Patents

Literature

33results about How to "Meet adjustment requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhesion agent as well as preparation method and application thereof

InactiveCN104446251APrevent peelingCounteract and absorb deformation stressWater basedMaterials science

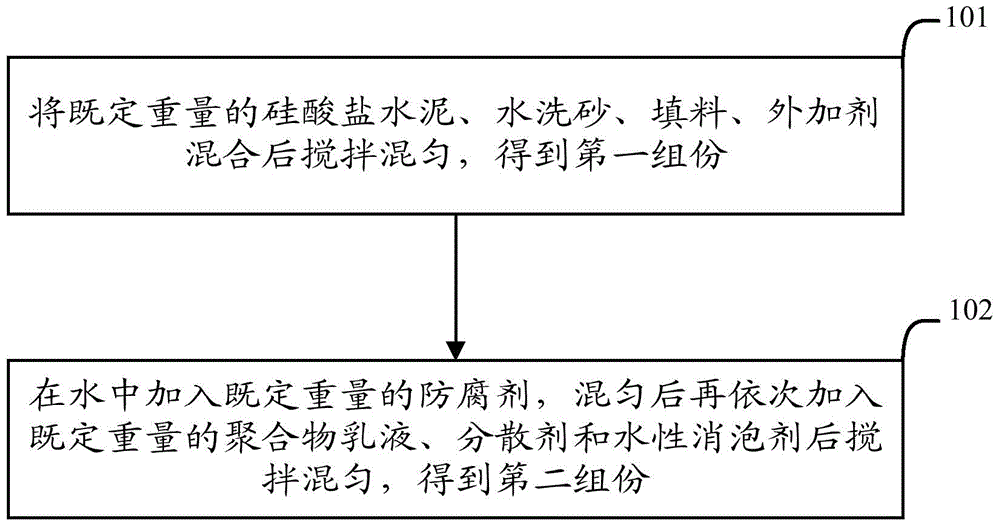

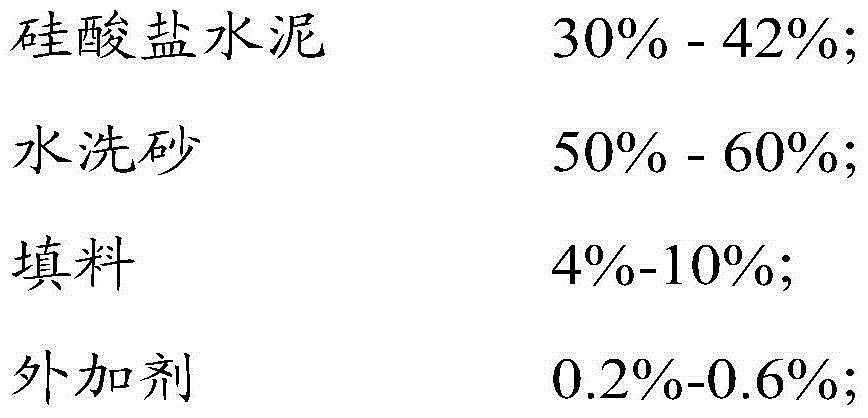

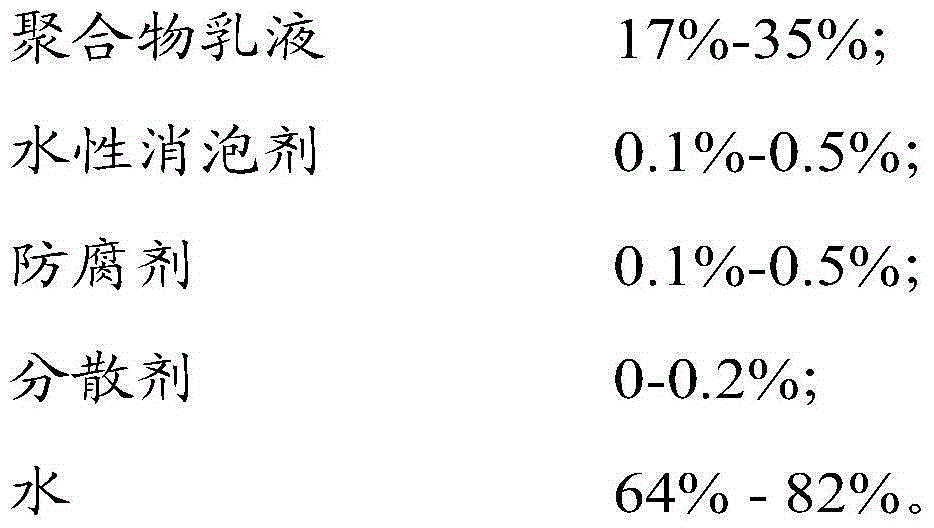

The invention provides an adhesion agent as well as a preparation method and application thereof, and relates to the technical field of building materials. Raw material components of the adhesion agent comprise a first component and a second component, wherein the first component comprises raw materials in percentage by weight: 30-42% of Portland cement, 50-60% of washed sand, 4-10% of stuffing and 0.2-0.6% of additives; the second component comprises raw materials in percentage by weight: 17-35% of polymer emulsion, 0.1-0.5% of water-based defoamer, 0.1-0.5% of corrosion remover, 0-0.2% of dispersing agents and 64-82% of water. The adhesion agent has the advantages of high adhesive strength, good water resistance, good heat resistance, good weather resistance, good vertical-flowing resistance, good anti-sliding performance, low cost and the like.

Owner:JIUZHU ENERGY SAVING TECH TIANJIN

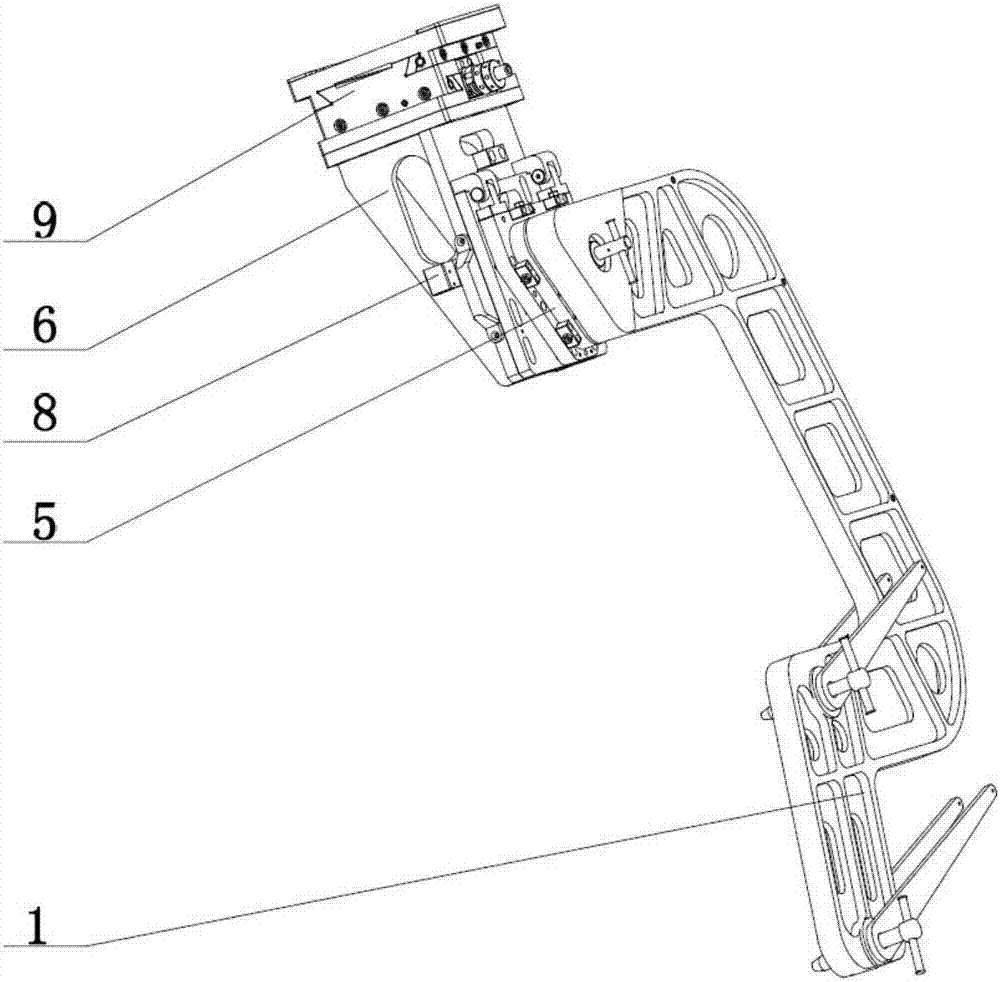

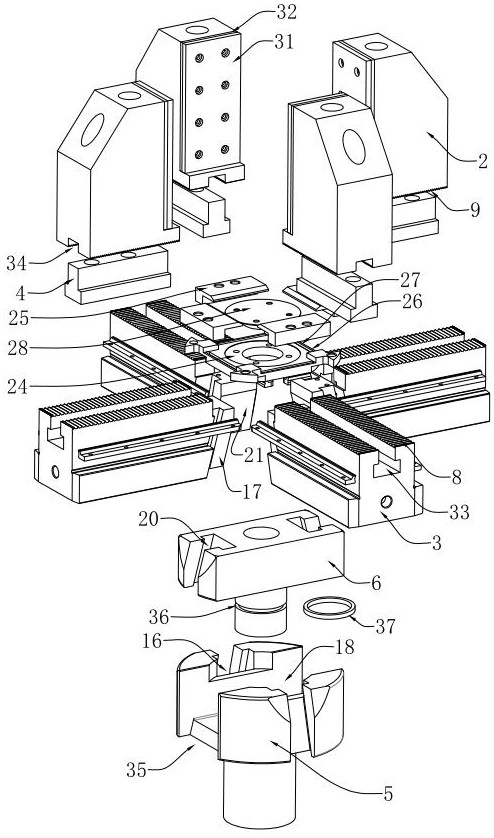

Positioning tool of aircraft wing box leading edge technological connector

The invention discloses a positioning tool of an aircraft wing box leading edge technological connector and belongs to the technical field of aircraft assembly. The positioning tool comprises a base unit, a support connected with the base unit and an intersection point positioning plate connected with the support. An adjusting unit is further arranged between the intersection point positioning plate and the support. The adjusting unit comprises a connecting plate, a first adjusting plate and a second adjusting plate. The connecting plate is connected with the support through a locking bolt, the first adjusting plate is rotatably connected with the connecting plate through a transverse rotary shaft, and the second adjusting plate is rotatably connected with the first adjusting plate through a longitudinal rotary shaft. Tapered bosses are evenly distributed on the second adjusting plate, tapered grooves matched with the tapered bosses are formed in the intersection point positioning plate, and the intersection point positioning plate penetrates through the second adjusting plate through a threaded positioning pin to be connected with the first adjusting plate. The intersection point positioning plate is provided with an interval spacer through the positioning pin. The positioning tool of the aircraft wing box leading edge technological connector is simple in structure and high in automatic degree.

