Scraping wall type dry powder mixing device

A dry powder mixing and wall scraping technology, used in mixers, mixing methods, solid and solid mixing, etc., can solve the problems of dry powder hanging on the wall, uneven mixing, loss of raw materials, etc., to achieve uniform and fine mixing, saving manpower and Time, weighing and accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

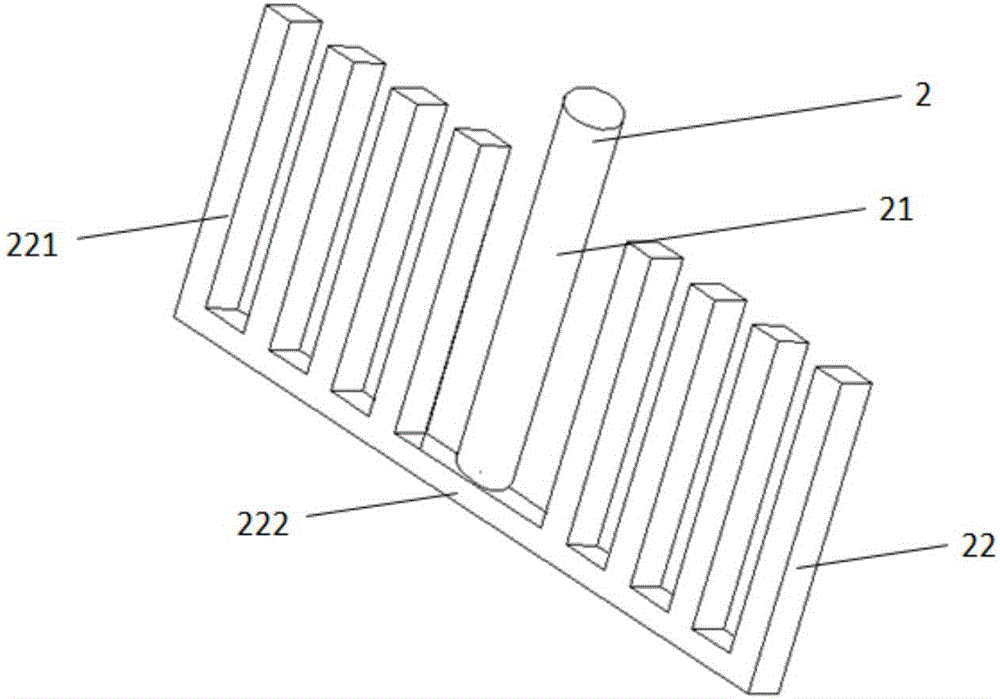

[0036] Such as figure 1 As shown, a scraping type dry powder mixing device, the stirring paddle includes a stirring shaft 21 and a stirring paddle 22; the stirring paddle 22 includes a paddle handle 221 and n paddle teeth 222 arranged in parallel, wherein n is not An even number less than 6; the blade teeth 222 are vertically connected to the blade handle 221; the blade handle 221 and a plurality of blade teeth 222 form a comb shape; the stirring shaft 21 is connected to the middle of the blade handle 221.

[0037] The blade teeth 222 are arranged symmetrically on the blade handle 221 with the stirring shaft 21 as a symmetrical axis.

[0038] The blade handle 221 and the blade teeth 222 are integrally formed.

[0039] Both the petiole 221 and the blade teeth 222 are cuboid or cylinder.

