Secondary mirror supporting structure of space optical remote sensing camera

A technology of space optical remote sensing and secondary mirror support, applied in the field of space optical remote sensing, can solve the problems of heavy support structure, large width of truss rods, and large obscuration ratio, etc., and achieves small obscuration, high lightweight rate, and small self-weight deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

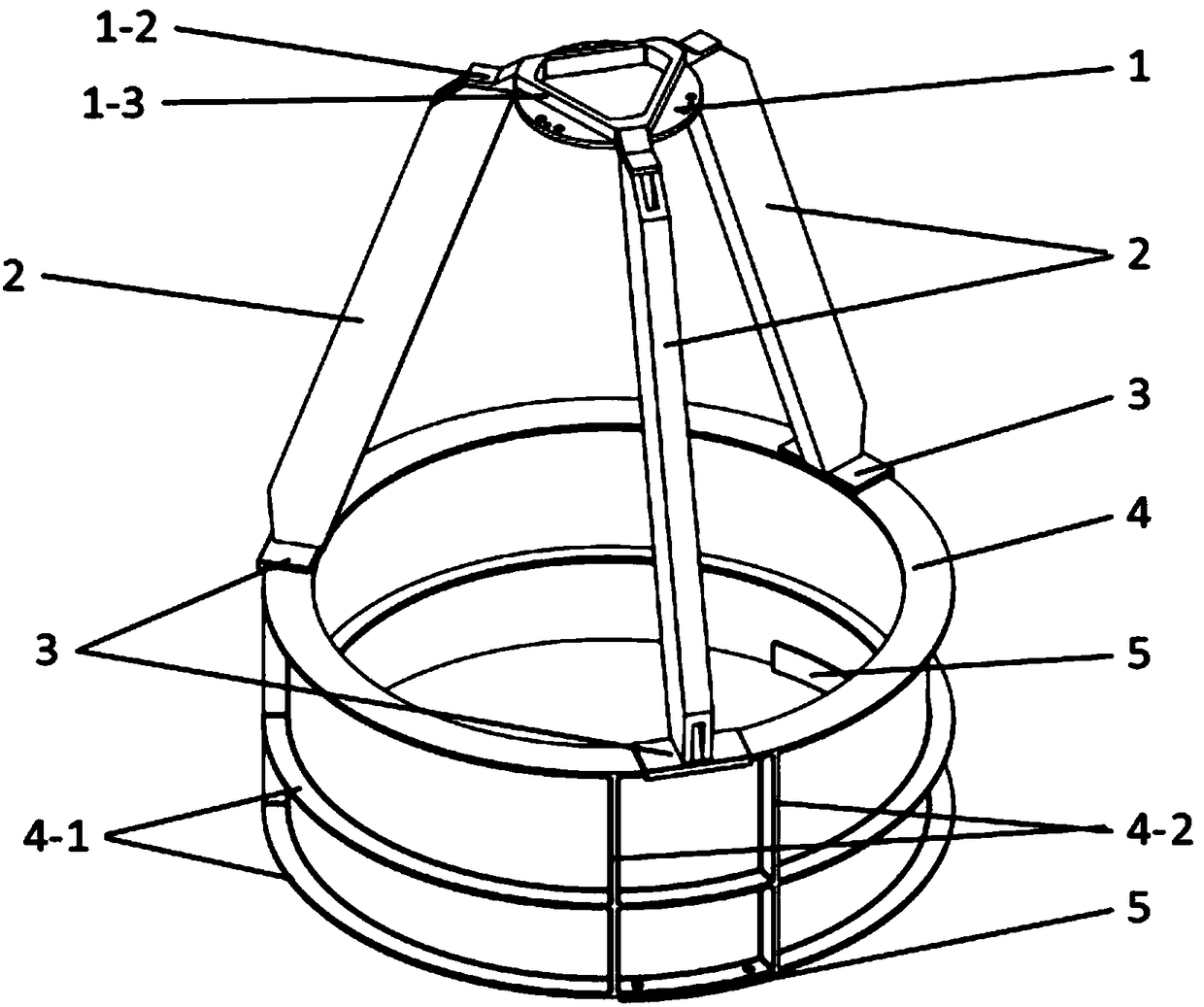

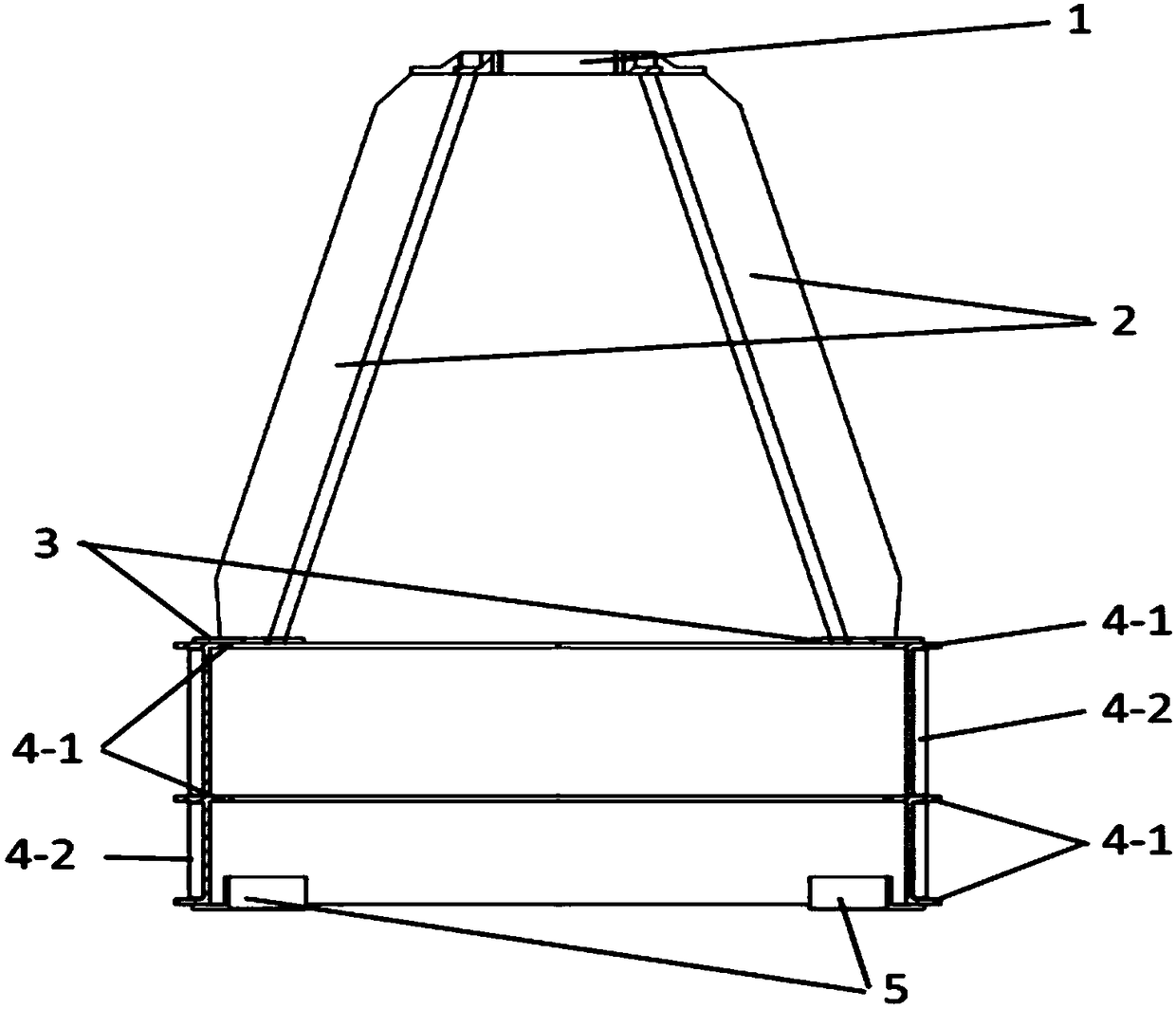

[0038] Specific embodiment one: as figure 1As shown, the number of the truss rod 2, the embedded part 5 and the circumferential rib 4-1 on the outer wall of the truss base 4 are three, and the circumferential rib 4-1 on the inner wall of the truss base 4- The number of 1 is two, and it corresponds to the two circumferential ribs 4-1 on the upper end of the outer wall of the truss base 4. The shape of the circumferential reinforcing rib 4-1 of the barrel seat is circular, and the diameters of the circumferential reinforcing ribs 4-1 of the barrel seat are the same. The three truss rods 2 and the three embedded parts 5 are evenly distributed in a circle of 120 degrees in the support structure. The number of groups of axial reinforcing ribs 4-2 on the outer wall of the truss cylindrical seat 4 is three groups, and the number of axial reinforcing ribs 4-2 in each group of cylindrical seat is two.

