Dipping method, dipping piece and laminating plate

A dipping tank and prepreg treatment technology, which is applied in the impregnation method, laminates, and the field of impregnated sheets prepared by this method, can solve the problems that affect the manufacturing quality of the impregnated sheet, the board is easy to warp, and cannot be well satisfied, and achieves Good industrial application prospects and the effect of maintaining reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

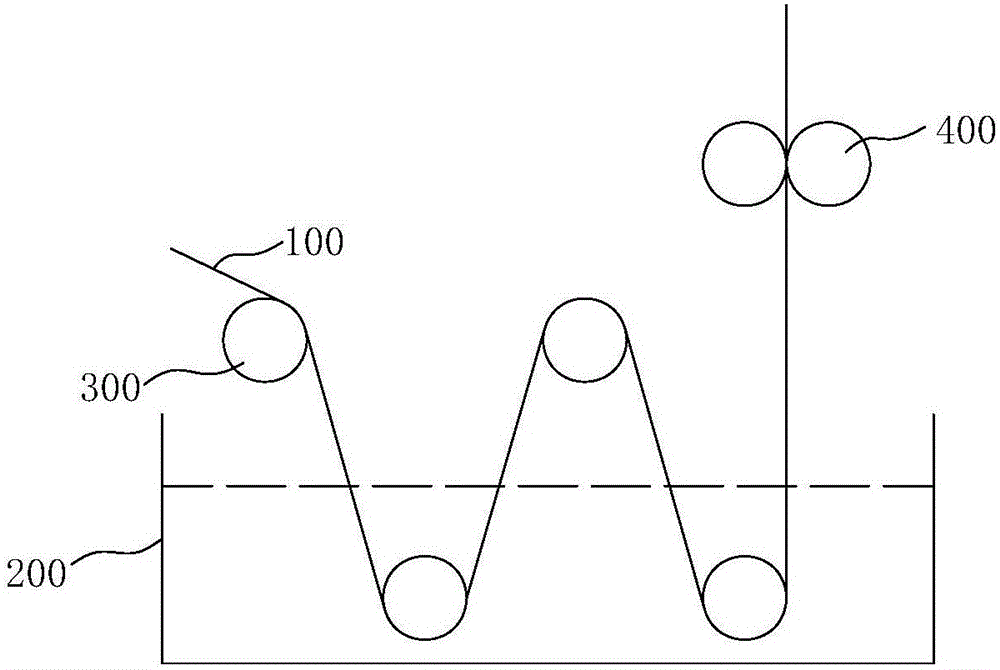

Method used

Image

Examples

Embodiment 1

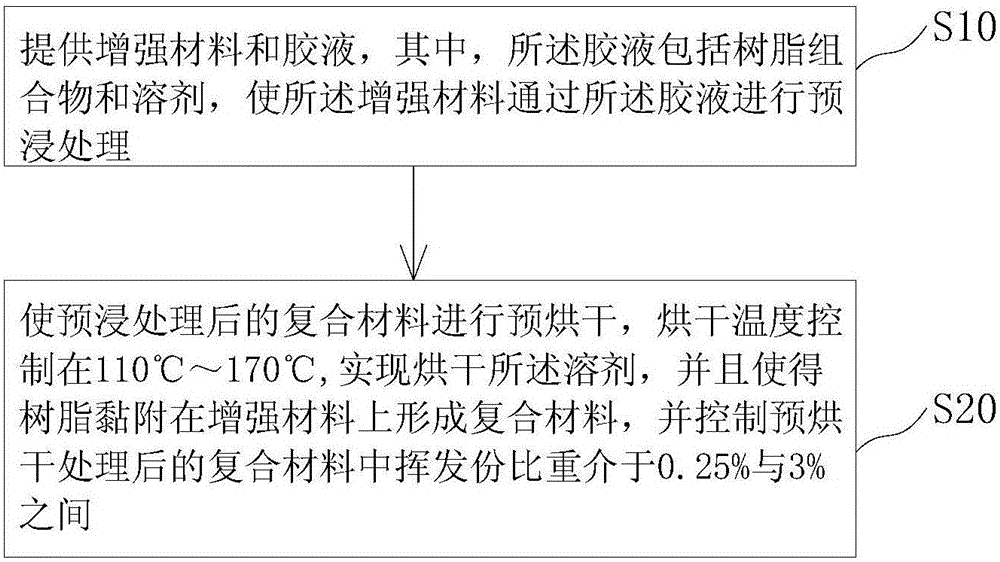

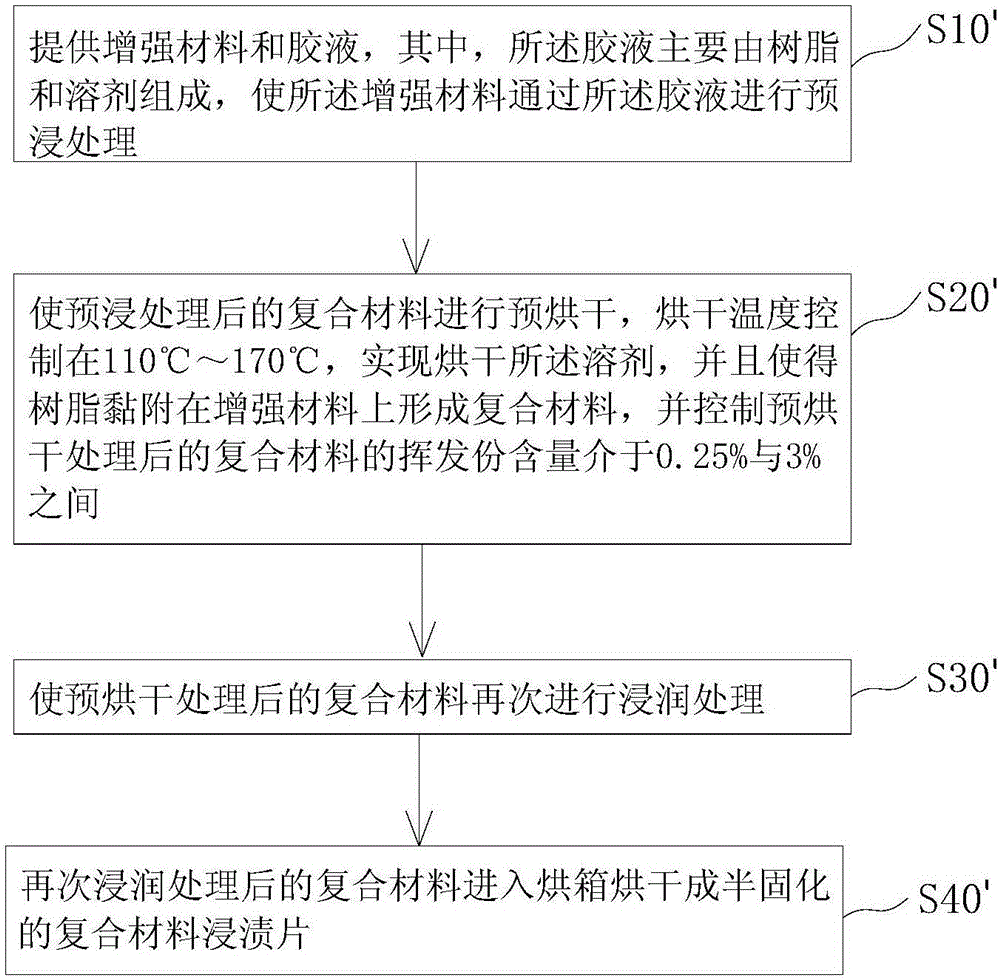

[0041] The production process of the impregnated sheet is as follows: step S10, prepreg treatment: provide reinforcing material and glue solution, wherein the reinforcing material is glass fiber cloth, and the glue solution is epoxy resin system, the density of the resin after curing of the system is 1.36g / cm 3 , making the reinforcing material prepreg through the glue solution; step S20, pre-drying treatment: pre-drying the composite material after the pre-preg treatment, the drying temperature is controlled at 110°C, and the drying process is realized. Solvent, and make the resin adhere to the reinforcing material to form a composite material, and control the volatile content of the composite material after the pre-drying treatment to be 3%; Step S30, re-wetting treatment: make the composite material after the pre-drying treatment be performed again Wetting treatment; step S40, drying treatment: the composite material after the wetting treatment is put into an oven and dried ...

Embodiment 2

[0044] The manufacturing process of the impregnated sheet and the laminated board of this embodiment is the same as that of the embodiment 1, the difference is that the pre-drying temperature is 112° C., and the volatile content of the composite material after the pre-drying treatment is controlled to be 2.85%.

Embodiment 3

[0046] The manufacturing process of the impregnated sheet and the laminated board of this embodiment is the same as that of Embodiment 1, the difference is that the pre-drying temperature is 115° C., and the volatile content of the composite material after the pre-drying treatment is controlled to be 2.65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com