Built-in pilot operated solenoid valve

A pilot solenoid valve, main valve technology, applied in the direction of lift valve, valve details, safety valve, etc., can solve problems such as inability to meet multiple starts, repeated use, adverse effects of assembly structure, inconvenient assembly testing, etc., to reduce the product. Structural size and weight, reduction of product size and weight, constant flow resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

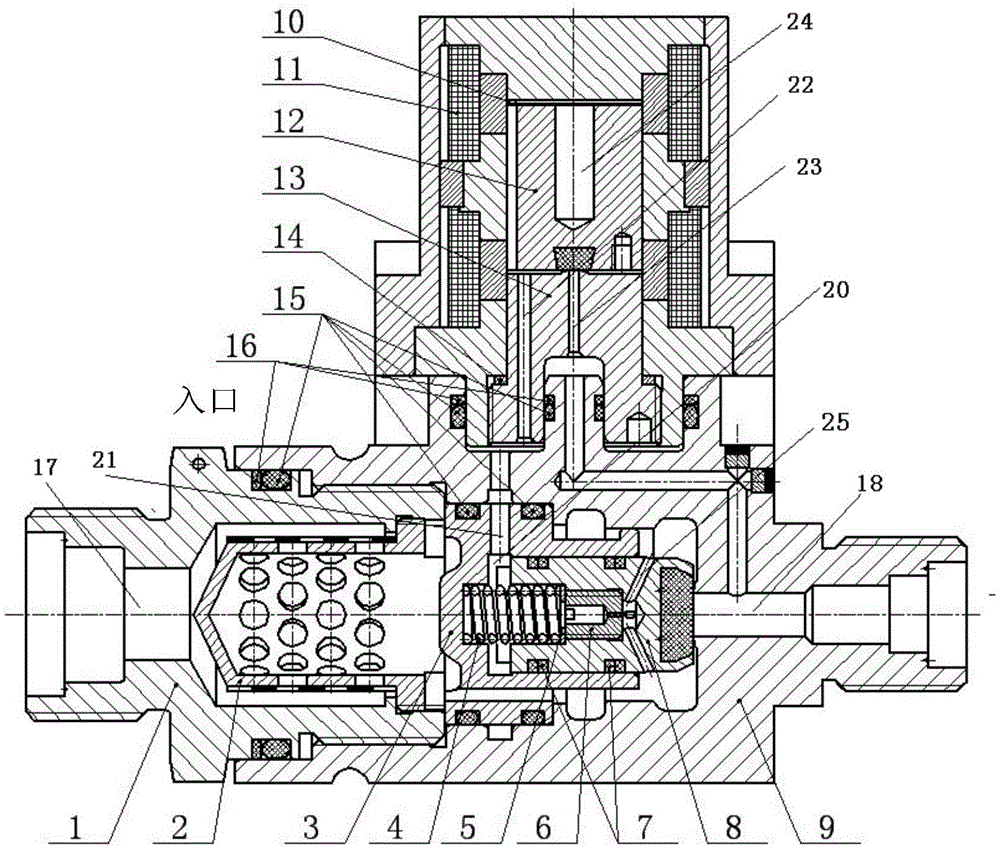

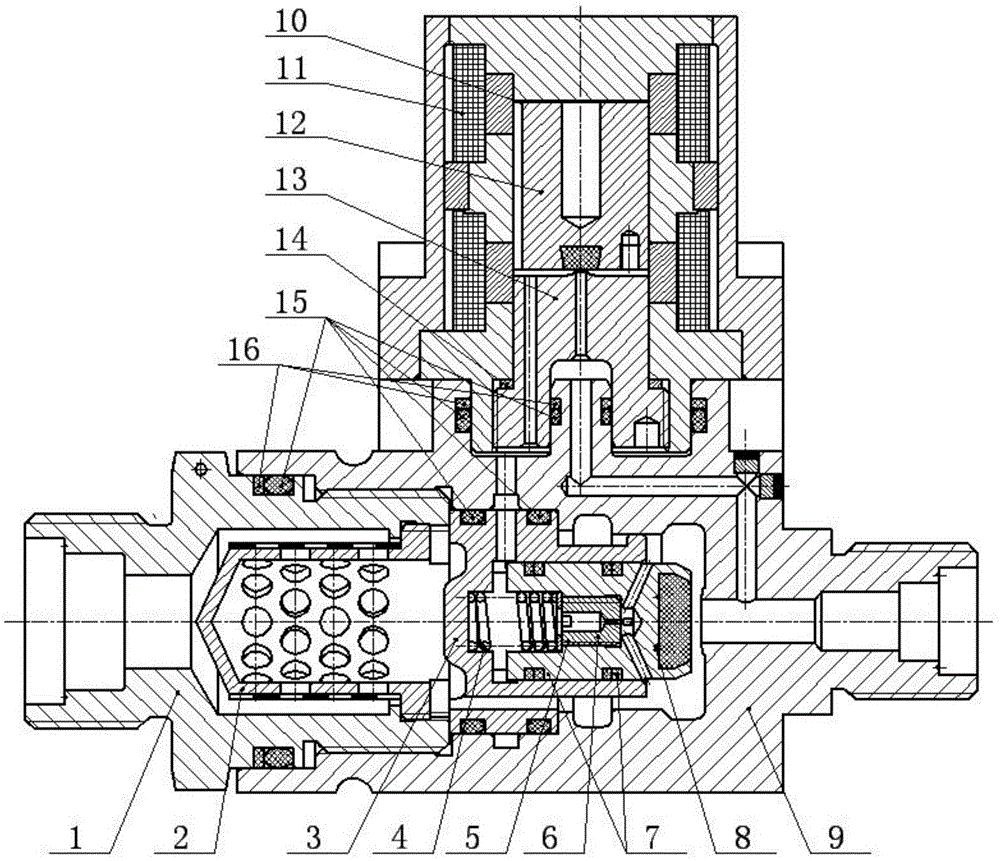

[0040] Such as figure 1 As shown, a built-in pilot solenoid valve with self-locking function, including nozzle 1, filter 2, valve sleeve 3, cylindrical spring 4, spring force adjustment pad 5, current limiting nail 6, baffle ring 7, main valve Core 8, main valve body 9, magnetic isolation pad 10, auxiliary valve coil assembly 11, auxiliary valve core 12, auxiliary valve seat 13, stroke adjustment pad 14, O-shaped rubber sealing ring 15, retaining ring 16, etc.

[0041]Installation relationship: magnetic isolation pad 10, auxiliary valve coil assembly 11, auxiliary valve core 12, auxiliary valve seat 13, stroke adjustment pad 14 are pre-installed as auxiliary valves, and the valve core can be adjusted by selecting magnetic isolation pads and stroke adjustment pads of different thicknesses The size of the initial air gap and working air gap at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com