Cask material arranging and press-fitting system

A technology of press-fitting and press-fitting device is applied in the field of barrel material discharge press-fitting system, which can solve the problems of low production efficiency, difficulty in adapting to mass production, poor product consistency, etc., so as to improve production efficiency, realize automatic manufacturing, improve The effect of product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

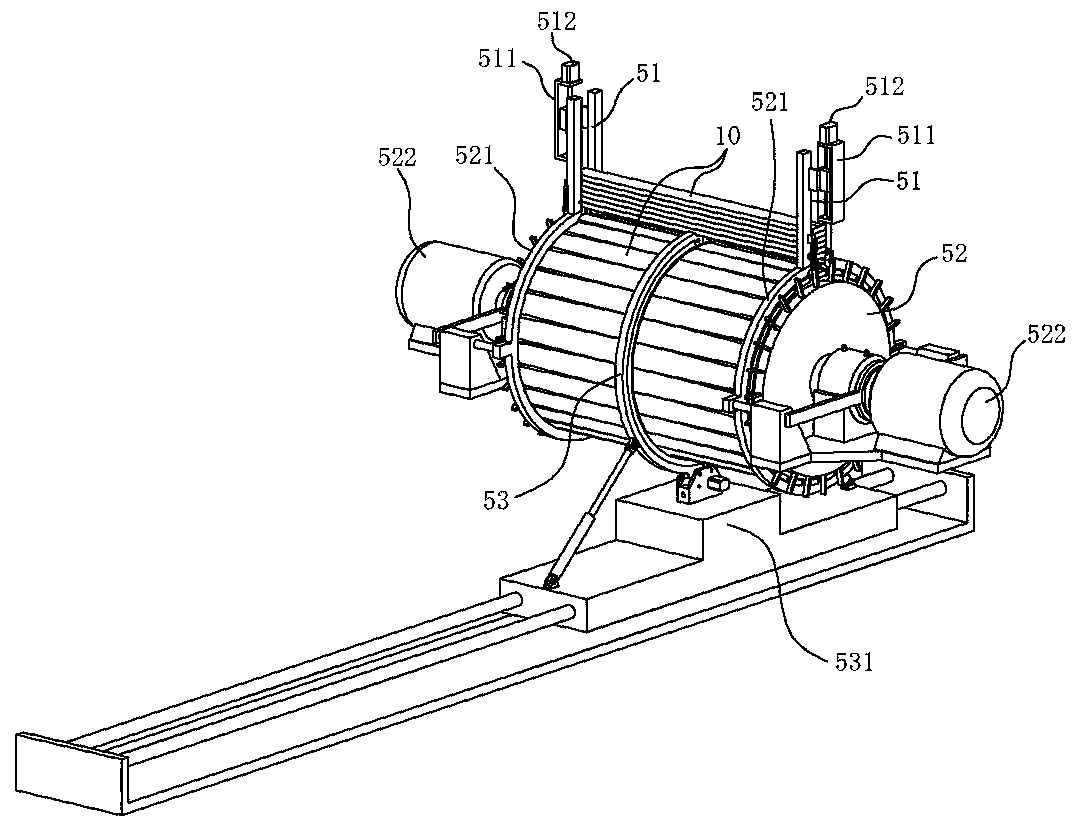

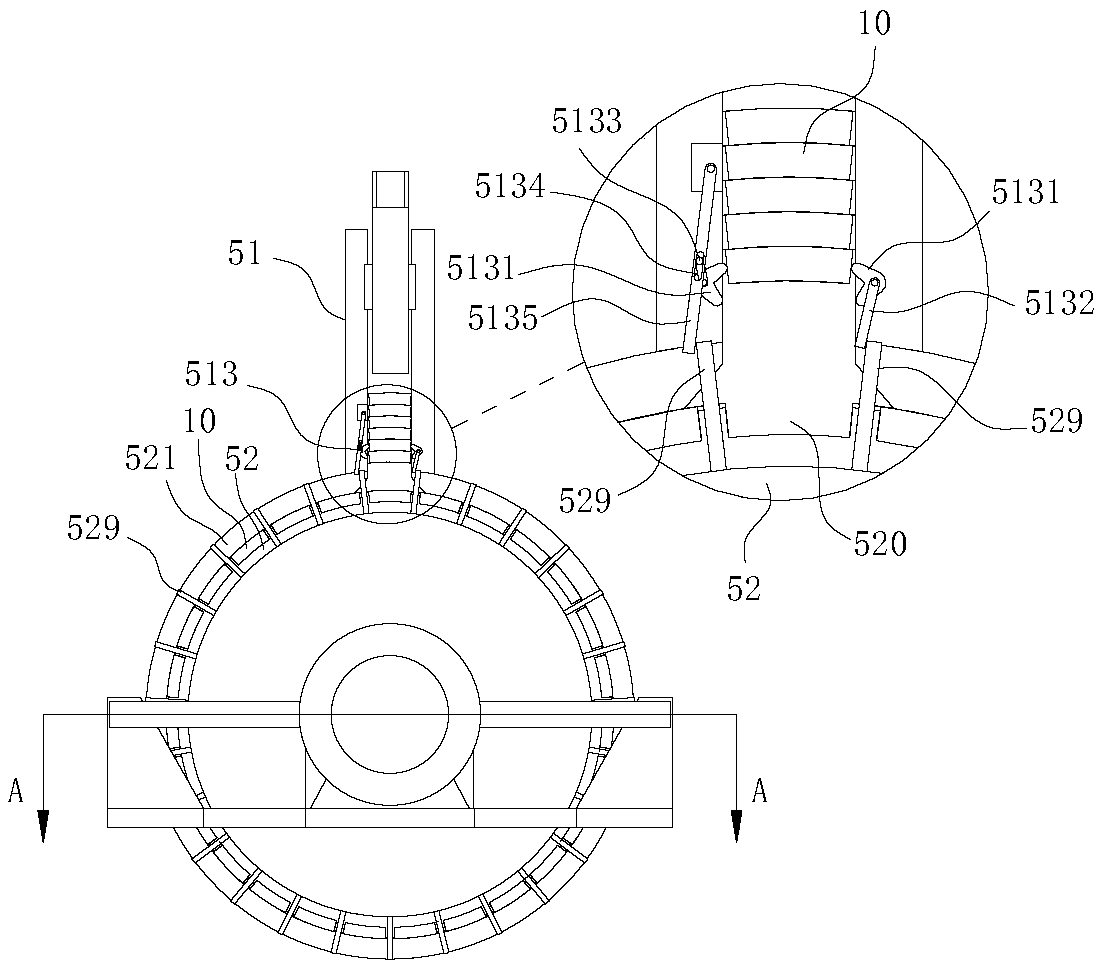

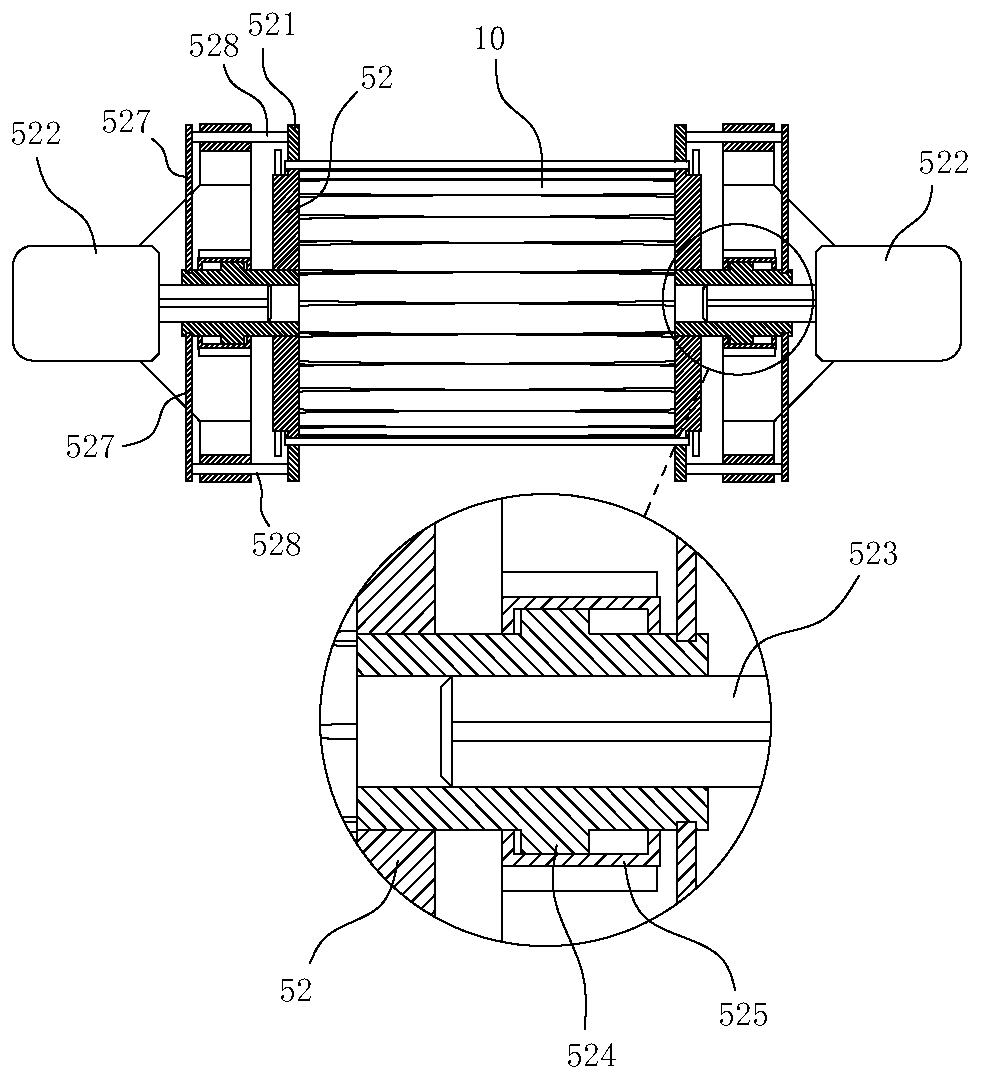

[0024] Such as Figures 1 to 14 As shown, a barrel material discharging and pressing system includes a discharging device, a transfer device and a pressing device, the discharging device is used to arrange the barrel materials into a cylindrical barrel wall, and the transferring device is used to arrange the barrel material The barrel wall of the cylinder is transferred to a press-fitting device, and the press-fitting device is used to press-fit the hoop onto the barrel wall so that each barrel material is fixed as a whole.

[0025] Such as Figures 1 to 4 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com