Patents

Literature

103results about How to "The amount added is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extruded hard pellet feed for lactating sows and preparation method thereof

ActiveCN102524582AFully gelatinizedImprove digestibilityFeeding-stuffAnimal feeding stuffAnimal scienceRapeseed

The invention discloses an extruded hard pellet feed for lactating sows, which is prepared by the following raw materials in parts by weight: 50-55 parts of corn, 3-4.5 parts of imported super steam fish meal, 3-5 parts of fermented soya bean meal, 8-10 parts of flour, 10-15 parts of wheat, 13.5-15.1 parts of non-transgenic soya bean, 2-4 parts of rapeseed meal, 5-10 parts of extruded-soybean, 1-2 parts of mineral substance premix, 0.2-0.3 parts of vitamins premix, 1.0-2.0 parts of calcium hydrogen phosphate, 2.5-4 parts of soybean oil, 1-2 parts of calcium propionate and 0.1-0.2 parts of oligosaccharide. The extruded hard pellet feed is prepared by tempering the raw materials in the formula by using a double-shaft squeezing well-done extruder under a certain condition and then curing under a certain curing condition. The crude protein of the extruded hard pellet feed is greater than 16.2%, the curing degree is above 80%, the extruded hard pellet feed has comprehensive nutrition and extrusion, the anti-nutrition factors are destroyed, and after the extruded hard pellet feed is used for feeding pregnant sows, the birth weights of piglets are above 1.6 kg in average.

Owner:安徽天邦饲料科技有限公司

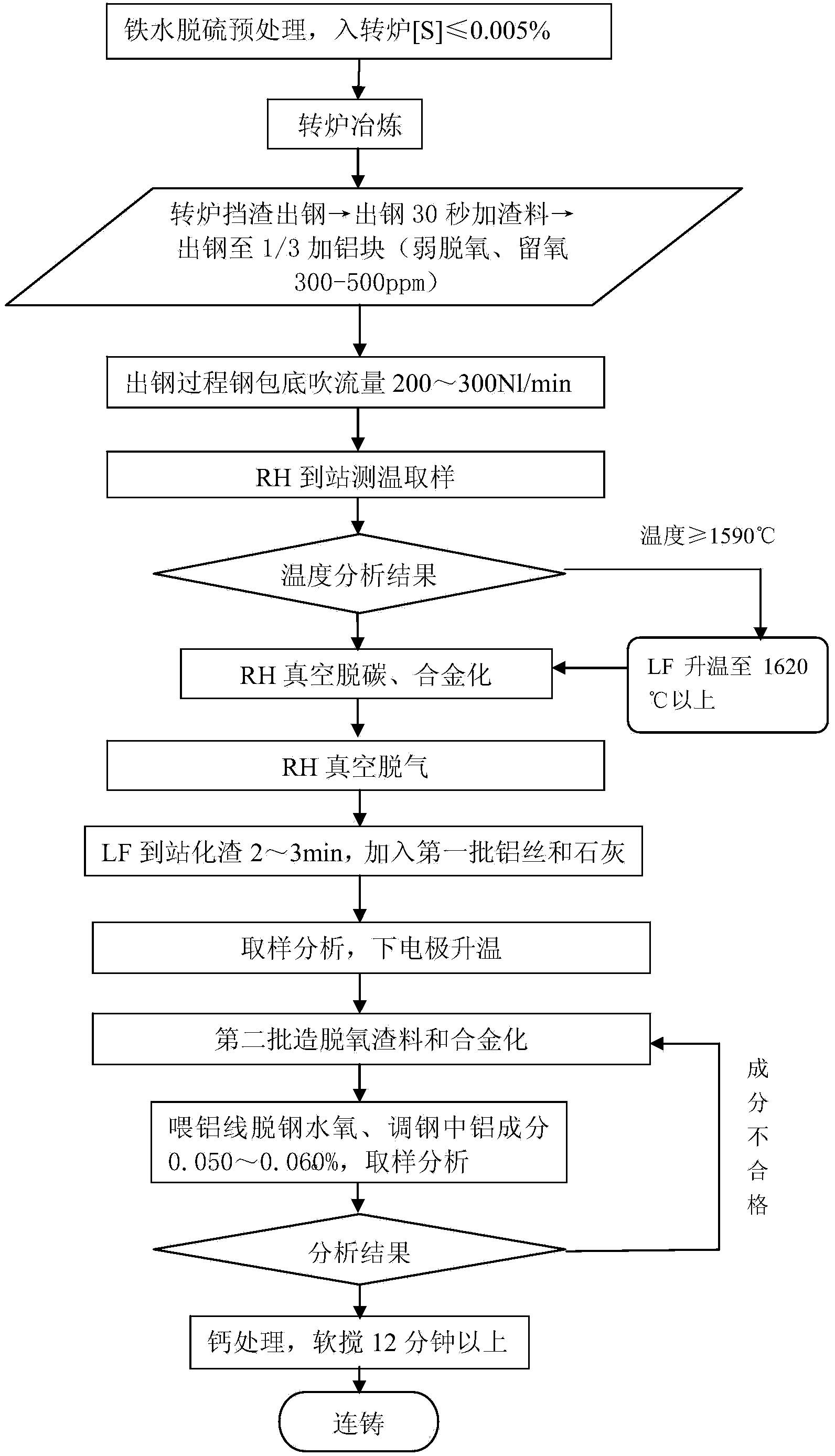

Low-carbon ultra-low sulfur steel smelting method

InactiveCN104232831AThe amount added is accurateStable flaw detection pass rateSteel manufacturing process aspectsManufacturing convertersSmelting processOxygen

The invention discloses a low-carbon ultra-low sulfur steel smelting method. The method comprises the following technological processes: pouring molten iron into a tank, pretreatment of molten iron, oxygen remaining operation of a converter, RH furnace vacuum decarburization, alloying and vacuum degassing in an RH furnace, deoxidization of aluminium yarn / aluminium wire in an LF refining furnace, slagging by using lime and CCM. Through combination of molten iron desulphurization and drossing, optimization of a converter steel tapping and oxygen remaining system and a slagging system, the vacuum decarburization, alloying and degassing control in the RH furnace, and the aluminium wire diffusing deoxidation slagging and aluminium wire sediment deoxidation in the LF furnace, deep decarburization and desulphurization are carried out. With an emphasis on combination of convertor steel tapping and oxygen remaining operations, RH deep decarburization and LF furnace deep desulphurization, technical optimization is carried out; due to reasonable ladle argon bottom blowing control in the smelting process, carbon content control and metallurgical thermodynamics and dynamics conditions of desulphurization are given a full play; the RH furnace decarburization is stable; LF furnace slagging and desulphurization and recarburization control effects are obvious; and low-carbon ultra-low sulfur steel smelting is achieved.

Owner:NANJING IRON & STEEL CO LTD

Preparation of high viscosity Poly(p-phenyleneterephthalamide) resin

The invention discloses a method for preparing poly p-phenylene terephtha-lamide resin with high viscosity. Firstly, para-phenylene diamine is fully dissolved and added into a prereactor, then paraphthaloyl chloride is added into the prereactor for prepolycondensation, then a prepolymer is added into a double screw extruder, a pyridine acid absorbent and a remained paraphthaloyl chloride low-temperature solution are respectively and synchronously added for a final polycondensation reaction through a liquid metering pump, and the extrusion is performed; and a polymer is kept stand, washed, dehydrated and dried. The inherent viscosity of the poly p-phenylene terephtha-lamide resin prepared by the method is between 6.5 and 9.5dl / g, the resin has good spinnability, and the spun fiber has good color and luster, high strength, and stable performance.

