Method for preparing calcium sulfate crystal whiskers by using impurity-containing gypsum as raw material

A technology of calcium sulfate whisker, calcium sulfate hemihydrate, applied in chemical instruments and methods, calcium/strontium/barium sulfate, single crystal growth, etc. Calcium sulfate is difficult to dissolve and transform, and the comprehensive utilization rate is less than 10%, so as to achieve the effects of high added value, regular morphology and large aspect ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

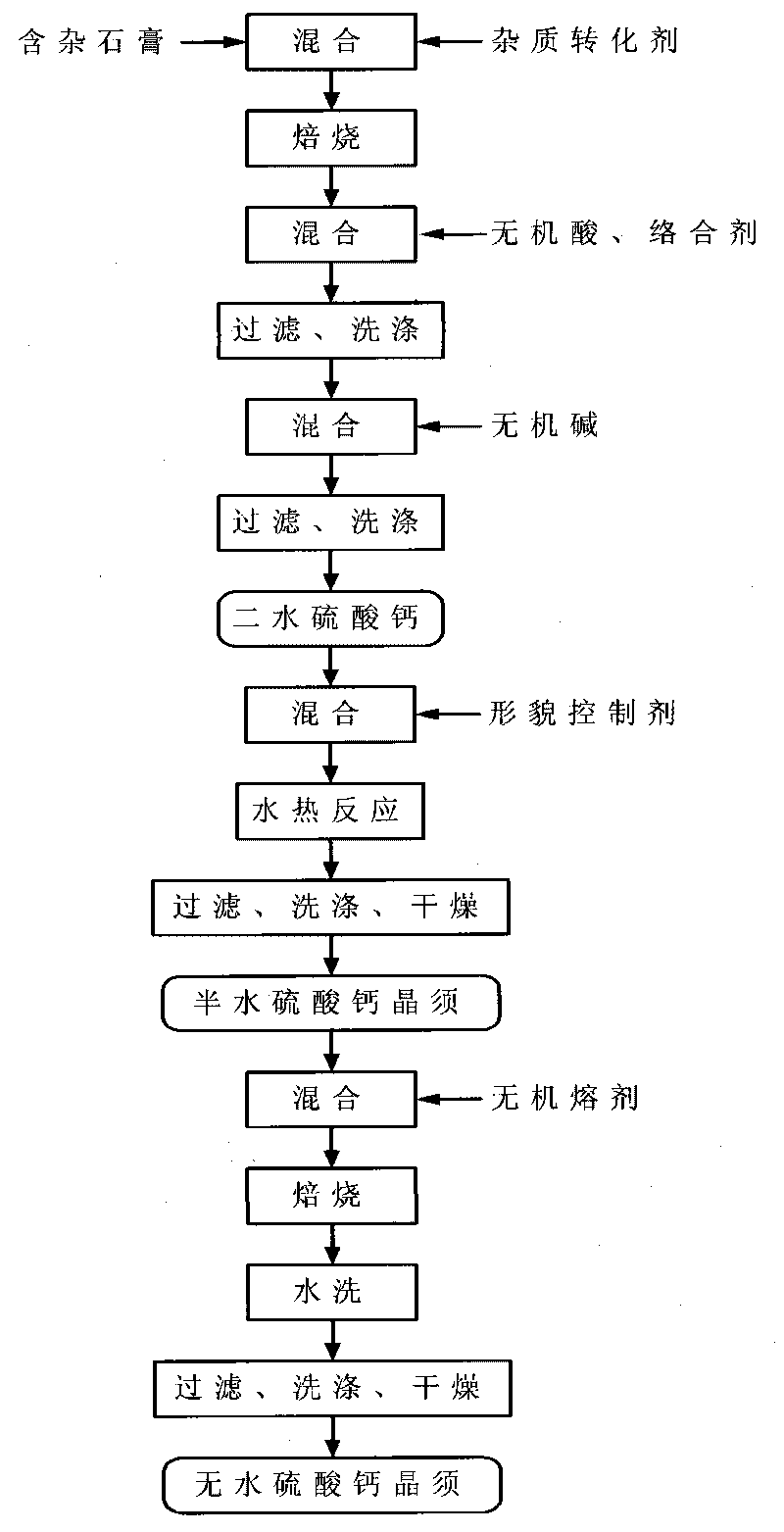

Method used

Image

Examples

Embodiment 1

[0045] Take by weighing natural gypsum (main composition: CaSO 4 2H 2 O: 99wt%, SiO 2 : 0.5wt%, Al 2 o 3 : 0, Fe 2 o 3 :0, MgO:0, P 2 o 5 :0,F:0,CO 3 : 0) 100g, sodium chloride 1g, the two are mixed and roasted at 300°C for 1h to obtain calcined sand. Add calcined sand to an aqueous solution containing 0.1mol / L hydrochloric acid and 0.1mol / L ethylenediaminetetraacetic acid to prepare a suspension with a solid content of 1 wt%, and react for 5 hours at 20°C with stirring (500 rpm) After filtering and washing the above slurry, add a sodium hydroxide solution with a concentration of 0.1mol / L to make a suspension with a solid content rate of 1wt%, react at 20°C for 5h under stirring (500 rpm), and filter 1. After washing, the calcium sulfate dihydrate precursor is obtained.

