Patents

Literature

79results about How to "Lower working height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

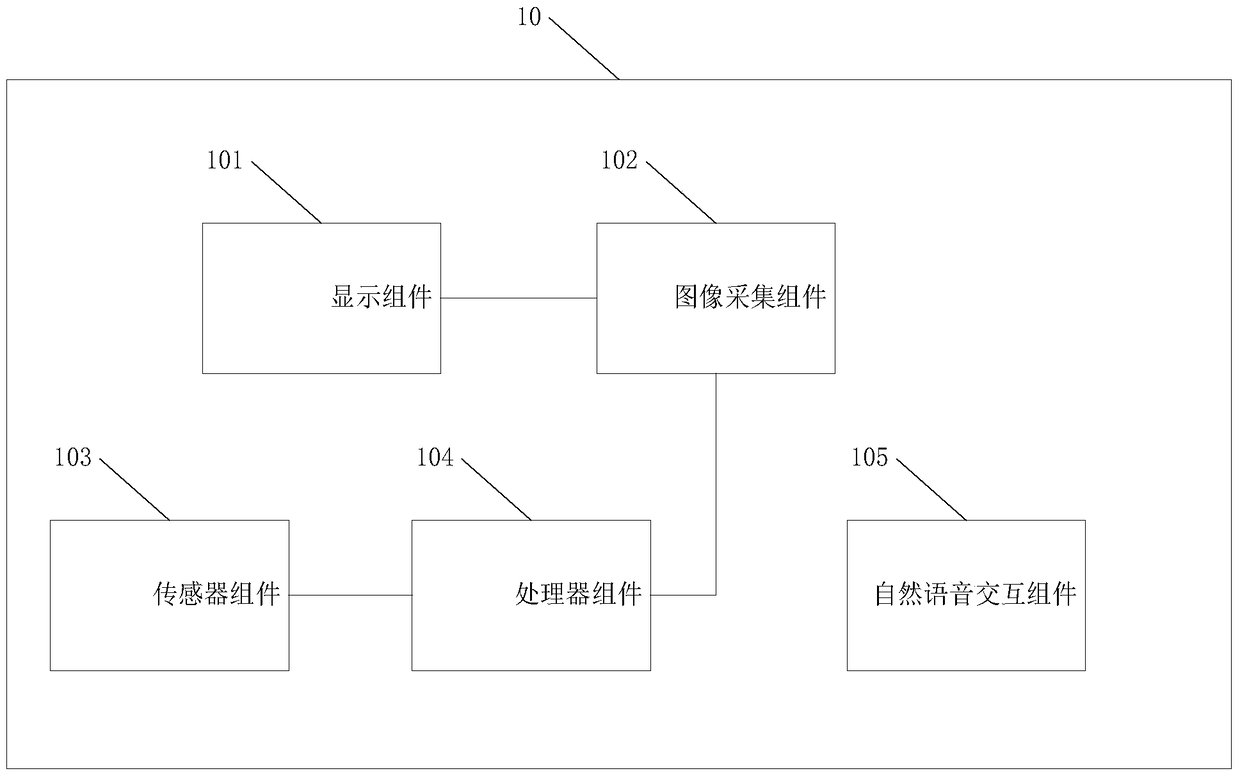

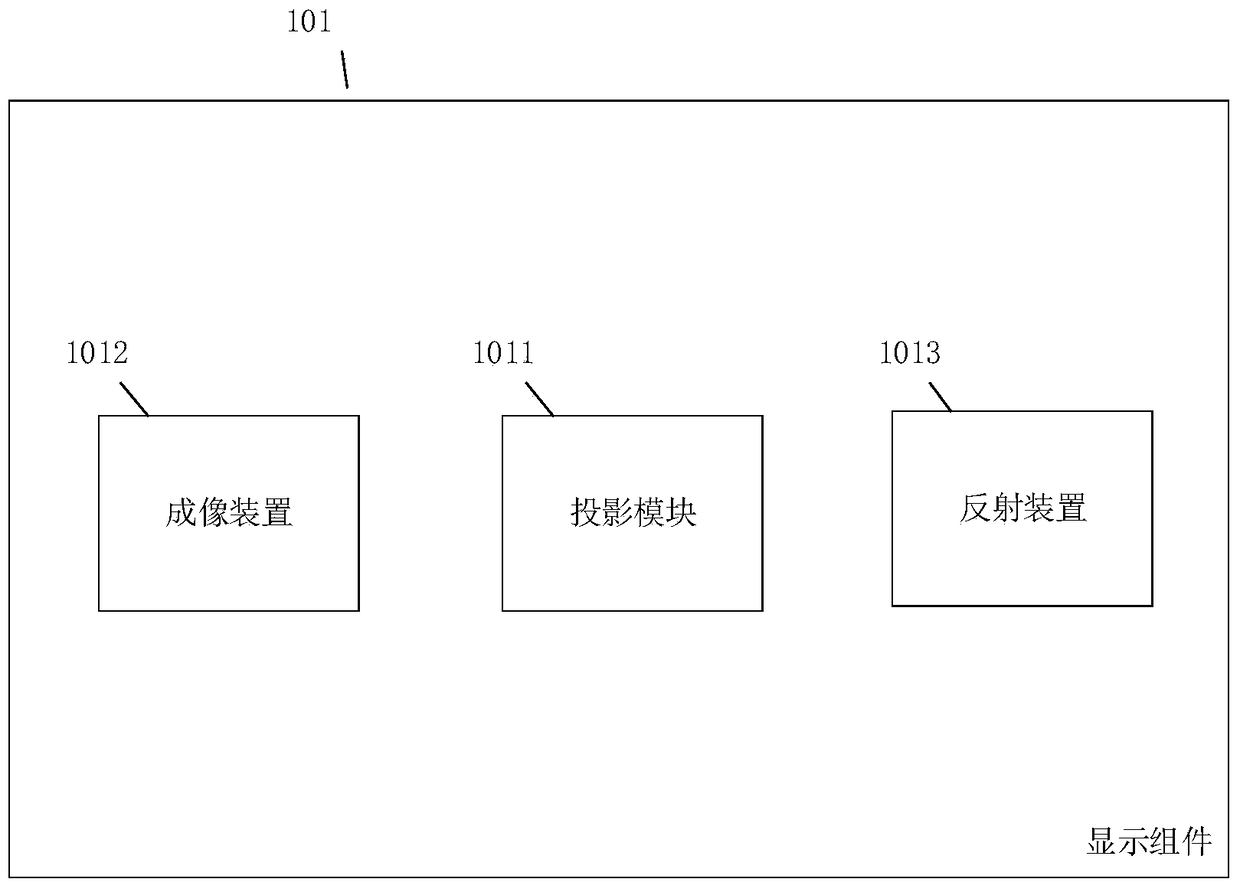

Intelligent head-up display system

ActiveCN105527710ARealize multiple rounds of voice interaction functionsAchieve normal displayInput/output for user-computer interactionGraph readingHead-up displayInteraction control

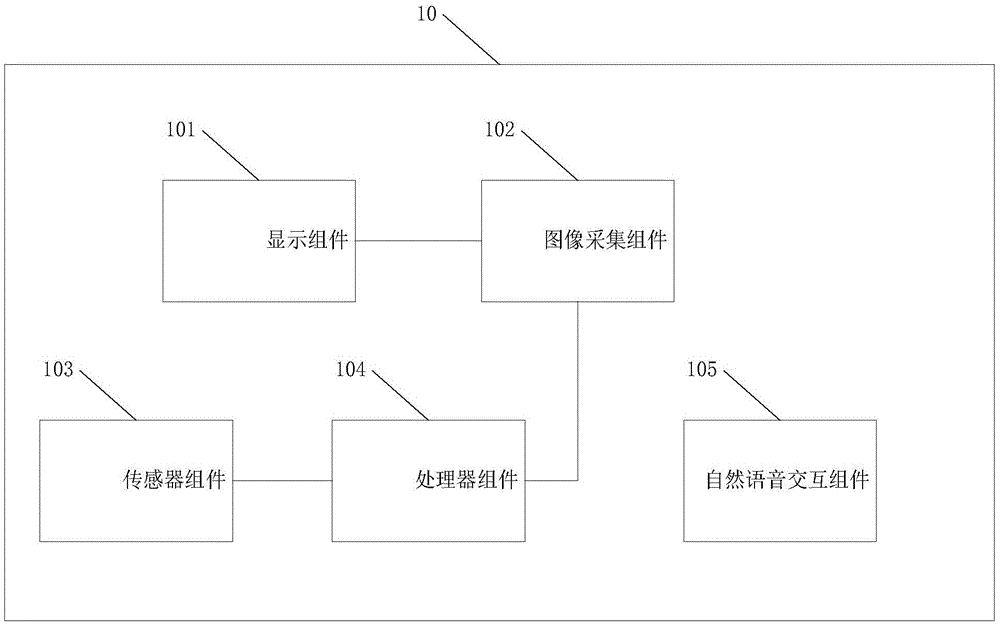

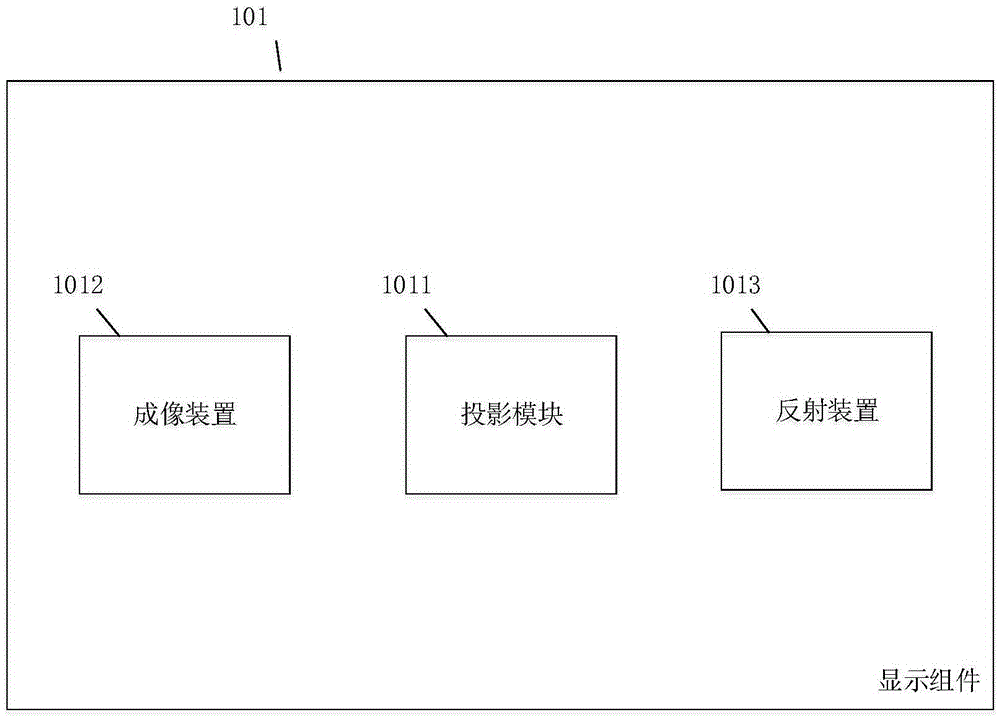

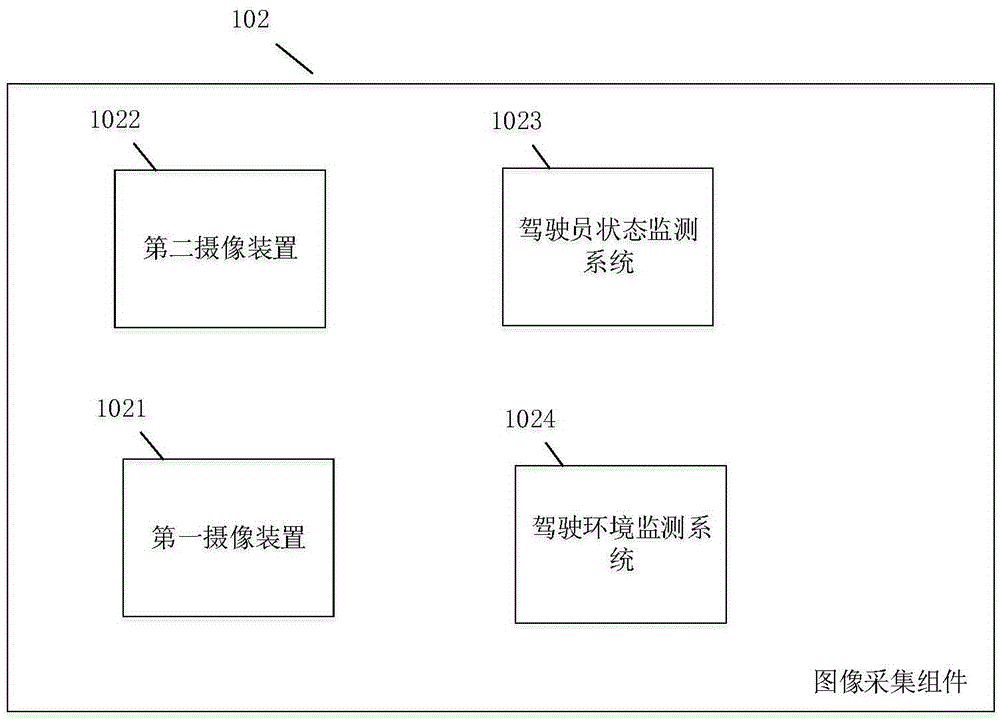

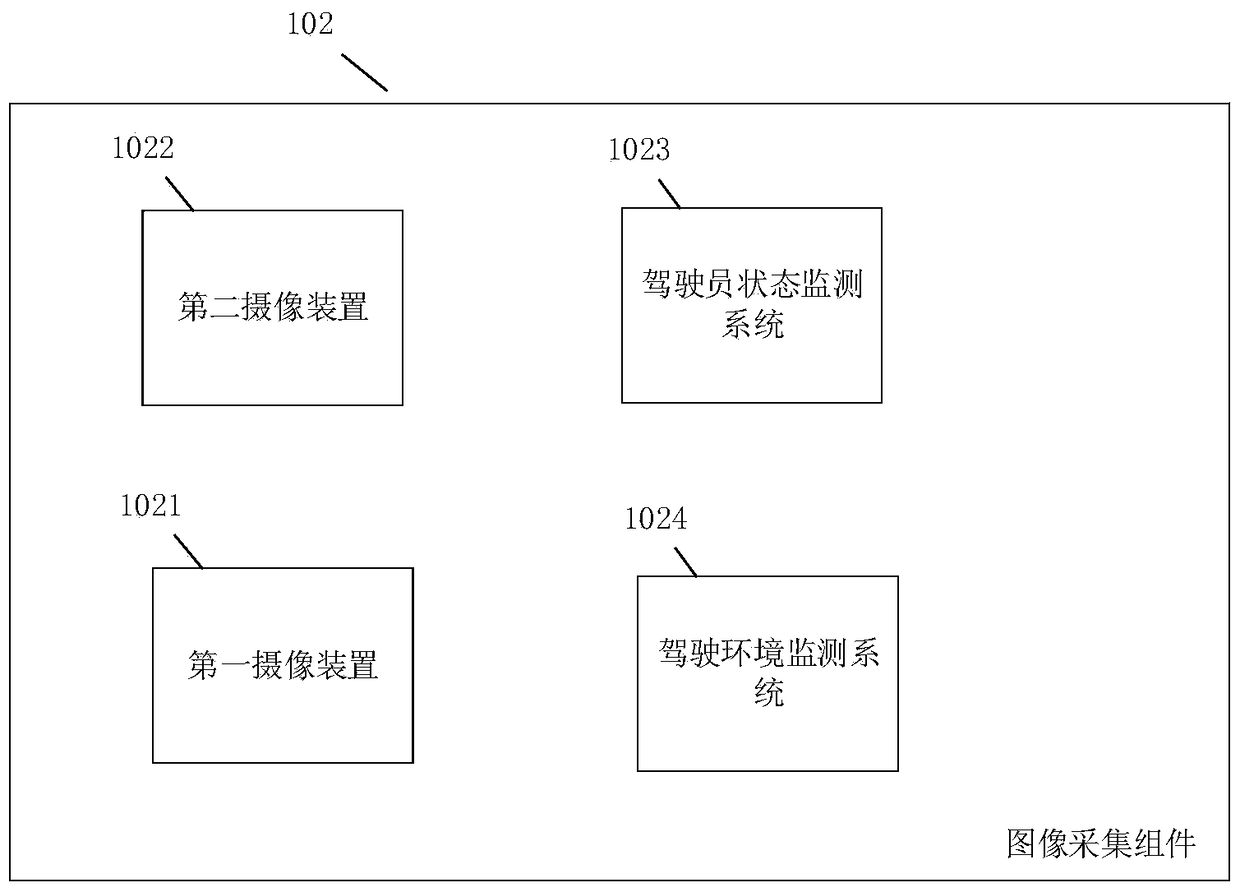

The invention discloses an intelligent head-up display system, which comprises a display assembly, an image acquisition assembly, a natural voice interaction assembly, a sensor assembly and a processor assembly. The display assembly is connected with the image acquisition assembly; the sensor assembly is connected with the processor assembly; and the image acquisition assembly is connected with the processor assembly. Compared with a convention head-up display system, the intelligent head-up display system can support more interaction control and can realize voice scheme interaction adoption, and meanwhile, can install various third-party applications to expand and enrich functions; furthermore, the intelligent head-up display system, carried with various sensors, can connect external equipment; and besides, the intelligent head-up display system has a camera module, which faces to the inner portion of a vehicle, so that the behavior and state of a driver can be identified, and safe driving reminding function and interaction control function can be realized.

