Carbon nano-tube / unsaturated polyester composite material and preparation thereof

A polyester composite material and carbon nanotube technology, which is applied in the field of nanomaterials and achieves the effects of convenient preparation, simple process and reduced volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Mix 500 mg of multi-walled carbon nanotubes with an average diameter of 8 to 15 nm and a length of 50 μm with 150 mL of H 2 8O 4 with HNO 3 mixed solution (98%H 2 SO 4 : 68% HNO 3 = 3:1) mixed, and reflux reaction for 4 hours at 35-40° C. and ultrasonic vibration. Then filter with a metafluoride membrane with a pore size of 0.45 μm, and wash with water until the pH is neutral. The product was placed in a vacuum oven and dried under vacuum at 40°C for 24h. Then the above-mentioned one-step acidified and washed product was placed in H 2 SO 4 with H 2 o 2 mixed solution (98%H 2 SO 4 : 30%H 2 o 2 =4:1) at 70°C for 2h. Then filter with a metafluoride membrane with a pore size of 0.45 μm, and wash with water until the pH is neutral. The product was placed in a vacuum oven and dried under vacuum at 40°C for 24h.

[0034] Step 2: Take 400 mg of the above-mentioned acidified carbon nanotubes and place them in a reaction flask, add 20 mL of SOCl 2 And 1mL...

Embodiment 2

[0038] The first step and the second step are prepared according to the method described in Example 1 to prepare acyl chloride carbon nanotubes.

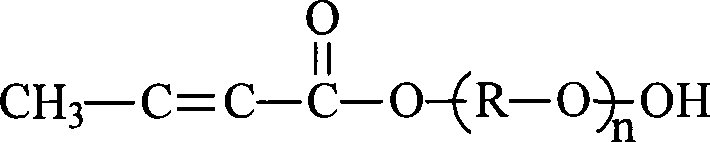

[0039] Step 3: Mix 0.2 g of carbonyl chloride carbon nanotubes and 30 g of hydroxyhexyl methacrylate evenly, and heat to reflux in an oil bath at 96° C. for 36 hours. After the reaction was completed, the excess hydroxyhexyl methacrylate was ultrasonically washed away with absolute ethanol, filtered with a microporous membrane (0.45 μm in diameter), washed several times, and dried in vacuum to obtain a polymerizable double bonded carbon on the surface. nanotube.

[0040] Step 4: Take 30 g of unsaturated polyester, take 0.3 g of carbon nanotubes modified with hydroxyhexyl methacrylate according to 1% of the total amount, add it to the unsaturated polyester, stir vigorously for 8 hours, disperse with ultrasonic waves for 4 hours, and mix evenly. Add 0.3 g of cobalt isooctanoate and 0.45 g of methyl ethyl ketone peroxide, and stir eve...

Embodiment 3

[0042] The first step and the second step are prepared according to the method described in Example 1 to prepare acyl chloride carbon nanotubes.

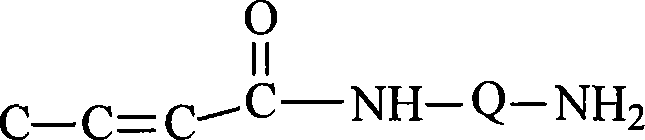

[0043] Step 3: Mix 0.2 g of carbonyl chloride carbon nanotubes and 30 g of the reaction product of acrylic acid and ethylenediamine (N-ethylaminovinylamide) evenly, and heat to reflux in an oil bath at 96° C. for 36 h. After the reaction is completed, ultrasonically wash with absolute ethanol until the pH is neutral, filter with a microporous membrane (0.45 μm in diameter), repeat the washing several times, and dry in vacuum to obtain carbon nanotubes with polymerizable double bonds on the surface.

[0044] Step 4: Take 30 g of unsaturated polyester, take 0.3 g of the above-mentioned modified carbon nanotubes according to 1% of the total amount, add them to the unsaturated polyester, stir vigorously for 8 hours, disperse by ultrasonic wave for 4 hours, and mix evenly. Add 0.3 g of cobalt isooctanoate and 0.45 g of methyl ethyl keton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com