Passenger car compressor installation tool

A technology of compressors and tooling, which is applied to workbenches, manufacturing tools, etc., can solve problems such as limited installation and operation space, large forklift volume, and high labor intensity, and achieve high overall structural strength, meet adjustment requirements, and improve installation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

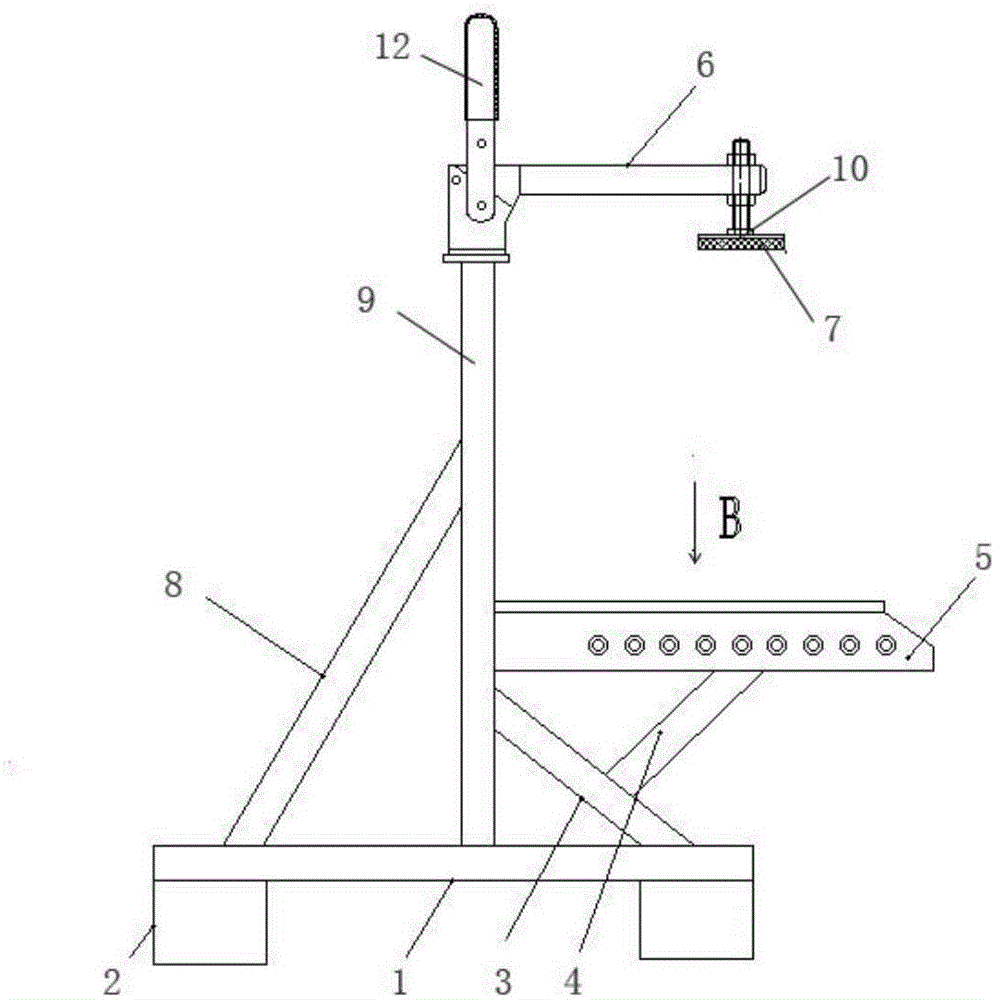

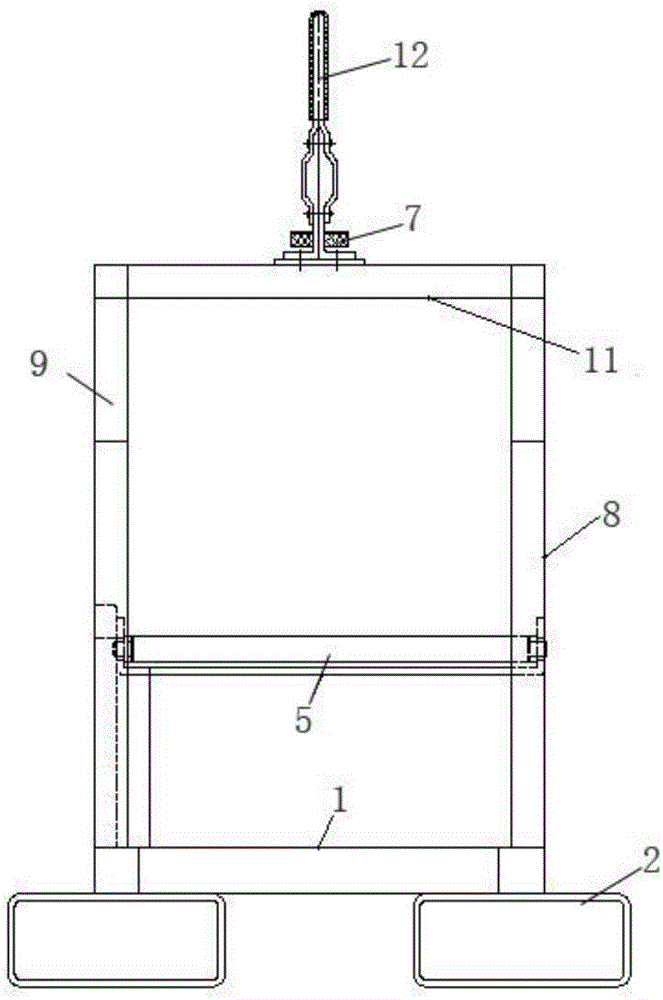

[0022] see figure 1 , figure 2 , a passenger car compressor installation tool, including a base frame assembly, a pallet assembly and a quick clamp, the quick clamp is a vertical quick clamp, the quick clamp includes a handle 12, a pressure rod 6 and a compression head 10, and the compression