Owner:BEIJING ILEJA TECH CO LTD

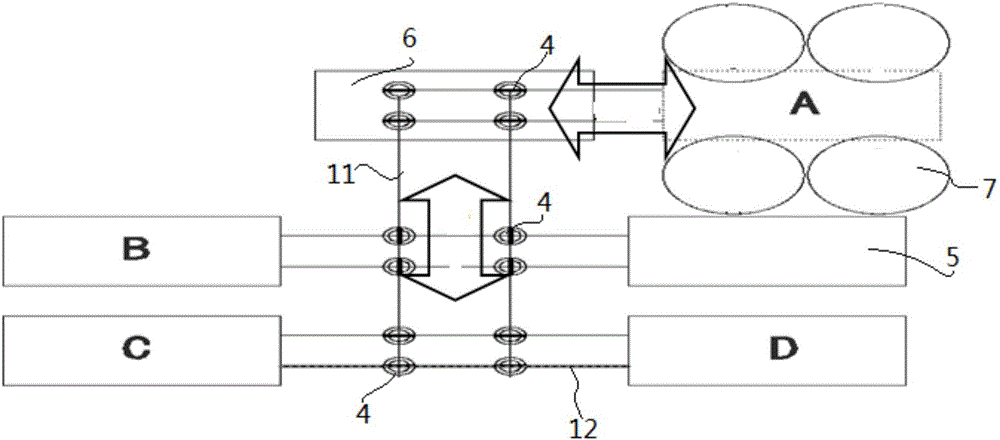

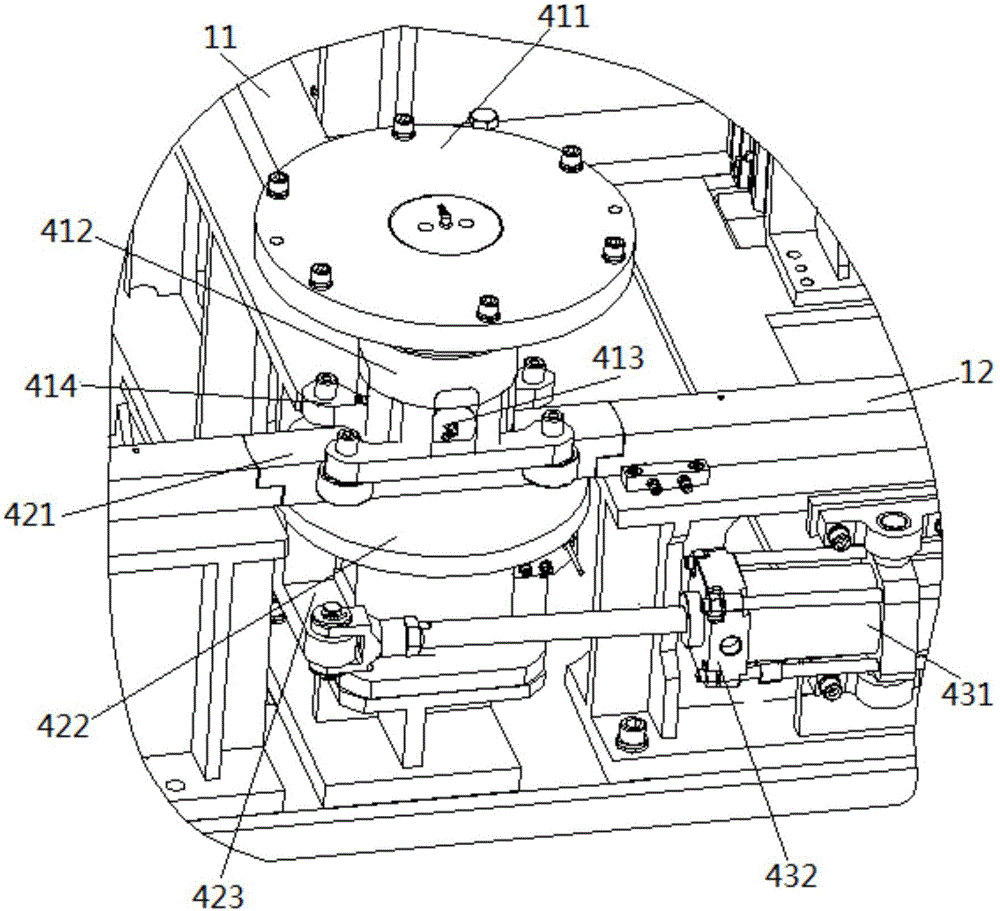

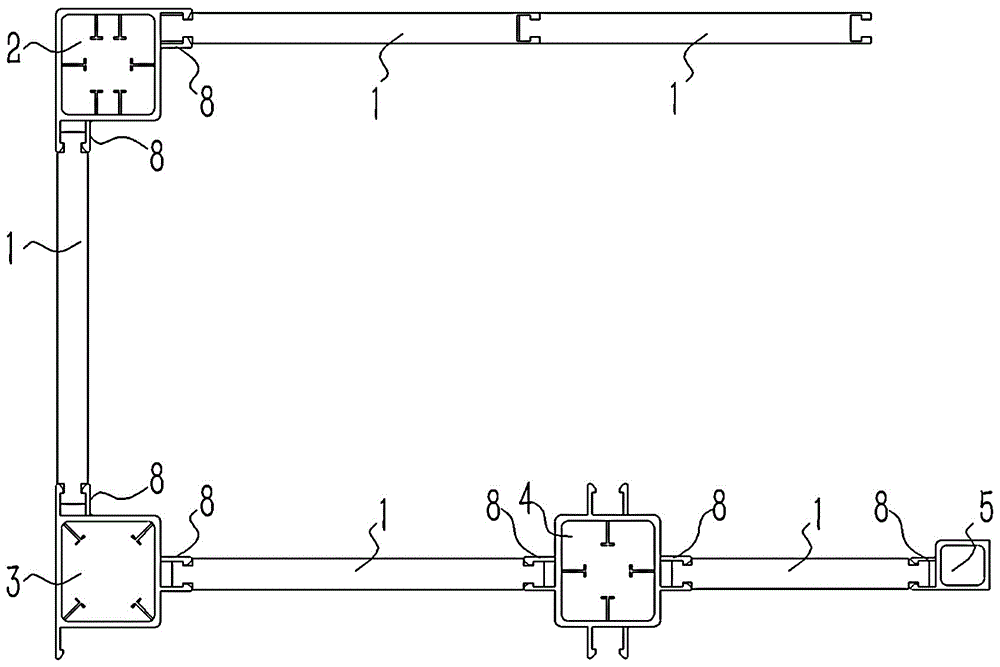

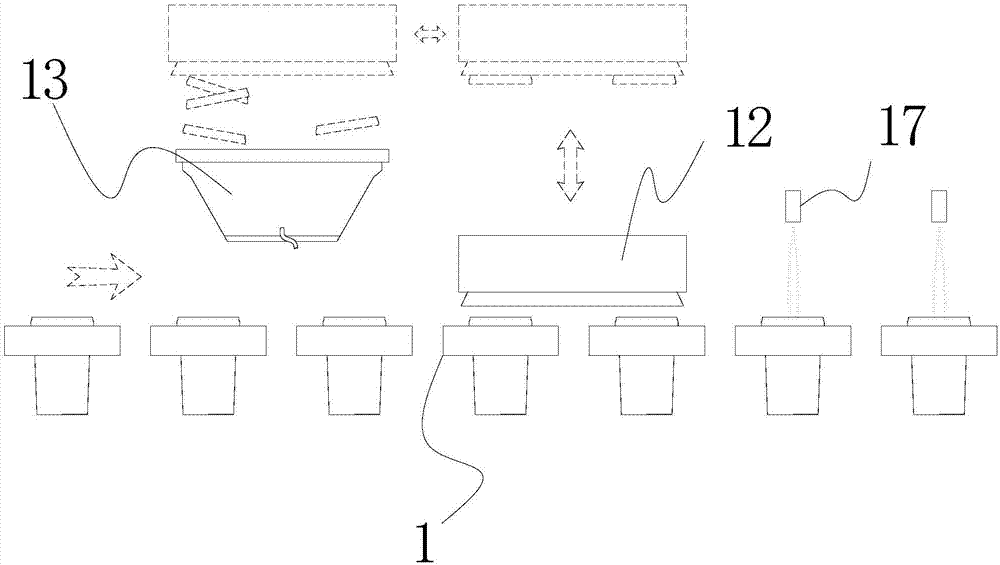

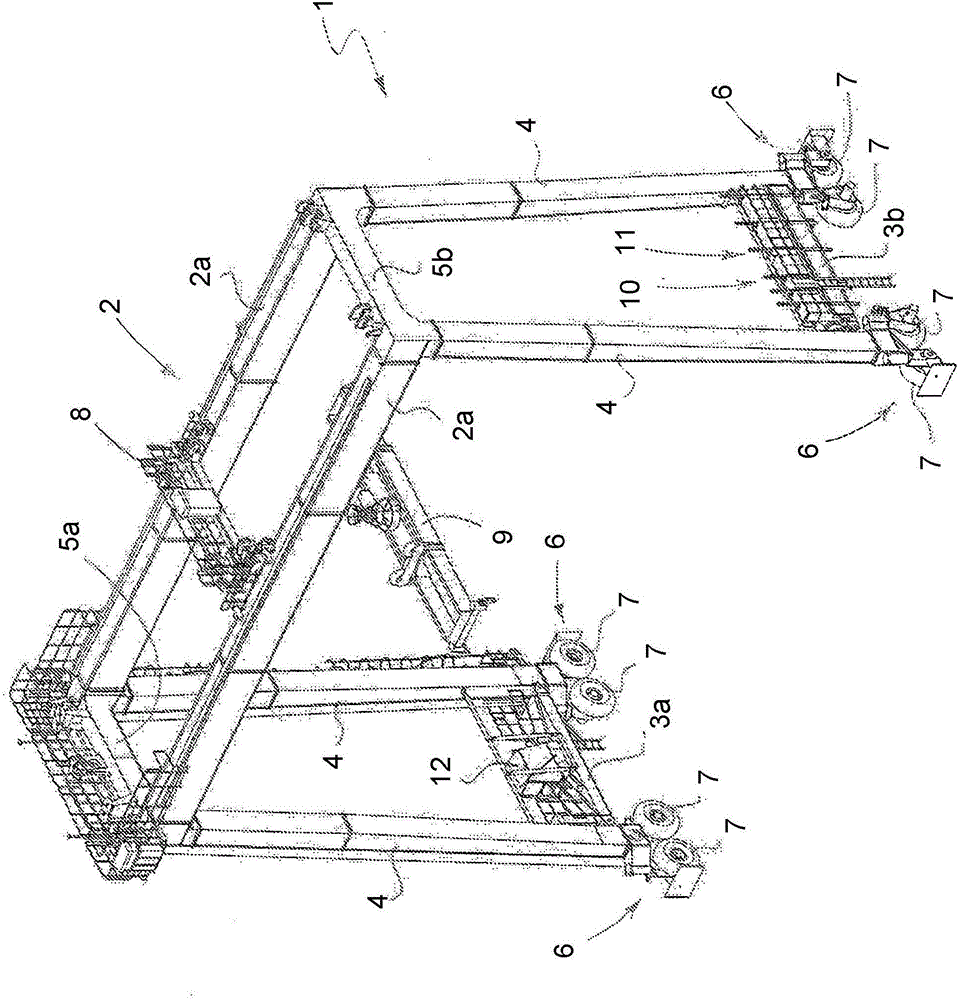

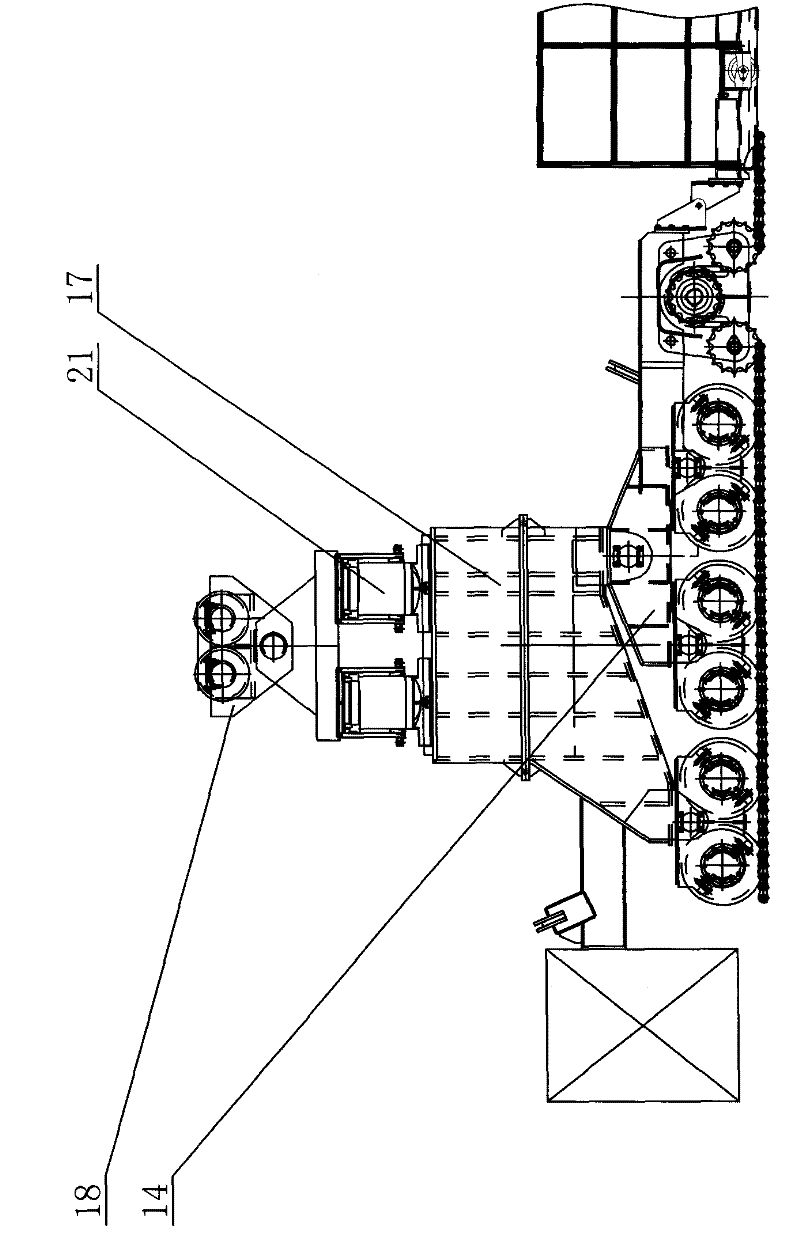

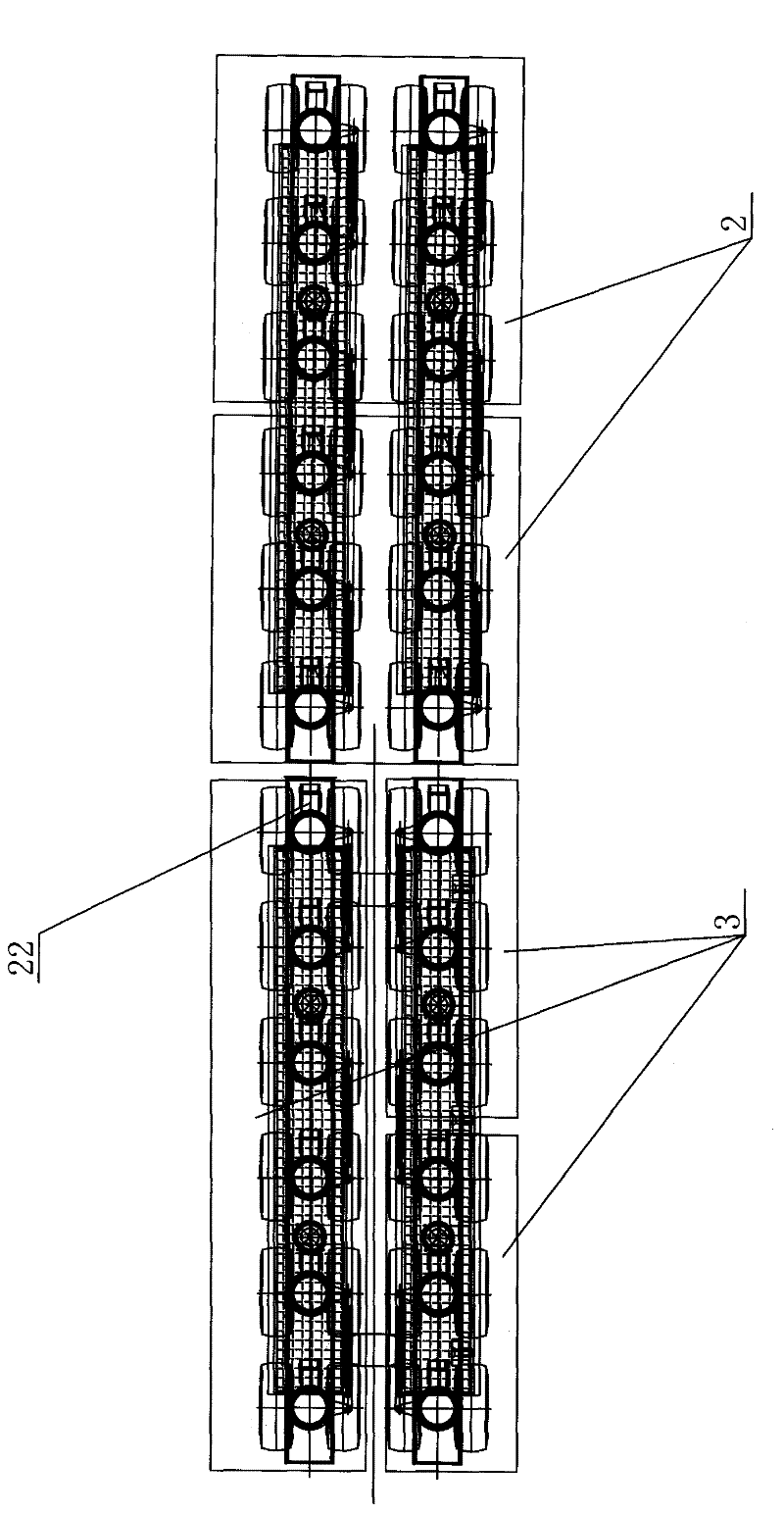

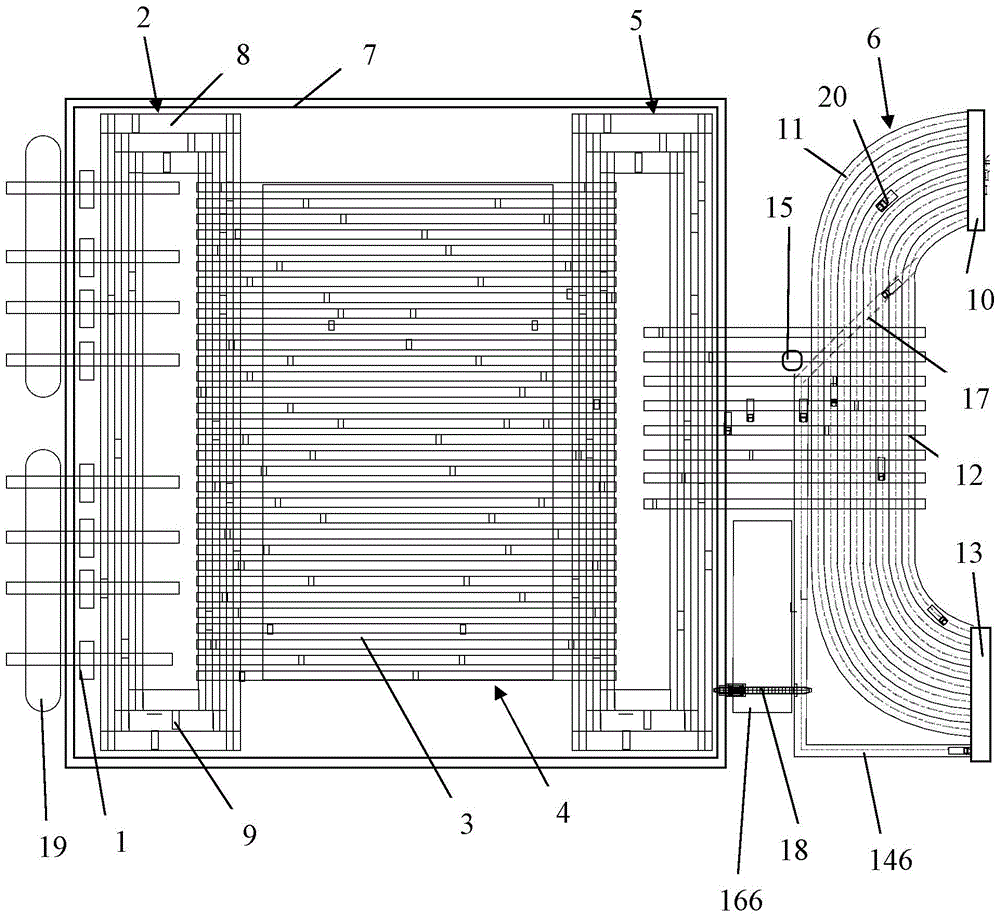

Loading and unloading system for distribution center type automated container terminal

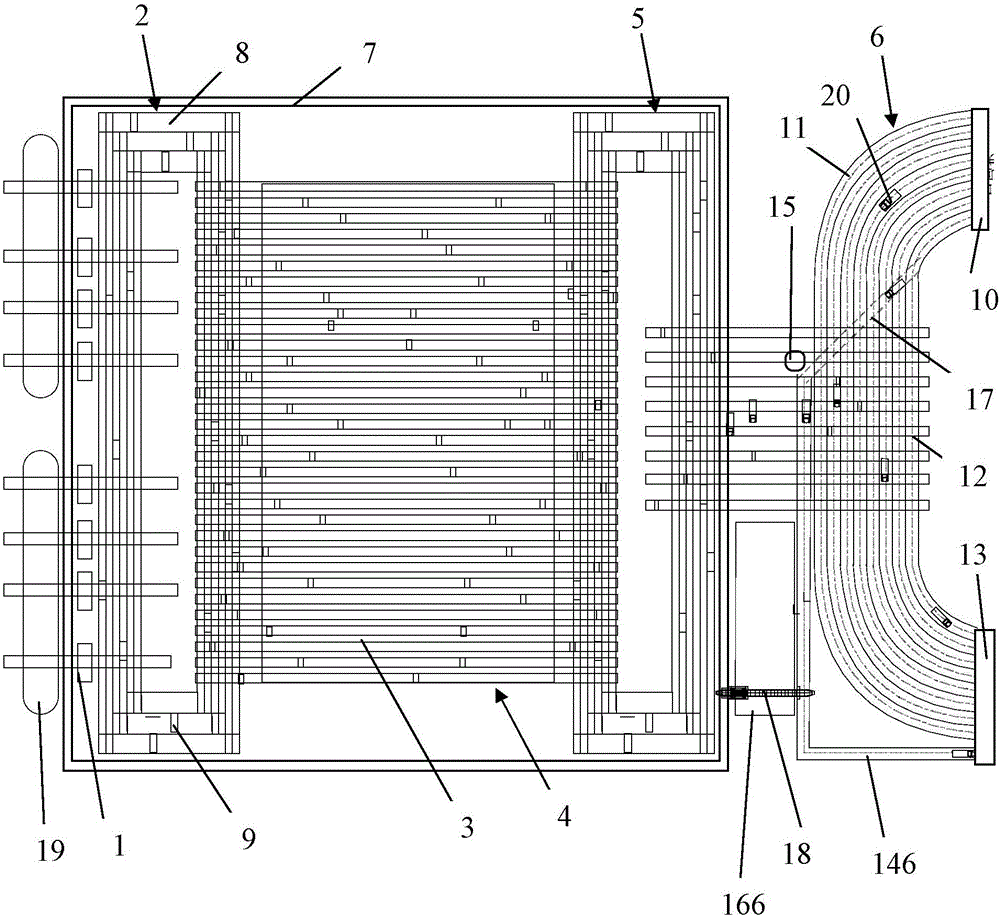

The invention relates to a loading and unloading system for a distribution center type automated container terminal. The loading and unloading system comprises a plurality of quay cranes, a nearshore multipath rectangular-ambulatory-plane automatic transportation system, an elevated container automatic loading and unloading system, a storage yard, a container evacuating port side multipath rectangular-ambulatory-plane automatic transportation system, a container evacuating port transportation system, an annular special container channel and a control system. Compared with the scheme of an existing automated container terminal, the loading and unloading system for the distribution center type automated container terminal is advantaged in that the loading and unloading system is creative and unique, and is high in production efficiency, safety, automation degree and stability, and is simple in structure, simple to control and complete in scheme.

Owner:TIANJIN PORT CONTAINER TERMINAL

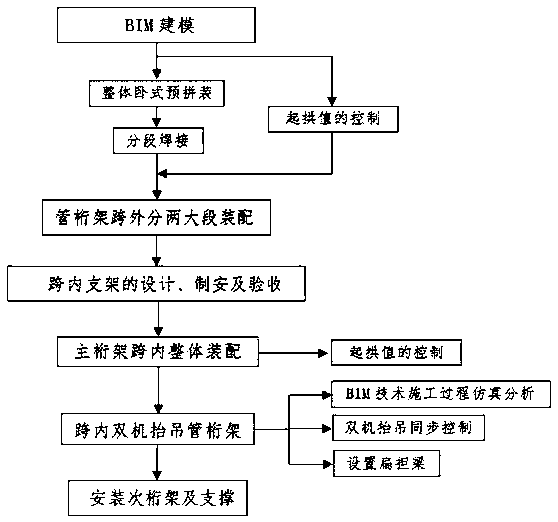

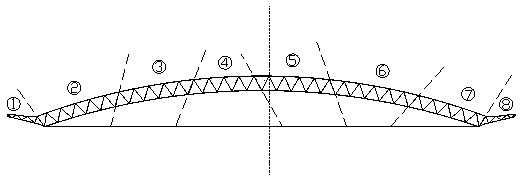

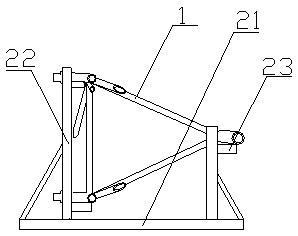

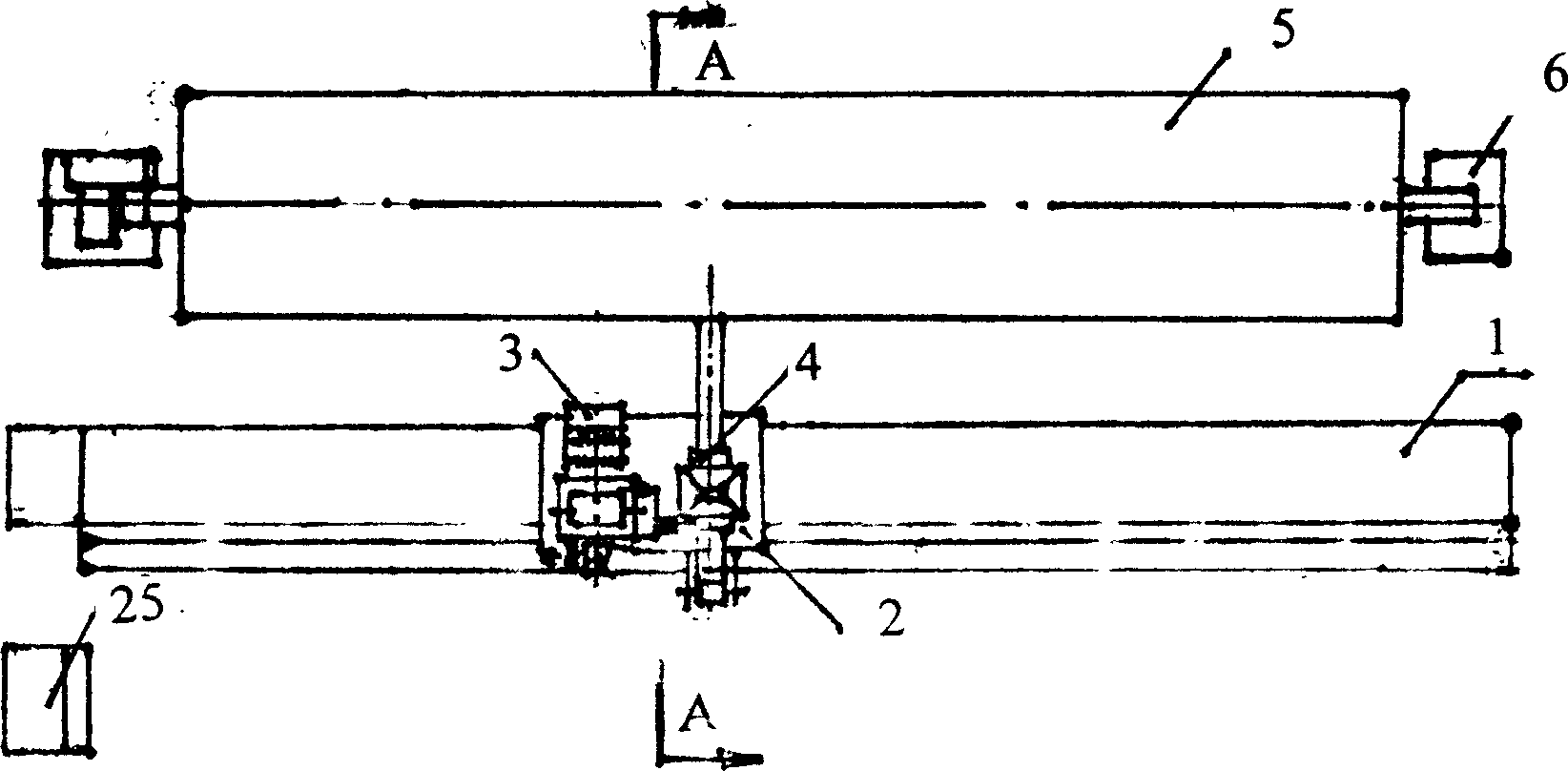

Rapid construction method of arched pipe truss

InactiveCN110259145ASee the connectionAccurately determine the center of gravityGeometric CADBuilding material handlingRisk strokeRapid construction

The invention discloses a rapid construction method of an arched pipe truss. The rapid construction method comprises the following steps that (1) a BIM structural model of the arched pipe truss is established; (2) horizontal integrated pre-assembly and segment welding are performed in a factory for the pipe truss to form truss bodies to be transport to a site; (3) the truss bodies are assembled to form two main trusses; (4) in-span brackets are installed; (5) the two main trusses are lifted and welded to connect the two main trusses into the pipe truss; (6) the assembled pipe truss is lifted in place to complete installation of the pipe truss; (7) the steps 2-6 are repeated to form two pipe trusses, a secondary truss and a roof support are installed, so that the installed part forms a whole force system; and (8) the steps 2-7 are repeated until all pipe trusses are installed. According to the rapid construction method of the arched pipe truss, in-span vertical one-time splicing rapid construction of the arched pipe truss can be completed in the case of poor on-site site conditions, the risks of working at height are reduced, the construction period is ensured, the construction cost is saved, and multiple purposes are achieved at one stroke.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

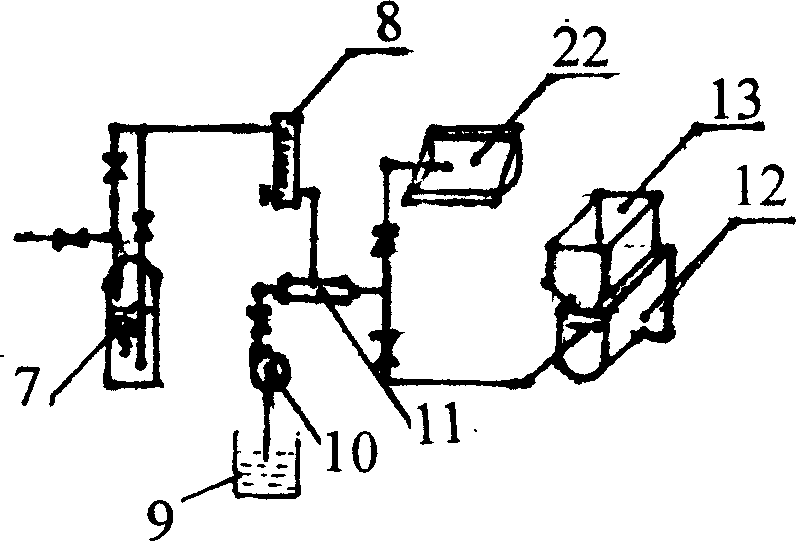

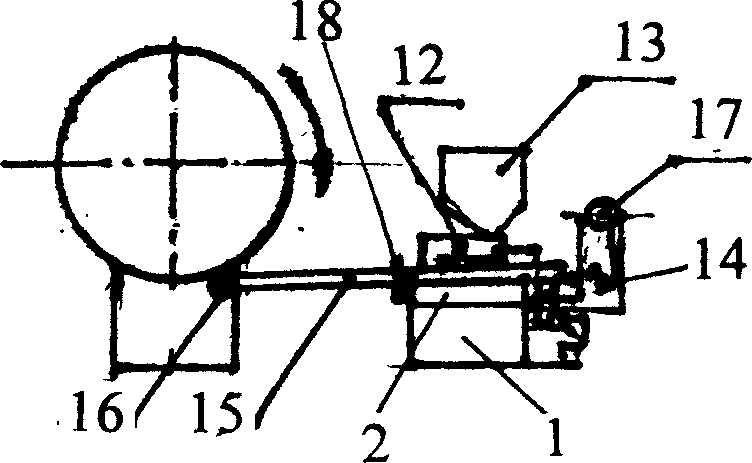

Making apparatus and method for wet type sanding and enwinding glass fibre reinforced plastic pipe from underside

The present invention relates to an equipment for making GFRP pipe by adopting wet sand-adding lower-winding process and method thereof. Said equipment is mainly formed from working table, running carriage, winding system, sand-adding system, mould and mould-supporting frame. Said invention also provides their connection arrangement and working mode. Said invented winding and sand-adding processes can be implemented under the GFRP pipe, and adopts wet sand-adding process so as to reduce dust pollution, and can raise working efficiency.