Embodiment 2

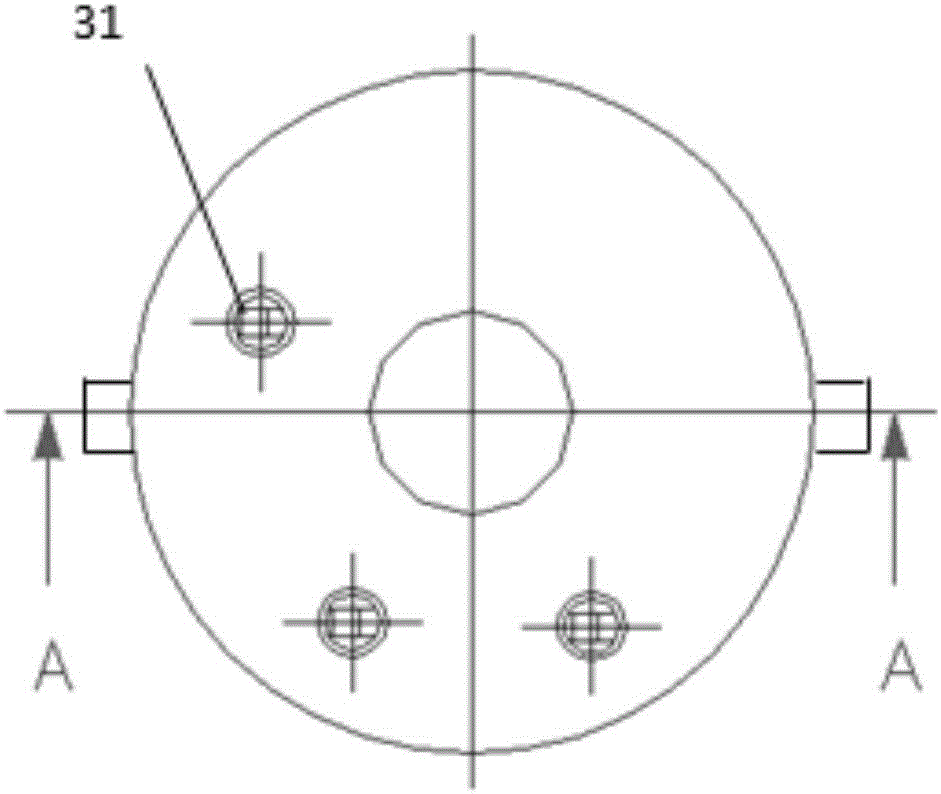

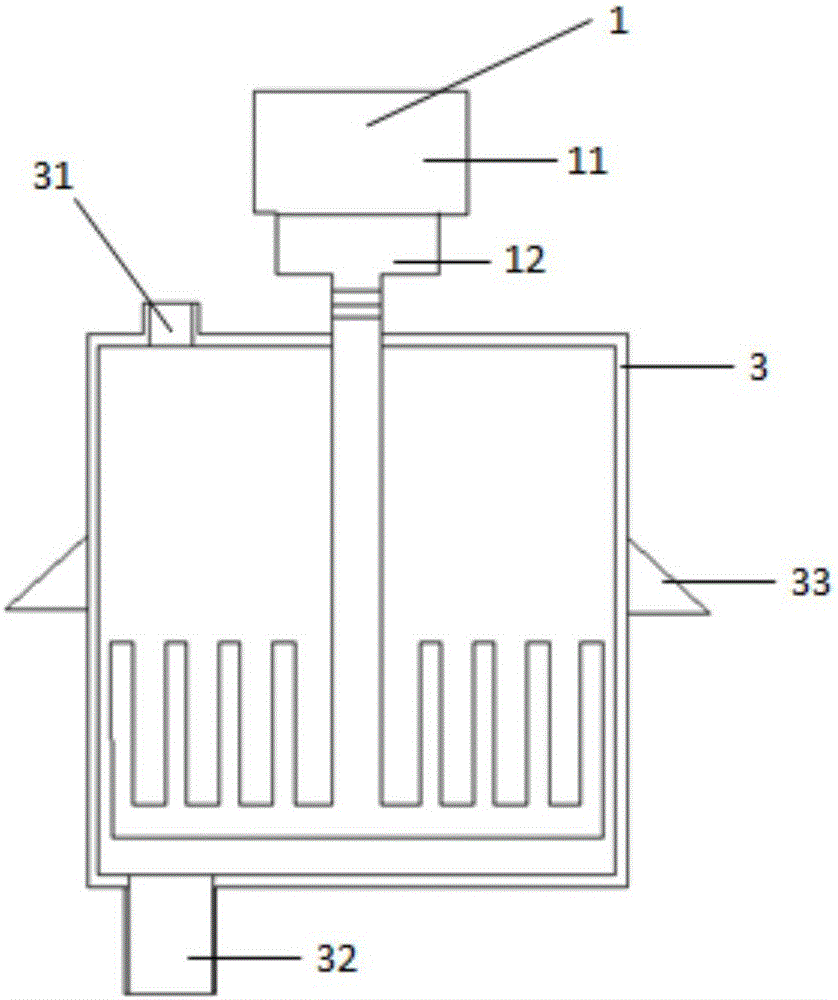

[0041] Such as Figure 1-3 As shown, this embodiment provides a wall-scraping dry powder mixing device, which includes a power unit 1, a stirring paddle 2 located inside a tank body 3, and a tank body 3; the power unit 1 includes a motor 11 and a reducer 12. The motor 11 is connected to the reducer 12; the stirring paddle 2 includes a stirring shaft 21 and a stirring paddle 22, wherein: the stirring paddle 22 includes a paddle handle 221 and n paddle teeth 222 arranged in parallel, wherein n It is an even number not less than 6; the paddle teeth 222 are vertically connected to the paddle handle 221; the paddle handle 221 and a plurality of paddle teeth 222 form a comb shape; the stirring shaft 21 is connected to the middle part of the blade handle 221; one end of the stirring shaft 21 is connected to the reducer 12 The other end is connected to the middle part of the petiole 221; the stirring shaft 21 passes through the top of the tank body 3 and is fixedly connected to the to...

Embodiment 3

[0043] Such as Figure 1-4As shown, in order to solve the problem of accurately controlling the amount of material added, this embodiment also provides a scraping type dry powder mixing device containing the scraping type stirring paddle of embodiment 1, the mixing device includes a power unit 1, a stirring paddle 2 , the tank body 3, the weighing device 4 and the computer 5 located outside the tank body 3; the power unit 1 includes a motor 11 and a speed reducer 12, and the motor 11 is connected with the speed reducer 12; the stirring paddle 2 is located inside the tank body 3; the stirring shaft 21 One end is connected with the reducer 12, and the other end is connected with the middle part of the petiole 221; the stirring shaft 21 passes through the top of the tank body 3 and is fixedly connected to the top of the tank body 3; the top of the tank body 3 is also provided with a feed port 31, The bottom is provided with a discharge port 32; the discharge port 32 is arranged a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com