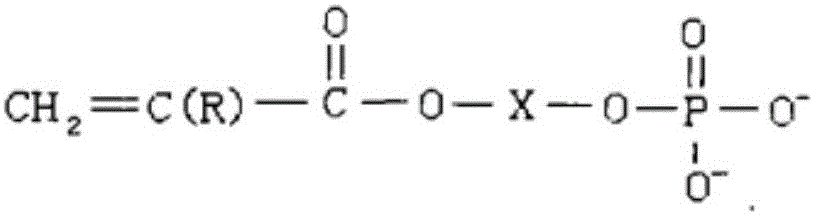

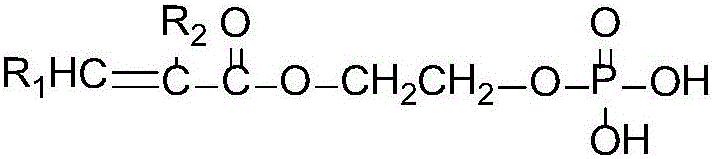

Unsaturated phosphate ester for producing high-slump-retaining type polycarboxylic acid water reducing agent

A polycarboxylic acid-based, unsaturated technology, applied in the direction of phosphorus organic compounds, chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, etc., can solve the problems of low carboxyl content, poor effect of water reducing The slump ability can not achieve the best effect, etc., to achieve the effect of delaying the hydration process, good adaptability, and insensitivity to mud content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

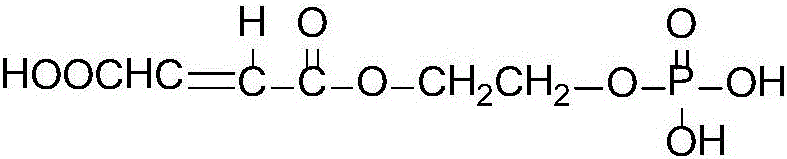

[0055] Prepare unsaturated phosphoric acid ester according to following raw material amount and process, specifically:

[0056] (1) Esterification reaction: To ensure that there is no residual water in the reaction kettle, first pass nitrogen into the kettle for 5 minutes, add 15 g of ethylene glycol, and then put 23.7 g of maleic anhydride into the bottom of the kettle, seal the mouth of the kettle, open and stir, and the temperature After keeping at 55°C for 1 hour, turn on the condensed water to lower the temperature, add 9.7 g of deionized water, stir for 5 minutes, and beat the material, turn off the nitrogen and circulating water to obtain ethylene glycol maleate;

[0057] (2) Phosphorylation reaction: Slowly add 42.3 g of the prepared ethylene glycol maleate into the reaction kettle, stir with the stirrer at low speed, and control the temperature of the water bath at 40°C; Add a total of 15g of phosphorus pentoxide in 4 batches, and each addition needs an interval of 15...

Embodiment 2

[0062] Prepare phosphoric acid-based high-slump polycarboxylate-based high-performance water-reducers according to the following raw material quantities and processes, specifically:

[0063] (1) Esterification reaction: To ensure that there is no residual water in the reaction kettle, first pass nitrogen into the kettle for 5 minutes, add 18g of ethylene glycol, and then put 39g of itaconic anhydride into the bottom of the kettle, seal the mouth of the kettle, open and stir, and keep the temperature After keeping at 60°C for 2 hours, turn on the condensed water to lower the temperature, add 10.1 g of deionized water, stir for 5 minutes, then beat the material, turn off the nitrogen, and circulate water to obtain ethylene glycol itaconate.

[0064] (2) Phosphorylation reaction: slowly add 28.8 g of the prepared ethylene glycol itaconate into the reaction kettle, stir with a stirrer at a low speed, and control the temperature of the water bath at 43°C. After the reactants are ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com