Owner:天津市天联滨海复合材料有限公司

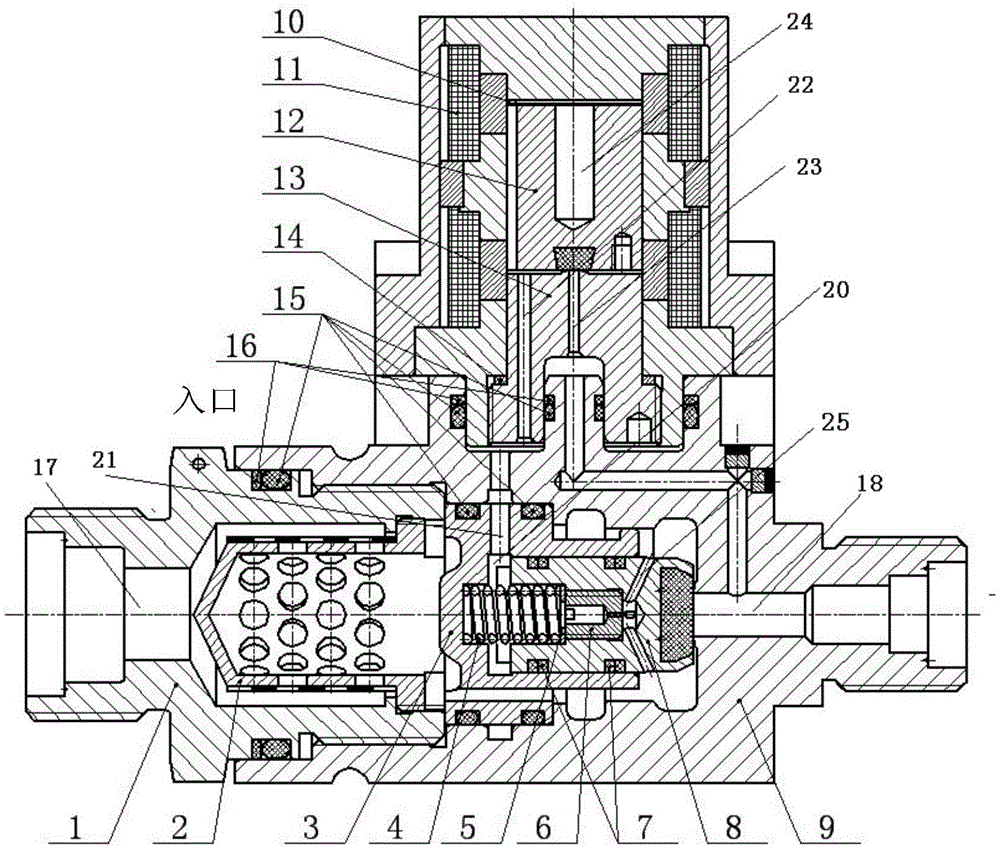

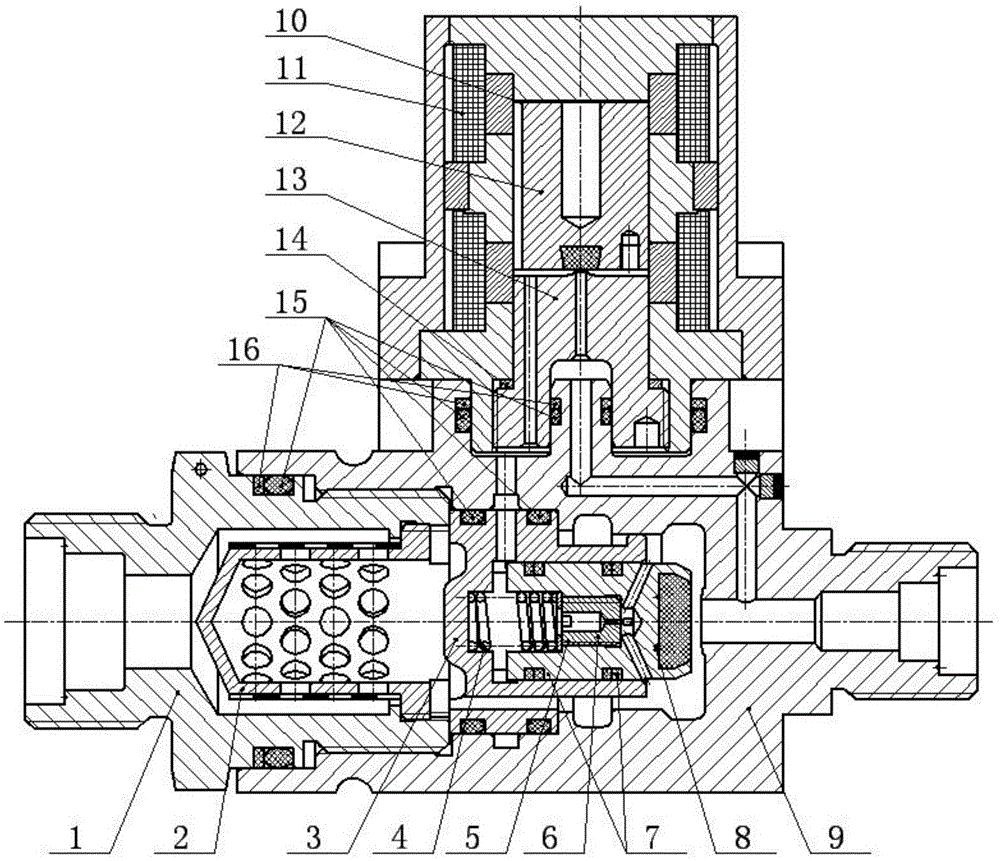

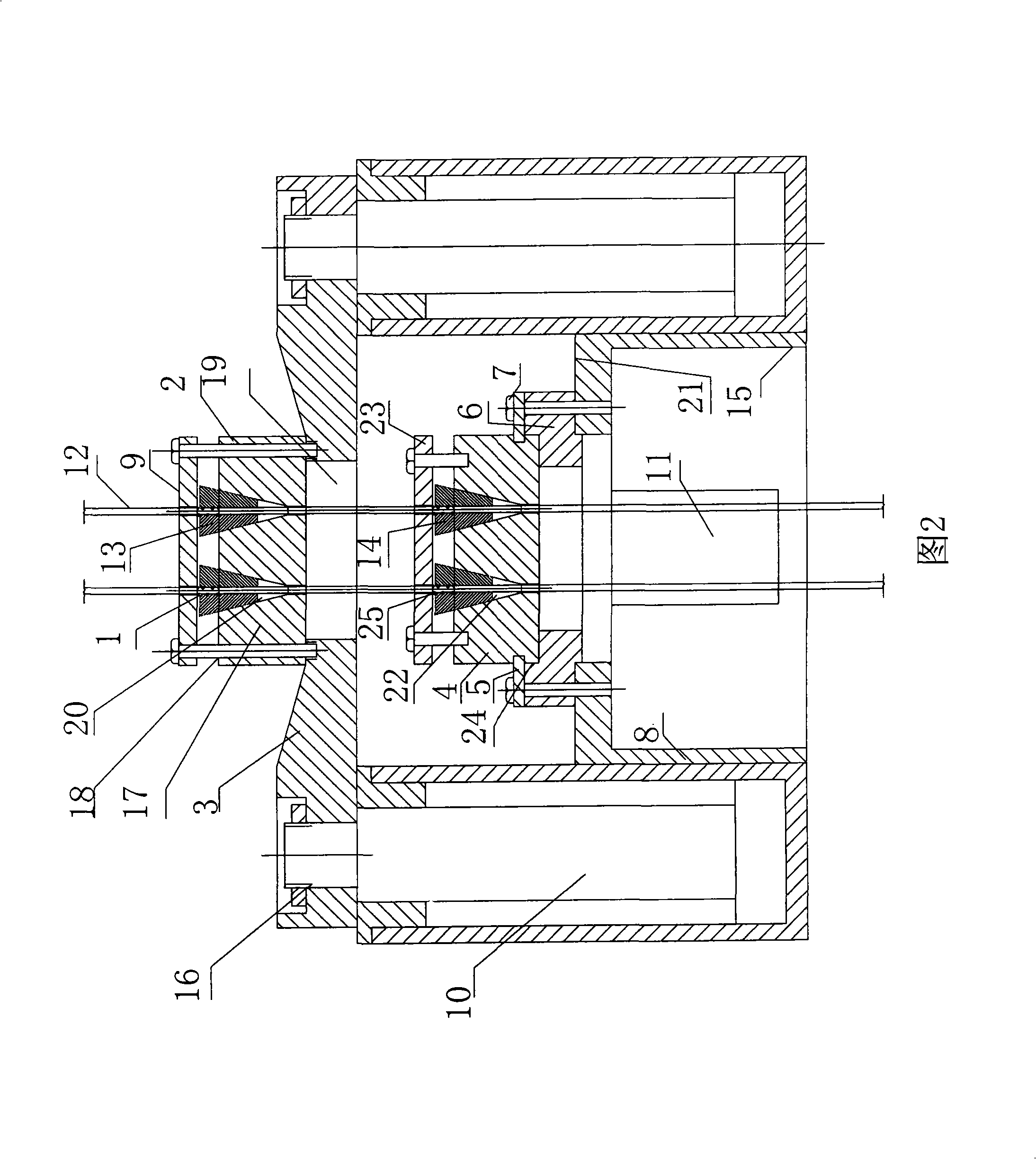

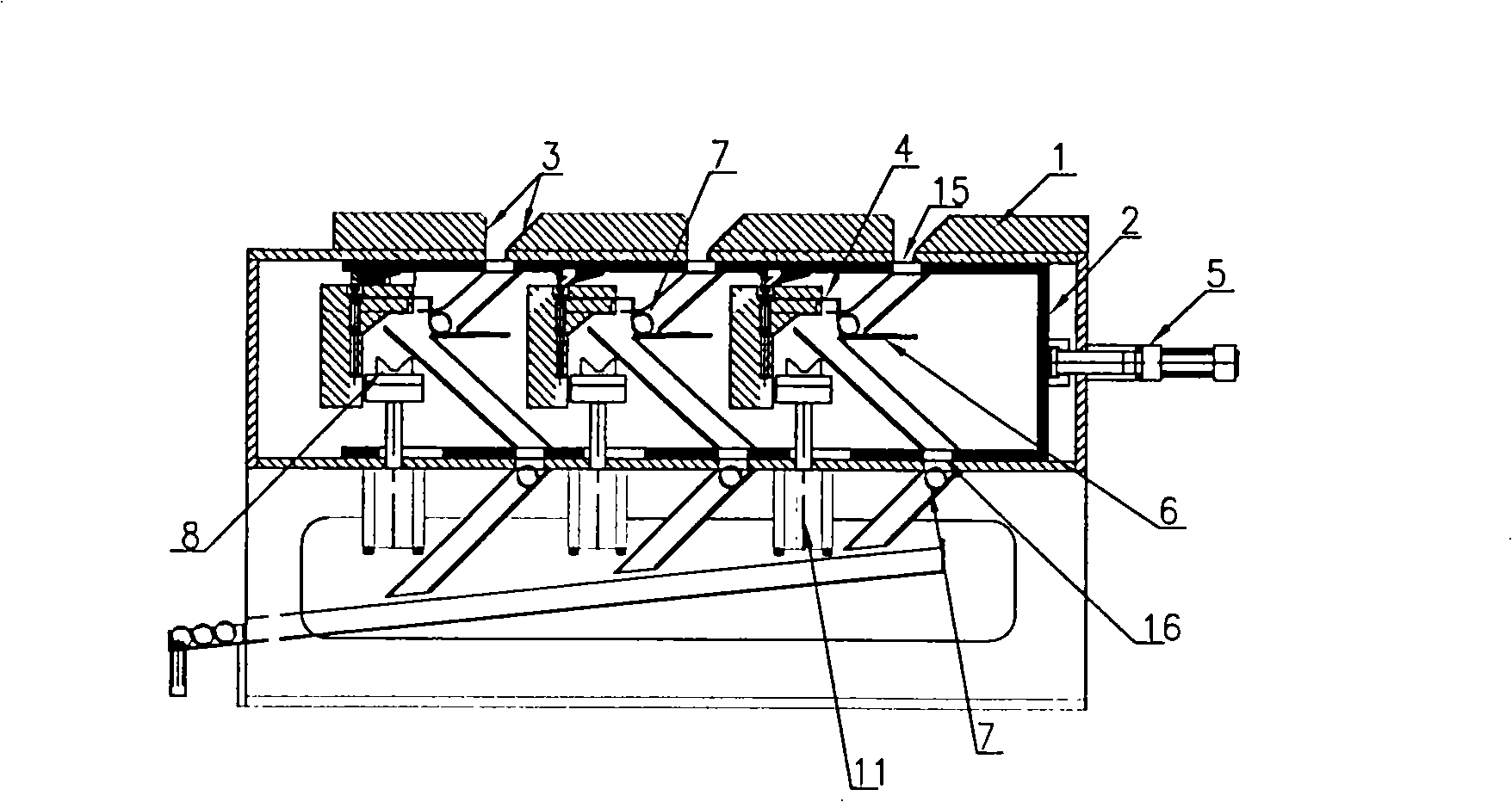

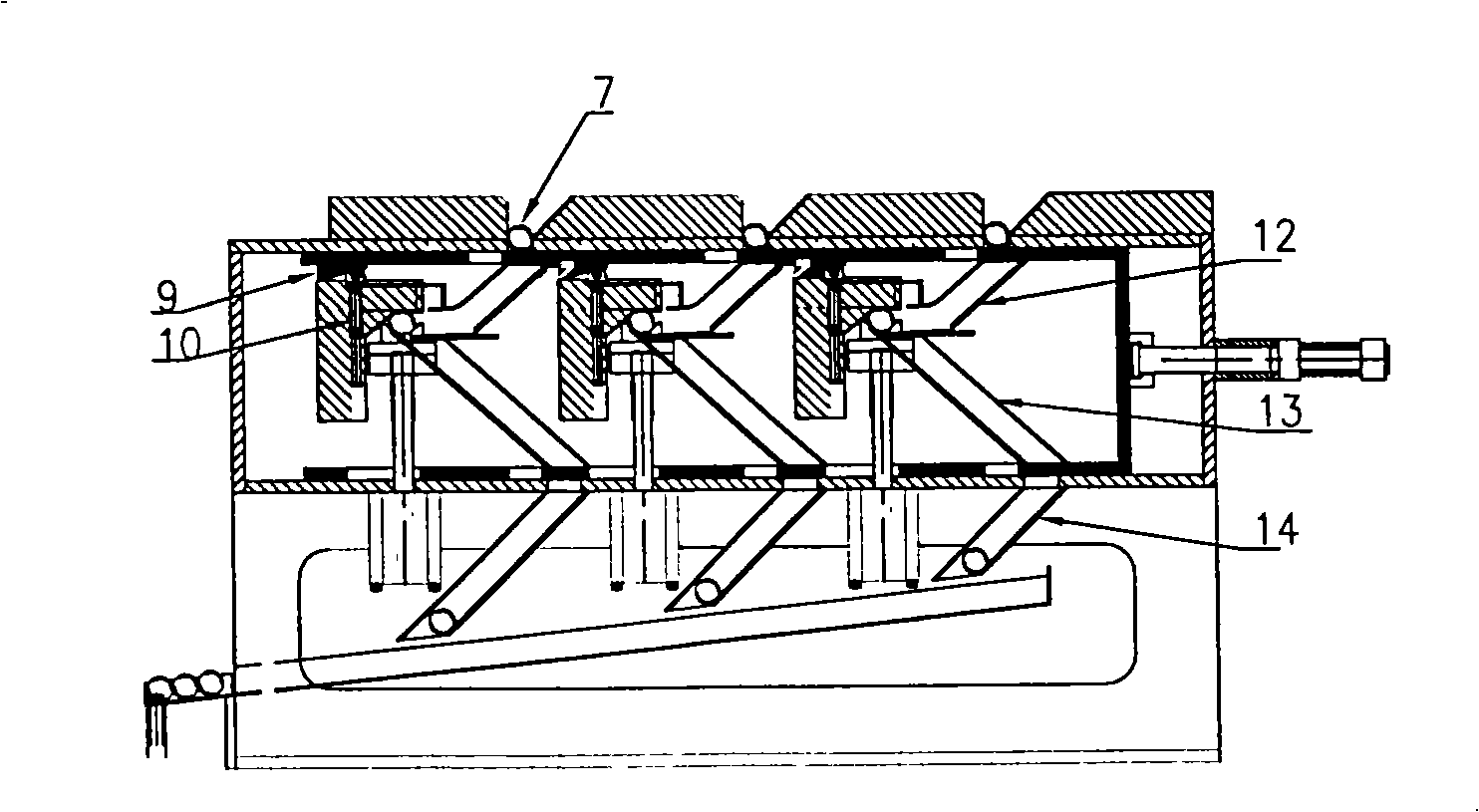

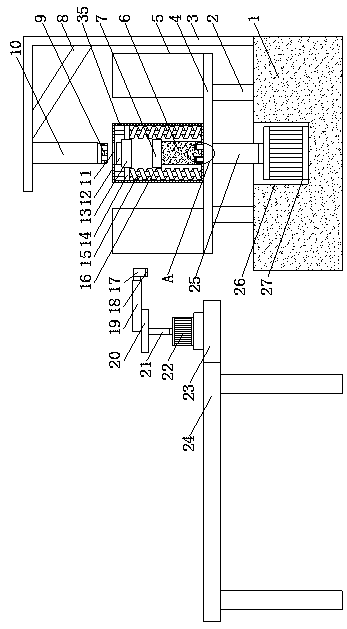

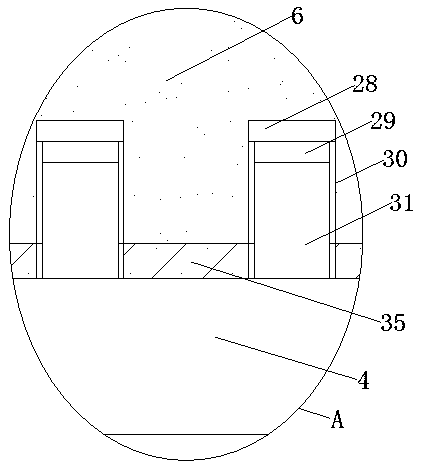

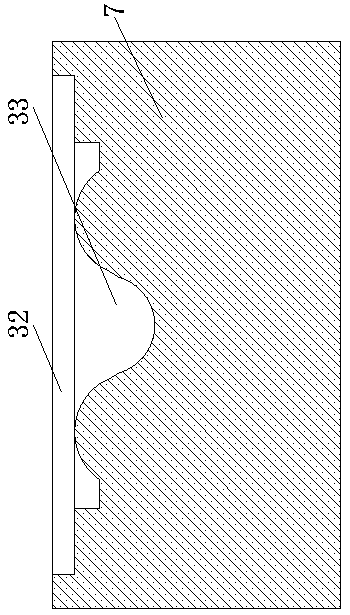

Built-in pilot operated solenoid valve

ActiveCN105570470ASimple structureSmall sizeOperating means/releasing devices for valvesEqualizing valvesCurrent limitingSolenoid valve

The invention discloses a built-in pilot operated solenoid valve with a self-locking function. The built-in pilot operated solenoid valve mainly consists of a primary valve body, a filter neck, a filter, a valve bush, a cylindrical spring, a spring force regulating pad, a current-limiting pin, current blocking rings, a primary valve element, a secondary valve coil assembly, a magnetism isolating pad, a secondary valve element and a secondary valve seat, wherein a secondary valve adopts a coil and permanent magnet combined drive source, has a bistable-state passive self-holding function, and power can be provided for state shifting by two coils. By virtue of matching between mounting force of the current-limiting pin and mounting force of the cylindrical spring, reliable action of a primary valve is realized. Under a small-flow working condition, a medium can flow to the downstream through a channel between the current-limiting pin and the secondary valve. A reverse sealing structure made of a metal-hard plastic can give consideration to gastight requirements of high-pressure and low-pressure working conditions. The product can be used gas and liquid-path switch valves with large-flow multi-action needs, and is especially suitable for a high-pressure medium. By virtue of interface adaptive improvement, the built-in pilot operated solenoid valve further can be used as a control valve of an attitude and orbit control liquid rocket engine.

Owner:XIAN AEROSPACE PROPULSION INST

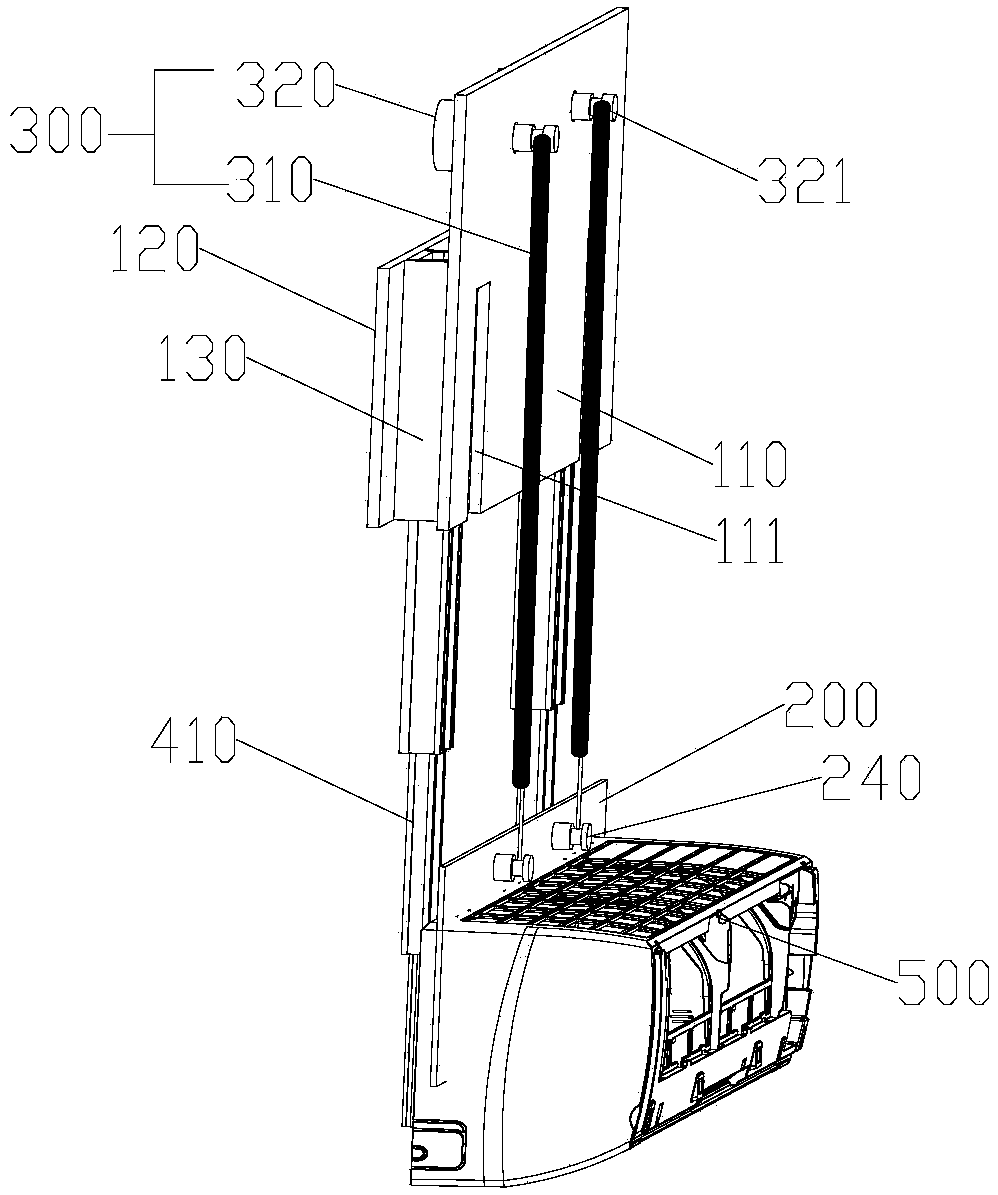

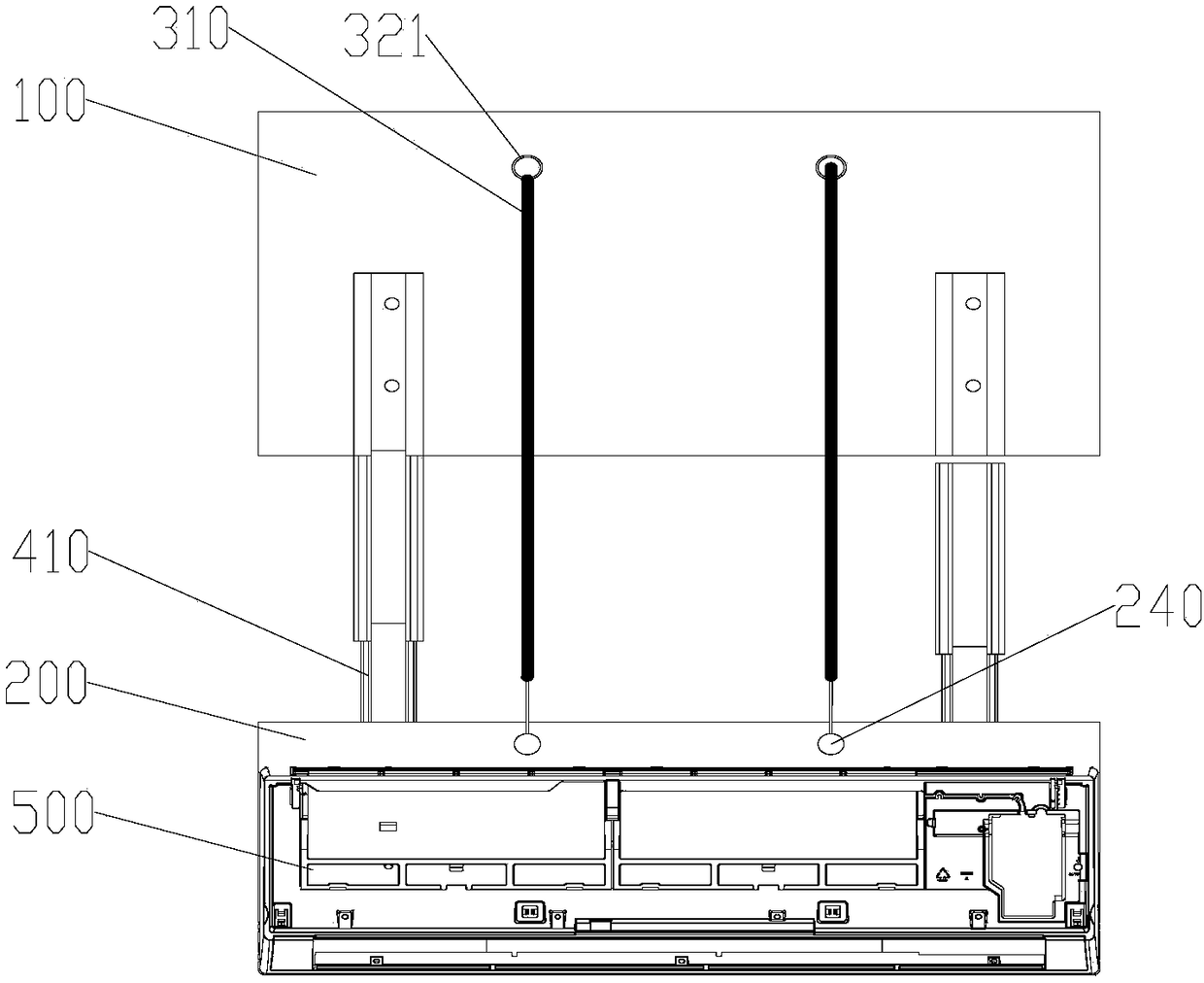

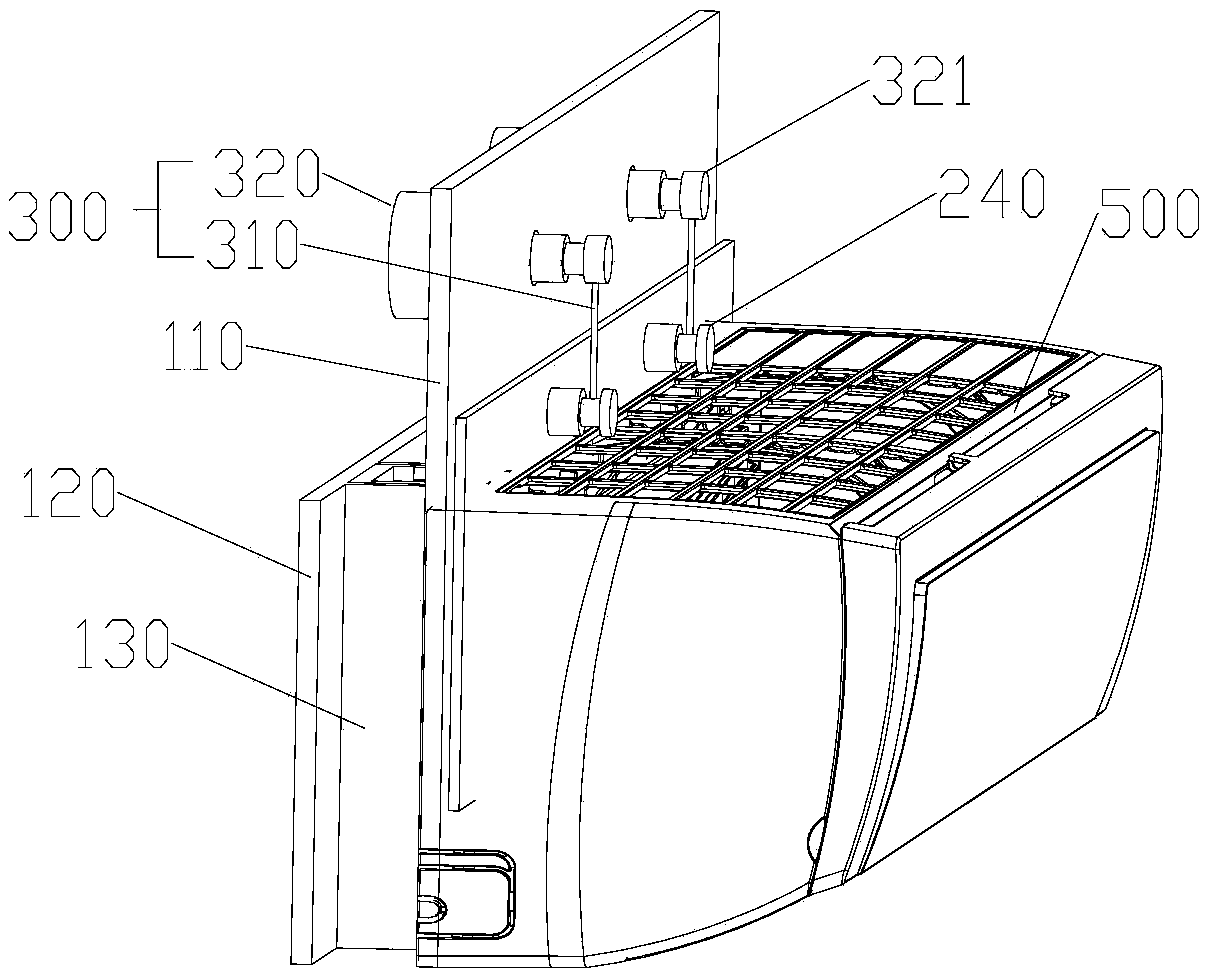

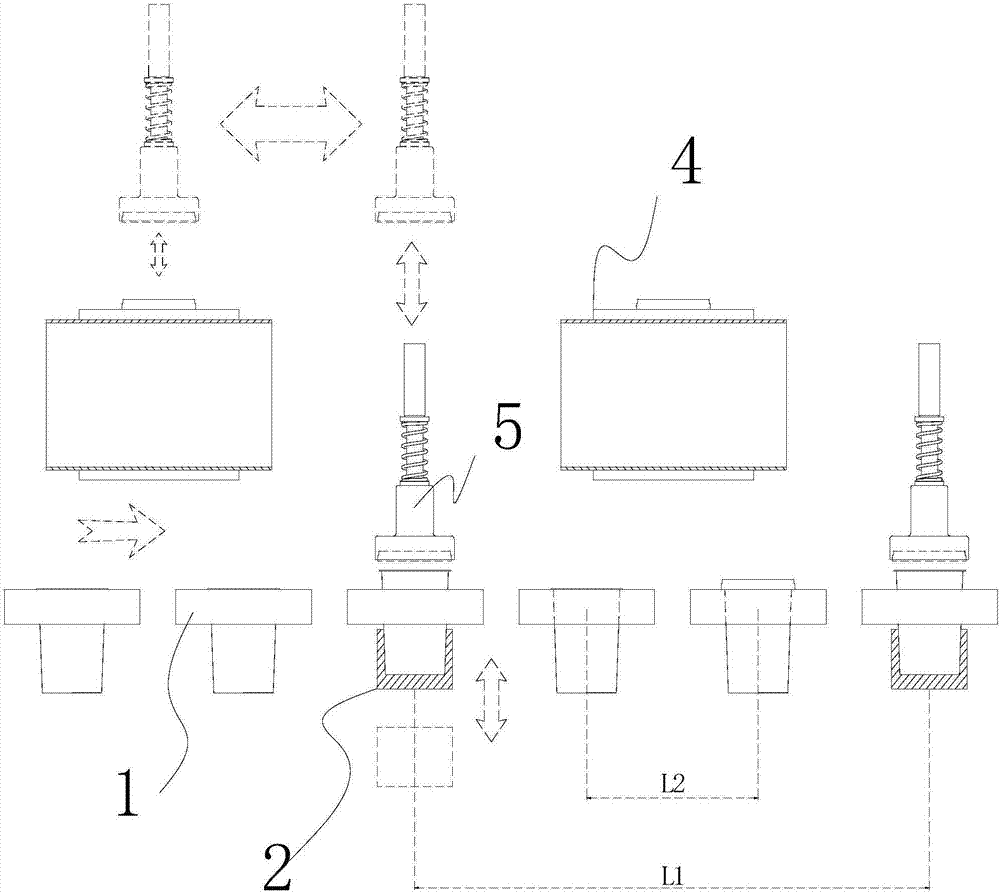

Mounting device and air conditioning system

PendingCN108458470ARealize up and down movementImprove installation efficiencyLighting and heating apparatusSpace heating and ventilation detailsEngineeringAir conditioning

The invention provides a mounting device and an air conditioning system. The mounting device comprises a mounting frame, a wall hanging plate and a traction assembly, wherein the mounting frame is fixed at the position for installation; the wall hanging plate is used for being connected with an air conditioner; and the wall hanging plate is adjustably connected with the mounting frame through thetraction assembly. The air conditioner has the advantage that the problem that the air conditioner is inconvenient to install in the prior art is solved.

