Pouring device for preparing foaming concrete

A foamed concrete and pouring tank technology, which is applied to clay preparation devices, control devices, mixing operation control devices, etc., can solve the problems of inability to automatically and accurately control the amount of material added, uneven mixing of the pouring device, and impact on product quality. The effect of saving manpower, saving manpower and time, and shortening foaming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

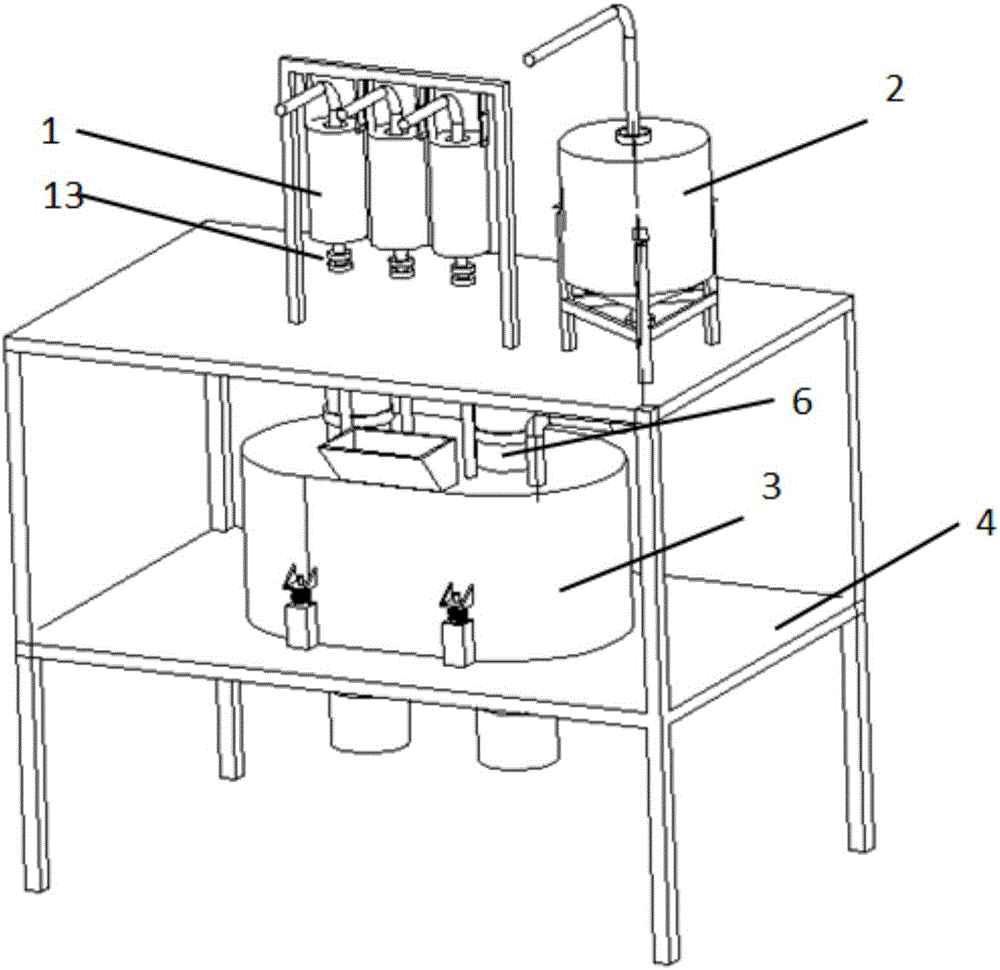

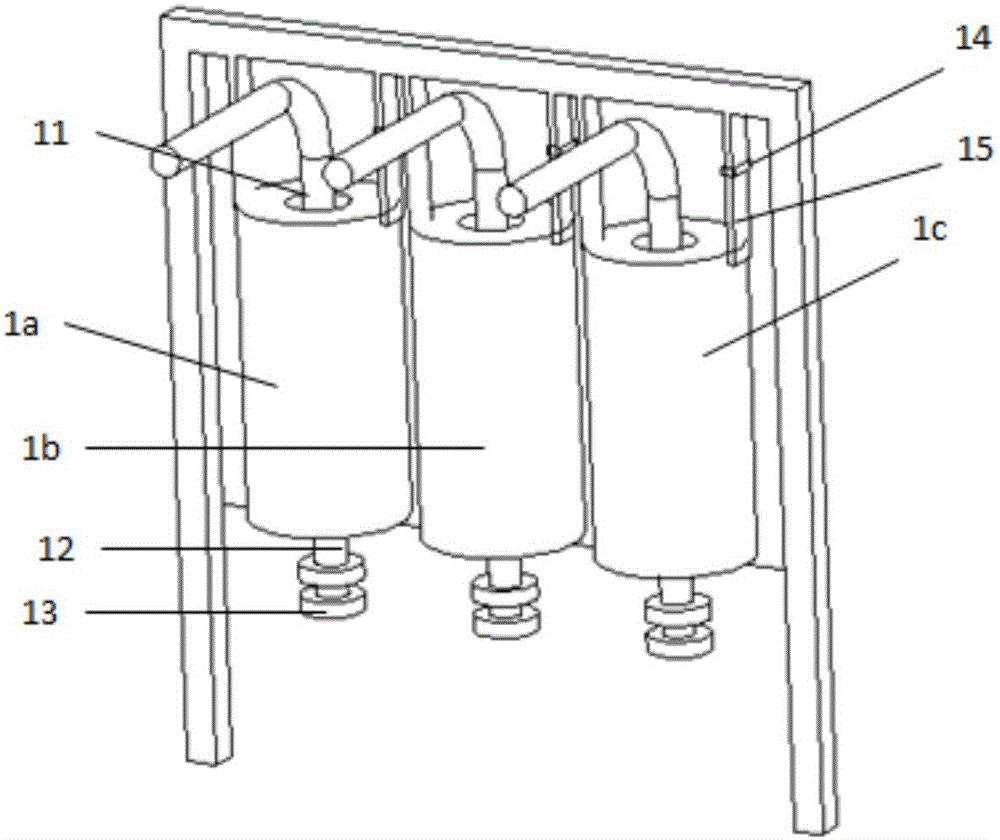

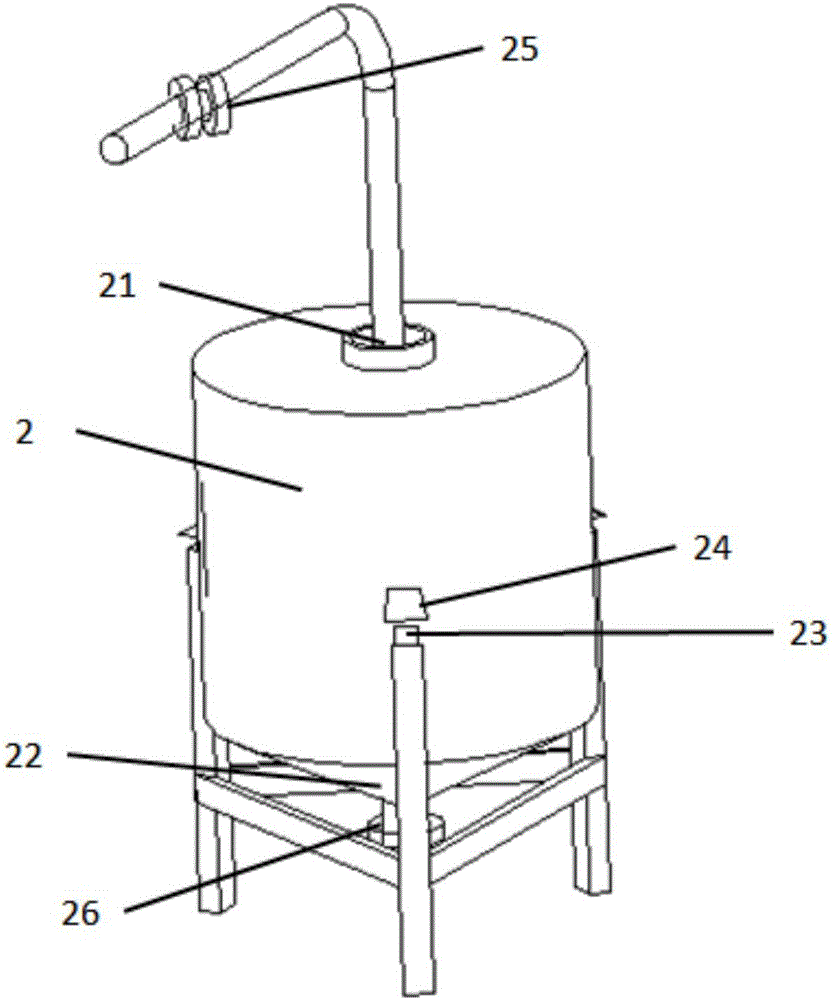

[0035] Such as figure 1 Shown, a kind of pouring device that is used to prepare foamed concrete, this pouring device comprises a plurality of auxiliary agent tanks 1, water tank 2, mixing pouring tank 3, workbench 4; The top of described auxiliary agent tank 1 is provided with Auxiliary agent feed port 11, the bottom is provided with auxiliary agent discharge port 12, and the auxiliary agent discharge port 12 is connected with mixing pouring tank 3; The top of the water tank 2 is provided with a water inlet 21, and the bottom is provided with a water outlet 22, the water outlet 22 is