A kind of anticorrosion material for sewage pool and its preparation method and construction technology

A technology of anti-corrosion materials and sewage pools, applied in sewage wells, general water supply saving, water supply devices, etc., can solve the problems of anti-corrosion hidden dangers, poor anti-corrosion effect, single anti-corrosion resin, etc., achieve convenient production and construction, and better anti-corrosion effect Good, high resin content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

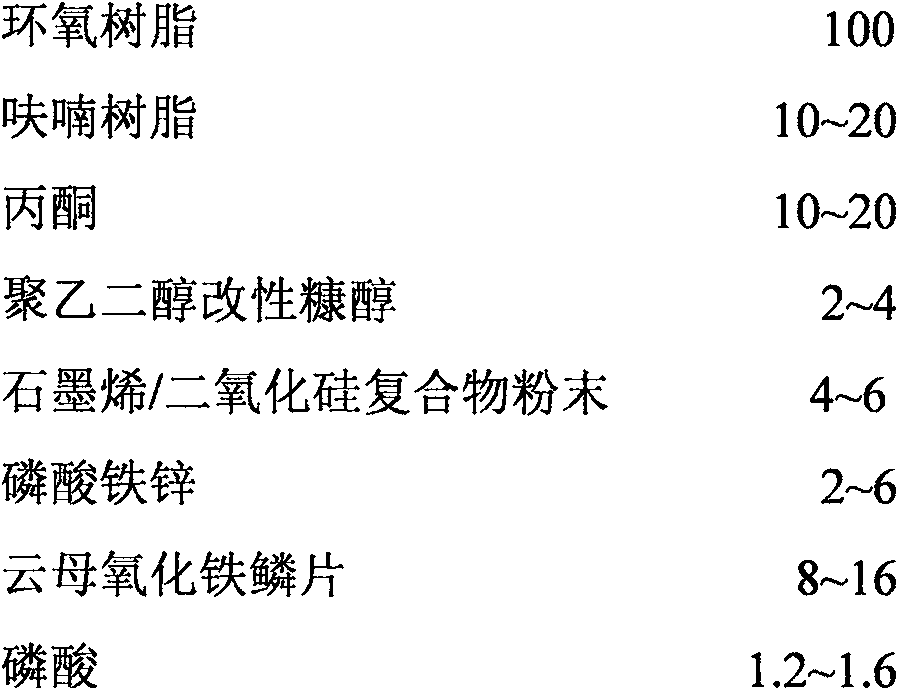

Method used

Image

Examples

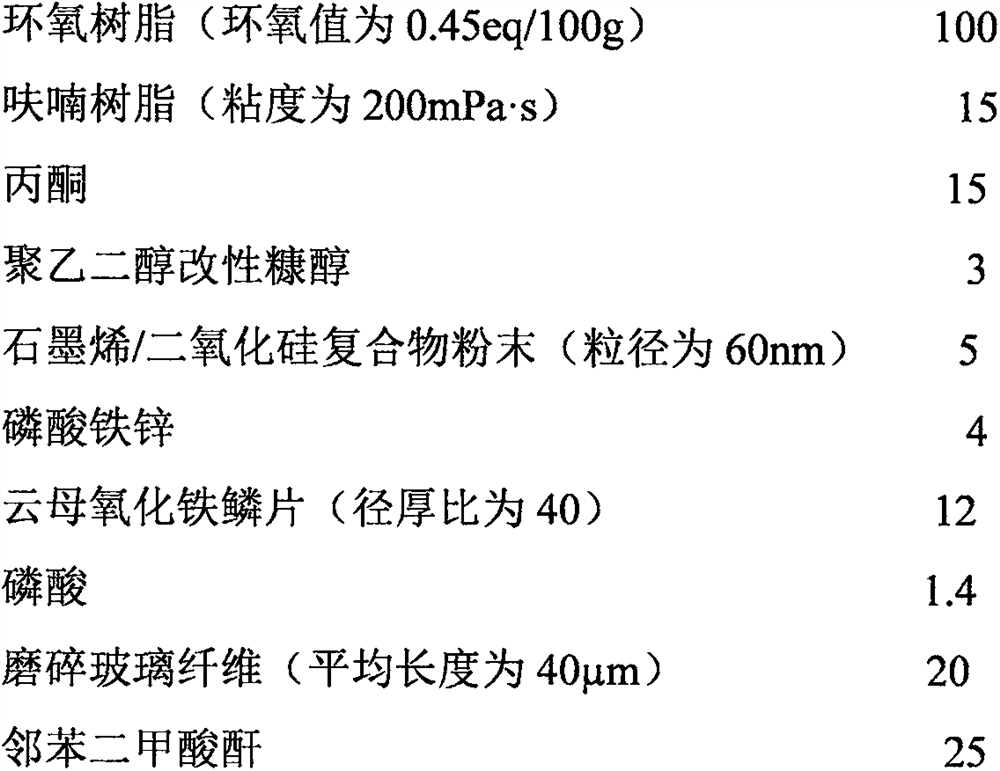

Embodiment 1

[0041] Embodiment 1: a kind of preparation method for the anticorrosion material of sewage pond is:

[0042] (1) Take ethylene glycol and furfuryl alcohol in a molar ratio of 1.1:2, put ethylene glycol into a container with a constant pressure dropping funnel, a condenser tube, and a magnetic stirrer, and fix the container in an 80°C oil bath, Turn on the stirrer and set the rotating speed to 35r / min and adjust its pH to 4.0 with hydrochloric acid. After the oil temperature reaches the set temperature, use a constant pressure titration funnel to slowly add the weighed furfuryl alcohol liquid into the container, control the dripping speed to ensure that the dripping is completed within 2.5 hours, and then keep warm for 1.3 hours before discharging to obtain poly Ethylene glycol modified furfuryl alcohol;

[0043] (2) Evenly disperse 0.7 parts by weight of graphene oxide into 200 parts by weight of deionized water for 1.5 h, and mix the dispersion with 1000 parts by weight of c...

Embodiment 2

[0060] Embodiment 2: a kind of preparation method for the anticorrosion material of sewage pond is:

