A position and angle adjustment device for T-type welding

An angle adjustment device and welding plate technology, which is applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of repeatable positioning, batch welding manufacturing, difficulty in ensuring the accuracy of welded joints, and difficulty in ensuring gap accuracy, etc. problems, to achieve the effect of improving the quality and efficiency of T-shaped welding, novel structure, and ensuring positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

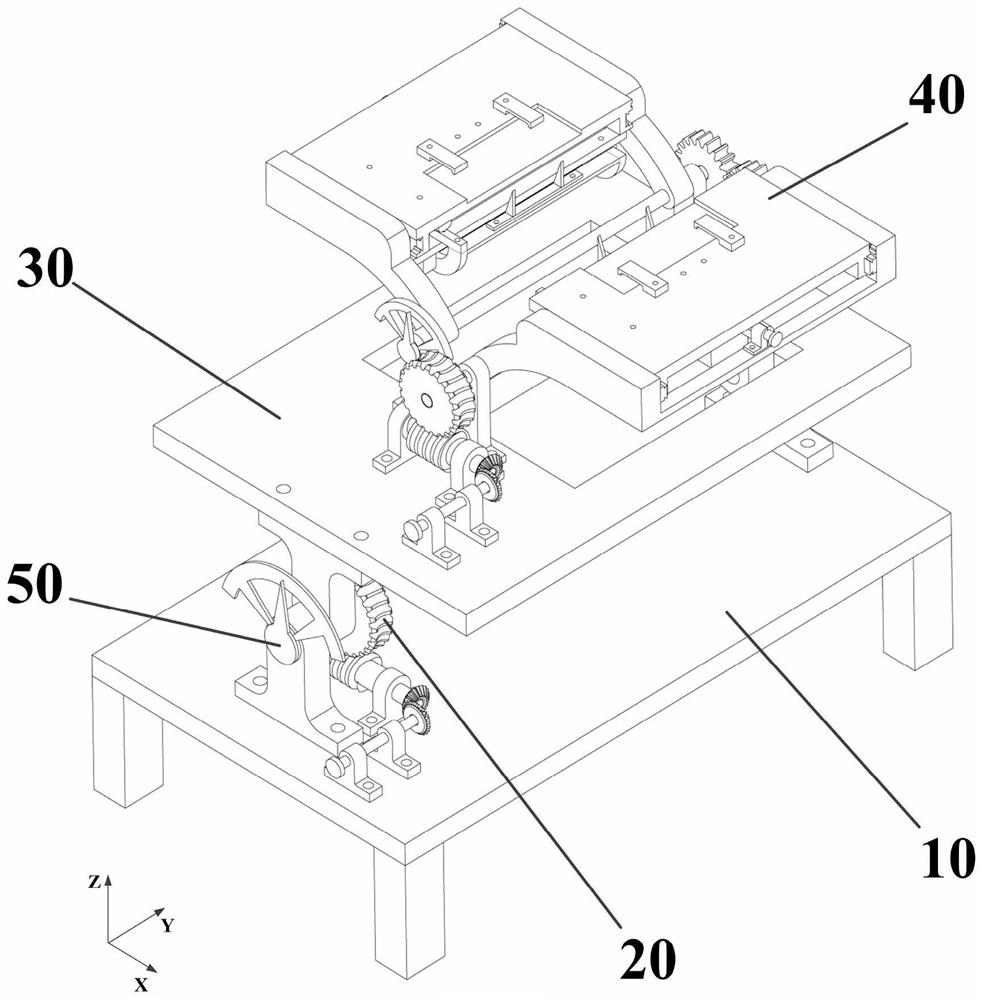

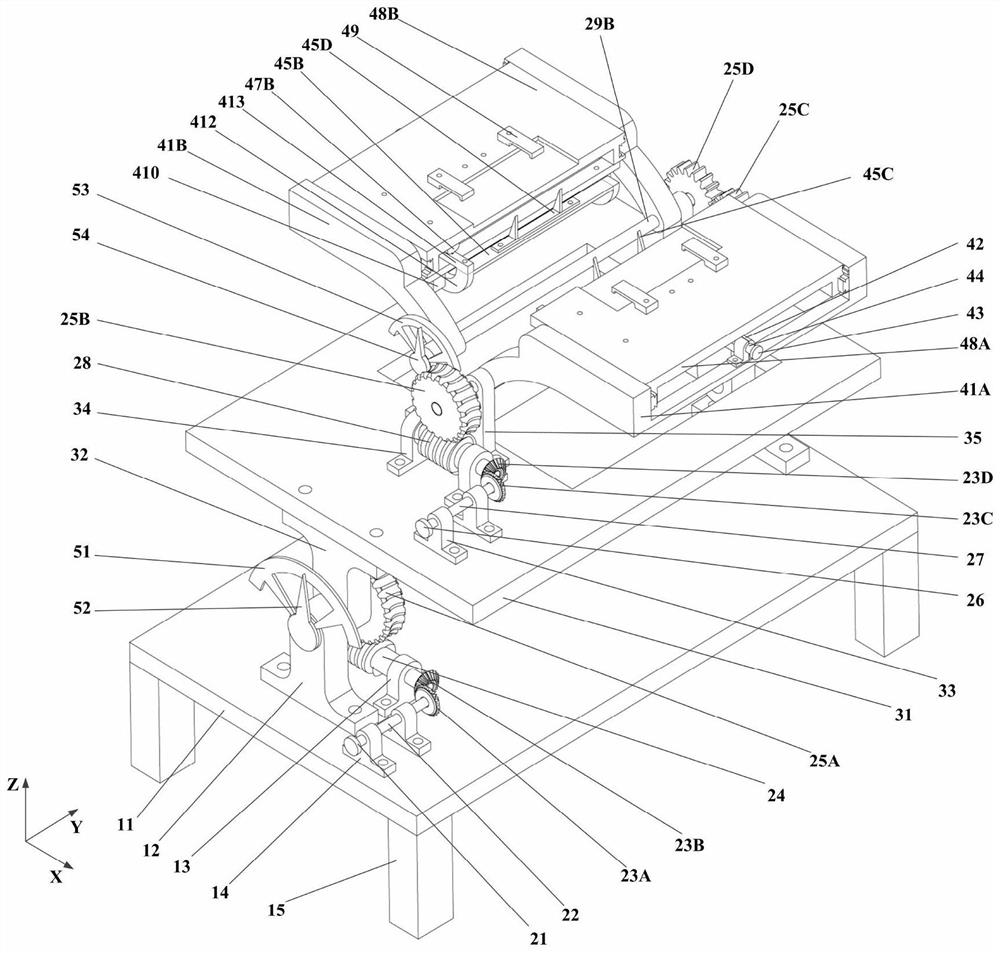

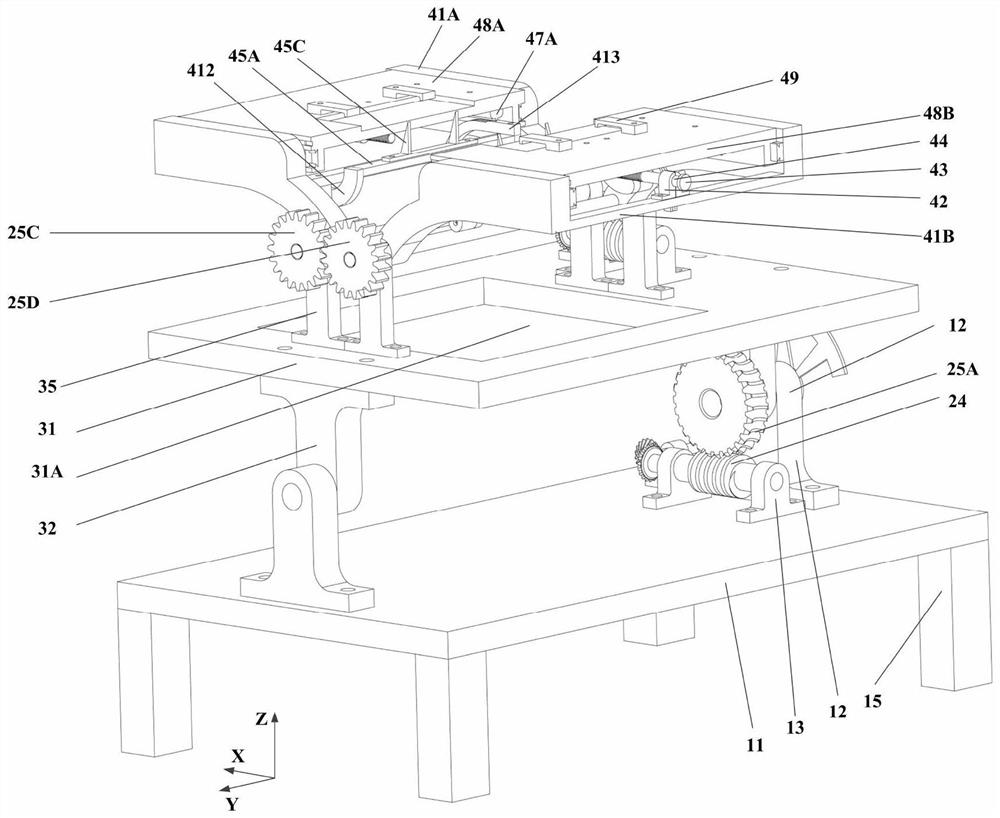

[0032] like figure 1 , figure 2 As shown, the device of the present invention includes a base assembly 10, a transmission mechanism 20, a fixing assembly 30, a positioning mechanism 40 and an indicating assembly 50,

[0033] A. The base assembly 10 includes a base plate 11, a long base plate support 12, a base plate middle support 13, a base plate short support 14 and a support rod 15, and the base plate long support 12, base plate middle support 13 and base plate short support 14 are located on the base plate 11 On the surface, the support rods 15 are arranged at the four corners of the bottom surface of the bottom plate 11, for supporting the bottom plate 11 and increasing the distance between the bottom plate 11 and the ground;

[0034] B, the transmission mechanism 20 includes the first drive rod 22, the first worm 24, the first worm wheel 25A, the second drive rod 27, the second worm 28, the second worm wheel 25B, the front gear shaft 29A, the rear gear shaft 29B, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com