Preparation method of green composite nano magnetic material for effectively removing heavy metals in environment

A technology of nano-magnetic materials and heavy metals, applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of environmental secondary pollution, cumbersome methods, expensive raw materials, etc., and achieve energy consumption The effect of few, wide source of raw materials, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

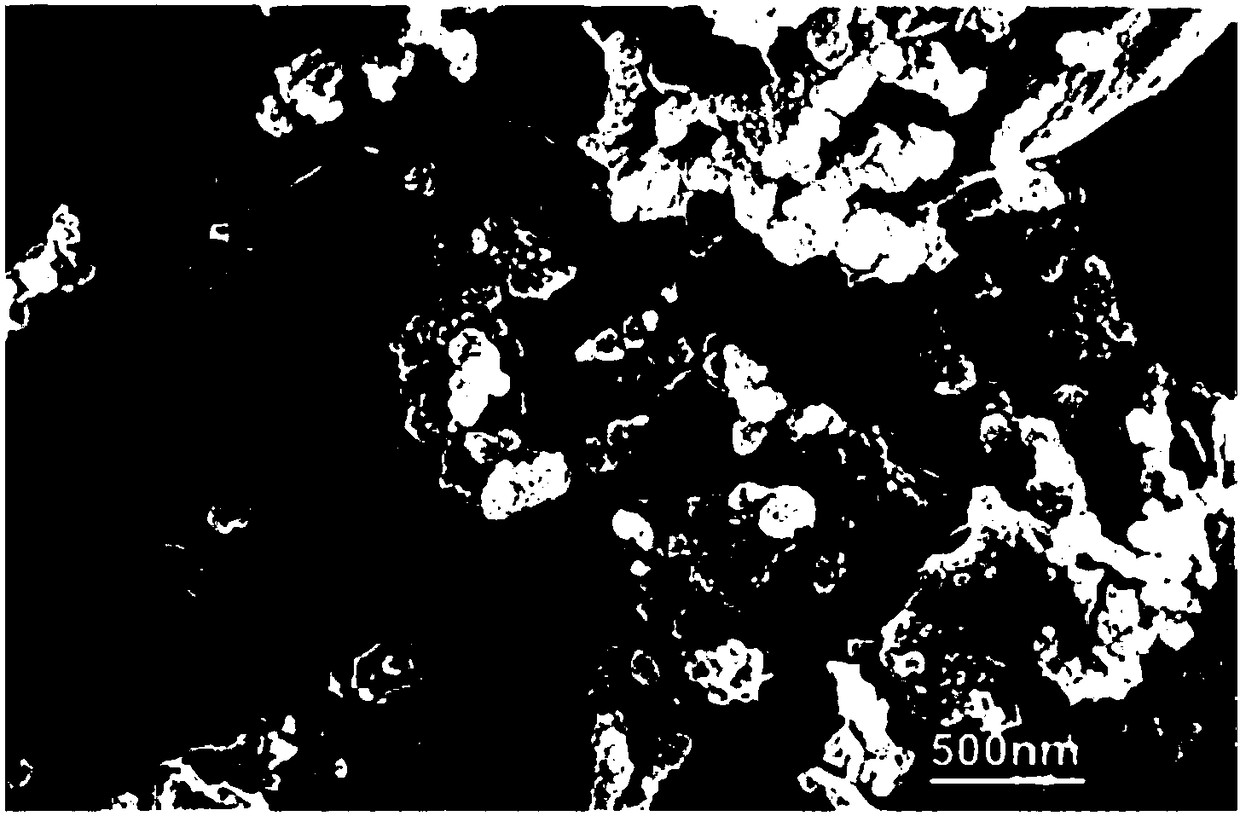

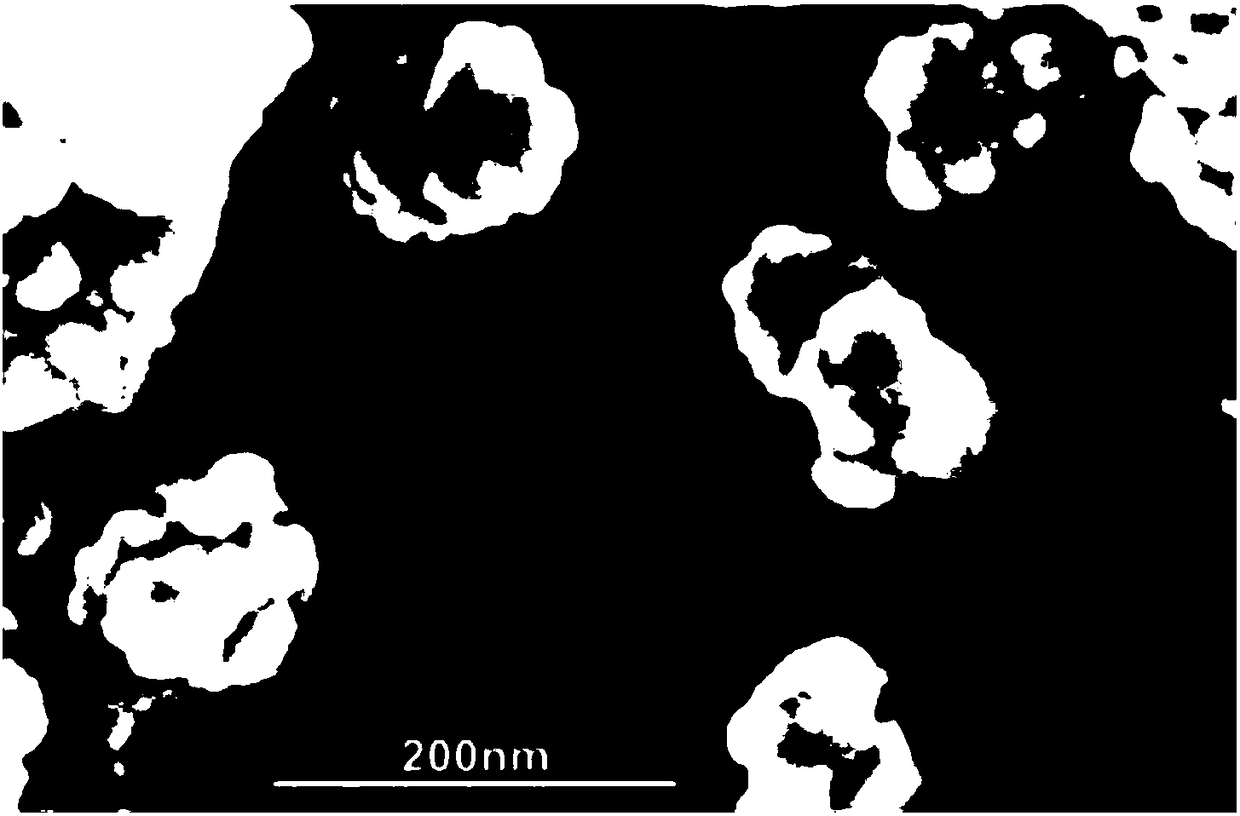

[0016] Specific embodiment 1: In this embodiment 1, the biomass waste is crushed, washed with ultrapure water for 2 to 3 times after passing through a 30-50 mesh sieve, and dried at a temperature of 30-50°C. Obtain biomass waste powder;

[0017] 2. Place the biomass waste powder in the quartz boat, transfer the quartz boat loaded with the biomass waste powder to the tubular pyrolysis furnace for pyrolysis, and increase the pyrolysis temperature at a heating rate of 10-20°C / min. Rise from room temperature to 550-650°C, and stay at 550-650°C for 60-120 minutes. During the pyrolysis process, nitrogen gas is continuously fed into the tubular pyrolysis furnace. Take out the quartz boat to obtain biochar raw material;

[0018] 3. Rinse the raw material of biochar with ultrapure water for 2 to 3 times and put it into FeCl 3 After mixing in the solution, stir at room temperature for 2.5 to 3.5 hours to obtain a suspension; the FeCl 3 The volume ratio of iron ion and biochar raw mat...

