Niobium and titanium composite added ultra-low carbon baking hardening steel plate and manufacturing method thereof

A compound addition and bake hardening technology, applied in the field of metal material processing, can solve the problems of large aging at room temperature and poor formability, and achieve the effects of high mechanical properties, high BH value, and good resistance to room temperature aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention uses a 50Kg vacuum electromagnetic smelting furnace to smelt molten steel conforming to the set composition control range and casts it into a billet, and forges it into a small billet of 30×100×100mm. After the steel billet is heated, it is hot-rolled and cold-rolled. The focus of hot-rolling is to control the finishing temperature and coiling temperature of hot-rolling. Finally, continuous annealing is used to produce the steel plate required by the present invention. The focus of annealing is to control the holding temperature and holding time. The obtained steel plate has ideal mechanical properties, suitable BH value and good room temperature aging resistance.

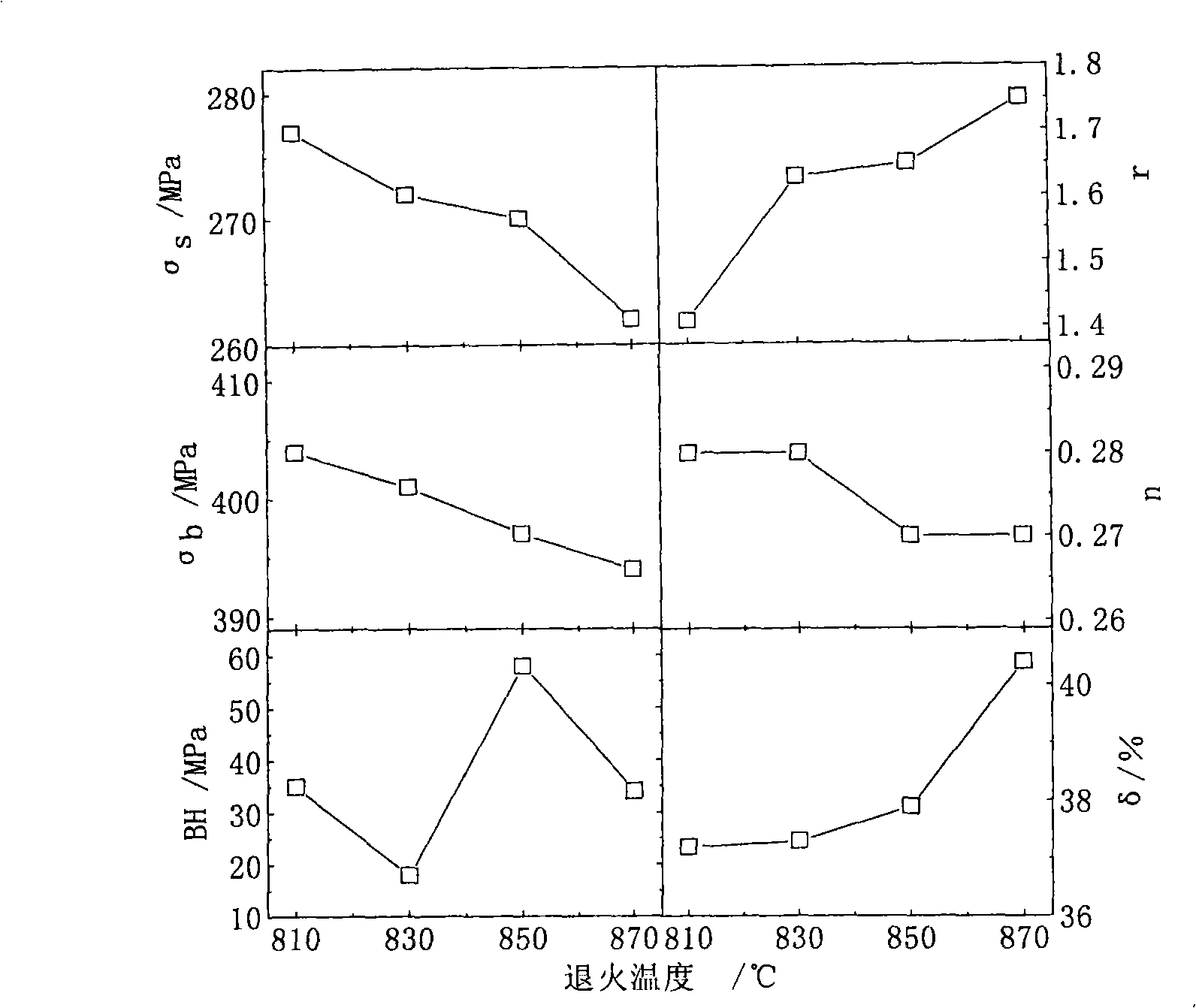

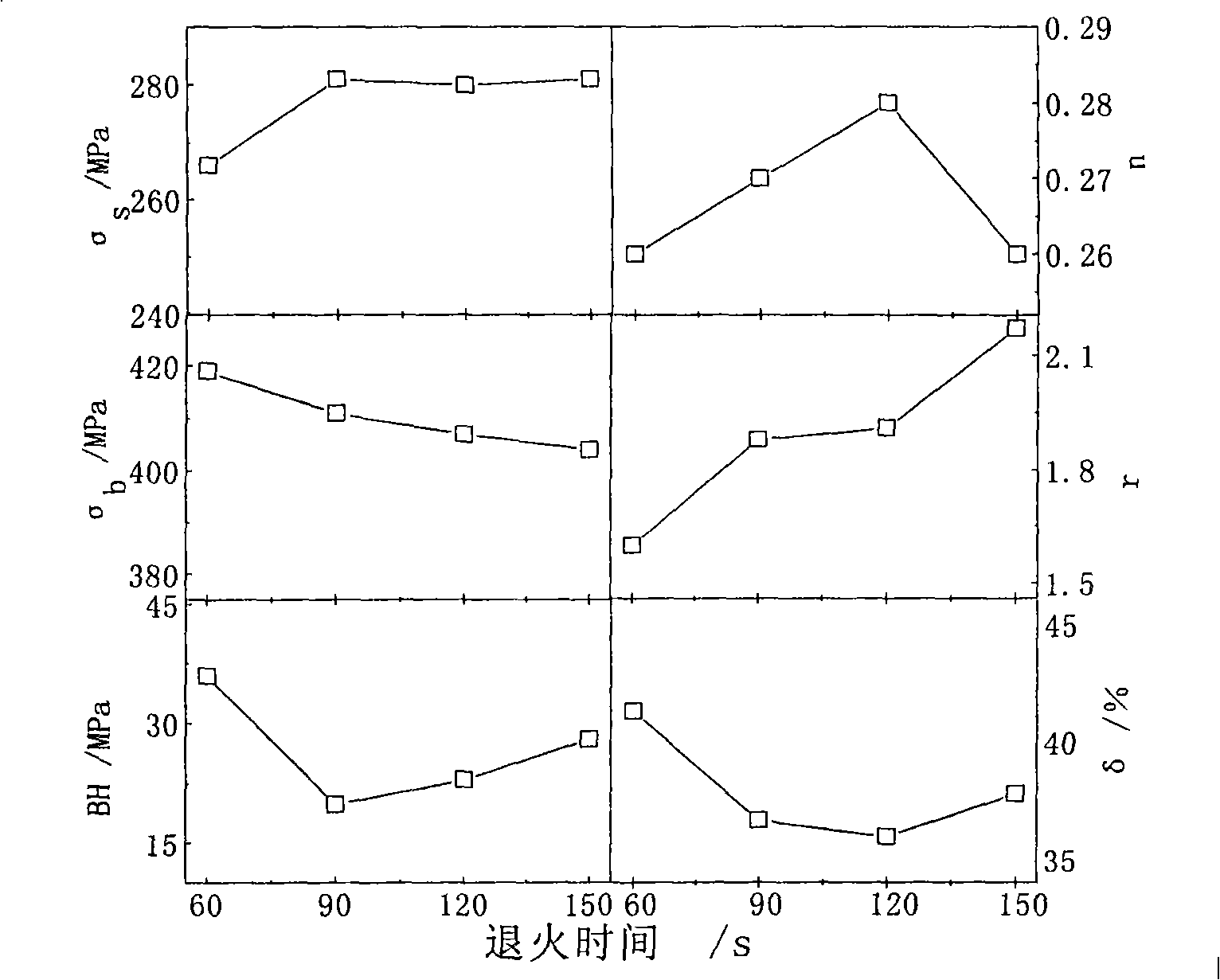

[0020] The present invention studies the influence of annealing temperature and annealing time on the properties of 390MPa ultra-low carbon bake-hardening steel plate conforming to the addition of Nb+Ti. Table 1 shows the properties of steel plates corresponding to different annealing process p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com