Moving crane

A technology for moving cranes and hoists, applied in the direction of cranes, trolley cranes, load hanging elements, etc., can solve problems such as adverse effects of weather and lighting conditions, inaccurate steering movements and activities, and cumbersome spare parts. , to achieve stable travel, improved weight distribution, and low carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

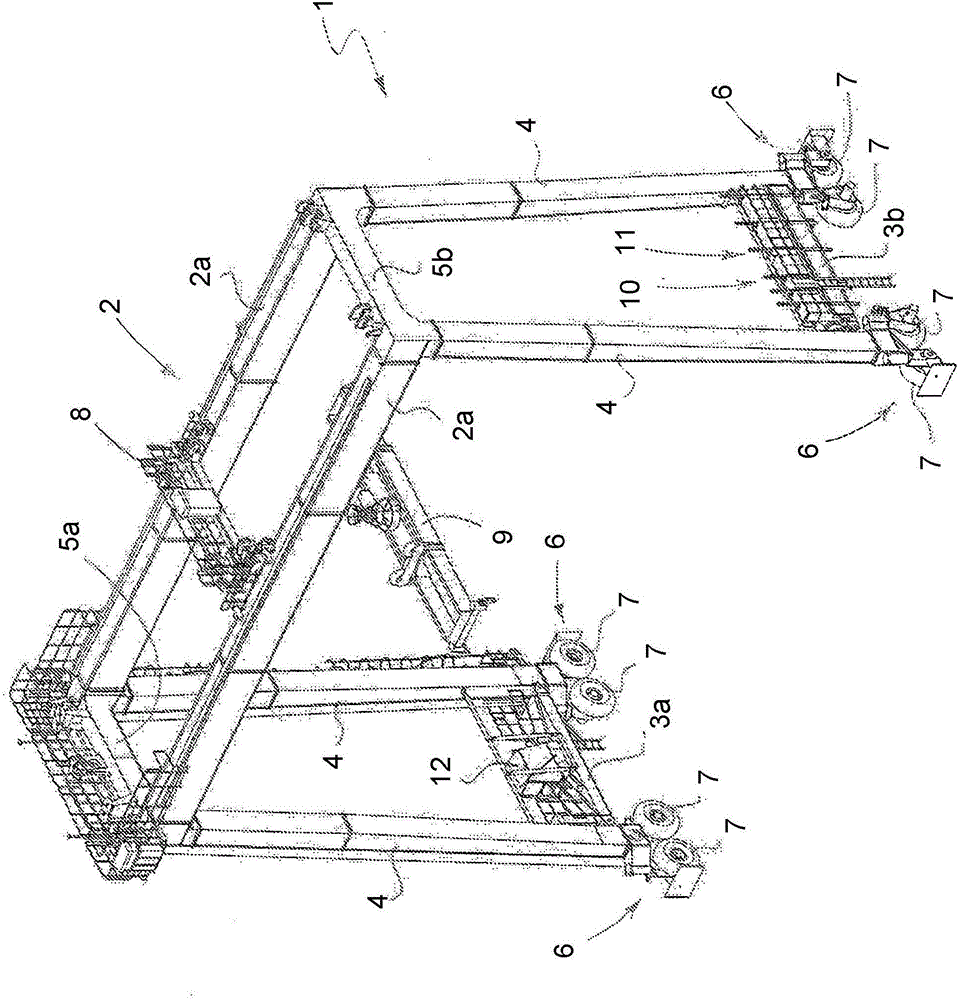

[0019] With reference to the drawings, a mobile crane according to the invention has a frame 1 having in its upper part a main support structure 2 and in its lower part and on opposite sides of the lower part of the frame 1 transverse The lower beam structures 3a and 3b of the main support structure 2. The main support structure 2 is connected by upstanding feet 4 to the lower beam structures 3a and 3b. The main support structure 2 here comprises two main supports 2a spaced apart from each other, running in parallel and connected to each other by means of upper beam structures 5a and 5b.

[0020] The ends of the lower beam structures 3 a and 3 b have bogie structures 6 each comprising two consecutive wheels 7 . The total number of bogie structures 6 is thus four, one in each lower corner of the crane. In this example the wheels are rubber wheels and generally one of the wheels 7 of each bogie structure 6 is a driving wheel and the other is a driven wheel. In relation to rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com