Preparation method of high-performance high-temperature titanium-alloy-based composite material

A high-temperature titanium alloy and composite material technology, which is applied in the field of preparation of high-performance high-temperature titanium alloy-based composite materials, can solve problems that have not yet been discovered, and achieve the effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

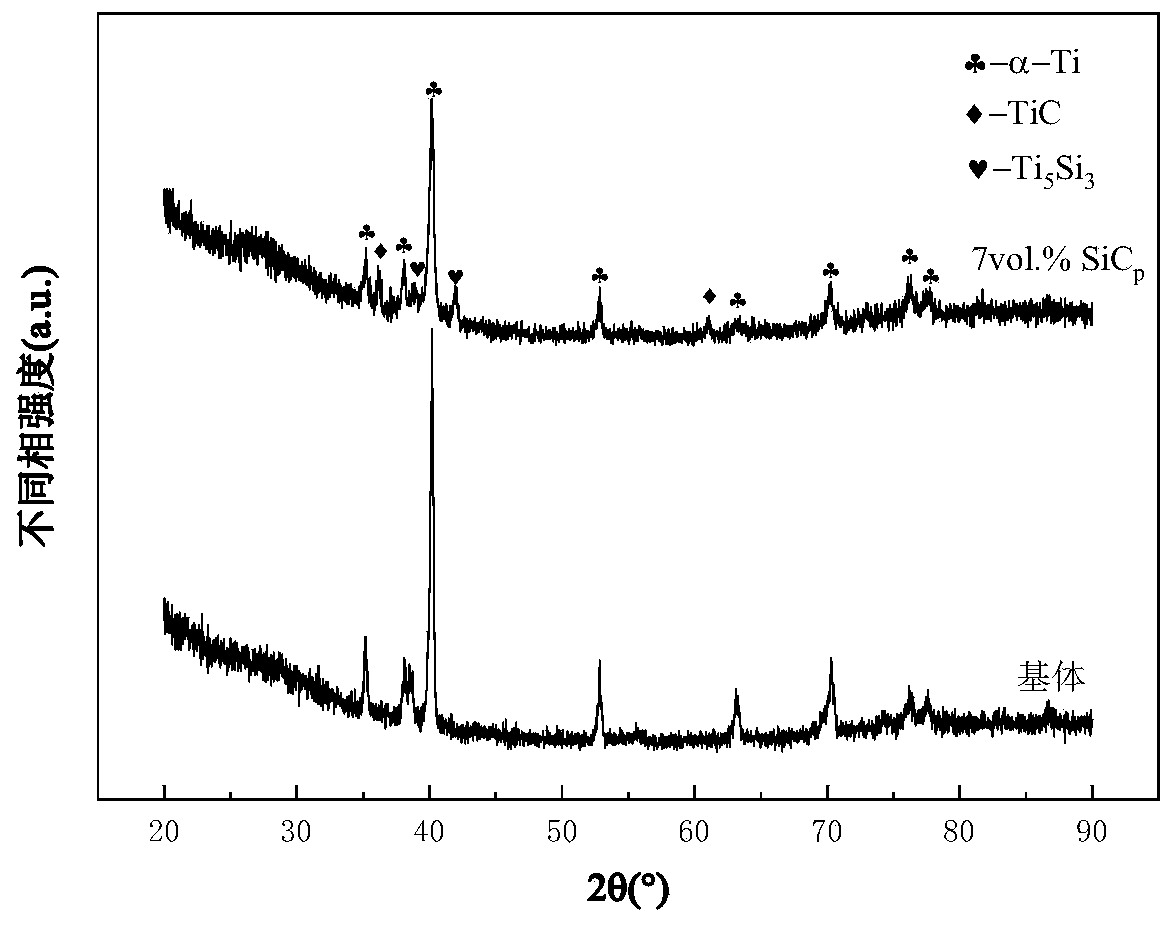

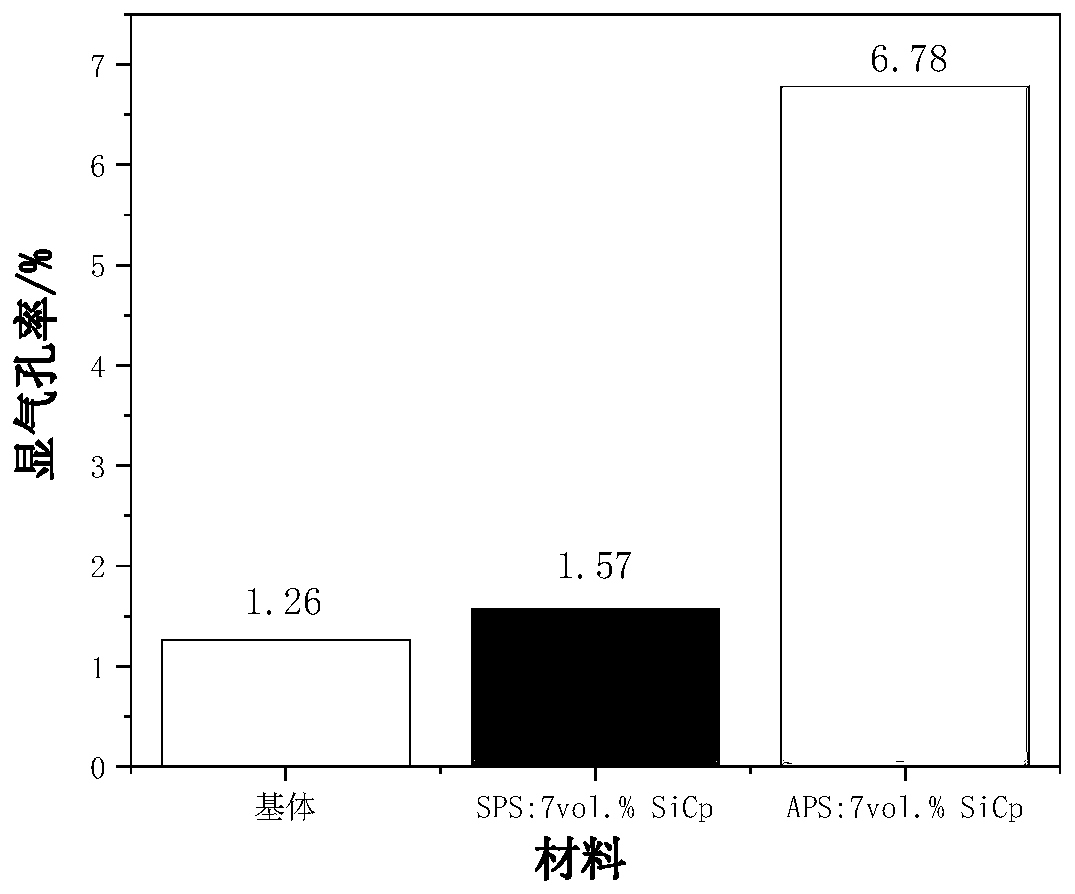

[0029] Such as Figure 1-6 shown.

[0030] A preparation method (SPS method) of a high-performance high-temperature titanium alloy-based composite material, using 93 vol % titanium matrix and 7vol.% SiCp as raw materials (the titanium matrix is made of 90wt.% Ti alloy powder Ti-6.01Al-2.55Sn -6.24Zr-1.23Nb-1.84Mo-0.19Si and 10wt.% pure Ti powder) generate TiC and Ti in situ by spark plasma sintering 5 Si 3 Reinforcement phase, which can improve the comprehensive performance of composite materials. Specific steps include:

[0031] (1) Prepare 90wt.% Ti alloy powder and 10wt.% pure Ti powder by atomization method to obtain matrix powder;

[0032] (2) Wet mill 7vol.% SiCp reinforcement powder; the particle size of the 7vol.% SiCp reinforcement used is 1 μm, the purity is greater than 99%, the ball mill speed is 300±50r / min, and the wet milling time is 24h;

[0033] (3) Wet grinding matrix powder and reinforcement mixed powder; ball mill speed 300±50r / min, wet grinding time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com