[0061] (1) Take ethylene glycol and furfuryl alcohol in a molar ratio of 1:2, put ethylene glycol into a container with a constant pressure dropping funnel, a condenser tube, and a magnetic stirrer, and fix the container in a 75°C oil bath, Turn on the stirrer and set the rotating speed to 30r / min and adjust its pH to 3.5 with hydrochloric acid. After the oil temperature reaches the set temperature, use a constant pressure titration funnel to slowly add the weighed furfuryl alcohol liquid into the container, control the dropping speed to ensure that the dripping is completed within 2 hours, and then keep warm for 1 hour to discharge the material to obtain polyethylene glycol Alcohol modified furfuryl alcohol;

[0062] (2) Evenly disperse 0.6 parts by weight of graphene oxide ultrasonically into 180 parts by weight of deionized water, and mix the dispersion with 1000 parts by ...

Embodiment 3

[0079] Embodiment 3: a kind of preparation method for the anticorrosion material of sewage pond is:

[0080] (1) Take ethylene glycol and furfuryl alcohol in a molar ratio of 1.2:2, put ethylene glycol into a container with a constant pressure dropping funnel, a condenser, and a magnetic stirrer, and fix the container in an oil bath at 85°C. Turn on the stirrer and set the rotating speed to 40r / min and adjust its pH to 4.5 with hydrochloric acid. After the oil temperature reaches the set temperature, use a constant pressure titration funnel to slowly add the weighed furfuryl alcohol liquid into the container, control the dropping speed to ensure that the dripping is completed within 3 hours, and then keep the temperature for 1.6 hours and then discharge the material to obtain polyethylene glycol. Glycol modified furfuryl alcohol;

[0081] (2) Evenly disperse 0.8 parts by weight of graphene oxide ultrasonically into 220 parts by weight of deionized water, and mix the dispersio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com