Production method of high-sensitivity biochemical sensor based on resonance type micro-cantilever structure

A technology of biochemical sensors and micro-cantilever beams, which is applied in the field of high-sensitivity biochemical sensors to achieve accuracy requirements, low cost, and reduced packaging difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

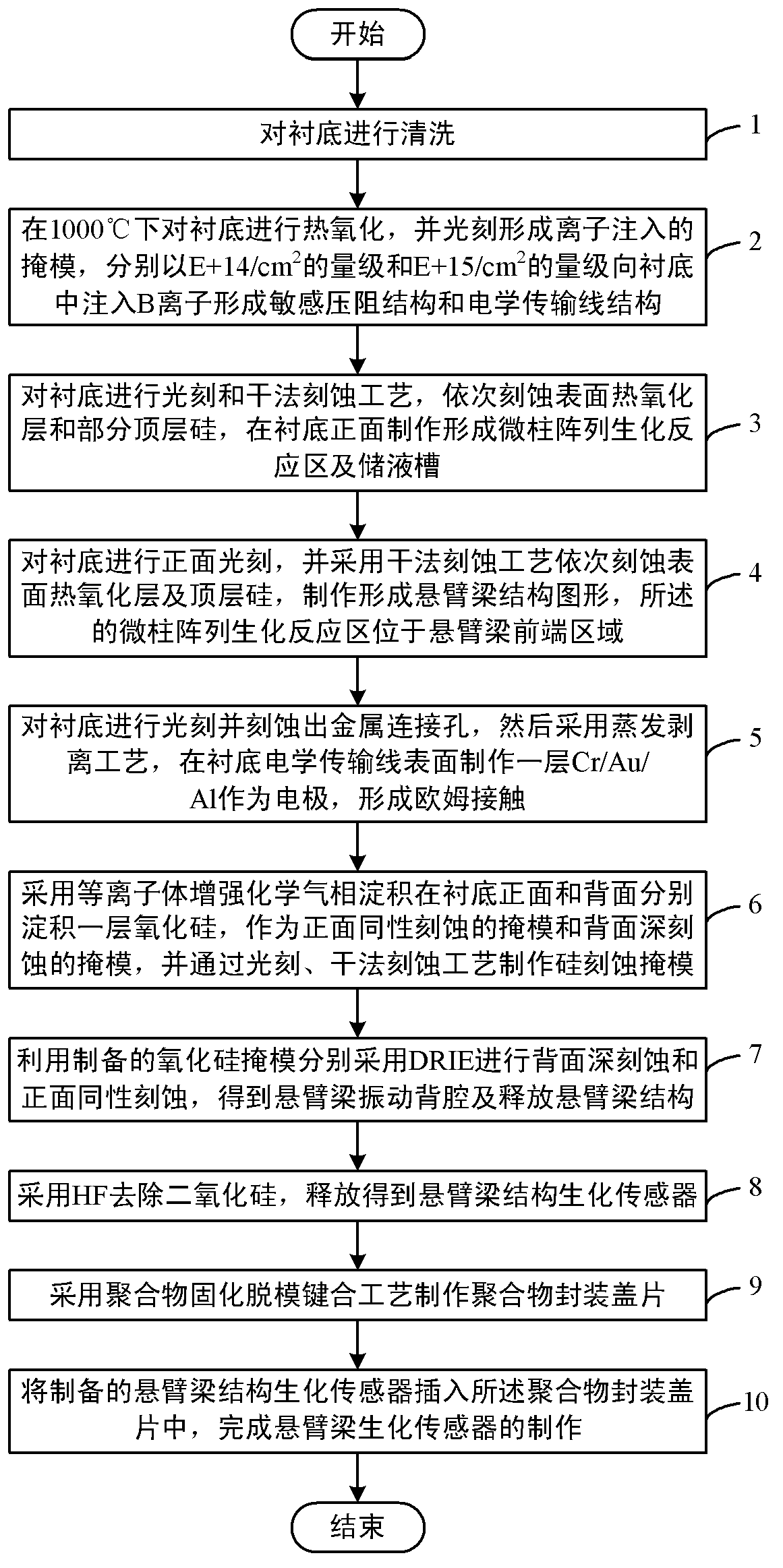

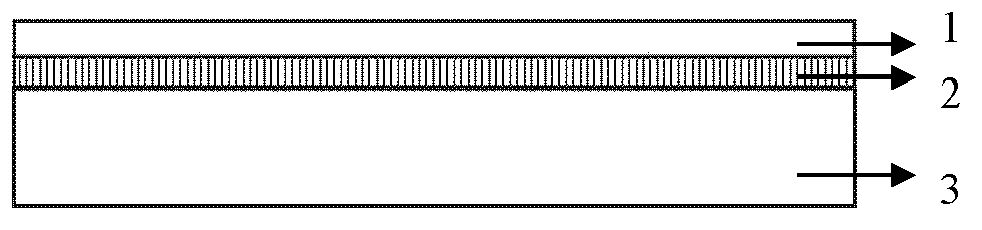

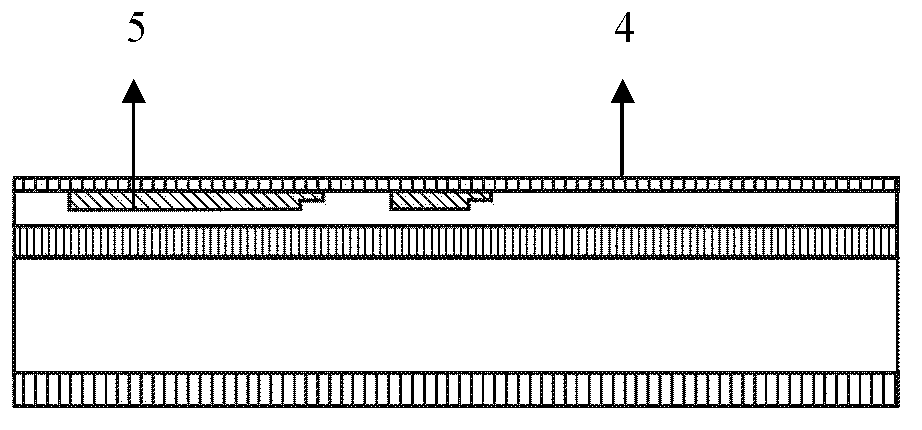

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0047] In order to realize the real-time on-site high-sensitivity detection of molecules to be tested by biochemical sensors, it is necessary to use high-sensitivity frequency detection technology, eliminate measurement errors caused by adsorption, reduce the impact of the detection environment on device stability, export biochemical waste liquid, and provide reliable and low-cost Technical breakthroughs have been made in aspects such as the packaging scheme and the like, for which the present invention proposes a method for manufacturing a highly sensitive biochemical sensor based on a resonant micro-cantilever beam structure. The invention designs a local modification structure at the free end of the cantilever beam, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com