Owner:SINOPEC YIZHENG CHEM FIBER

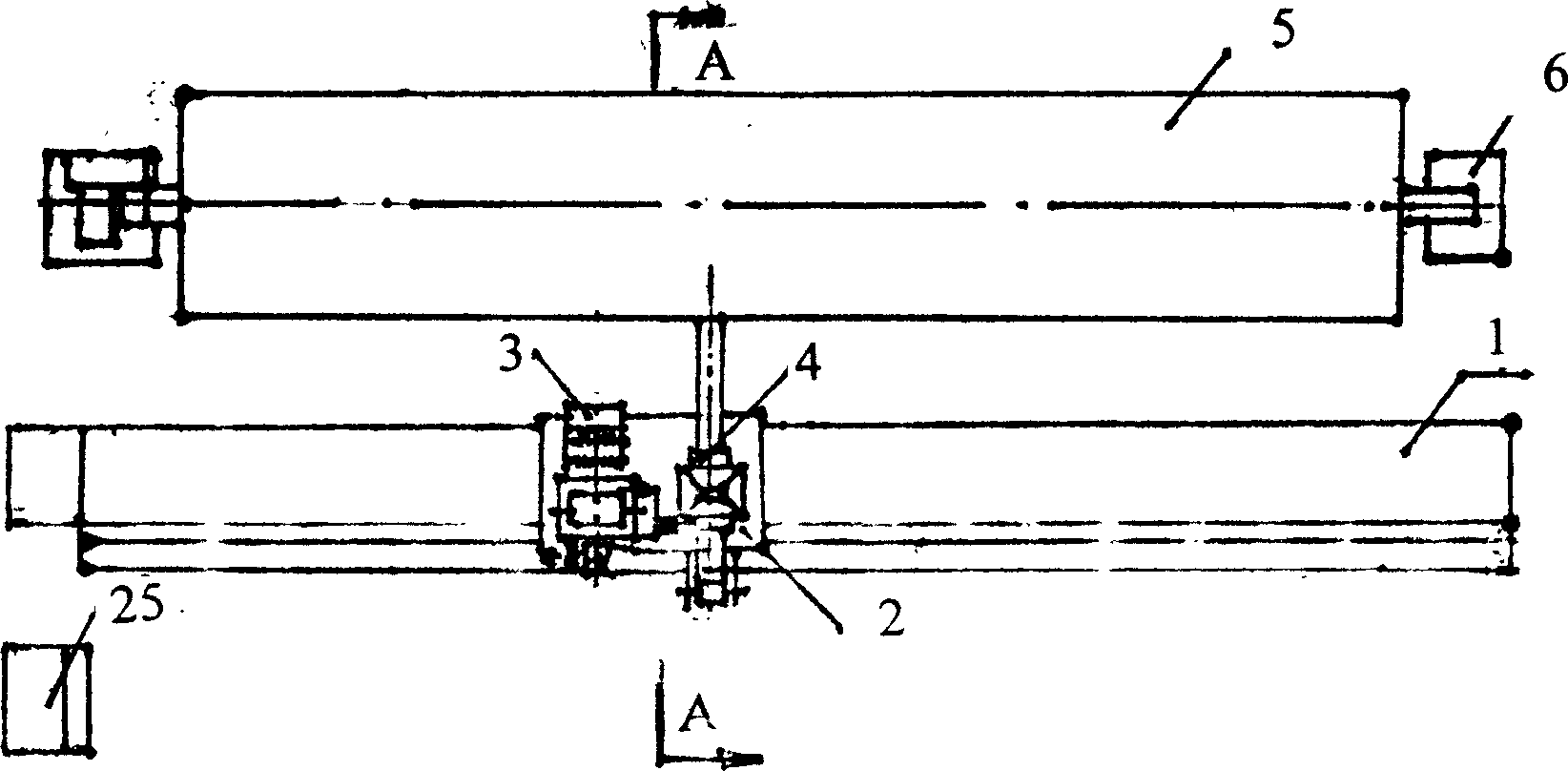

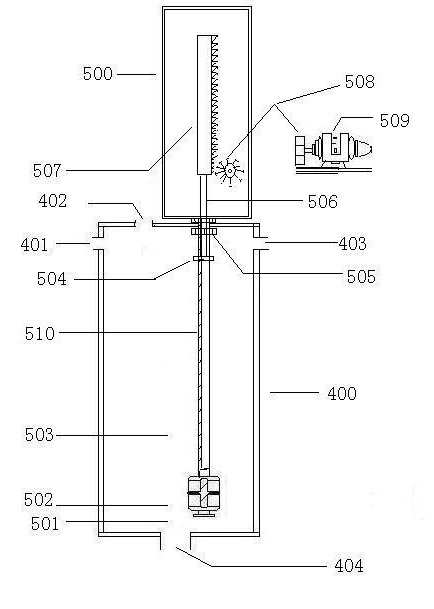

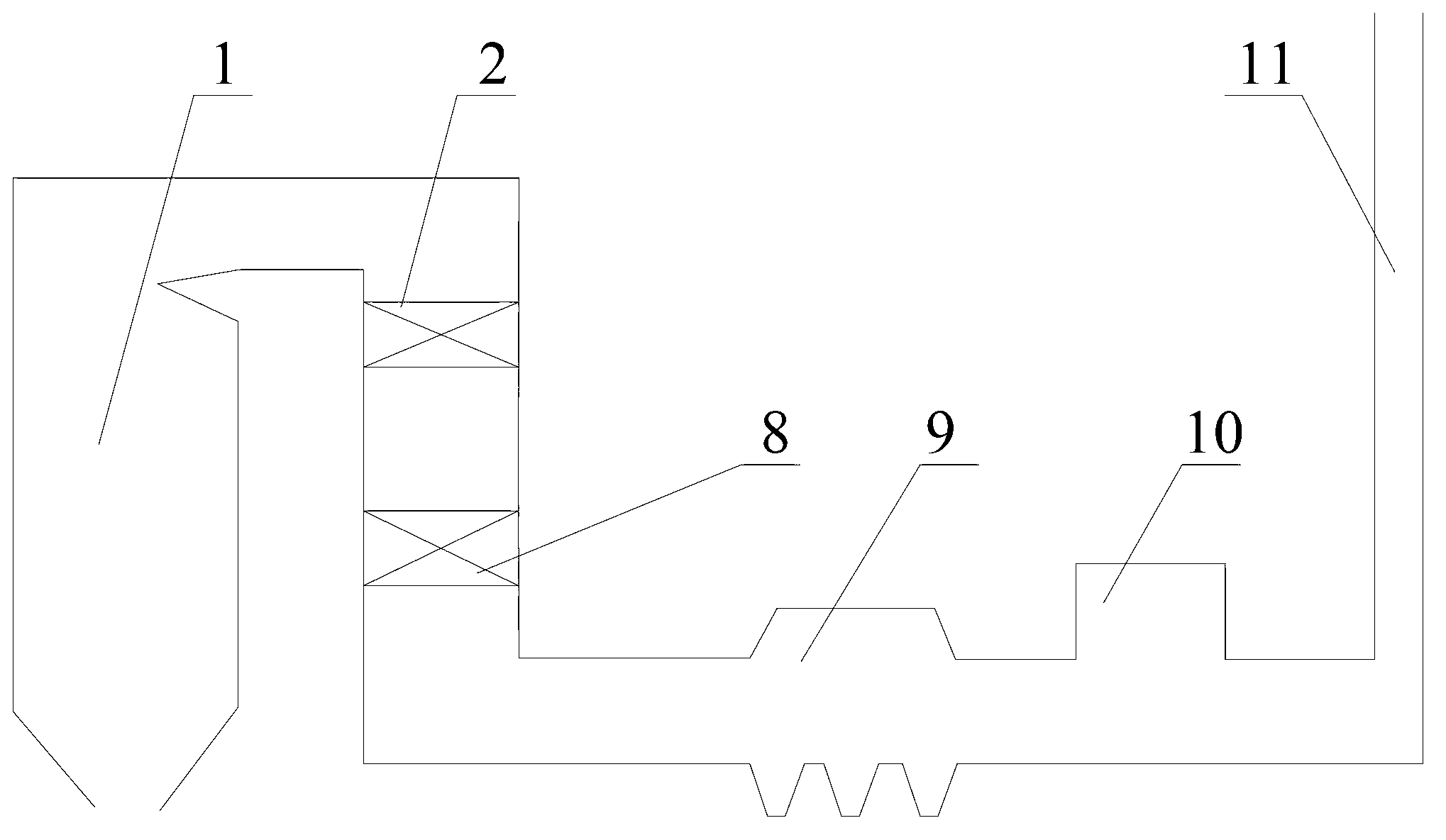

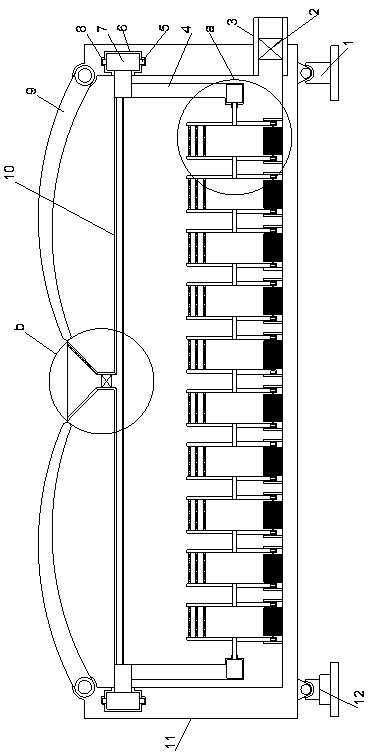

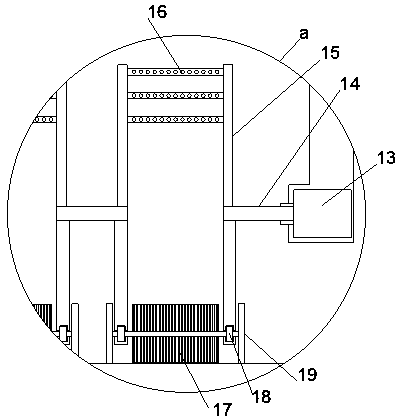

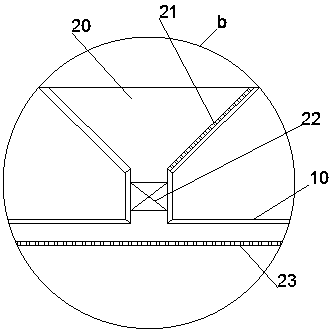

Making apparatus and method for wet type sanding and enwinding glass fibre reinforced plastic pipe from underside

The present invention relates to an equipment for making GFRP pipe by adopting wet sand-adding lower-winding process and method thereof. Said equipment is mainly formed from working table, running carriage, winding system, sand-adding system, mould and mould-supporting frame. Said invention also provides their connection arrangement and working mode. Said invented winding and sand-adding processes can be implemented under the GFRP pipe, and adopts wet sand-adding process so as to reduce dust pollution, and can raise working efficiency.

Owner:天津市天联滨海复合材料有限公司

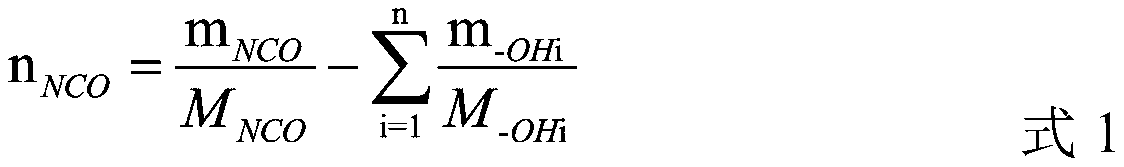

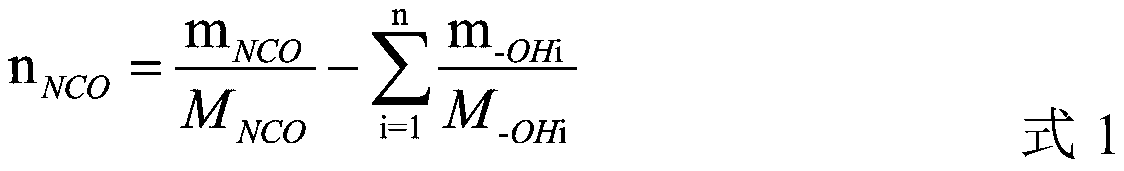

Semi-latent curing type single-component polyurethane waterproof coating and preparation method thereof

InactiveCN111117468AEasy to storeAccurate dosagePolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention belongs to the field of materials, and discloses a semi-latent curing type single-component polyurethane waterproof coating and a preparation method thereof. The preparation method comprises the following steps: 1) uniformly mixing polyether polyol, a plasticizer, a defoaming agent, a dispersing agent and solid powder, heating, and carrying out vacuum dehydration; 2) when the moisture content in the mixture in the step 1) is less than or equal to 0.02 wt%, and cooling the mixture, when the temperature is reduced to 75-85 DEG C, adding solvent oil, continuously cooling the mixtureto 60-70 DEG C, adding isocyanate, then heating the mixture to 80-90 DEG C, and carrying out a reaction; 3) cooling the mixture obtained in the step 2), then adding a catalyst, heating the mixture, and carrying out a reaction; and 4) cooling the mixture obtained in the step 3), adding a latent curing agent and a leveling agent, continuously cooling to 40-60 DEG C, and degassing the product undervacuum to obtain the semi-latent curing type single-component polyurethane waterproof paint which has the advantages of no bubbles in appearance, high drying speed and favorable storage performance.

Owner:河南东方雨虹建筑材料有限公司

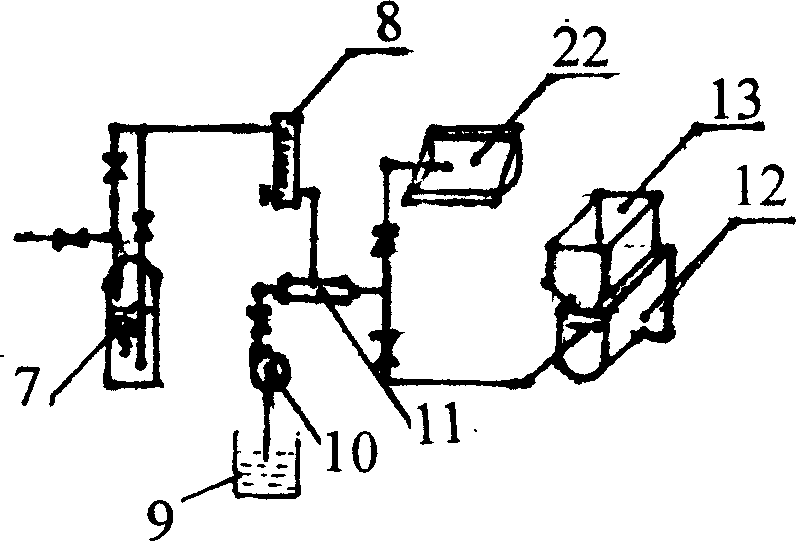

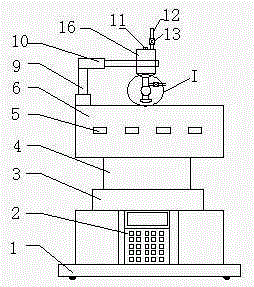

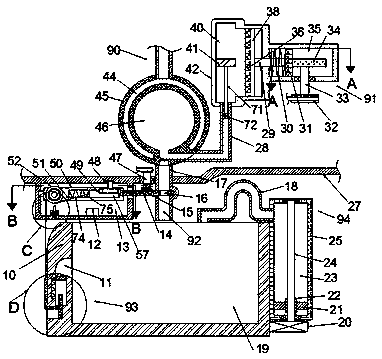

Quantitative liquid adding device for full-automatic medical cleaner and control method thereof

ActiveCN102078220APrevent problems such as flyingPrecisely control the amount addedDiagnosticsSurgeryPeristaltic pumpElectricity

The invention provides a quantitative liquid adding device for a full-automatic medical cleaner, which comprises a liquid medicine input part, a liquid medicine mixing chamber, an exhaust part, a pure water input part, a liquid medicine output part and a control system, wherein the liquid medicine input part is connected with an external liquid medicine storing container; the liquid medicine output part is used for discharging liquid medicine; and the control system is electrically connected with all parts. The quantitative liquid adding device is characterized by also comprising a peristaltic pump which is arranged between the liquid medicine input part and the liquid medicine mixing chamber, the peristaltic pump is electrically connected with the control system to quantitatively convey the liquid medicine in the external liquid medicine storing container to the liquid medicine mixing chamber. The invention also provides a control method of the quantitative liquid adding device. As the peristaltic pump driven by electric power is used for adding liquid, firstly, without additionally adding external high-pressure gas to drive the liquid medicine to enter the mixing chamber from the storing container, the quantitative liquid adding device effectively prevents the problems of liquid medicine scattering and the like caused by air pressure variation; and secondly, as the peristaltic pump can accurately control the added quantity of the liquid medicine per se, the whole quantitative liquid adding device has simpler structure and accurate added quantity of the liquid medicine and is easier to control.

Owner:LAOKEN MEDICAL TECH

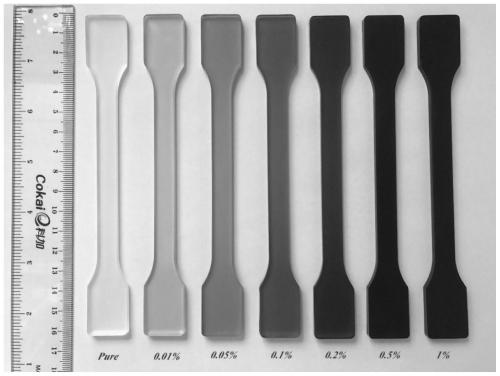

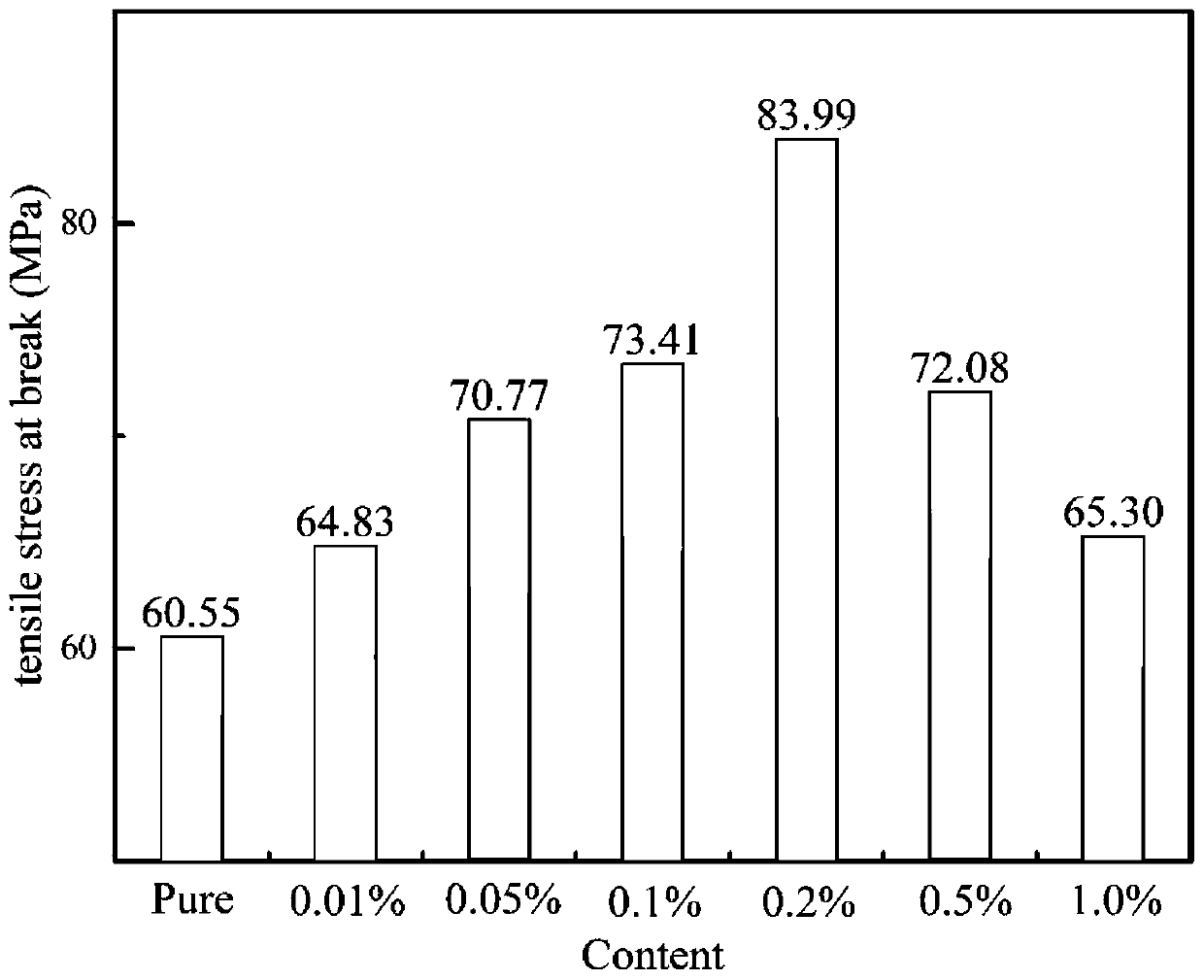

Preparation method of epoxy resin/MXene composite material

The invention provides a preparation method of an epoxy resin / MXene composite material. The preparation method comprises the following steps: preparing a single-layer MXene, determining the addition amount of the single-layer MXene, compounding the single-layer MXene and an epoxy resin material, and the like. The preparation method is simple in process, short in time, high in efficiency and low incost, and the prepared epoxy resin / MXene composite material is remarkably improved in tensile breaking strength and good in mechanical property.