Owner:GREE ELECTRIC APPLIANCES INC

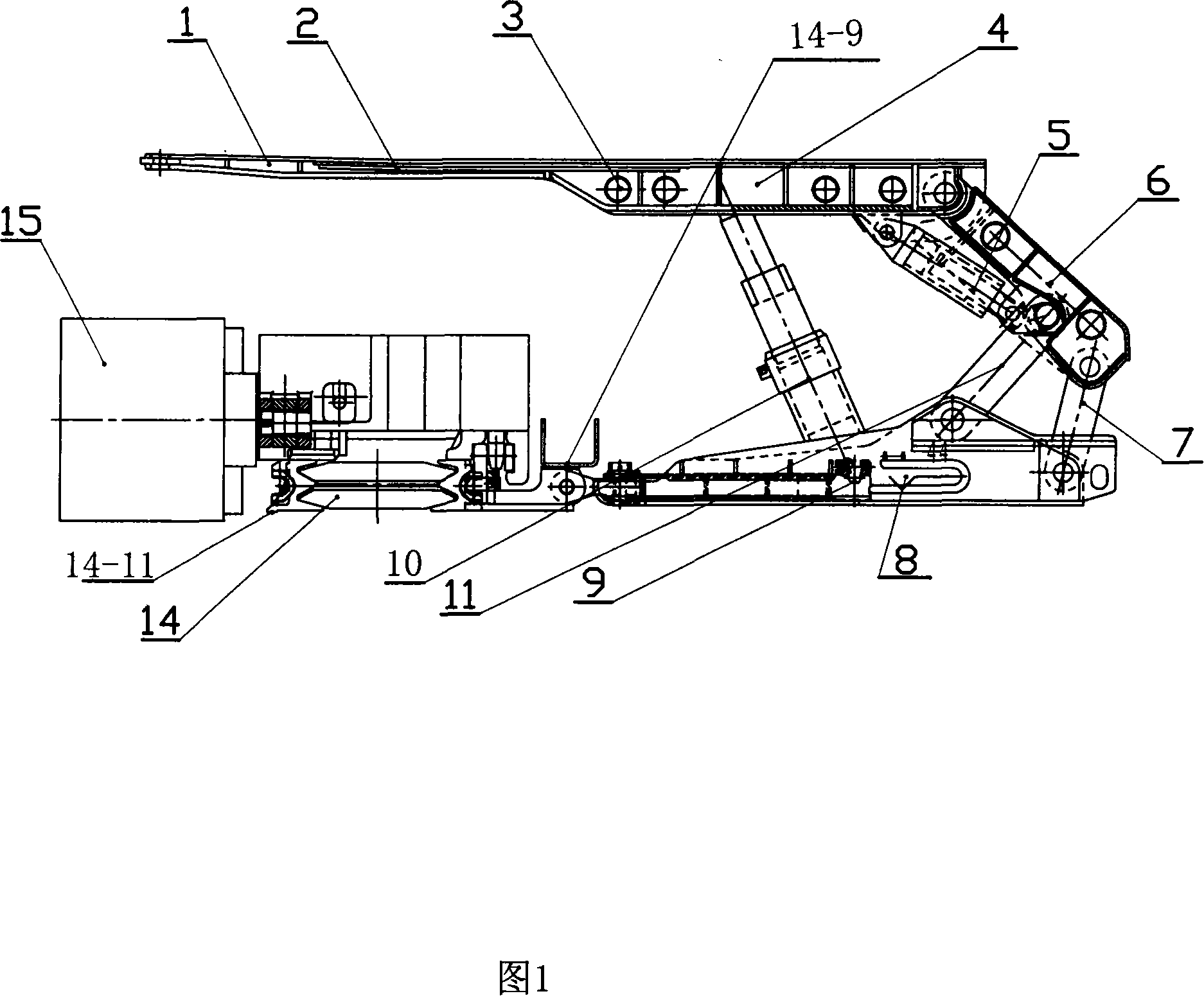

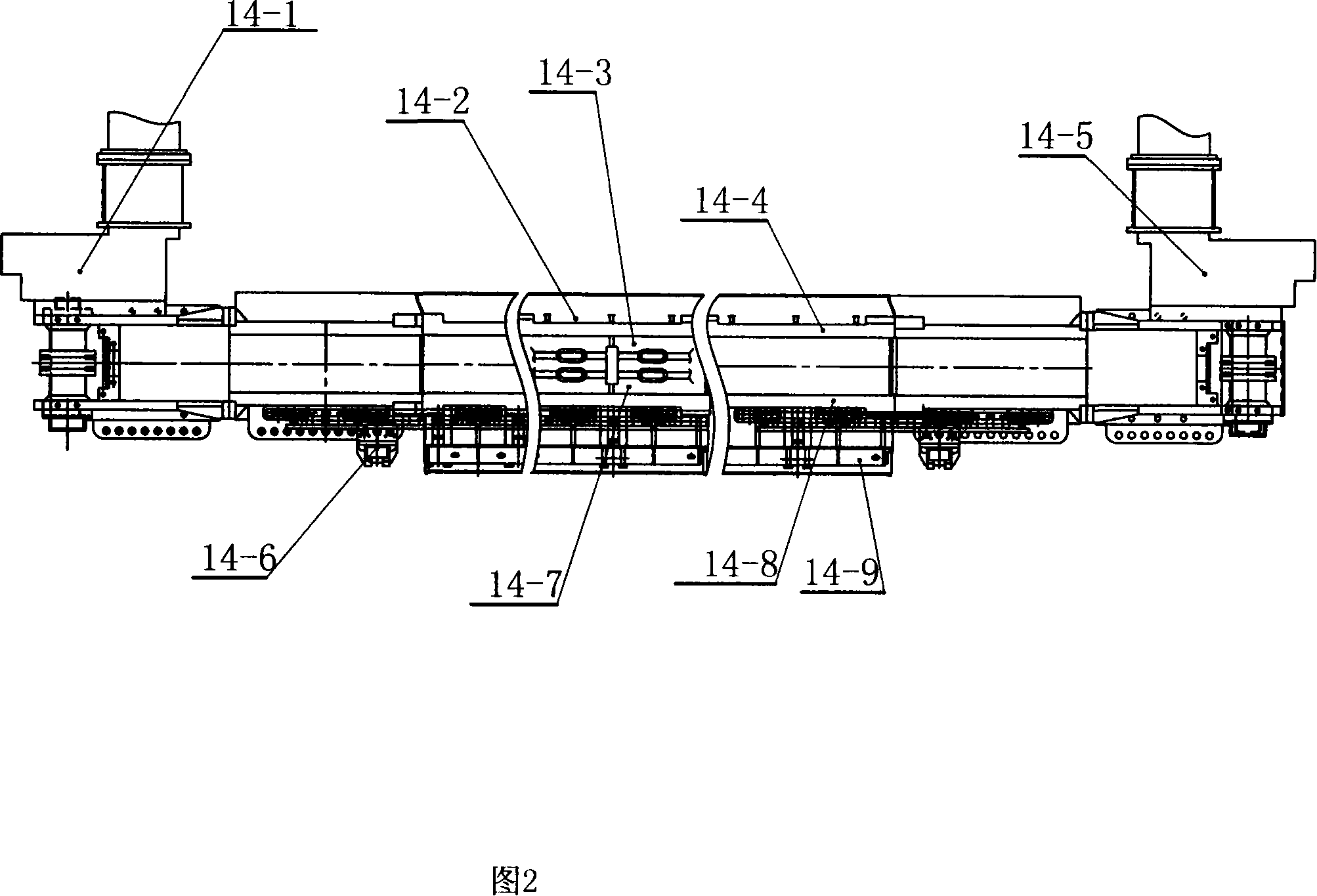

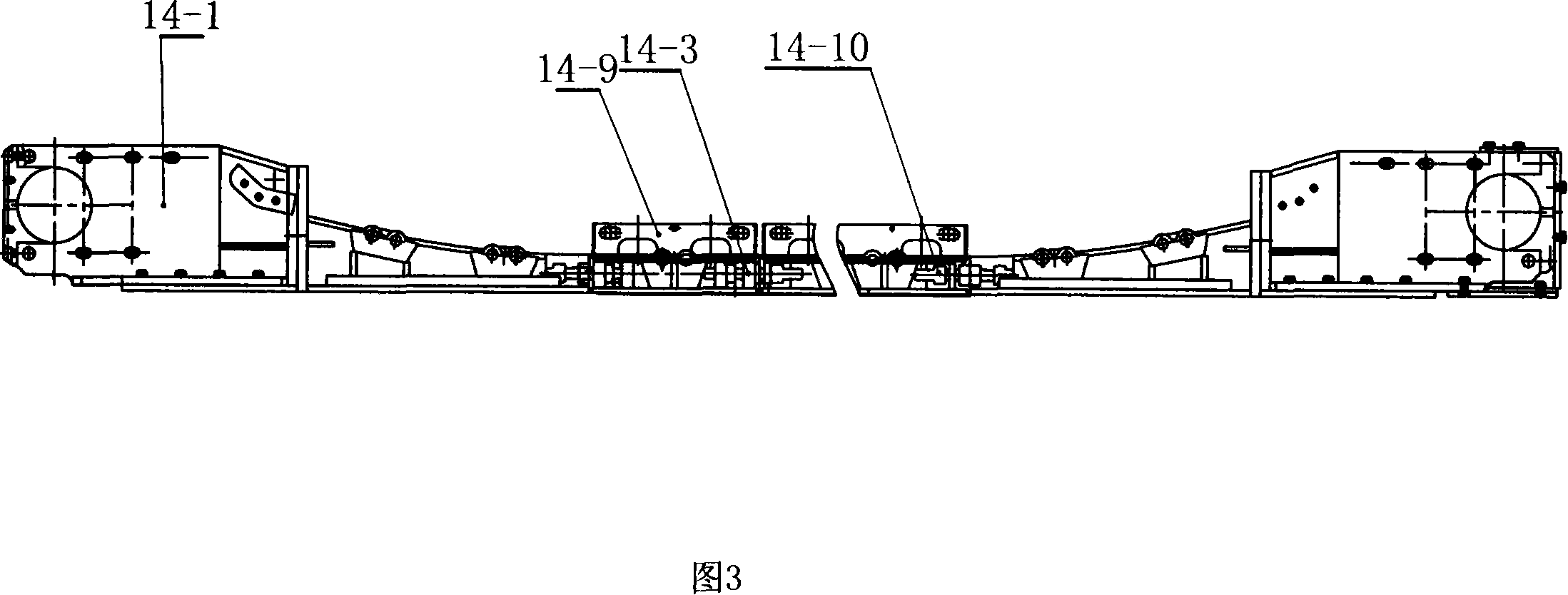

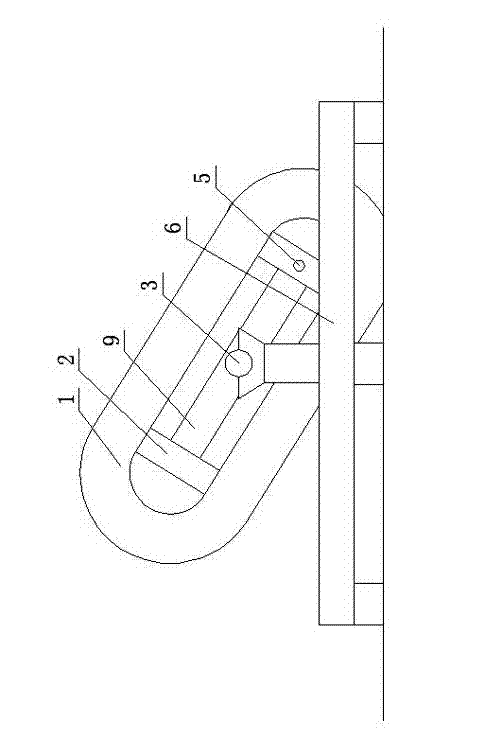

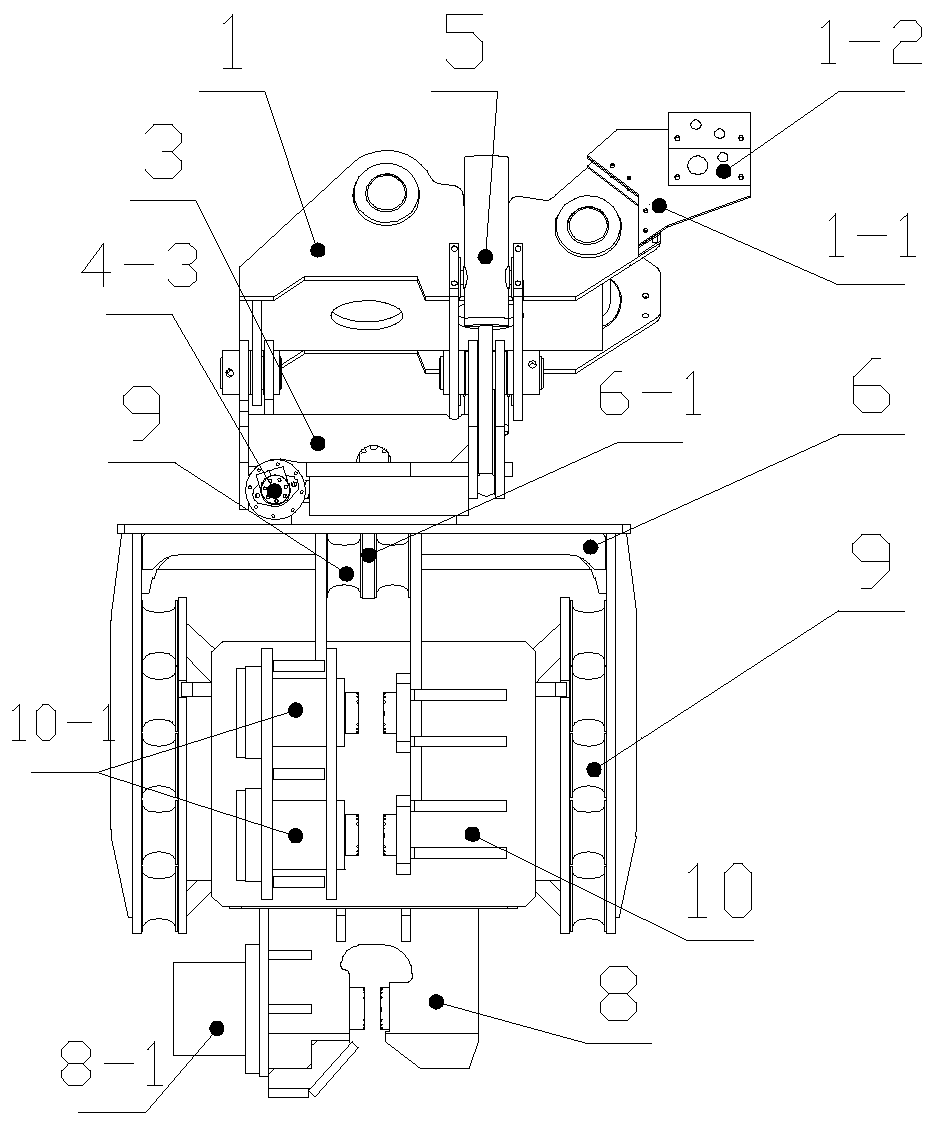

Down-hole coal excavation apparatus

InactiveCN101100941AReduce labor intensityLower working heightSlitting machinesMine roof supportsElectricityHydraulic cylinder

A coal excavation device for thin and super thin coal bed includes coal excavation device, protective hydraulic bracket and scraper blade transmission machine. An electric liquid control system is included in a single bracket on the protective hydraulic bracket. The control system includes a bracket controller, electric liquid valve set, pressure sensor of hydraulic piston, routing sensor of moving hydraulic jack, routing sensor of balance jack, routing sensor of side push jack, hydraulic piston sensor and signal cables connected to related input port. Hydraulic cylinder and jack cylinders are connected to the valve set. Bracket controller is connected to the valve set. A left roller rail is extended to the bottom of the left slot. There is cable slot on the chute moving bracket with a cable hook to the slot right wall. The moving bracket is connected to the cable slot.

Owner:ZAOZHUANG MINING GRP CO LTD

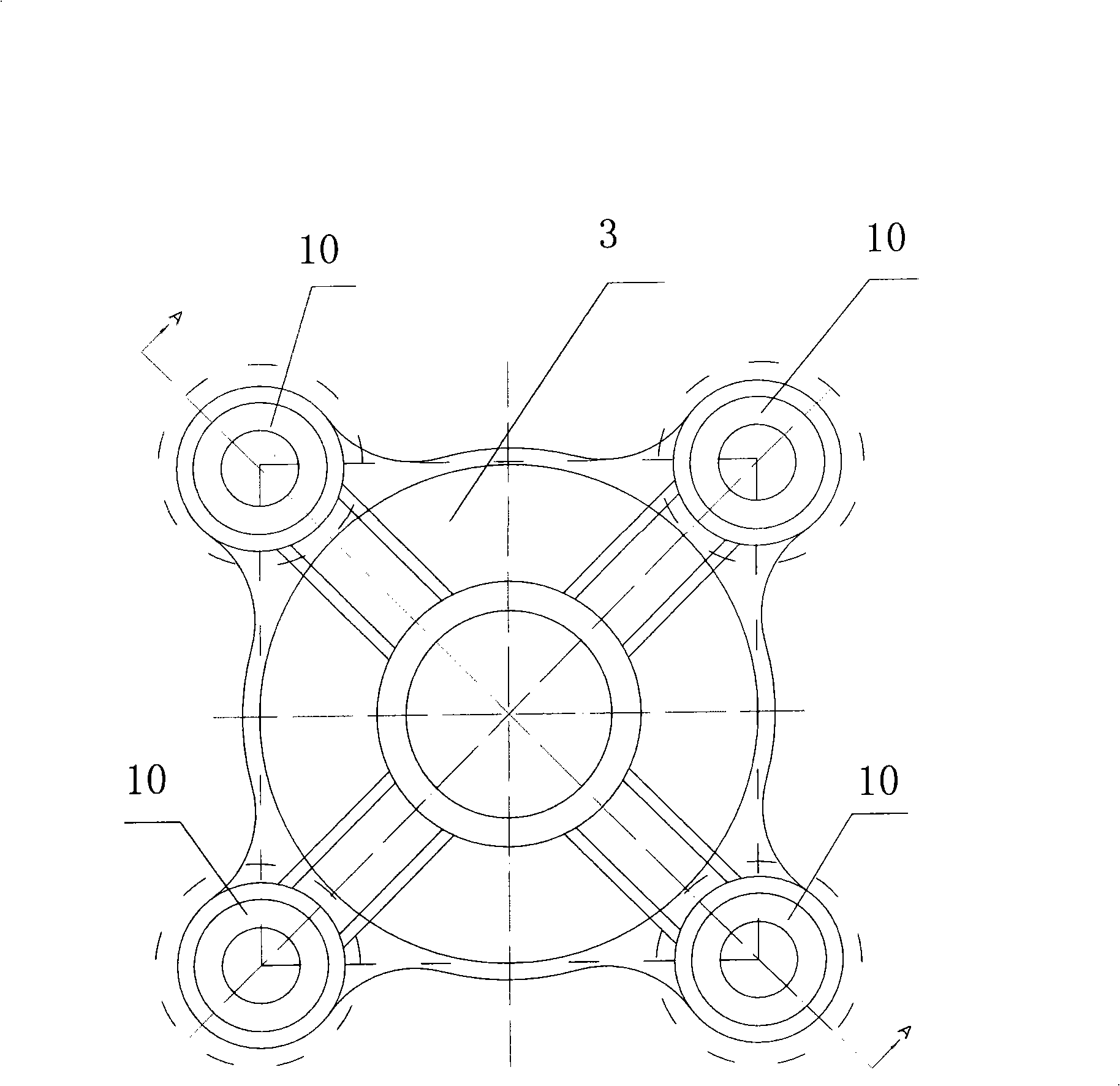

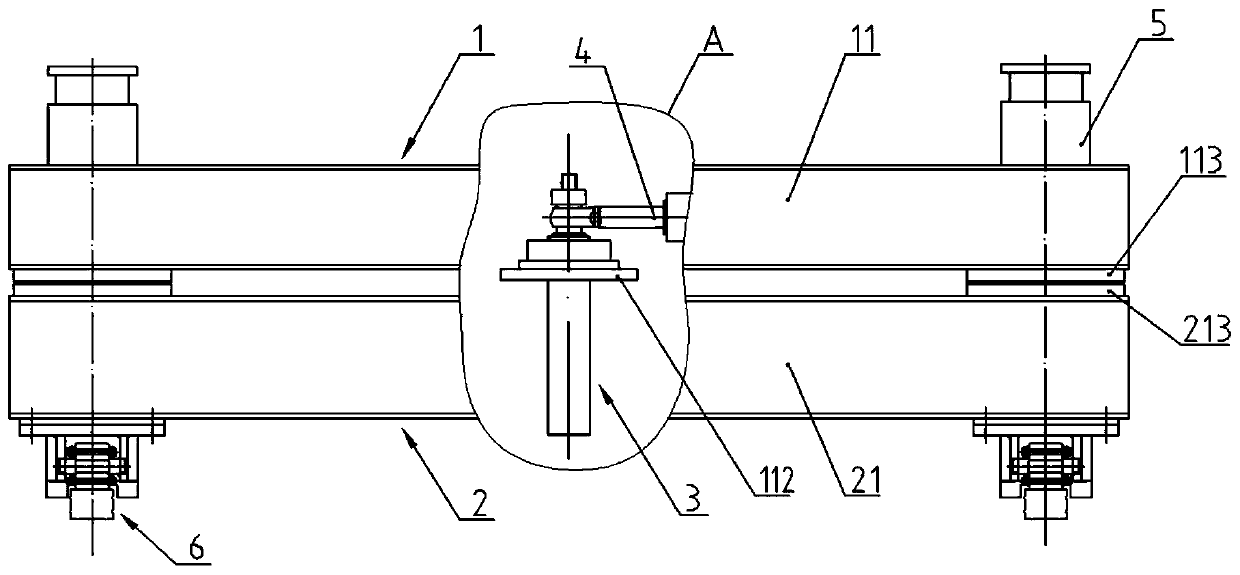

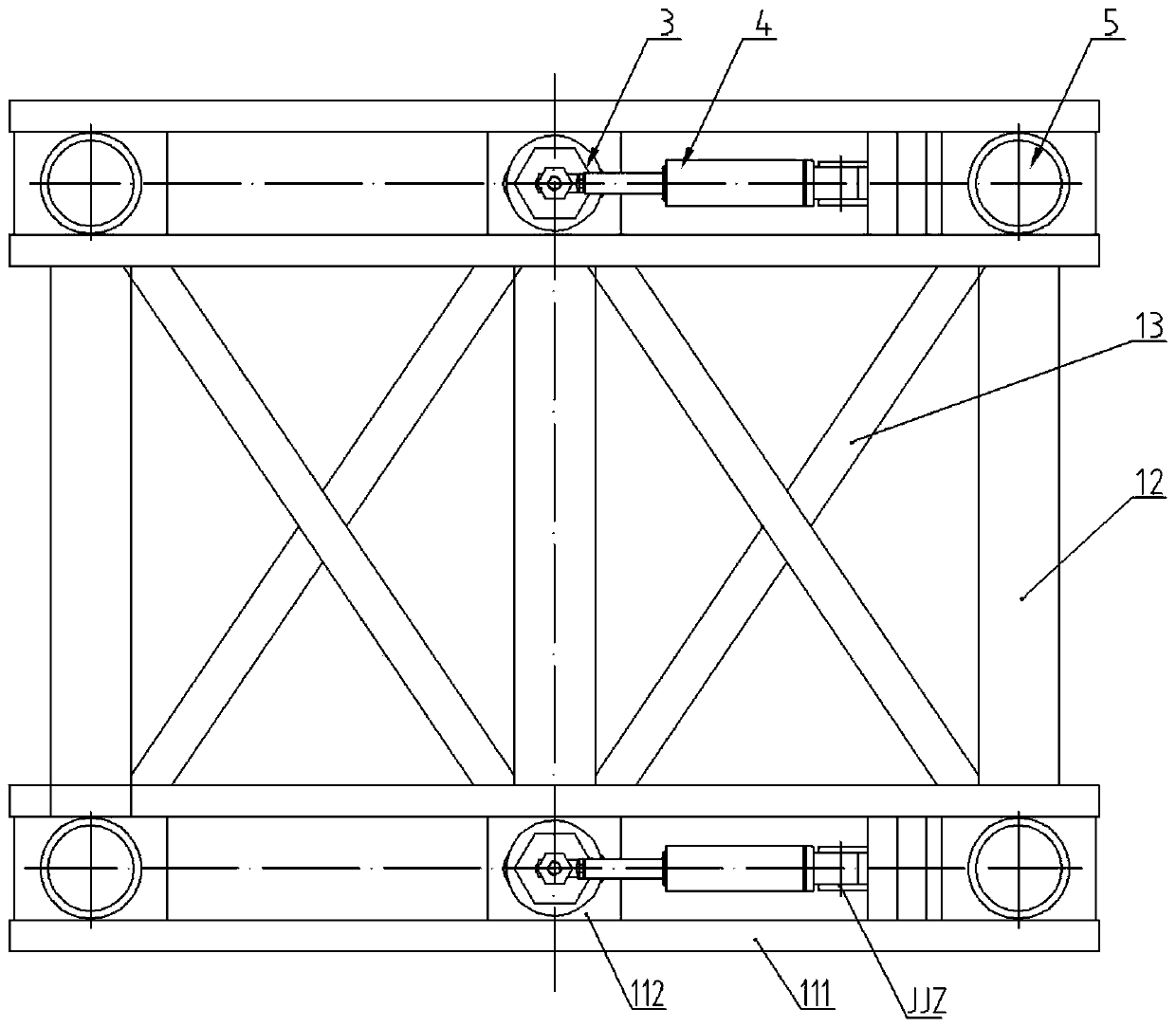

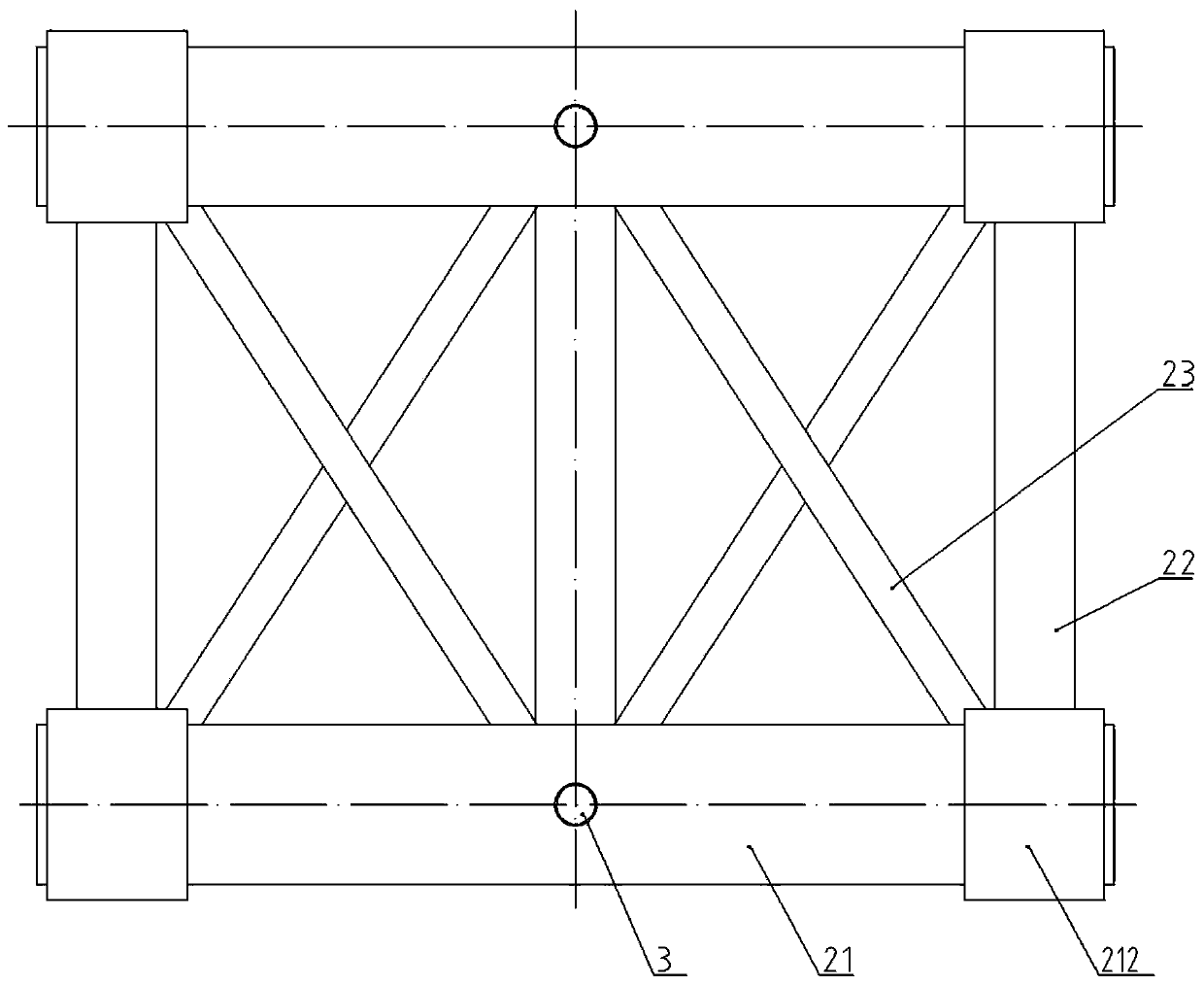

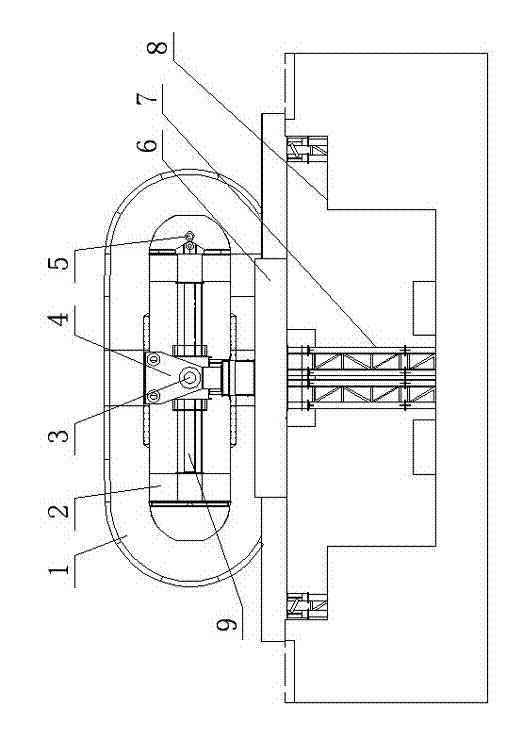

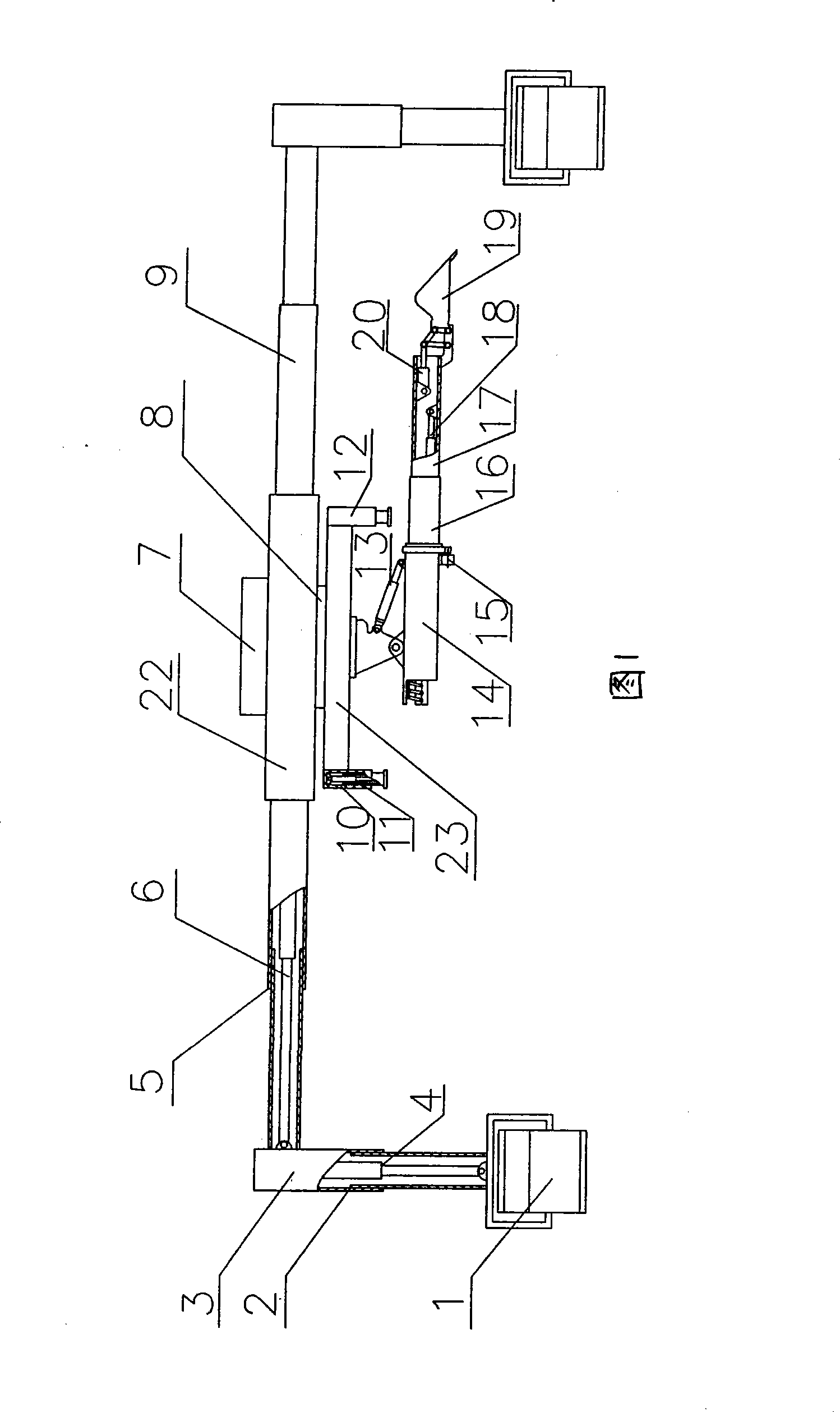

Switching system of sliding rail

InactiveCN105033524ARealize collinear productionReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPiston rod

The invention discloses a switching system of a sliding rail and belongs to the technical field of automobile welding production. The switching system of the sliding rail is characterized by comprising a fixed rail set, a servo drive mechanism, a sliding trolley and single-unit switching mechanisms, wherein the single-unit switching mechanisms are located at the intersecting position of rails of the fixed rail set, and each single-unit switching mechanism comprises a rotating rail set, a universal supporting wheel set and an air cylinder drive set; each rotating rail set comprises a rotating rail, a rotating wheel and a rotating side arm; the two ends of each rotating rail are connected with the rails of the fixed rail set, and each rotating rail is fixedly connected to the corresponding rotating wheel; each rotating wheel is fixedly connected with the corresponding rotating side arm, and the other end of each rotating side arm is hinged to a piston rod of the corresponding air cylinder; each universal supporting wheel set comprises a fixed wheel, a connecting body, a universal sphere and a sliding wheel, and each sliding trolley is fixedly connected with the corresponding fixed wheel; and the sliding wheels are arranged at the lower end of the corresponding universal sphere and clamped on the two sides of the corresponding rotating rail. By means of the single-unit switching mechanism, production of multiple vehicle models on the same line is achieved on the same plane. The switching system of the sliding rail has the beneficial effects of reducing cost and improving efficiency.