Owner:ZHEJIANG UNIV

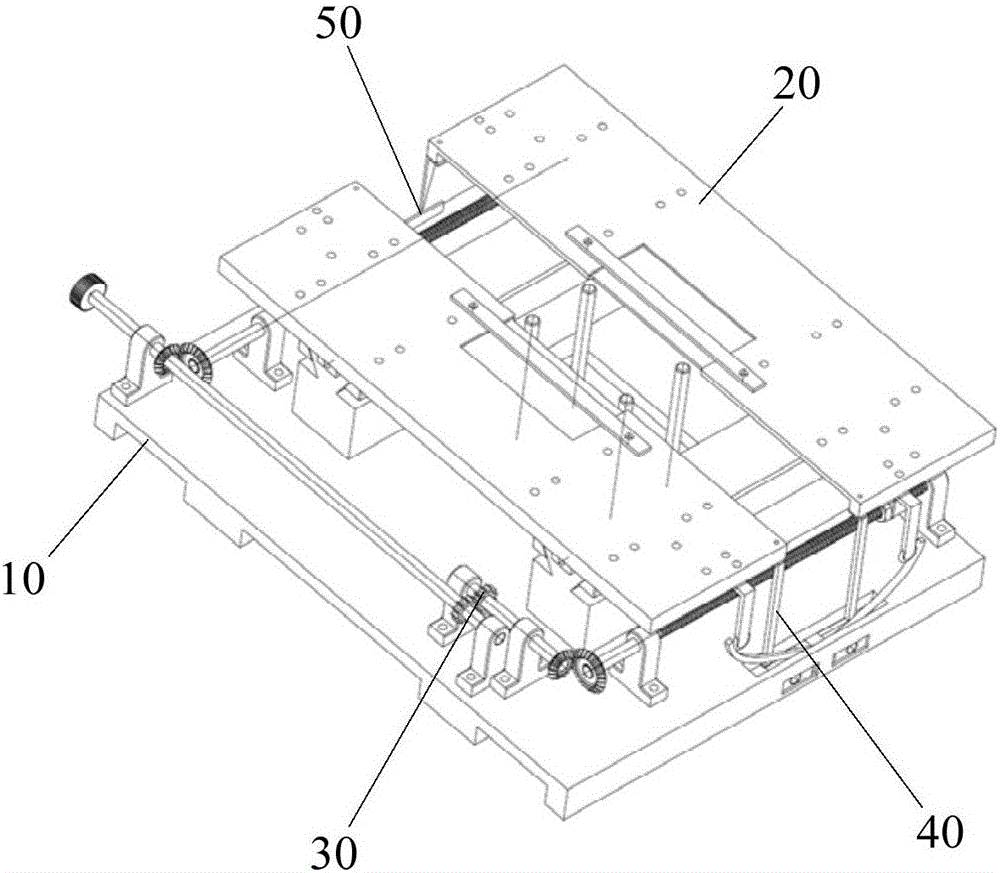

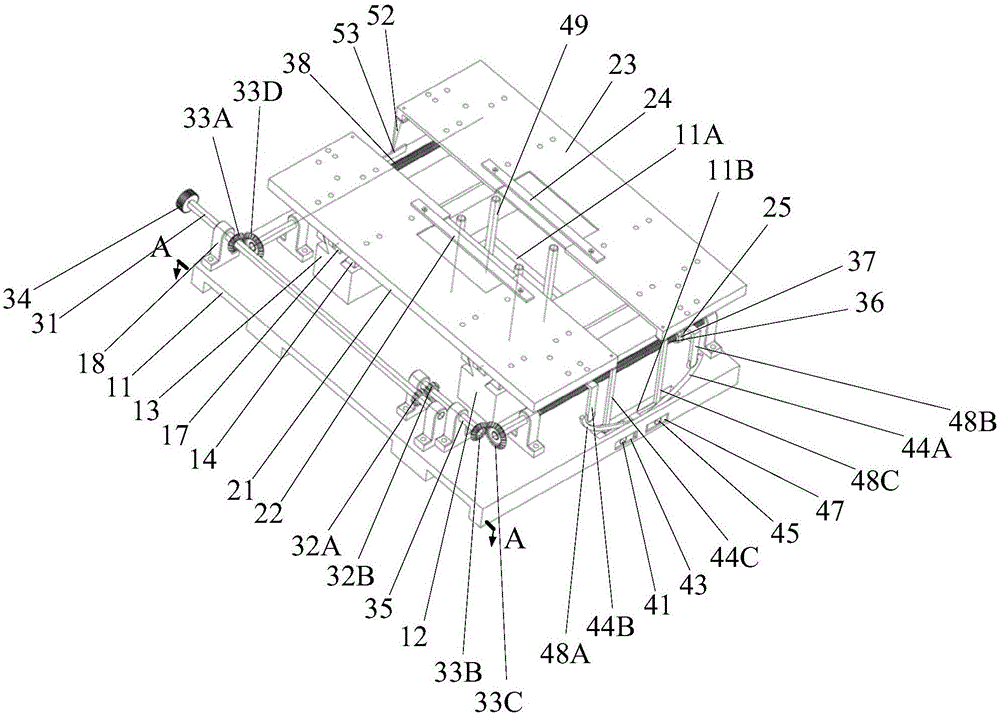

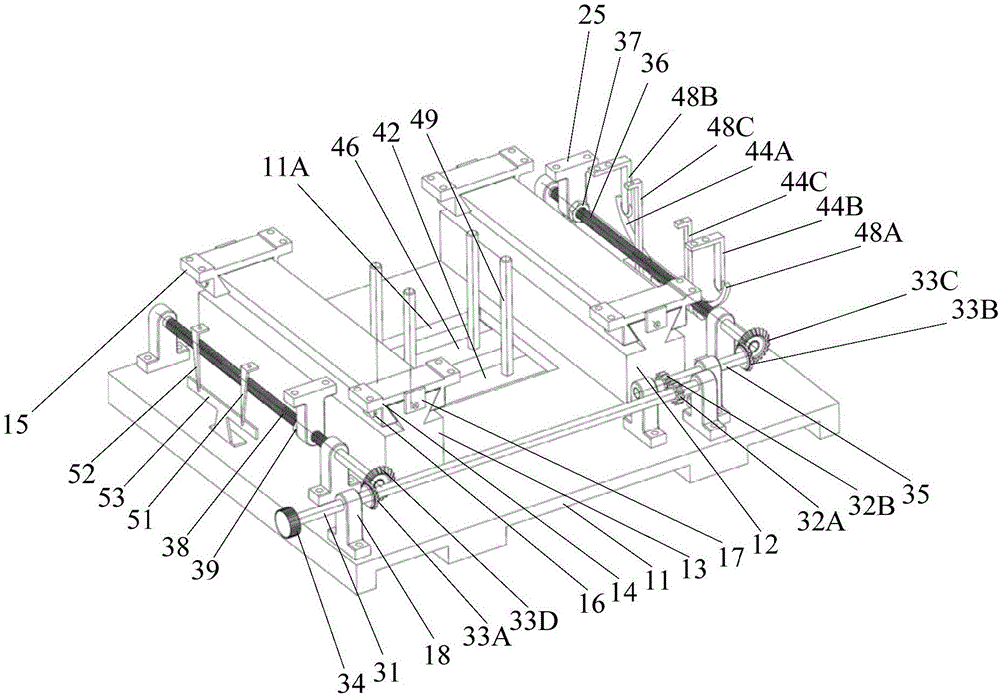

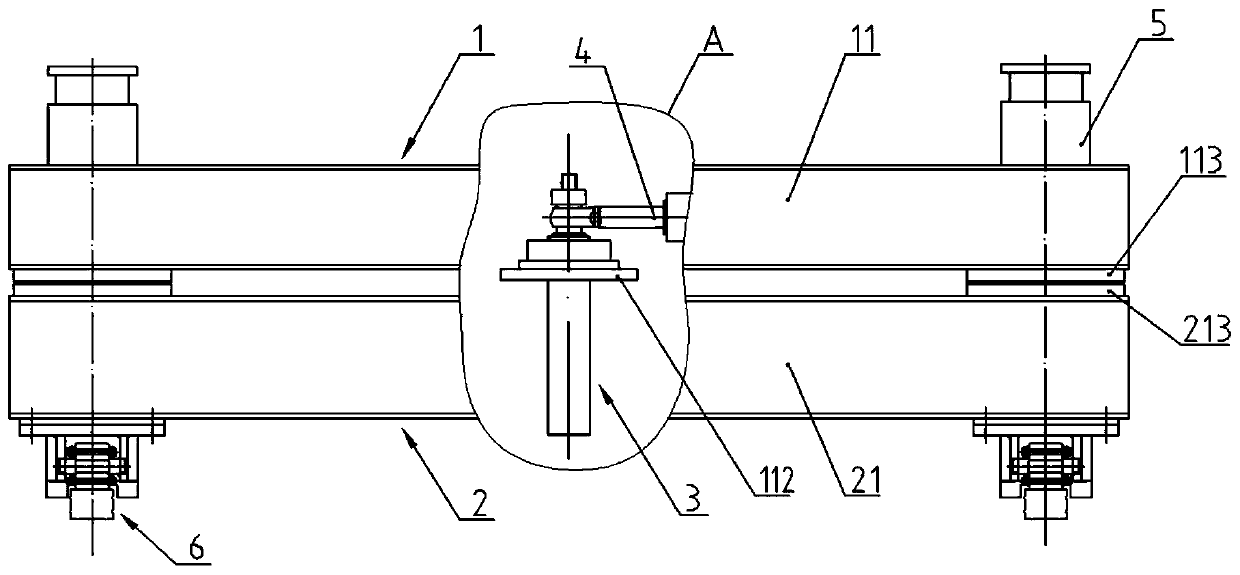

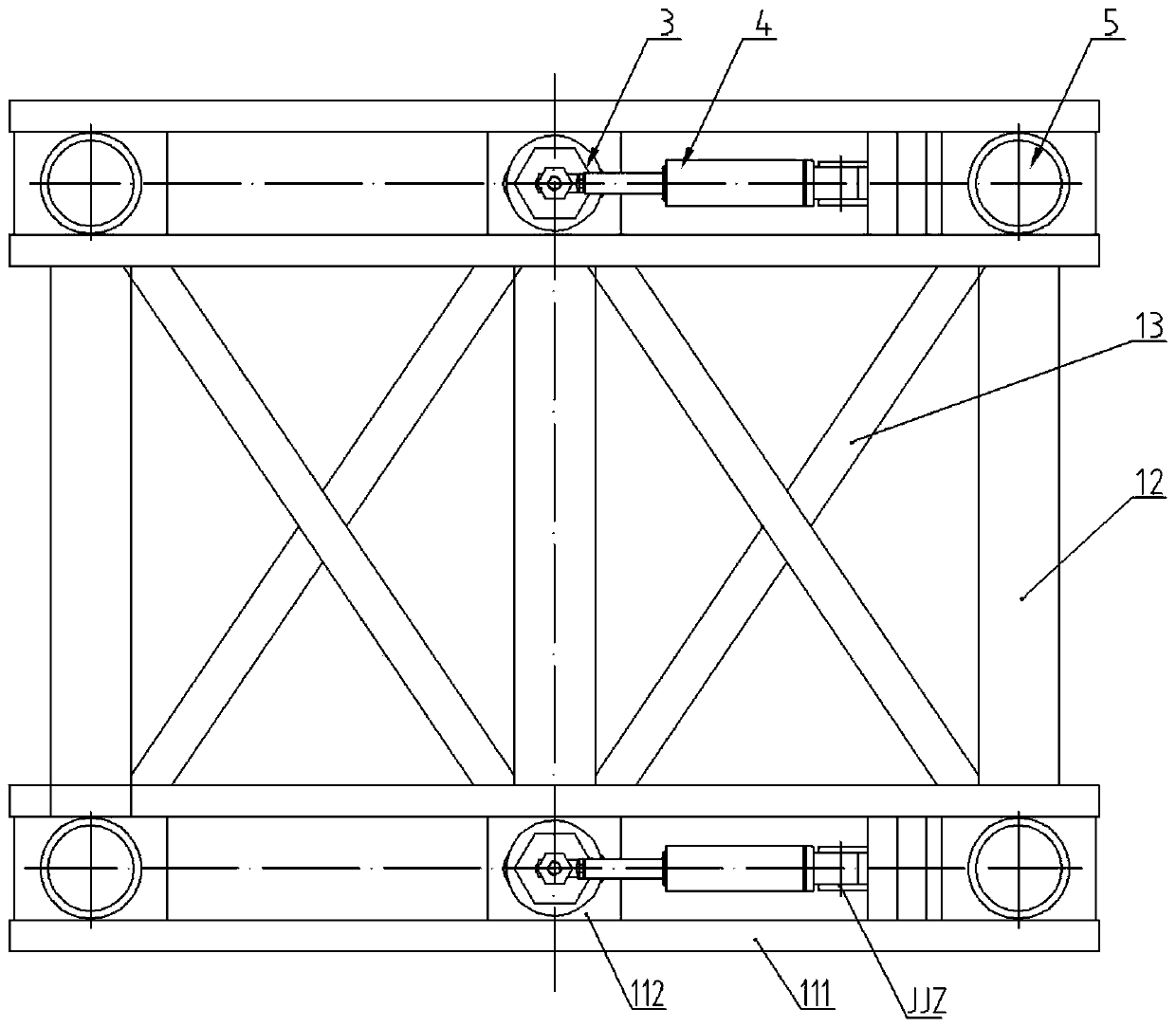

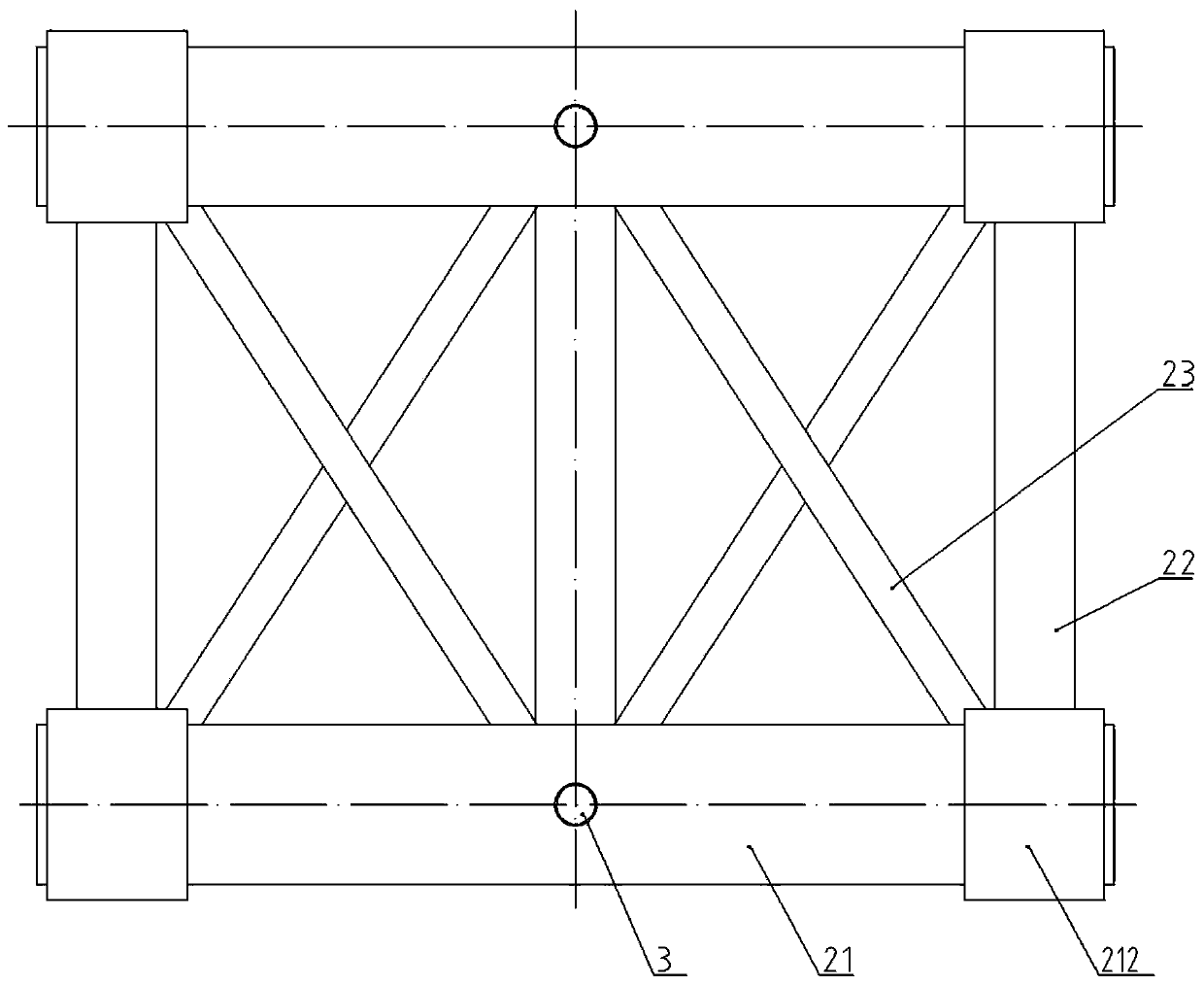

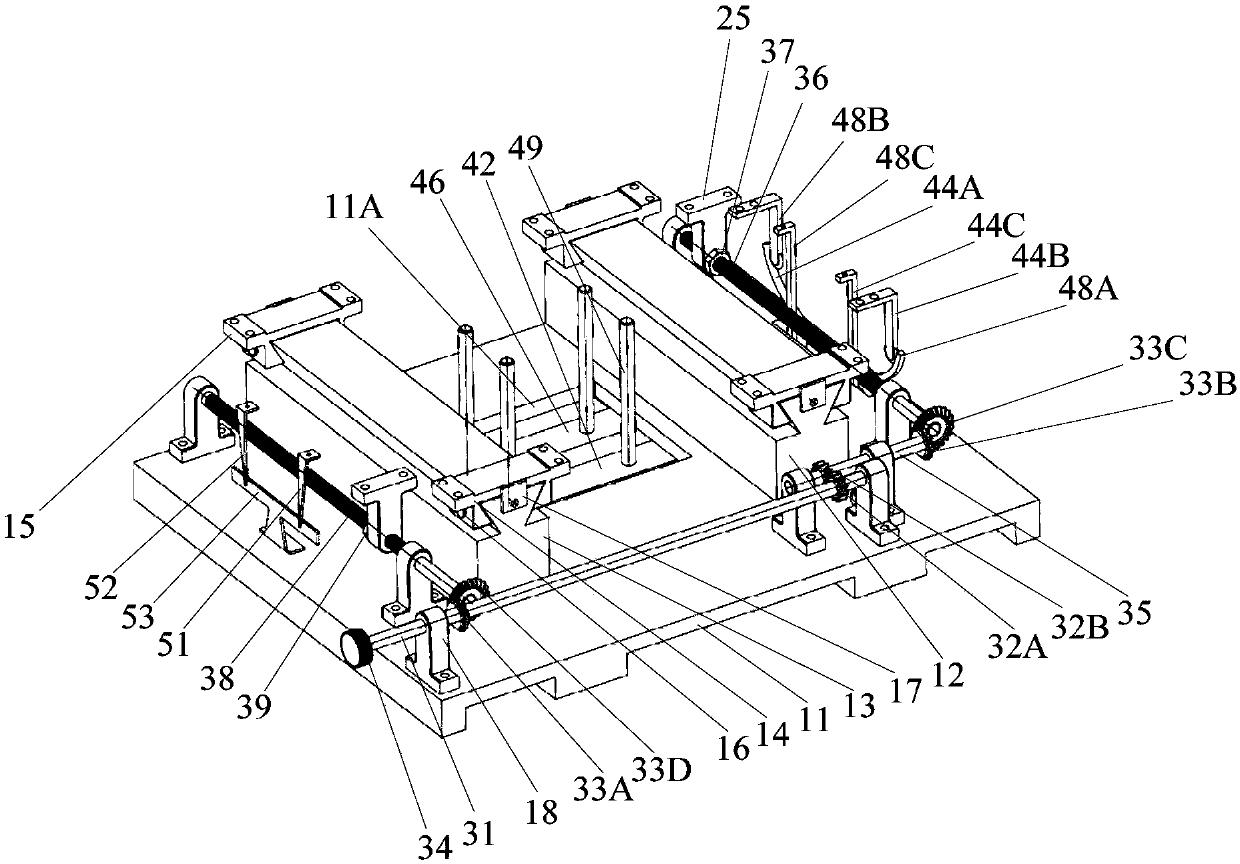

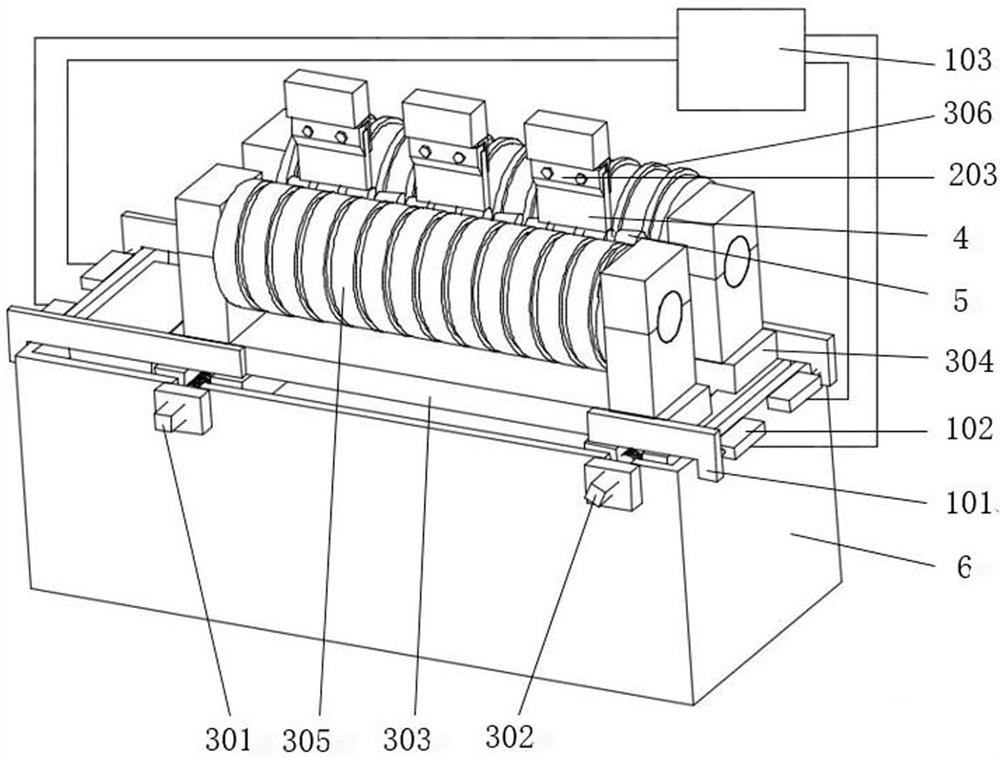

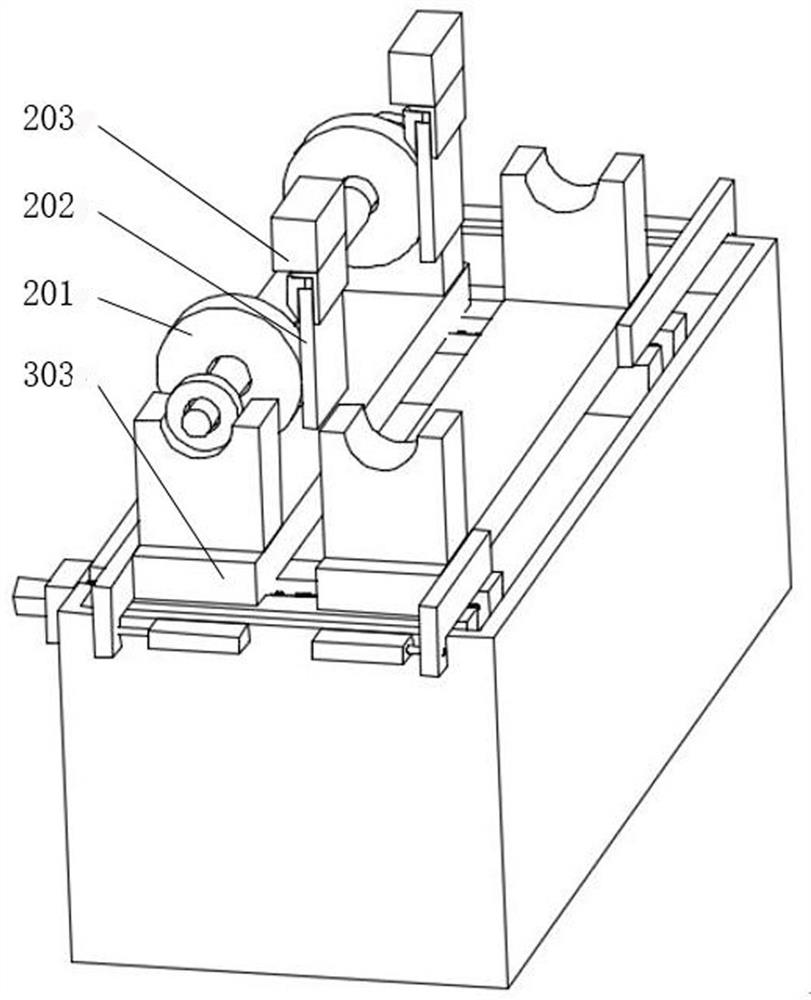

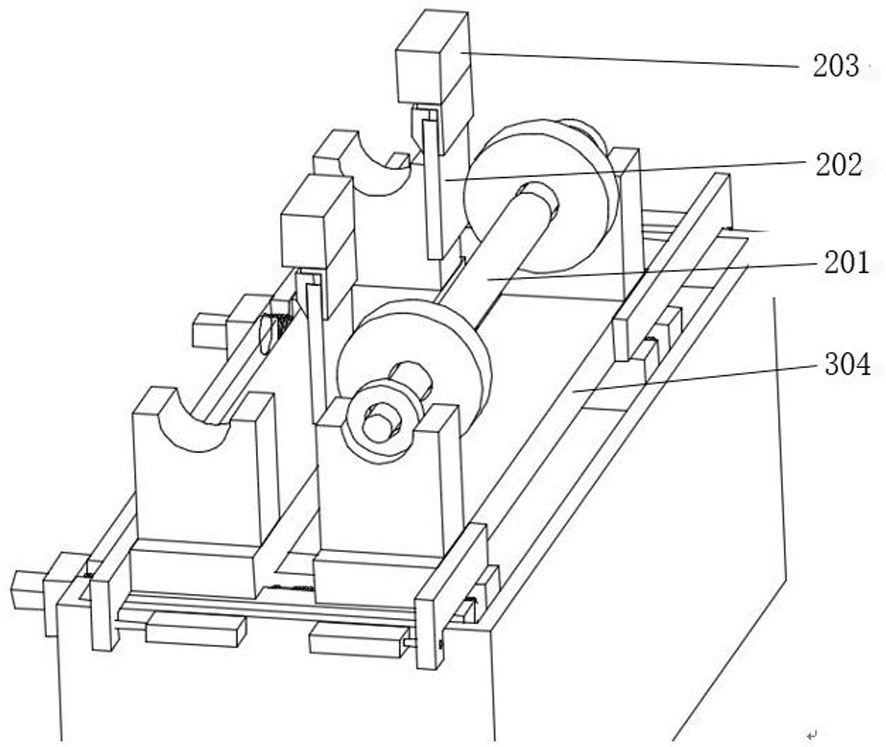

Steel plate butt welding gap adjusting device

ActiveCN106493499AEasy to moveHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesButt weldingSheet steel

The invention discloses a steel plate butt welding gap adjusting device, and belongs to steel plate position adjusting devices. The problem that according to an existing steel plate butt welding positioning device, the butt welding steel plate gap is difficult to precisely adjust is solved. The device comprises a base assembly, a fixing assembly, a transmission mechanism, a positioning mechanism and a gap indicating assembly; the base assembly comprises a bottom plate, a front guide rail and a rear guide rail; the fixing assembly comprises a left fixing plate, a right fixing plate, a left pressing plate and a right pressing plate; the transmission mechanism comprises a transmission shaft, a reverse shaft, a front screw and a rear screw; the positioning mechanism comprises a left camshaft, a right camshaft, a left long positioning sliding block, a right long positioning sliding block, a left short positioning sliding block, a right short positioning sliding block, a left pressing strip, a right pressing strip, a left shifting fork, a right shifting fork, a left driving rod, a right driving rod and a positioning pin; the gap indicating assembly is composed of a left pointer, a right pointer and a ruler; the device is simple in structure, low in manufacturing cost, small in work environment influence, easy and convenient to operate, capable of ensuring the steel plate butt welding gap and precise positioning and greatly improving the welding quality and the welding efficiency and suitable for multiple welding processes of lasers, electric arcs and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

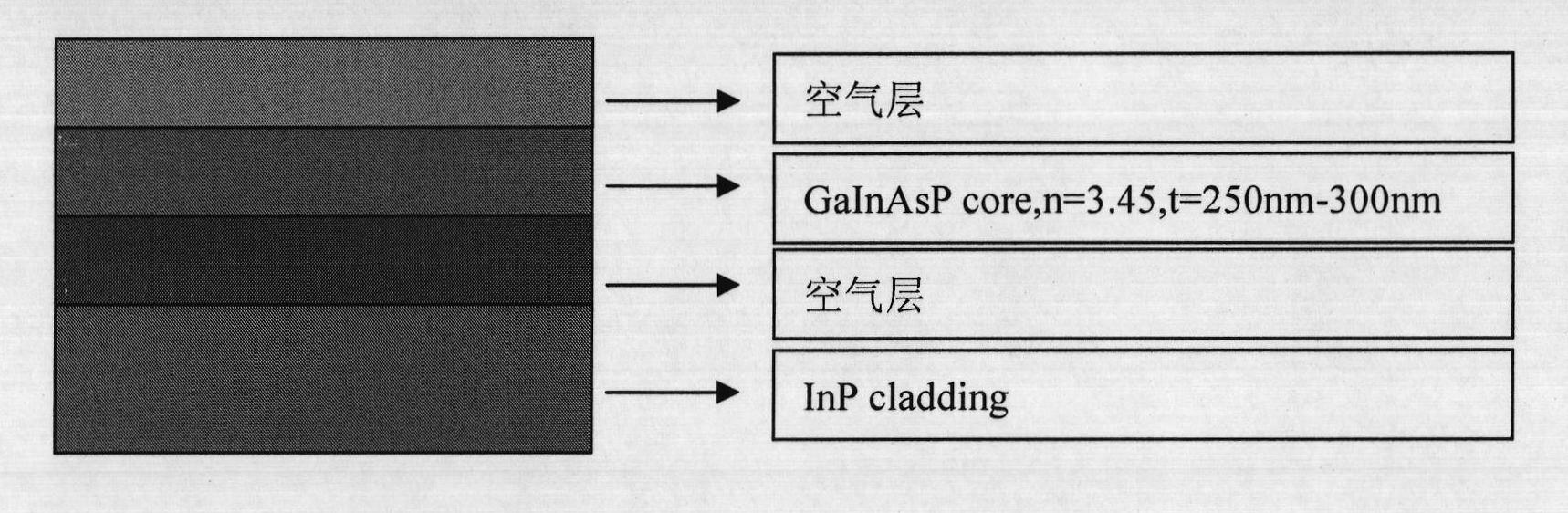

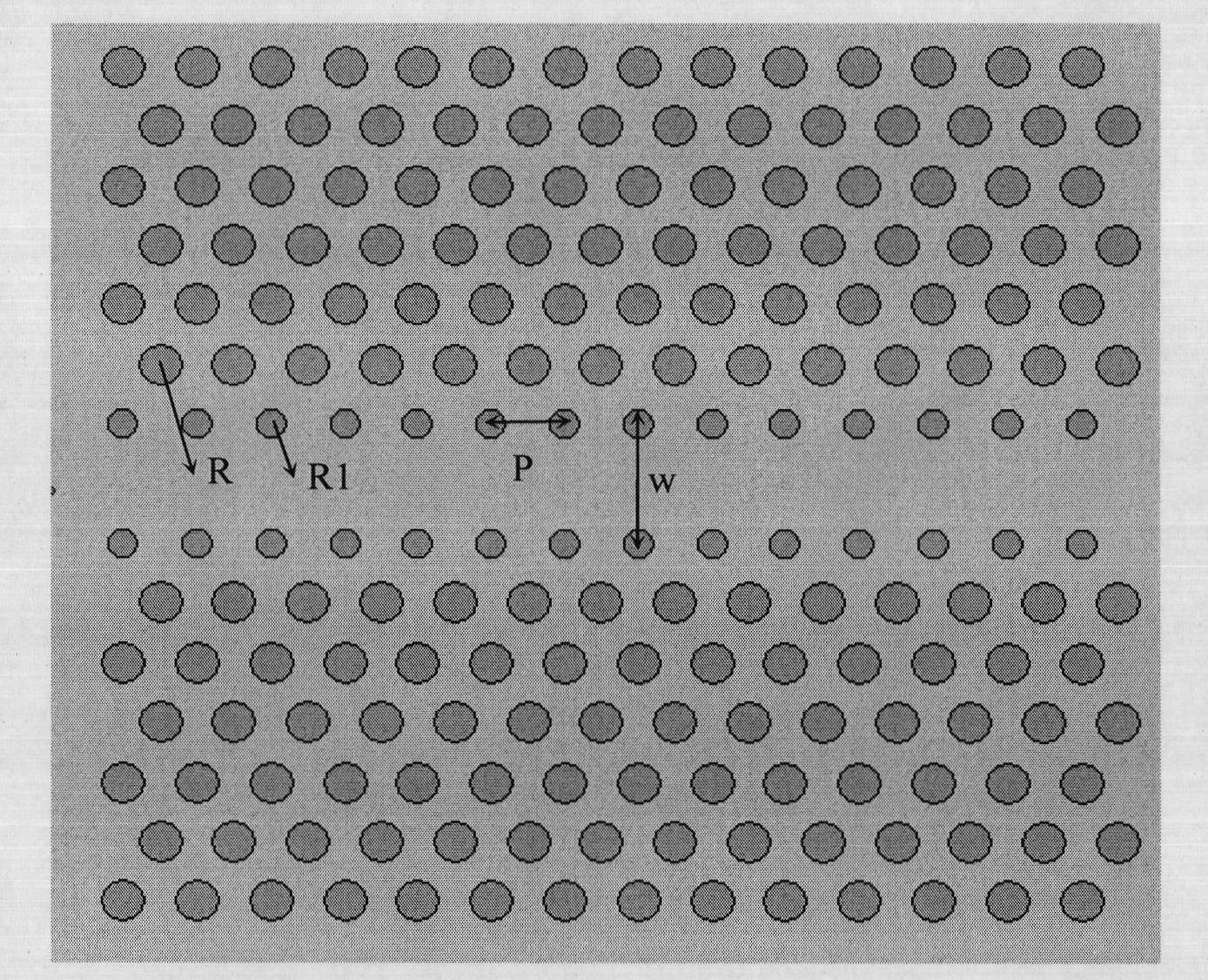

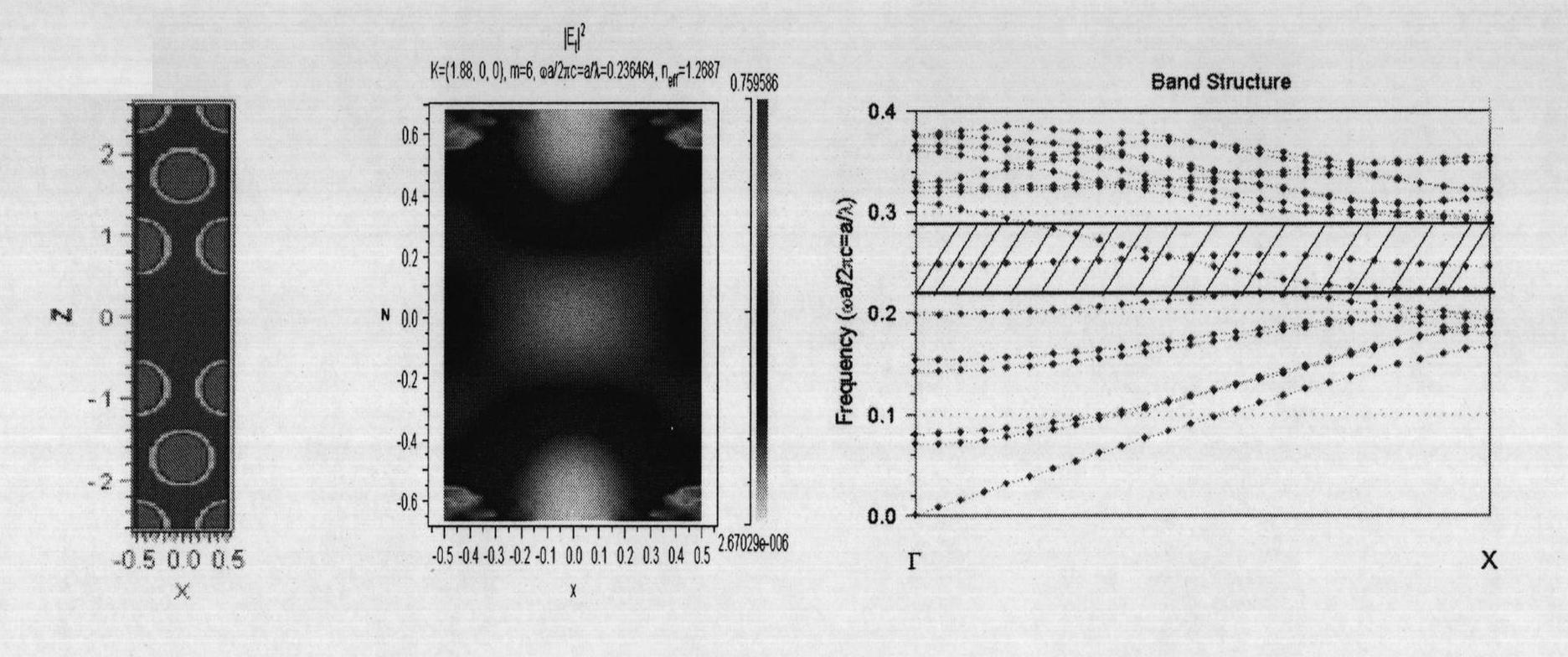

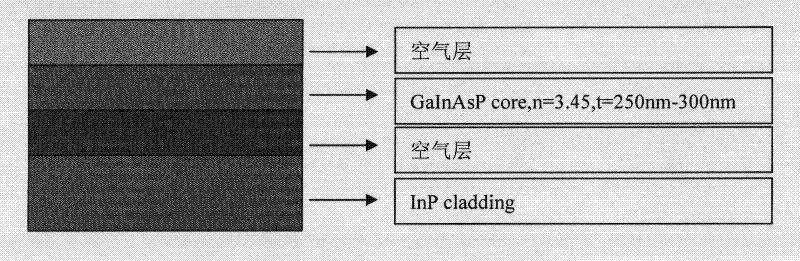

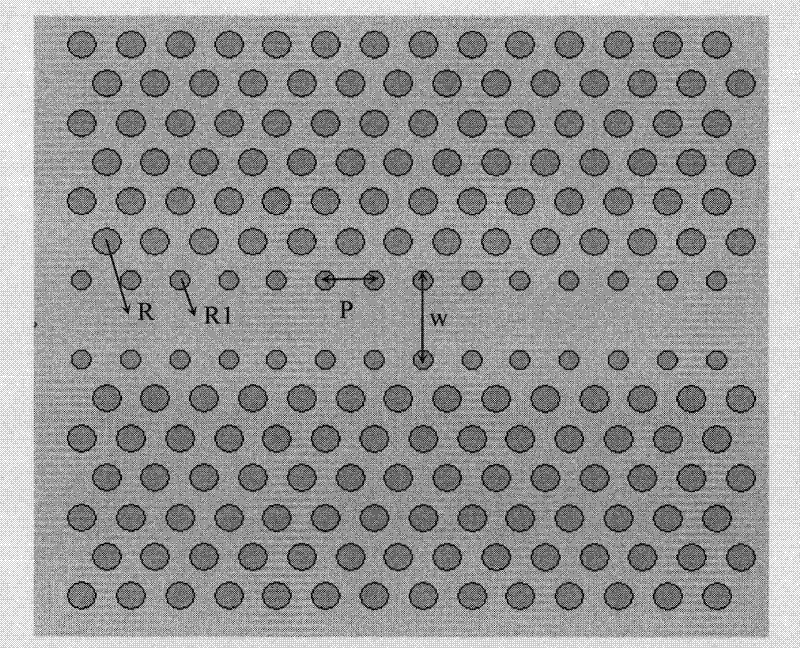

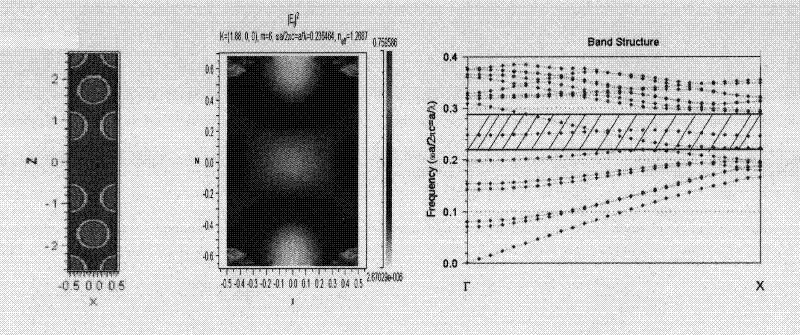

Slow light waveguide structure based on photonic crystal air bridge structure

InactiveCN101963736AReduce adjustment requirementsMeet adjustment requirementsOptical light guidesNon-linear opticsFiberSemiconductor materials

The invention discloses a slow light waveguide structure based on a photonic crystal air bridge structure, which adopts a line defect photonic crystal structure, and comprises a longitudinal structure and a horizontal structure, wherein, the longitudinal structure is an air bridge multi-layer structure which comprises an air layer, a semiconductor material layer, an air layer and a substrate material layer from the top layer to the bottom layer; the horizontal structure adopts a triangular lattice structure, the period is P, and the radius is R; and the waveguide is formed through removing a row of holes. Through changing the size of the line defect nearby hole, the slow light waveguide structure of the invention realizes a slow light working area reaching up to 50 nanometers; the central wavelength can be adjusted through the width of the waveguide, which can be realized only in need of the small holes with two types of apertures within the requirement range of hundreds of nanometers of operating wavelengths, thus lowering the requirement of device parameter adjustment in a certain technological condition. By utilizing the slow light photonic crystal waveguide of the slow optical waveguide structure based on the photonic crystal air bridge structure, the bandwidth can cover the C wave band of the fiber-optical communication, and can achieve 50nm.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