connected with the mixing pouring tank 3; the top of the mixing pouring tank 3 is provided with a dry material inlet 31, the bottom is provided with a pouring port 32, and the inside is provided with a stirring paddle 33; the stirring paddle 33 Connect with power unit 6 to provide power.

[0036] The auxiliary agent tank 1 includes a quick-setting enhancer tank 1a, a stabilizer tank 1b and a foam...

Embodiment 2

[0042] Such as Figure 1-4 As shown, a pouring device for preparing foamed concrete includes a plurality of auxiliary tanks 1, a water tank 2, a mixing pouring tank 3, a workbench 4, and a computer 5; the top of the auxiliary tank 1 is provided with an auxiliary The feed port 11 is provided with an auxiliary agent outlet 12 at the bottom, and the auxiliary agent outlet 12 is connected with the mixing pouring tank 3; the auxiliary agent tank 1 is also provided with a first weighing device 14 outside the first weighing device. One end of 14 is connected to the support of the workbench 4 directly above it, and the other end is connected to the auxiliary agent tank 1 through the connecting part. The first weighing device 14 is provided with a weight sensor inside; the auxiliary agent outlet 12 is also provided with an auxiliary agent tank Pneumatic control valve 13; the top of the water tank 2 is provided with a water inlet 21, and the bottom is provided with a water outlet 22, an...

Embodiment 3

[0053] The difference between this embodiment and embodiment 2 is that: the inner wall of the pouring tank 3 is also provided with a detachable liner. The stirring paddle 33 is a frame type stirring paddle.

[0054] The feature of device of the present invention is:

[0055] 1) This pouring device is equipped with multiple auxiliary agent tanks and water tanks, which can be added sequentially according to the order in which the additives are added;

[0056] 2) The weighing device can monitor the weight change of the mixing tank at any time, and control the amount of materials added at any time. The weighing is accurate and fast, and can realize the precise control of the amount of materials added. The whole process is controlled by the computer, saving manpower and time;

[0057] 3) A temperature sensor is provided on the stirring paddle, and the temperature sensor collects temperature information and sends the temperature signal to the computer for data processing, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com