Voltage transformer expander with top wiring

A technology of voltage transformer and expander, which is applied in the direction of inductor, transformer/inductor cooling, transformer/inductor shell, etc., can solve the problems such as inability to adjust flexibly, inconvenient wiring, and inability to realize arbitrary direction rotation of primary terminals, etc. Achieve the effect of meeting the requirements of one-time terminal adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

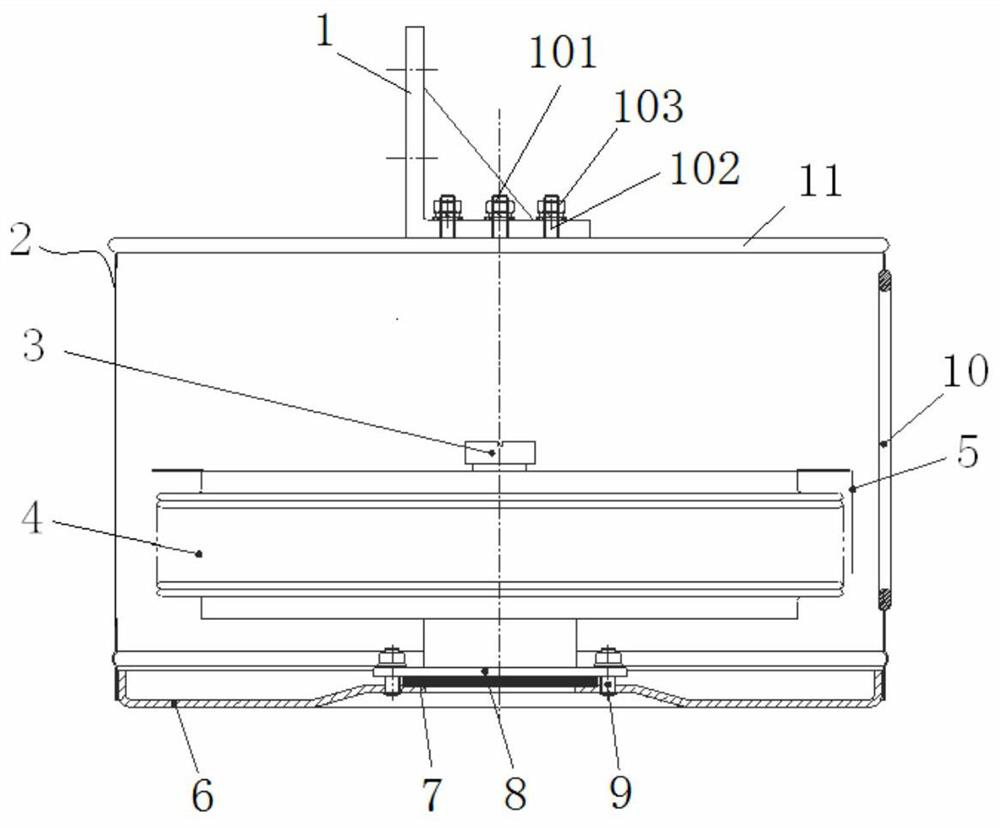

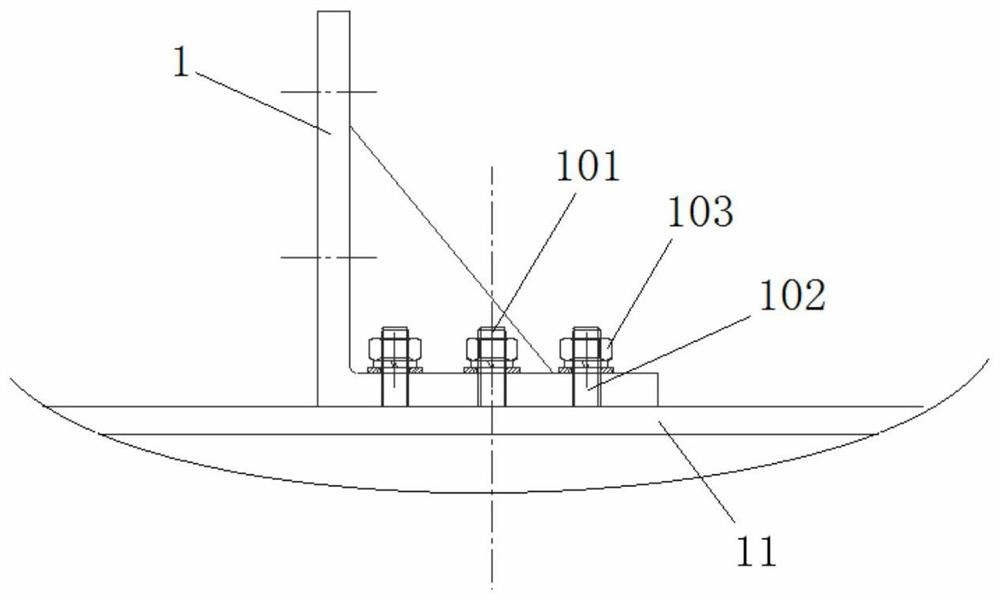

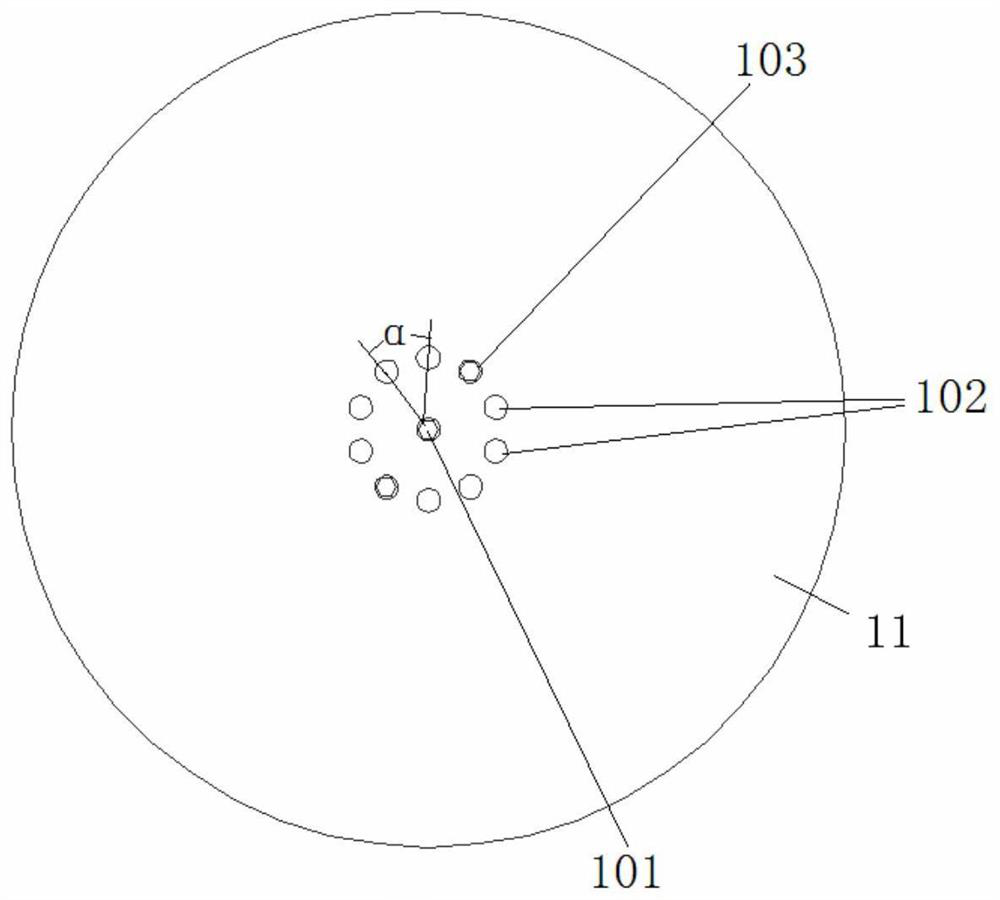

[0025] like Figure 1~3 As shown, in this embodiment, each screw 102 is arranged in the middle of the top plate 11 of the housing 2 in an annular shape, and a central rotating shaft 101 is provided at the annular center of the screw 102, and the horizontal side of the upper terminal board 1 except In addition to the annular through holes corresponding to each screw rod 102, a central hole corresponding to the central rotating shaft 101 is also provided at the circular center of the through hole, and the central rotating shaft 101 and each screw rod 102 pass through. On the horizontal side of the upper terminal board 1 , the compression nut 103 is set on the central rotating shaft 101 and the corresponding screw rod 102 to compress and fix the horizontal side of the upper terminal board 1 .

[0026] The working principle of this embodiment is:

[0027] like Figure 2~3 As shown, the angle between the adjacent through holes of the upper terminal board 1 is α, compared to Imag...

Embodiment 2

[0029] like Figure 4~5 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, four screw rods 102 arranged in a square shape are arranged in the middle of the top plate 11 of the housing 2, and the central rotating shaft 101 is not provided. The horizontal side is provided with four square through holes corresponding to the screw rod 102. During installation, the upper terminal board 1 can be adjusted along four horizontal directions at an integer multiple of 90 degrees to meet customer requirements. After the position of the upper terminal board 1 is determined, the four screw rods 102 are fitted with compression nuts 103 to compress and fix the horizontal side of the upper terminal board 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com