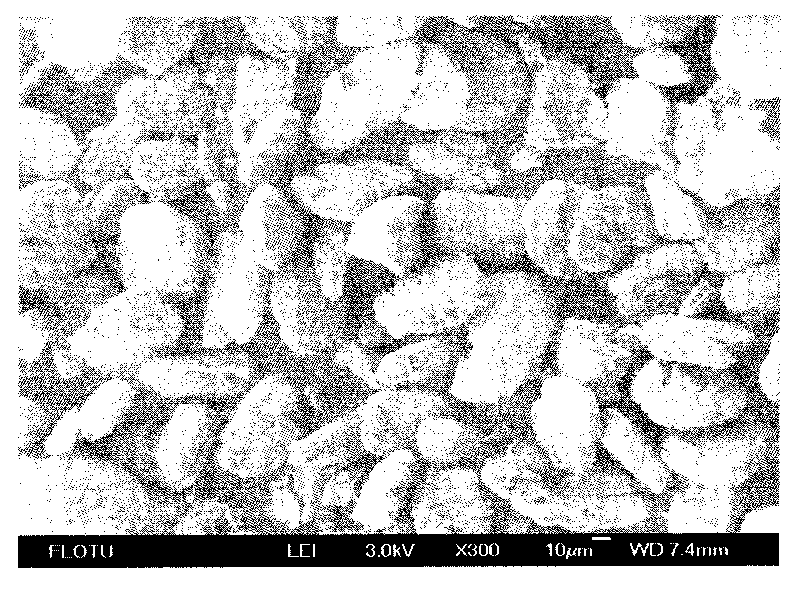

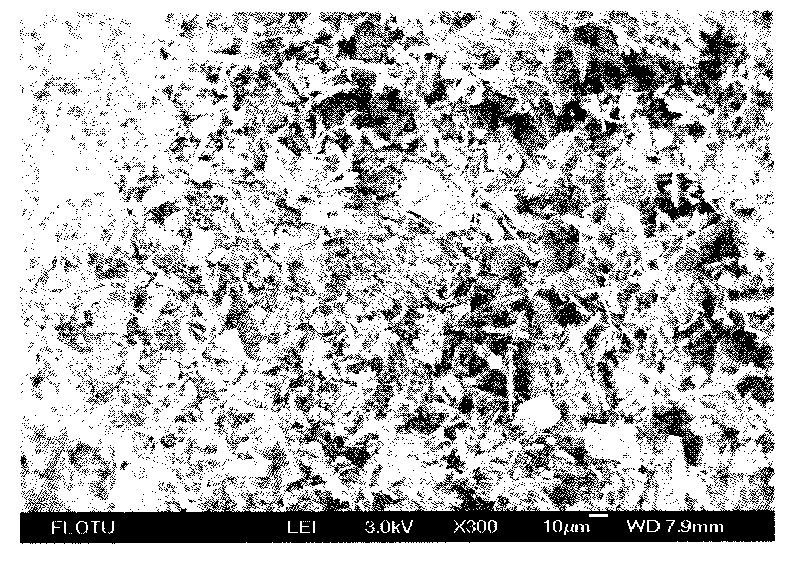

[0046] Put the calcium sulfate dihydrate precursor into the autoclave, add 0.005mol / L sodium chloride solution to adjust the solid content to 0.1wt%, and perform a hydrothermal reaction at 100°C for...

Embodiment 2

[0048] Take by weighing phosphogypsum (main composition: CaSO 4 2H 2 O: 70wt%, SiO 2 : 2wt%, Al 2 o 3 : 5wt%, Fe 2 o 3 : 5wt%, P 2 o 5 : 5wt%, F: 2wt%, CO 3 : 2wt%) 100g, potassium chloride 20g, after the two are mixed, roast at 800°C for 5h to obtain calcined sand. Add calcined sand to an aqueous solution containing 5mol / L hydrochloric acid and 0.5mol / L succinic acid to make a suspension with a solid content of 30wt%, and react for 1 hour at 100°C under stirring (50 rpm); After the slurry is filtered and washed, a potassium hydroxide solution with a concentration of 5 mol / L is added to make a suspension with a solid content rate of 30 wt%, and reacted at 100° C. for 1 hour under stirring (50 rpm) conditions, filtered and washed to obtain Precursor of calcium sulfate dihydrate.

[0049] Put the precursor of calcium sulfate dihydrate into a high-pressure reactor, add 5mol / L potassium chloride solution to adjust the solid content to 25wt%, react hydrothermally at 250°C...

Embodiment 3

[0051] Weigh desulfurized gypsum (main composition: CaSO 4 2H 2 O: 80wt%, SiO 2 : 2.5wt%, Al 2 o 3 : 2.5wt%, Fe 2 o 3 : 2wt%, CO 3 : 10wt%) 100g, ammonium chloride 10g, the two are mixed and roasted at 500°C for 2.5h to obtain calcined sand. Add calcined sand to an aqueous solution containing 2mol / L hydrochloric acid and 1mol / L citric acid to make a suspension with a solid content of 10wt%, and react for 2 hours at 40°C under stirring (250 rpm); filter the above slurry After washing, add ammonia solution with a concentration of 2.5mol / L to make a suspension with a solid content of 10wt%, react at 40°C and stir (250 rpm) for 2.5h, filter and wash to obtain dihydrate Calcium sulfate precursor.

[0052]Put the calcium sulfate dihydrate precursor into the autoclave, add 2mol / L sodium sulfate solution to adjust the solid content to 5wt%, react hydrothermally at 150°C for 2h under stirring (250 rpm), cool, filter, and wash , Drying (105°C, 4h), the intermediate product of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com