Wire hydrostatic extrusion device and method for extruding superfine grain wire using the device

An extrusion device, hydrostatic extrusion technology, applied in metal extrusion control equipment, metal extrusion, metal extrusion dies, etc., can solve problems such as sealing difficulties, achieve easy operation, quality assurance, and simple device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Prepare φ3mm nanocrystalline 2017 aluminum alloy wire.

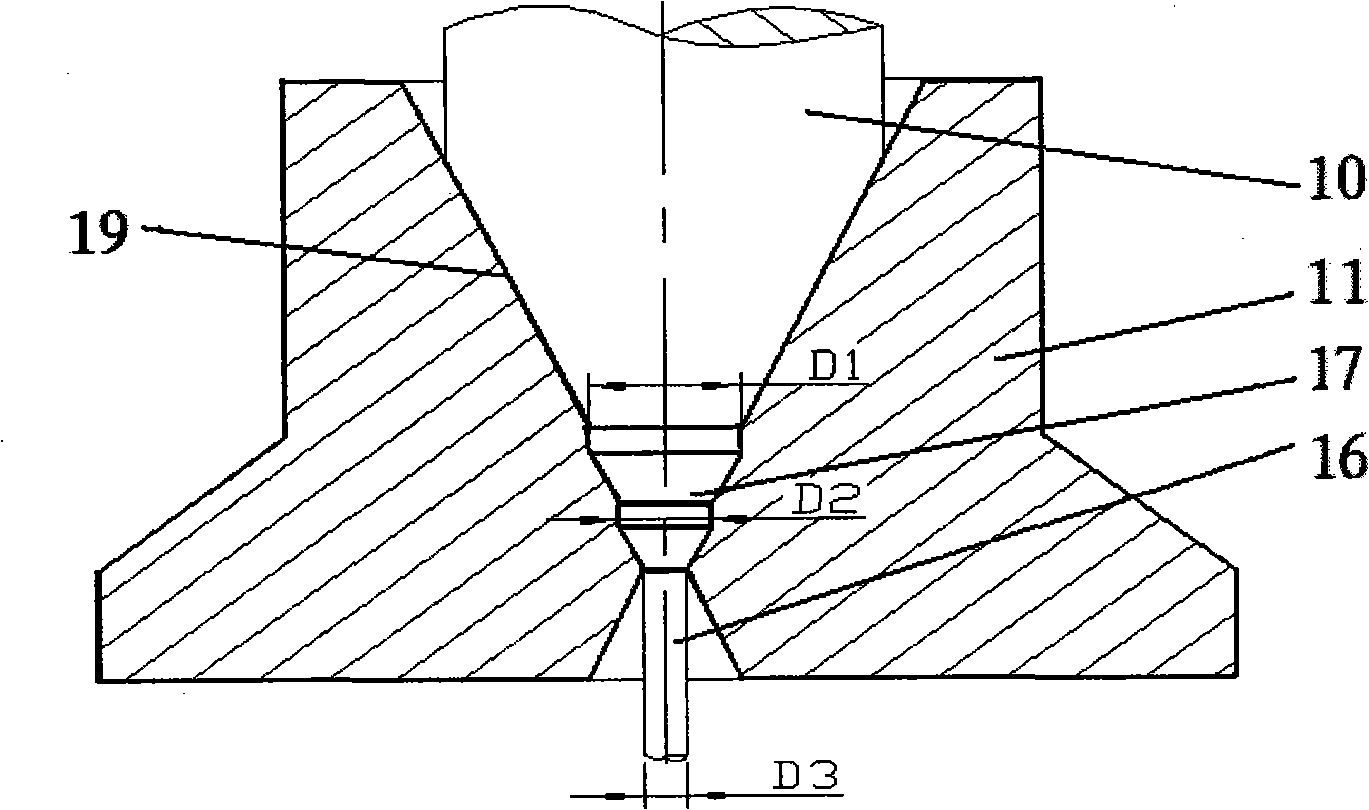

[0047] Step 1. Prepare the extrusion die. Select the corresponding extrusion die 11 according to the wire to be extruded, and set the diameters D1, D2, and D3 of the three steps of the extrusion hole 17 to 10 mm, 6 mm, and 3 mm, respectively.

[0048] Step 2, preparing the aluminum alloy billet 10 . The industrial 2017 aluminum alloy conventional extrusion material was prepared into a cylindrical rod with a diameter of 30 mm, and the head was turned into a cone angle consistent with the angle of the extrusion die 11 to produce an aluminum alloy billet 10 .

