Slow light waveguide structure based on photonic crystal air bridge structure

A technology of photonic crystal and waveguide structure, which is applied in the direction of light guide, optics, optical components, etc., can solve the problems that the design of large bandwidth has not been reported yet, the design is more difficult, and it is difficult to meet the large bandwidth of optical communication.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

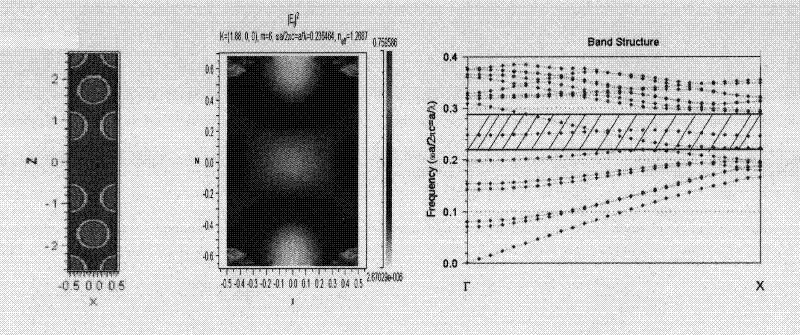

[0029] The existing photonic crystal slow light waveguide, the slow light working area (the area where the group refractive index is greater than 10 is defined here) is relatively small, generally a few nanometers, and the adjustment of the central working wavelength needs to be realized by maintaining the duty ratio and adjusting the lattice period. This requires high design and process requirements. Different operating wavelengths require different process conditions to achieve, or complex design parameter adjustments to match certain process conditions.

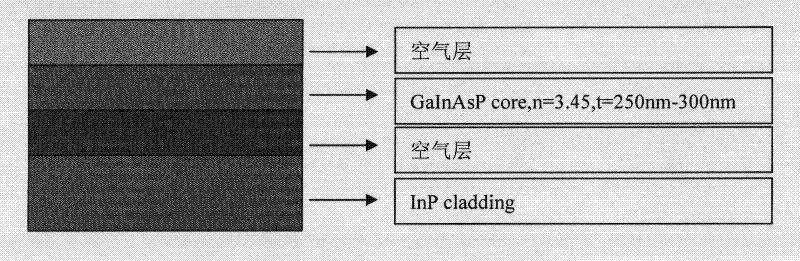

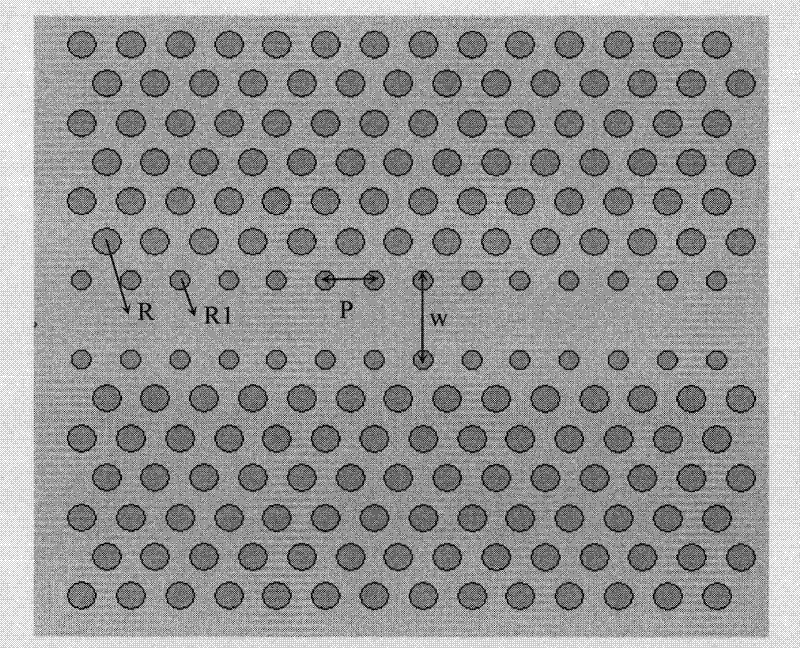

[0030] The present invention proposes a slow light waveguide structure based on a photonic crystal air bridge structure, which is a novel large bandwidth slow light ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com