Owner:HOHAI UNIV

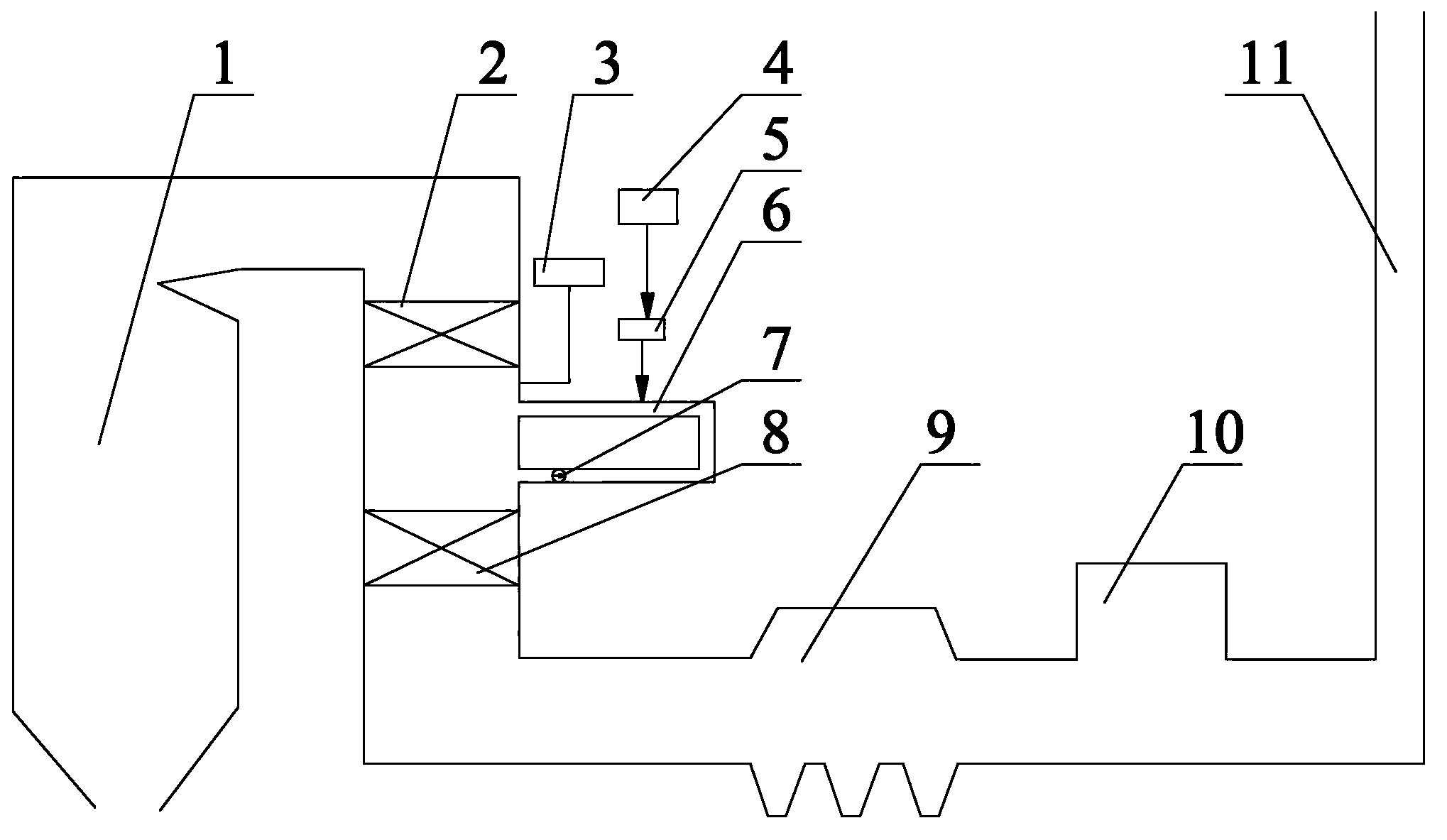

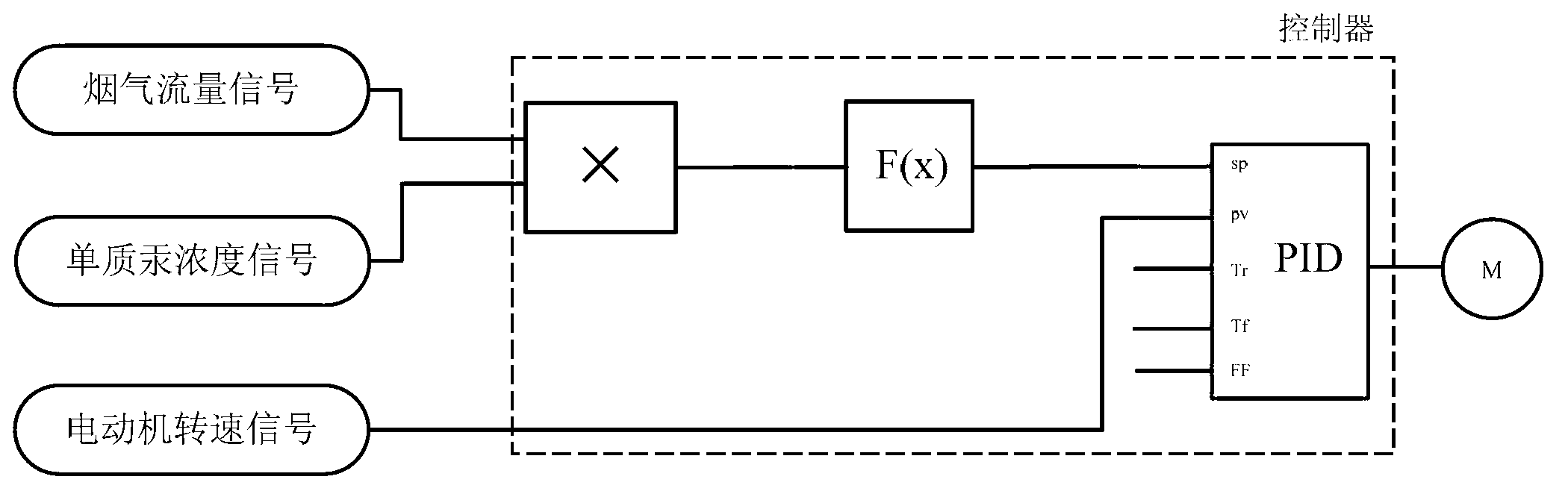

Intelligent demercuration addition agent adding system for coal-fired power plant

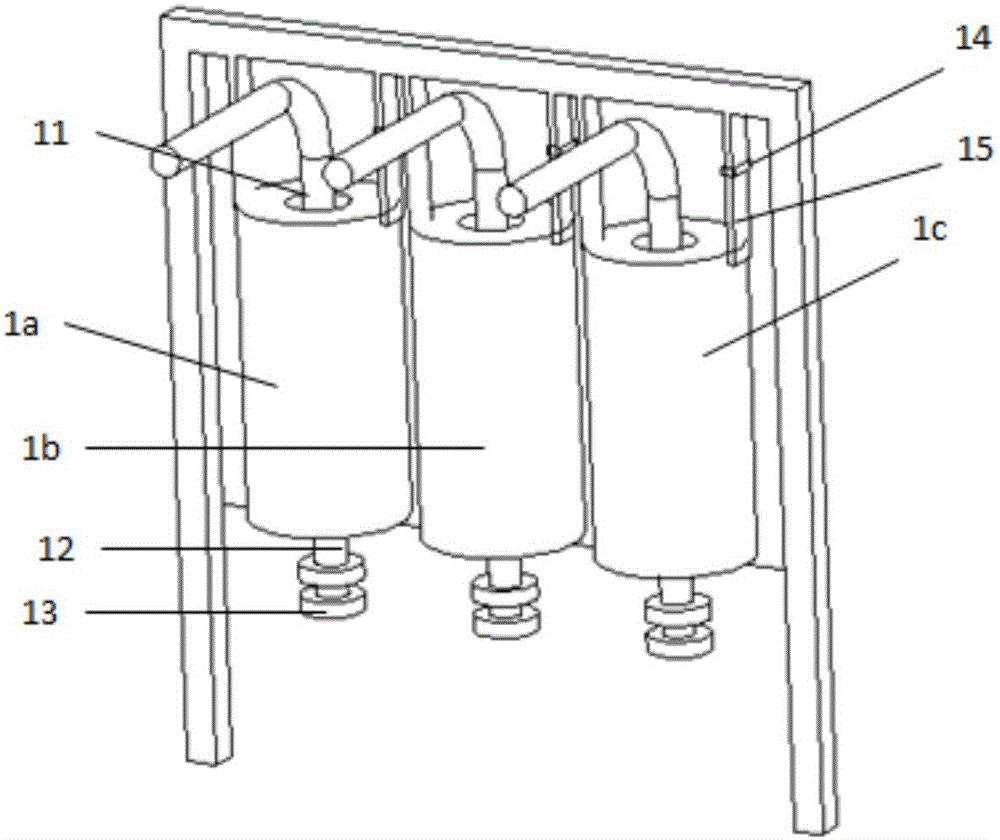

ActiveCN103170236AThe amount added is accurateImprove utilization efficiencyLighting and heating apparatusDispersed particle separationAir preheaterEngineering

The invention discloses an intelligent demercuration addition agent adding system for a coal-fired power plant. The intelligent demercuration addition agent adding system comprises a smoke mercury continuous on-line monitoring plant, a crushing device, a screw feeder, a circulating flue, a fan and an intelligent control device, wherein a smoke outlet of the circulating flue is formed in the outlet of an economizer in a tail flue, and a smoke inlet of the circulating flue is formed in the inlet of an air preheater in the tail flue; the fan is arranged in the circulating flue, a feeding port of the screw feeder is communicated with a discharge port of the crushing device, the discharge port of the screw feeder leads to the circulating flue, and a monitoring probe of the smoke mercury continuous on-line monitoring plant is arranged in the tail flue; and the smoke mercury continuous on-line monitoring device and the screw feeder are respectively and electrically connected with corresponding ports of the intelligent control device. The intelligent demercuration addition agent adding system provided by the invention has the characteristics that additive amount of a demercuration addition agent is exact, the utilization efficiency is high and a demercuration effect is good.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

Method for preparing golden mushroom nutritional noodles

InactiveCN102342432AUniform moistureAvoid excessive water absorptionDough treatmentFood preparationFerrous GluconateLYSINE HYDROCHLORIDE

The invention provides a method for preparing golden mushroom nutritional noodles. The method comprises the following steps of: putting common flour and water into a dough kneader, after kneading the dough for 5-10 minutes, adding golden mushroom powder, whole-egg powder, cabbage powder, corn starch, ferrous gluconate, calcium gluconate and L-lysine hydrochloride to the dough kneader, continuing kneading the dough for 5-20 minutes, then putting the dough into a ripening machine to be ripened for 5-20 minutes, and then carrying out calendering, strip cutting, drying and cutting-off processes in sequence to obtain the golden mushroom nutritional noodles. The invention has the following advantages: the preparation process is simple; the quality of a finished product is high; the shelf life is long; the noodles prepared by the method have balanced nutrition and fragrant and sweet taste; the taste of the noodles is easy to like by the children; and the noodles are especially suitable for serving as the complementary food of vegetables eaten by the children.

Owner:宜垦(天津)农业制品有限公司

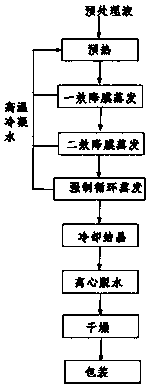

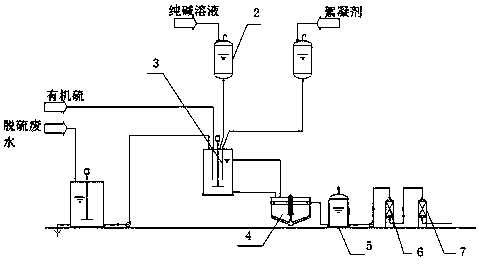

Desulfurization wastewater treatment process

InactiveCN108328835AReduce usageIncrease profitWater contaminantsTreatment involving filtrationCentrifugationSulfur

The invention discloses a desulfurization wastewater treatment process characterized by comprising the following process steps: step 1, pretreatment, namely adding organic sulfur, carbonate and a flocculant into desulfurization wastewater to carry out a reaction, and removing calcium ions and heavy metal ions in the desulfurization wastewater to obtain a pretreatment solution; step 2, evaporationand concentration, namely evaporating and concentrating the pretreatment solution until the content of sodium chloride in a feed liquid is 200-280mg / l; step 3, cooling crystallization, namely carryingout cooling crystallization on the evaporated and concentrated feed liquid to obtain slurry, wherein the crystallization temperature is 20 DEG C or below, and the crystallization time is 0.25-1h; andstep 4, centrifugation and drying, namely carrying out centrifugation and drying treatment on the slurry subjected to cooling crystallization to obtain MgSO4-7H2O. During pretreatment, excessive calcium ions cannot be introduced, and the troublesome step that calcined soda is added to remove the calcium ions is not needed, so that the use amount of a reagent is reduced; in addition, the finally obtained product is MgSO4-7H2O, so that the economic benefit of the wastewater treatment process is increased.

Owner:中国电建集团透平科技有限公司

Carrot nutrition noodle

The invention provides a carrot nutrition noodle, the method for producing the carrot nutrition noodle comprises the following steps: (1) selecting the following raw materials by weight part: 90-100 parts of common flour, 1-10 parts of organic carrot powder, 0.1-0.2 parts of L-lysine hydrochloride, 0.003-0.004 parts of nicotinic acid, 0.3-0.5 parts of calcium gluconate and 0.02-0.05 parts of zinc gluconate; (2) mixing the above raw materials and putting into a dough-making machine, adding 20-30 parts of purified water, mixing flour for 5-20 minutes, putting into a cooking machine for cooking for 5-20 minutes, rolling, cutting into strips, drying, cutting off to obtain the carrot nutrition noodle. The carrot nutrition noodle has the advantages of convenient making, balanced nutrition and good mouthfeel, and is especially suitable for being a vegetable auxiliary food for children.