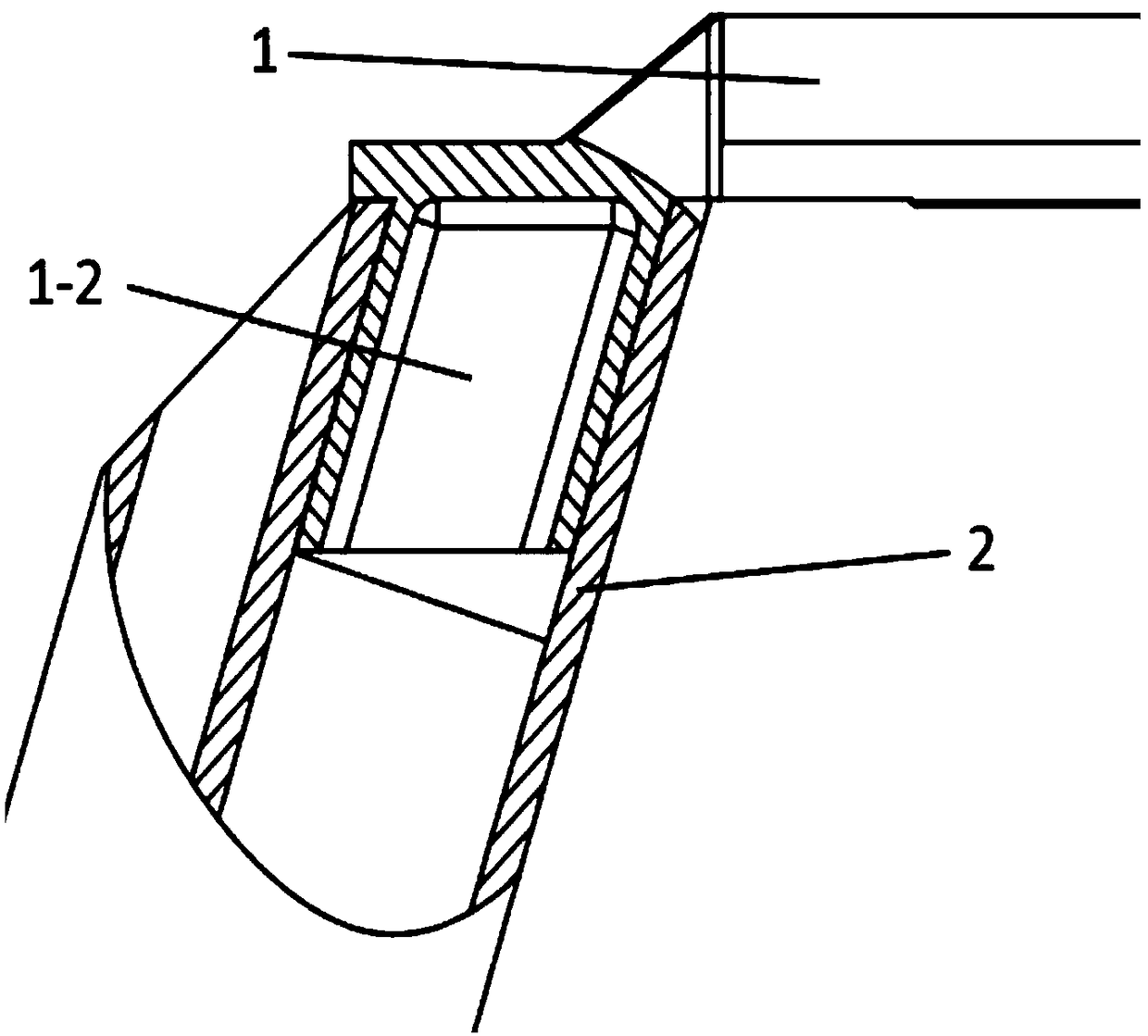

[0039] The shape of the flange 1 is circular, and the ribs 1-3 of the flange are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com