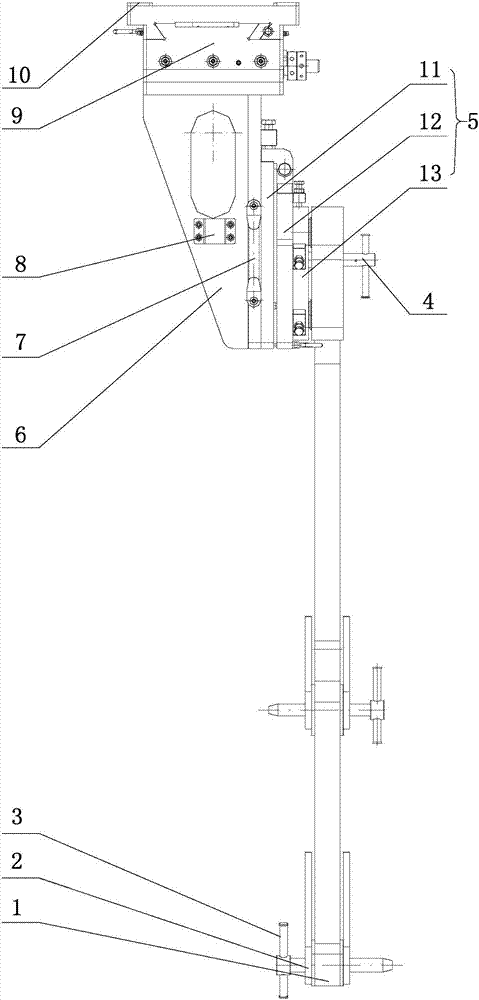

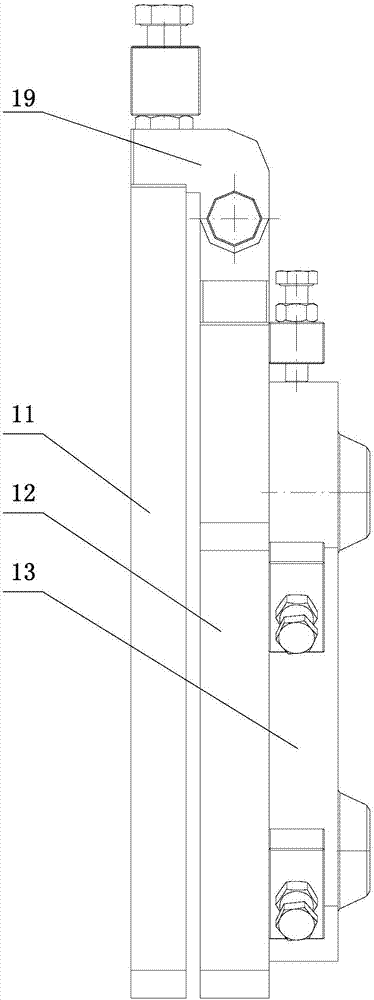

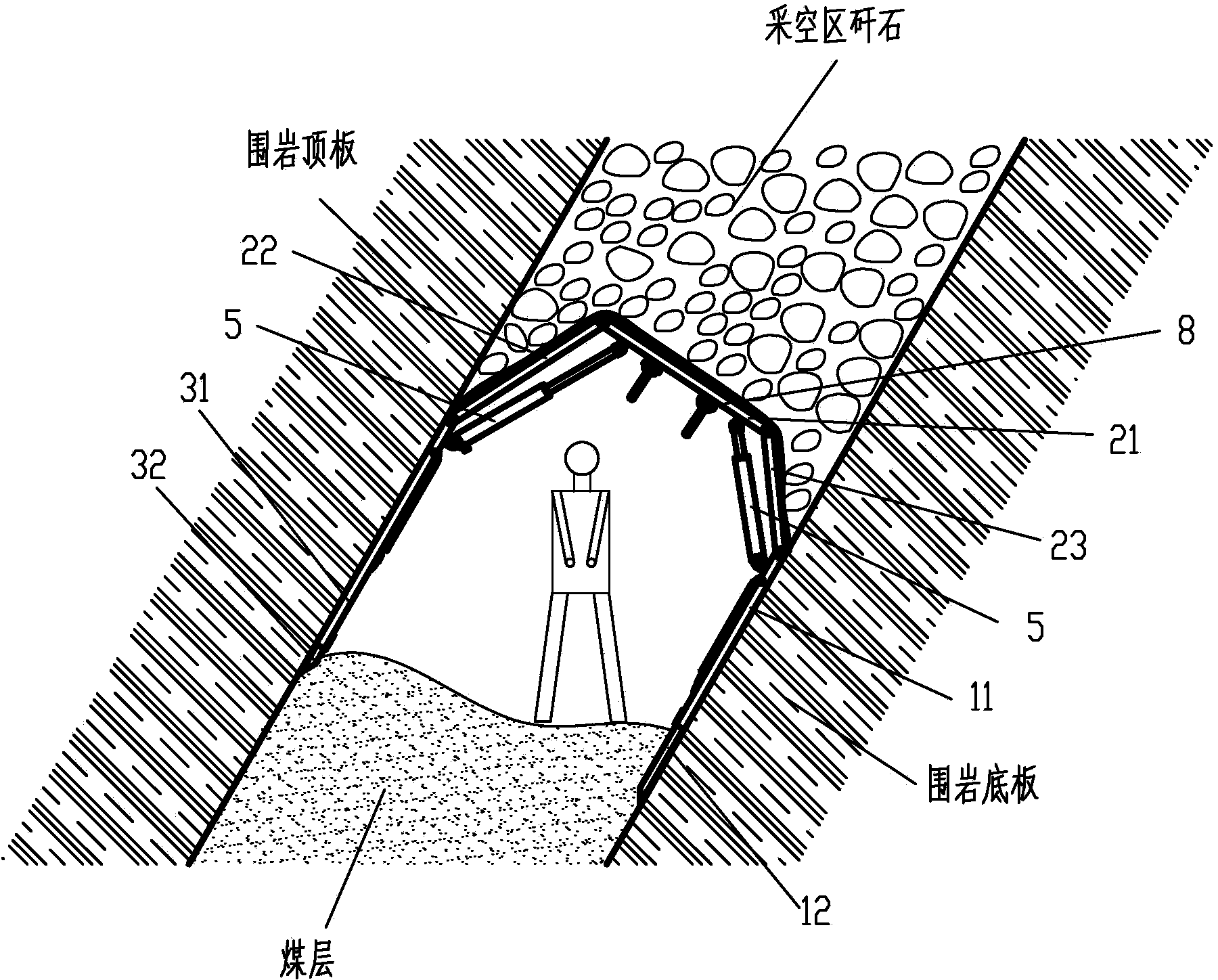

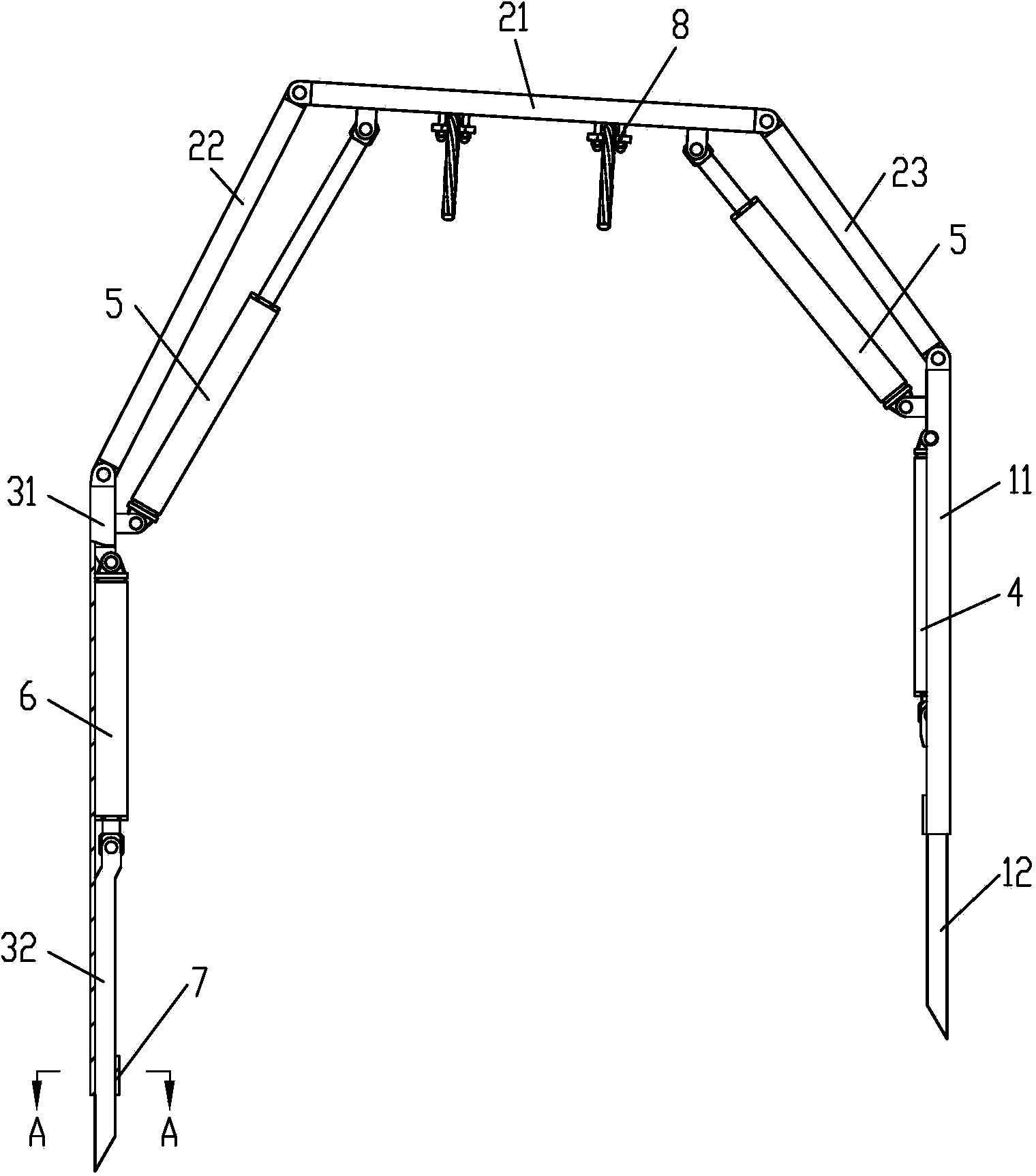

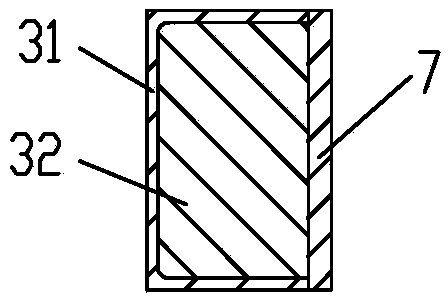

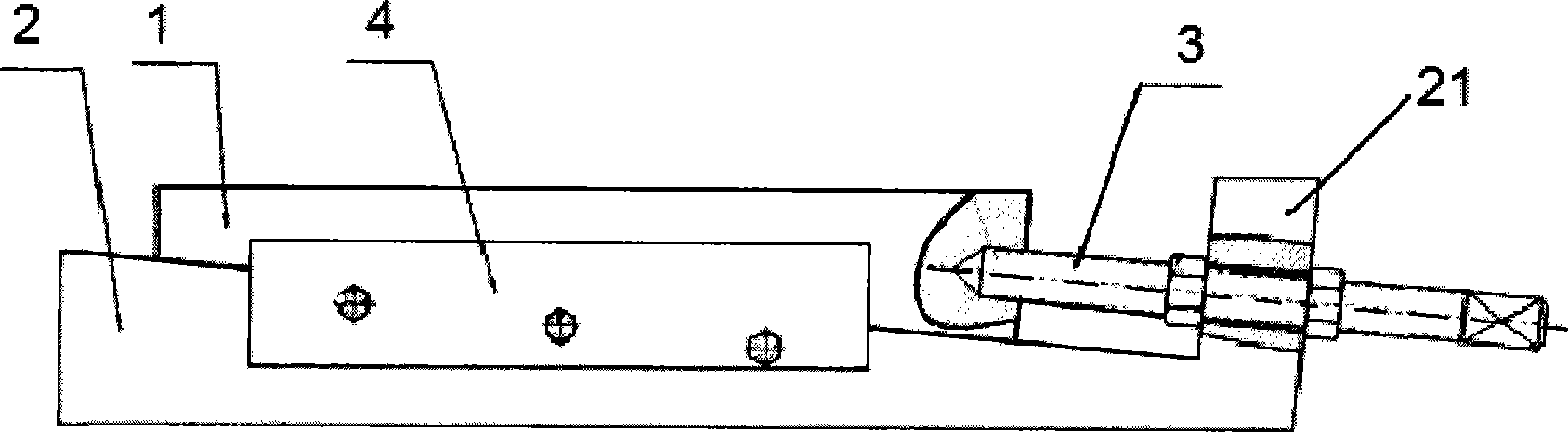

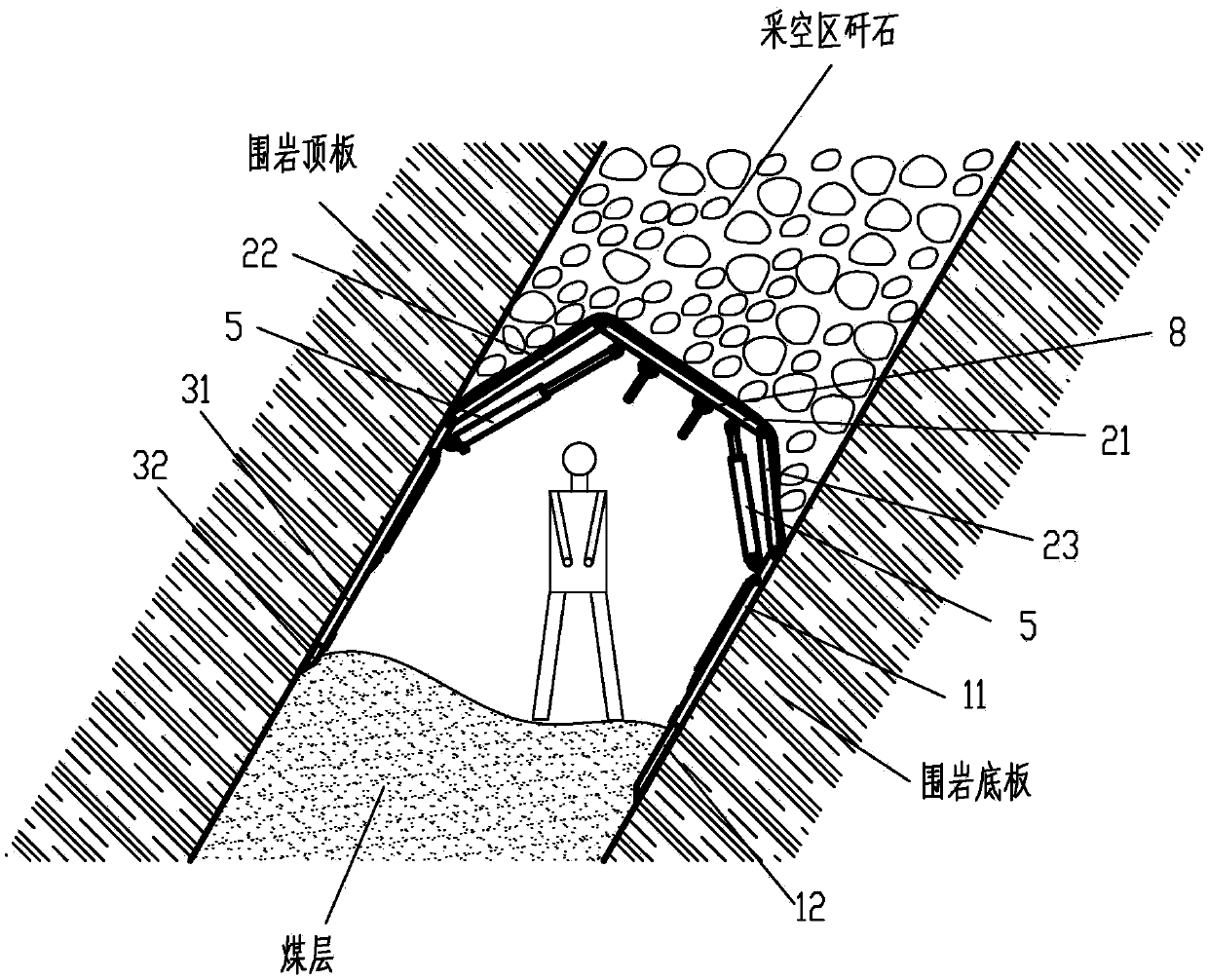

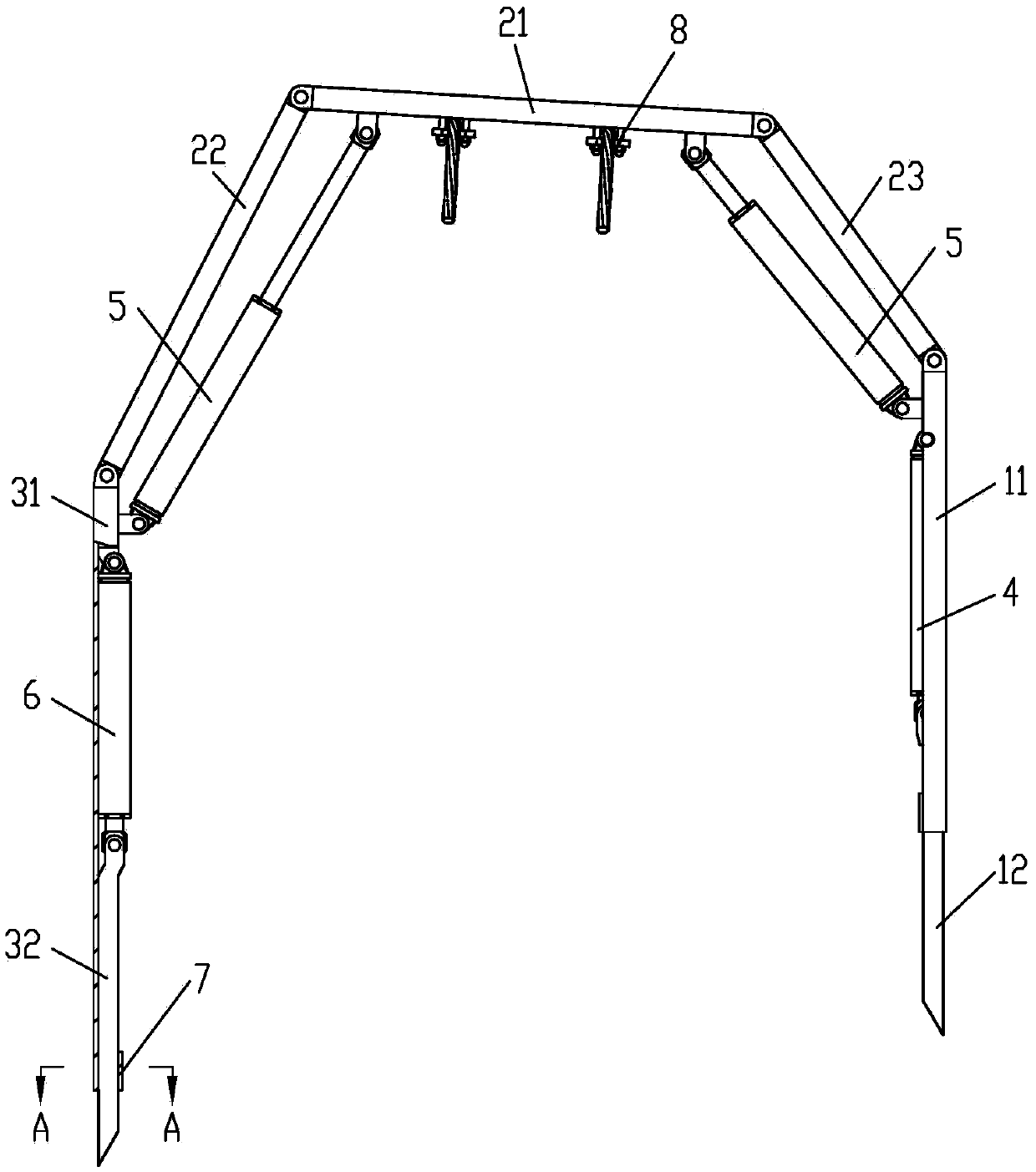

Shield support for steep medium-thickness coal seam

ActiveCN103643980AIncrease frictional resistanceImprove support strengthMine roof supportsHydraulic cylinderLeg extension

The invention discloses a shield support for a steep medium-thickness coal seam, which comprises a lower landing leg and a support beam mutually articulated, wherein the support beam is arched; a free end of the support beam is further articulated with an upper landing leg; the lower landing leg and the upper landing leg are linear; first hydraulic cylinders are movably connected between the upper landing leg and the support beam and between the lower landing leg and the support beam respectively; the lower landing leg comprises a lower landing leg main body and a lower landing leg extension body; the upper end of the lower landing leg main body is articulated with the support beam; a sharp head is arranged at a free end of the lower landing leg extension body; a second hydraulic cylinder is movably connected between the lower landing leg main body and the lower landing leg extension body; the first hydraulic cylinder on the lower landing leg is articulated with the lower landing leg main body by the bottom end of a cylinder body of the first hydraulic cylinder; and the tail ends of piston rods of the two first hydraulic cylinders are articulated with the support beam respectively. The support has the benefits that the support is good in stability and safety and can be adjusted with changes in coal seam thickness and a dip angle, and a coal seam recovery ratio and a level of mechanization are high.

Owner:重庆天巨承机械制造有限责任公司

Apparatus and method for adjusting horizon of low speed diesel engine frame

InactiveCN101251223ATroubleshooting Level Adjustment DifficultiesMeet adjustment requirementsMachine framesLow speedDiesel engine

The invention relates to an adjustment device for the level of a marine low-speed diesel engine frame. The device mainly comprises an upper inclined block, a lower inclined block and an adjusting stud, the upper inclined block and the lower inclined block respectively comprises an inclined surface and a horizontal surface, the included angle between the inclined surface and the horizontal surface of the upper inclined block is equal to the included angle between the inclined surface and the horizontal surface of the lower inclined block, one end of the thicker end of the upper inclined block is provided with a screw hole matched with the adjusting strut, the thinner end of the lower inclined block is provided with a protuberance perpendicular to the inclined surface, the whole lower inclined block is approximately of L shape, the protuberance is provided with a through unthreaded hole, the unthreaded hole is coaxial with the screw hole on the upper inclined block, the inclined surface of the upper inclined block is downward placed on the inclined surface of the lower inclined block, the thicker end of the upper inclined block is near the protuberance, one end of the adjusting strut passes through the unthreaded hole and is fixed in the screw hole of the upper inclined block, a nut screwed on an adjusting strut is respectively arranged close to both sides of the protuberance. The adjustment device of the invention solves the problem that the rigid plane has difficult horizontal adjustment, and has the advantages of high adjusting accuracy and strong reliability.

Owner:HUDONG HEAVY MACHINERY

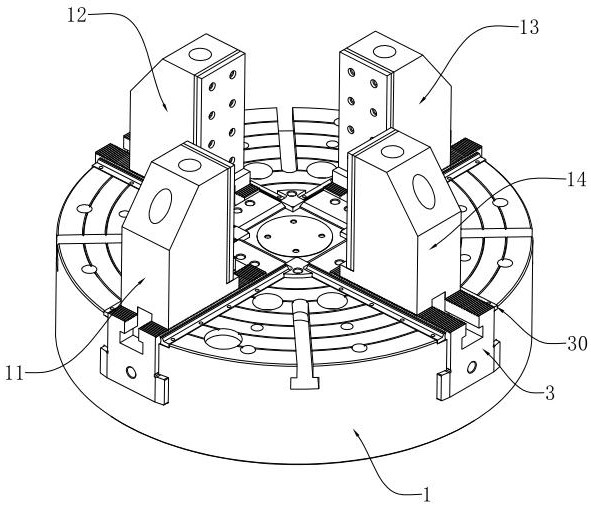

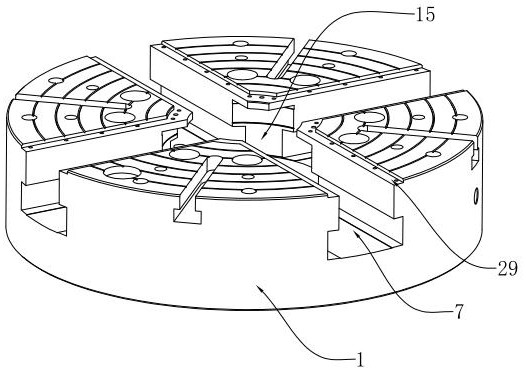

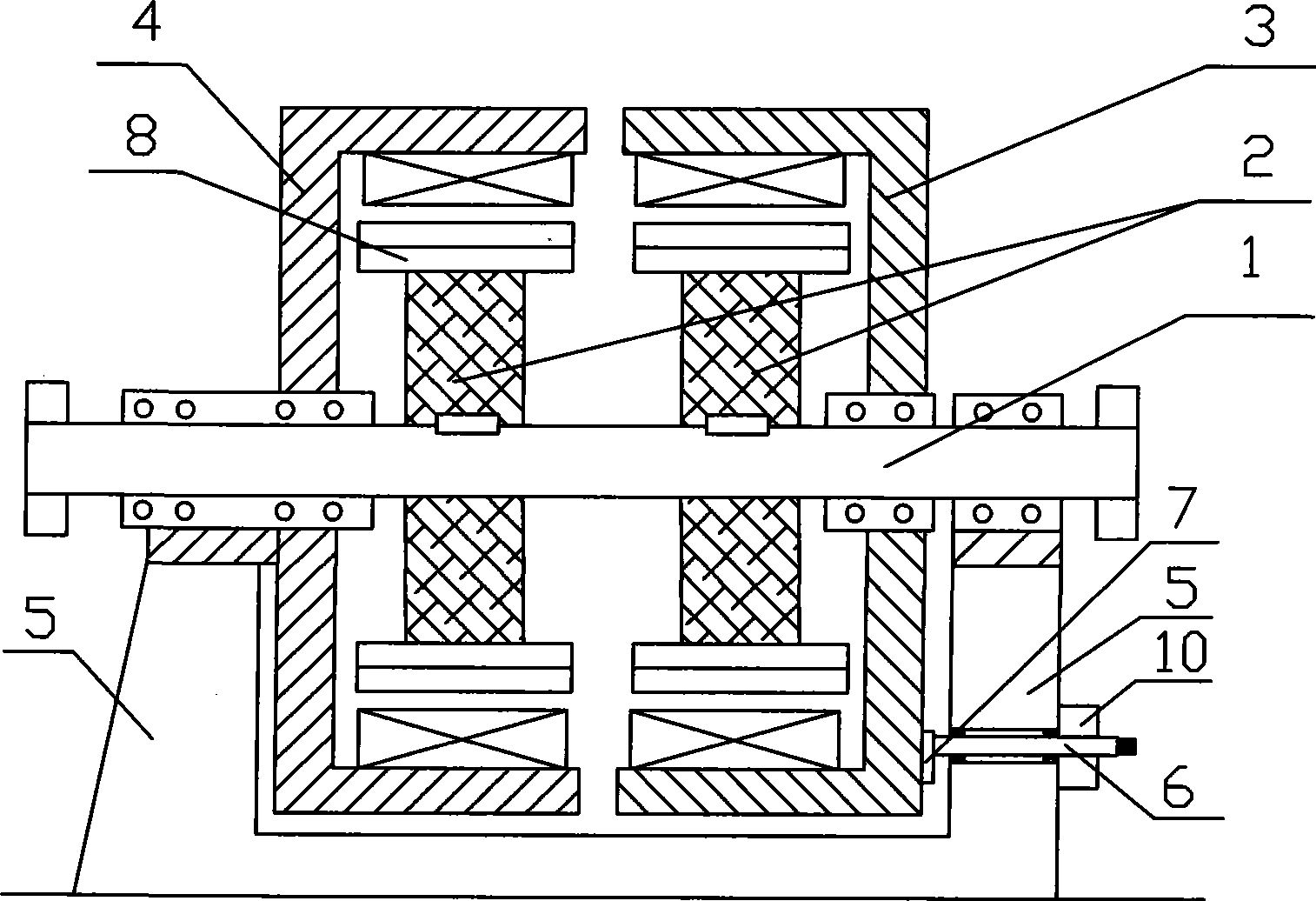

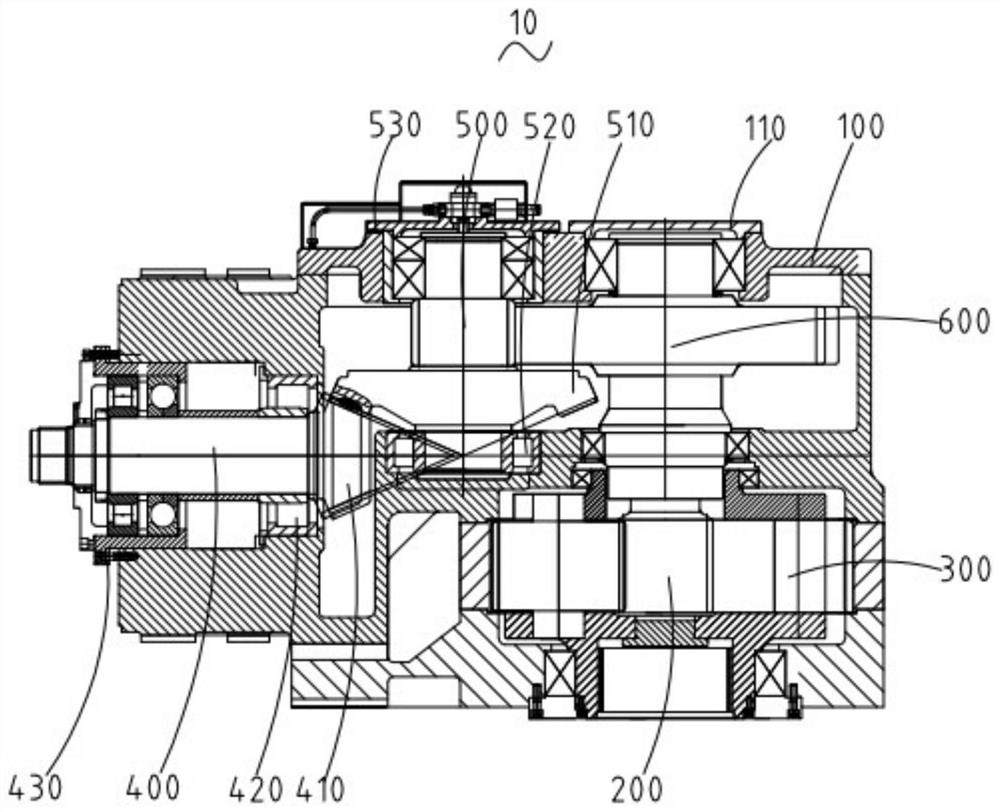

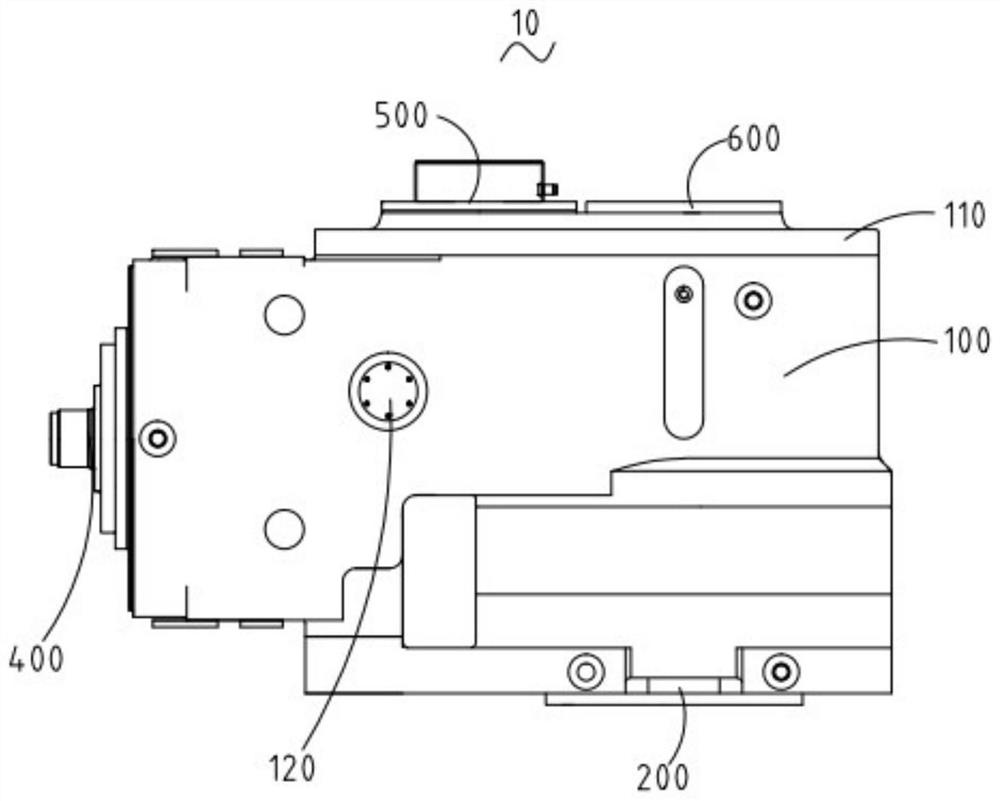

Hydraulic four-jaw double-acting centering chuck

PendingCN112247172AExtended service lifeLarge clamping forceChucksPositioning apparatusStructural engineeringCylinder block

The invention relates to a hydraulic four-jaw double-acting centering chuck. The hydraulic four-jaw double-acting centering chuck comprises a chuck body, clamping jaws, a sliding base, T-shaped blocks, a first wedge core sleeve and a second wedge core sleeve, wherein the sliding base is installed on the chuck body in a sliding mode, the clamping jaws are indirectly fixed to the sliding base through the T-shaped blocks, every two opposite clamping jaws in the four clamping jaws form one group in pairs, the first wedge core sleeve and the second wedge core sleeve are installed in the chuck body,a cylindrical cavity is formed in the chuck body, the first wedge core sleeve is matched with one group of clamping jaws in a wedge shape and then installed in the cylindrical cavity in a sliding mode, a square cavity is formed in the upper end of the first wedge core sleeve, the second wedge core sleeve is matched with the other group of clamping jaws in a wedge shape and then installed in the square cavity in a sliding mode, and a double-acting oil cylinder on the same side is mounted on a lathe, and independently pulls the first wedge core sleeve and the second wedge core sleeve to drive the two groups of clamping jaws in the opposite directions to move to clamp a square workpiece. The two groups of clamping jaws form a double-acting effect and conduct clamping from the side faces of abreaking hammer cylinder body correspondingly, the requirement for adjusting the positions of the clamping jaws by an operator is lowered, and meanwhile, the service life of the oil cylinder can be prolonged.