Owner:ANHUI RUIXIANG IND

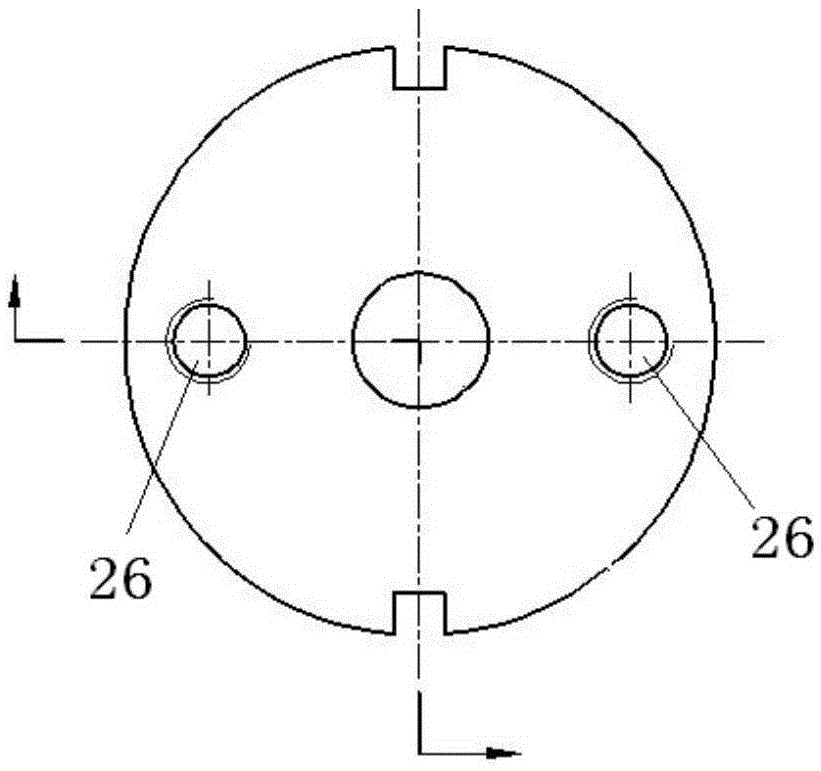

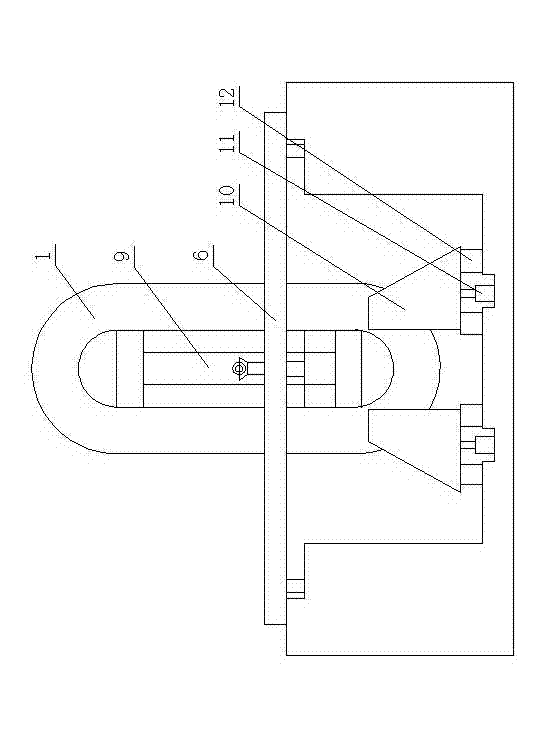

Inclined guy cable stretching torsion-proof jack

The invention discloses a tension anti-torsion jack of a stayed cable, comprising a support. No less than two oil cylinder jack are evenly arranged on the support. A piston rod of the oil cylinder jack is connected with a raising plate. A first clamping device for a steel strand is arranged on the raising plate and a second clamping device for the steel strand is arranged in the support. The oil cylinder jacks moves simultaneously, and tension aim is achieved by shifted clamping the steel strand of the stayed cable using the first and the second clamping devices when the stayed cable tends, so torsion of the stayed cable is avoided effectively. An raising momentum system is broken up the whole into parts and an anti-torsion system is formed depending on the raising device, so torsion of the stayed cable is avoided in tension process; working height of the stayed cable system is reduced largely by closely combining a frame brace used in stayed cable tension with the jack, and requirement for space of the stayed cable tension is reduced largely.

Owner:CCCC SECOND HARBOR ENG +1

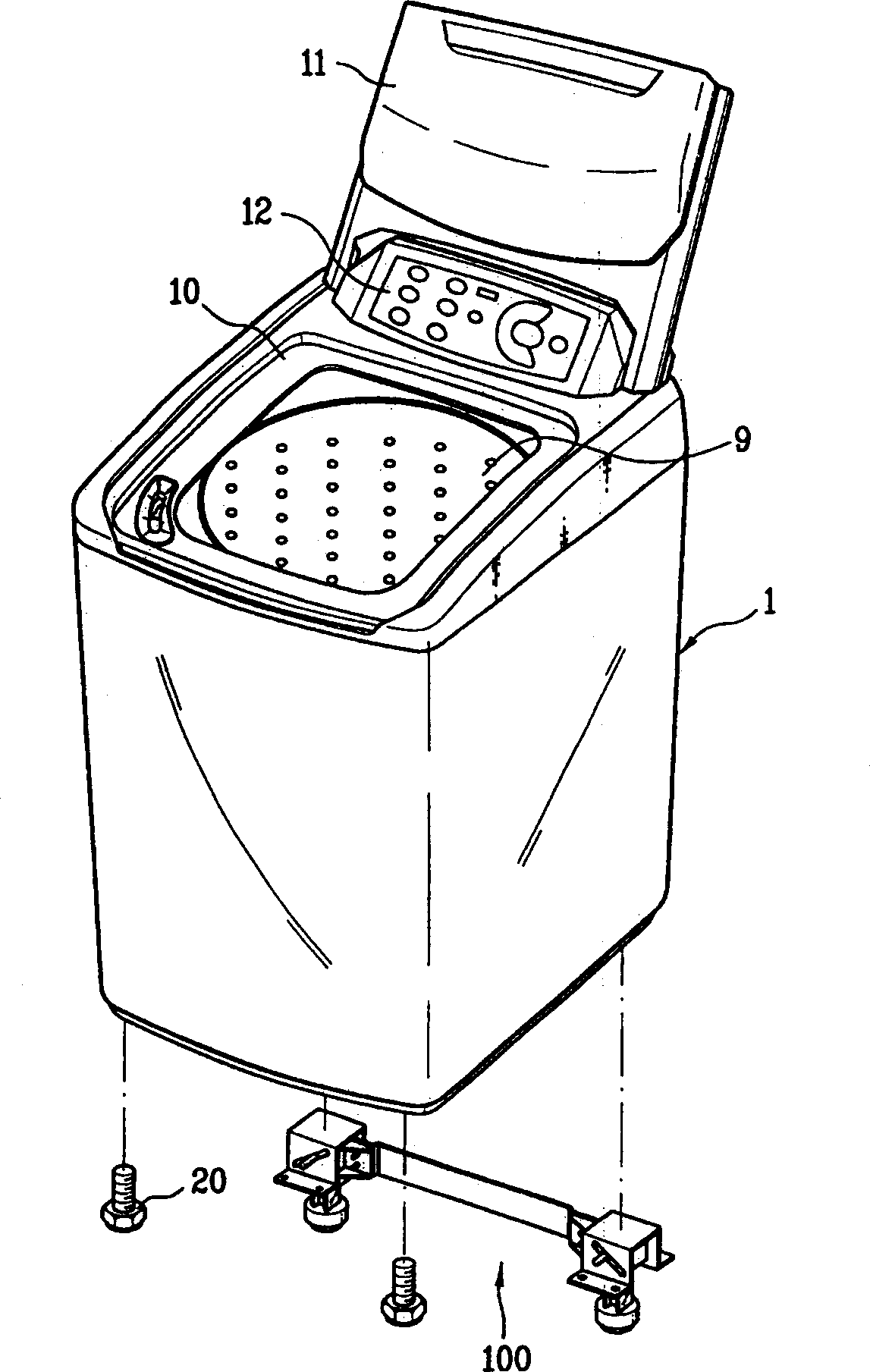

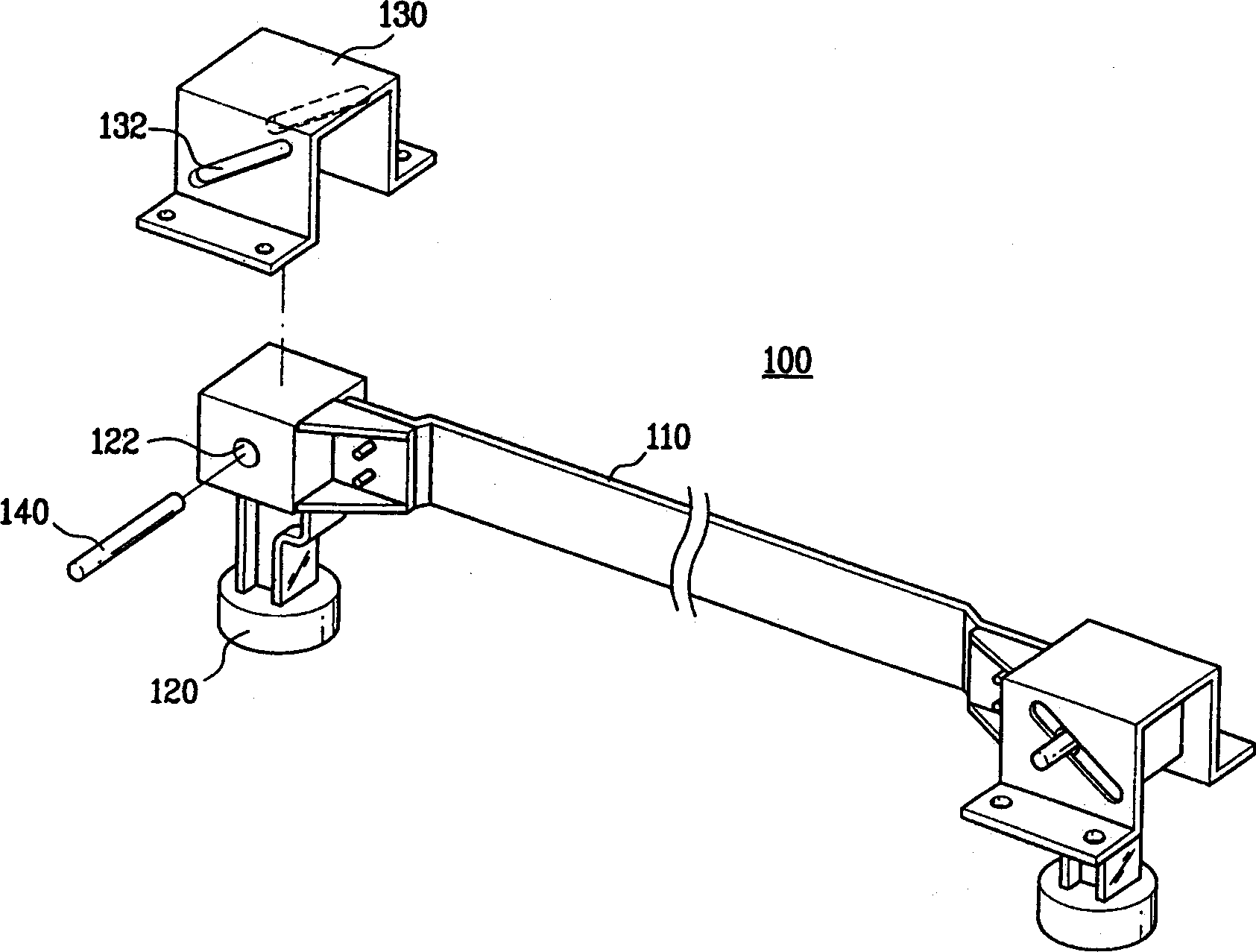

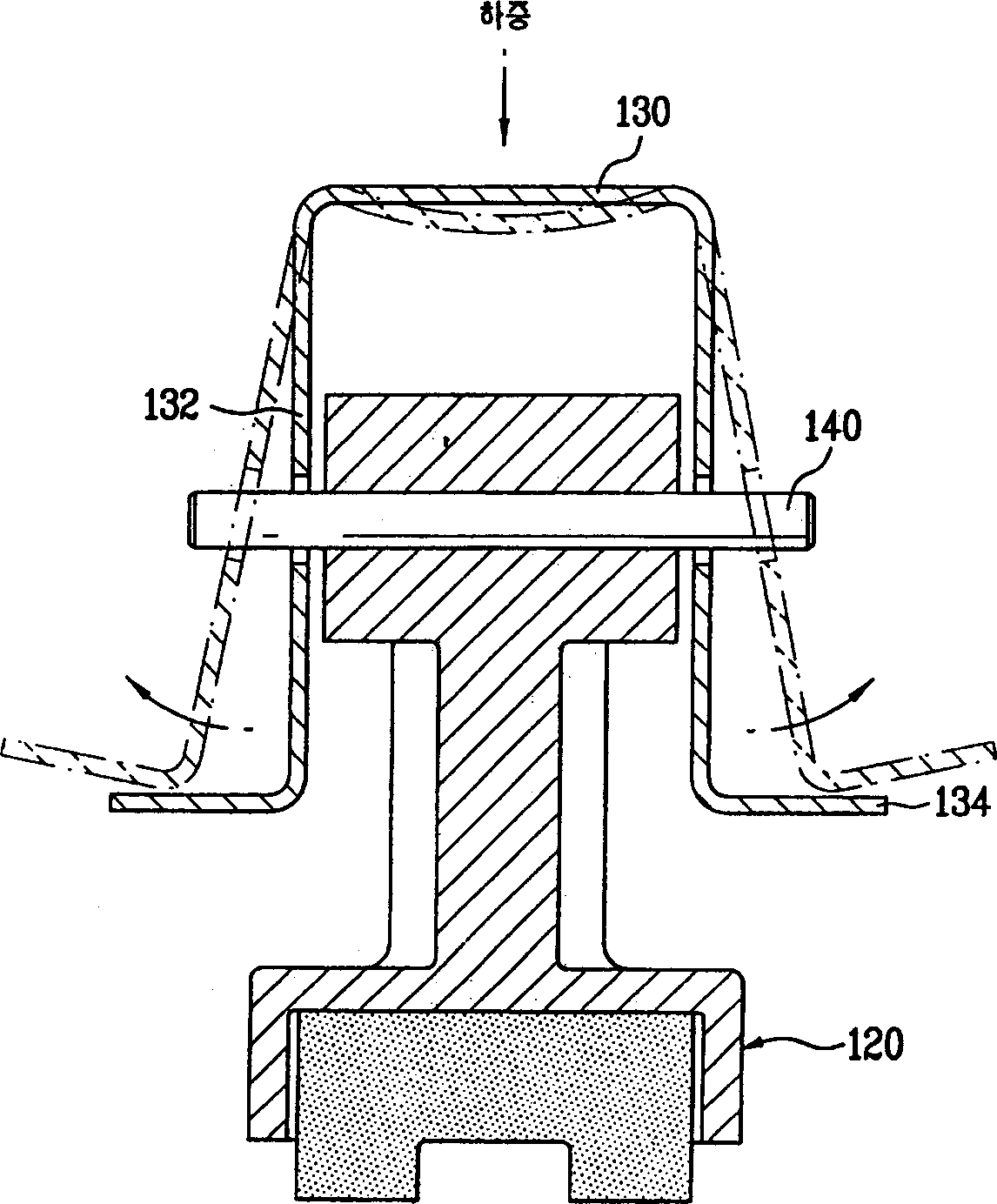

Automatic structure for regulating level part and preventing frame from opening of washing machine

InactiveCN1715517AAvoid staggeringLower working heightOther washing machinesTextiles and paperEngineeringMechanical engineering

The frame opening preventing structure for automatic level regulating part of washing machine consists of connecting rod assembly, racks and upper frames and is set in the bottom of washing machine. The racks are set vertically on two ends of the connecting rod assembly, and the bent upper frames are installed on the racks and can be shifted diagonally relative to the racks. The present invention features that the reinforcing frame comprising support ribs and connecting part can prevent the upper frame under the action of the washing machine weight from opening outwards, with the support ribs supporting the ends of the upper frame and the connecting part connecting the support ribs. The present invention can prevent the outward opening of the upper frame and the descent of the work height of the automatic level regulating part, and can also prevent the dislocation of sliding slot and the shaft to ensure the normal operation of the automatic level regulating part.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

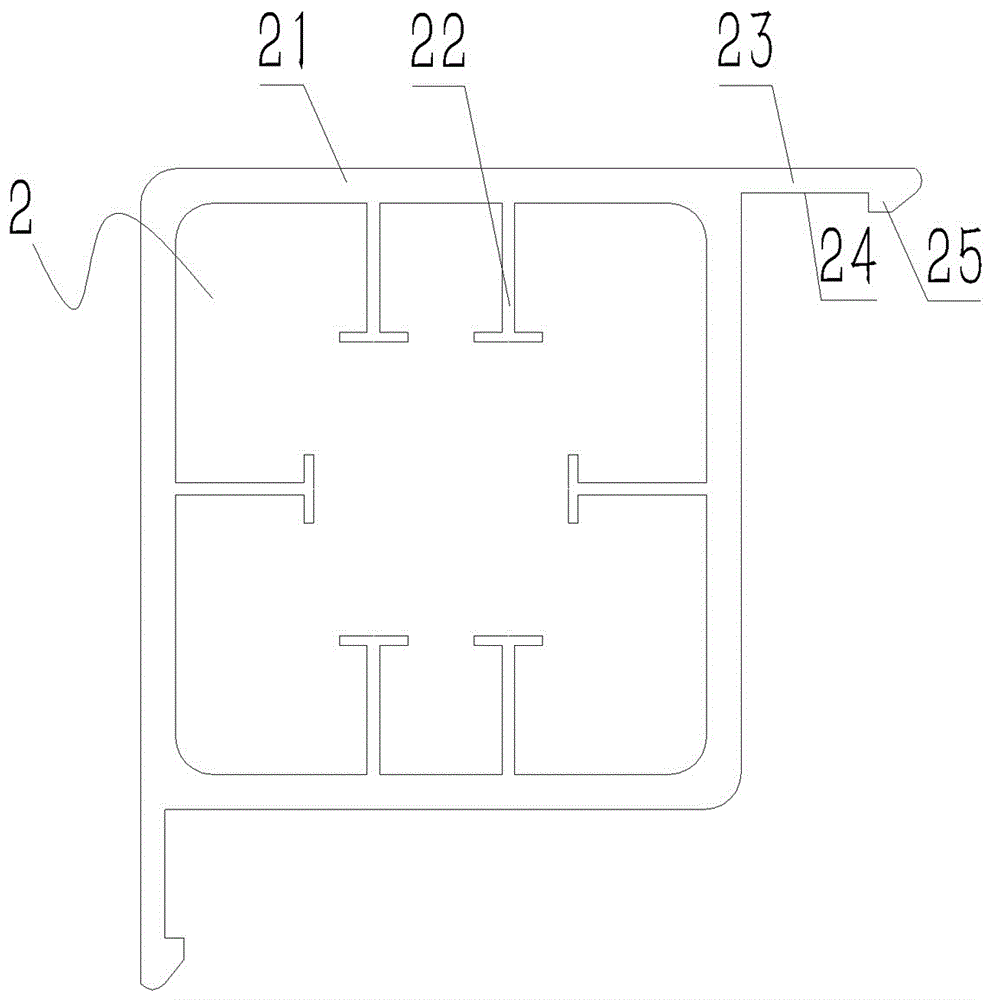

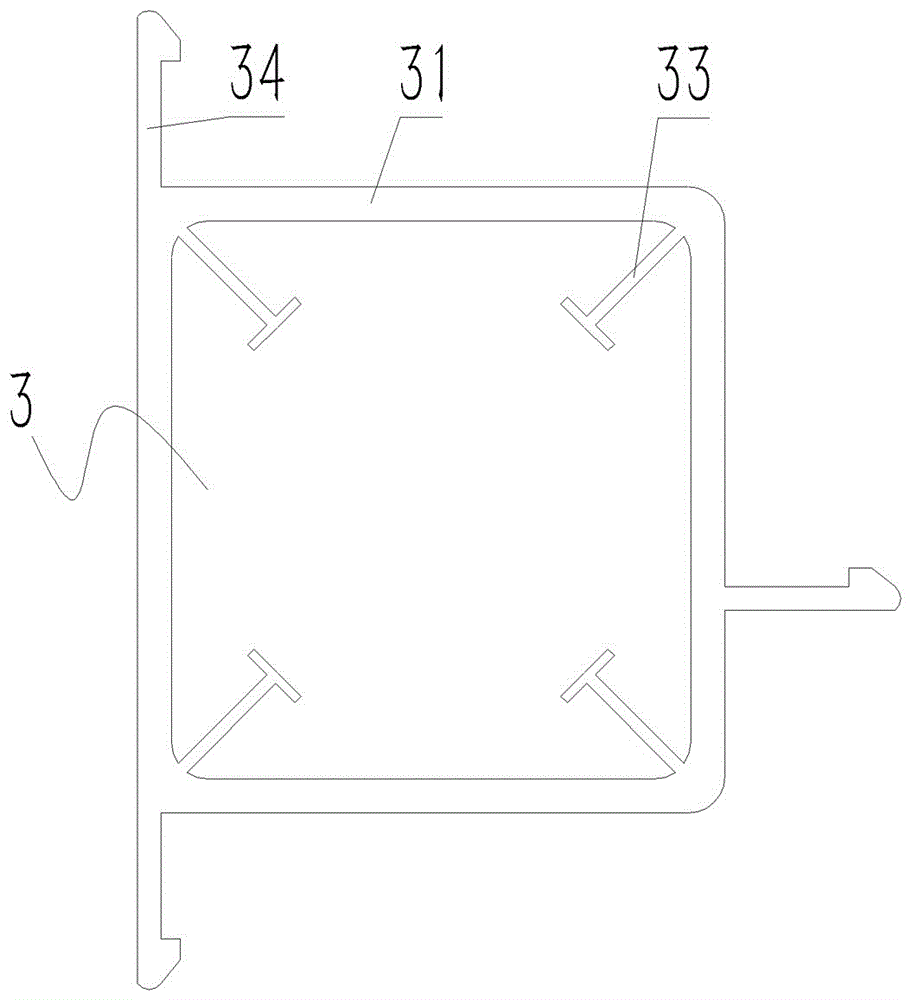

Steel structure building and wall construction method thereof, and girder and column steel member

The invention discloses a steel structure building and a wall construction method thereof, and a girder and column steel member. The wall construction method of the steel structure building includes the following steps that firstly, the prefabricated steel member serving as a stand column and / or a roof girder is fixedly installed, the steel member comprises a steel member body extending in the column height or girder length direction, and the steel member body is provided with prefabricated rib plates extending in the same direction on the side surfaces in an outward convex mode; secondly, when a wall board is erected, the wall board is horizontally moved till the edge of the board surface on one side is placed on the corresponding prefabricated rib plate, and the vertical edge of the attaching side of the wall board faces the side surface, where the prefabricated rib plate is located, of the steel member body; and thirdly, the side, away from the prefabricated rib plate, of the wall board is pressed with connecting rib plates. The prefabricated rib plates are prefabricated on the steel member, the prefabricated rib plates can play a role in prepositioning the wall board, the wall board can be installed in a horizontal moving mode after being erected, and thus the operation difficulty of wall board installation is reduced, and the wall construction safety and efficiency are improved.