Owner:宜垦(天津)农业制品有限公司

High-temperature-resistant and high-toughness hot work die steel and preparation method thereof

InactiveCN111057950AImprove toughnessAvoid performance incompatibility problemsElectric arc furnaceHot work

The invention relates to the technical field of special steel forgings, in particular to high-temperature-resistant and high-toughness hot work die steel and a preparation method thereof. The hot workdie steel comprises the following components of, in percentage by weight, 0.38 %-0.40% of C, 0.25 %-0.40 % of Si, 0.45 %-0.55 % of Mn, 4.75 %-5.3 % of Cr, 1.7 %-1.9 % of Mo, 0.60 %-0.80 % of V, 0.30%-0.50 % of Ni, less than or equal to 0.002 % of S, less than or equal to 0.0015 % of P, and the balance Fe. The preparation method comprises the following steps of electric arc furnace smelting, external refining, casting, atmosphere protection electroslag remelting, forging, quenching oil cooling treatment and spheroidizing annealing treatment. According to the steel and the method, the raw material proportion of the hot work die steel is optimized, and the content of Si, V, Mo, Ni and other elements is limited within an accurate adjustment and control range, so that the adding amount of corresponding Si, V, Mo, Ni and other elements can be accurate, and the problem that all properties of the die steel are incompatible is solved; and the high-performance hot work die steel can be directly manufactured by selecting the numerical value of the content within the range, so that the finished product rate is remarkably increased.

Owner:潘少俊

Tomato lemon noodles

InactiveCN102342435AThe formula is scientific and reasonableHigh nutritional valueDough treatmentFood preparationLemon juicePurified water

The invention provides tomato lemon noodles, which are prepared by the following steps of: (1) selecting the following raw materials in part by weight: 10 to 15 parts of tomato powder, 8 to 10 parts of lemon juice, 5 to 10 parts of pear juice, 0.1 to 0.5 part of salt, 5 to 10 parts of purified water and 70 to 80 parts of flour; and (2) putting the flour into a flour mixer, mixing other raw materials uniformly, pouring the uniformly mixed raw materials into the flour mixer, mixing the raw materials for 5 to 20 minutes, putting the mixture into a curing machine, curing the mixture for 5 to 20 minutes, calendering, slitting, drying, cutting, and thus obtaining the tomato lemon noodles. The noodles are convenient to prepare, delicious, white and unique in mouthfeel, and are particularly suitable for eating after cooking and refrigerating in hot days.

Owner:宜垦(天津)农业制品有限公司

Mushroom chicken noodle

InactiveCN102366039AMeeting nutritional needsNutritional balanceDough treatmentFood preparationAnimal scienceNiacin

The invention provides a mushroom chicken noodle, which is a nutrition fortified noodle prepared by the steps of: adding of chicken meal, mushroom meal, celery meal, ferrous gluconate, calcium gluconate, niacin, taurine, and L- lysine hydrochloride into ordinary flour, flour kneading, curing, calendering, strip cutting, drying and cutting. The mushroom chicken noodle of the invention has the advantages of convenient preparation, balanced nutrition, attractive taste, and is especially appropriate to serve as complementary food for satisfying the nutritional demands of infant bodies.

Owner:宜垦(天津)农业制品有限公司

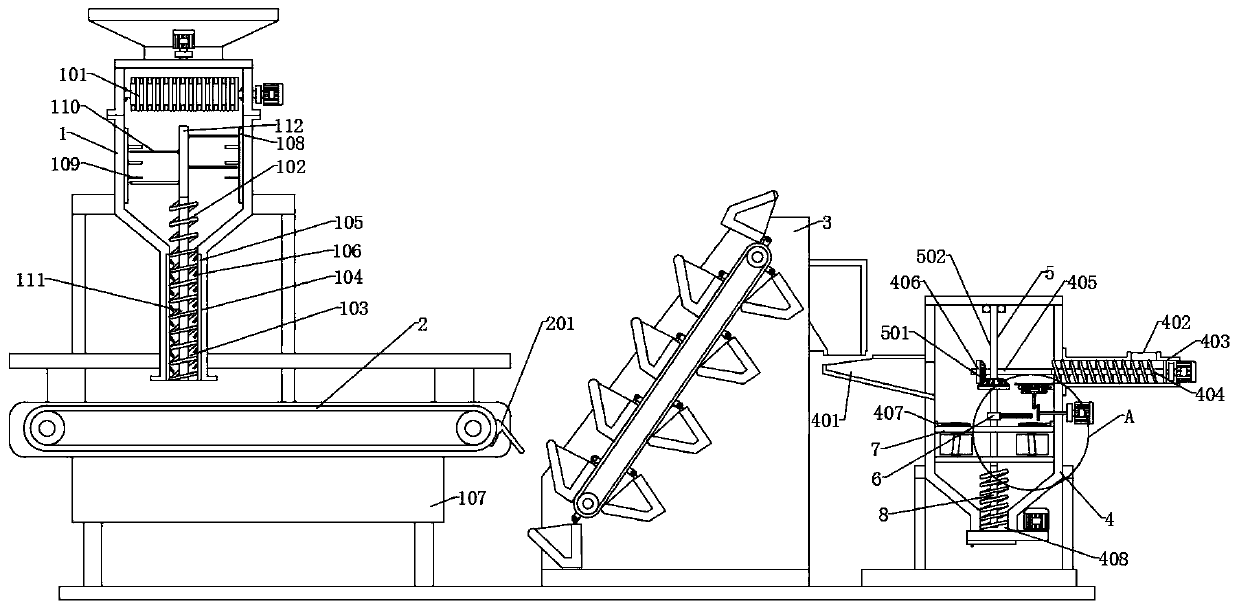

Automatic waste adding device

ActiveCN109702898AThe amount added is accurateMaster the delivery accuracyMixing operation control apparatusCement mixing apparatusReamerLoad cell

The embodiment of the invention discloses an automatic waste adding device which comprises a crushing bin. A cutting and crushing mechanism is arranged in the crushing bin. A discharging conveying reamer is arranged ahead of the cutting and crushing mechanism. A discharging opening is formed in the lower end of the crushing bin. The discharging conveying reamer is located in the discharging opening. A belt scale is arranged right below the crushing bin. According to the equipment, the belt scale is arranged under the crushing bin, the device has prefeeding and quantitative material feeding functions, and precision of the addition amount of waste can be ensured. Meanwhile, a weighing sensor is arranged on a gypsum conveying assembly and can calculate the thrown gypsum amount, a user can setthe addition amount according to the requirement of the technology formula, when it is detected that the gypsum conveying assembly is not started, the waste is not added through an outside controller, in the operation process, the conveying precision of the waste can be well mastered, whether addition can be carried out or not is detected automatically, compared with traditional equipment, in theusing process, the mixing proportion can be well mastered, and the automatic waste adding device is high in practicality.

Owner:北新建材(苏州)有限公司 +1

Hawthorn-containing nutritive noodles

InactiveCN102370136AMeeting nutritional needsNutritional balanceDough treatmentFood preparationGluconic acidFerrous Gluconate

The invention provides hawthorn-containing nutritive noodles. The preparation method of the hawthorn-containing nutritive noodles comprises the following steps of: 1, selecting the following raw materials in parts by weight: 1-3 parts of hawthorn powder, 1-2 parts of carrot powder, 2-5 parts of corn starch, 95-100 parts of plain flour, 0.048-0.06 part of ferrous gluconate, 0.3-0.5 part of calcium gluconate, 0.02-0.05 part of zinc gluconate, 0.003-0.004 part of nicotinic acid, 0.03-0.05 part of taurine, 0.1-0.2 part of L-lysine hydrochloride; 2, mixing the raw materials and putting in a flour-mixing machine, adding 20-30 parts of purified water, and making dough for 5-20 minutes; curing the dough in a curing machine for 5-20 minutes; calendering, cutting into noodles, drying and cutting off to finally obtain the hawthorn-containing nutritive noodles. The hawthorn-containing nutritive noodles are easy to make, in nutritional balance, has good taste and is quite suitable to be used as a complementary feed for promoting children to eat vegetables.