Owner:烟台众和机床附件有限公司

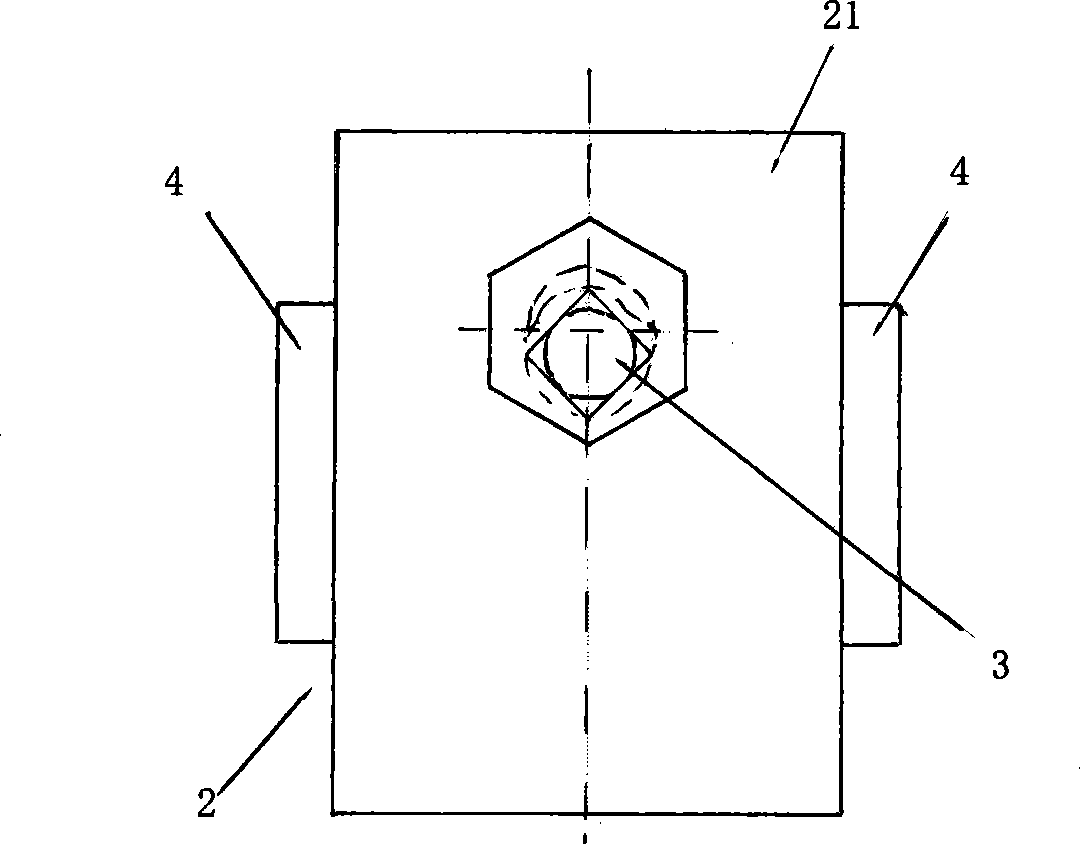

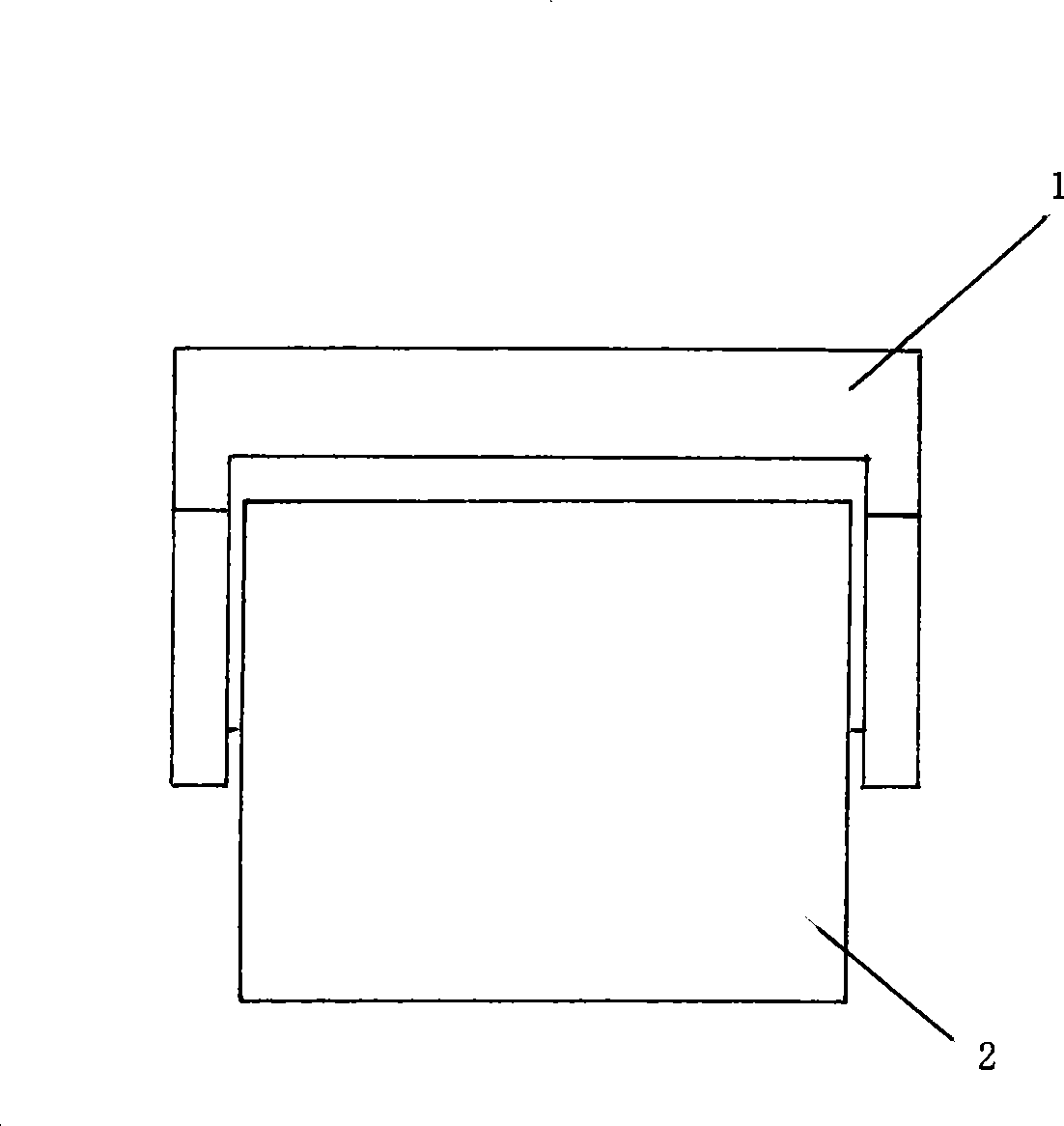

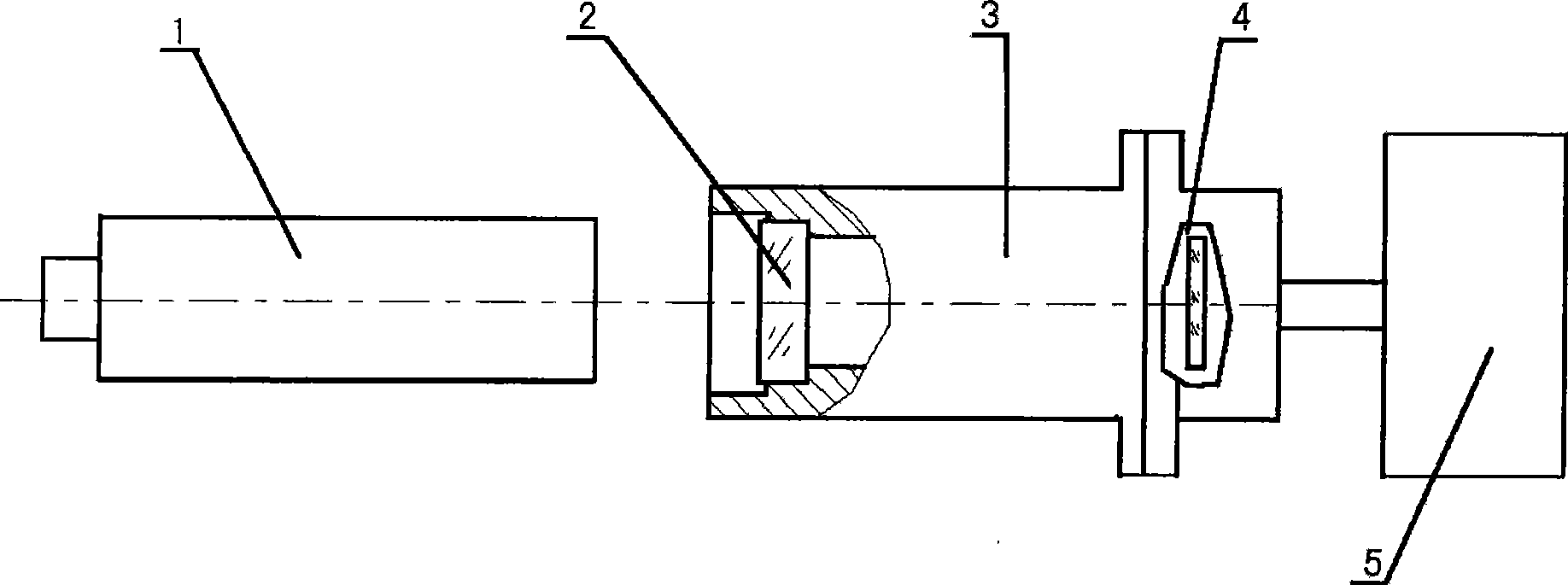

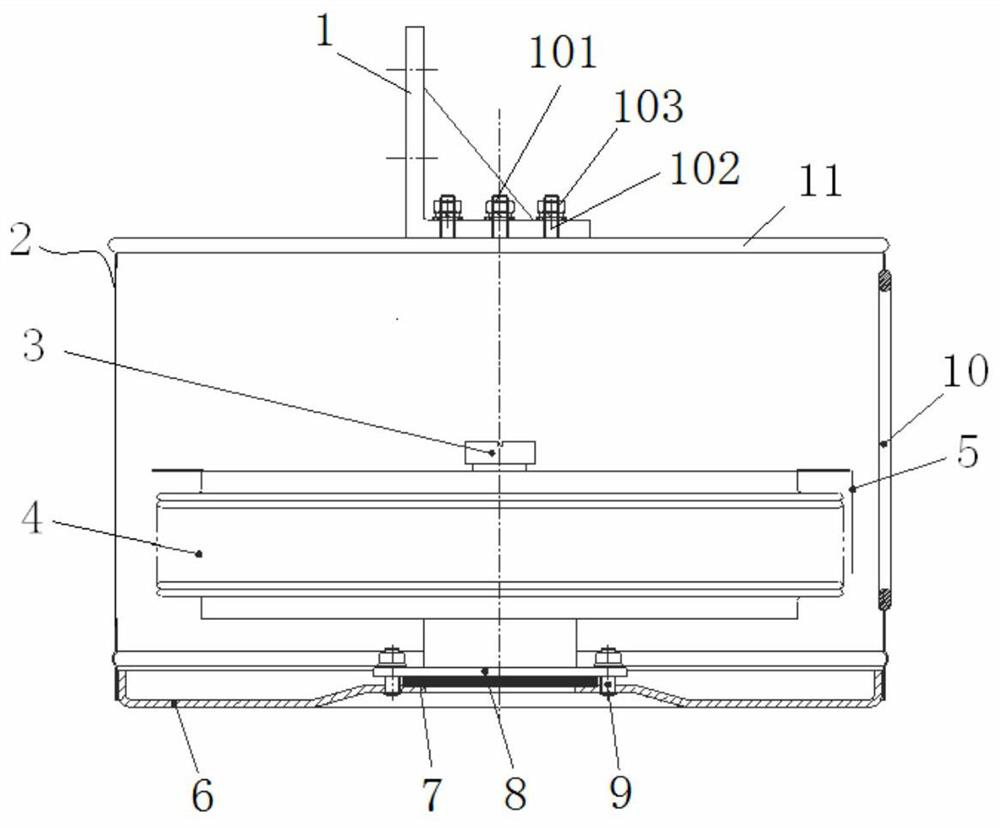

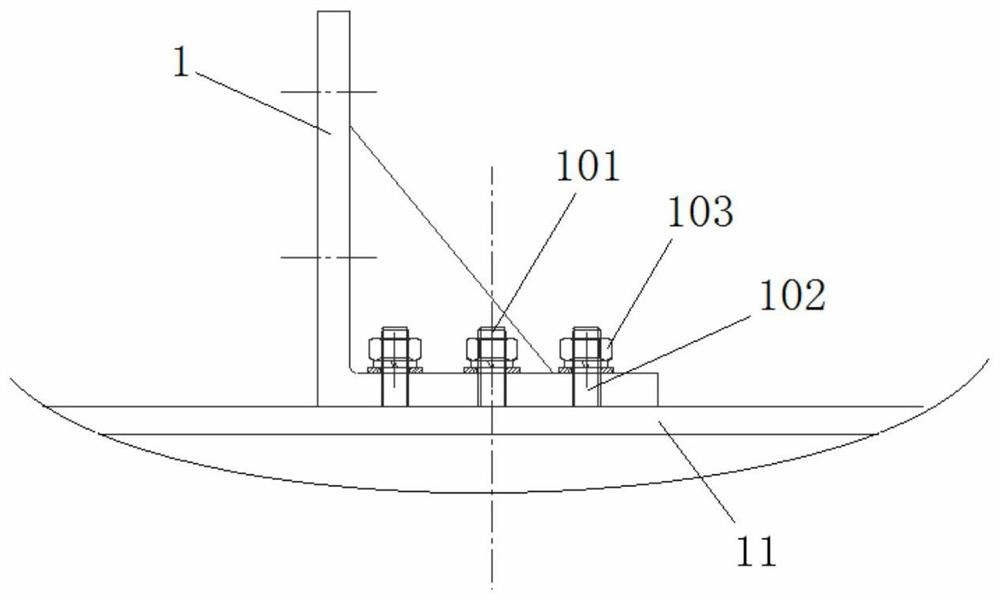

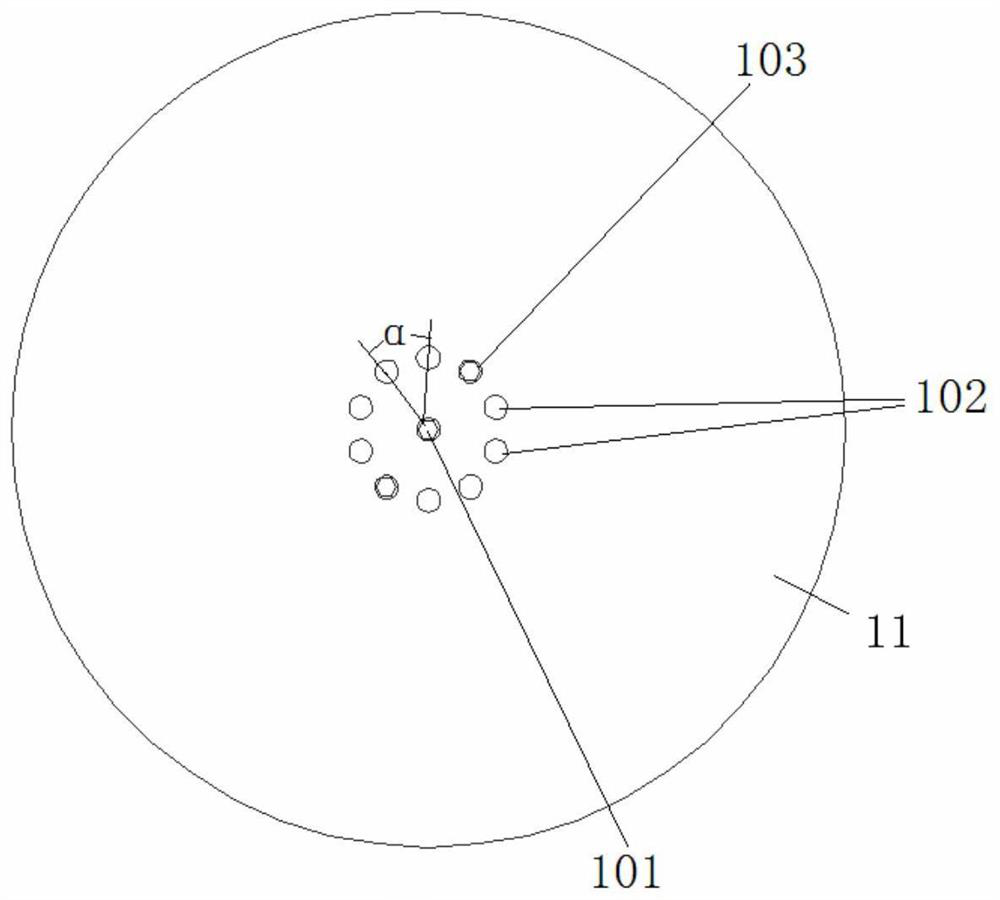

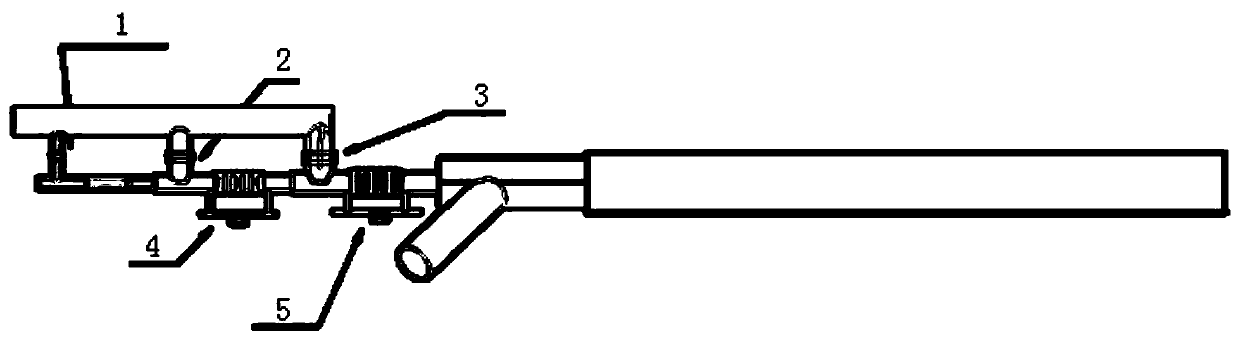

Real-time regulating system for centering optical axis of CCD stereo camera

InactiveCN101470899AHigh precisionAchieving positional accuracy requiresImage analysisUsing optical meansStereo cameraOptical axis

The invention relates to a system for adjusting an optical axis of a CCD stereo camera to the center in real time. The system for adjusting an optical axis of a CCD stereo camera to the center in real time which is provided by the invention comprises parallel light pipes (1), window glass (2), a stereo camera lens (3), a CCD (4) and a computer data collecting system (5), wherein the window glass (2), the stereo camera lens (3) and the CCD (4) are arranged on the optical axis of the parallel light pipes (1) in turn, and the computer data collecting system (5) is connected with the CCD (4). The invention provides the system for adjusting an optical axis of a CCD stereo camera to the center in real time with convenient adjustment, which can obtain the central deviation value in real time, for solving the technical problem in an existing CCD stereo camera that the real time adjustment of the optical axial with high precision to the center is difficult.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

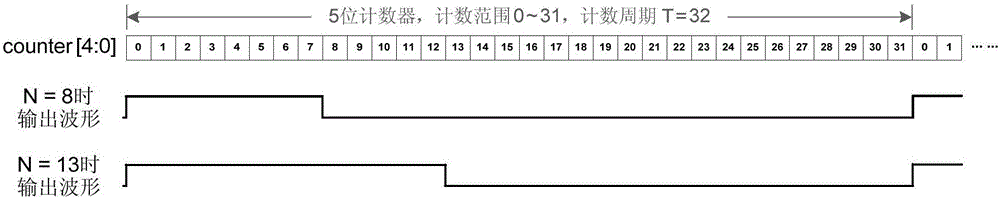

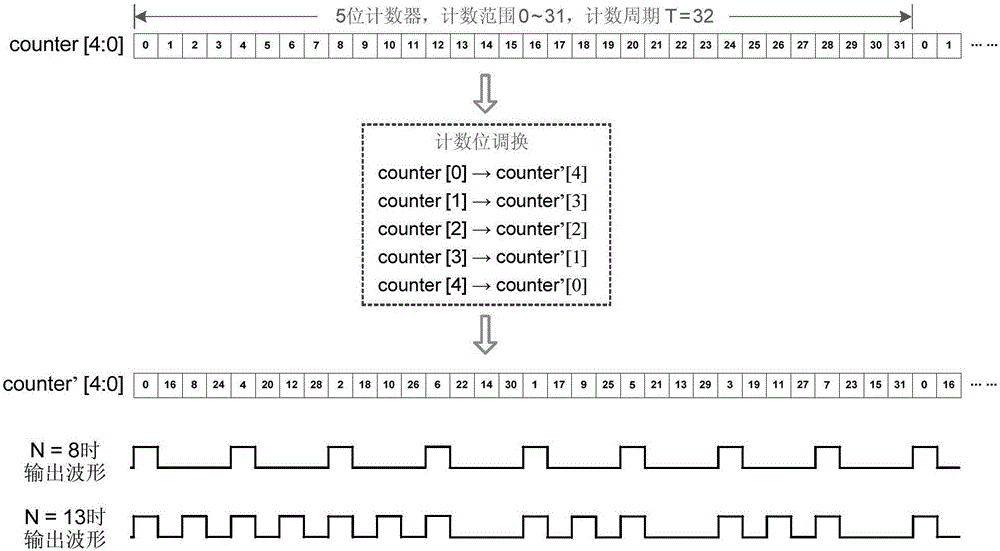

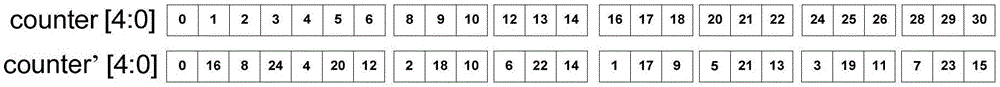

Control methods of discrete PWM and multi-channel PWM and LED system

ActiveCN106793262AAccuracy adjustableMeet adjustment requirementsElectrical apparatusElectroluminescent light sourcesElectrical and Electronics engineeringPulse waveform

The invention provides a control method of a discrete PWM. The height position of each count digit of a counter counting value M is changed to obtain a new counting value M'; a pulse waveform with the duty ratio of N / T is outputted; when M' is smaller than N, the outputted pulse waveform is a high level; and when the M' is larger than or equal to N, the outputted pulse waveform is a low level. The invention also provides a control method of a multi-channel discrete PWM, the height position of each count digit of the counter counting value M is changed to obtain a new counting value M'; the counting period T of a counter is divided into at least two intervals, and each interval is corresponding to one channel; when the counting value M' is in a first interval, the first channel outputs a high level, and when the counting value M' is outside the first interval, the first channel outputs a low level; when the counting value M' is in a second interval, the second channel outputs a high level, and when counting value M' is outside the second interval, the second channel outputs a low level, and so on.