head 10 is located on Push the handle 12 on the end of the compression rod 6, the compression rod 6 moves outward, and the compression head 10 moves downward under the action of thrust to compress;

[0023] The base frame assembly includes a rectangular frame 1 and two cross-joint boxes 2. The rectangular frame 1 is arranged horizontally. The two cross-joint boxes 2 are respectively arranged on the bottom surfaces of opposite sides of the rectangular frame 1. open rectangular box;

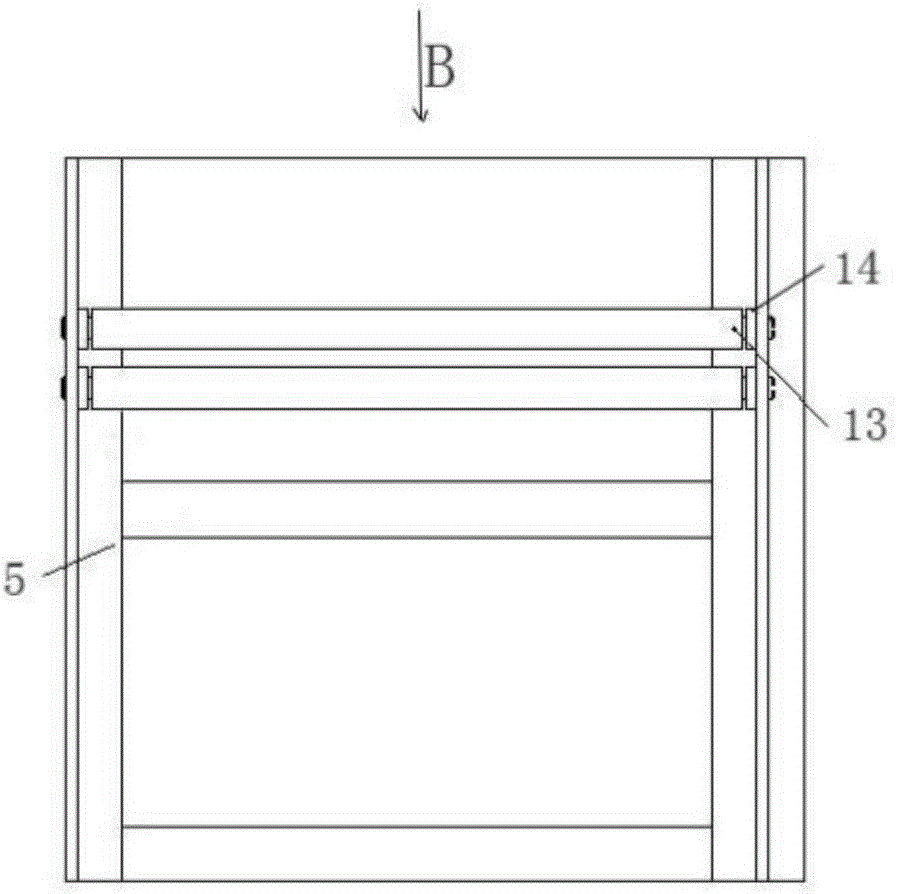

[0024] Described pallet assembly comprises vertical frame, pallet 5, and vertical frame is made up of cross bar 11, two vertical rods 9, and wherein two vertical rods 9 are vertically arranged on the top su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com