Patents

Literature

373results about "Superfinishing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

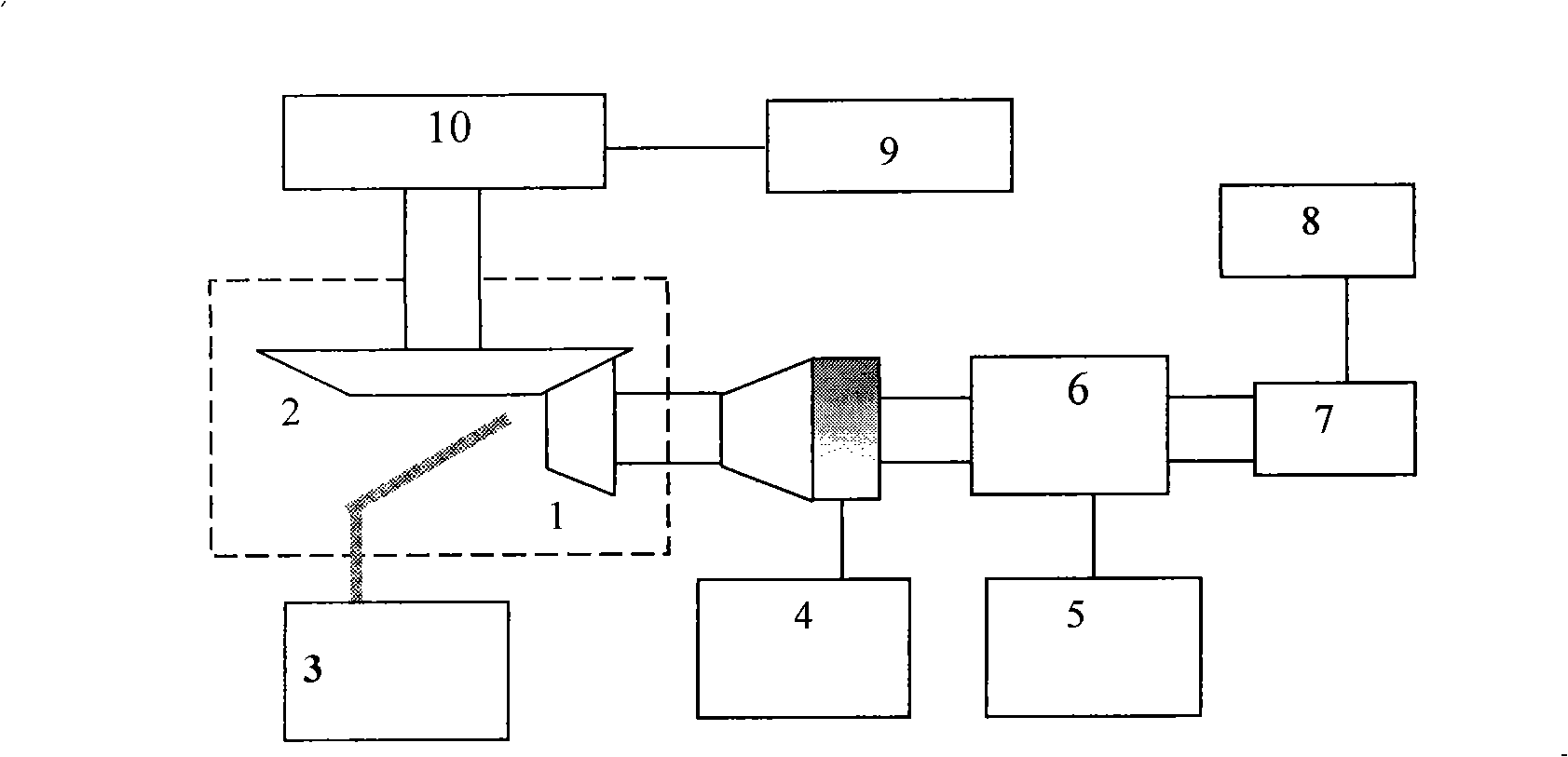

