tmcp type large-thickness high-strength toughness steel plate and production method thereof

A technology with high strength and toughness and a production method, which is applied to the TMCP type large-thickness high-strength and toughness steel plate and its production field, can solve the problems of high rolling process requirements, increased smelting cost, prolonged smelting time, etc., and achieves loose process system and low production cost. , The effect of stable comprehensive mechanical properties of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

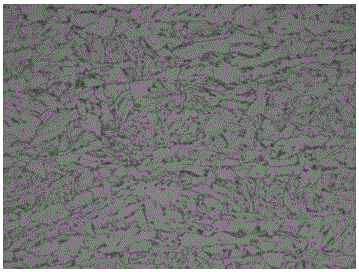

Embodiment 1

[0034] Example 1: The molten steel after smelting is prepared with a superheat of 10°C and a continuous casting casting speed of 0.9m / min to produce a continuous casting slab with a specification of 300mm*2400mm; the cooled continuous casting slab is heated at a heating temperature of 1230°C, heating coefficient 10min / cm, heating time in soaking section (time in furnace) 56min. Stage II rolling is adopted, the rolling temperature of stage I (complete recrystallization zone) is 1000℃~1050℃, the reduction rate of single pass is ≥20%, the cumulative reduction rate is 80%, and the thickness to be heated in the middle (thickness of air-dried steel) 120mm; Stage II (non-recrystallization zone) starting rolling temperature 845°C-855°C, final rolling temperature 800°C-820°C, single pass reduction rate ≥ 10%, and the total rolling pass is controlled at 16 passes. After rolling, ACC cooling is adopted, the cooling rate is 6°C / s, the ratio of upper and lower water is controlled at 1:1.50...

Embodiment 2

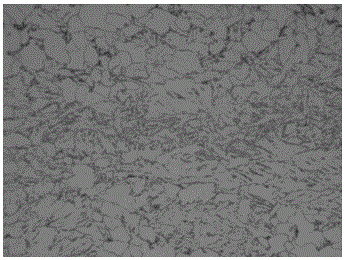

[0035]Example 2: The molten steel after smelting is prepared with a superheat of 18°C and a continuous casting casting speed of 0.9m / min to produce a continuous casting slab with a specification of 300mm*2400mm; the cooled continuous casting slab is heated, and the heating temperature is 1240°C, heating coefficient 10min / cm, heating time in soaking section (time in furnace) 50min. Stage II rolling is adopted, the rolling temperature of stage I is 1050℃~1100℃, the reduction ratio of a single pass is ≥20%, the cumulative reduction ratio is 74%, and the thickness of the intermediate temperature is 150mm; the stage II (non-recrystallization zone) starts The rolling temperature is 845°C to 855°C, the final rolling temperature is 800°C to 810°C, the single pass reduction rate is ≥10%, and the total rolling pass is controlled at 13 passes. After rolling, ACC cooling is adopted, the cooling rate is 5°C / s, the ratio of upper and lower water is controlled at 1:1.10, and the steel plat...

Embodiment 3

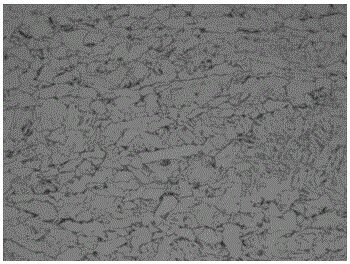

[0036] Embodiment 3: The molten steel after smelting is made a continuous casting slab with a specification of 300mm*2400mm at a superheat of 20°C and a continuous casting casting speed of 0.8m / min; the cooled continuous casting slab is heated, and the heating temperature is 1235°C, heating coefficient 10min / cm, heating time in soaking section (time in furnace) 70min. Stage II rolling is adopted, the rolling temperature of stage I (completely recrystallized zone) is 1040°C~1080°C, the reduction rate of a single pass is ≥20%, the cumulative reduction rate is 77%, and the thickness to be heated in the middle (thickness of air-dried steel) 130mm; Stage II (non-recrystallization zone) rolling temperature 850°C-860°C, final rolling temperature 800°C-820°C, single-pass reduction rate ≥ 12%, and total rolling passes controlled at 14 passes. After rolling, ACC cooling is adopted, the cooling rate is 7°C / s, the ratio of upper and lower water is controlled at 1:1.50, and the reddening t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com