Owner:XIAMEN UNIV OF TECH

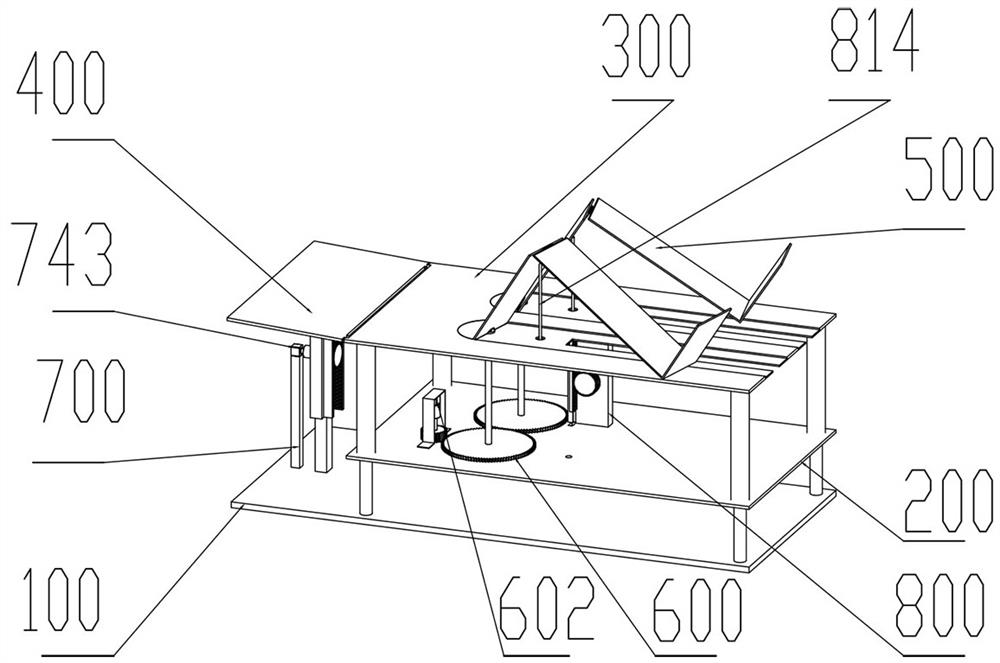

Bottom die trolley of short-line matching prefabricated box girder

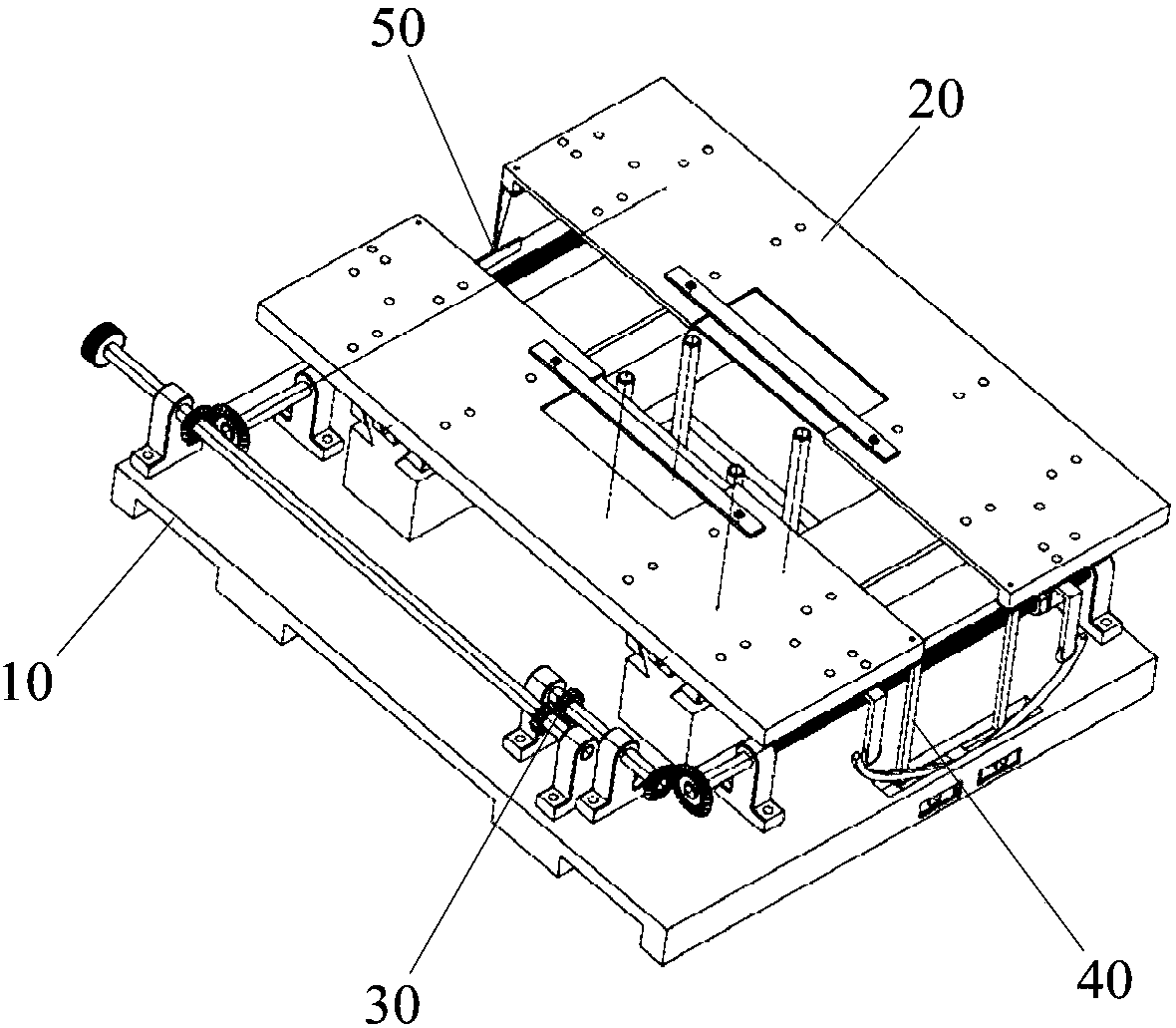

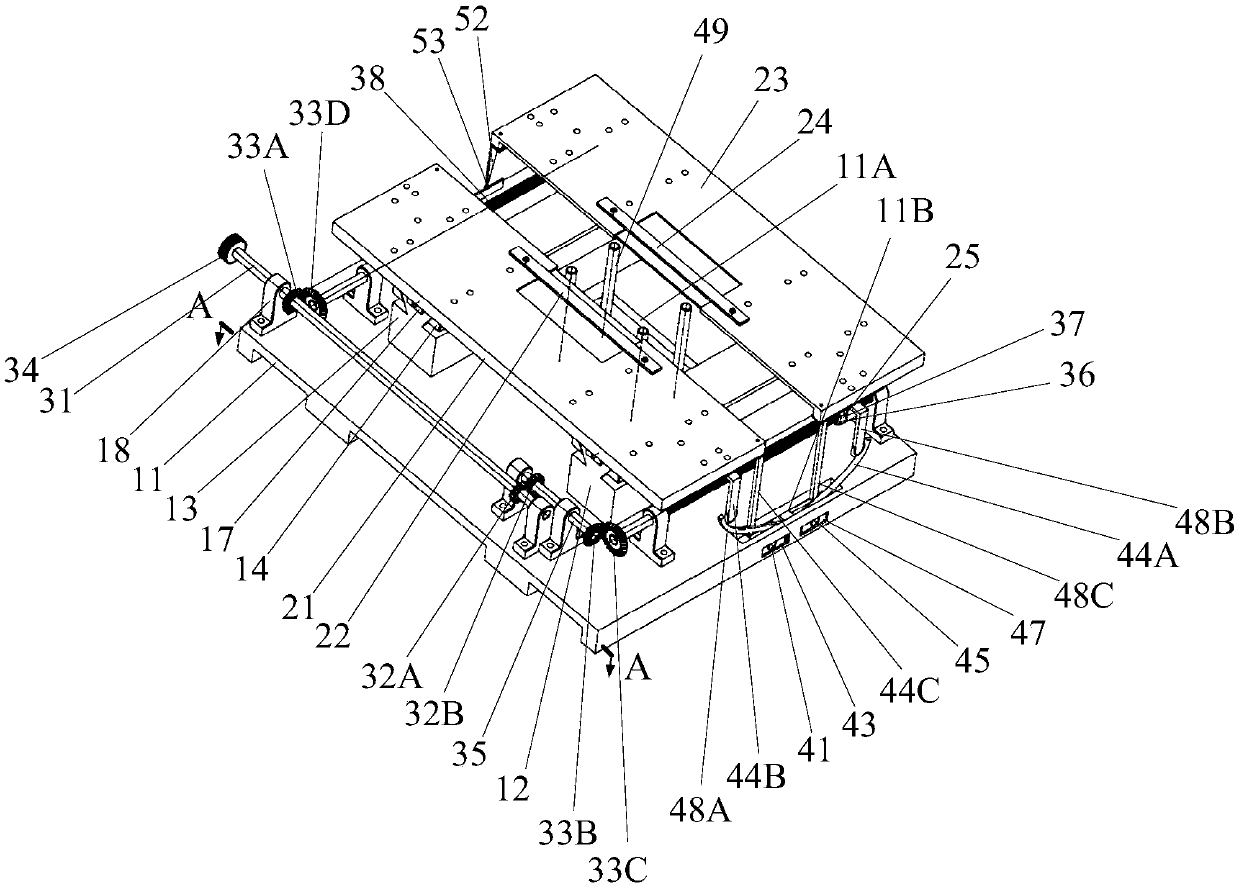

PendingCN110924316ALower center of gravityAvoid safety hazardsBridge erection/assemblyBridge materialsBox girderFastener

The invention discloses a bottom die trolley of a short-line matching prefabricated box girder. The bottom die trolley comprises an upper-layer support, a lower-layer support, an adjusting device, a jacking device and a walking device. The two supports are vertically stacked, and are small in size and low in center of gravity. The walking devices are connected to the bottoms of the two transversesides of the lower-layer support. Vertical limiting columns are connected to the middle positions of the front end and the rear end of the lower-layer bracket; the limiting column penetrates through the upper-layer support to enable the two supports to be vertically limited through a fastener, the adjusting device is a telescopic device arranged in the horizontal direction, one end of the adjusting device is hinged to a hinge base on the upper-layer support, the other end of the adjusting device is hinged to the limiting column and vertically limited, and the multiple jacking devices are vertically connected to the upper-layer support. Horizontal transverse movement of the upper-layer support relative to the lower-layer support and rotation of the upper-layer support around the limiting column on one side can be achieved through telescopic movement of the adjusting device, the jacking device is used for jacking the matching beam, the vertical height or inclination angle of the matchingbeam can be adjusted, longitudinal movement of the matching beam carried by the bottom die trolley is achieved through the walking device, and operation is easy.

Owner:湖南五新智能科技股份有限公司

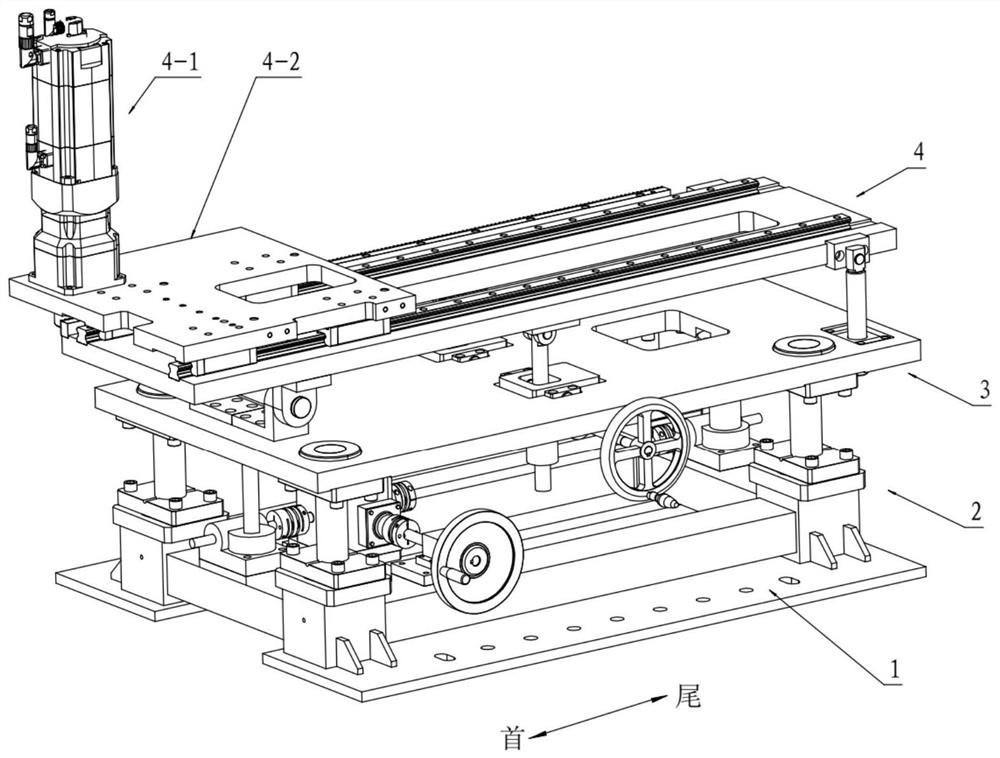

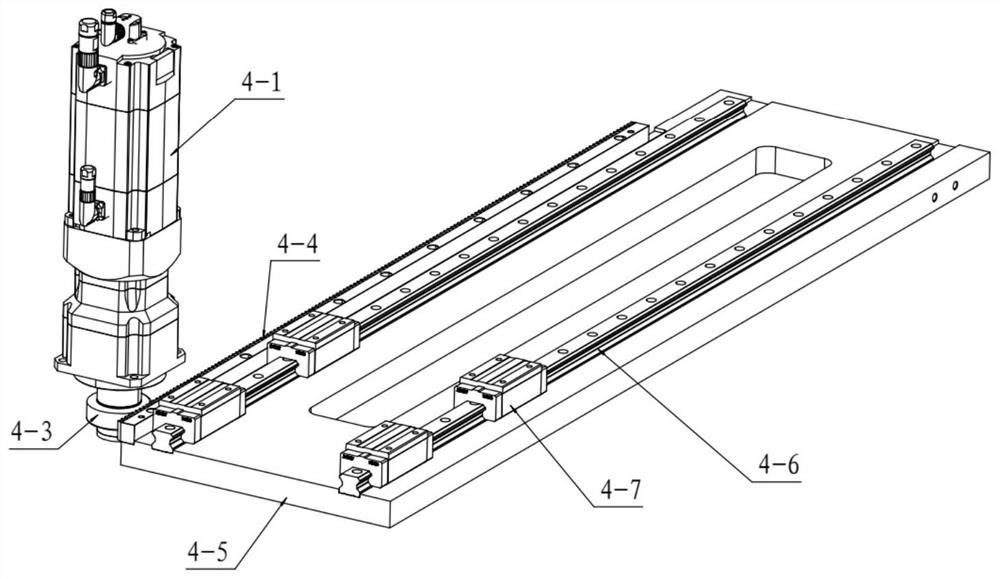

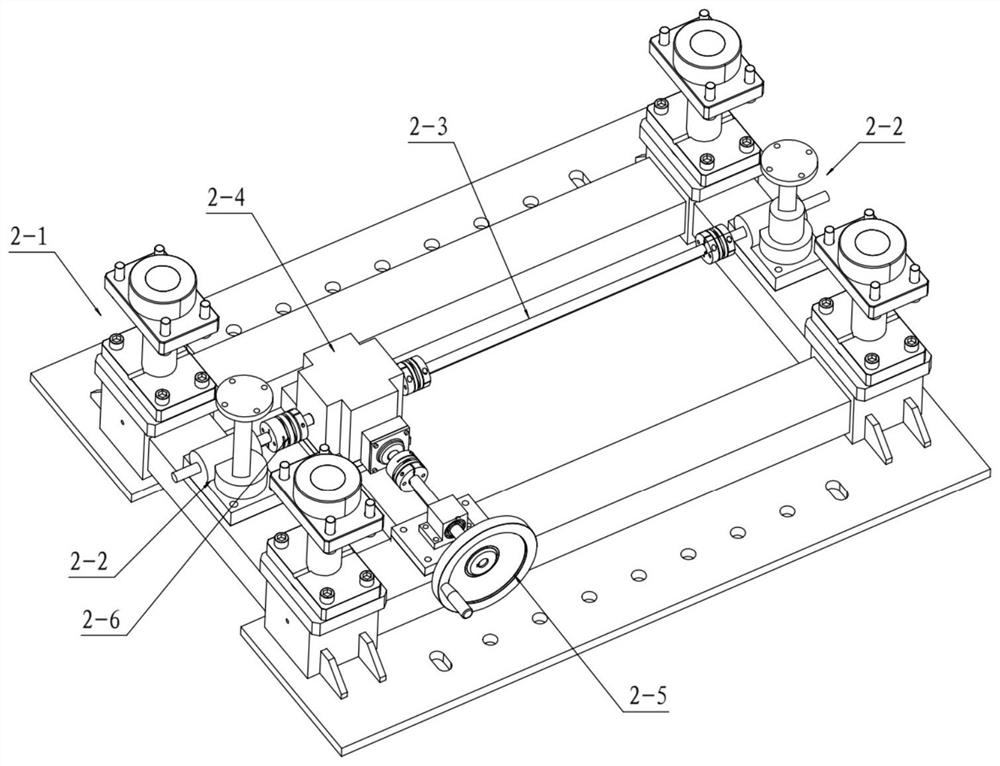

A gap adjustment device for butt welding of steel plates

ActiveCN106493499BHigh positioning accuracyMeet adjustment requirementsWelding/cutting auxillary devicesAuxillary welding devicesSheet steelButt welding

The invention discloses a steel plate butt welding gap adjusting device, and belongs to steel plate position adjusting devices. The problem that according to an existing steel plate butt welding positioning device, the butt welding steel plate gap is difficult to precisely adjust is solved. The device comprises a base assembly, a fixing assembly, a transmission mechanism, a positioning mechanism and a gap indicating assembly; the base assembly comprises a bottom plate, a front guide rail and a rear guide rail; the fixing assembly comprises a left fixing plate, a right fixing plate, a left pressing plate and a right pressing plate; the transmission mechanism comprises a transmission shaft, a reverse shaft, a front screw and a rear screw; the positioning mechanism comprises a left camshaft, a right camshaft, a left long positioning sliding block, a right long positioning sliding block, a left short positioning sliding block, a right short positioning sliding block, a left pressing strip, a right pressing strip, a left shifting fork, a right shifting fork, a left driving rod, a right driving rod and a positioning pin; the gap indicating assembly is composed of a left pointer, a right pointer and a ruler; the device is simple in structure, low in manufacturing cost, small in work environment influence, easy and convenient to operate, capable of ensuring the steel plate butt welding gap and precise positioning and greatly improving the welding quality and the welding efficiency and suitable for multiple welding processes of lasers, electric arcs and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

A shield support for steeply inclined medium-thick coal seam

ActiveCN103643980BIncrease frictional resistanceImprove support strengthMine roof supportsHydraulic cylinderLeg extension

The invention discloses a shield support for a steep medium-thickness coal seam, which comprises a lower landing leg and a support beam mutually articulated, wherein the support beam is arched; a free end of the support beam is further articulated with an upper landing leg; the lower landing leg and the upper landing leg are linear; first hydraulic cylinders are movably connected between the upper landing leg and the support beam and between the lower landing leg and the support beam respectively; the lower landing leg comprises a lower landing leg main body and a lower landing leg extension body; the upper end of the lower landing leg main body is articulated with the support beam; a sharp head is arranged at a free end of the lower landing leg extension body; a second hydraulic cylinder is movably connected between the lower landing leg main body and the lower landing leg extension body; the first hydraulic cylinder on the lower landing leg is articulated with the lower landing leg main body by the bottom end of a cylinder body of the first hydraulic cylinder; and the tail ends of piston rods of the two first hydraulic cylinders are articulated with the support beam respectively. The support has the benefits that the support is good in stability and safety and can be adjusted with changes in coal seam thickness and a dip angle, and a coal seam recovery ratio and a level of mechanization are high.

Owner:重庆天巨承机械制造有限责任公司

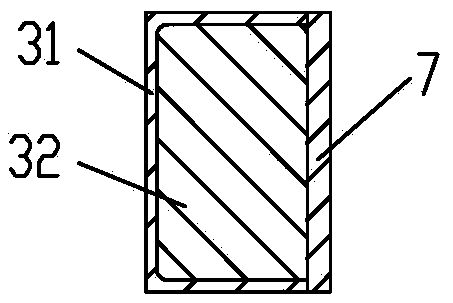

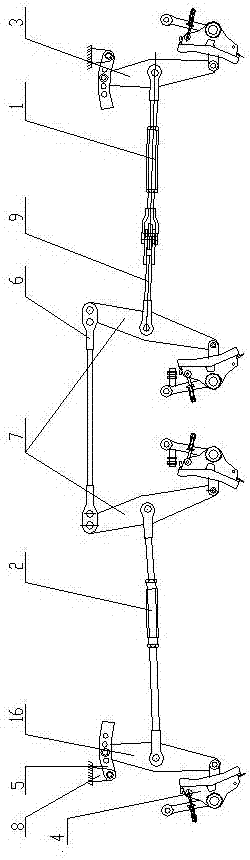

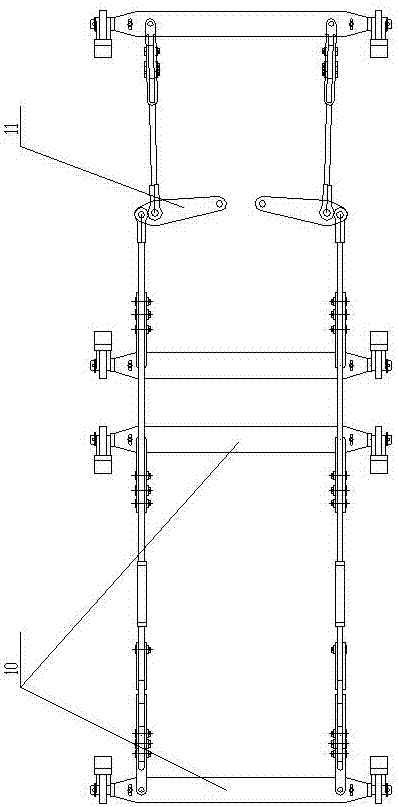

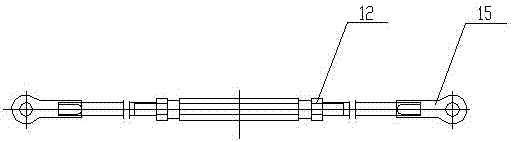

Adjustable type foundation brake device and adjusting method

InactiveCN107161172AEasy to adjustEasy to operateBrake wear compensation mechanismEngineeringBrake shoe

The invention relates to an adjustable type foundation brake device and an adjusting method. Currently, a used long and large goods transport vehicle has the characteristics of being large in load capacity, complex in structure and the like and is limited by a structural space, thus gaps between brake-shoes and wheel pairs cannot be adjusted, and the transporting difficulty of conveying and loading of large equipment such as a crane is caused. The adjustable type foundation brake device comprises a set of middle pull rod device bodies A (1) and a set of middle pull rod device bodies B (2); one ends of the middle pull rod device bodies A are connected with the middles of brake levers A (3) through round pins correspondingly; the other ends of the middle pull rod device bodies A are connected with horizontal brake levers (11) through round pins; the upper portions of the horizontal brake levers are connected with one ends of brake pull rods (9) through round pins; the other ends of the brake pull rods are connected with middle brake levers (7) through round pins; and the middle pull rod device bodies B are connected between the middle brake levers and brake levers B (16) through round pins.