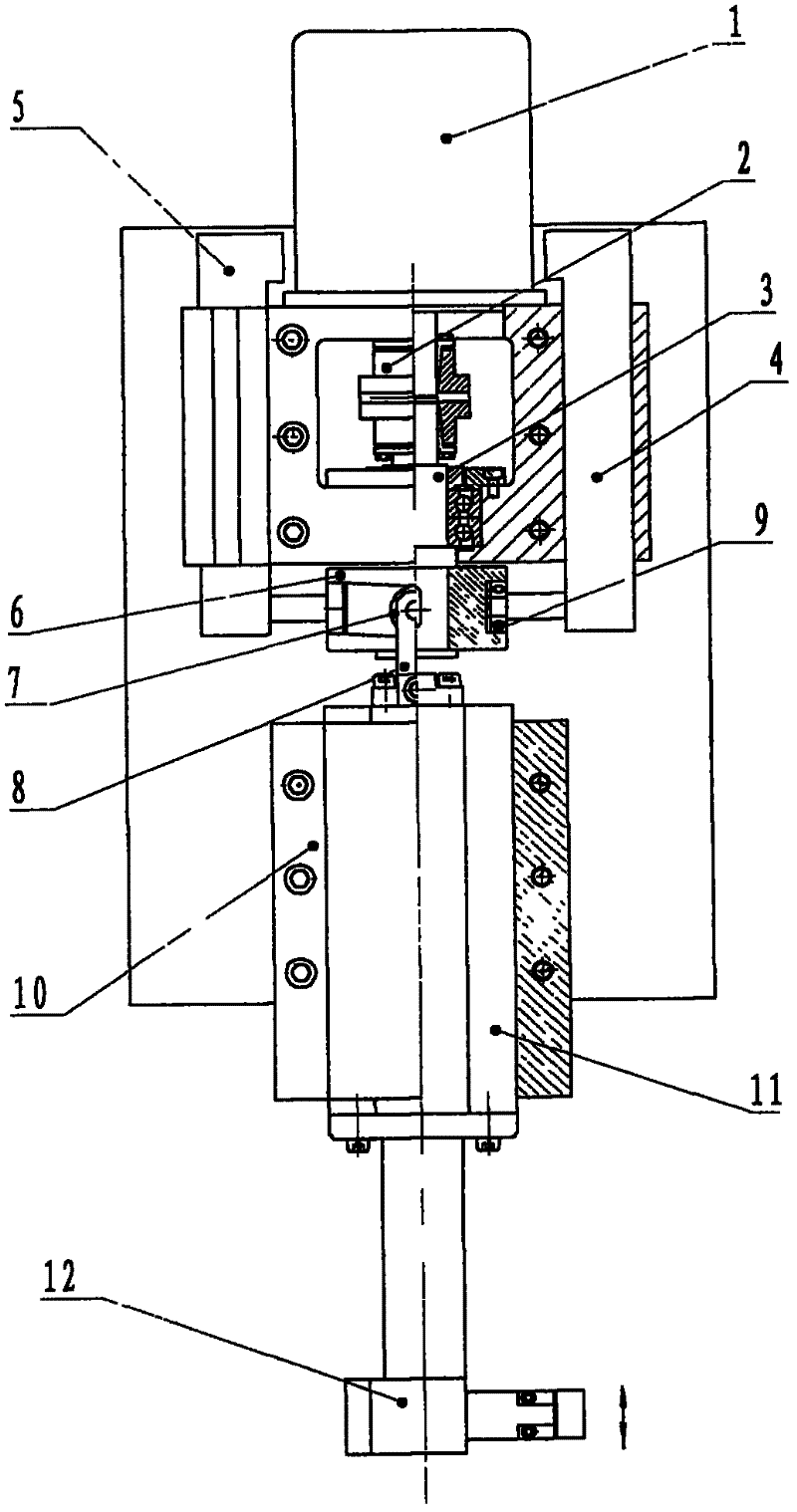

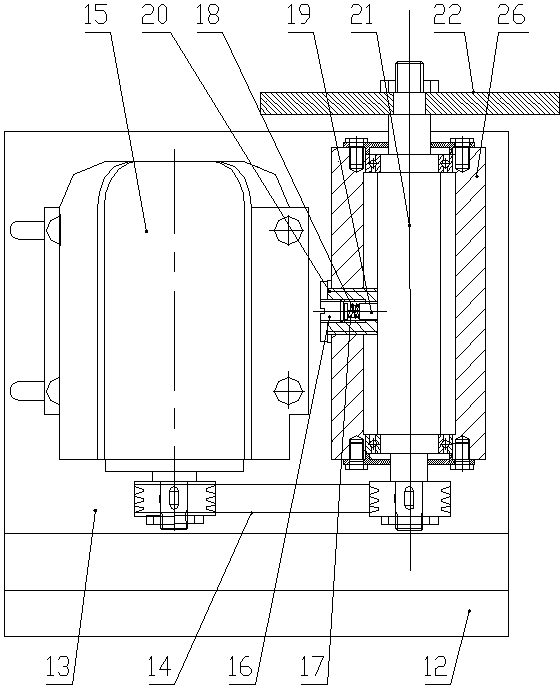

Two dimensional ultrasonic vibration assistant grinding device for grinding large-sized structural parts

