Washing material adding method for washing feather and washing material adding washing machine thereof

A feeding method and down technology, which is applied in the field of down cleaning, can solve the problems affecting the quality of down and down, and can not achieve precise control of the dosage, so as to achieve the effect of adding an accurate amount, improving the quality, and cleaning cleanly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

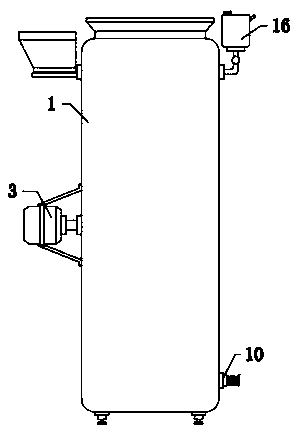

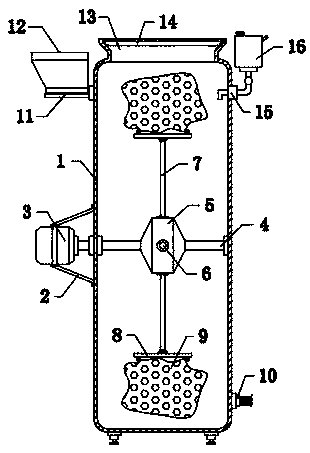

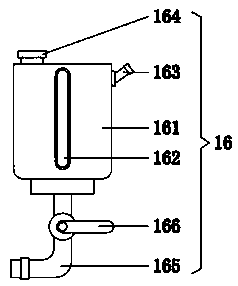

[0034] During use, calculate the proportioning amount of down and water, washing material, the working time of timing motor 3 according to the use requirement of washing material, after support cover 12 is placed on the upper side of weighing equipment 11, weigh weighing equipment 11 Calibrate zero, place the total amount of feather down in the support cover 12 and weigh it, obtain the amount of water added and the amount of washing material required according to the above-mentioned ratio, and evenly disperse the feather down on each cleaning net 9, inject water into the cleaning outer barrel 1 through the cleaning port 13, the amount of water injected is the water quantity of the calculated ratio, the timing motor 3 is connected to an external power supply, and the working time of the timing motor 3 is set. When the timing motor 3 is working, the timing motor 3 The output shaft drives the turntable 5, the support rod 7, the support plate 8 and the cleaning net 9 to rotate thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com