Owner:CRRC HARBIN VEHICLES CO LTD

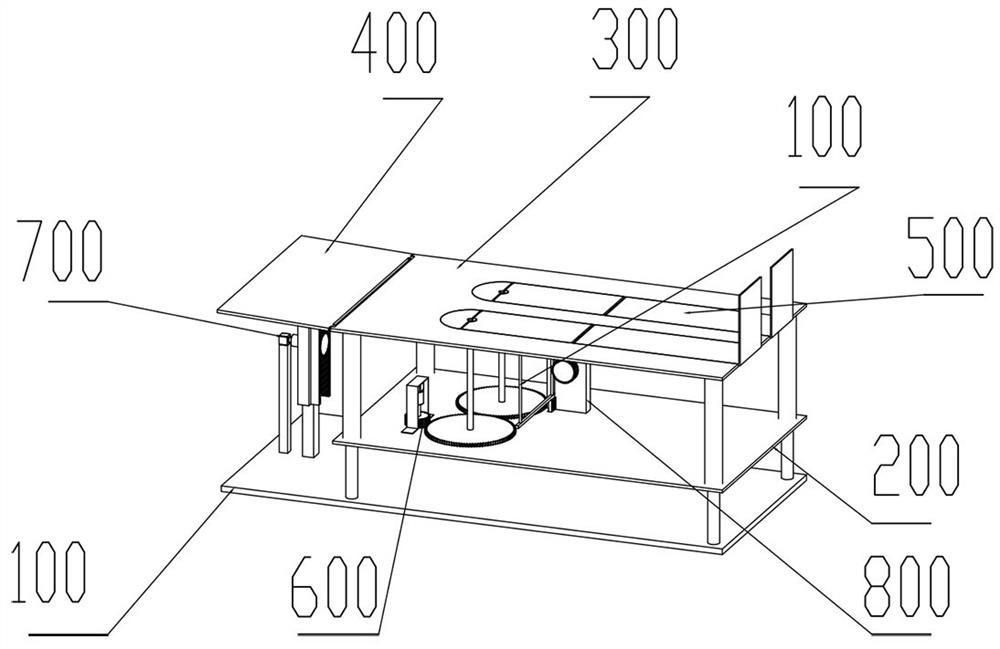

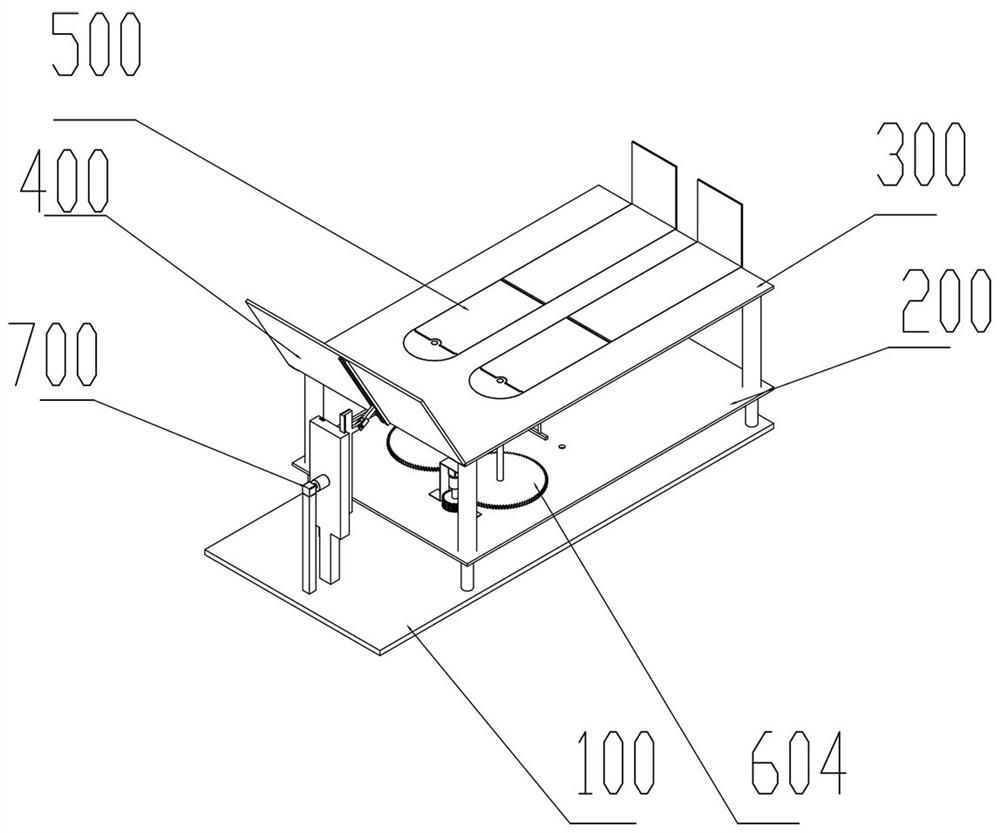

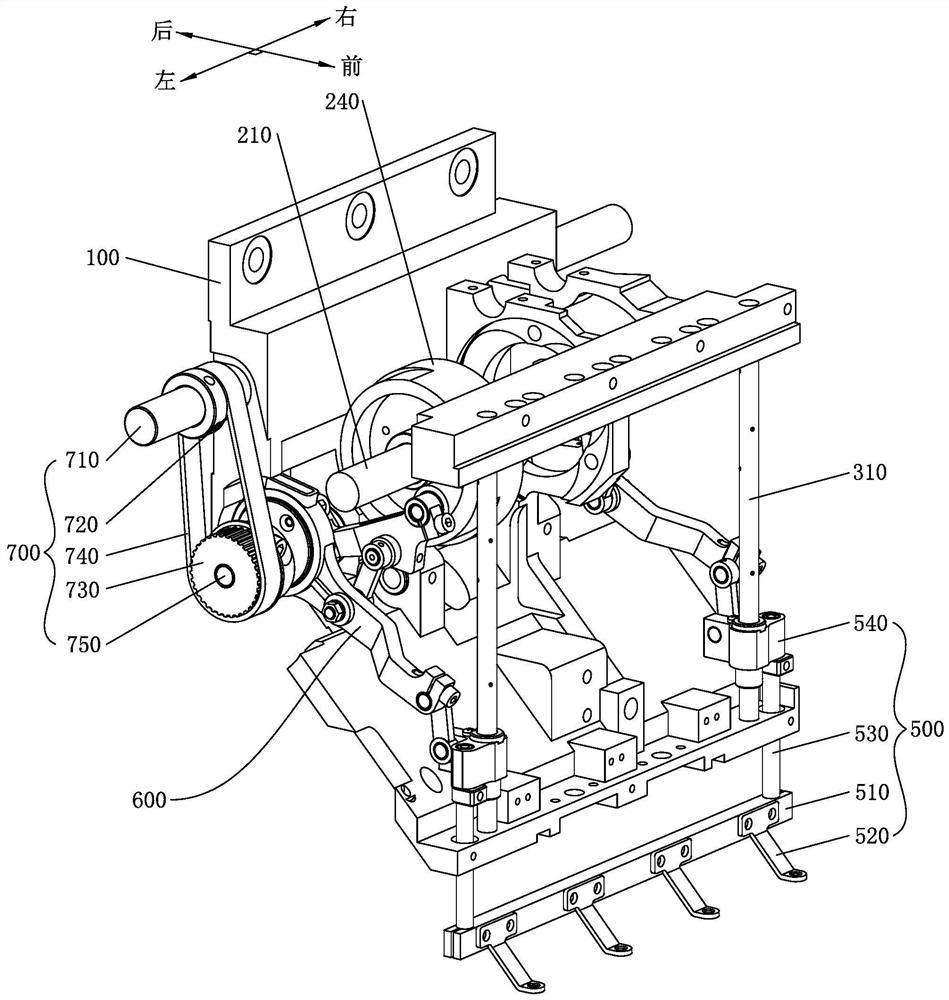

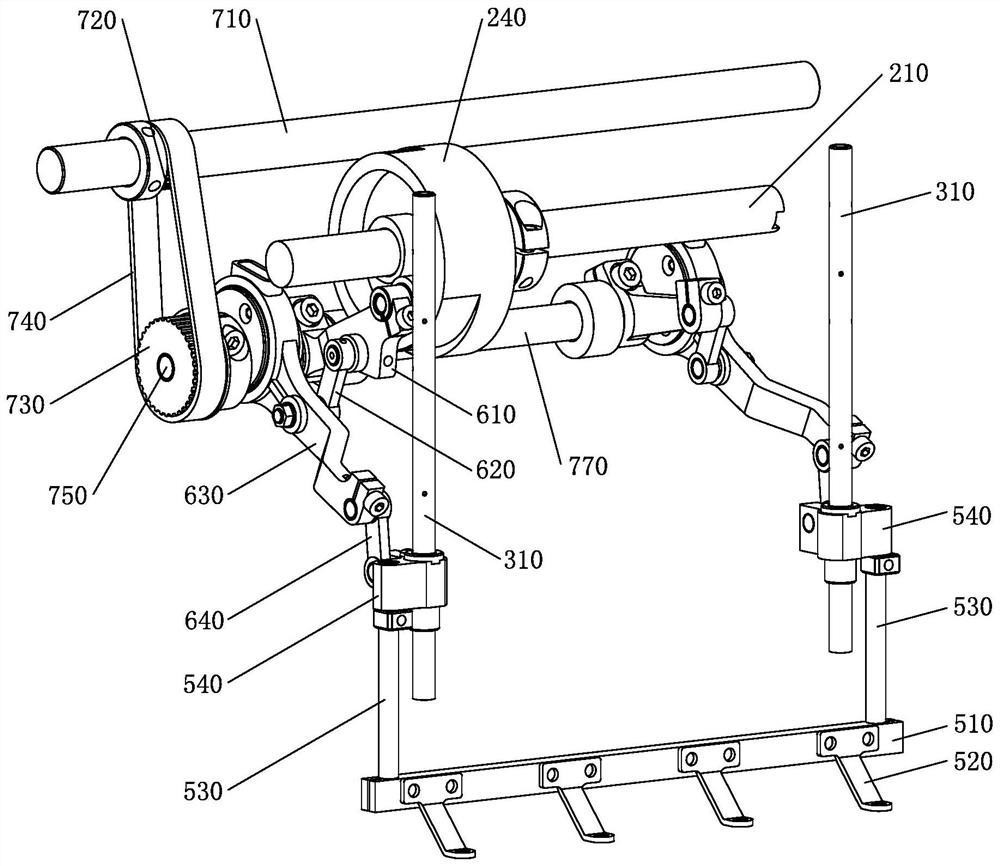

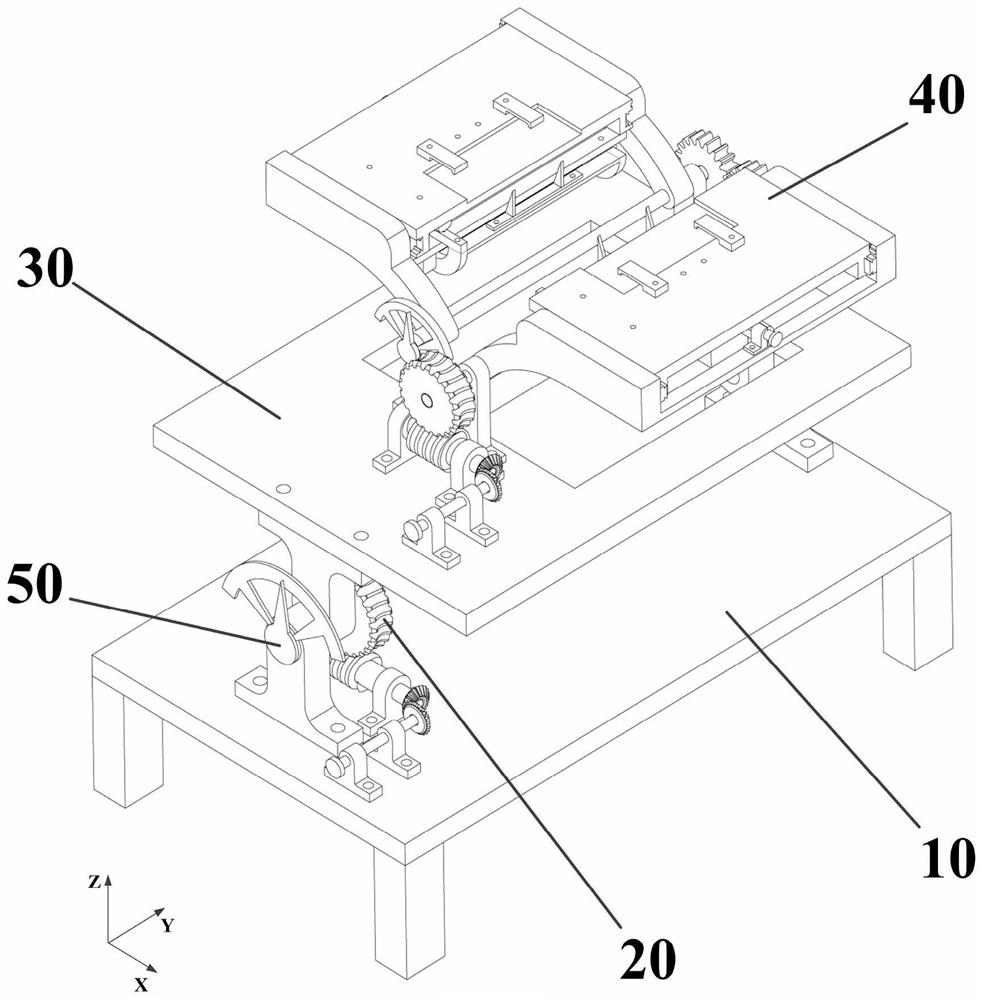

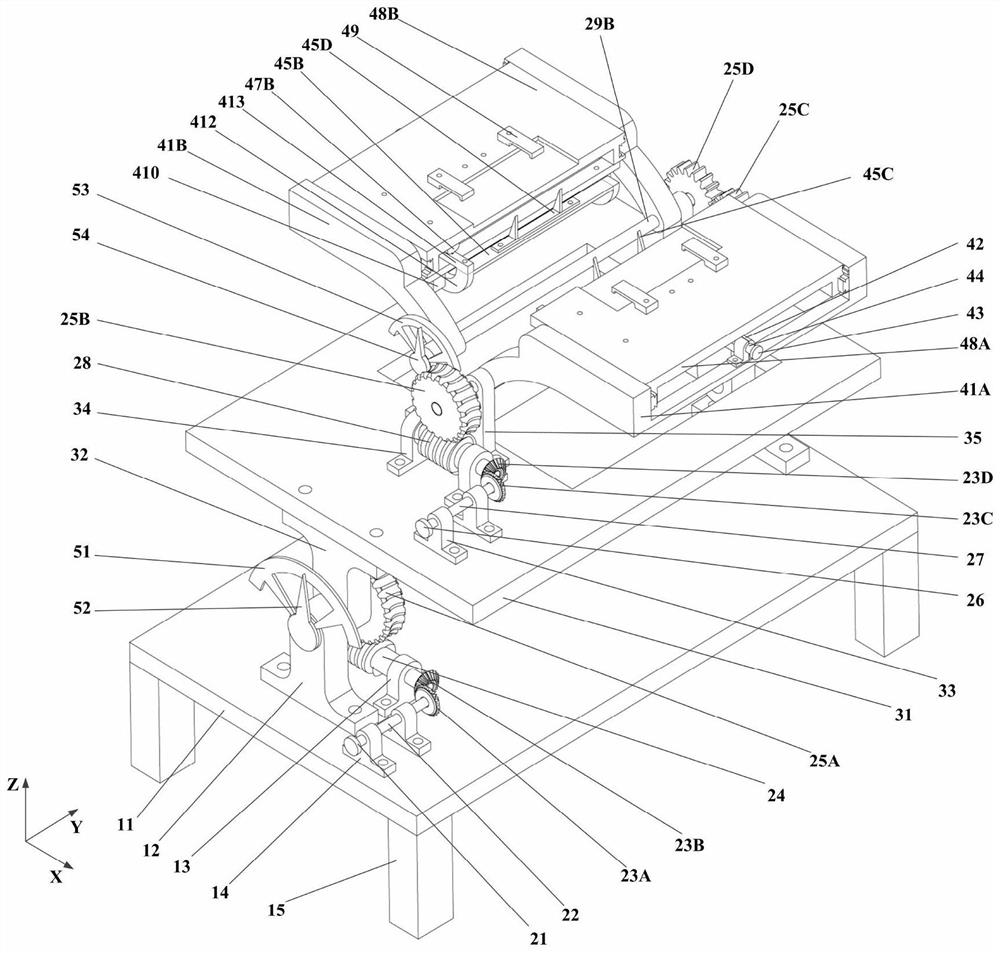

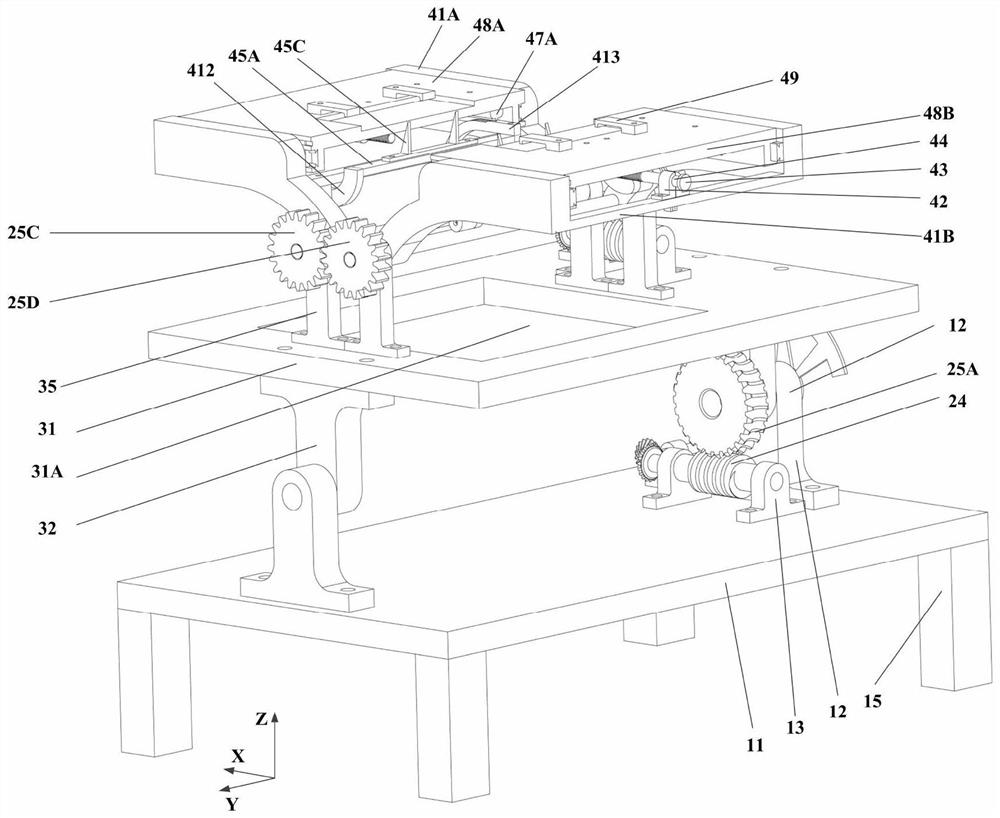

Online follow-up machining device for product parts

PendingCN112894018AMeet adjustment requirementsEasy to replaceLarge fixed membersGear wheelReduction drive

The invention discloses an online follow-up machining device for product parts. The device comprises a base, a lifting adjusting mechanism, an angle adjusting mechanism and a follow-up mechanism which are arranged from bottom to top, the lifting adjusting mechanism is used for adjusting the height position of the follow-up mechanism, and the angle adjusting mechanism is used for adjusting the angle of the follow-up mechanism relative to the running direction of the product parts. The follow-up mechanism is provided with a servo motor, a gear, a rack, a follow-up mounting plate and a tool apron mounting plate, the tool apron mounting plate is located at the upper portion of the follow-up mounting plate, the servo motor is assembled on the tool apron mounting plate and is in transmission connection with the gear through a speed reducer, the gear and the rack are in meshing transmission, the rack is fixedly connected with the follow-up mounting plate, and the tool apron mounting plate is used for mounting a cutting tool. The servo motor acts to drive the tool apron mounting plate to move relative to the follow-up mounting plate. Height adjustment and inclination angle adjustment can be conducted on the follow-up mechanism, the three-dimensional space position adjustment requirement is met, the device is suitable for cutting off different strip-shaped products, use is flexible, the application range is wide, feeding is smooth, and the scratch risk is avoided.

Owner:LINGYUN INDAL CORP

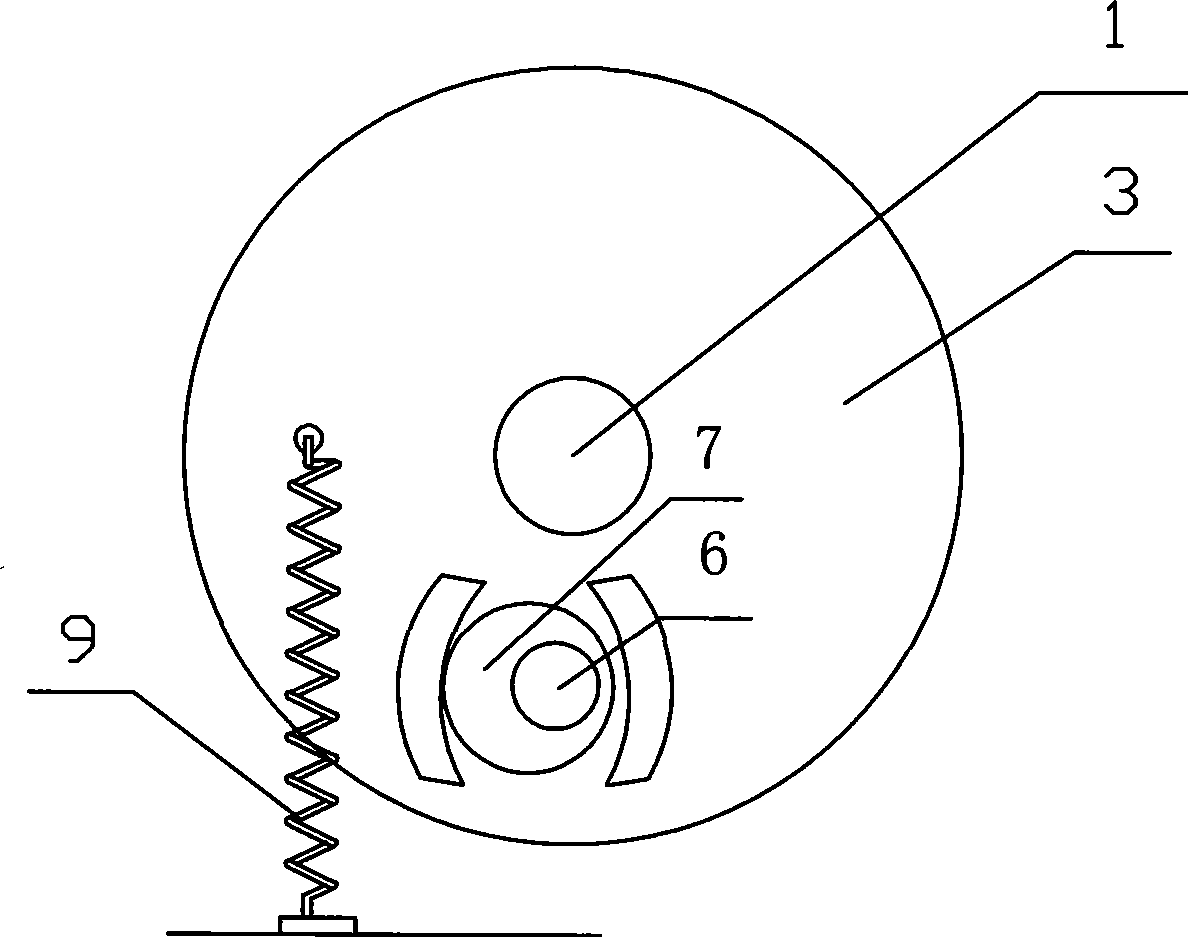

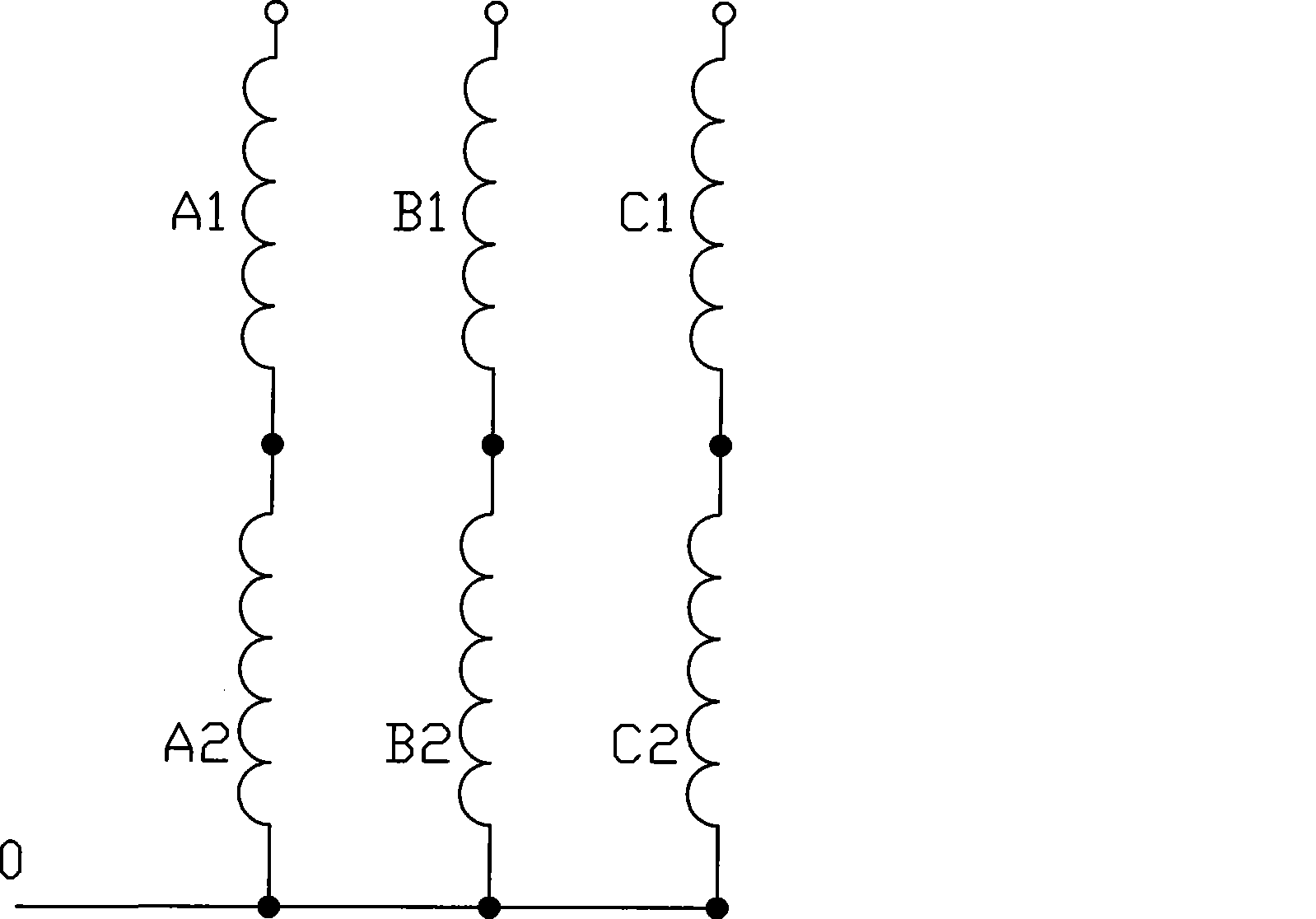

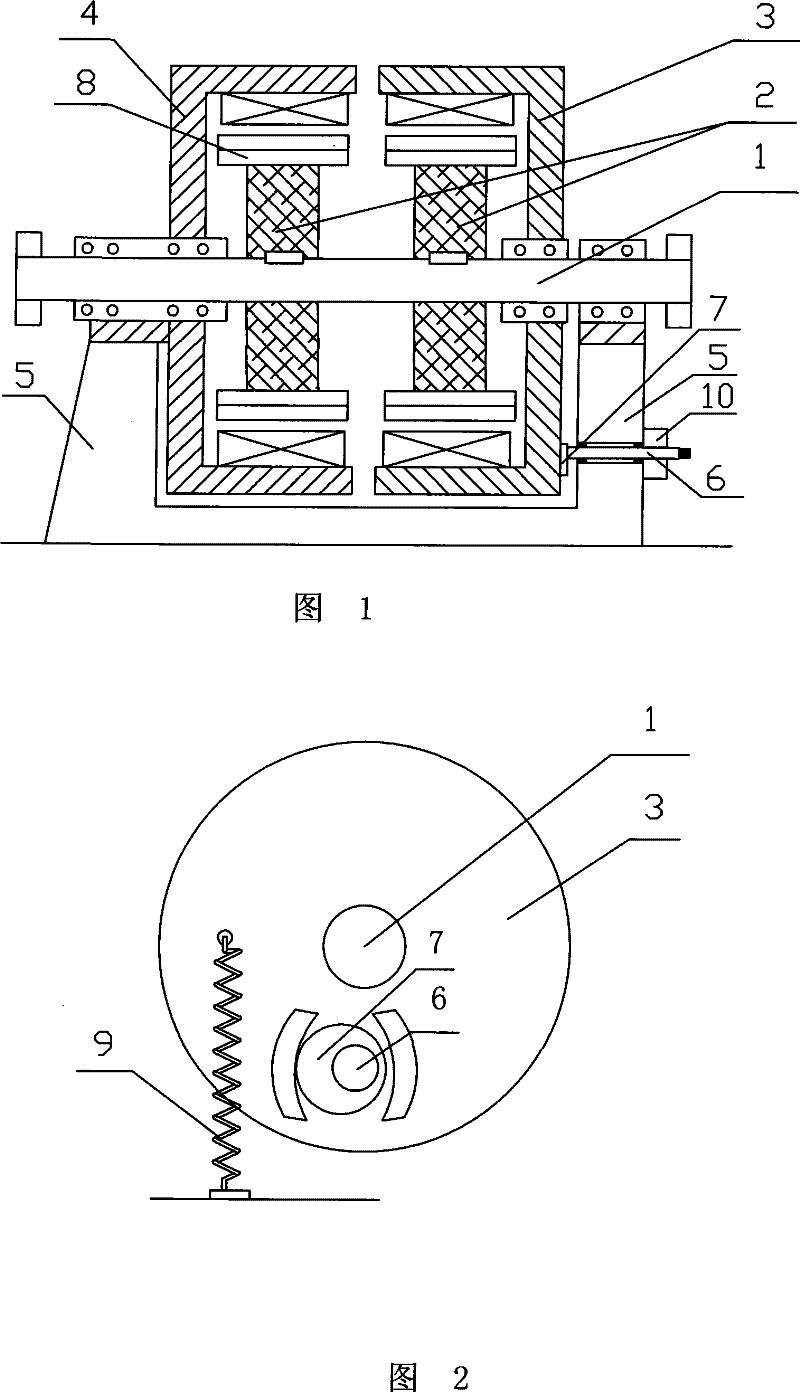

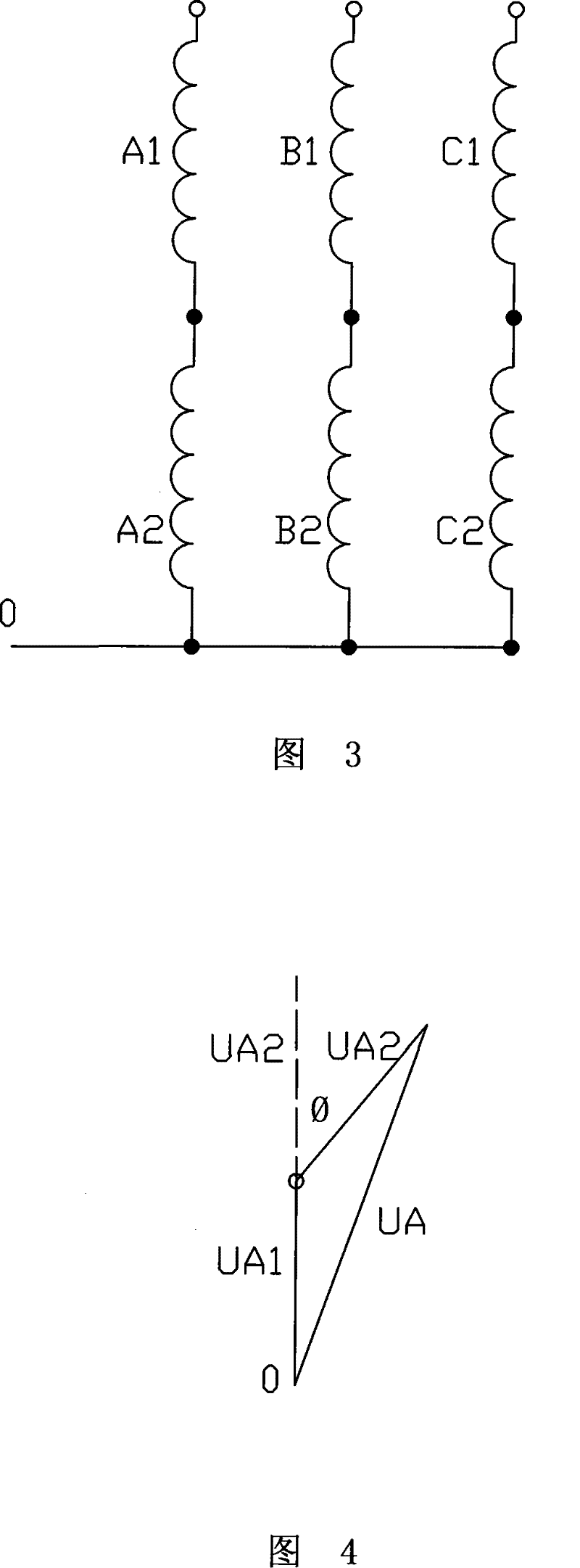

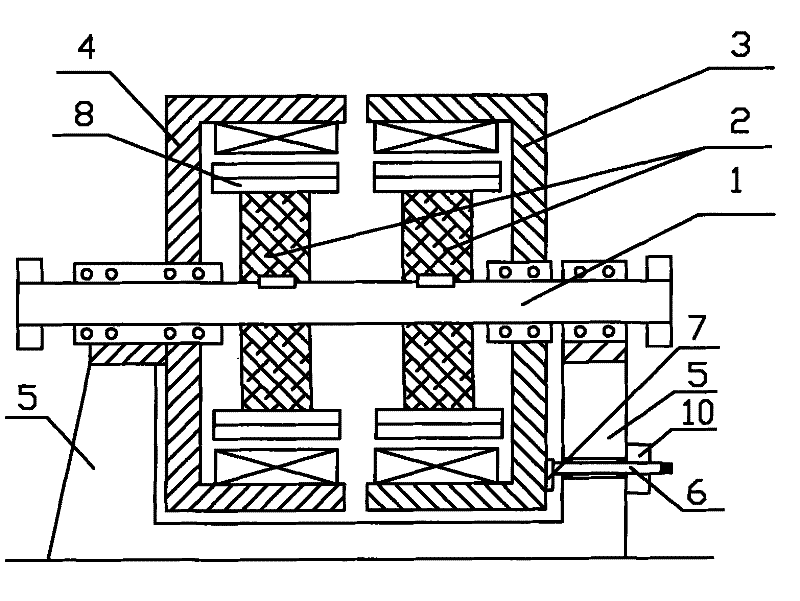

Permanent magnet generator with adjustable voltage

InactiveCN101442240AMeet the requirements of power factor adjustmentMeet adjustment requirementsMechanical energy handlingElectric generator controlManufacturing cost reductionStator coil

The invention relates to a generator, in particular to an adjustable voltage permanent-magnet generator, which comprises a main shaft, a rotor fixedly arranged on the main shaft, and stators arranged around the rotor. The rotor is fixedly arranged on the main shaft, a permanent magnet is fixedly arranged on the rotor, the stators are arranged on the main shaft through a bearing, the stators at least comprise a fixed stator and an adjustable stator on which a fixed stator coil and an adjustable stator coil are arranged respectively, phase lines of the fixed stator coil and the adjustable stator coil are correspondingly connected in series respectively, the fixed stator is fixedly connected with a generator bracket, the adjustable stator is connected to the generator bracket through a spring, and the adjustable stator is also provided with a deflection adjusting mechanism. The generator saves a rectification-inversion device in a parallel network of the permanent-magnet generator, has adjustable output voltage, lowers manufacturing cost greatly, and improves reliability of products.

