Bottom die trolley of short-line matching prefabricated box girder

A short-line matching and bottom mold technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve problems such as overturning, increased operating height, and high production costs, and achieve the effect of simple and efficient operation and reduced operating height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

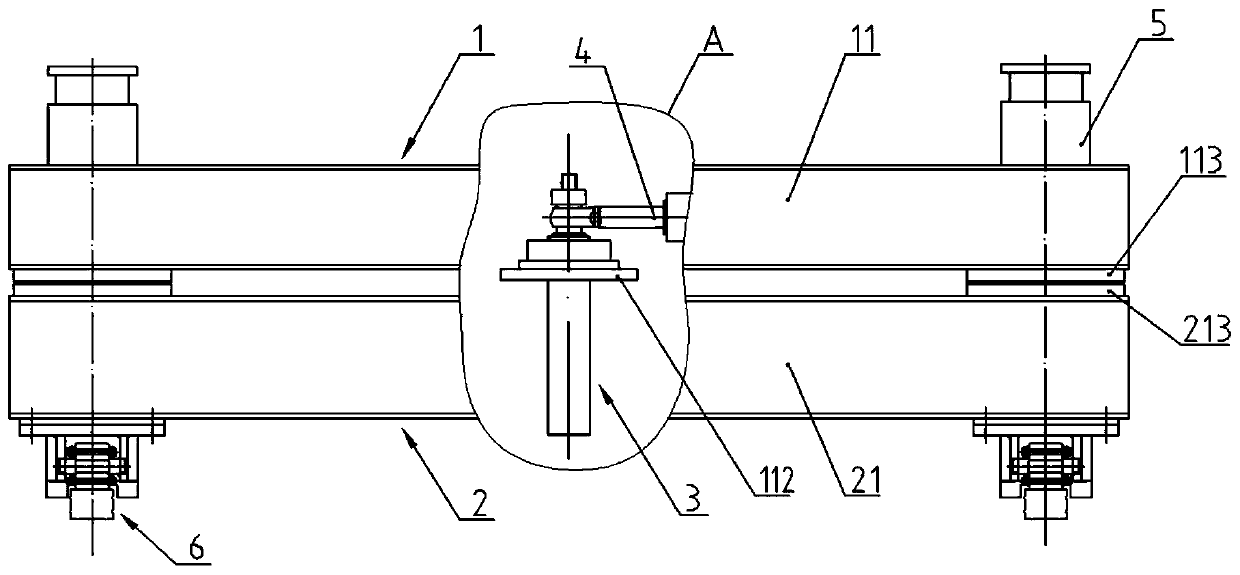

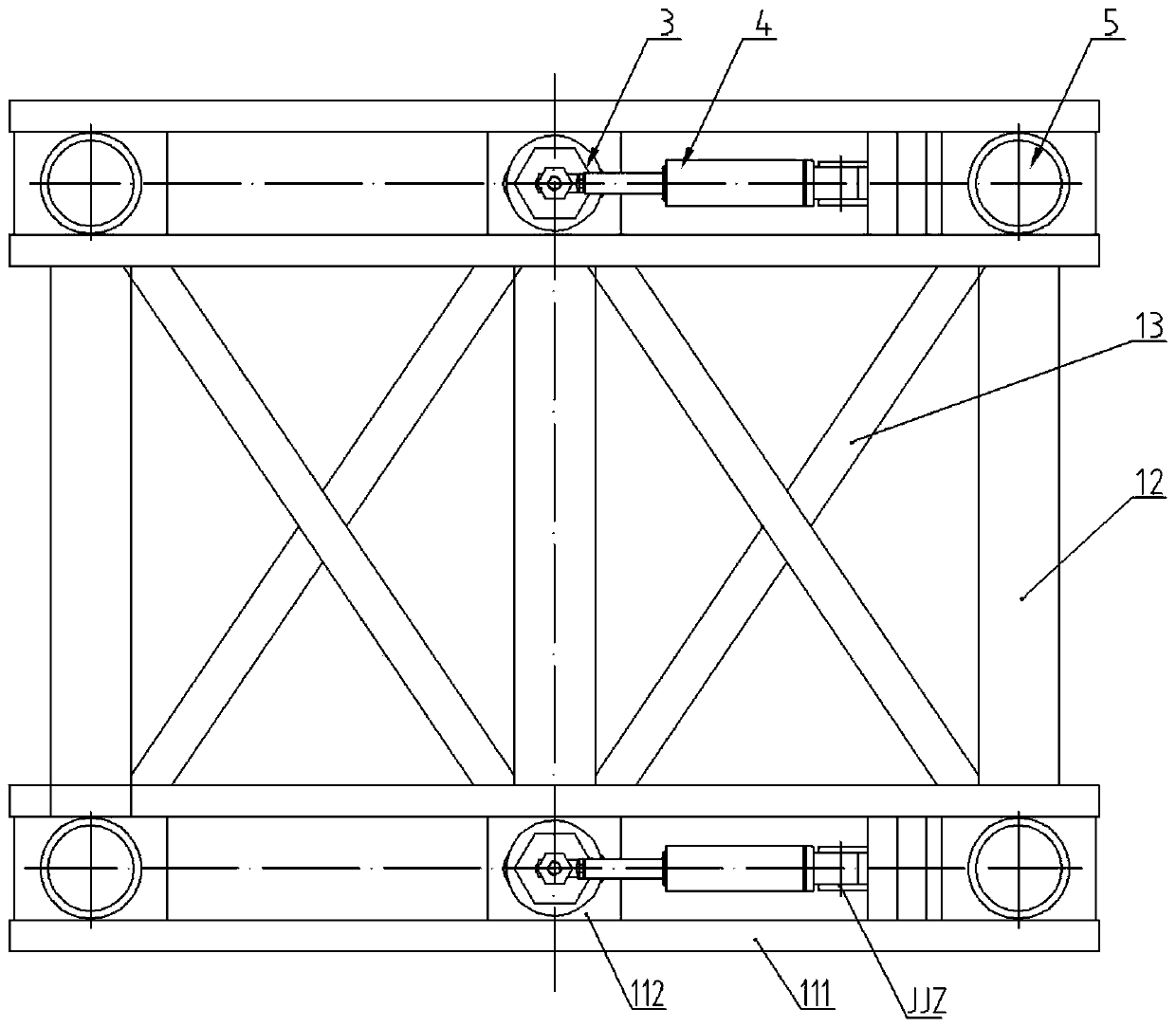

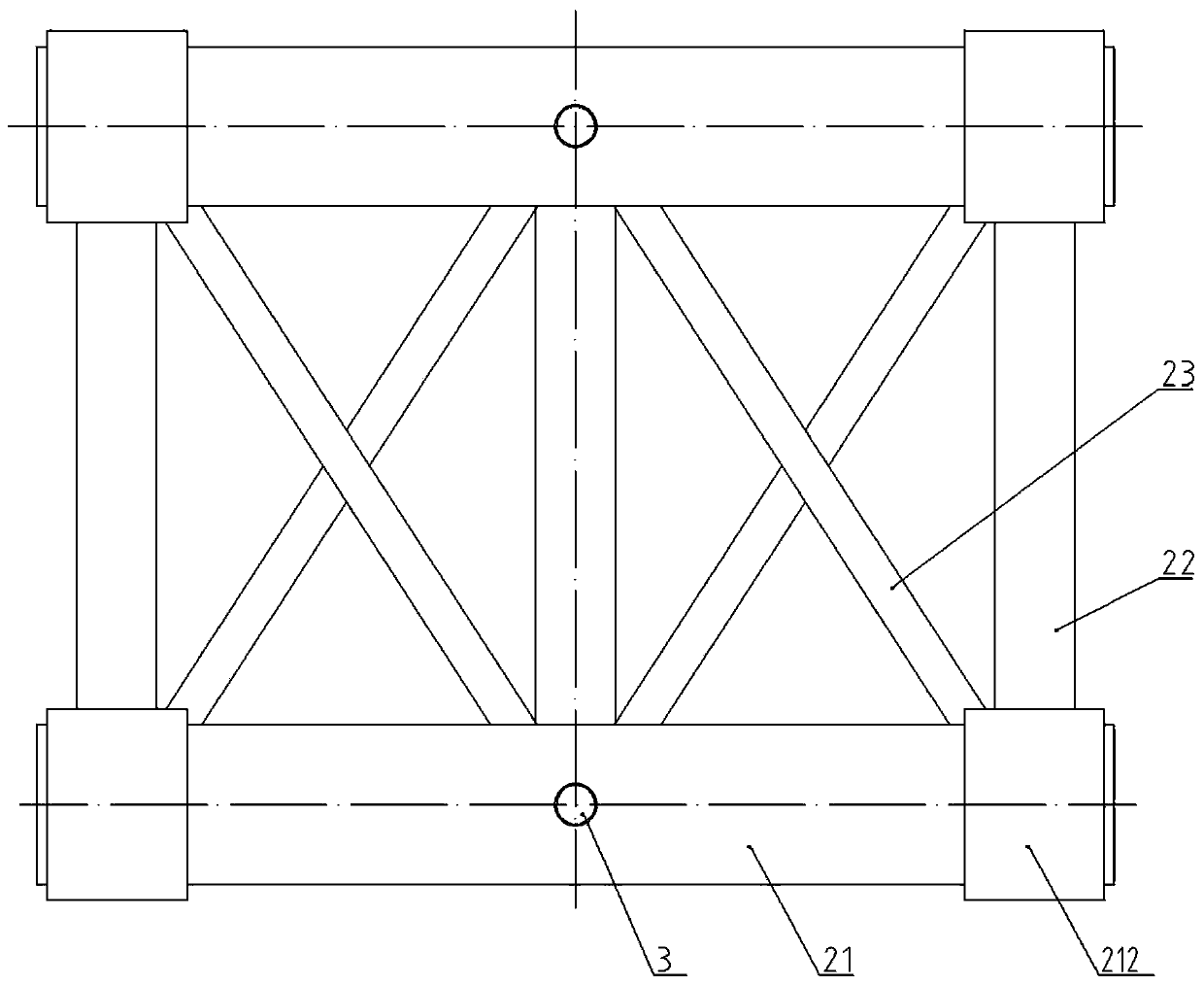

[0024] like figure 1 As shown, the bottom mold trolley for short-line matching prefabricated box beams disclosed in this embodiment includes an upper bracket 1 , a lower bracket 2 , a limit post 3 , an adjustment device 4 , a jacking device 5 , and a running device 6 .

[0025] The upper bracket 1 and the lower bracket 2 are square frames with the same plane size.

[0026] combine figure 1 , figure 2 and Figure 5 It can be seen that the upper bracket 1 is welded into a square frame by the upper beam 11 , the upper longitudinal beam 12 and the upper reinforcing beam 13 .

[0027] The upper beam 11 includes a channel steel 111, a middle connecting plate 112 and an end connecting plate 113. The two channel steels 111 are symmetrically arranged with openings facing each other with a gap, so that a transverse groove is formed between the two channel steels, and the middle connecting plate 112 is welded on. On the bottom surface of the middle position in the length direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com