Owner:常华北

Capping device

The invention discloses a capping device. In the capping device, a cap conveying path is arranged in the direction perpendicular to a cup conveying path, and the length of the cap conveying path is increased in the direction. Functional differentiation of the cap conveying path is achieved. A cap supplying station is externally arranged. Circulation operation is conducted on the cap conveying path. By the adoption of the capping device, the cap conveying path structure is optimized, the capping operation area is arranged on the side of the cup conveying path, so that the capping operation height is reduced, and the safety, stability and convenience of the operation of the whole machine are greatly improved.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

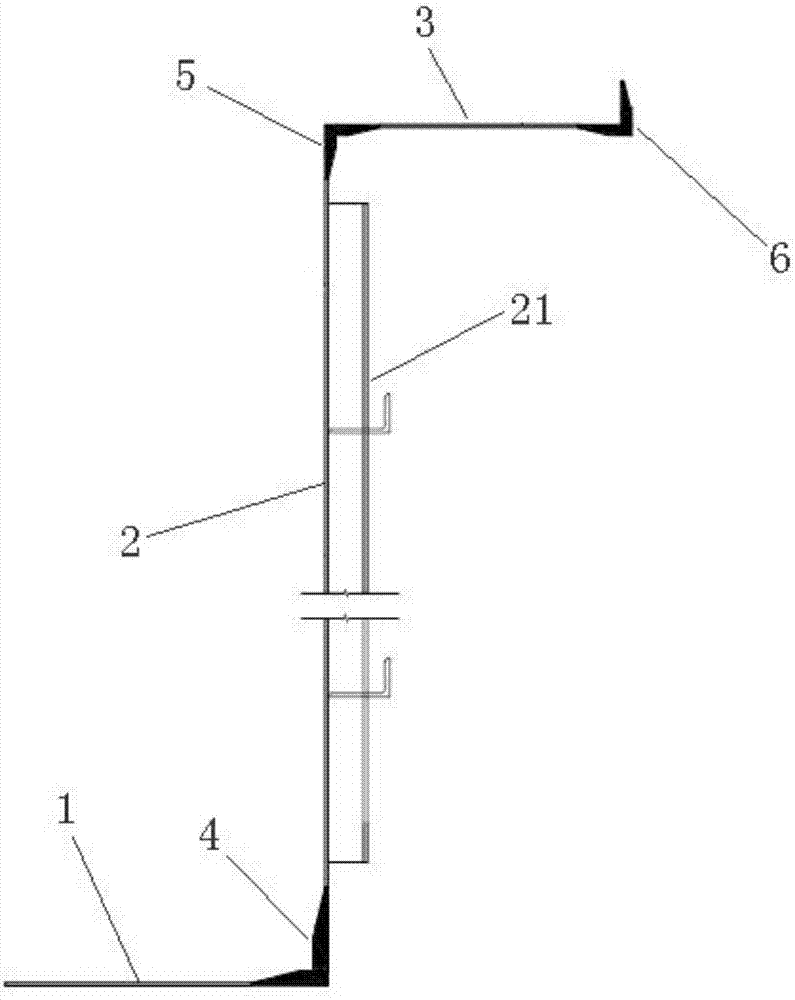

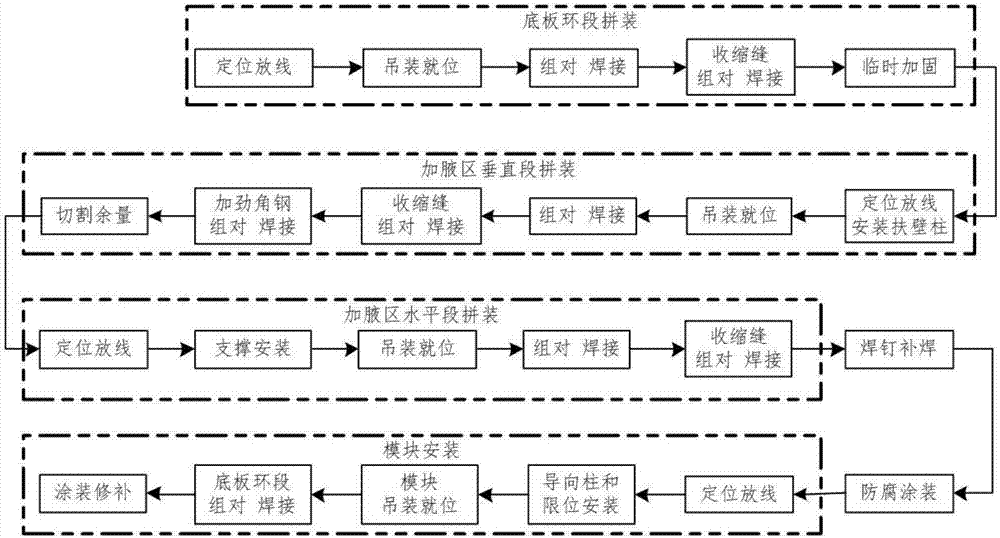

Integrated connection module structure of nuclear power station safe shell steel lining and mounting method thereof

ActiveCN107545937ASimple and efficient operationLower working heightNuclear energy generationContainmentWall plateNuclear power

The invention discloses an integrated connection module structure of a nuclear power station safe shell steel lining. The structure comprises a baseplate ring segment, a haunching area wall plate anda horizontal segment, the baseplate ring segment and the horizontal segment are both horizontally arranged, and the haunching area wall plate is vertically arranged; the baseplate ring segment is fixedly connected with the lower end of the haunching area wall plate, the upper end of the haunching area wall plate is fixedly connected with one end of the horizontal segment, and a first reinforcing joint is arranged on the connection portion of the baseplate ring segment and the haunching area wall plate; a second reinforcing joint is arranged on the connection portion of the haunching area wallplate and the horizontal segment, a third reinforcing joint is arranged at the end, away from the haunching area wall plate, of the horizontal segment, and the baseplate ring segment, the haunching area wall plate, the horizontal segment, the first reinforcing joint, the second reinforcing joint and the third reinforcing joint are integrally assembled into an entirety and then fixedly connected with the lowest layers of the baseplate ring segment and a nuclear power station safe shell steel lining cylinder. The integrated connection module structure has the advantages that module assembly is conducted on an assembly field, hoisting in position at a time is achieved, and the intersecting construction time of construction with an inner shell is reduced.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

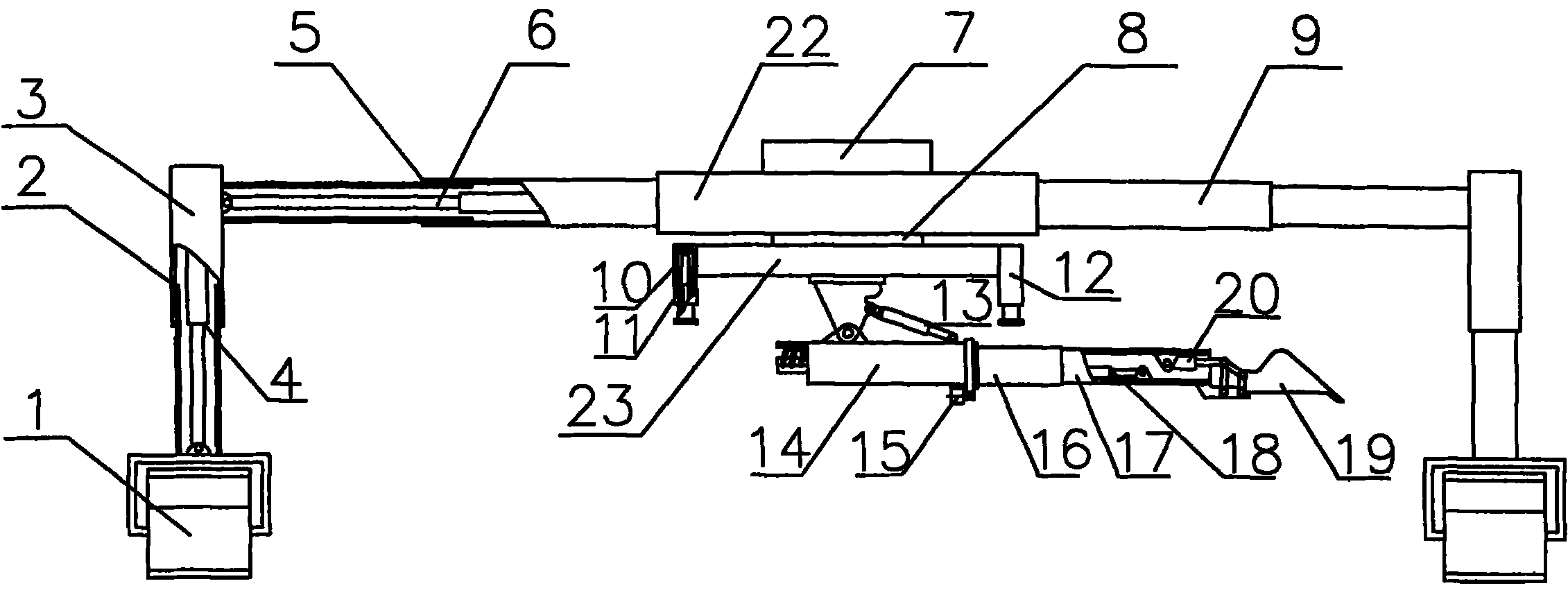

Moving crane

InactiveCN106232516AOperational securityLower working heightTrolley cranesLoad-engaging elementsEngineering

Owner:KONECRANES GLOBAL

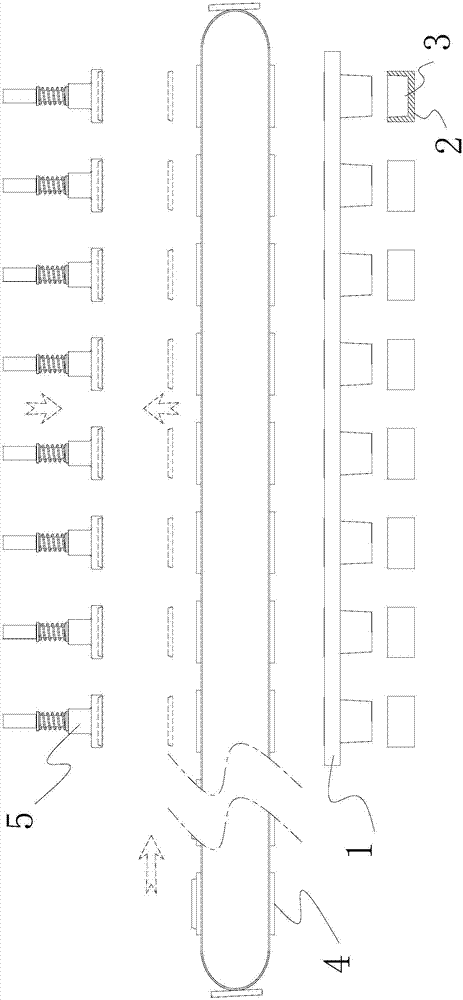

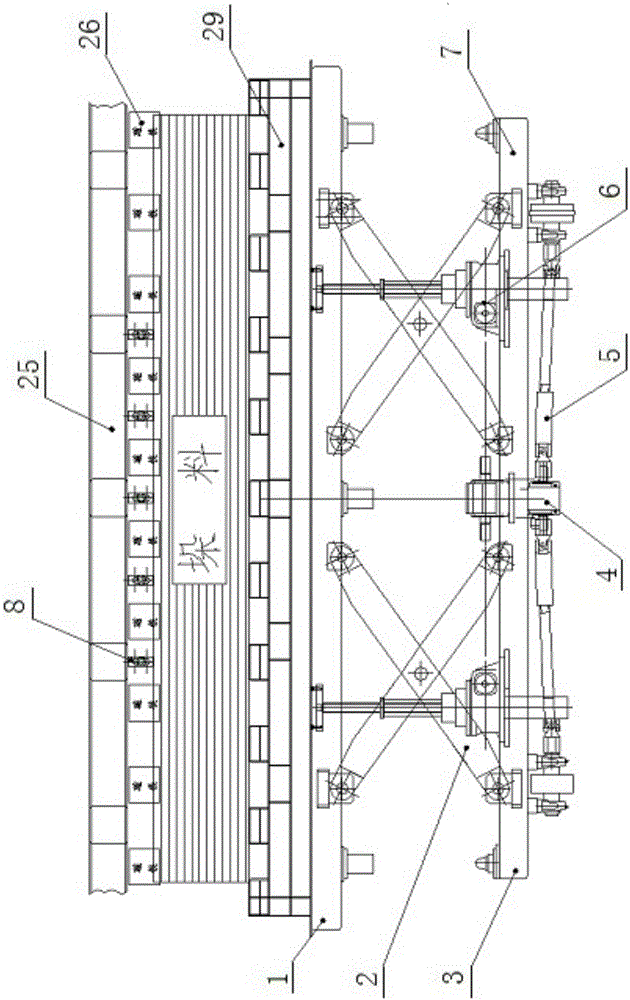

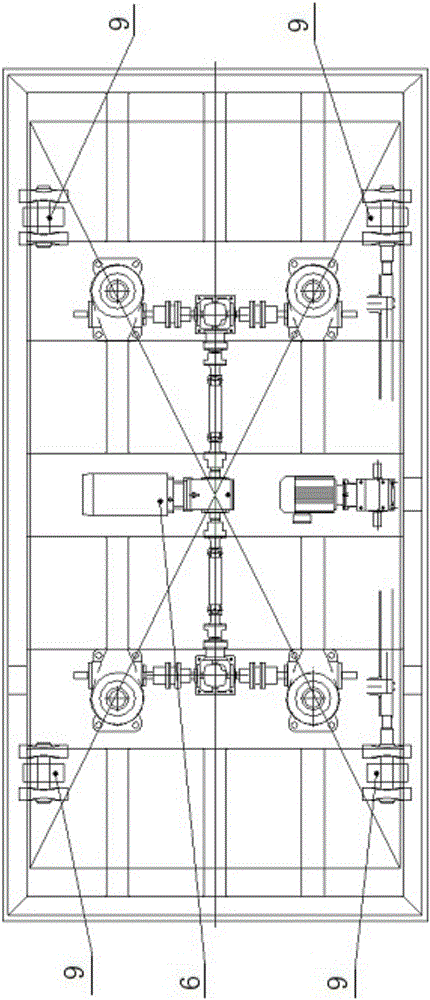

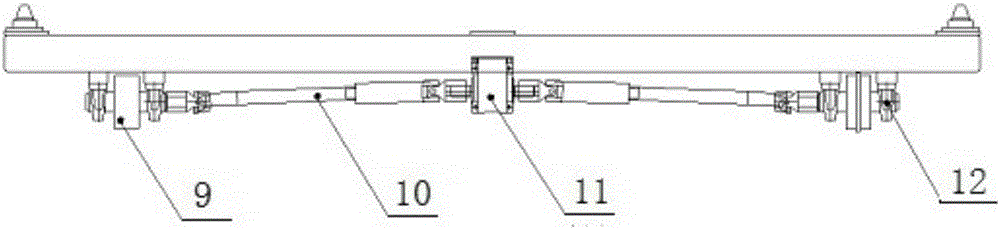

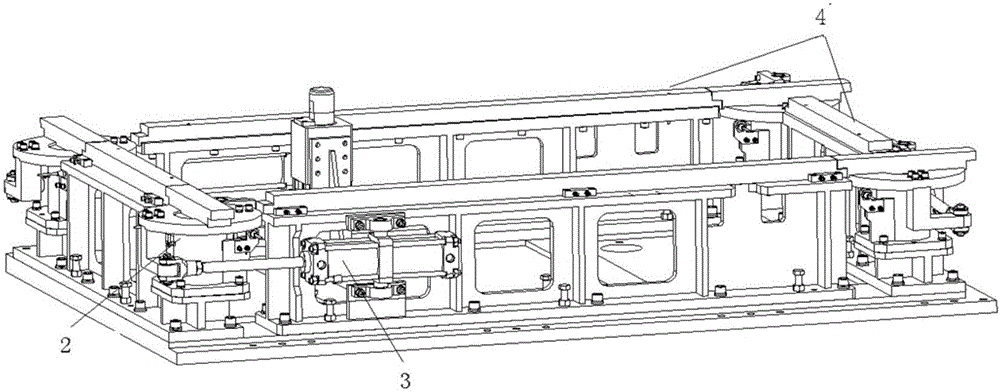

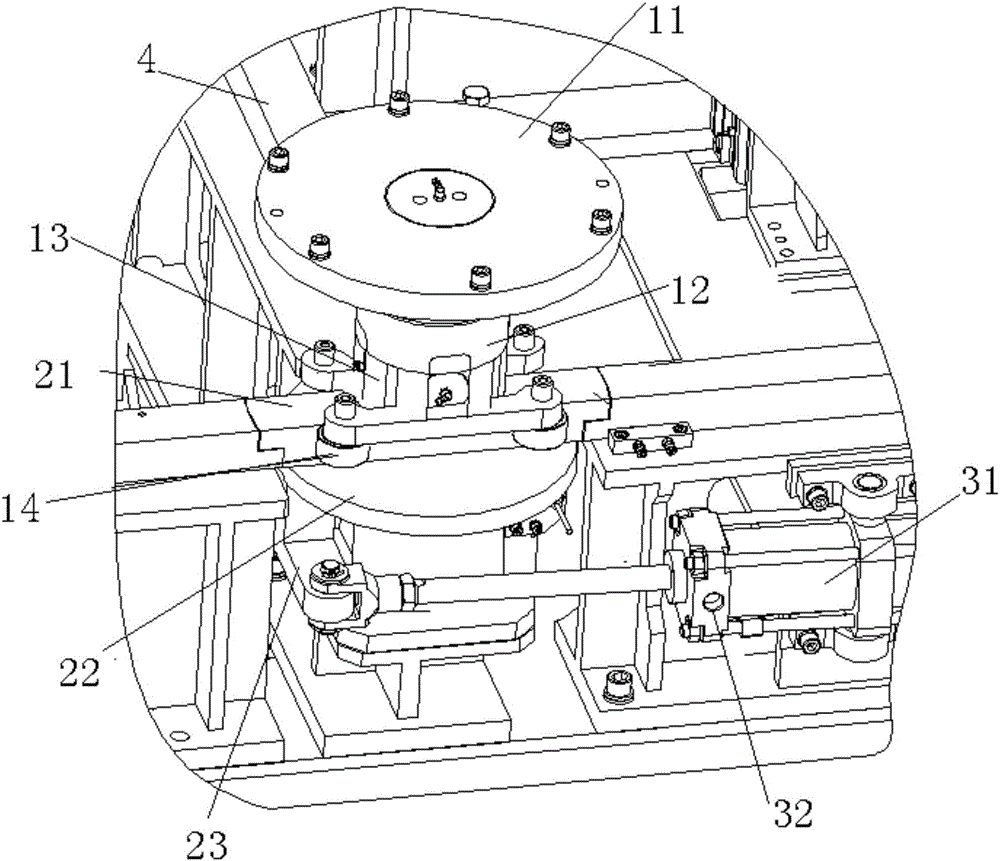

Double-screw type automatic lifting trolley

InactiveCN106494897ALower working heightLarge lifting strokeDe-stacking articlesLower faceEngineering

The invention discloses a double-screw type automatic lifting trolley which comprises a trolley body, a walking device, a lifting device and an optoelectronic switch. The trolley body comprises a top cover, a shear fork type guide device and a base, the shear fork type guide device comprises a linear guideway fixed to the base, a left knife and fork and a right knife and fork, and the knives and forks are connected with the top cover and the base through a pin shaft and the linear guideway; the walking device is installed on the lower face of the base, the lifting device is arranged between the top cover and the base, the top end of the lifting device is fixedly connected with the top cover through a flange, and the bottom end of the lifting device is fixed to the base through a bolt; and the top cover is provided with a material support, a magnetic force tension dividing device transverse beam is arranged above the material support, and the optoelectronic switch is installed at the lower end of the magnetic force tension dividing device transverse beam. The double-screw type automatic lifting trolley is small in working height and large in lifting stroke, the production efficiency is improved, and the labor intensity of workers is reduced. The double-screw type automatic lifting trolley is novel in structure and compact in overall structural layout, and the total line cost is reduced.

Owner:JIER MACHINE TOOL GROUP

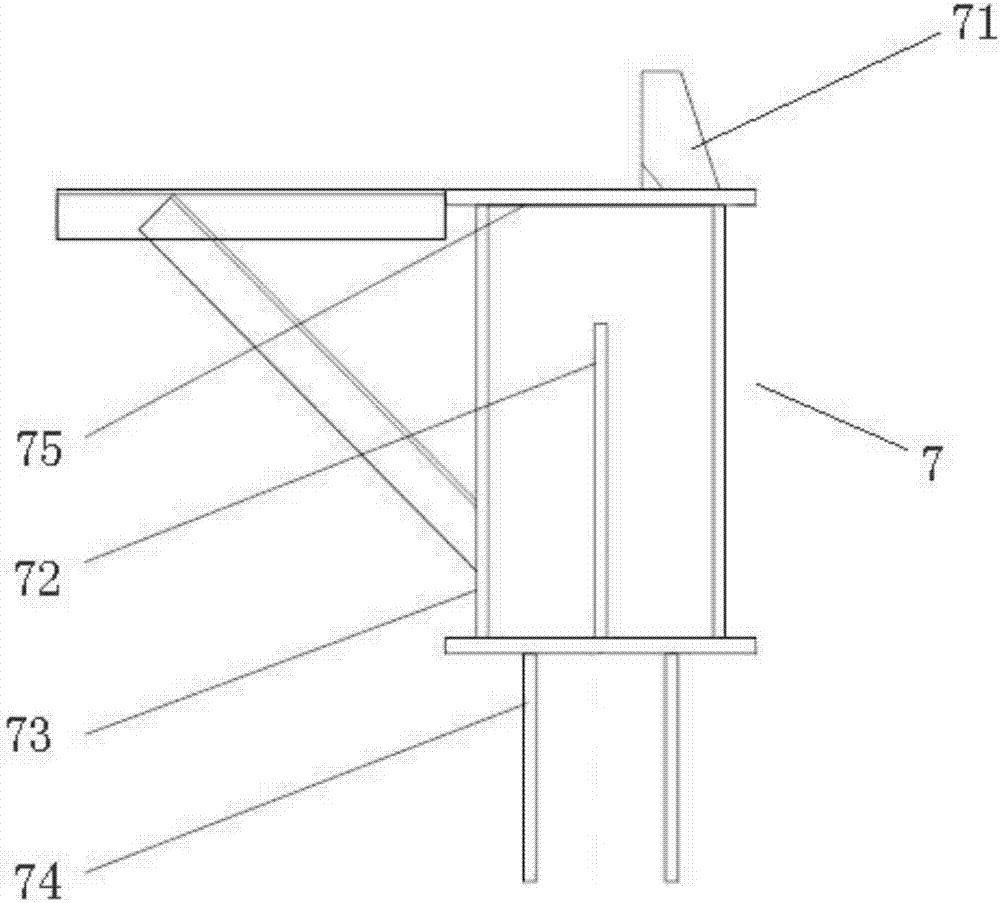

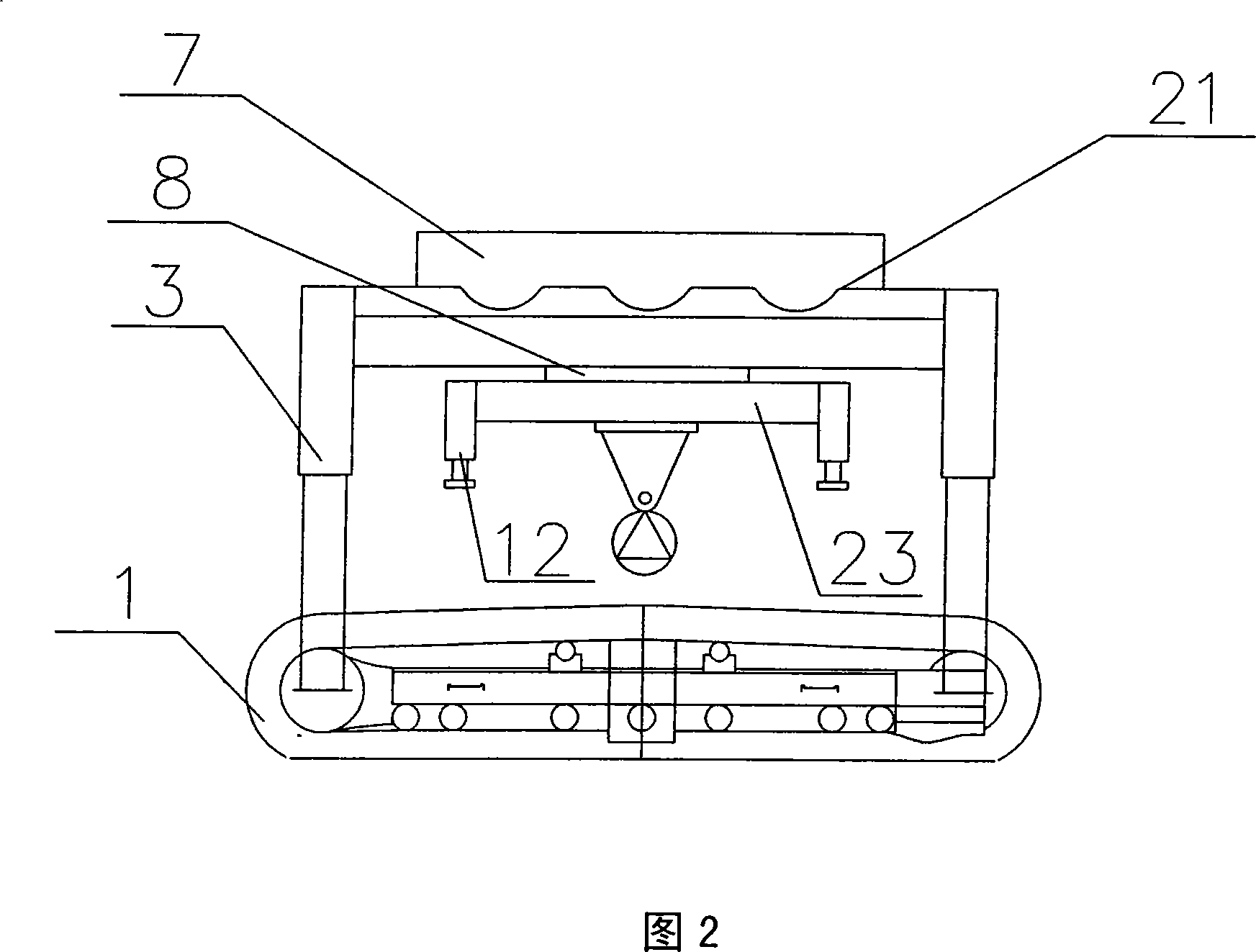

Bottom die trolley of short-line matching prefabricated box girder

PendingCN110924316ALower center of gravityAvoid safety hazardsBridge erection/assemblyBridge materialsBox girderFastener

The invention discloses a bottom die trolley of a short-line matching prefabricated box girder. The bottom die trolley comprises an upper-layer support, a lower-layer support, an adjusting device, a jacking device and a walking device. The two supports are vertically stacked, and are small in size and low in center of gravity. The walking devices are connected to the bottoms of the two transversesides of the lower-layer support. Vertical limiting columns are connected to the middle positions of the front end and the rear end of the lower-layer bracket; the limiting column penetrates through the upper-layer support to enable the two supports to be vertically limited through a fastener, the adjusting device is a telescopic device arranged in the horizontal direction, one end of the adjusting device is hinged to a hinge base on the upper-layer support, the other end of the adjusting device is hinged to the limiting column and vertically limited, and the multiple jacking devices are vertically connected to the upper-layer support. Horizontal transverse movement of the upper-layer support relative to the lower-layer support and rotation of the upper-layer support around the limiting column on one side can be achieved through telescopic movement of the adjusting device, the jacking device is used for jacking the matching beam, the vertical height or inclination angle of the matchingbeam can be adjusted, longitudinal movement of the matching beam carried by the bottom die trolley is achieved through the walking device, and operation is easy.

