A gap adjustment device for butt welding of steel plates

A gap adjustment device and butt welding technology, applied in auxiliary devices, welding/welding/cutting items, welding equipment, etc., can solve problems such as difficult to accurately adjust the gap between butt steel plates, and achieve the effect of convenient and fast movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below through the accompanying drawings and examples.

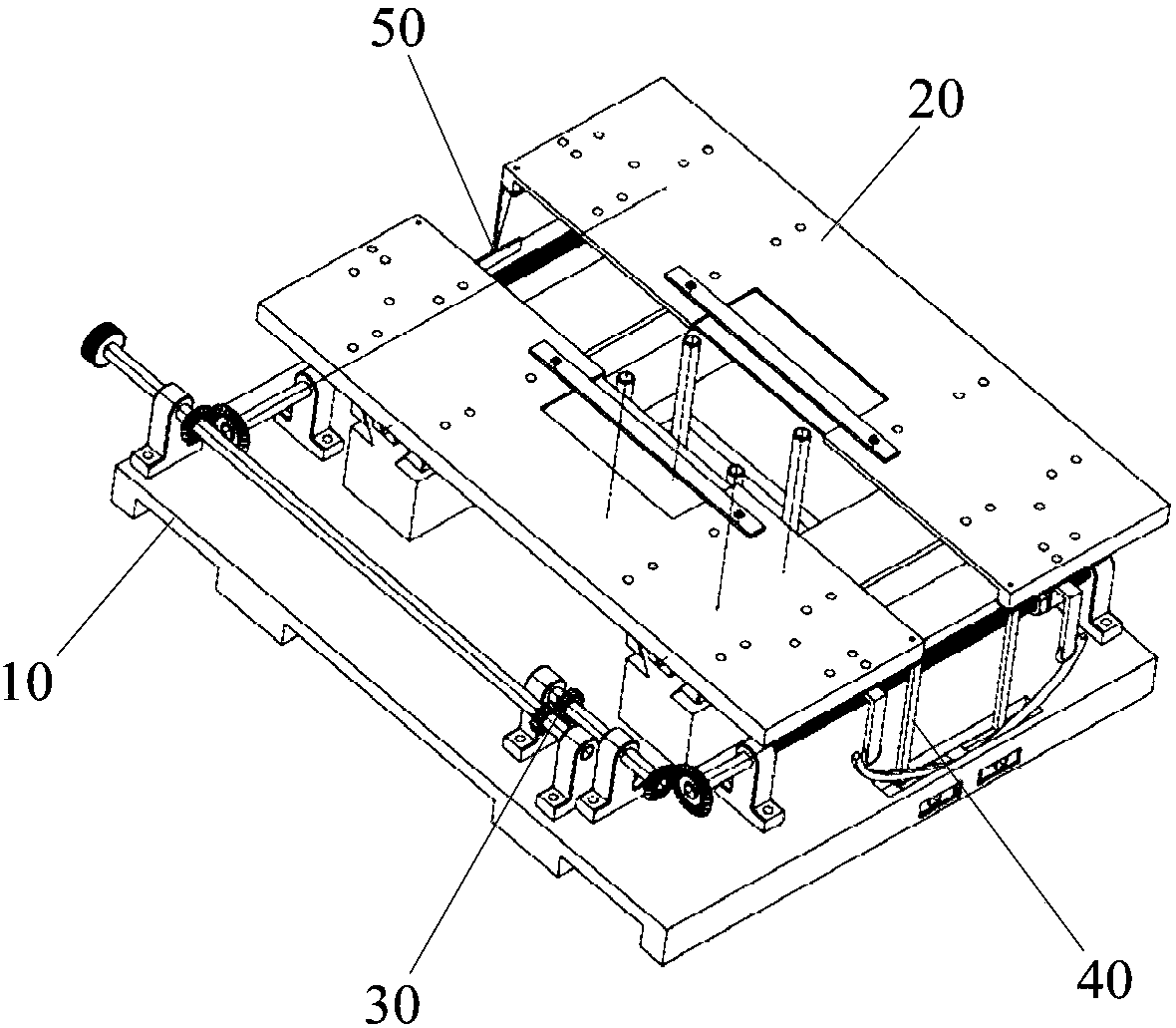