Owner:王光顺

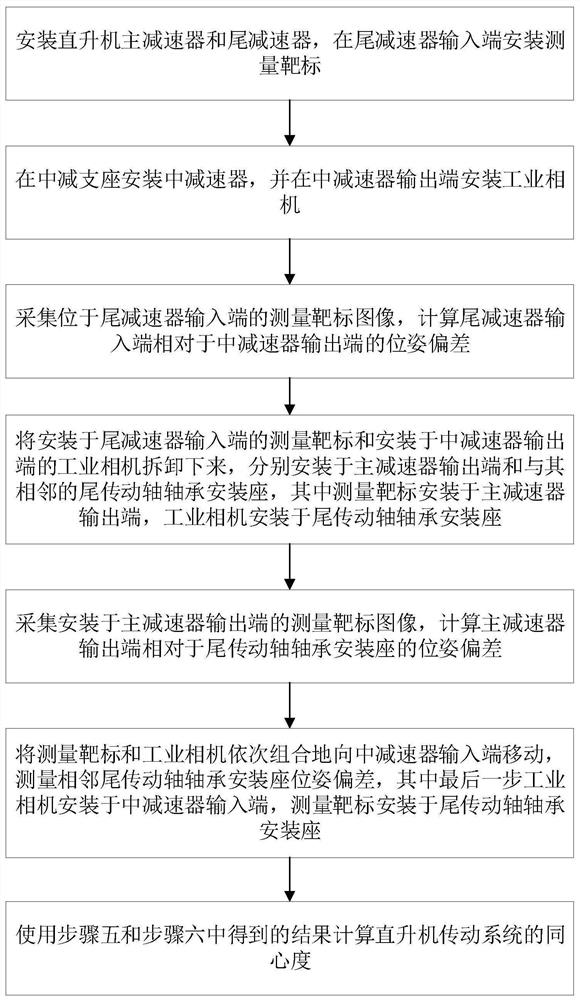

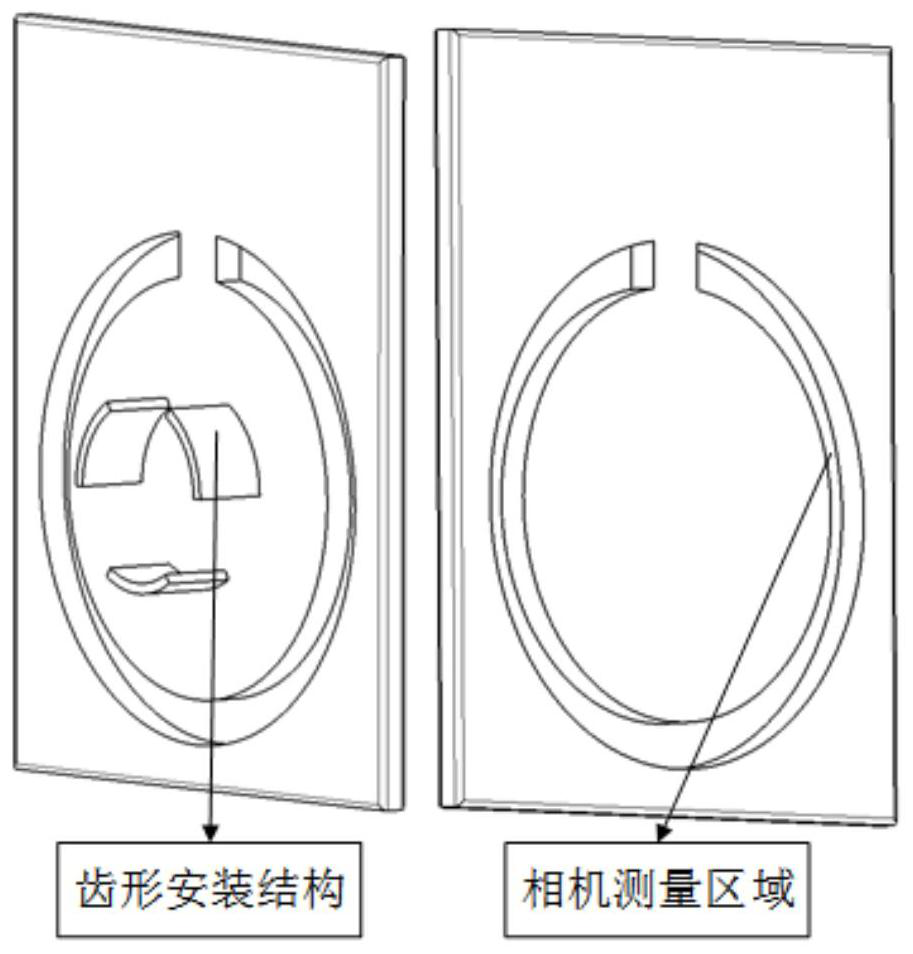

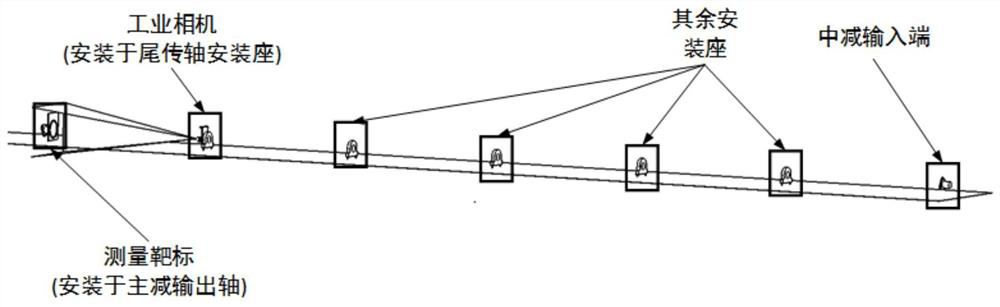

Helicopter transmission system concentricity measuring method based on monocular vision

ActiveCN113390368AAccurate measurementLow working environment requirementsUsing optical meansMedicineEngineering

The invention discloses a helicopter transmission system concentricity measuring method based on monocular vision, wherein a measuring toolmainly adopts industrial cameras, measuring targets is used as an auxiliary tool, the industrial cameras are arranged at the input end and the output end of a middle speed reducer of a helicopter, the targets are arranged at the output end of a main speed reducer, the input end of a tail speed reducer and a tail transmission shaft bearing mounting seat, and in a concentricity measurement process, the industrial cameras collect target images and correspondingly process, analyze and calculate the images, and then the concentricity of the transmission system is calculated. According to the helicopter transmission system concentricity measuring method based on monocular vision, the system adopts the high-resolution industrial camera as a measurement unit, so that the measurement precision is high, and the technical requirement of the model on concentricity adjustment of the transmission system is met; and the traditional mode of repeated measurement, manual reading and adjustment by adopting special gauges such as a level gauge and the like can be replaced, so that the measurement efficiency is higher.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Diagnostic bed device for ultrasonic inspection

ActiveCN112386285AMeet adjustment requirementsEasy to adjustPatient positioningOperating tablesEngineeringAcoustics

The invention relates to a diagnostic bed device for ultrasonic inspection. The diagnostic bed device comprises a bottom plate, a middle plate, a bed board, a bedside plate, a leg device, a leg powerdevice, a bed body lifting device and a leg lifting device, wherein the lower part of the bed board is provided with four guide posts, the middle plate is provided with four fixing holes, the fixing holes are fixedly connected with lower parts of the guide posts, the middle of each guide post has a guiding hole, the bottom plate is provided with four bottom plate upright posts, the bottom plate upright posts are in slip connection with the guiding holes, the guiding holes slide on the bottom plate upright posts, the front side of the bed board is provided with bed board pin holes, the rear side of the bedside plate is provided with bedside plate pin holes, and pins penetrate through the bed board pin holes and the bedside plate pin holes so as to hinge the bed board and the bedside plate together.

Owner:黑龙江省医院

Planetary reducer and planetary reducer bevel gear installation and adjustment method

ActiveCN110185744BEffective regulationEasy to adjustToothed gearingsGearing detailsReduction driveDrive shaft

Owner:NINGXIA TIANDI BENNIU IND GRP +1

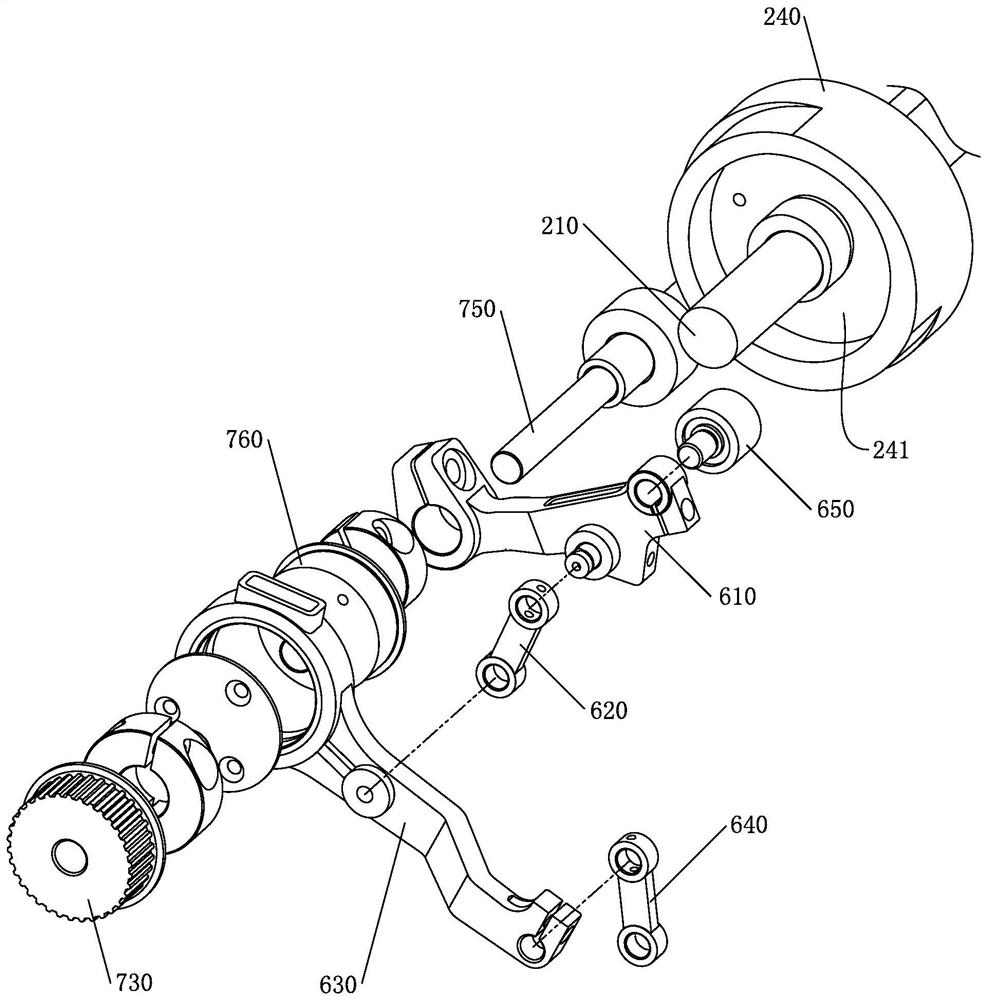

Multi-needle presser foot embroidery machine head and embroidery machine

PendingCN112663235AImprove scalabilityEfficient compressionFeedersPhysical medicine and rehabilitationEngineering

The invention discloses a multi-needle presser foot embroidery machine head and an embroidery machine, and belongs to the technical field of embroidery machines. The embroidery machine head comprises a machine shell, a needle rod driving shaft, a presser foot driving wheel, a presser foot mechanism, a presser foot transmission mechanism and a presser foot adjusting mechanism, wherein the presser foot mechanism comprises a presser foot strip, a presser feet and a presser foot lifting rod; the presser foot transmission mechanism is arranged between the presser foot driving wheel and the presser foot lifting rod and used for driving the presser foot mechanism to move up and down; and the presser foot adjusting mechanism is arranged on the machine shell and adjusts the vertical position of the presser foot mechanism through the presser foot transmission mechanism. The needle rod driving shaft drives the presser foot mechanism to move up and down through the presser foot driving wheel and the presser foot transmission mechanism, so that the presser foot mechanism can effectively press an upper thread when the embroidery machine works, and thus the embroidery quality is improved. The presser foot adjusting mechanism can adjust the vertical position of the presser foot mechanism through the presser foot transmission mechanism, the presser foot mechanism is convenient to lift, and thus the presser foot mechanism is prevented from interfering with embroidery cloth replacement and other operations.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

Slow light waveguide structure based on photonic crystal air bridge structure

InactiveCN101963736BReduce adjustment requirementsMeet adjustment requirementsOptical light guidesNon-linear opticsFiberSemiconductor materials

The invention discloses a slow light waveguide structure based on a photonic crystal air bridge structure, which adopts a line defect photonic crystal structure, and comprises a longitudinal structure and a horizontal structure, wherein, the longitudinal structure is an air bridge multi-layer structure which comprises an air layer, a semiconductor material layer, an air layer and a substrate material layer from the top layer to the bottom layer; the horizontal structure adopts a triangular lattice structure, the period is P, and the radius is R; and the waveguide is formed through removing a row of holes. Through changing the size of the line defect nearby hole, the slow light waveguide structure of the invention realizes a slow light working area reaching up to 50 nanometers; the centralwavelength can be adjusted through the width of the waveguide, which can be realized only in need of the small holes with two types of apertures within the requirement range of hundreds of nanometersof operating wavelengths, thus lowering the requirement of device parameter adjustment in a certain technological condition. By utilizing the slow light photonic crystal waveguide of the slow opticalwaveguide structure based on the photonic crystal air bridge structure, the bandwidth can cover the C wave band of the fiber-optical communication, and can achieve 50nm.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

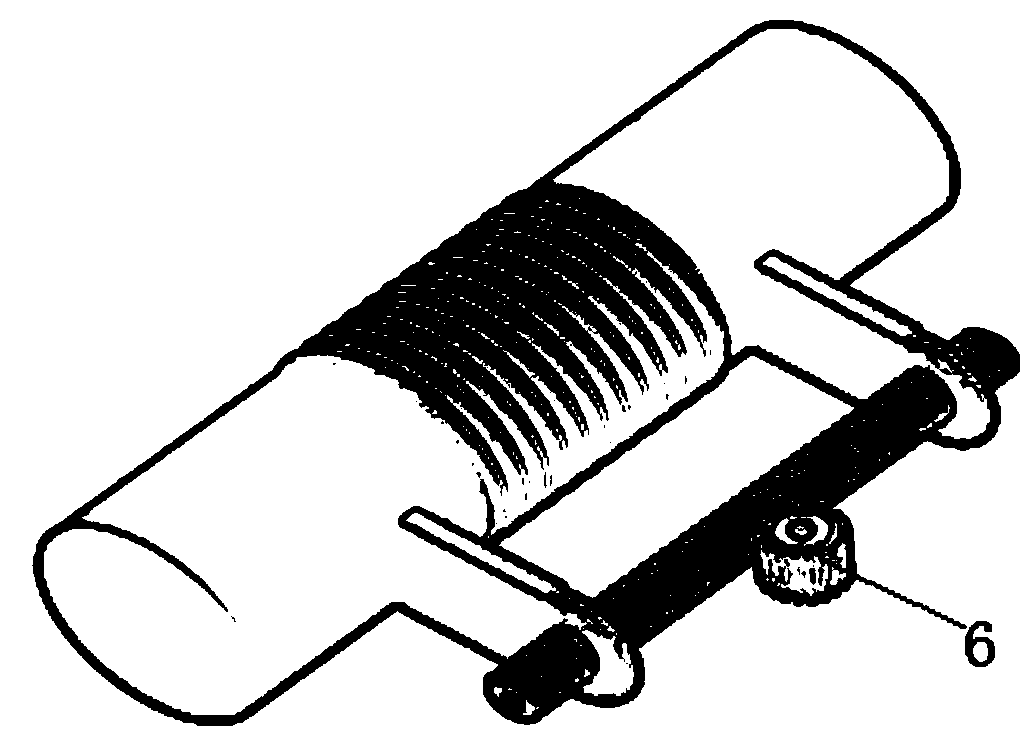

Centerless through type superfinishing machine guide roller adjusting device and method

PendingCN112571271AHigh adjustment accuracyGood consistencyGrinding feed controlSuperfinishing machinesPhysicsEngineering

A centerless through type superfinishing machine guide roller adjusting device comprises a transmission assembly, a position sensing and displaying assembly and a calibration assembly; a displacementsensor in the position sensing and displaying assembly detects the position of a sensor pressing plate and outputs the position to a display module for displaying; the calibration assembly is composedof a calibration rod kit, a calibration flat plate and an oilstone clamp; the calibration flat plate is clamped in the oilstone clamp and used for representing the position of an oilstone; the calibration rod kit is composed of a calibration rod, a supporting disc and a standard diameter disc; and position data of a front guide roller and a back guide roller are calibrated through the standard diameter disc and the calibration flat plate. The guide roller position data are calculated and used as a design value on the basis of the calibrated reference position according to the adjustment requirement of the workpiece relative to the front and back positions of the oilstone and the adjustment requirement of the center distance between the front and back guide rollers; and the front and backpositions of the front and back guide rollers are adjusted, when the data displayed by the display module are consistent with the design values, the adjustment is considered to be in place. The devicehas the advantages of high adjusting precision, good consistency and rapidness and convenience in adjustment.

Owner:HENAN UNIV OF SCI & TECH

Voltage transformer expander with top wiring

PendingCN114496505ARealize the purpose of top wiringMeet adjustment requirementsTransformers/inductances coolingTransformersTransformerEngineering

The invention relates to the field of voltage transformers, in particular to a top wiring type voltage transformer expander which comprises a shell and an expander corrugated pipe, the expander corrugated pipe is arranged in the shell, an oil injection valve is arranged at the upper end of the expander corrugated pipe, an oil level indication mark is arranged on one side of the expander corrugated pipe, and an oil level indicator is arranged on the other side of the expander corrugated pipe. An inspection window corresponding to the oil level indication mark is arranged on one side of the shell, a plurality of screw rods are fixedly arranged in the middle of a top plate of the shell, the upper terminal plate is L-shaped, a plurality of through holes are formed in the horizontal side of the upper terminal plate, each screw rod penetrates through the corresponding through hole in the horizontal side of the upper terminal plate, and the upper terminal plate is fixedly connected with the upper terminal plate. The horizontal side of the upper terminal plate is sleeved on the corresponding screw rod through a compression nut to be compressed and fixed, and the primary wiring is fixedly connected with the vertical side of the upper terminal plate. The upper terminal plate capable of being rotationally adjusted is arranged in the middle of the top plate of the shell, so that the purpose of wiring at the top end of the expander is achieved, and the requirement for primary terminal turning is met.

Owner:DALIAN NORTH INSTR TRANSFORMER GROUP

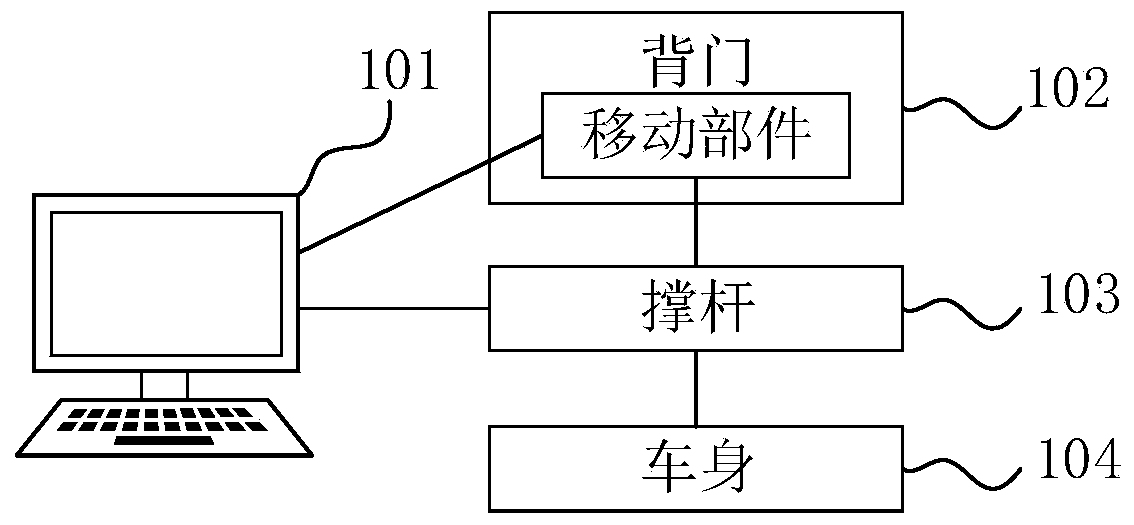

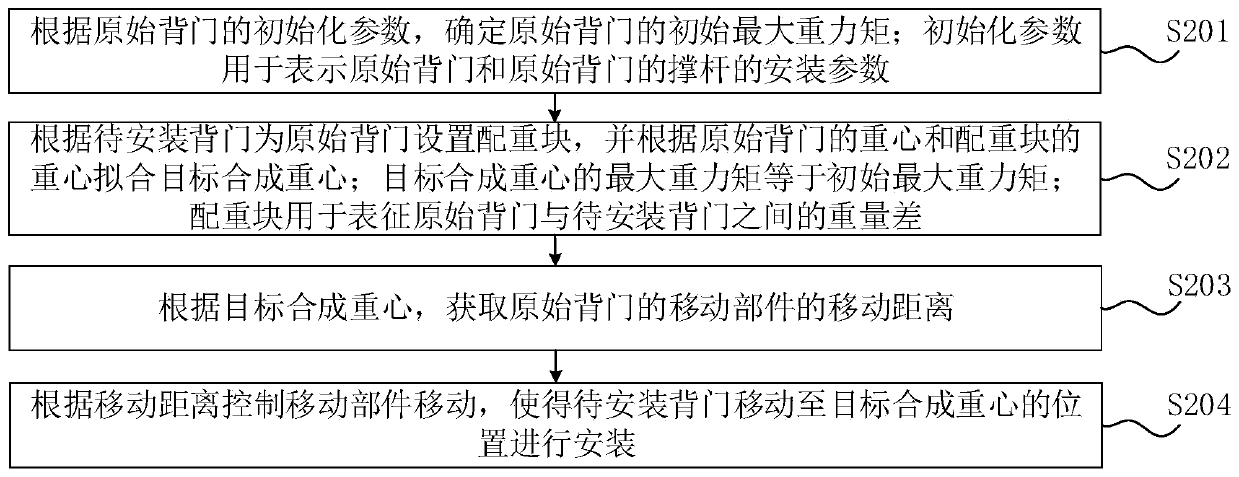

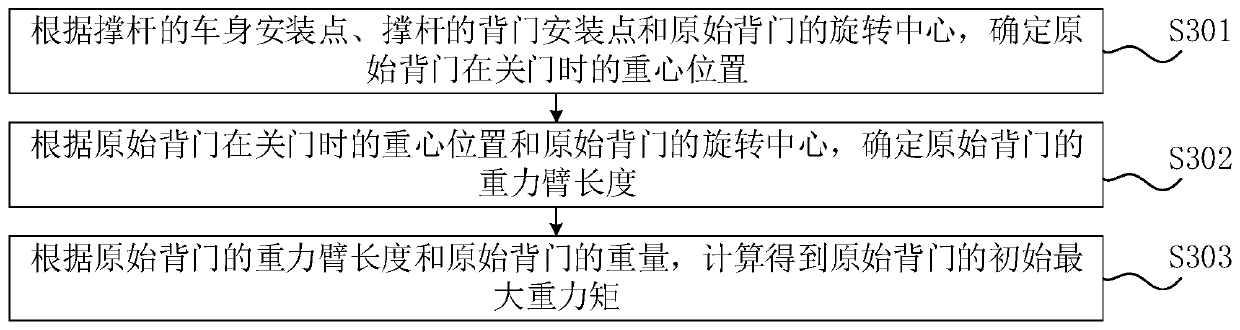

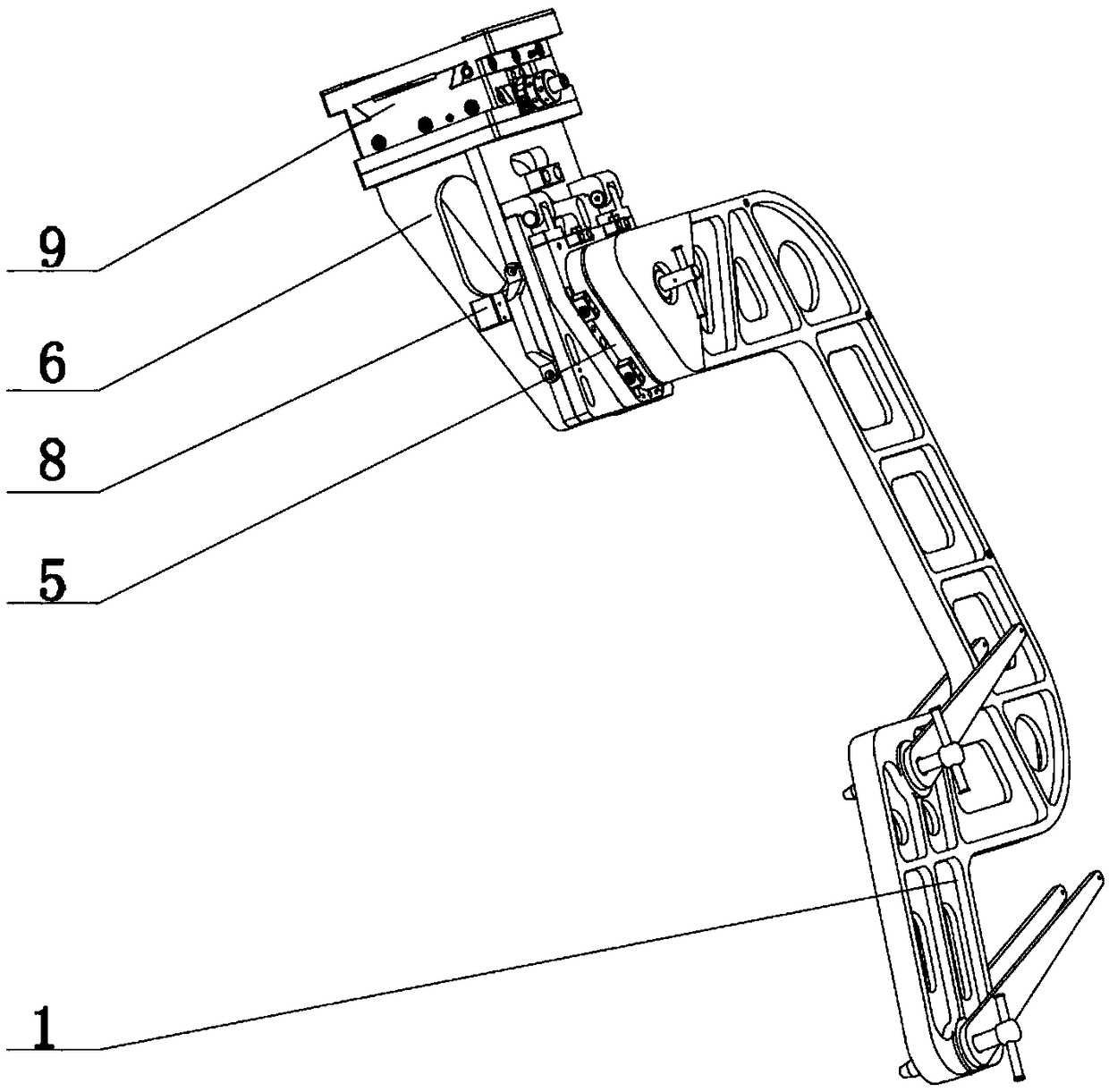

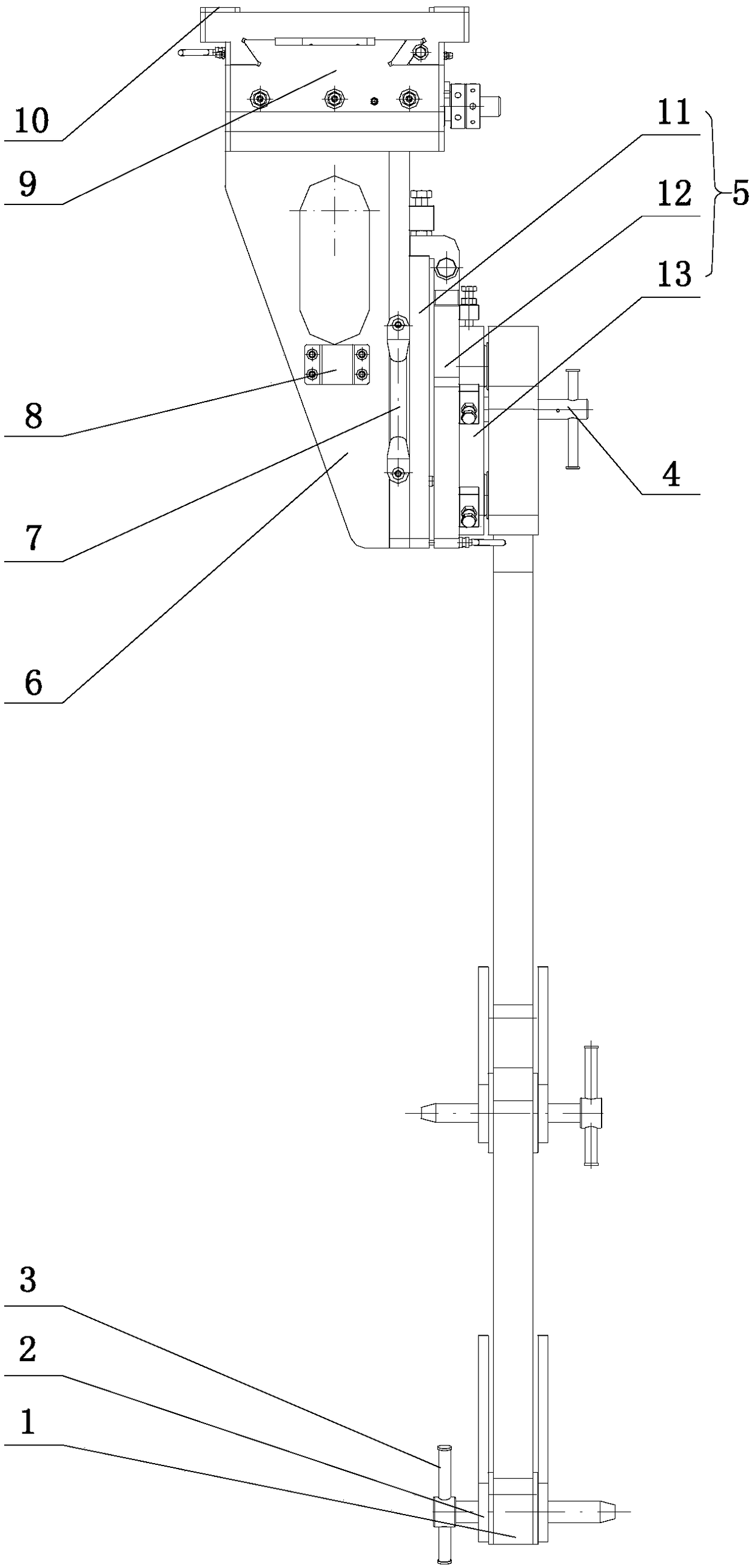

Back door installation method and device, computer equipment and storage medium

ActiveCN111444576AQuick verificationConsistent positionGeometric CADSustainable transportationEngineeringGravity center

The invention relates to a back door installation method and device, computer equipment and a storage medium. The method comprises the following steps: according to the initialization parameters of anoriginal back door, the computer equipment determines the initial maximum gravitational moment of the original back door; by taking that the gravitational moment of the target synthesis gravity center is equal to the initial maximum gravitational moment as the condition, a balancing weight is arranged for the original back door according to the back door to be installed; a target synthetic gravity center is fitted according to the gravity center of the original back door and the gravity center of the balancing weight, and the moving distance of the moving part of the original back door is obtained according to the target synthetic gravity center, thereby controlling the moving part to move according to the moving distance, and enabling the back door to be installed to move to the positionof the target synthetic gravity center for installation. In the method, the computer equipment can adjust the position of the moving part of the original back door and the weight of the balancing weight according to different positions of the target back door so as to meet the design change of different vehicle model design stages, extra resources do not need to be input, the development cost isreduced, and the development efficiency is improved.