Owner:湖南五新智能科技股份有限公司

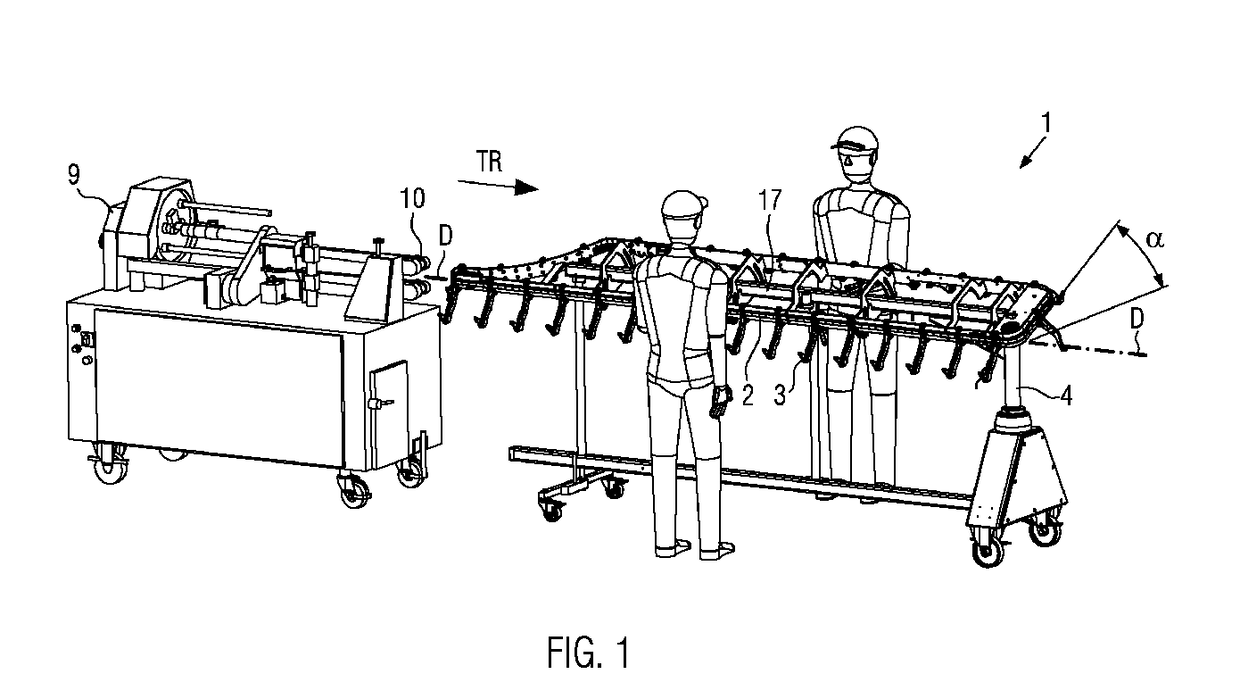

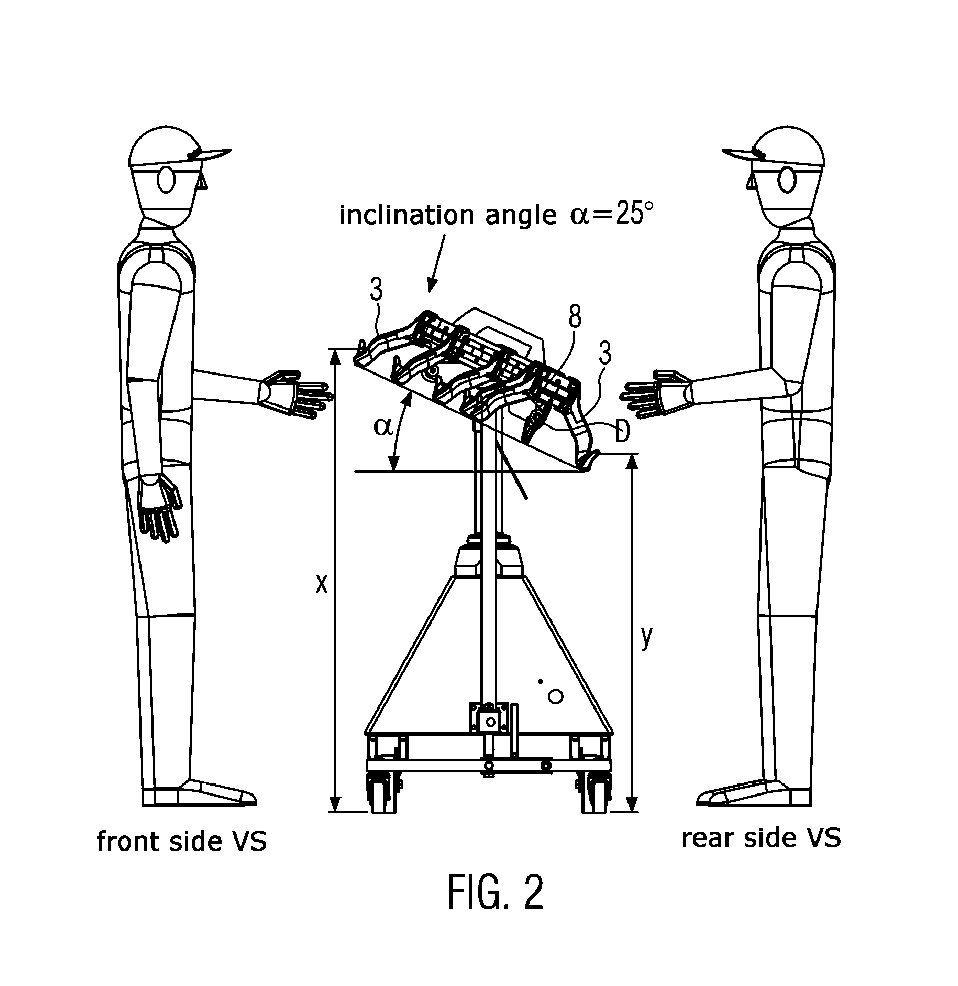

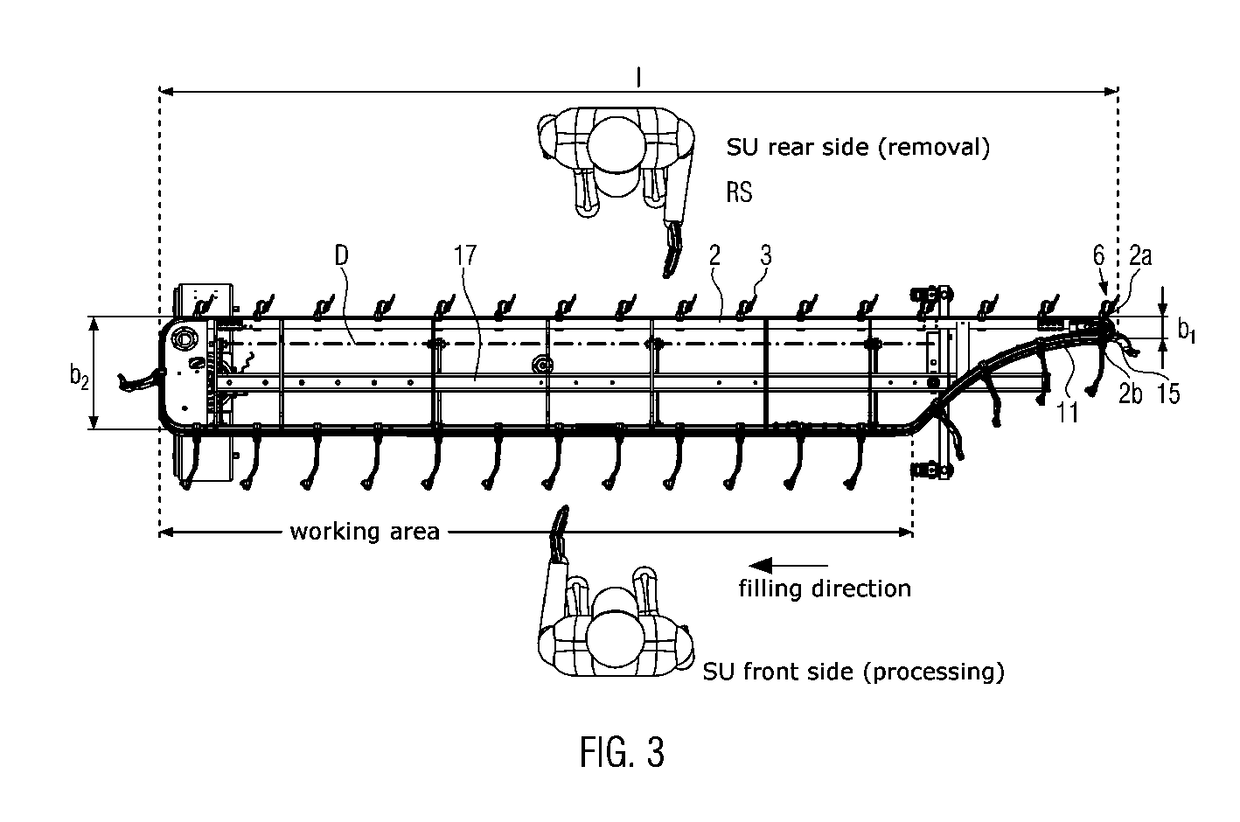

Suspension unit with inclined guide rail

ActiveUS20190000093A1Easy to disassembleImprove ergonomicsMeat/sausage hanging-upHorizontally conveying sausagesEngineeringMechanical engineering

Owner:ALBERT HANDTMANN MASCHFABRICK

Workpiece conveying device

InactiveCN101306763ASimple structureLower working heightCharge manipulationConveyor partsFixed frameEngineering

The invention relates to a workpiece delivery device, which is characterized in that an air cylinder (or oil cylinder) for controlling a movable frame is installed at one side of a fixed frame; the movable frame is installed inside the fixed frame; a guide column is installed on the fixed frame; a workpiece holding device with a V-shaped groove is installed on an cylinder (or oil cylinder) for controlling the workpiece holding device with the V-shaped groove; a feeding track is formed on the movable frame, a movable baffle is fixed on the fixed frame via an expansion link with a spring, an inclined movable track is arranged on the movable frame, a sloping block on the movable frame is fixed on the movable frame, and the inclined plane of the sloping block on the movable frame is connected with the expansion link with the spring; and the movable track capable of moving leftwards and rightwards with the movable frame is fixed on the movable frame. The inventive workpiece delivery device has the advantages of simple structure, automatic feed, isolation and discharge, low operating height, convenient operation, improved efficiency, and simultaneous delivery of workpieces at a plurality of rows.

Owner:JIANGSU SUSHENG AUTOMATION EQUIP

Method for laterally turning heavy rack

InactiveCN102807177ALower working heightReduce construction difficultyLifting devicesJackscrewEngineering

The invention relates to a method for laterally turning a heavy rack. According to the method, a support upright is built inside a foundation trench, the rack is turned to the support upright, a turning bracket is arranged at a foundation trench opening, an inner support is arranged inside the rack, and the inner support is connected with a rotary support; a hanging point is selected from the tail part of the rack so as to connect the rack with a crown block; the support upright is removed, and the rack turns under the action of self-gravity of the rack; and after the rack is turned, a temporary support device is installed, the turning bracket is removed, and the temporary support device is removed under the matching of a jack. According to the turning method, the heavy rack can be installed in a common workshop under the condition that a workshop structure is not dismounted, the work height is lowered, the construction difficulty and the risk of work high above the ground are reduced, the rack can be turned only by using the workshop crown block and without a large crane and heavy hydraulic lifting and hydraulic sliding devices, the construction cost is reduced, the construction efficiency is improved, the time limit for a project is shortened, the controllability is strong, the safety and the reliability of the construction site are improved, and the method is suitable for turning various heavy racks.

Owner:CHINA 22MCC GROUP CORP +1

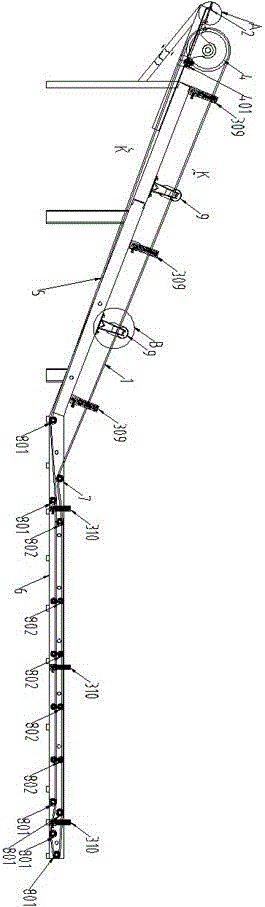

Ultralow belt conveyer

InactiveCN103332431ALower working heightSmall shaft diameterConveyorsRollersEngineeringBelt conveyor

The invention relates to an ultralow belt conveyer. The ultralow belt conveyer comprises a machine frame, a conveying belt, a belt supporting device, a tensioning device and a power device, wherein the machine frame comprise an upper machine frame and a lower machine frame, the upper machine frame is arranged obliquely, the lower machine frame is arranged horizontally, the included angle between the upper machine frame and the lower machine frame is smaller than 22 degrees, a belt pressing shaft device is arranged at the junction between the lower machine frame and the upper machine frame, the conveying belt is tightly pressed by the belt pressing shaft device and elevation steering is achieved, the belt pressing shaft device comprises a pair of belt pressing shaft fittings, the belt pressing shaft fittings are arranged at the two sides of the conveying belt respectively, the length of each belt pressing shaft is far smaller than the width of the conveying belt, and each belt pressing shaft fitting comprises a belt pressing shaft, a bearing and a bearing seat. The ultralow belt conveyer further comprises a rotary shaft fitting and a belt blocking device, wherein the rotary shaft fitting is used for bearing the weight of the conveying belt and limiting the travel distance of the conveying belt, and the belt blocking device is used for correcting the deviation of the conveying belt. The ultralow belt conveyer has the advantages that the size is small, the weight is low, no pit needs to be dug on the ground, and the belt conveyer can be moved manually.

Owner:ZHENGZHOU DINGLI DRYING EQUIP

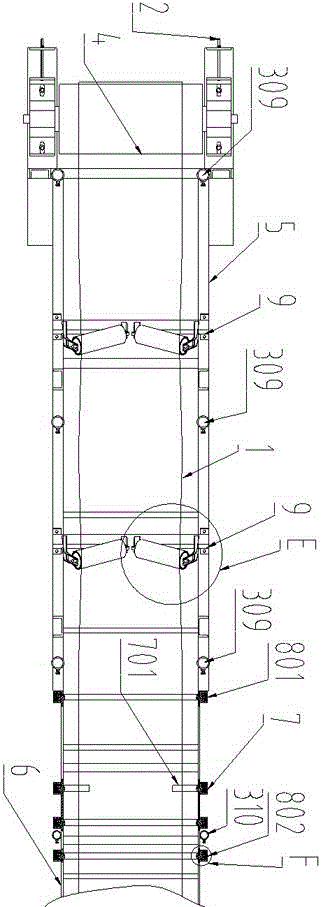

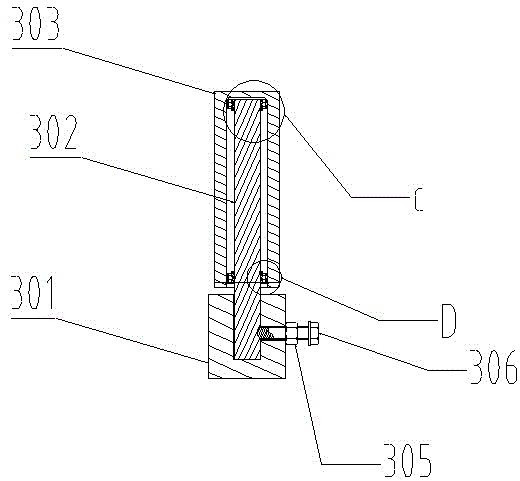

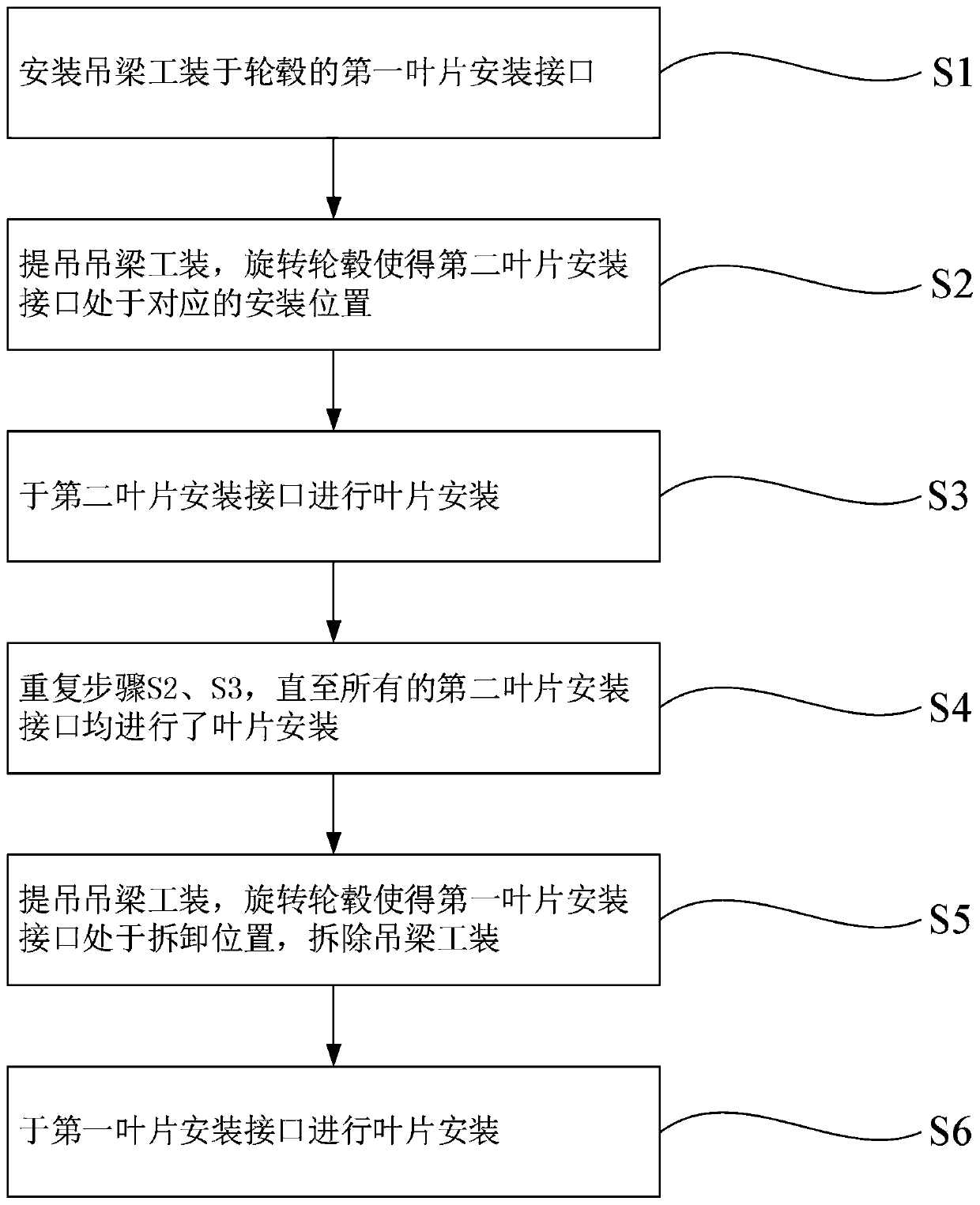

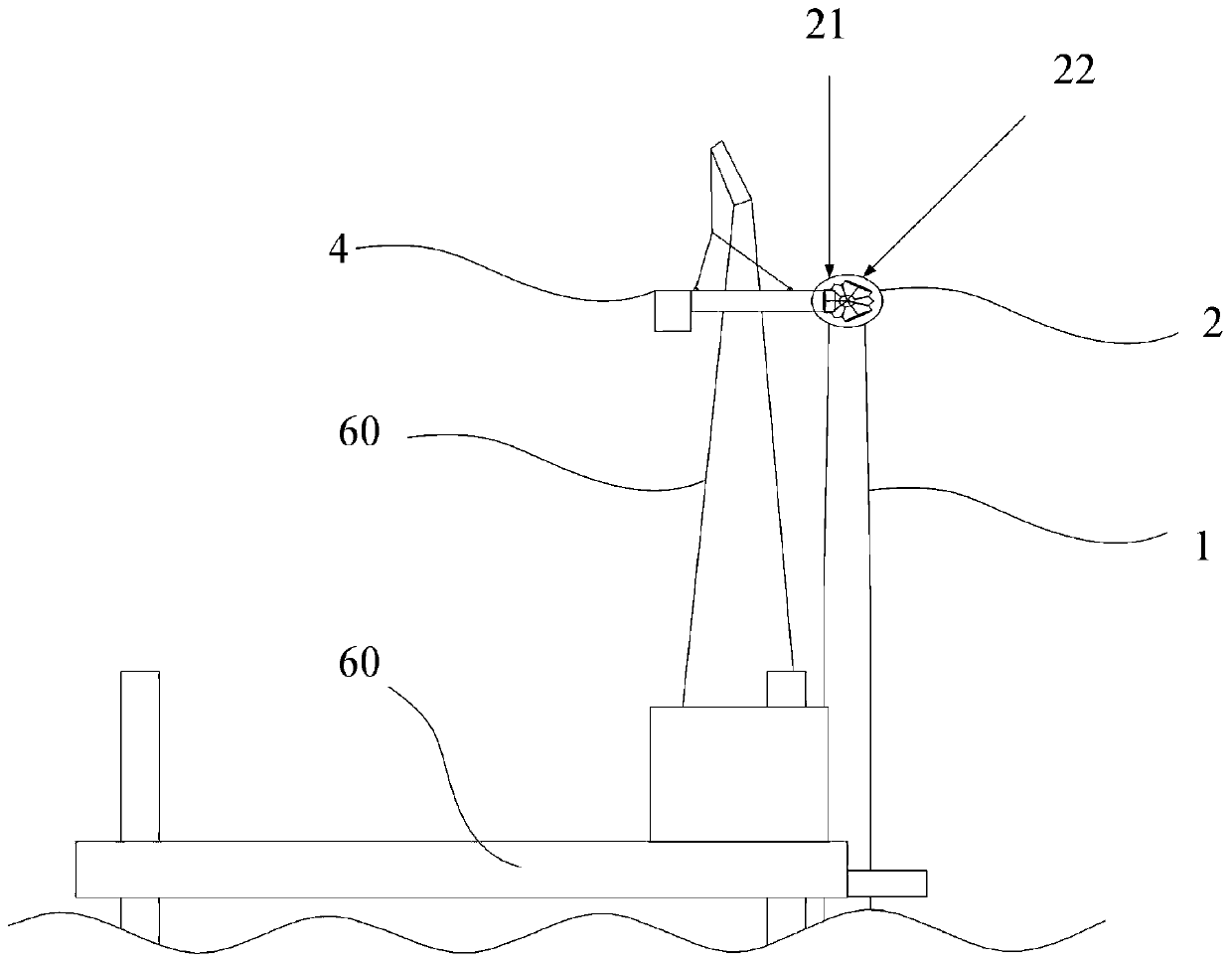

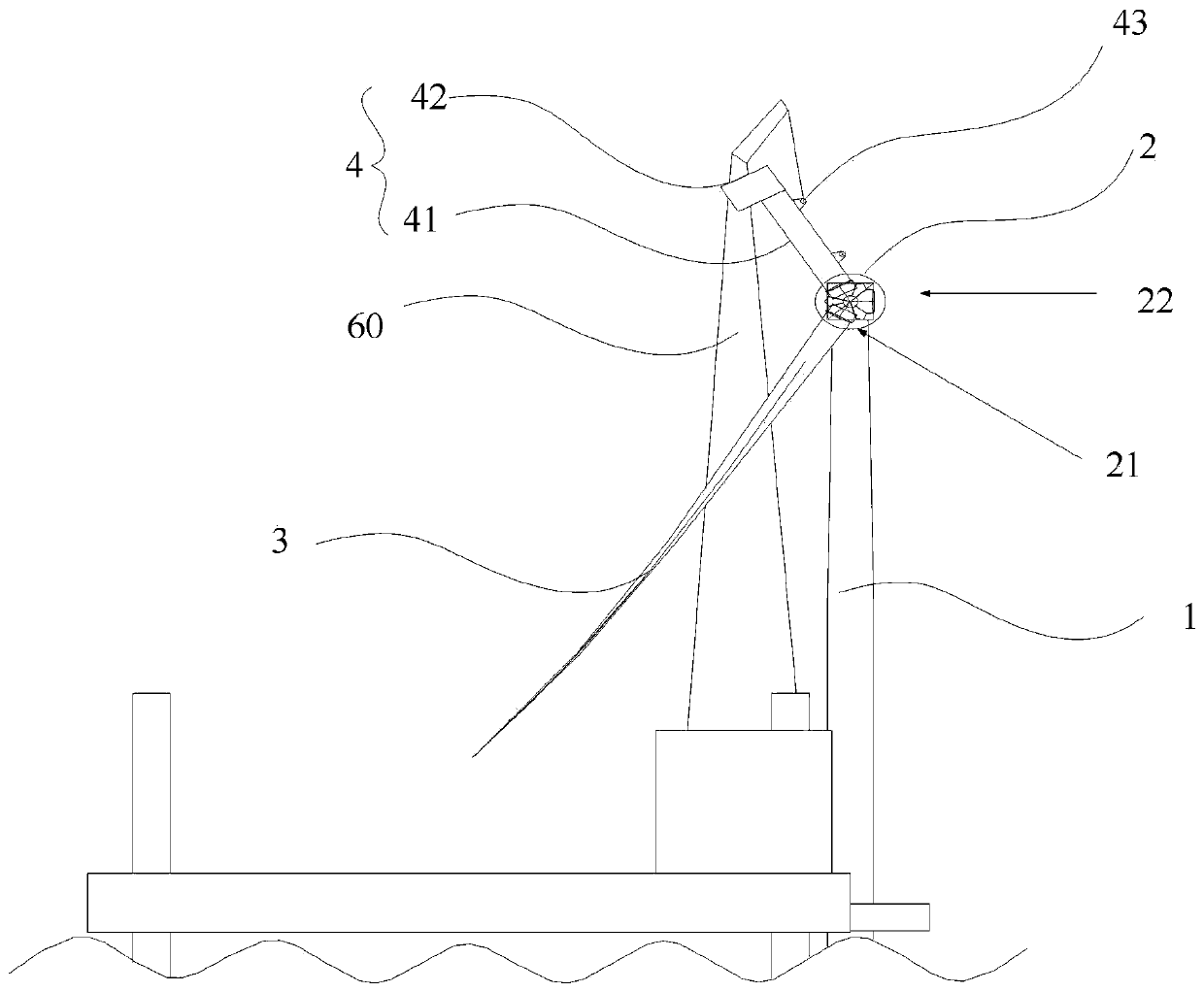

Wind driven generator and method for hoisting blades thereof

ActiveCN111410125ALower working heightEasy to installWind motor assemblyWind energy generationWind drivenElectric generator

The invention discloses a wind driven generator and a method for hoisting blades thereof. The method comprises the following steps: S1, mounting a hanging beam tool on a first blade mounting interfaceof a hub; S2, lifting the hanging beam tool, and rotating the hub to enable second blade mounting interfaces to be at corresponding mounting positions; S3, mounting blades on the second blade mounting interfaces; S4, repeating the steps S2 and S3 until the blades are mounted on all the second blade mounting interfaces; S5, lifting the hanging beam tool, rotating the hub to enable the first blademounting interface to be in a dismounting position, and dismounting the hanging beam tool; and S6, mounting blades on the first blade mounting interface. According to the hoisting method, the hangingbeam tool is utilized, the hub is rotated by controlling the hanging beam tool, so that the blade mounting interfaces to be mounted are rotated to better mounting positions, the operation height of hoisting equipment is reduced, and the economic benefit is improved.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

Sheet metal bending device and bending method

PendingCN110560520AEasy to installEasy to disassembleMetal-working feeding devicesStripping-off devicesHydraulic cylinderArchitectural engineering

The invention discloses a sheet metal bending device and a bending method. The sheet metal bending device comprises a base, wherein an inverted L-shaped support is fixedly mounted on one side of the top of the base, a hydraulic cylinder is fixedly mounted at the top of the inner wall of the inverted L-shaped support, a mounting groove is formed in the middle of the top of the base, a second rotating motor is fixedly mounted in the mounting groove, and the output end of the second rotating motor is fixedly connected with a second rotating shaft. According to the sheet metal bending device and the bending method, through the corporation of a circular rotary plate, a bending device, a lower mold base, the hydraulic cylinder, an inlet-outlet opening, an upper mold base, a limiting block, a limiting rod, a spring, the second rotating shaft, the mounting groove, the second rotating motor, a storage groove and a forming cavity for use, the working intensity of workers is greatly reduced, andthe sheet metal bending efficiency is improved; and meanwhile, the storage groove can define the position of a metal plate, so that shifting of the metal plate before the metal plate is bent can be avoided, the sheet metal bending quality is improved, and the workers can conveniently place the metal plate.