Owner:宜垦(天津)农业制品有限公司

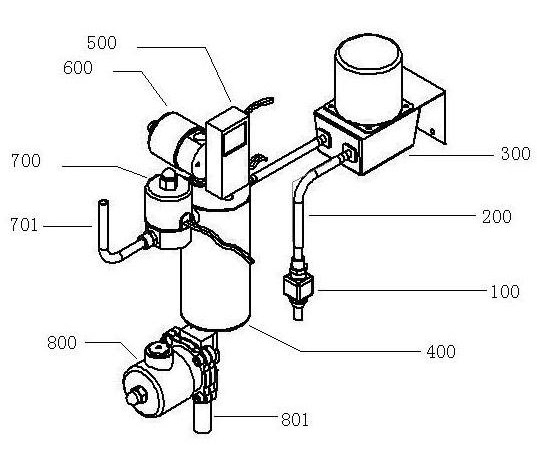

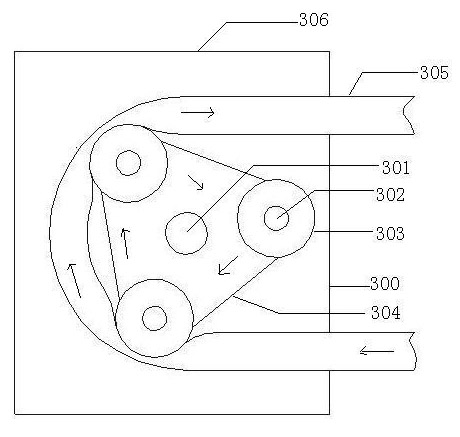

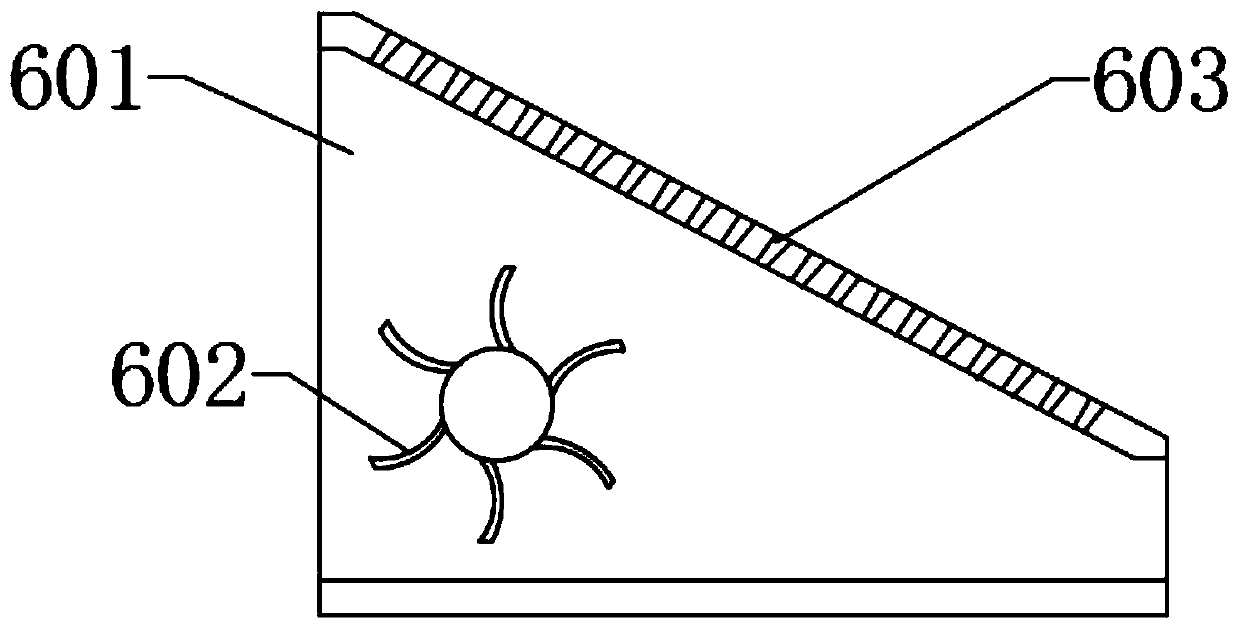

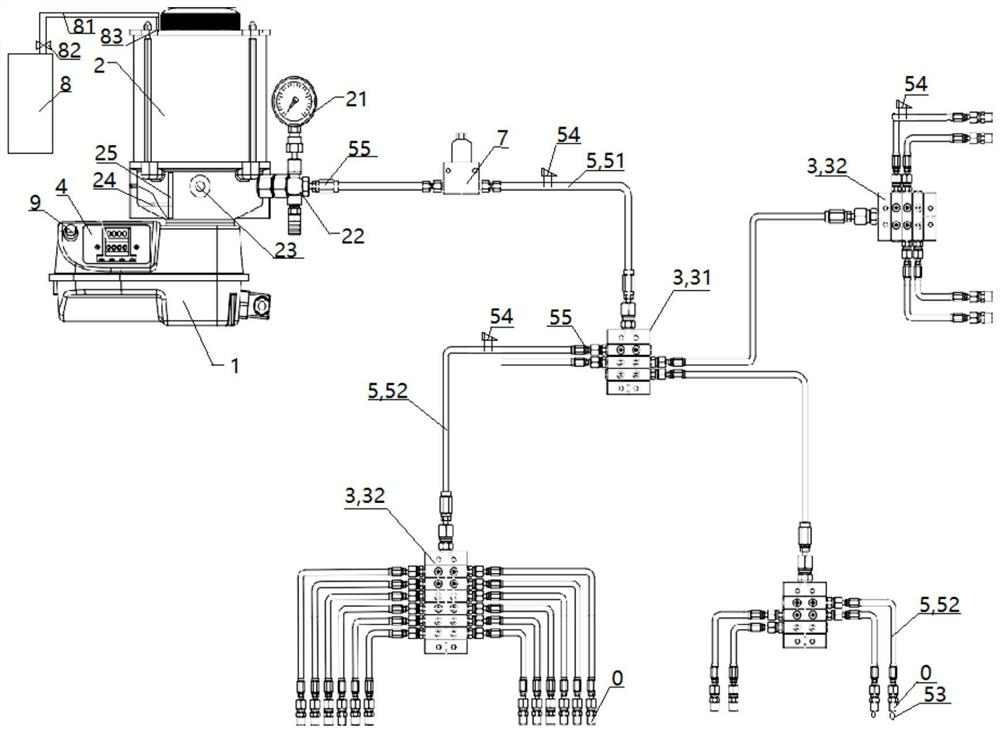

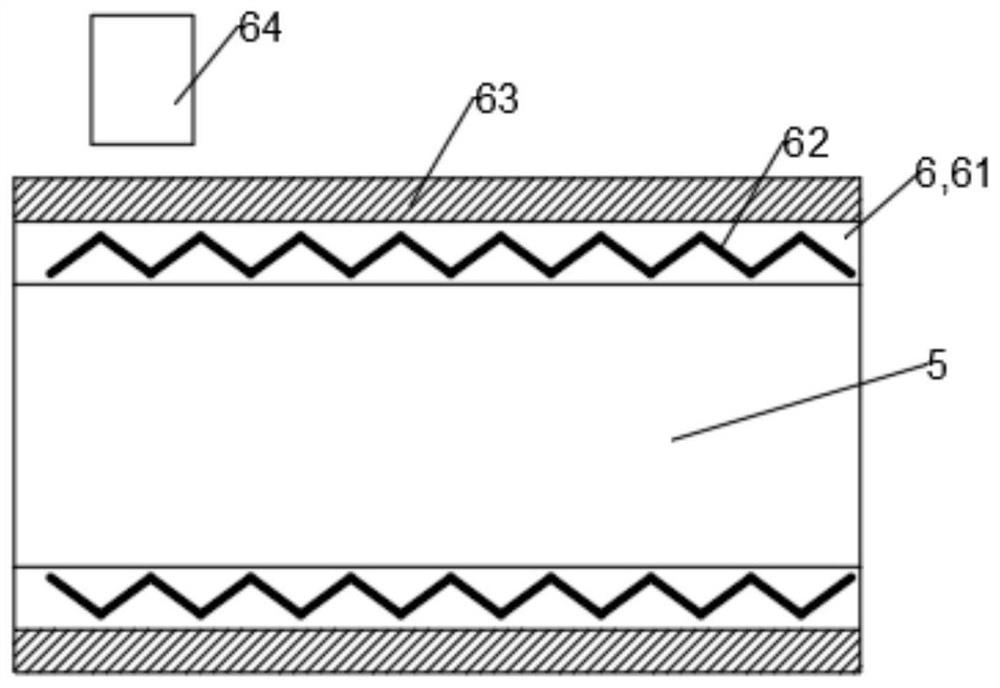

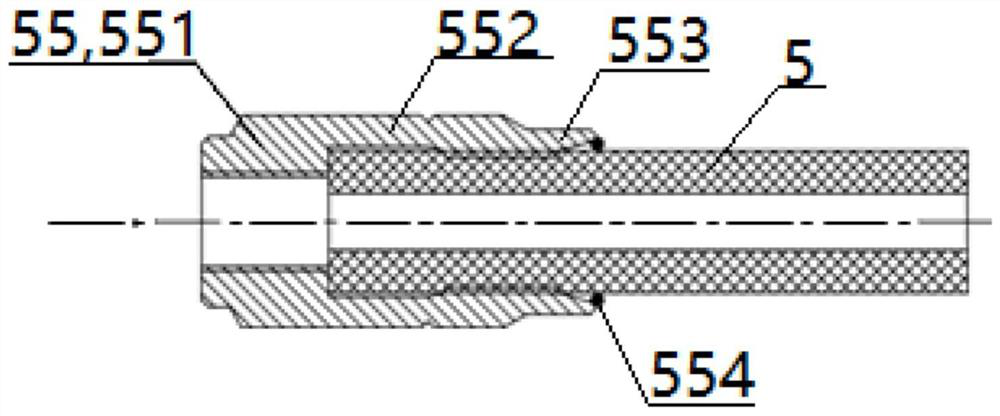

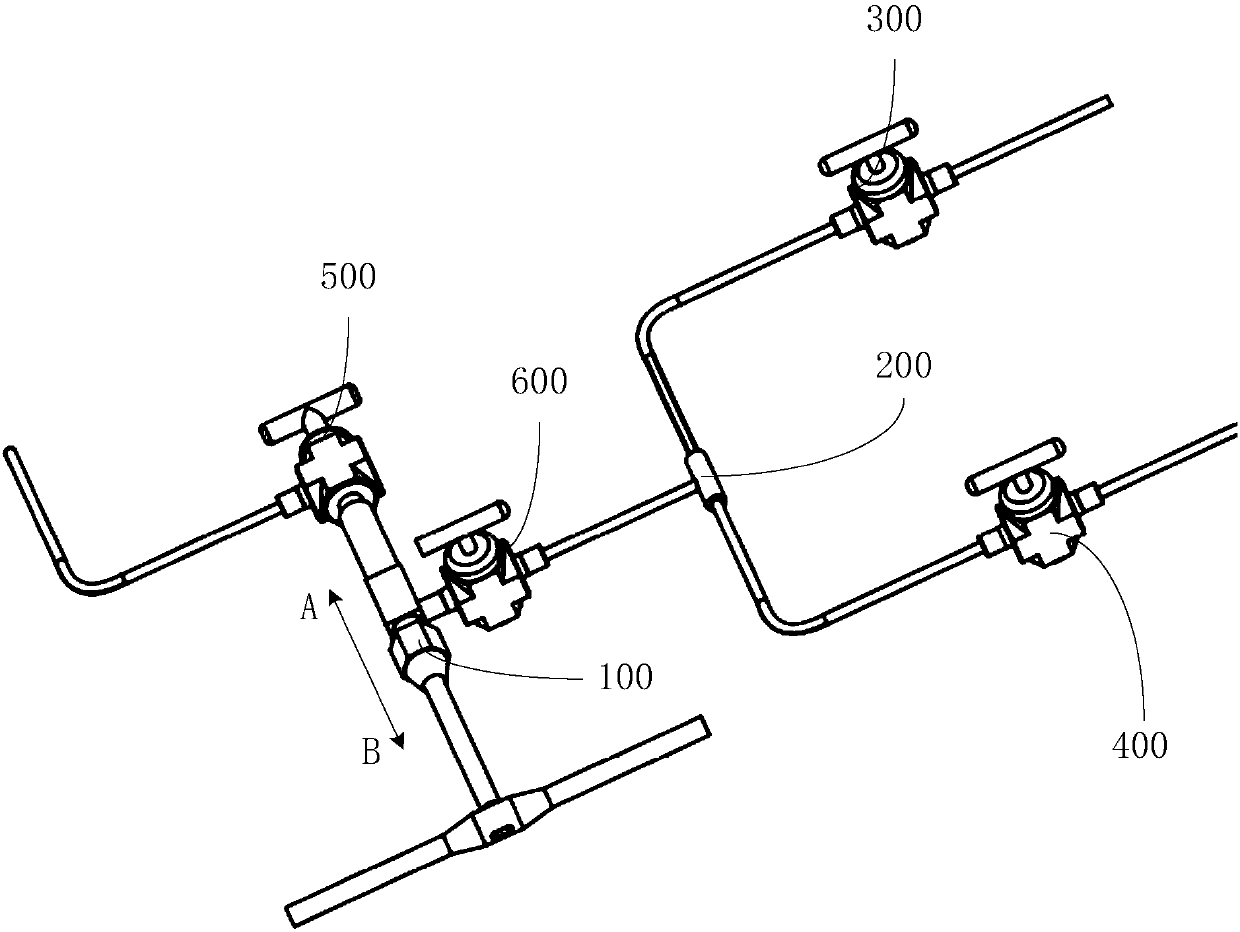

Intelligent oiling device with externally-hung overhead crane

PendingCN113405008AGuaranteed uptimePrevent spoilage and stickinessConduits/junctionsLubrication containersOil canGas cylinder

The invention relates to an intelligent oiling device with an externally-hung overhead crane. The device comprises a lubricating pump, an oil storage tank, a distribution device and a controller, wherein the lubricating pump is horizontally arranged below the oil storage tank and is connected with the oil storage tank; an oil outlet of the oil storage tank communicates with the distribution device through a pipeline; a heat preservation sleeve is arranged on the pipeline, and the heat preservation sleeve comprises a pipe body, an electric heating wire and a photovoltaic panel; the photovoltaic panel is connected with the electric heating wire through an external photoelectric transducer; a grease filter is arranged between the outlet of the oil storage tank and the inlet of the distribution device; the oil storage tank is externally connected with an inert gas cylinder; the inert gas cylinder and the oil storage tank pass through a balance pipe; an automatic valve is arranged on the balance pipe; and an in-tank pressure sensor is arranged on the oil storage tank and is electrically connected with the automatic valve. The oiling device ensures the stability of lubricating oil adding in a sealed state and is not prone to deterioration in a severe environment, the lubricating oil can be automatically added in a fixed-time, fixed-point and quantitative manner, lubrication is reliable, abrasion of parts is reduced, and the working efficiency is improved.

Owner:CHANGZHOU KEHUA ASSOC HEATING MATERIAL

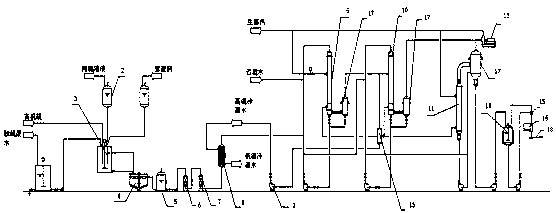

Preparation process of sevelamer carbonate

InactiveCN105732865AAvoid wastingThe amount added is accurateOrganic active ingredientsMetabolism disorderSevelamerCarbonate

The invention relates to the technical field of production of sevelamer carbonate. A preparation process of sevelamer carbonate comprises the steps as follows: firstly, an epichlorohydrin acetonitrile solution is added to a poly (allylamine hydrochloride) solution in proportion, curing is performed, and polymerized jelly is obtained; after polymerization, the jelly is milled to 50 meshes by a colloid mill, then a 4% sodium hydroxide aqueous solution is added, the stirring reaction is performed, and sevelamer alkali is obtained; finally, purified water is added to the sevelamer alkali, then the temperature is raised, carbon dioxide is fed in, centrifugation and drying are preformed after heat-preserved stirring reaction, and sevelamer carbonate is obtained. By adopting the preparation process of sevelamer carbonate, the product energy consumption can be greatly lowered, the product quality is improved, and the problem of production of waste water is solved; meanwhile, the labor intensity can also be reduced, and the labor productivity is raised; the product quality is improved, the qualified rate of finished products reaches 99.6%, and the yield reaches 64.7%.

Owner:JIANGSU TIANHE PHARMA CO LTD

Environment-friendly anti-dryer and preparation method thereof

The invention relates to an environment-friendly anti-dryer and a preparation method thereof. The environment-friendly anti-dryer is prepared by raw materials of, by mass, 15%-20% of antioxidant 2246, 10%-15% of food grade phenol antioxidants, 40%-50% of dioctyl phthalate and 20%-30% of high boiling point solvent oil, and the preparation method includes heating the dioctyl phthalate to 35 DEG C to 60 DEG C, slowly adding tertiary butyl hydroquinone in a thermal insulation state for a fully stirring until a mixture is completely dissolved, adding dioctyl adipate, slowly adding an antioxidant 2246 for the fully stirring until a mixture is completely dissolved at the temperature between 80 DEG C and 90 DEG C, and continuously stirring for 40-60 minutes in the thermal insulation state so as to guarantee that the antioxidant is uniformly distributed in a solvent to obtain a finished product. According to the environment-friendly anti-dryer and the preparation method thereof, the problems that the yellow ink turns green and blue ink is rusted and the like are effectively solved, the anti-dryer is almost insoluble in water, thereby the anti-dryer has no negative effect on water-ink balance and is safe and environment-friendly, the smell is small, the intermiscibility of the anti-dryer and ink is good, the antioxidant efficiency is high, and ink can opening time and retention time of the ink on a printer can be effectively prolonged.

Owner:TIANJIN MEILIANDA INK AUXILIARIES

Washing material adding method for washing feather and washing material adding washing machine thereof

InactiveCN109183161AThe amount added is accurateClean upWool fibre washing/scouringWater savingCoupling

The invention discloses a washing material adding method for washing feather and a washing material adding washing machine thereof and belongs to the technical field of feather cleaning. The method comprises the steps of (S1) placing feather to be cleaned on an electronic scale to be weighed and recording a weight after weighing, (S2) setting the amount of water corresponding to the weight value of the weighed feather in step (S1), and (S3) starting washing according to a washing time of set washing device corresponding to the weight of the weighed feather in step (S1). The washing material adding washing machine comprises a cleaning outer barrel, the middle portion of the left side wall of the washing outer barrel is fixedly connected to a motor frame by screws, a timing motor is laterally installed on the motor frame, and the right end of an output shaft of the timing motor is connected to a rotating shaft through a coupling. According to the scheme, through a scientific measurementmode, the amount of an added washing material is more accurate, the cleaning is good, the water and the washing material can be saved, the working efficiency is improved, and the quality of a productis improved.

