Steel structure building and wall construction method thereof, and girder and column steel member

A construction method and steel structure technology, applied to building components, building structures, buildings, etc., can solve the problems of slow construction progress, hidden dangers of construction safety, poor performance of wind resistance and horizontal load resistance, etc. Difficulty, reduce the working height, improve the effect of safety and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiment of the steel structure building in the present invention: the steel structure building belongs to the combined steel-concrete prefabricated structure. The building is mainly composed of columns, wall panels, floor decks, and roof beams. The characteristic of this building form is that the total weight of the building is reduced. 30%-60%, there is no need to make another insulation layer for the wall, no need to tie up steel bars and support and dismantle formwork for columns and beams, no need to build and disassemble load-bearing construction scaffolding, no need to use formwork and other turnover materials, and reduce costs by 40%-60% The construction period and turnover materials are used, energy saving and environmental protection, the construction cost is reduced by 20%-40%, the earthquake resistance effect is greatly improved, and the economic efficiency is obvious.

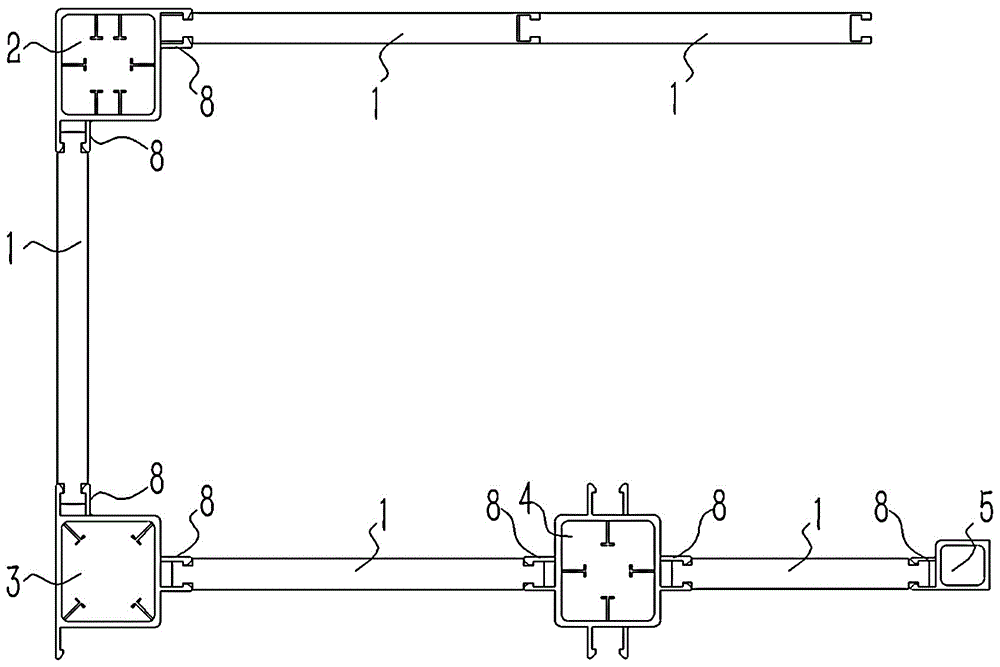

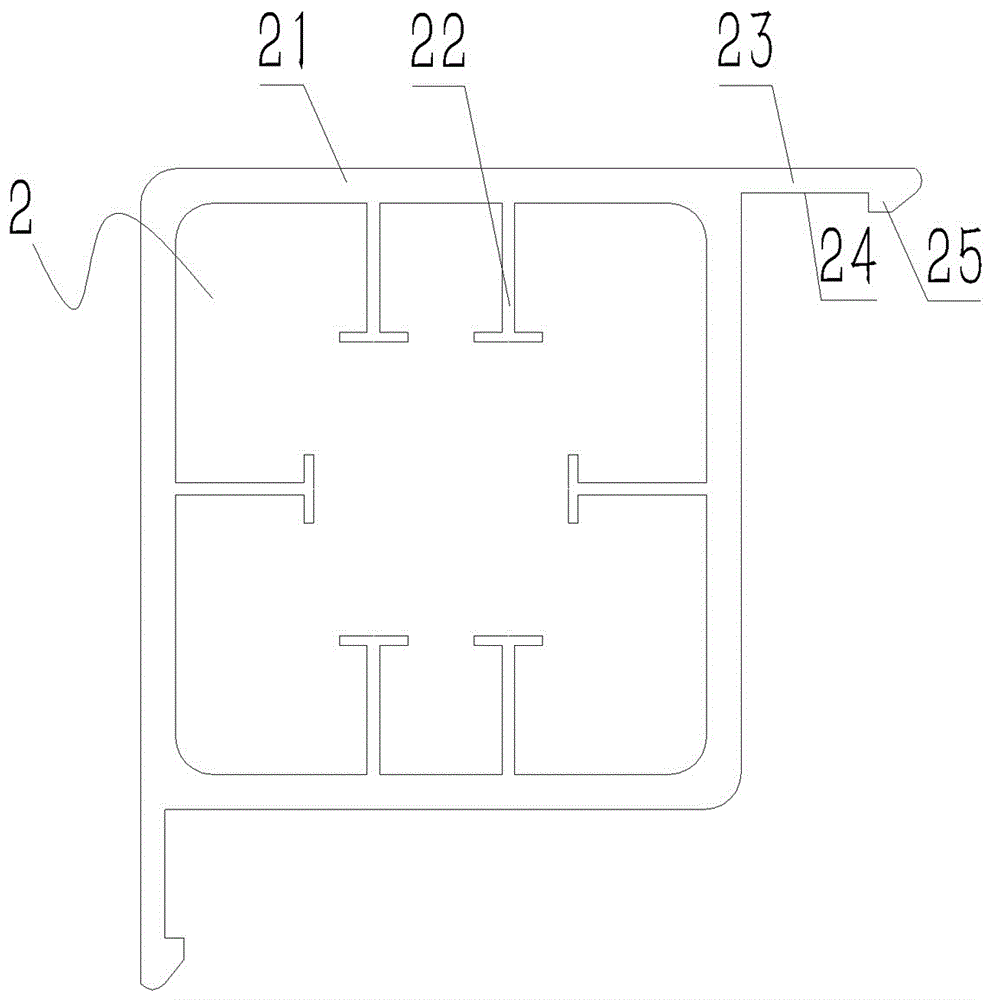

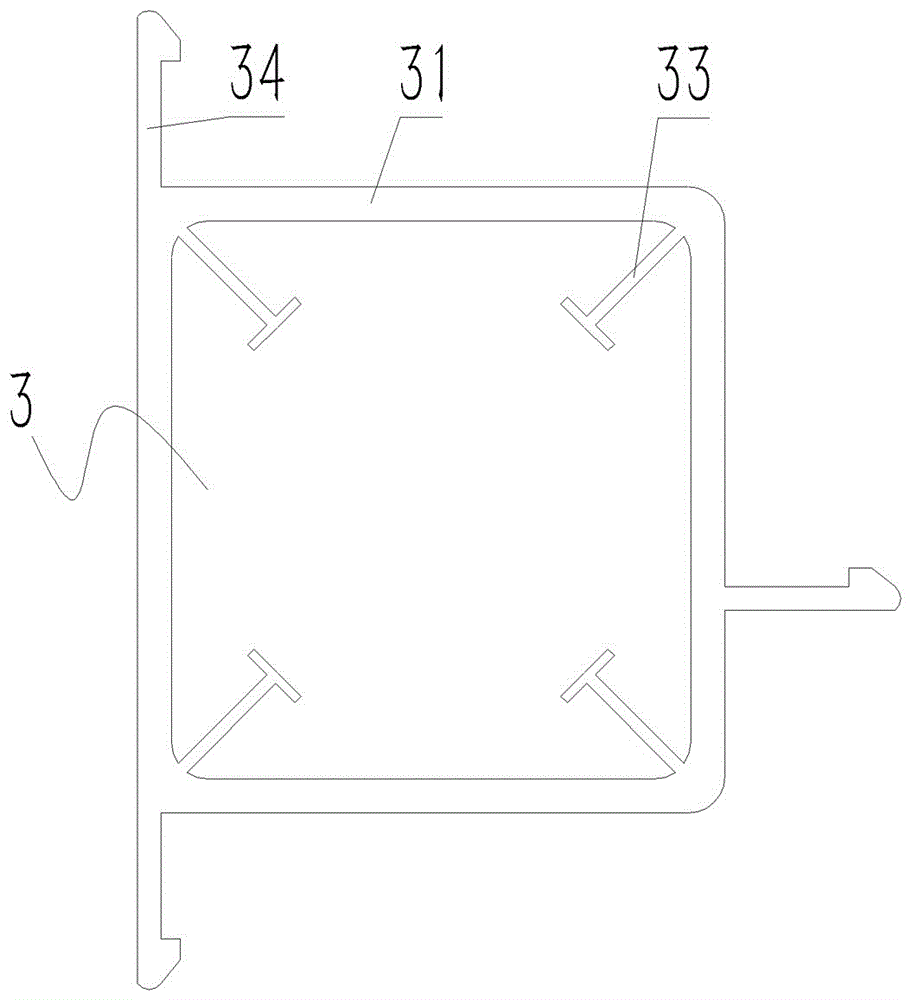

[0034] like figure 1 As shown, the wall of the steel structure building is mainly form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com