Owner:TIANJIN BAOJUN TECH DEV

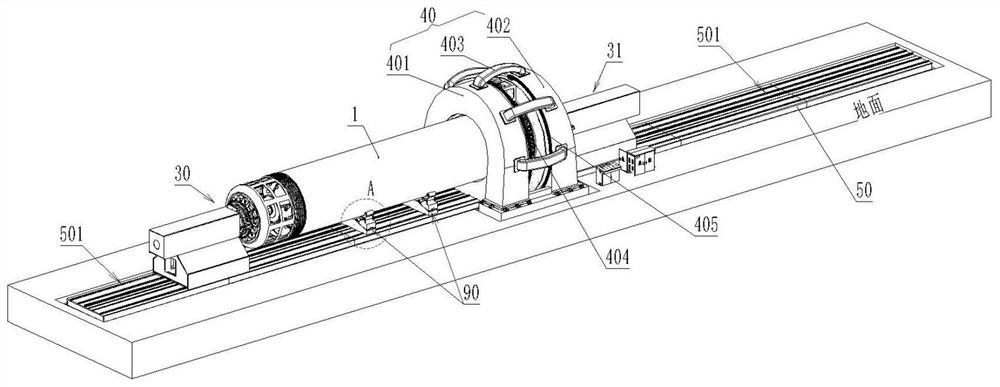

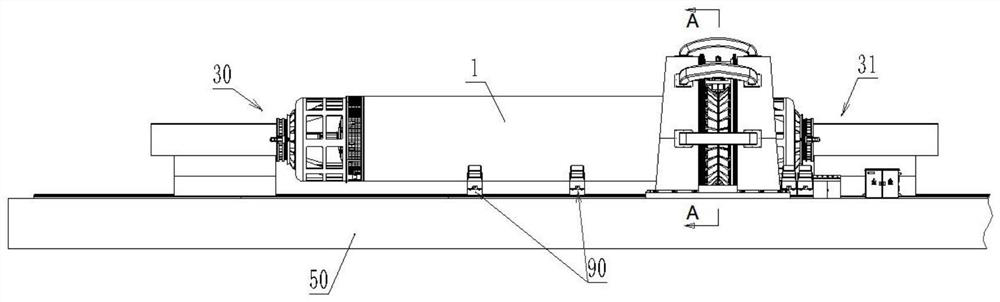

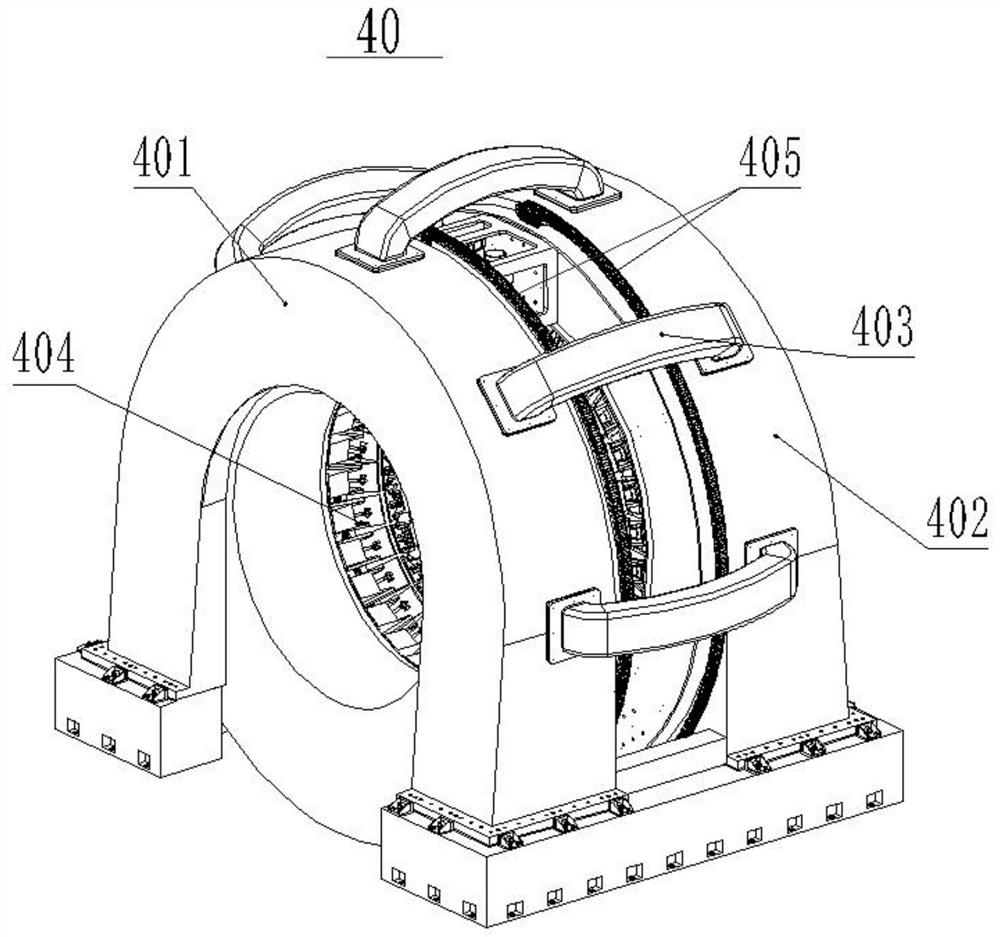

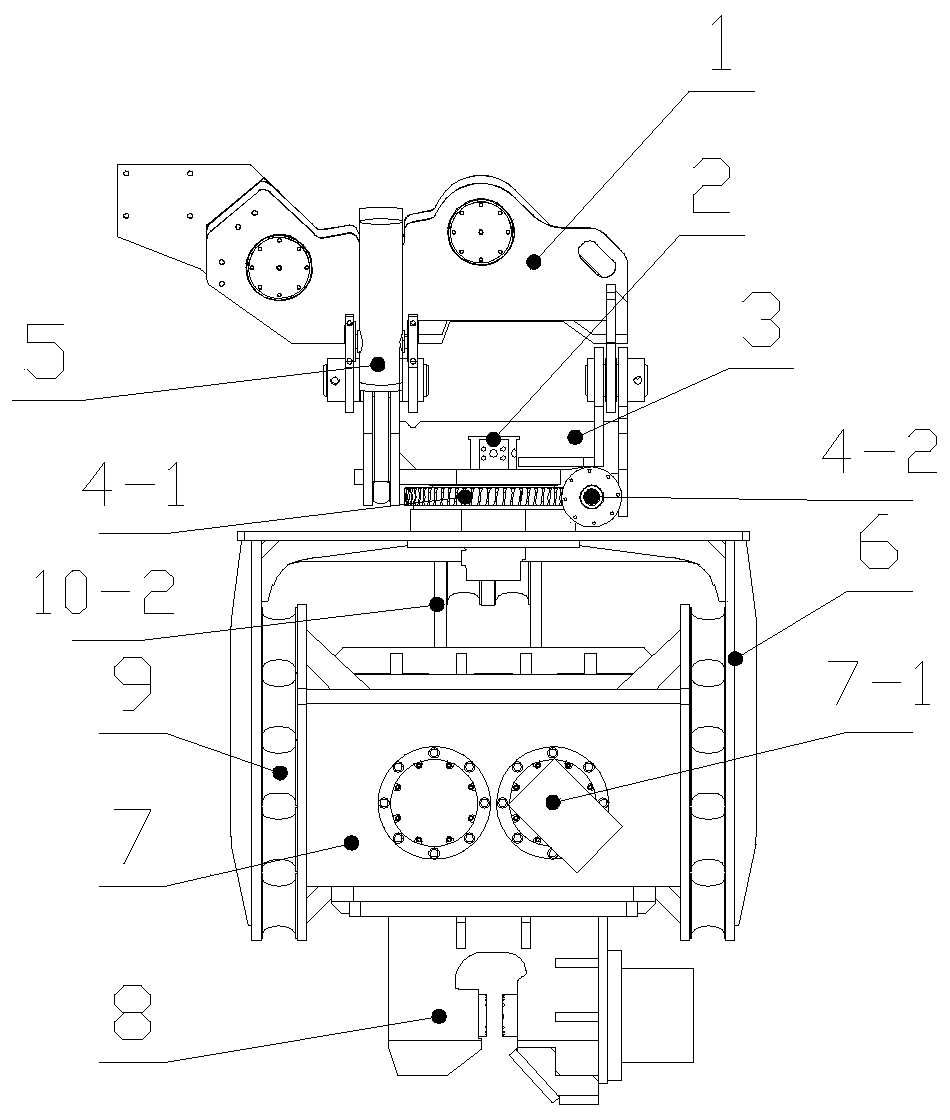

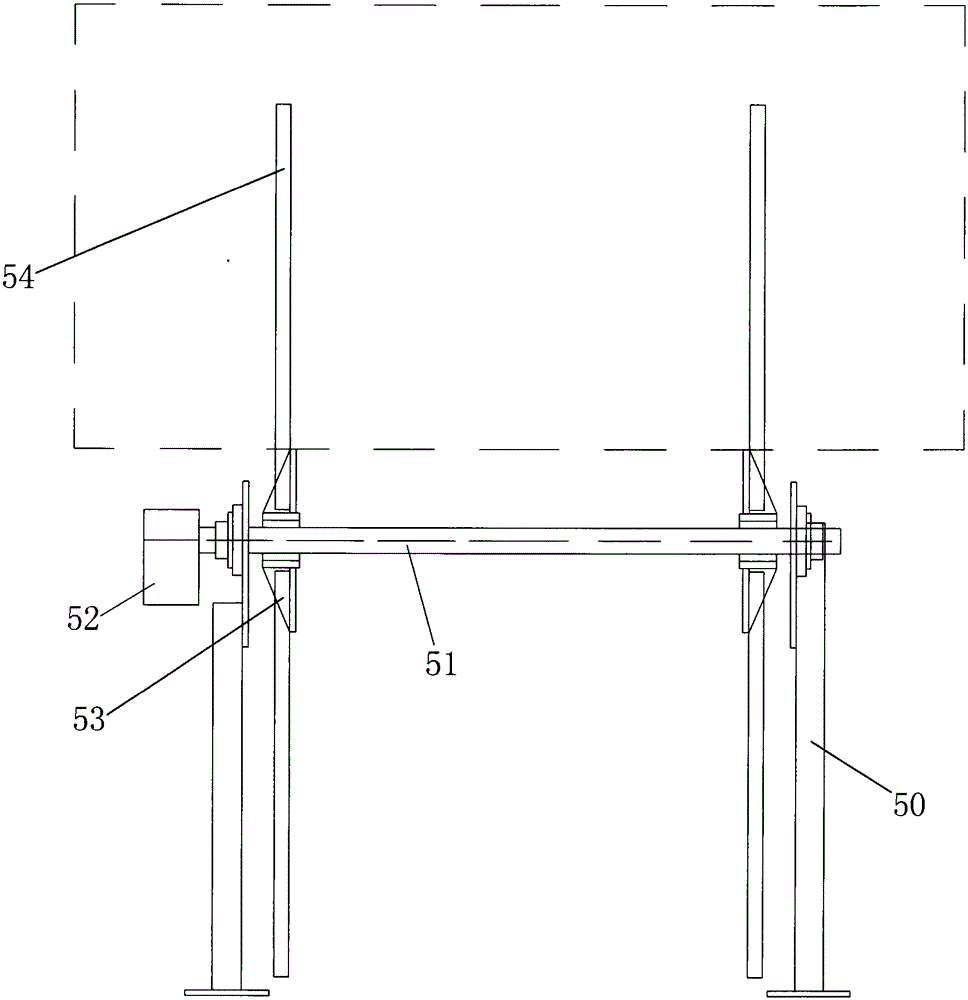

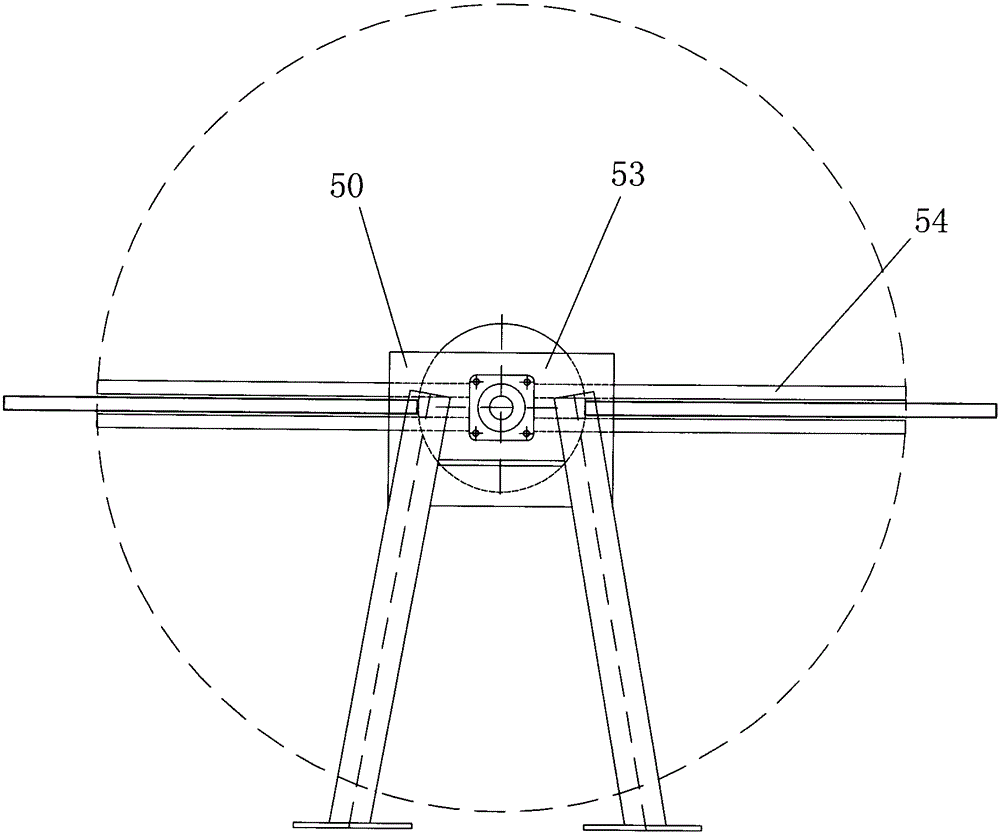

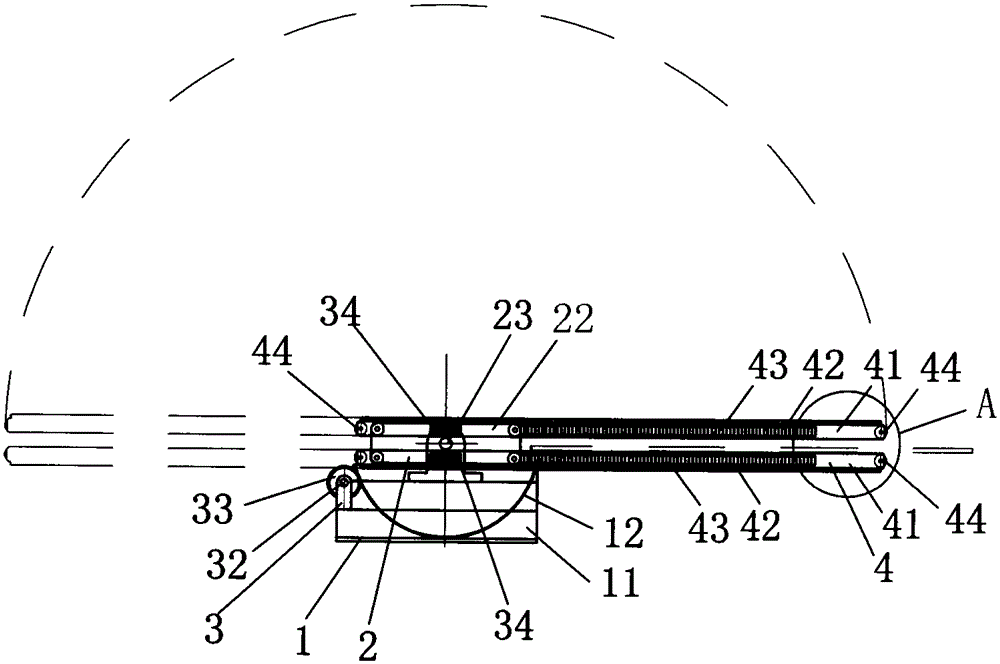

Circular seam milling and friction stir welding integrated device for aluminum alloy storage tank

InactiveCN113798857AAvoid wear and tearAvoid precisionOther manufacturing equipments/toolsMilling equipment detailsFriction weldingStructural engineering

The invention discloses a circular seam milling and friction stir welding integrated device for an aluminum alloy storage tank. The circular seam milling and friction stir welding integrated device comprises a friction stir welding machine head and a milling machine head and further comprises an annular gantry, a lathe bed, a headstock and a tailstock. The annular gantry is arranged in the middle of the lathe bed. Transmission sliding rails are arranged at the positions, on the two sides of the annular gantry, of the lathe bed. The headstock and the tailstock are installed on the transmission sliding rails on the two sides of the annular gantry correspondingly. A swing mechanism is arranged on the annular gantry, and the friction stir welding machine head and the milling machine head are installed on the swing mechanism. When the circular seam milling and friction stir welding integrated device is used for carrying out circular seam milling and friction stir welding on the aluminum alloy storage tank, a workpiece is mounted on the headstock and the annular gantry as well as the tailstock and the annular gantry, the workpiece does not need to rotate, the friction stir welding machine head and the milling machine head rotate around the workpiece through the swing mechanism to carry out milling machining or welding machining, the problem of device abrasion or precision reduction caused by large inertia brought by workpiece rotation is avoided, and the milling machining quality and the welding quality are guaranteed.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

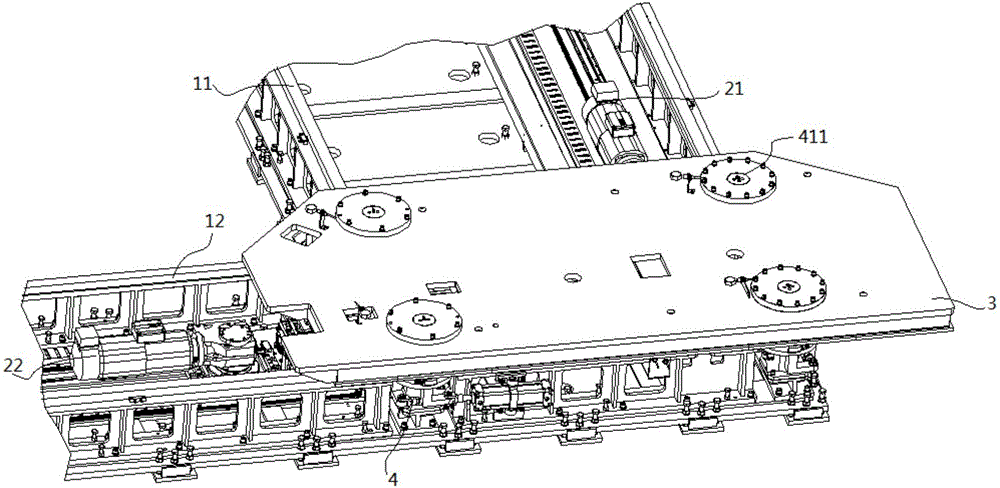

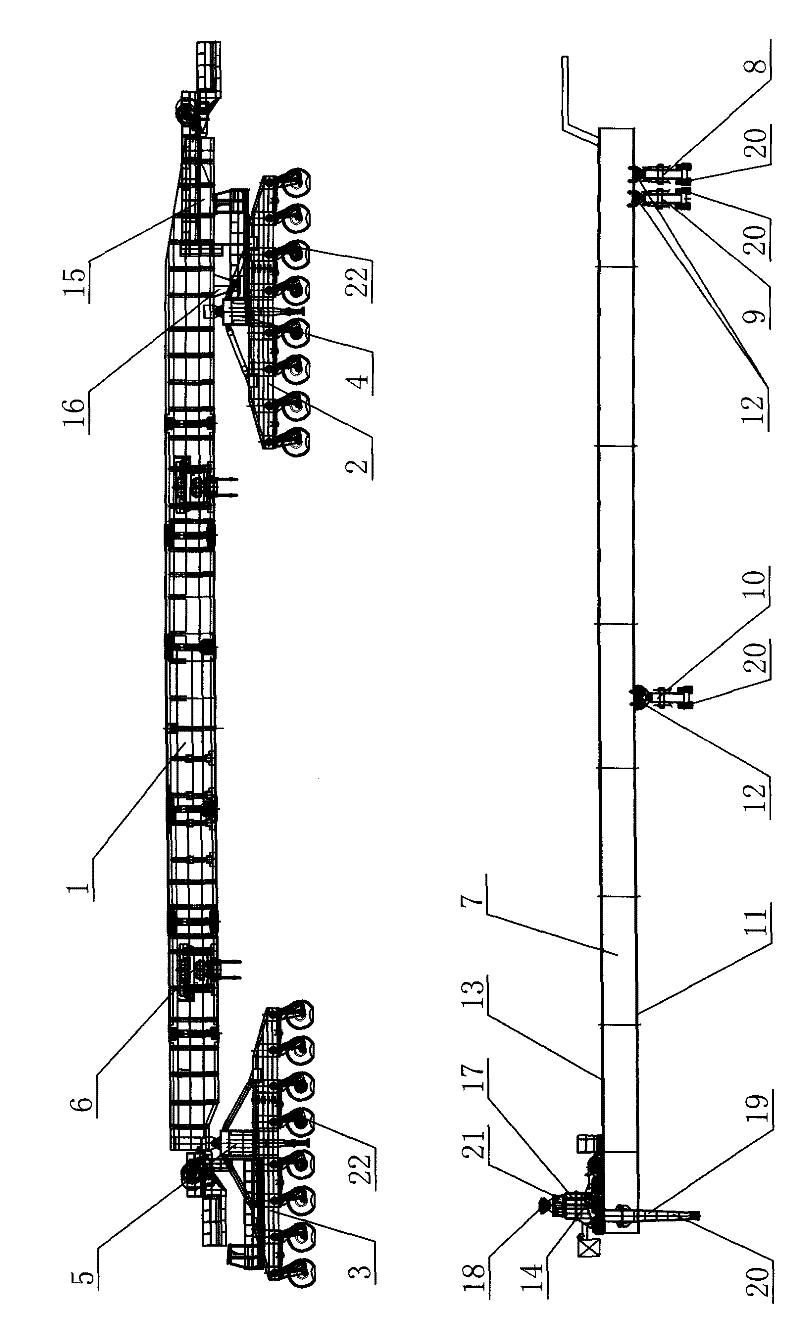

Integrative bridge erection machine of shift type transporting and erecting girder and bridge erecting method

ActiveCN101793007BSimple processImprove efficiencyBridge erection/assemblyArchitectural engineeringMachine

The invention provides an integrative bridge erection machine of a shift type transporting and erecting girder, which relates to a bridge erecting device. The invention aims at providing an integrative bridge erection machine of a shift type transporting and erecting girder and a bridge erecting method, which effectively solves of erecting a bridge in a tunnel and a first hole out of a tunnel opening and erecting a bridge with a smaller curve radius. The integrative bridge girder erection machine of the shift type transporting and erecting girder comprises a girder transporting and erecting machine and a lower girder guiding machine, wherein the girder transporting and erecting machine comprises a girder, a front running wheel group and a rear running wheel group; the lower girder guidingmachine comprises a guiding girder, front, middle and rear roller wheel legs and a girder erecting dolly; the movable girder erecting dolly is arranged on the guiding girder, the front part of a maingirder is provided with a main girder shifting and stretching section which extends forwards, the connection of the main girder shifting and stretching section and the main girder is provided with a downward shift supporting seat, and a shift supporting and moving mechanism is arranged on the girder erecting dolly and can slide along the bottom of the main girder shifting and stretching section under the shift supporting seat. When the erection moves ahead, the shift supporting and moving mechanism is raised step by step by the running wheel groups to convert the load to the girder erecting dolly step by step, thereby completing the conversion of carrying and supporting points.

Owner:北京万桥兴运工程技术有限公司

Distribution Center Automatic Container Terminal Loading and Unloading System

The invention relates to a loading and unloading system for a distribution center type automated container terminal. The loading and unloading system comprises a plurality of quay cranes, a nearshore multipath rectangular-ambulatory-plane automatic transportation system, an elevated container automatic loading and unloading system, a storage yard, a container evacuating port side multipath rectangular-ambulatory-plane automatic transportation system, a container evacuating port transportation system, an annular special container channel and a control system. Compared with the scheme of an existing automated container terminal, the loading and unloading system for the distribution center type automated container terminal is advantaged in that the loading and unloading system is creative and unique, and is high in production efficiency, safety, automation degree and stability, and is simple in structure, simple to control and complete in scheme.

Owner:TIANJIN PORT CONTAINER TERMINAL

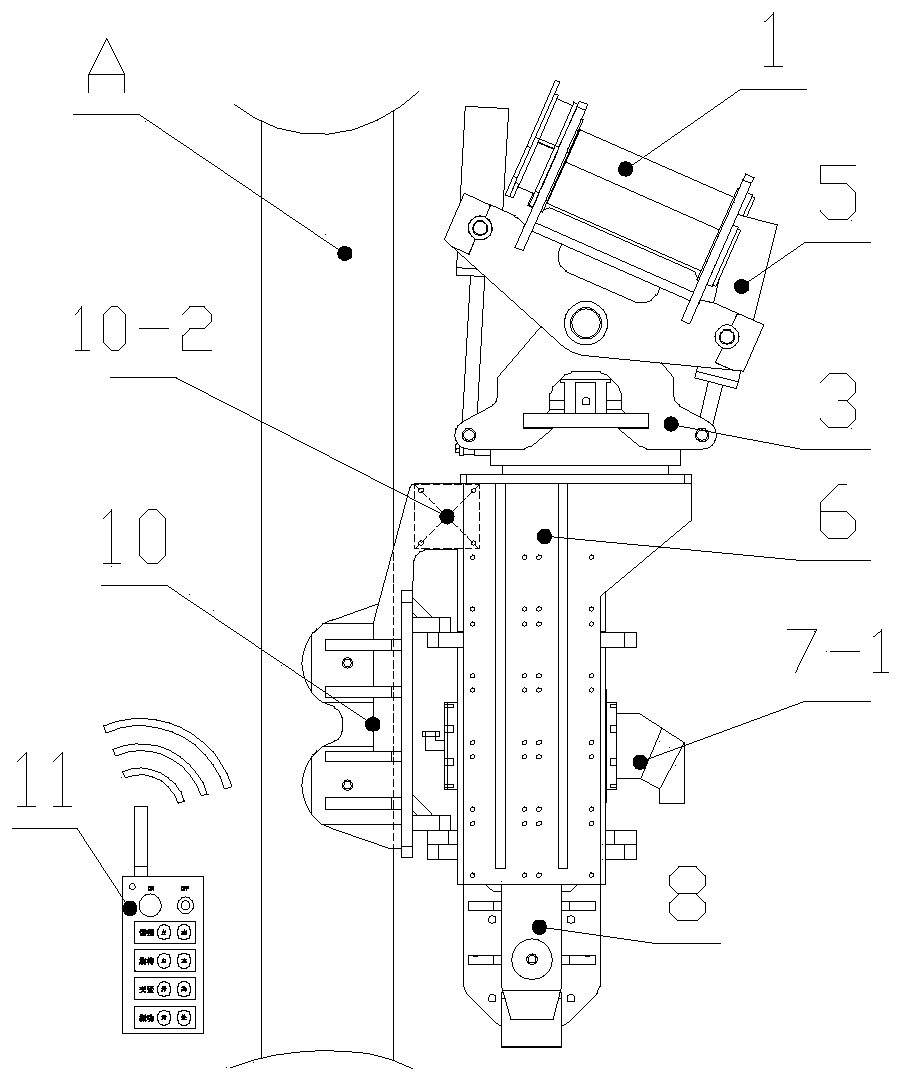

Single-sided clamping type piling device

The invention discloses a single-sided clamping type piling device. The single-sided clamping type piling device structurally comprises a driving device, an adjusting assembly, a clamping device and acontrol system, wherein the driving device comprises a vibration excitation driving device and a rotary driving device, the vibration excitation driving device comprises a vibration excitation box body and a vibration excitation motor, and the rotary driving device comprises a rotary motor and a gear reducer composed of a rotary gear and a speed reduction worm; the adjusting assembly comprises aconnecting frame, a deflection rotating disc, a deflection oil cylinder and a rotary driving device; and the clamping device comprises a side clamping device and a straight push clamping mouth at thelower part of the whole device. The single-sided clamping type piling device has the advantages that the device is not limited by the operation height when working; the structure is smooth and steady;the interference of a pile body and the rotating disc at the upper end is avoided during pile clamping work; the self-locking position function is achieved; the any angle rotation of a connecting suspension arm and parts below the connecting suspension arm is achieved; the device completes the pile driving and extracting operation at each posture and angle; and the device posture control and thepile driving state control can be achieved through wired control or wireless remote control when the device is used.

Owner:江苏坤龙机械科技有限公司

An intelligent head-up display system

ActiveCN105527710BRealize multiple rounds of voice interaction functionsAchieve normal displayInput/output for user-computer interactionGraph readingHead-up displayThird party

The invention discloses an intelligent head-up display system, which comprises a display assembly, an image acquisition assembly, a natural voice interaction assembly, a sensor assembly and a processor assembly. The display assembly is connected with the image acquisition assembly; the sensor assembly is connected with the processor assembly; and the image acquisition assembly is connected with the processor assembly. Compared with a convention head-up display system, the intelligent head-up display system can support more interaction control and can realize voice scheme interaction adoption, and meanwhile, can install various third-party applications to expand and enrich functions; furthermore, the intelligent head-up display system, carried with various sensors, can connect external equipment; and besides, the intelligent head-up display system has a camera module, which faces to the inner portion of a vehicle, so that the behavior and state of a driver can be identified, and safe driving reminding function and interaction control function can be realized.

Owner:BEIJING ILEJA TECH CO LTD

Turnover machine

The invention discloses a turning-over machine which comprises a machine frame, a rotating mechanism, a moving mechanism and at least four sets of fork rods. The rotating mechanism and the moving mechanism are both installed on the machine frame. The rotating mechanism is provided with at least two rotating discs fixed at two ends of a rotating shaft. Each rotating disc is provided with a moving roller supporting and limiting the fork rods to conduct linear movement. Two pairs of fork rods are symmetrically and vertically installed on the moving rollers with the axis of the rotating shaft as the symmetrical center. Two pairs of synchronous gears are connected coaxially, meshed with synchronous racks on the outer sides of the two pairs of fork rods and vertically installed on the rotating shaft. When a moving gear of the moving mechanism rotates, the moving gear drives moving racks on the lower sides of the lower fork rods to move linearly. Under the effect of the synchronous gears and the synchronous racks, moving racks on the upper fork rods also move in the same direction synchronously. When the two pairs of fork rods clamp a plate from the plate feeding position, after the rotating mechanism rotates through 180 degrees, the two pairs of fork rods are driven by the moving mechanism to be pushed backwards to the original plate feeding position to achieve the aim that the two pairs of fork rods clamp the plate in a circulation mode and turn over the plate. Due to the fact that the fork rods only rotate on the upper half ring of the turning-over machine, working height of the turning-over machine is reduced.

Owner:张铭勇

Orbit transferring switching mechanism

The invention discloses an orbit transferring switching mechanism and belongs to the field of switching mechanisms. The orbit transferring switching mechanism comprises four single switching mechanisms, a fixed orbit set and an electric control system. The upper end of a connecting body in each single switching mechanism is fixedly connected with a fixing wheel. The lower end of each connecting body is fixedly connected with the upper end of a universal ball. A sliding wheel is arranged at the lower end of a spherical shell of each universal ball and matched with a rotating orbit, the rotating orbit and orbits of the fixed orbit set are located on the same plane, the rotating orbit is combined with the orbits of the fixed orbit set and fixedly connected to a rotating wheel, a rotating side arm is arranged below the rotating wheel, and the rotating side arm is fixedly connected with a piston rod of a cylinder. The cylinder drives the rotating side arm to rotate and meanwhile drives the rotating orbit to rotate, and vehicle type switching is achieved. Due to the adoption of the technical scheme, the switching speed is high, the structure is simple, the manufacturing cost is low, maintaining is convenient, and the comprehensive utilizing efficiency of a welding workshop is high.

Owner:ANHUI RUIXIANG IND

Construction method for deep pit excavation

ActiveCN101187208BAvoid Personal Safety AccidentsEfficient removalExcavationsStructural engineeringEnergy analysis

The invention relates to the technical field of underground engineering, in particular to a construction method for excavating deep foundation ditch, wherein the bottom of an excavating machine is provided with a walking device to realize and finish selection of excavating positions, a support beam along the vertical direction of the excavating machine is arranged into a perpendicular adjustable beam which can be vertically adjusted along the vertical direction to realize adjustment of working height of the excavating machine, and a support beam along the horizontal direction of the excavating machine is arranged into a level adjustable beam which can be horizontally adjusted along the horizontal direction to realize adjustment of working scope of an excavating bucket of the excavating machine. After the selection and regulation are finished, the excavating is finished. The invention has the advantages of high safety when in construction, high efficiency, energy-saving, and environmental protection, and can excavate in omnibearing and in multi-angles.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com