Owner:WEST ANHUI UNIV +2

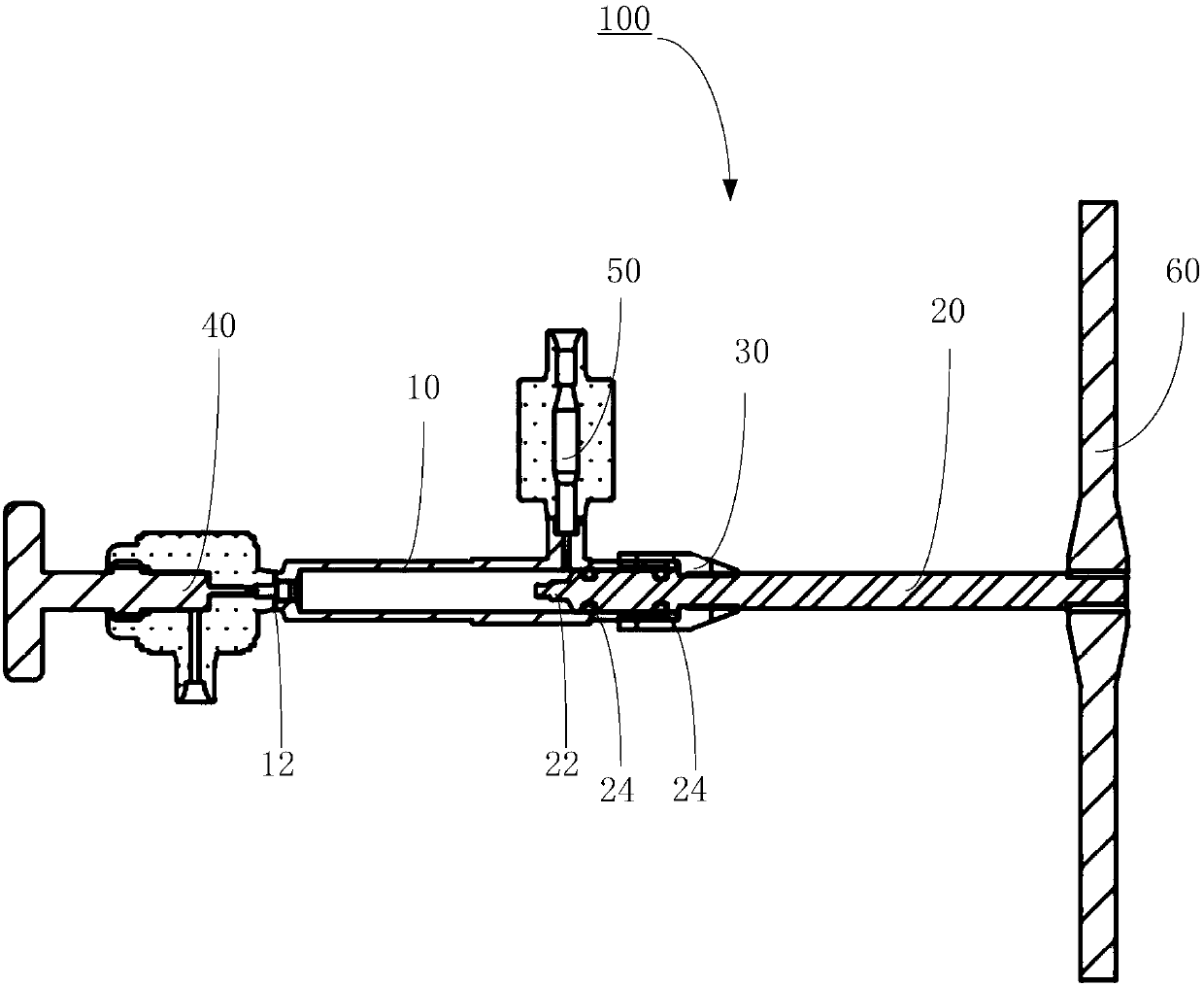

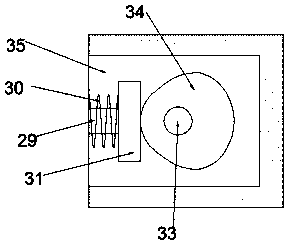

High-pressure charging valve body and high-pressure charging system

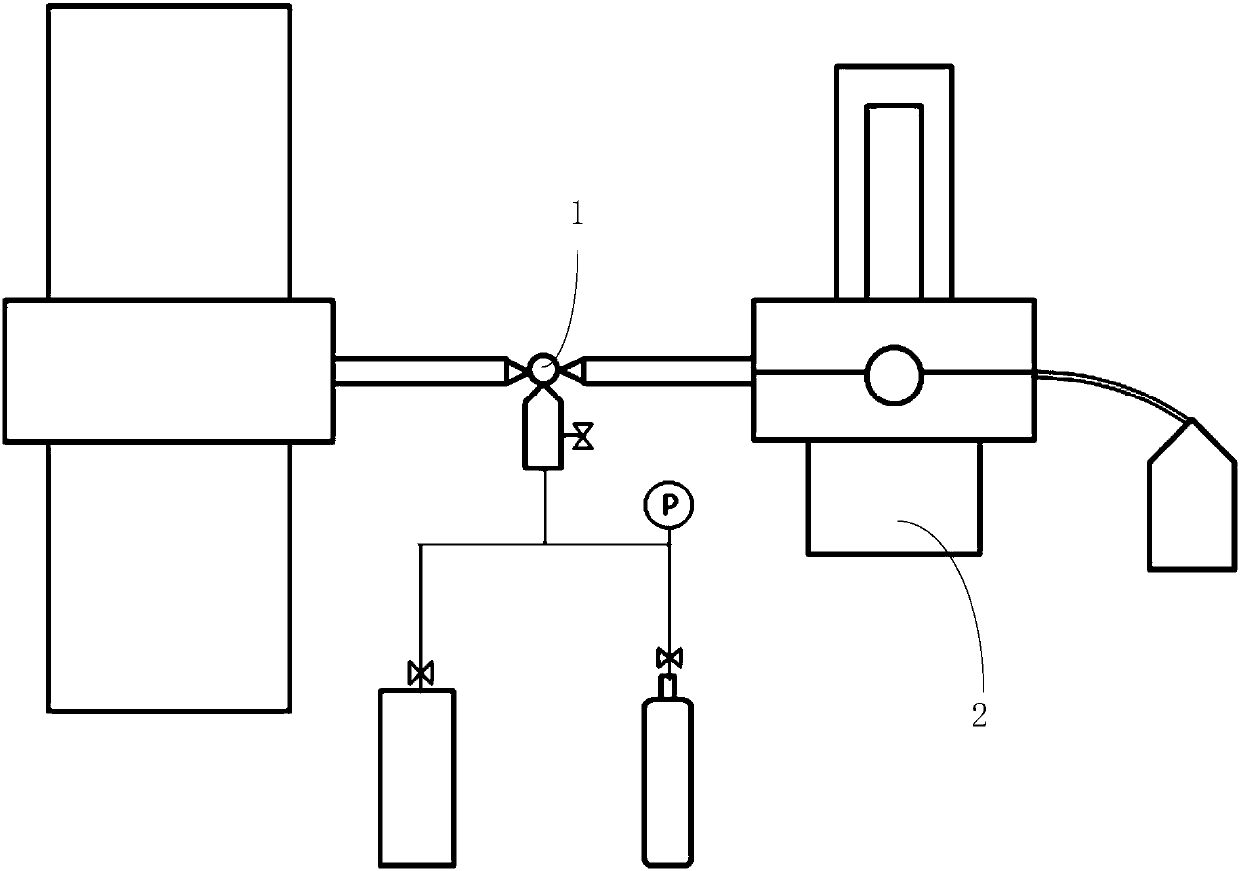

ActiveCN107829905AFlexible operationAccurate measurementPositive displacement pump componentsMovable measuring chambersPistonNeedle valve

The invention relates to a high-pressure charging valve body. The high-pressure charging valve body comprises a cylinder, a piston, a connecting sleeve, a first needle valve and a second needle valve,wherein one end of the piston is arranged in the cylinder, one end of the connecting sleeve sleeves one end, on which the piston is arranged, of the cylinder, the other end of the connecting sleeve is in threaded connection with the piston, the piston rotatably moves in the cylinder, the piston is in dynamic seal matching with the cylinder, the first needle valve is arranged on the end, which isfar from one end of the piston, of the cylinder, the second needle valve is arranged on the side wall of one end, which is sleeved by the connecting sleeve, of the cylinder, and the first needle valve, the cylinder and the second needle valve communicate with one another. According to the high-pressure charging valve body, the piston is in threaded fit with a connecting piece, so that the piston rotatably moves, the reaction of high-pressure air in the cylinder can be prevented, all air in the cylinder is extruded, the accurate is high, the high pressure is resistant, the operation is flexible, and milligram trace gas can be continuously added for many time by designing the appropriate size, so that accurate measurement of the gas flow is realized. In addition, the invention further provides a high-pressure charging system which adopts the high-pressure charging valve body.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Noodles with tomato and egg taste

InactiveCN102342431AThe formula is scientific and reasonableThe entrance is deliciousDough treatmentFood preparationIcing sugarGARLIC POWDER

The invention provides noodles with tomato and egg taste. The noodles are produced from the following raw materials in parts by weight: 3-8 parts of whole-egg powder, 5-10 parts of tomato powder, 0.5-2 parts of salt, 0.1-1 part of powdered sugar, 0.1-0.5 part of coriander powder, 0.1-0.5 part of garlic powder, 85-90 parts of flour and 20-30 parts of purified water. A production method is characterized by putting all the raw materials except the purified water into a dough kneader according to the parts by weight, then adding 20-30 parts of purified water, kneading dough for 10 minutes, then putting the dough into a ripening machine to be ripened for 10 minutes and then carrying out calendering, strip cutting, drying and cutting-off processes, thus obtaining the noodles with tomato and egg taste. The noodles with tomato and egg taste are nutritional and wholesome, dispense with additional condiments during cooking, are convenient and fast to cook, and have delicious taste.

Owner:宜垦(天津)农业制品有限公司

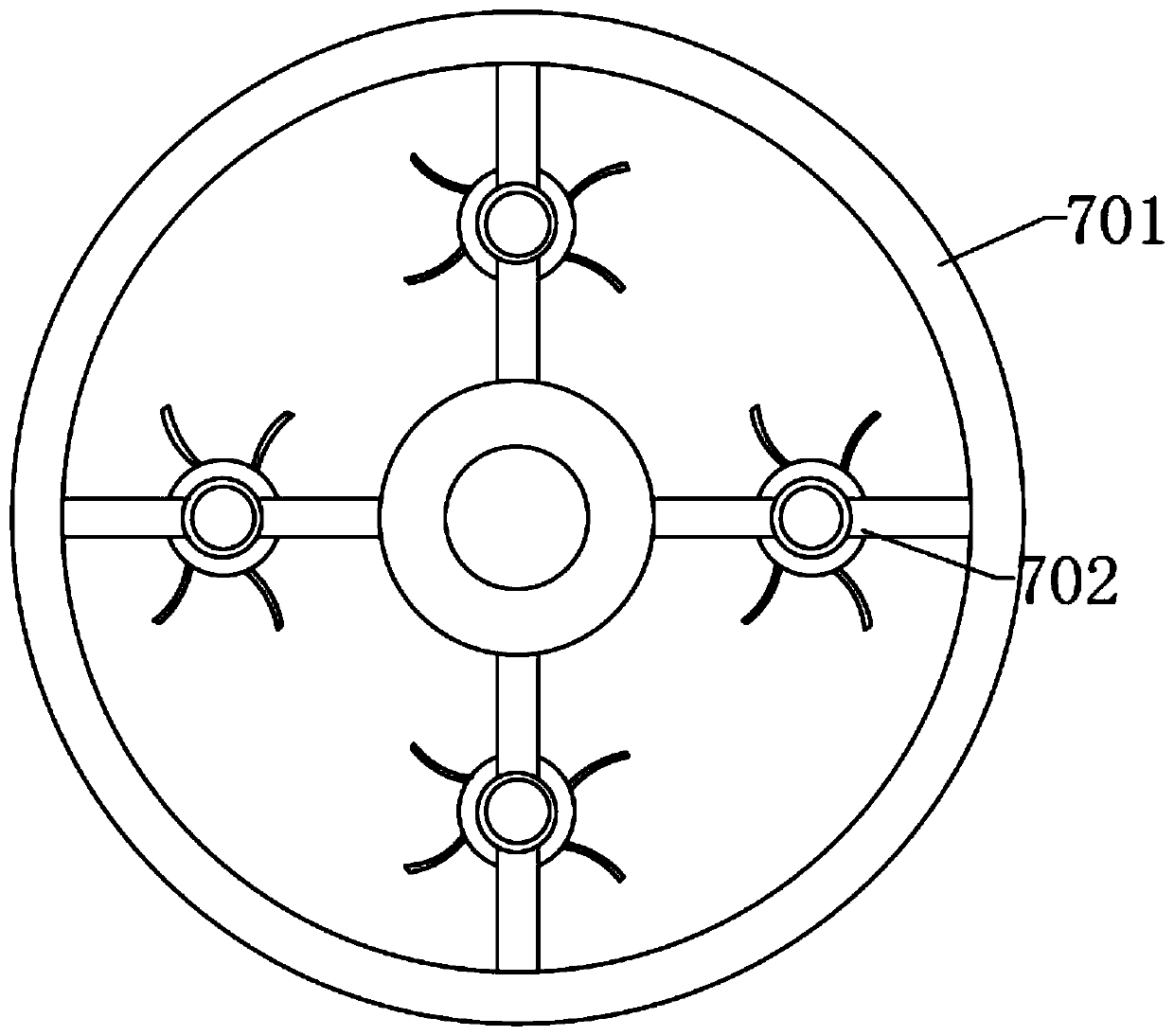

Liquid-phase medicament premixing device for pharmacy department

InactiveCN105413563AWell mixedThe amount added is accurateTransportation and packagingMixer accessoriesAutomatic controlBiochemical engineering

The invention discloses a liquid-phase medicament premixing device for a pharmacy department. The liquid-phase medicament premixing device is characterized in that a rotating shaft is rotationally connected with a rotating motor; a bottle storage rack is arranged above the rotating shaft and is fixedly connected with the rotating shaft; a shelf is arranged in an inner cavity of the bottle storage rack; a telescopic cross rod is arranged above the left side of the bottle storage rack; a medicament metering device is arranged at the right end of the telescopic cross rod; a metering sensor is arranged at the middle part above a metering bottle; the rotating motor, an ultrasonic generating device and the metering sensor are all electrically connected with an automatic control device through connecting wires. The liquid-phase medicament premixing device for the pharmacy department, disclosed by the invention, has the advantages that the structural design is reasonable, the automation degree is high, high efficiency and practicability are realized, the mixing is uniform and quick, and the like; meanwhile, the working efficiency can be substantially increased, and the working pressure of medical staff can be reduced.

