio is 6:1, first ball mill for 48 hours, then add the binder phase Co, and then ball mill for 80 hours, and turn the ball mill cylinder once every 12 hours during the ball milling process;

[0050] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com