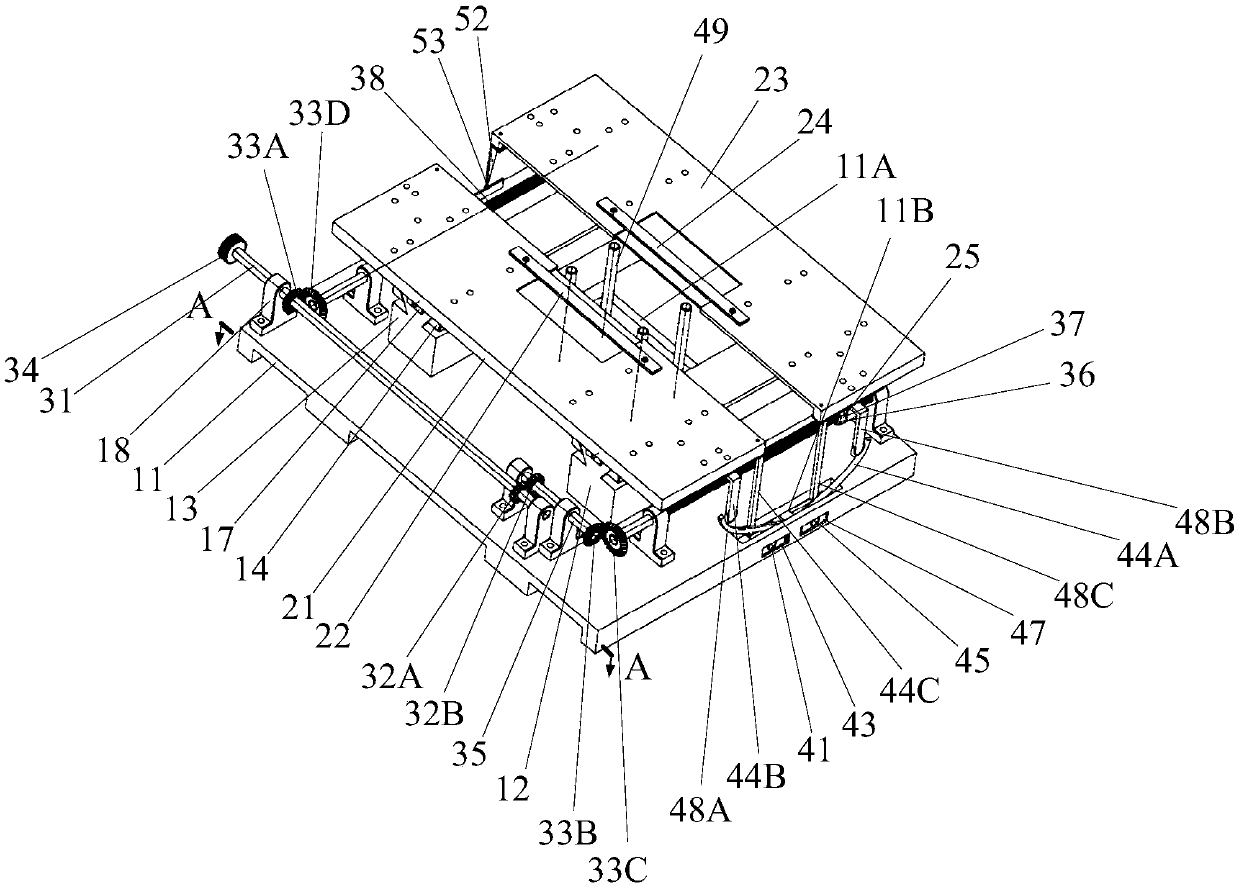

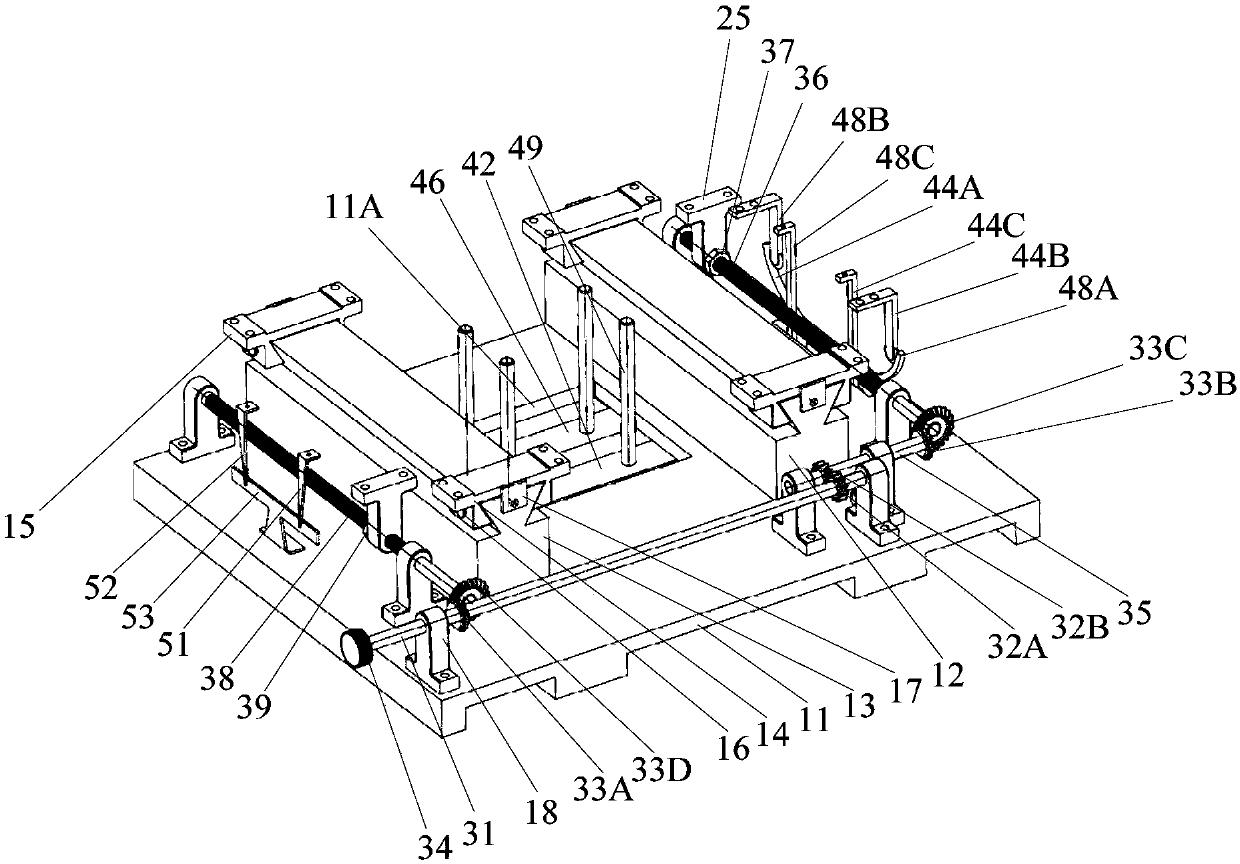

[0059] like figure 1 , figure 2 As shown, the present invention includes a base assembly 10, a fixing assembly 20, a transmission mechanism 30, a positioning mechanism 40 and a gap indicating assembly 50, driven by the transmission mechanism 30, the fixing assembly 20 and the positioning mechanism 40 are linked;

[0060] A. The base assembly 10 includes a base plate 11, a front guide rail 12 and a rear guide rail 13, and the front guide rail 12 and the rear guide rail 13 are fixed on the upper surface of the base plate 11 in parallel;

[0061] B. The fixing assembly 20 includes a left fixing plate 21, a left pressing plate 22, a right fixing plate 23, and a right pressing plate 24. The left fixing plate 21 is located on the left side of the front guide rail 12 and the rear guide rail 13 and can slide linearly along them. The plate 23 is located on the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com