Owner:王文慧

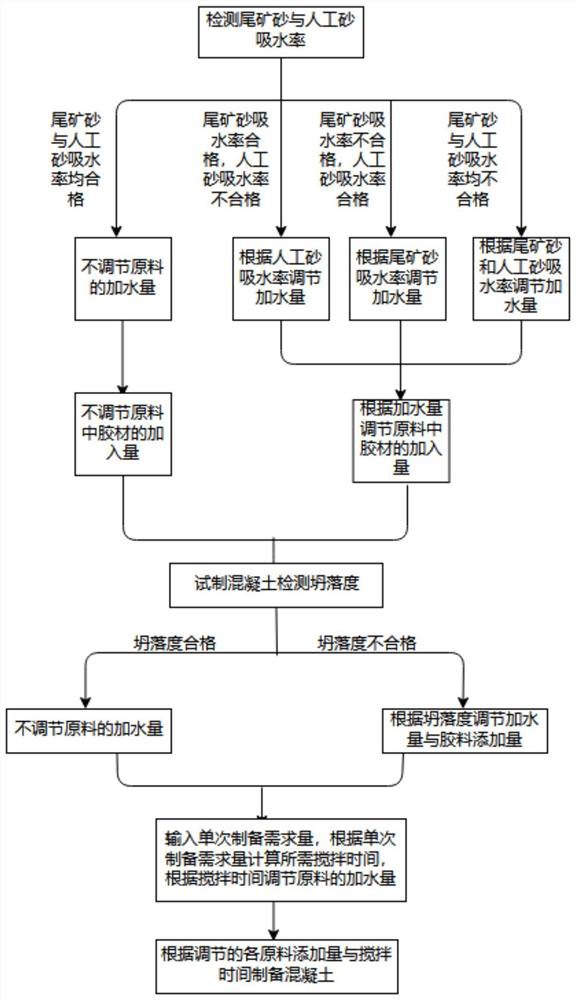

Preparation method of tailing sand and artificial sand composite concrete

ActiveCN112847781AImprove liquiditySave resourcesSolid waste managementPreparing sample for investigationSoil scienceRiver sand

The invention relates to a preparation method of tailing sand and artificial sand composite concrete. The method comprises the following steps of step 1, detecting the water absorption rates of tailing sand and artificial sand, and adjusting the addition amount of water and a glue material during concrete preparation according to the water absorption rates of the tailing sand and the artificial sand; step 2, trial-producing concrete according to the addition amount calculated in the step 1, calculating the slump of the concrete, and further adjusting the addition amount of the water and the glue material during preparation according to the slump of the trial-produced concrete; and step 3, determining the required amount of the concrete, determining the concrete stirring duration according to the required amount, and further adjusting the addition amount of the water during concrete preparation according to the stirring duration. According to the method, river sand is replaced by the tailing sand and the artificial sand, due to the fact that the grain size distribution of the tailing sand is concentrated, and the smaller tailing sand is large in cohesiveness and poor in fluidity, the smaller tailing sand is matched with the artificial sand with the large grain size, the slump of the concrete is increased, and the prepared concrete keeps excellent fluidity.

Owner:LANGFANG RONGSHENG CONCRETE

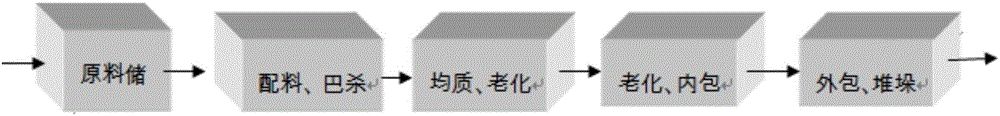

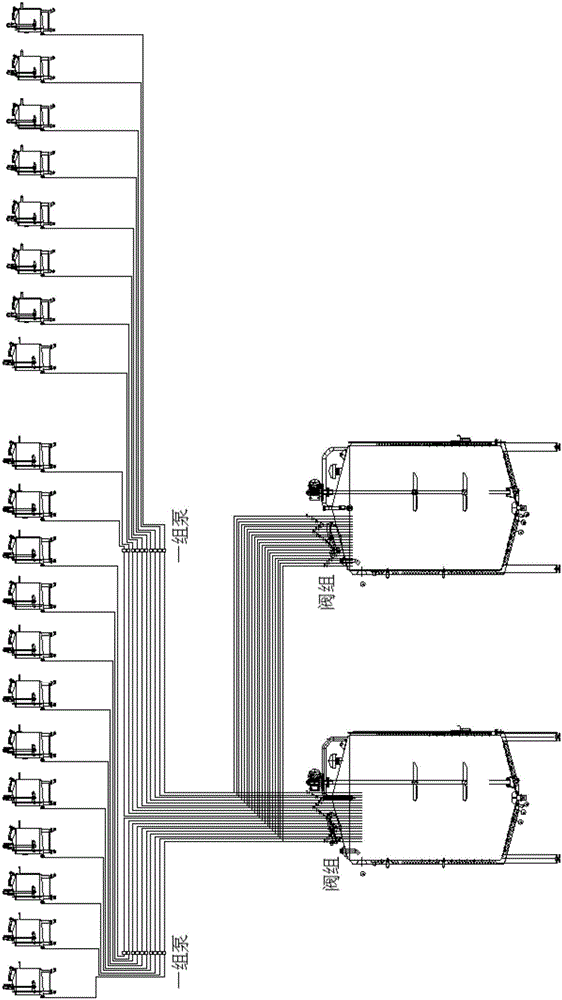

Cream production line raw material storing and spice adding system

PendingCN106135461APrevent feeding errorsImprove product qualityEdible oils/fats production/working-upProduction lineBarcode

The invention relates to a cream production line raw material storing and spice adding system which comprises a raw material storing system and a spice adding system. The raw material storing system comprises multiple storage zones, and each storage zone is provided with 10-20 raw material storing tanks. Each storage zone is provided with a first code scanning device, and each storing tank is provided with a second code scanning device. Before powdery material storing bags are fed into the storage zones, bar codes are identified through the first code scanning devices, and the bags can enter after verification is passed. Before the powdery material storing bags are charged into the raw material storing tanks, bar codes are identified through the second code scanning devices, and charging can be performed after secondary verification is passed. The spice adding system is composed of multiple spice adding units. The spice adding units are respectively, mutually and sequentially connected with an essence tank, eccentric stepping pumps, a premixing tank and a valve, wherein the tail end of a delivery pipe is located at the upper portion of a premixing cylinder, and liquid spice, dissolved powdery spice or diluted colloidal spice is quantitatively added to the premixing cylinder through respective eccentric stepping pumps.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

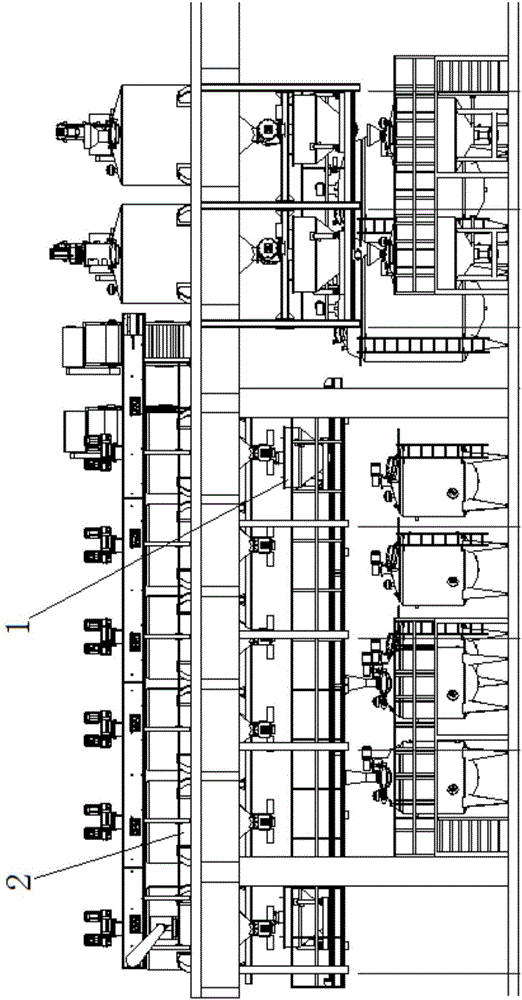

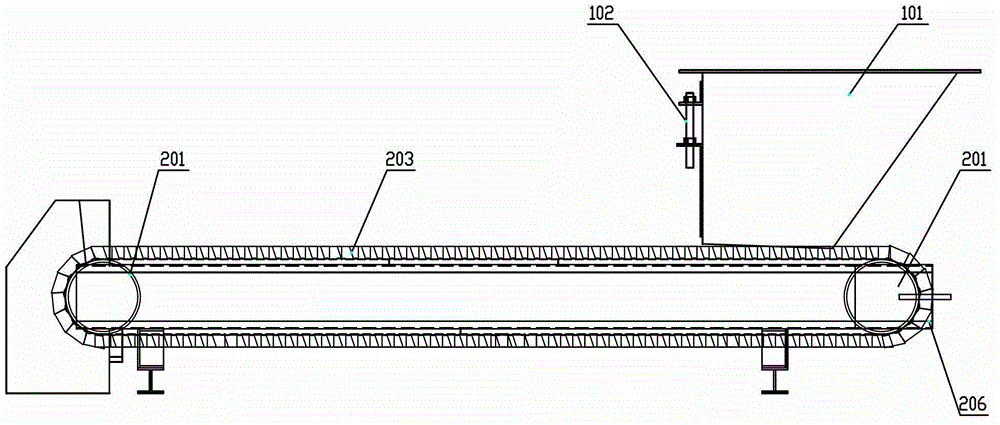

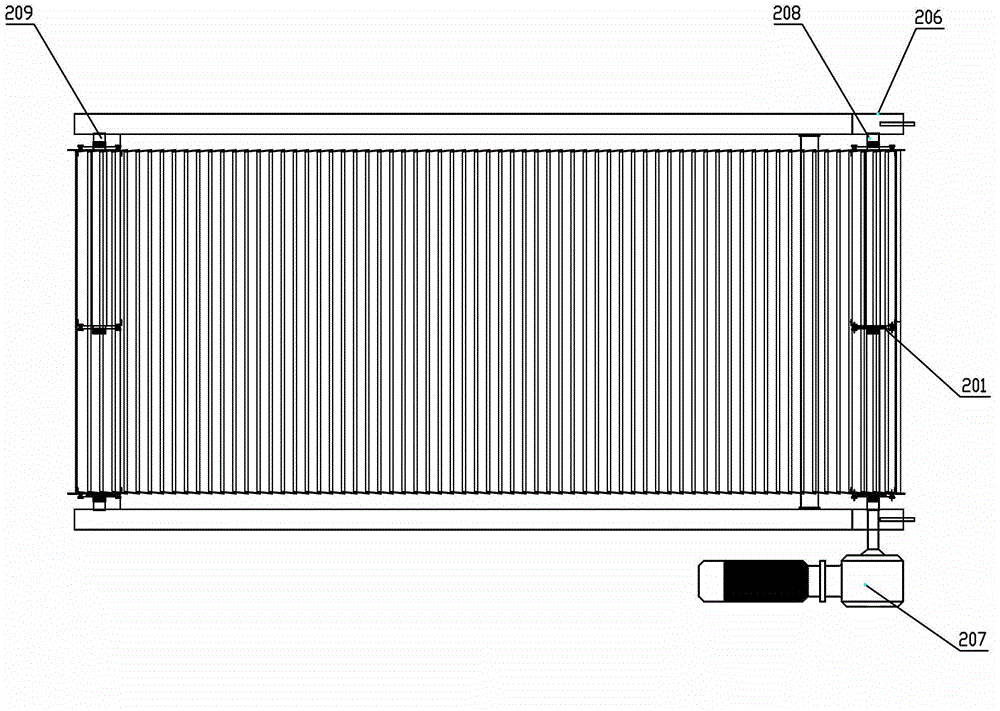

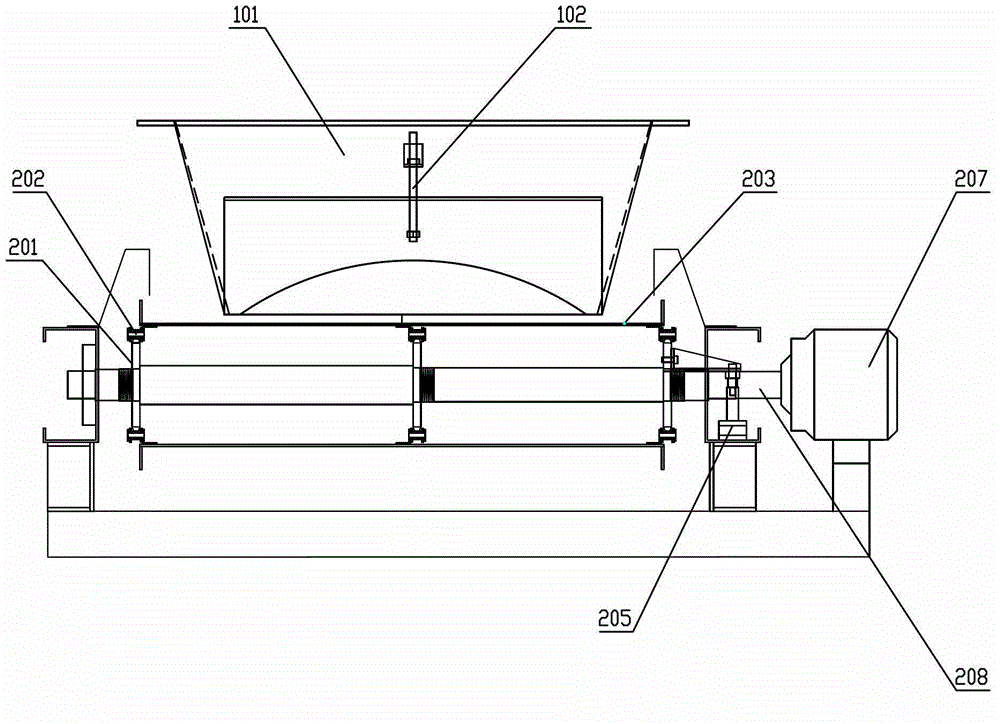

Link plate type high-temperature automatic constant weight feeder

The invention provides a link plate type high-temperature automatic constant weight feeder, comprising a conveying control metering device arranged below a feeding hopper, a cleaning device arranged below the conveying control metering device, and a program control system. The link plate type high-temperature automatic constant weight feeder is mainly and technically characterized in that the conveying control metering device is a single-faced board turning link plate driven by a chain wheel; a link plate conveying belt is coated on the single-faced board turning link plate; a sensor device is further arranged below the conveying control metering device; the sensor device is provided with a plurality of flexible guide rails below the link plate conveying belt; a plurality of supporting guide rails are connected with the flexible guide rails at both sides; and sensors are respectively connected with the supporting guide rails. With the adoption of the link plate type high-temperature automatic constant weight feeder provided by the invention, the metering precision is influenced by the high temperature of a material in conveying and metering processes, and the influence on the precision, caused by factors of high temperature, belt stretching and the like when a high-temperature material is metered, are avoided, so that the metering precision is improved from 3% to 1%, and the cement quality can be effectively ensured.

