Method of preparing thin crystal layer on magnesium alloy surface

A magnesium alloy and fine-grain technology, which is applied in the field of surface modification, can solve the problems of high energy consumption, surface oxidation of magnesium alloys, complicated processes, etc., and achieves the effects of simple process, grain refinement and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

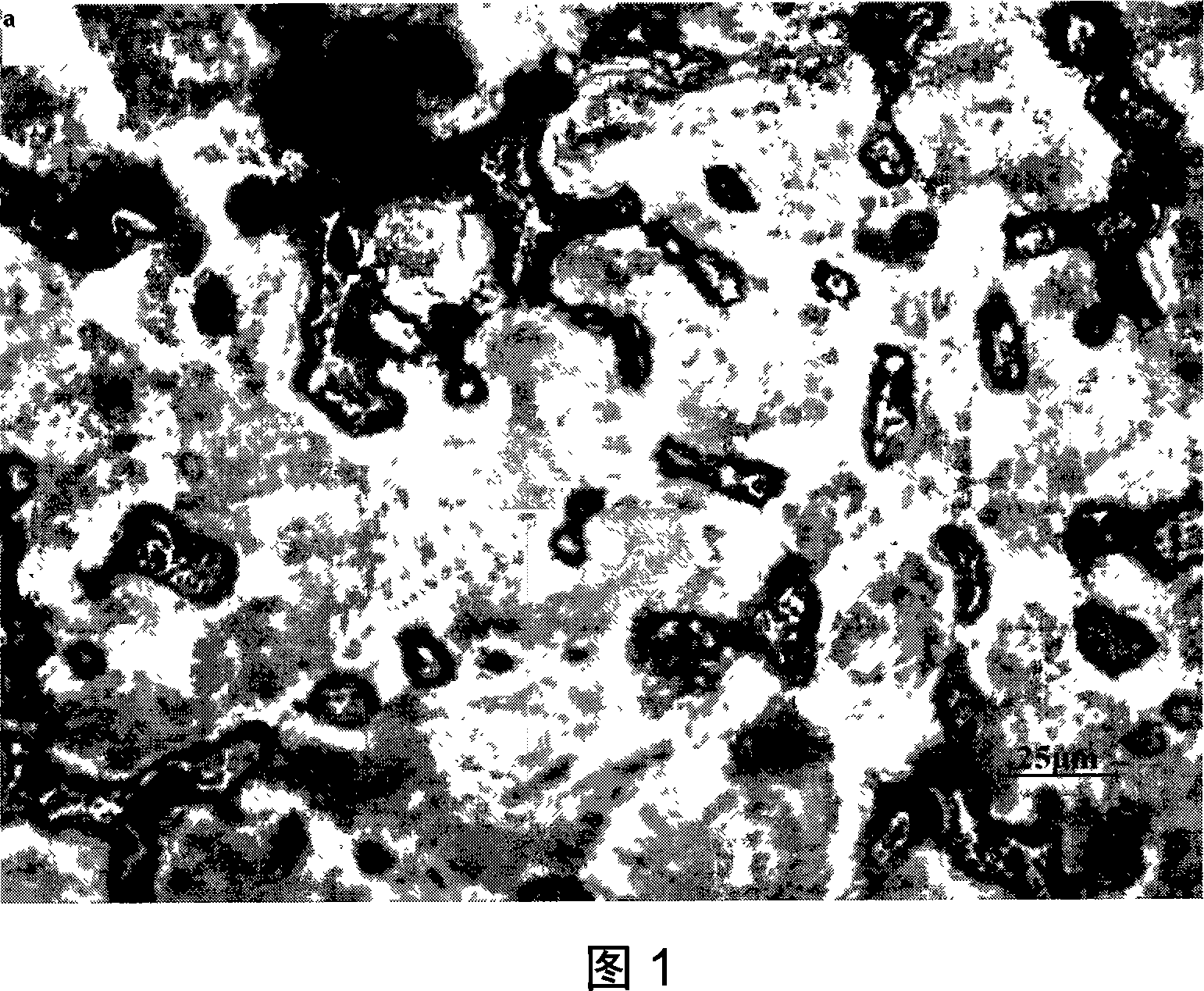

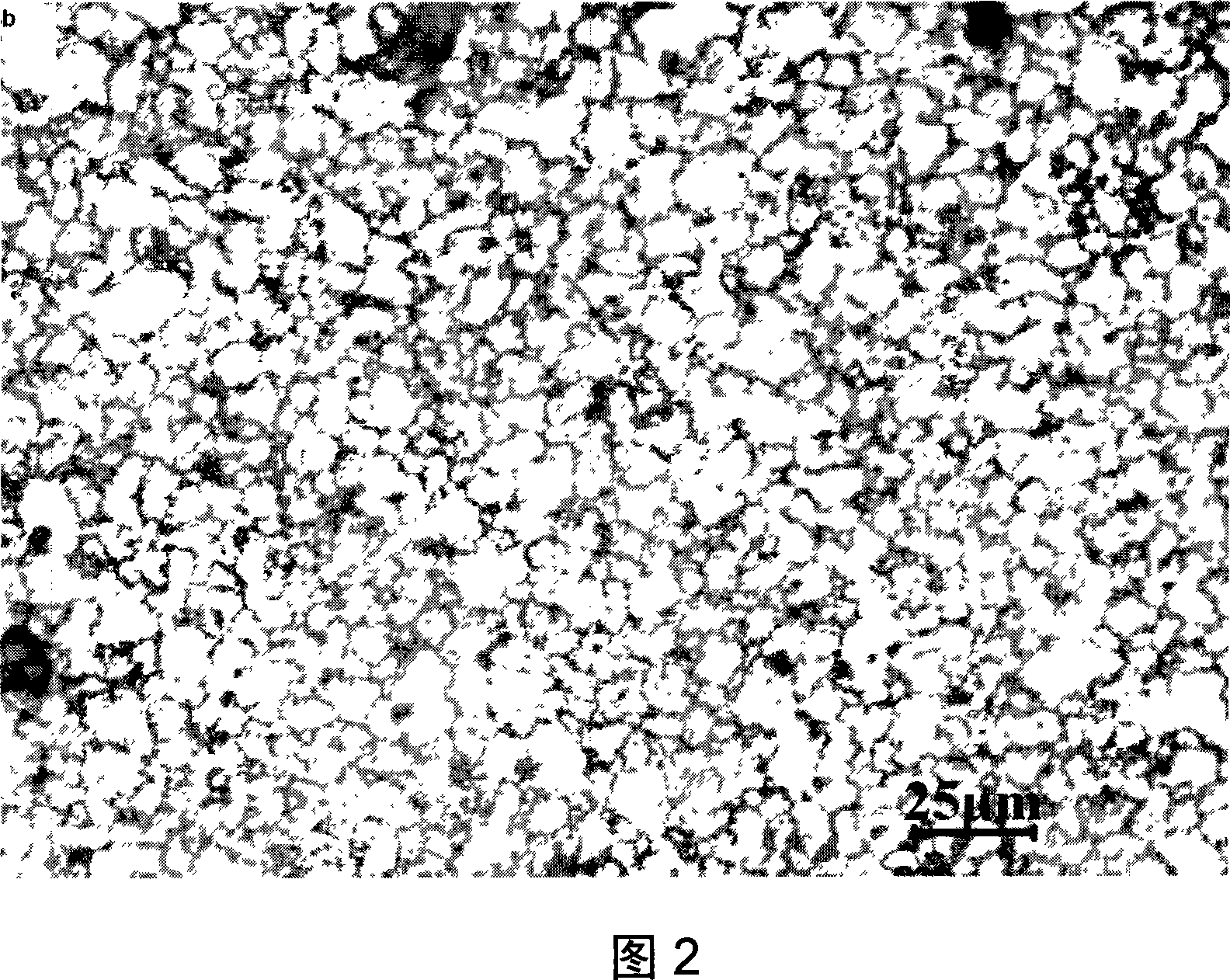

[0007] The AZ91D magnesium alloy obtained by metal mold casting is firstly polished on the surface of the magnesium alloy, and then directly mounted on the friction stir welding machine to process the surface of the magnesium alloy. The speed of the friction stir welding machine is 250-500 rpm The speed is 160-450mm / second. A layer of fine-grained structure with fine grains, uniform and dense structure, and no casting defects is obtained. Figure 1 shows the surface electron microscope microstructure of the magnesium alloy before friction stir processing, the structure is extremely inhomogeneous, eutectic Mg 17 al 12 Discontinuous network or thin rod distribution, extremely coarse grains. As shown in Figure 2, after friction stir processing, the eutectic Mg 17 al 12 disappeared completely, and the crystal grains became very fine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com