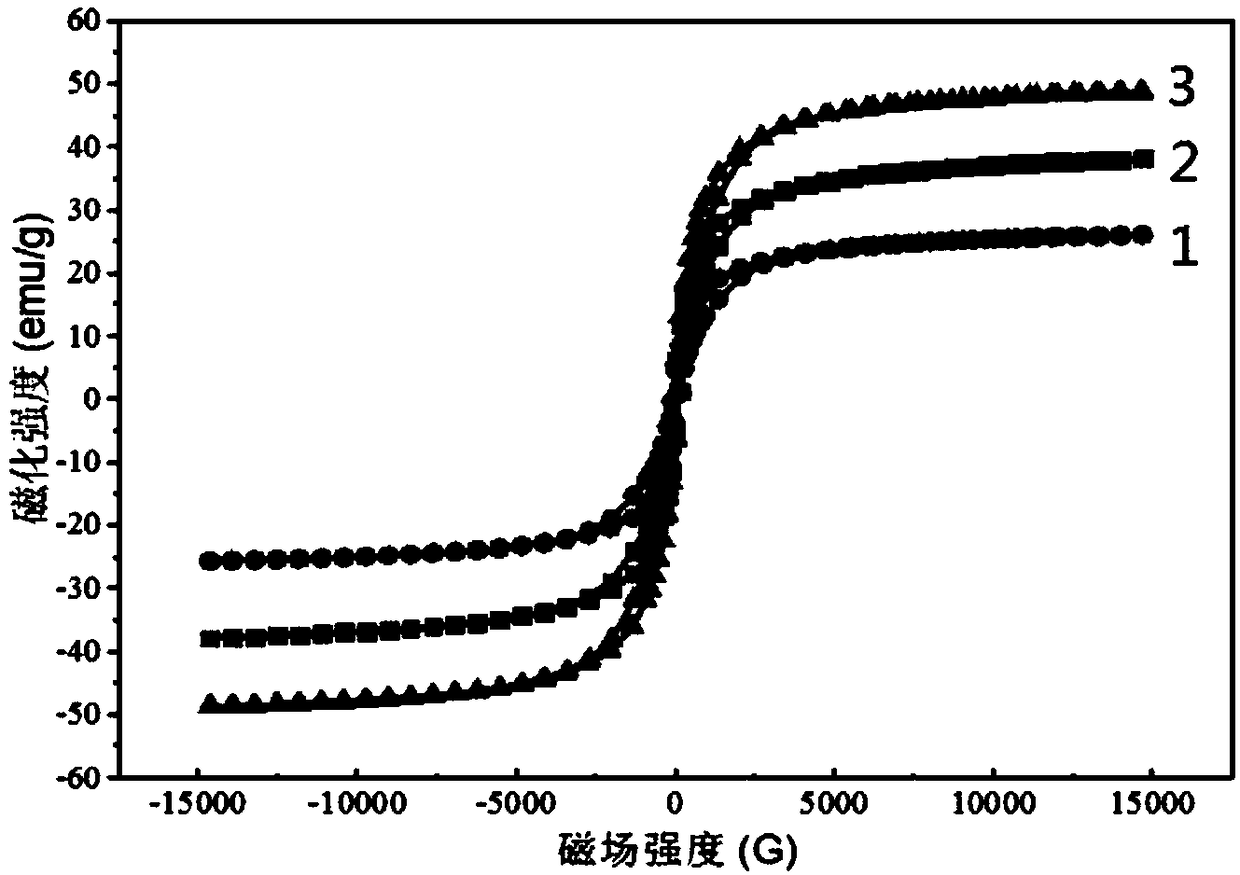

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that the biomass waste described in step 1 is reed stalks. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: in step 1, after passing through a 40-mesh sieve, use ultrapure water to rinse 2 to 3 times. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com