Owner:HANGZHOU QIAOXING AUTOMATIC CONTROL EQUIP

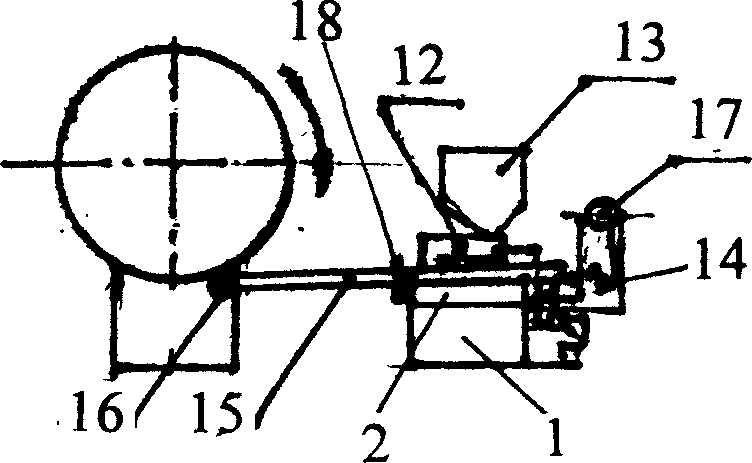

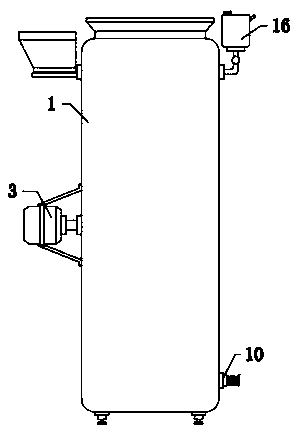

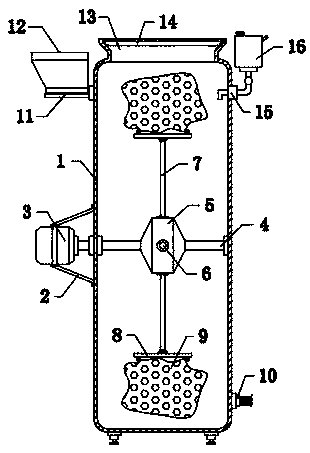

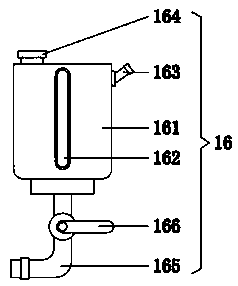

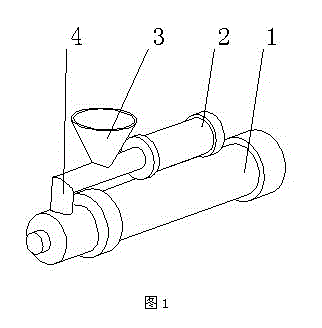

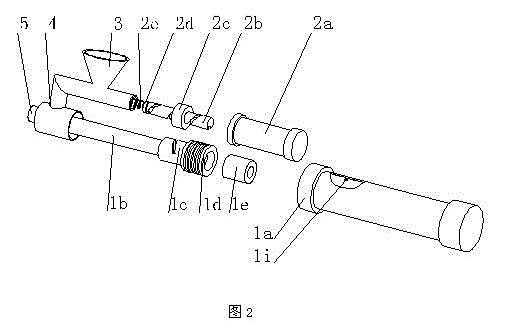

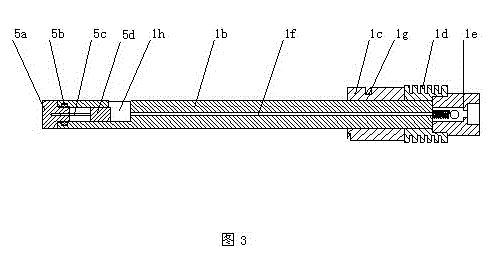

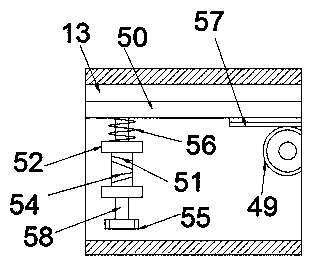

Die-casting machine punch lubricating machine

The invention discloses a die-casting machine punch lubricating machine which comprises a hopper, a material taking mechanism and a feeding mechanism. The feeding mechanism comprises a feeding air cylinder, wherein the feeding air cylinder comprises a feeding air cylinder piston rod, a feeding air cylinder body and a feeding air cylinder piston. The hopper is connected to a material taking pipe, the tail end of the material taking pipe is connected with the material taking mechanism and is connected with the feeding air cylinder, the material taking pipe rightly faces a material tank led to the inside of the feeding air cylinder piston rod, a material taking device is arranged at the front section of the feeding air cylinder piston, a rotary fixed column is arranged inside the feeding air cylinder body, and the material taking device is matched with the rotary fixed column to drive the feeding air cylinder piston rod to perform whole material taking when the feeding air cylinder operates. The die-casting machine punch lubricating machine directly pours lubricating particles into lubricating position by using the material tank, can ensure that the adding amount of the lubricating particles is accurate and enables a punch to be fully lubricated, the service life of the punch is greatly prolonged, and the production cost is saved. In addition, the quality of a die-casting product is fully ensured, the problem that traditional feeding and blowing enable particles to be splashed all around is avoided, and the die-casting machine punch lubricating machine adopts an integral structure and is simple in structure, capable of saving space, convenient to install, low in fault rate and easy to maintain.

Owner:TAIZHOU SHENG WORLD MECHANICS

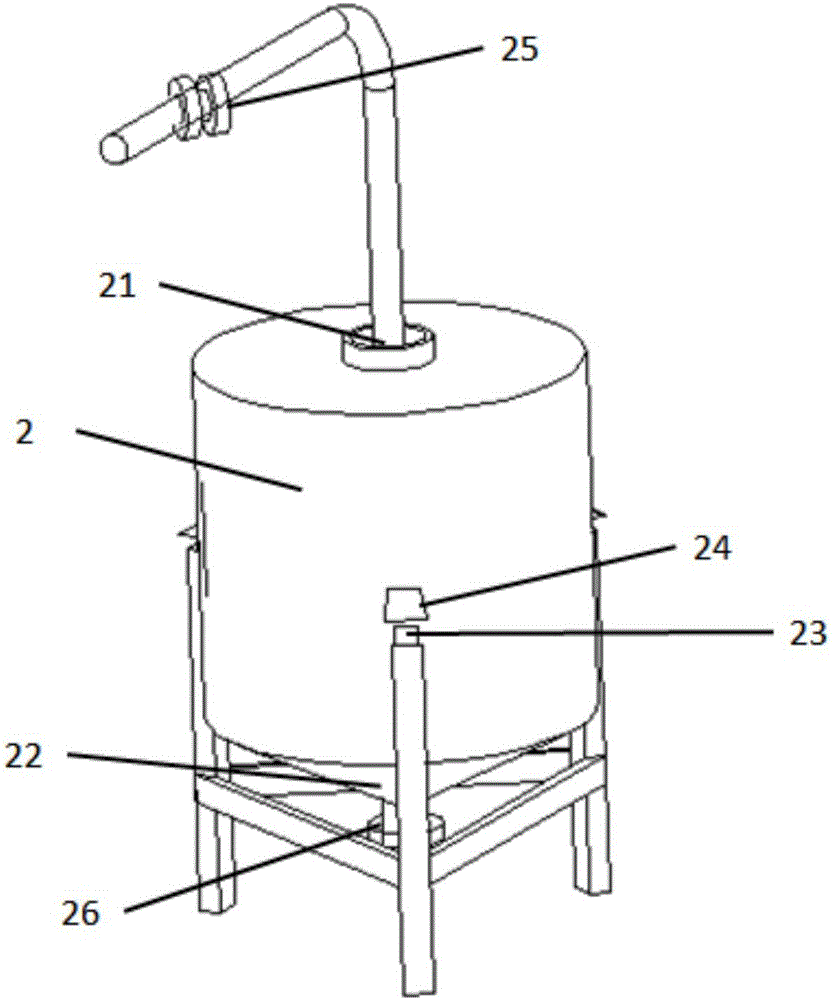

Pouring device for preparing foaming concrete

InactiveCN106738342AMonitor weight changes at any timeControl the amount added at any timeMixing operation control apparatusIngredients proportioning apparatusFoam concretePolymer science

The invention discloses a pouring device for preparing foaming concrete and belongs to the technical field of building block equipment. The pouring device comprises a plurality of additive tanks, a water tank, a mixing and pouring tank and a worktable. The tops of the additive tanks are provided with additive feed inlets, and the bottoms of the additive tanks are provided with additive discharge outlets which communicate with the mixing and pouring tank. The top of the water tank is provided with a water inlet, and the bottom of the water tank is provided with a water outlet which communicates with the mixing and pouring tank. The top of the mixing and pouring tank is provided with a dry material feed inlet, and the bottom of the mixing and pouring tank is provided with a pouring outlet. The mixing and pouring tank is internally provided with a stirring paddle which is connected with a power device to supply power. According to the pouring device, materials can be sequentially added according to the process order, meanwhile, a weighing device is arranged and can accurately control the addition amount of the materials, the whole pouring process is controlled through a computer, and manpower, material resources and time are saved.

Owner:HARBIN TIANSHUN CHEM TECH DEV CO LTD

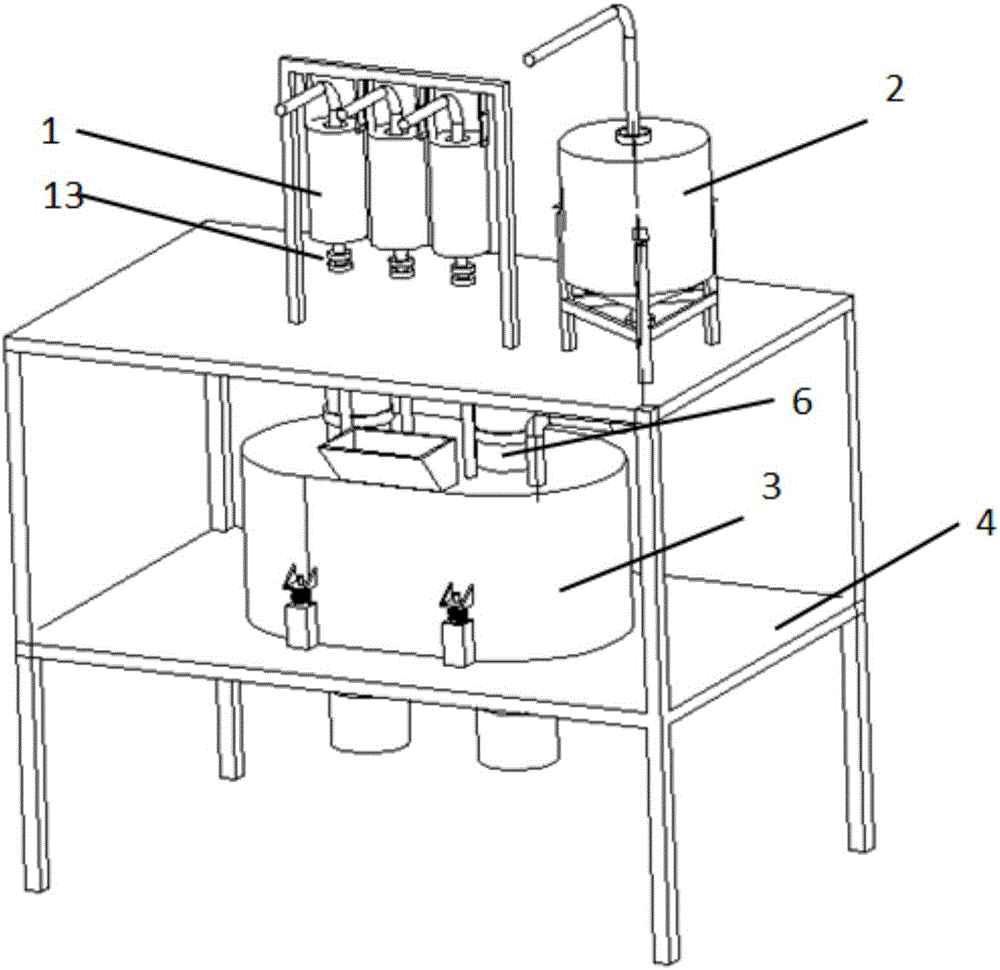

Carbon residue recovering and utilizing device in aluminum electrolysis industry

ActiveCN110142146AThe amount added is accurateLow costFlotationBiochemical engineeringAluminum electrolysis

The invention discloses a carbon residue recovering and utilizing device in the aluminum electrolysis industry. The device comprises a floatation tank and a processing tank arranged in the floatationtank. The processing tank is opened upwards. The upper side of the processing tank is provided with a support. A delivery mechanism is fixedly arranged on the support. The delivery mechanism deliversa carbon residue solution to the processing tank and comprises a temperature detection unit and a valve unit. A liquid level detection mechanism is arranged in the processing tank. When the carbon residue solution in the floatation tank reaches a predetermined amount, the feeding is stopped automatically; at the same time, during the feeding process, the temperature of the carbon residue solutionis measured, after the feeding is stopped, a capture agent is added automatically based on the temperature of the carbon residue solution; compared with artificial adding, the efficiency is largely improved, moreover, the amount of the capture agent is more accurate, the waste of the capture agent is avoided, and the cost is reduced for the enterprises.

Owner:临沂长荣环保科技有限公司

Fertilizing-type soil condition agent production stirring device

InactiveCN110639387AThe amount added is accurateAdd evenlyTransportation and packagingRotary stirring mixersAgricultural scienceAgricultural engineering

The invention relates to the field of pesticide production, in particular to a fertilizing-type soil condition agent production stirring device. The device comprises a horizontally arranged stirring mounting cylinder, a flow guide pipe is arranged at the lower right corner of the stirring mounting cylinder, a manual valve is arranged inside the flow guide pipe, the upper end of the stirring mounting cylinder is symmetrically provided with rotating cover plates, limit driving rotating shafts are symmetrically arranged on that cylinder wall of the upper half part of the stirring mounting cylinder, limit rotating grooves are arranged on that stirring mounting cylinder cooperating with the limit driving rotating shaft, a uniform flow guide cylinder is horizontally connected and arranged between the limit drive rotating shafts at both ends, coaxial drive is adopted to realize the coordination of coarse stirring and fine stirring, so that the stirring efficiency and effect of the device aresignificantly improved. Through intuitive control of liquid level, accurate addition amount is realized, and uniform flow diversion is matched, so that materials in the stirring area are uniformly added, and the stirring is accelerated. Through hydraulic control, the tilt of the device is realized, and the export of materials is convenient.

Owner:SHANDONG JIELIER FERTILIZER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com