Full-automatic production line for PEEK production

A production line, fully automatic technology, applied in the field of fully automatic production lines, can solve the problems of uneven feeding, uneven discharge, insufficient resin content and apparent quality of prepreg, and improve the adhesion rate, resin content and apparent quality. Improves and improves the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

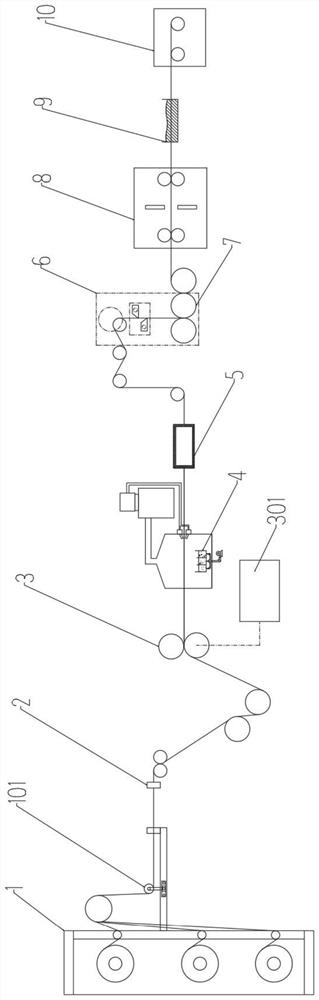

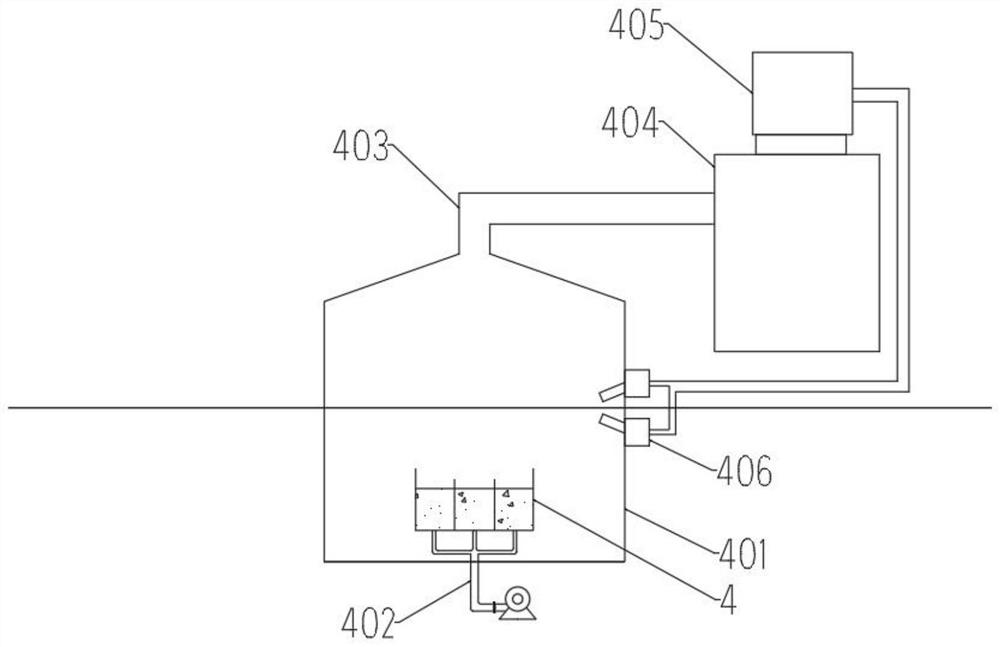

[0028] Such as Figure 1-7 As shown, a fully automatic production line for PEEK production, including a creel 1, a yarn collecting plate 2, a yarn spreading roller 3, a powder tank 4, a heat dryer 5, a melt impregnation Module 6, three-roll calender 7, cooling tractor 8, cooling pool 9 and winder 10;

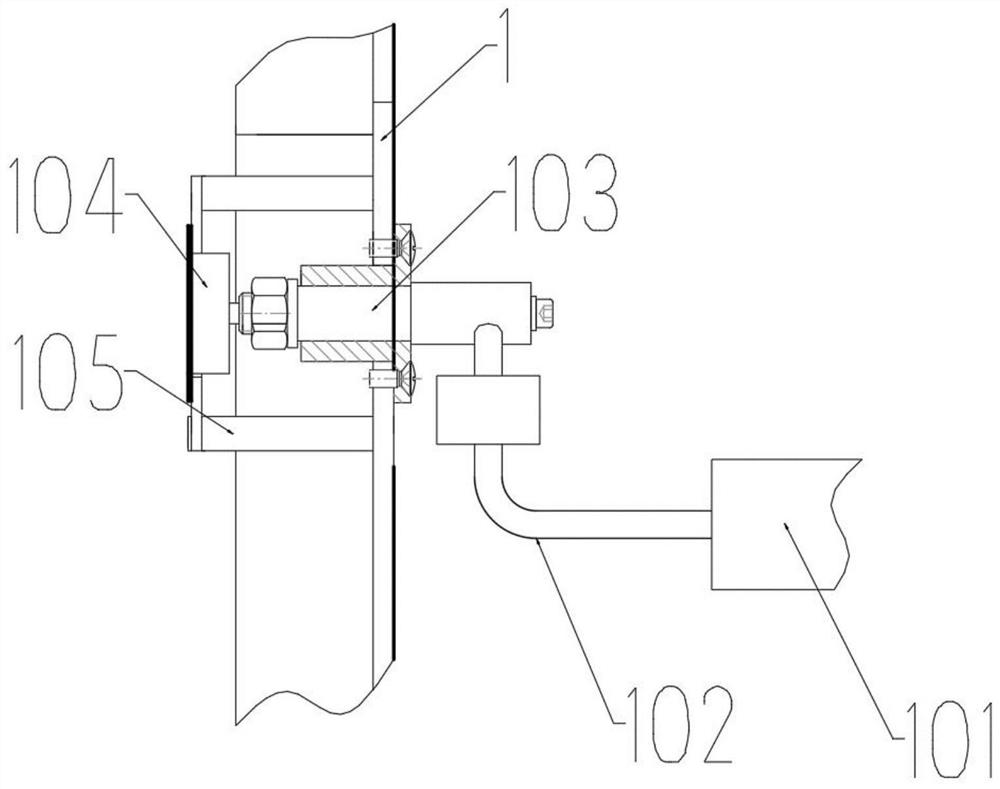

[0029] A tension measurement roller 101 is provided between the creel 1 and the yarn collecting plate 2, and the tension measurement roller 101 is connected to the angle positioning shaft 103 through the crank swing arm 102, and the angle positioning shaft 103 is connected to the creel 1 rotating connection, the rear end of the angle positioning s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com