Composite implantation device of composite honeycomb noise elimination cap

An implanted device, honeycomb technology, applied in the field of intelligent manufacturing, can solve the problems of poor consistency, cumbersome operation process, low production efficiency, etc., to achieve the effect of simplifying the device and production process, simplifying the device, improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be discussed in detail below in conjunction with the accompanying drawings.

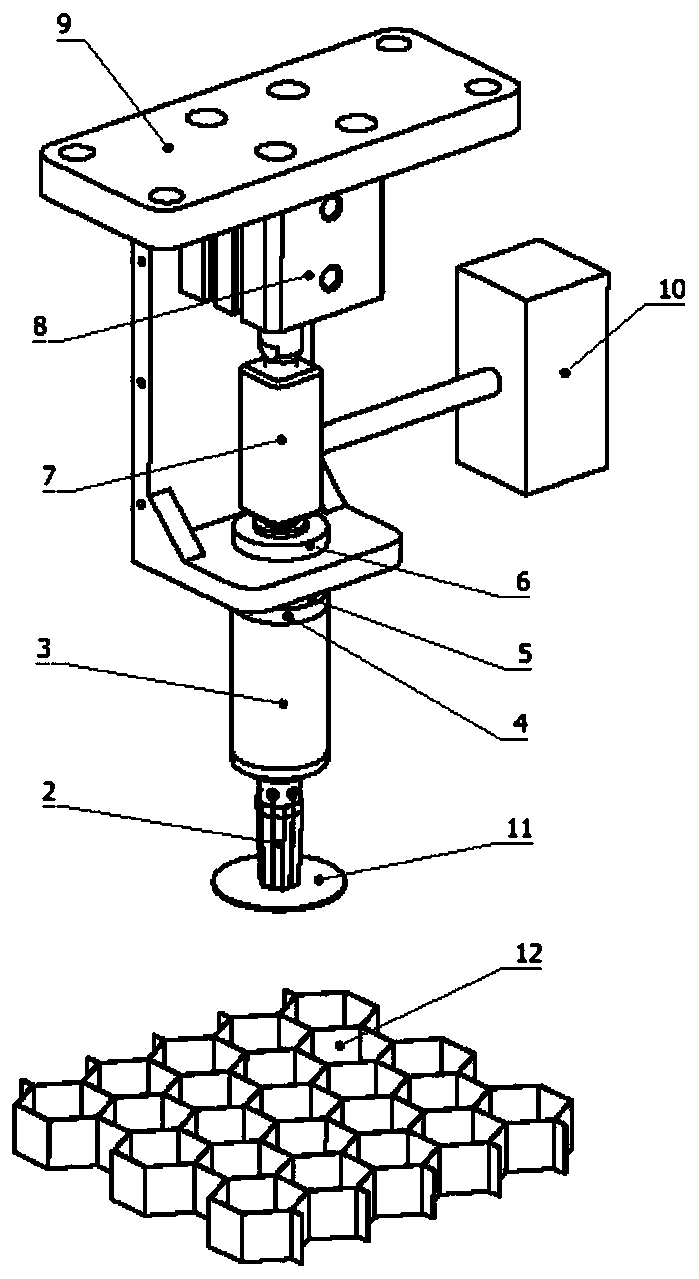

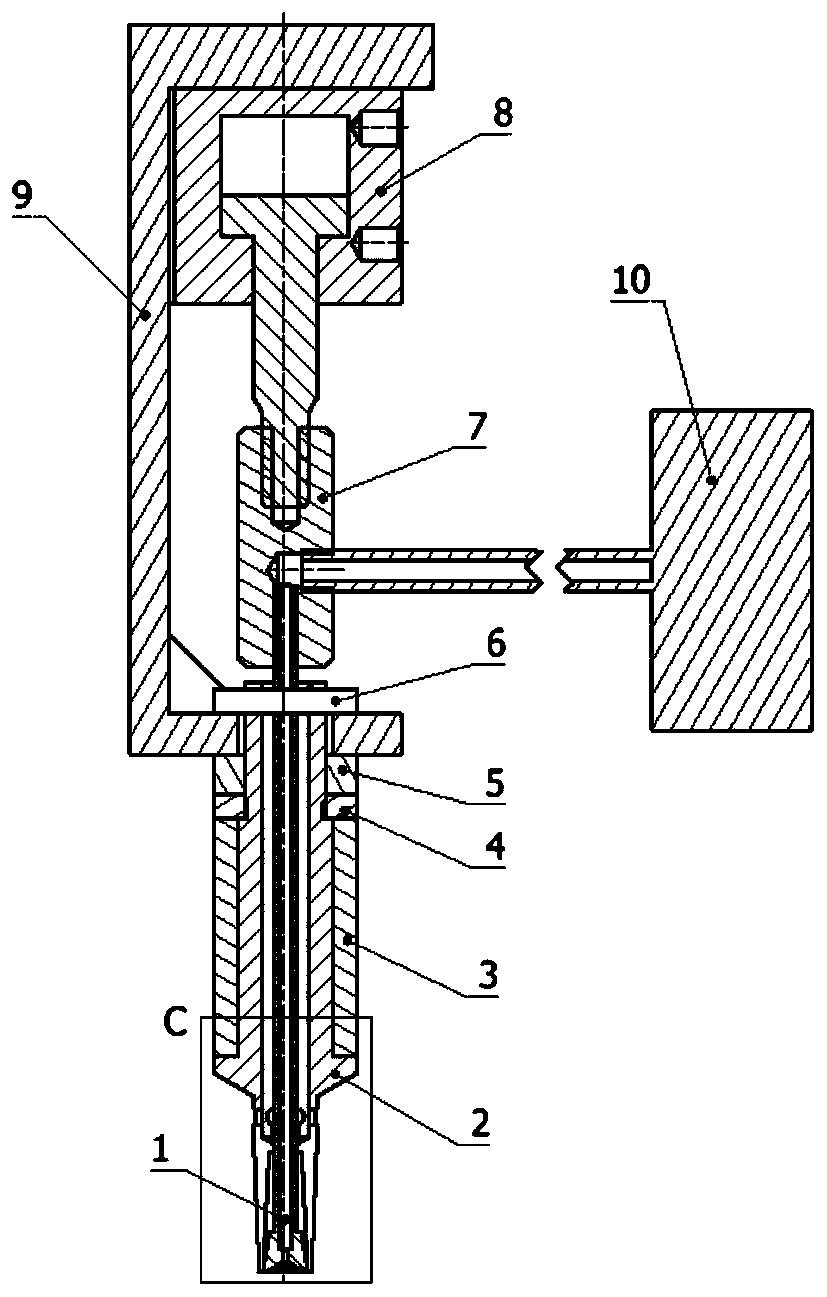

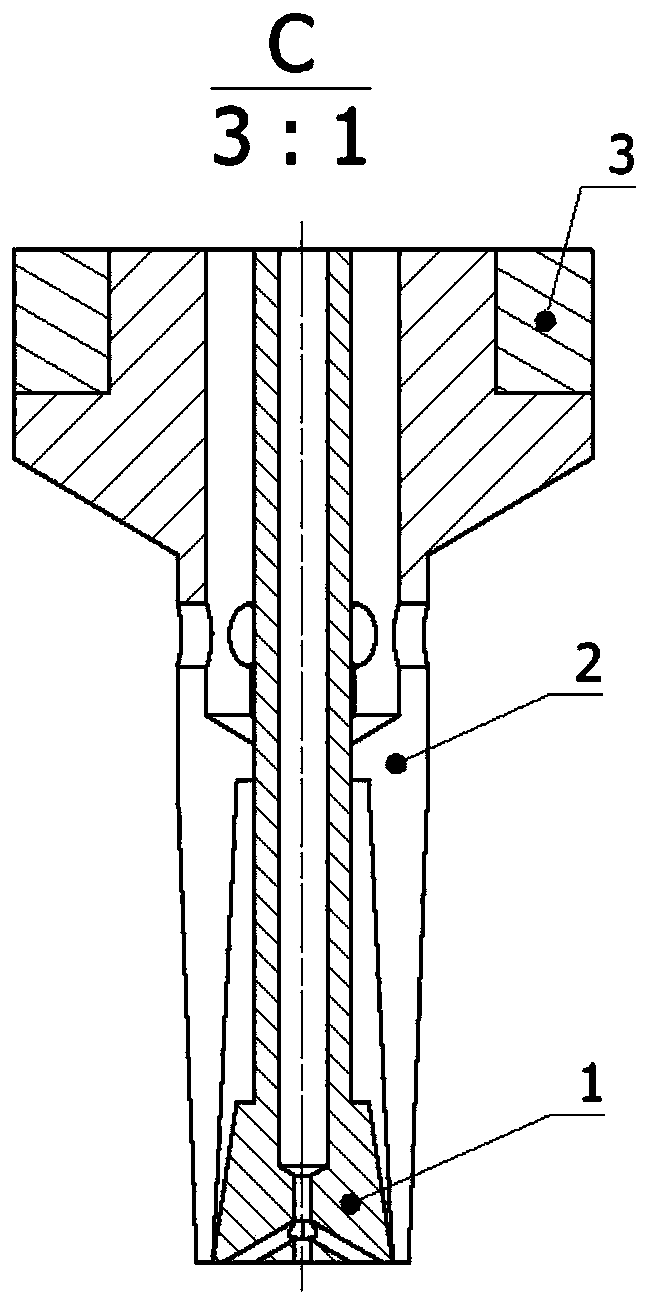

[0025] according to figure 1 , the present invention provides a composite implantation device of a composite material honeycomb sound-absorbing cap, comprising: a mounting plate; a triple piece connecting a stretching device, a mandrel and a vacuum generator; a stretching device, the stretching device is fixed on the mounting plate Above; the deformation body, the deformation body is composed of an umbrella structure, which can be opened and expanded; the mandrel, the mandrel is provided with a through suction port, one end of the mandrel is connected with the stretching device through a triple piece, and the other end is installed with the deformation body ; Heating ring, the heating ring is set on the deformable body, and heats the adhesive layer through the heat conduction of the deformable body; the deformable body lock nut, the deformable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com