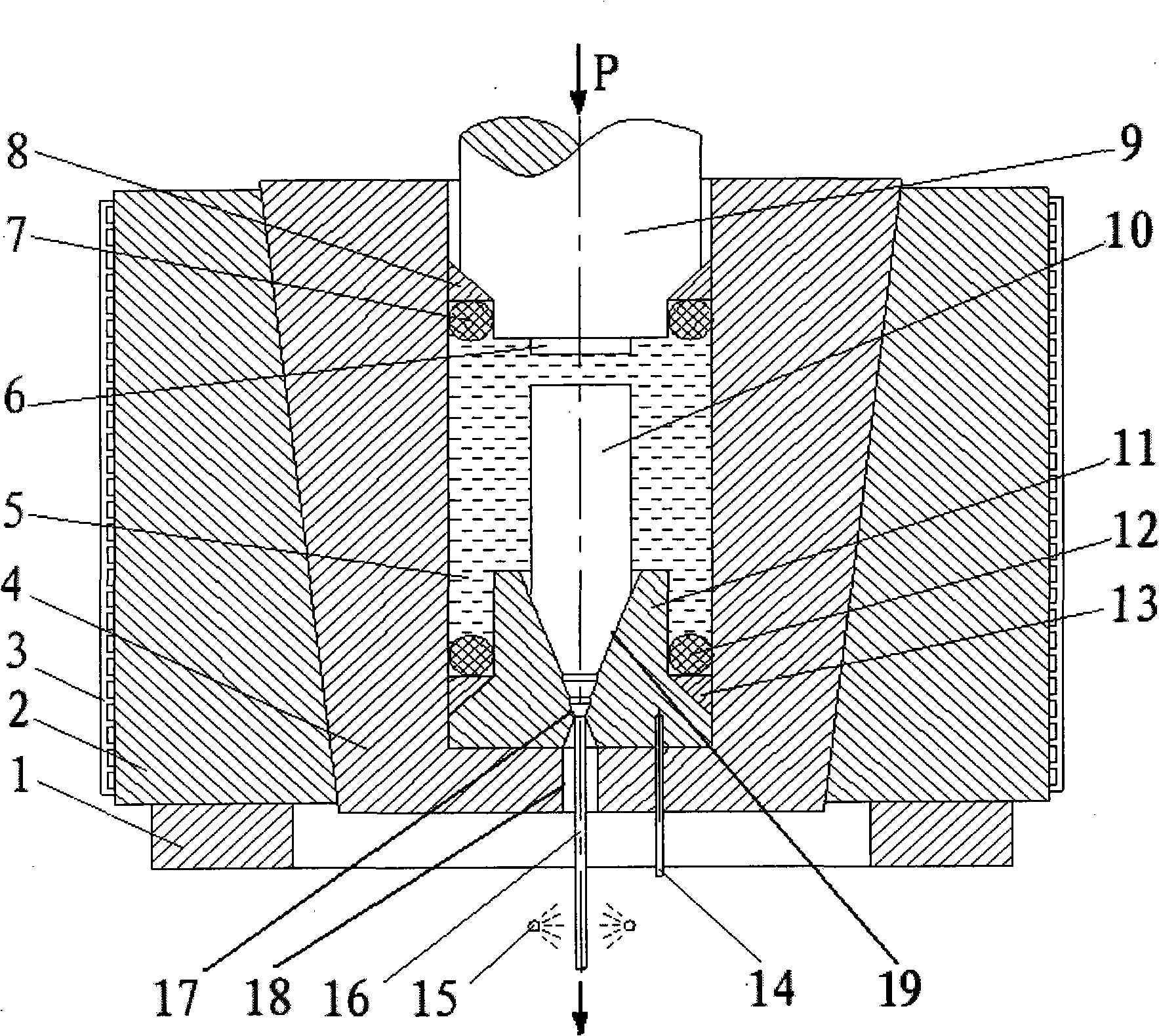

[0049] Step 3, loading and assembling equipment. After the aluminum alloy billet 10 to be extruded is cleaned and lubricated, it is put into the cone angle of the extrusion die 11, and the extrusion die 11, the inner extrusion cylinder 4 and its "O" type sealing ring 17 and the beryllium copper sealing ring I 8 are connected in turn, and then hydraulic medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com