Multi-section aluminum foil pasting device for shell of gas generator

A gas generator and pasting device technology, which is applied in transportation and packaging, pedestrian/passenger safety arrangement, vehicle safety arrangement, etc., can solve the problems of high risk of failure and air leakage, poor control of the relative position of the membrane and the shell, etc., to achieve The positional relationship is stable, the process is stable and reliable, and the effect of reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

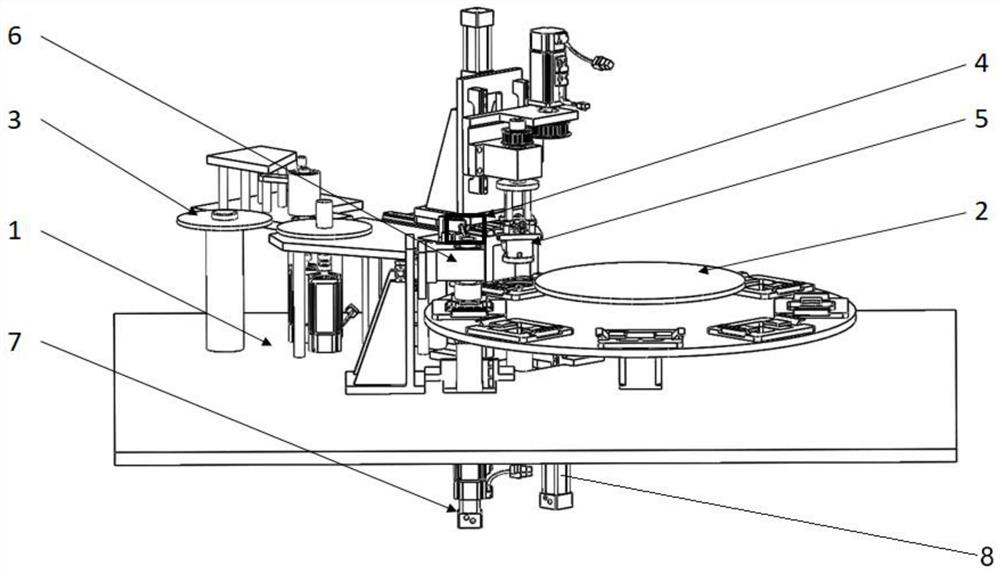

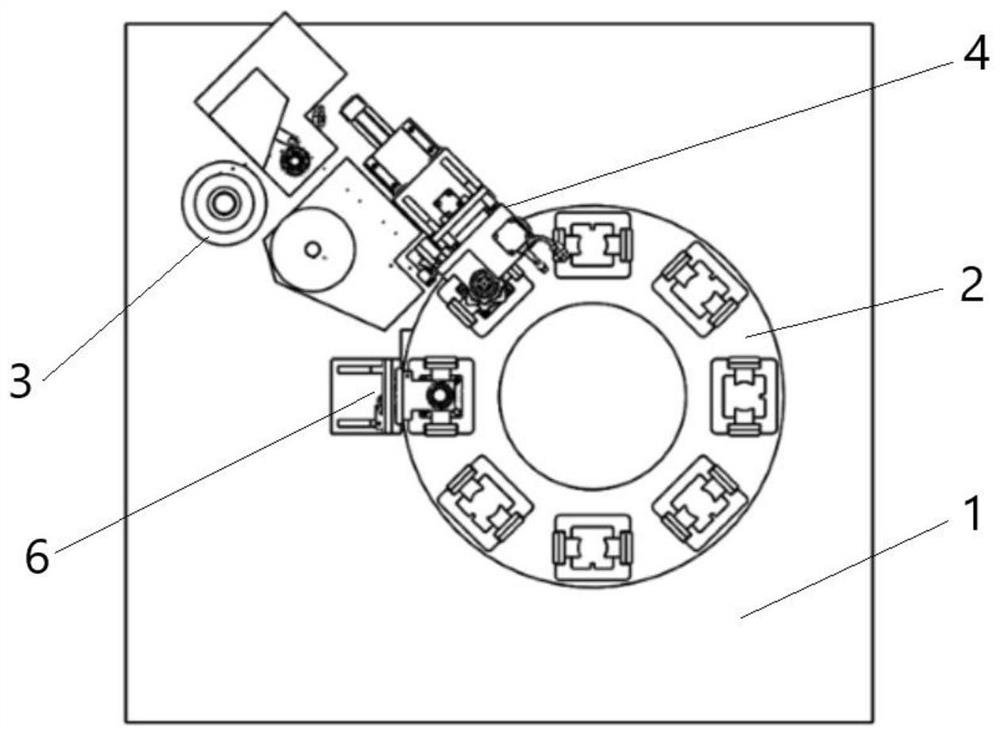

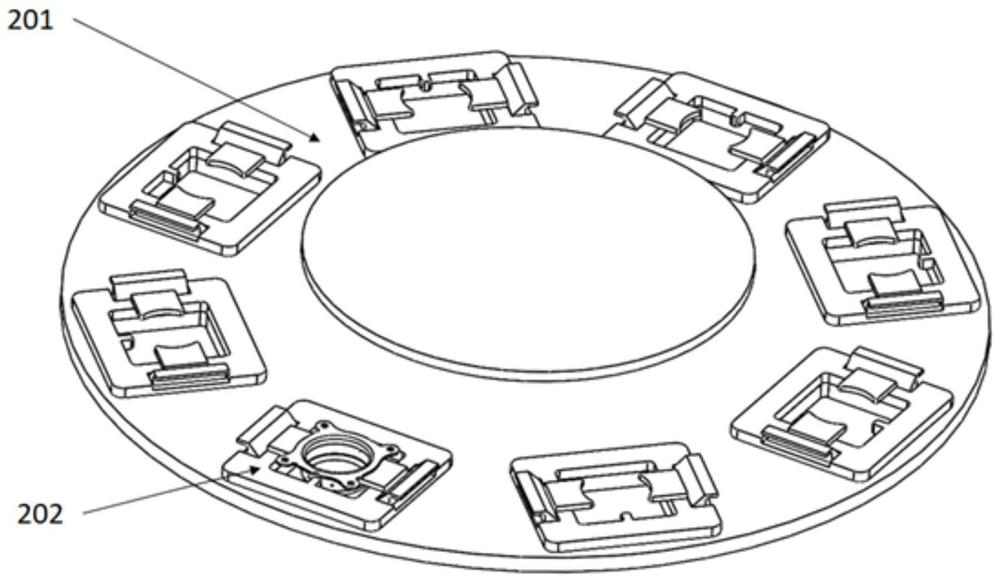

[0033] figure 1 , 2 , 3, the present invention includes a housing transfer carousel 201, a film take-up and release mechanism 5 arranged along the edge of the housing transfer carousel 201, a rolling film sticking mechanism 6; the housing transfer carousel 201 is evenly distributed with a plurality of The jig 202 of the housing; the lower part of the housing transfer carousel 201 is provided with an ejection mechanism 8 for ejecting the housing in the jig 202 to the film releasing station corresponding to the film taking and releasing mechanism 5 .

[0034] The film take-up and release mechanism 5 includes a film suction cylinder 503 for putting the adhesive-backed aluminum foil conveyed by the feeding mechanism 3 into the position required for pasting the film on the inner wall of the housing at the film release station, and for driving the suction film at the mold take station. The film cylinder rotates to wind the multi-sections of aluminum foil to be pasted from the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com