Manufacture method of flexible and rigid composite circuit board

A soft-hard composite, flexible circuit board technology, applied in the direction of multi-layer circuit manufacturing, assembling printed circuit with electrical components, forming electrical connection of printed components, etc. easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

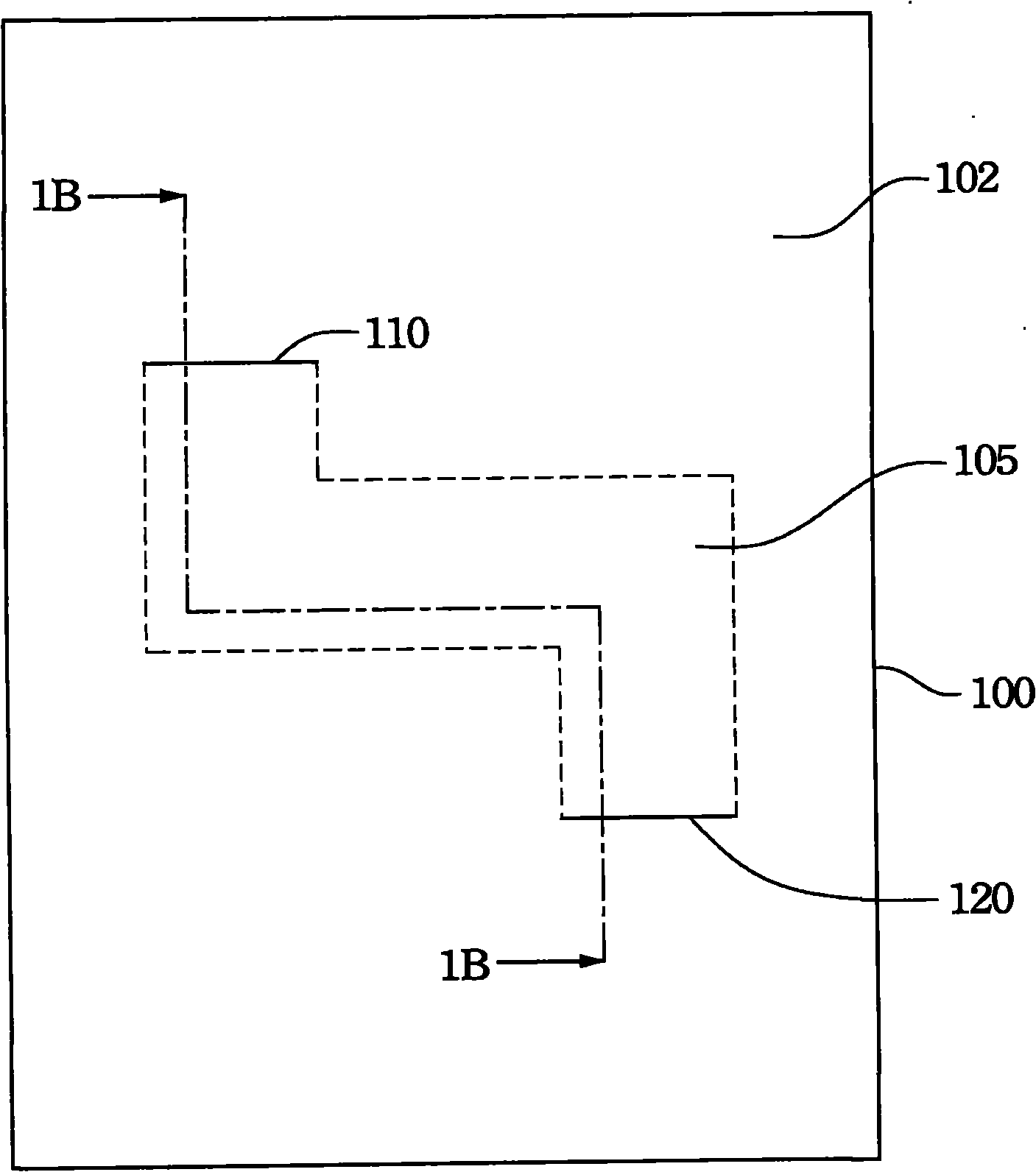

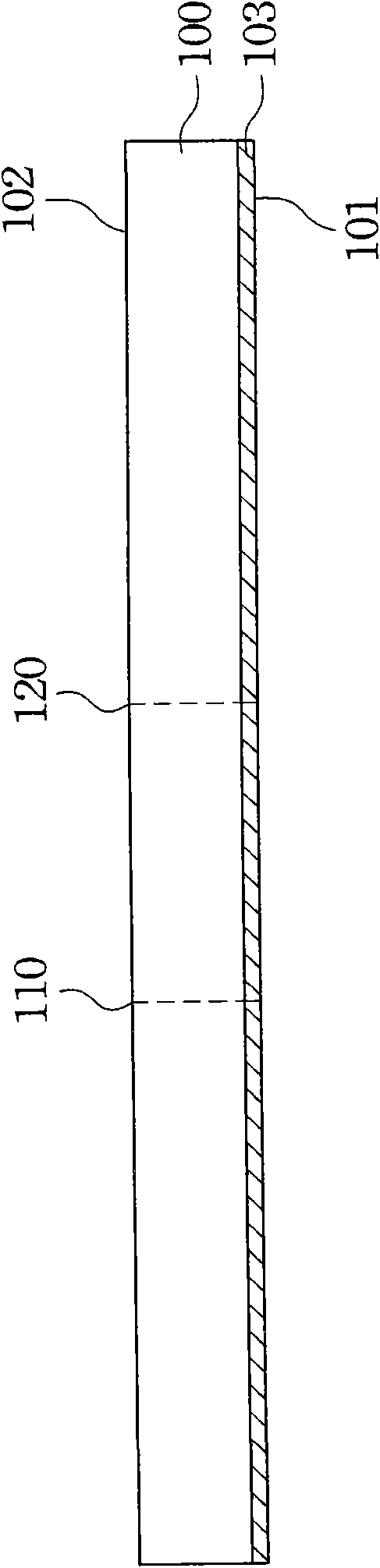

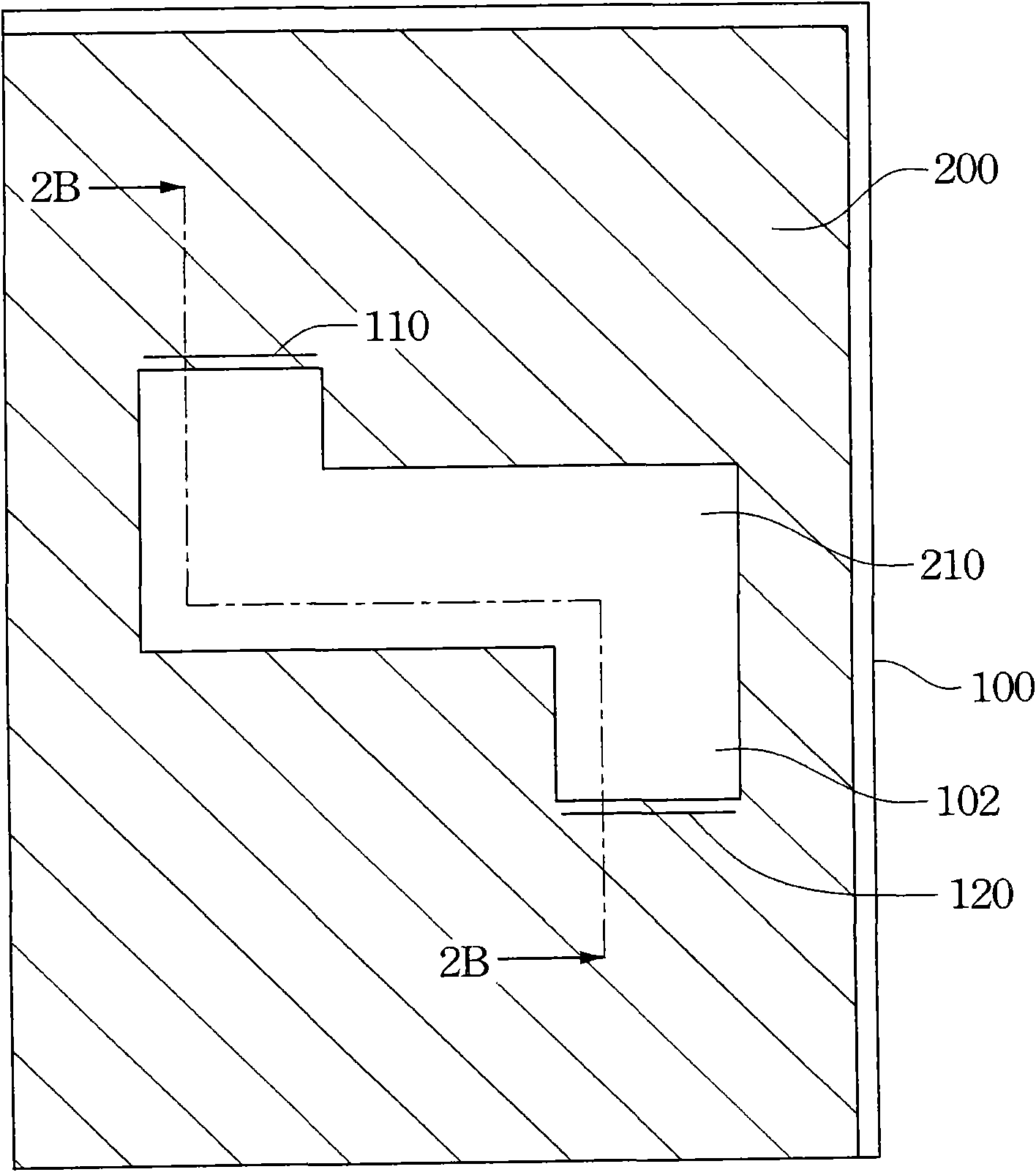

[0066] Figure 1A to Figure 9C It is a manufacturing process diagram of the manufacturing method of one embodiment of this invention. Please refer to Figure 1A and Figure 1B , first provide the first rigid substrate 100 . Figure 1A is a schematic top view of the first rigid substrate 100, Figure 1B for Figure 1A Schematic cross-section of 1B to 1B. Such as Figure 1B As shown, opposite sides of the first rigid substrate 100 respectively have a first surface 101 and a second surface 102 , and the first surface 101 has a first copper layer 103 (first metal layer). Of course, the second surface 102 may also have an alignment mark (not shown) formed by another metal layer (such as a copper layer). In one embodiment, the first rigid substrate 100 is a thermosetting material, such as a glass fiber cloth substrate (eg Flame Retardant 4, FR4 substrate), which has been widely used in printed circuit boards.

[0067] Such as Figure 1A As shown, a first cutting line 110 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com