Shield support for steep medium-thickness coal seam

A technology for shielding supports and thick coal seams, which is applied to mine roof supports, mining equipment, earth-moving drilling and other directions, can solve the problems of unsuitable coal face support, hidden danger of collapse and unbalance, etc., so as to improve the safety of coal mining. , good stability and security, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

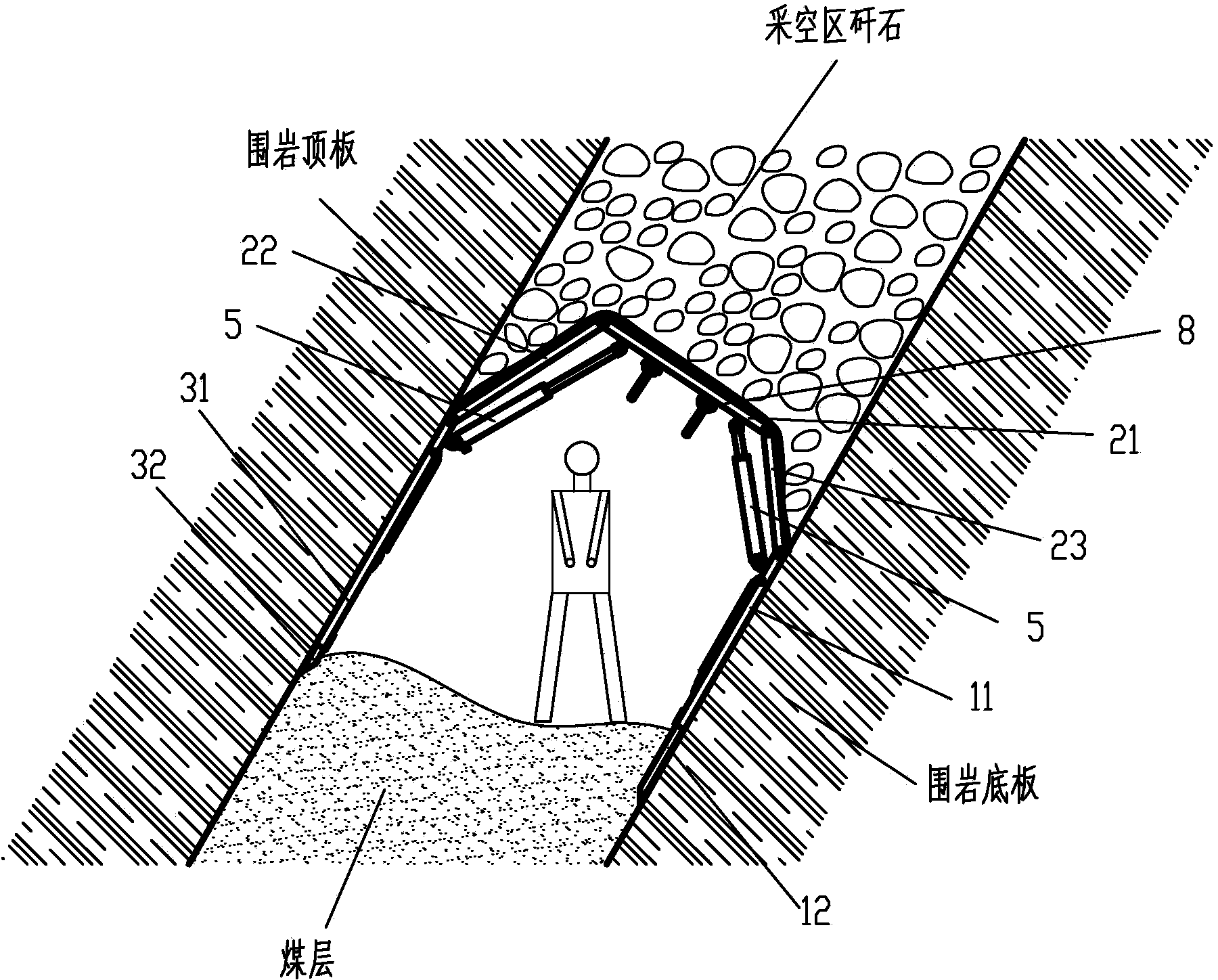

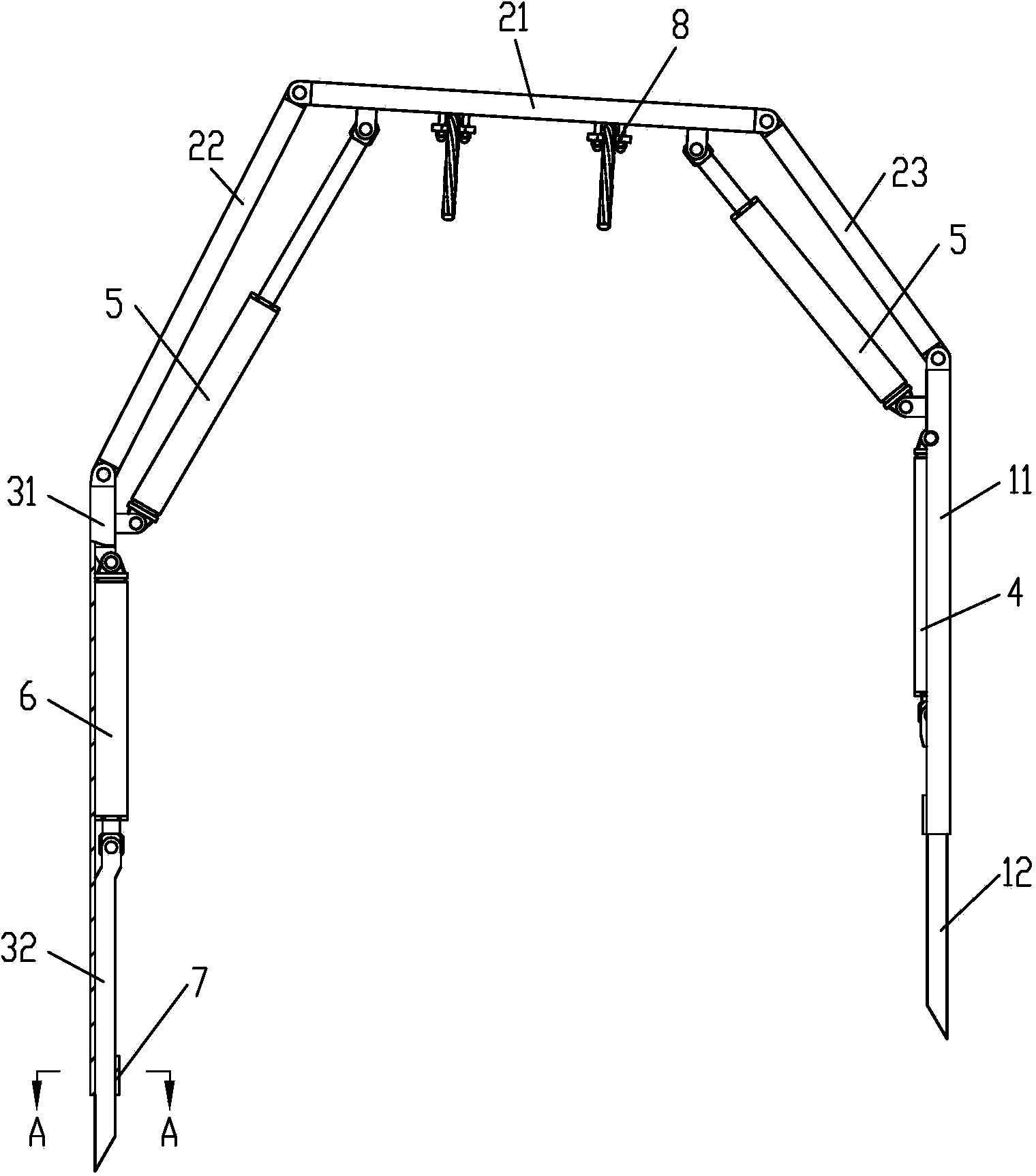

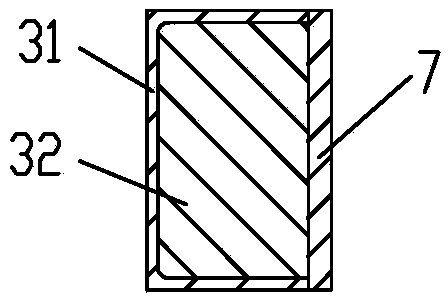

[0022] Example 1, see figure 1 , figure 2 , image 3 , a shield bracket for steeply inclined medium-thick coal seams, the bracket is provided with a plurality of wire rope chucks 8 for fixing the wire ropes, the bracket includes mutually hinged lower legs and a support beam, and the support beam consists of three sections of beams Hinged into an arched structure, the free end of the support beam is also connected to the upper leg; the lower leg and the upper leg are linear, between the upper leg and the support beam and between the lower leg and the support A first double-acting hydraulic cylinder 5 is movably connected between the guard beams; wherein, the support beam includes a top beam 21, the upper end of the top beam 21 is hinged with an upper support beam 22, and the lower end of the top beam 21 is hinged with a lower shield beam 23; The lower leg includes a lower leg main body 11 and a lower leg telescopic body 12, the upper end of the lower leg main body 11 is hing...

Embodiment 2

[0026] Example 2, see Figure 4 The ends of the piston rods of the two first double-acting hydraulic cylinders 5 are respectively hinged to the upper parts of the upper support beam 22 and the lower shield beam 23 .

[0027] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0028] Example 3, see Figure 5 , the supporting beam consists of the upper supporting auxiliary beam section 24a, the upper supporting main beam section 22a, the top beam section 21a and the lower covering beam section 23a to form a rigid arched structure, and the supporting beam is respectively supported by the upper The free end of the auxiliary beam section 24a and the free end of the lower shield beam section 23a are respectively hinged with the upper leg body 31 and the lower leg body 11; the piston rod ends of the two first double-acting hydraulic cylinders 5 are respectively hinged at both ends of the top beam section 21a. There are two wire rope chucks 8, and the two wire rope chucks 8 are fixedly connected to the top beam section 21a.

[0029] In this embodiment, the upper supporting main beam section 22a, the lower shielding beam section 23a, the lower outrigger main body 11 and the upper outrigger main body 31 can be fixedly connected with the wire rope chuck 8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com