Owner:WINBO DONGJIAN AUTOMOTIVE TECHNOLOGY CO LTD

A positioning tool for the process joint of the leading edge of the aircraft wing box

ActiveCN107054686BMeet adjustment requirementsHas a guiding roleAircraft assemblyLeading edgeTroffer

Owner:ZHEJIANG UNIV

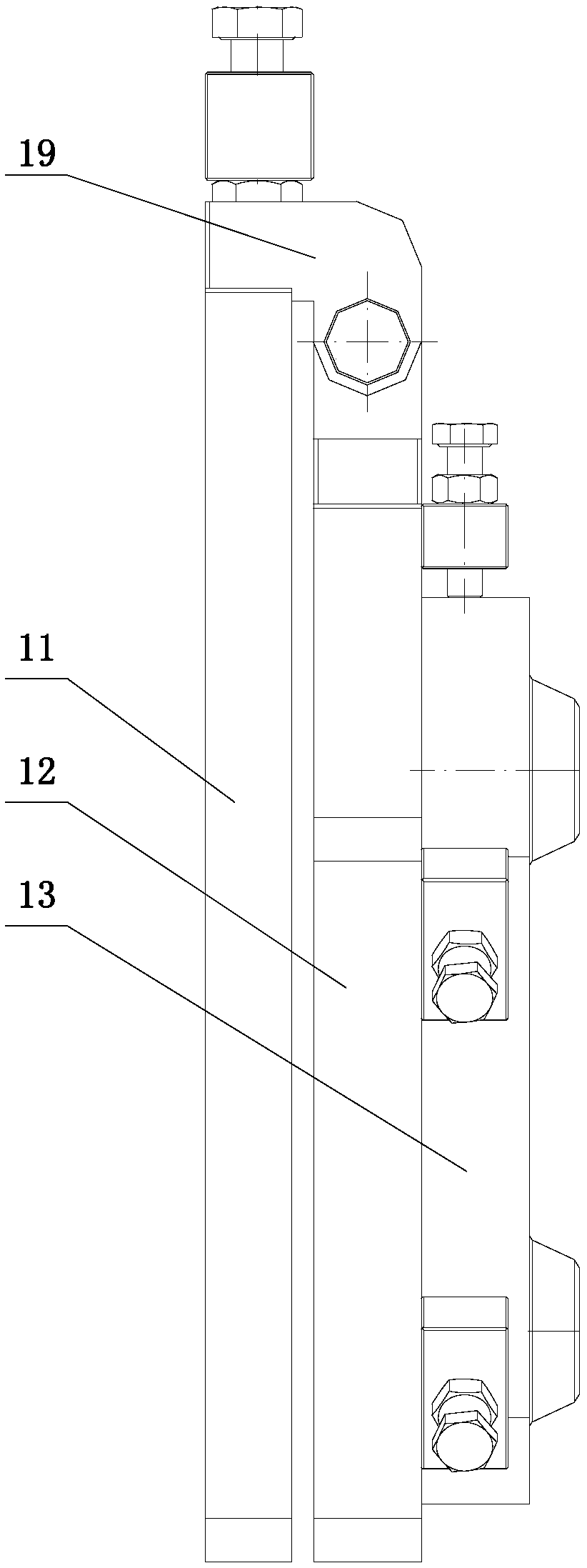

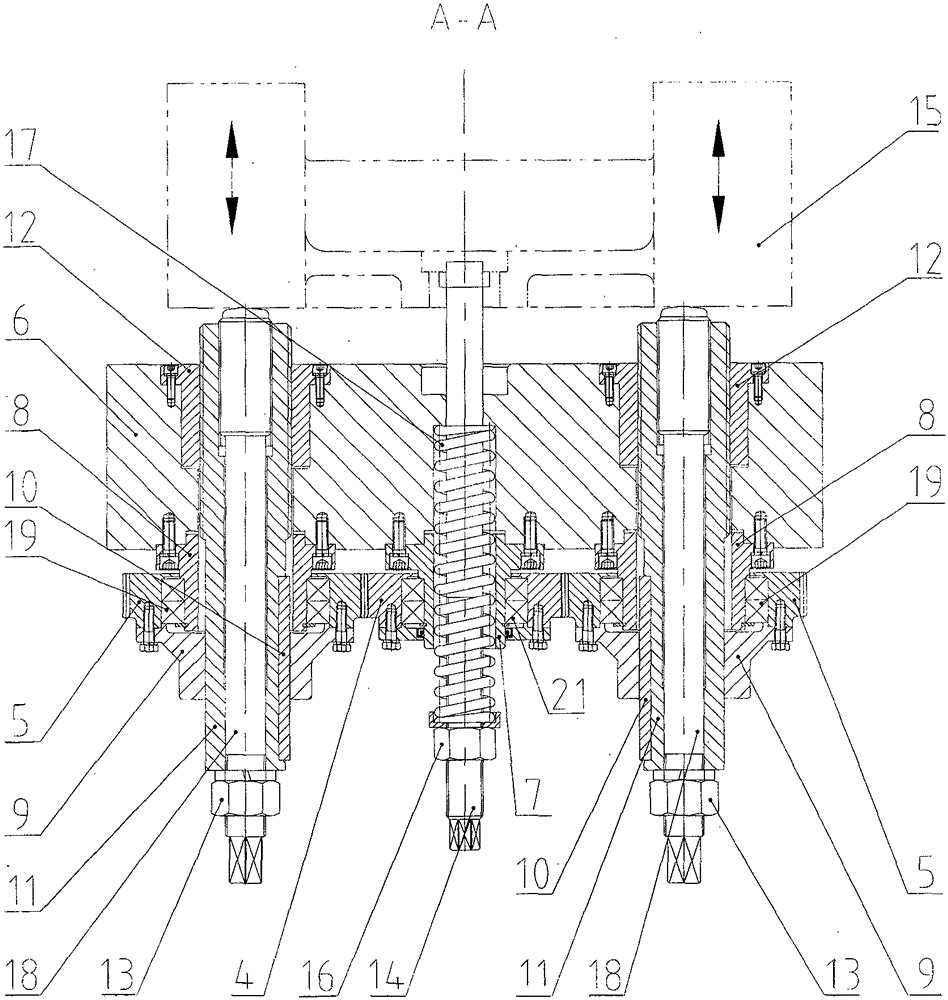

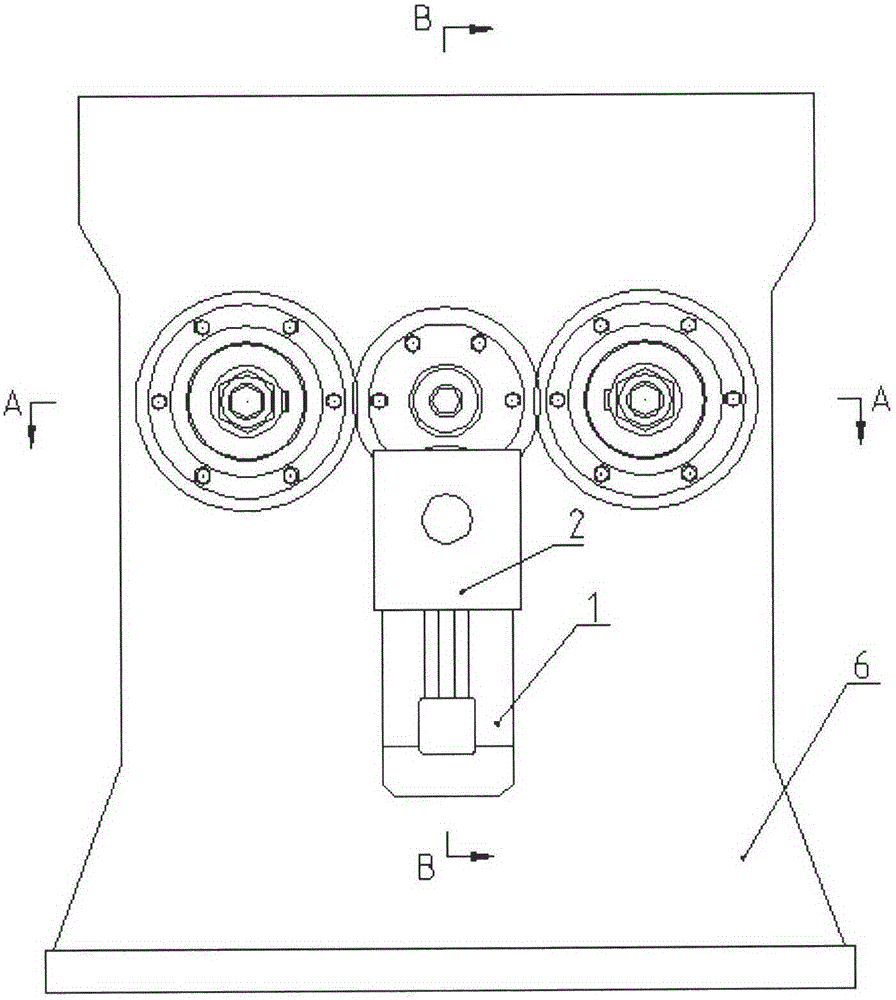

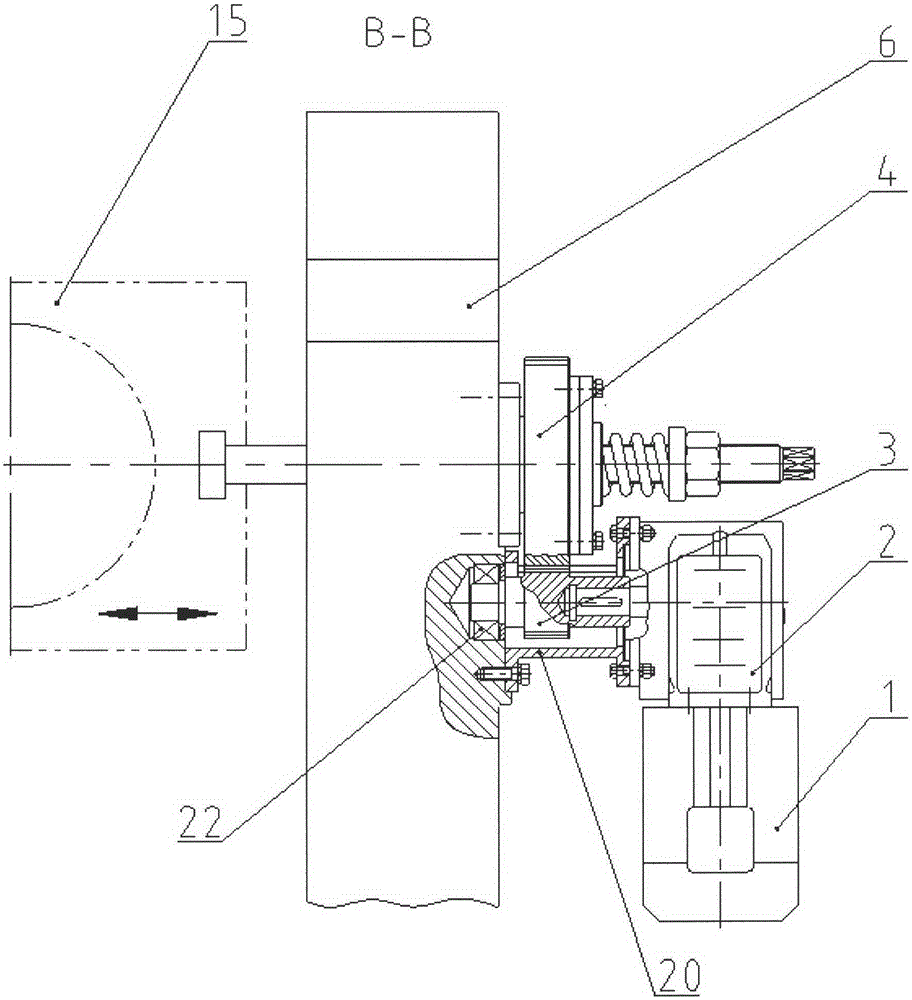

Double-screw-rod roller side pressure adjusting device

ActiveCN106270318AFulfilling adjustment requirementsMeet adjustment requirementsMetal rolling stand detailsBearing componentsGear driveReducer

The invention provides a double-screw-rod roller side pressure adjusting device, and the adjusting device is of a bilateral symmetry structure. A motor is in a direct connection with a reducer, and the reducer is installed on a supporting frame; a gear assembly comprises a small gear, a middle gear and an outer gear; the first end of the small gear is fixed to an output shaft of the reducer, and an assisting bearing is fixed to the second end of the small gear; a supporting seat assembly comprises the supporting frame, an inner supporting seat and an outer supporting seat; the middle gear is rotated by the inner supporting seat through a bearing, and the outer gear is rotated by the outer supporting seat through a bearing; the outer gear drives an outer screw rod through a bearing cover and a key, and the outer screw rod slides axially in an inner hole of the bearing cover; a nut assembly comprises an outer nut and a locknut; the outer screw rod and the outer nut form a thread pair; an inner thread of the outer screw rod and an inner screw rod form a thread pair; and the locknut and the inner screw rod form a thread pair. According to the double-screw-rod roller side pressure adjusting device, overall roller integrated adjusting is achieved by utilizing the outer screw rod in a linkage electric adjusting mode, and roller micro-adjusting is achieved by utilizing the inner screw rod in an individual adjustment mode.

Owner:无锡苏创机械设备制造有限公司

Permanent magnet generator with adjustable voltage

InactiveCN101442240BMeet the requirements of power factor adjustmentMeet adjustment requirementsMechanical energy handlingElectric generator controlManufacturing cost reductionStator coil

The invention relates to a generator, in particular to an adjustable voltage permanent-magnet generator, which comprises a main shaft, a rotor fixedly arranged on the main shaft, and stators arranged around the rotor. The rotor is fixedly arranged on the main shaft, a permanent magnet is fixedly arranged on the rotor, the stators are arranged on the main shaft through a bearing, the stators at least comprise a fixed stator and an adjustable stator on which a fixed stator coil and an adjustable stator coil are arranged respectively, phase lines of the fixed stator coil and the adjustable stator coil are correspondingly connected in series respectively, the fixed stator is fixedly connected with a generator bracket, the adjustable stator is connected to the generator bracket through a spring, and the adjustable stator is also provided with a deflection adjusting mechanism. The generator saves a rectification-inversion device in a parallel network of the permanent-magnet generator, has adjustable output voltage, lowers manufacturing cost greatly, and improves reliability of products.

Owner:王光顺

Automatic adjusting mechanism and adjusting method for internal and external air of combustor

PendingCN110657449AFlexible adjustmentRealize remote adjustmentAir supply regulationAuto regulationCombustor

The invention discloses an automatic adjusting mechanism and an adjusting method for internal and external air of a combustor. The adjusting mechanism enables a traditional combustor manual adjustingmode to be mechanically modified into a mixed adjusting mode of two modes of common motor driving and servo motor driving, and the adjustment amount is output through a 4-20 mA signal to realize the remote adjustment through a DCS. The automatic adjusting mechanism and the adjusting method for the internal and external air of the combustor have the advantages that an electric adjusting mechanism is used for replacing an original manual adjusting mechanism, so that the labor amount of the manual adjustment process is reduced, adjustment and fire observation are synchronously carried out, the original situations that adjustment is firstly carried out, then fire observation is carried out, next, adjustment is carried out again and then fire observation is carried out again are thoroughly avoided, and the desired flame shape can be quickly achieved in the dynamic adjustment process; and by means of the DCS remote adjustment digitalization mode, the adjustment can be more flexible and quicker, moreover, an intelligent control system can be connected, so that the industrial intelligent real-time online fine adjustment is realized, and the adjustment effect is enabled to reach the optimalstate.

Owner:沈忠东

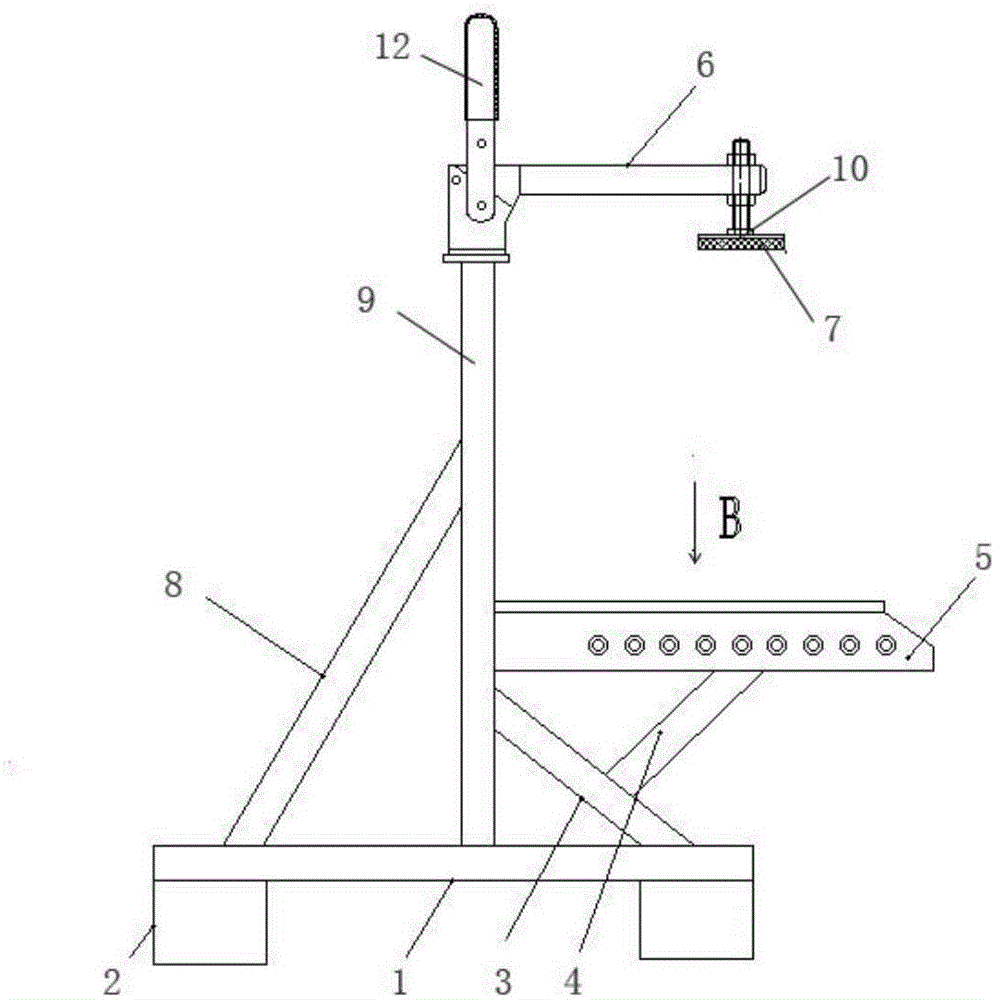

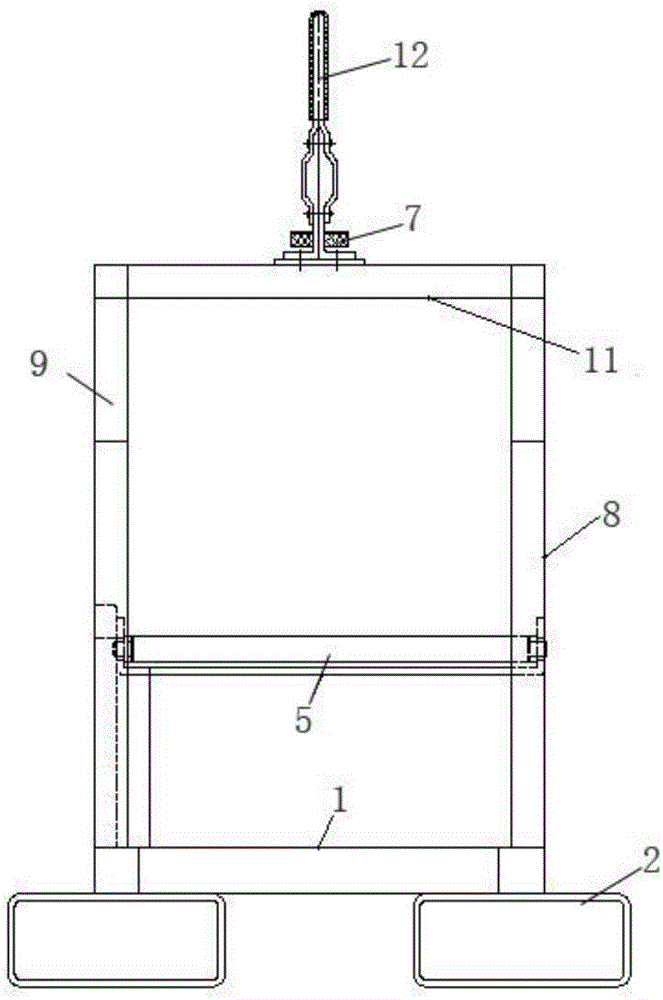

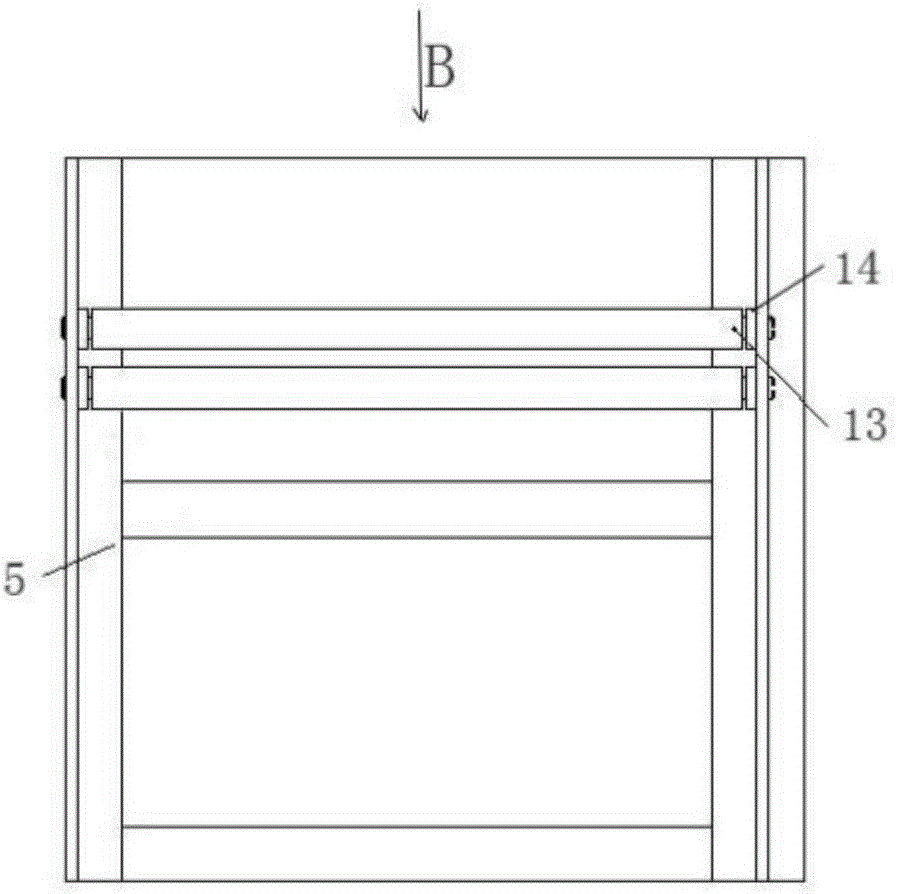

Passenger car compressor installation tool

PendingCN106826719AImprove installation efficiencyRealize mobile liftingWork benchesStructural engineeringCar passenger

The invention discloses a passenger car compressor installation tool. The passenger car compressor installation tool comprises a bed frame assembly, a layer board assembly and a rapid clamp. The rapid clamp comprises a handle, a pressing rod and a compressing head which is arranged on the end portion of the pressing rod. The bed frame assembly comprises a rectangular frame and two fork-joint boxes, the rectangular frame is horizontally arranged, the two fork-joint boxes are arranged on the bottom faces of two opposite sides of the rectangular frame, and the fork-joint boxes are in a rectangular box shape with the two ends open. The layer board assembly comprises a vertical frame and a layer board, the vertical frame is composed of a transverse rod and two vertical rods, the two vertical rods are vertically arranged on the middle portions of the top faces of the two opposite sides of the rectangular frame, and the transverse rod is horizontally connected with the top portions of the two vertical rods. The layer board is horizontally connected to the two vertical rods, two parallel supporting plates are symmetrically arranged on the top face of the layer board, and rollers are distributed between the two supporting plates in the transverse direction. The rapid clamp is arranged on the middle portion of the transverse rod of the vertical frame, the pressing rod is horizontally arranged, and the compressing head is located above the layer board. By means of the passenger car compressor installation tool, the installation efficiency of a compressor is improved.

Owner:ANHUI ANKAI AUTOMOBILE

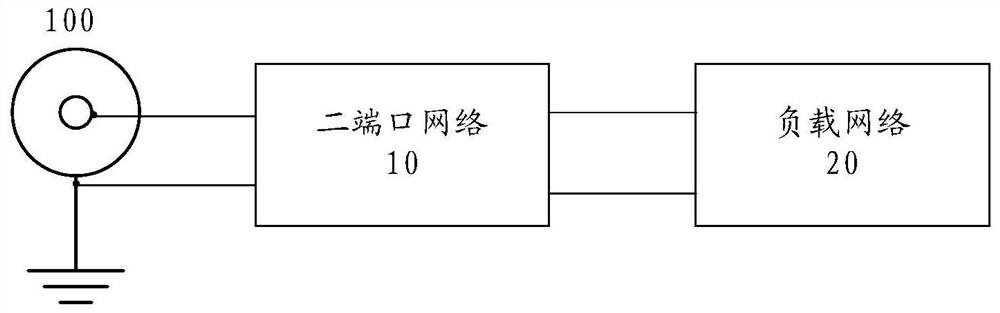

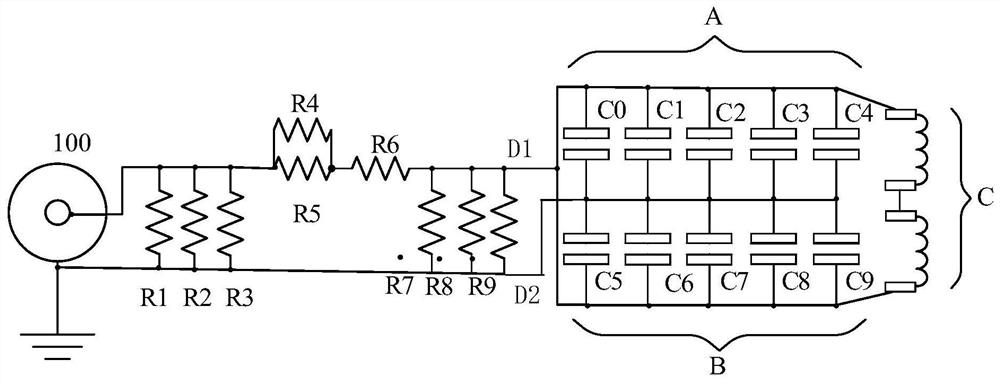

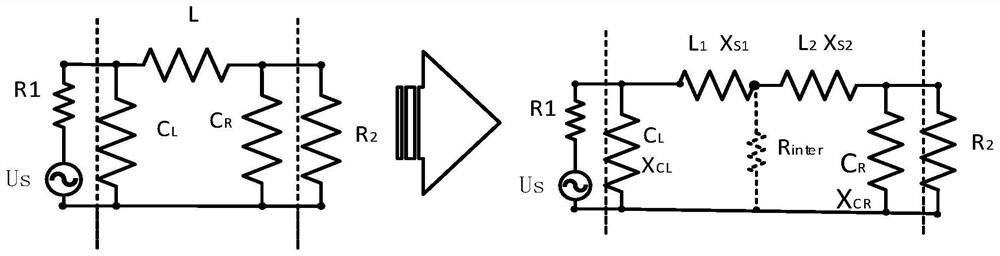

Phase simulation equipment

ActiveCN112904093AHealth hazardMeet different impedanceResistance/reactance/impedenceAntenna radiation diagramsNetwork outputInput impedance

The invention discloses phase simulation equipment. The phase simulation equipment comprises a two-port network and a load network. The two-port network comprises a network input end and a network output end, the network input end is used for being connected with a signal output end of the network analyzer, and the input impedance of the two-port network is equal to the output impedance of the two-port network and is the same as the output impedance of the signal output end; the load network is connected with the network output end, and the impedance of the load network is the same as that of the signal output end. Through configuration of the two-port network, the two-port network can meet the requirements of different impedances and attenuations, so that the phase simulation device can be used for simulating a physical CAU when the CAU is measured and adjusted, and the phase simulation device does not emit high-power radiation, so that the measurement and adjustment requirements are met, and no harm is caused to the health of experimenters.

Owner:BEIJING RAILWAY SIGNAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com