InactiveCN101380721AExpand the domain of plastic processingImprove processing efficiencySuperfinishing machinesTransformerTransducer

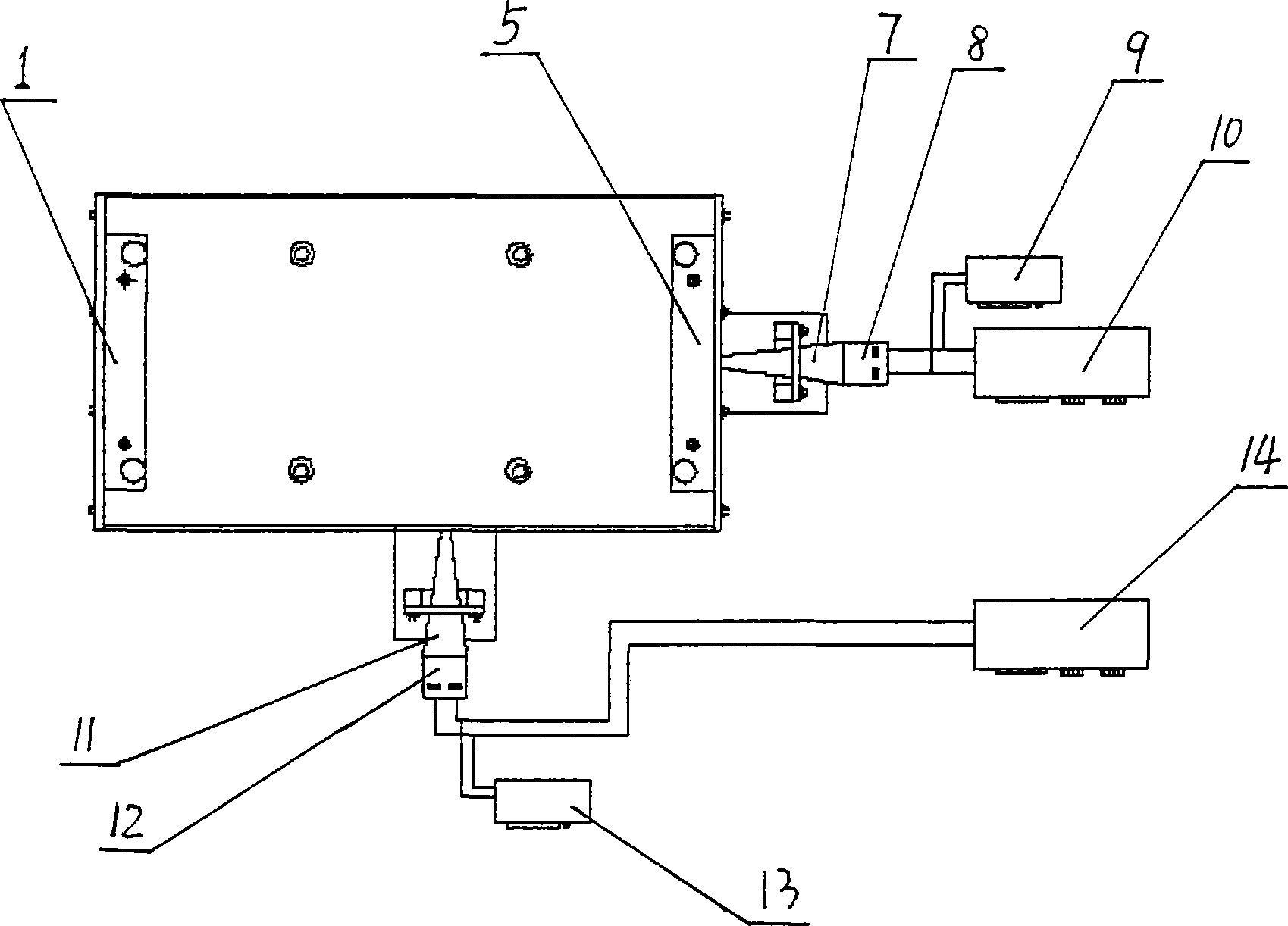

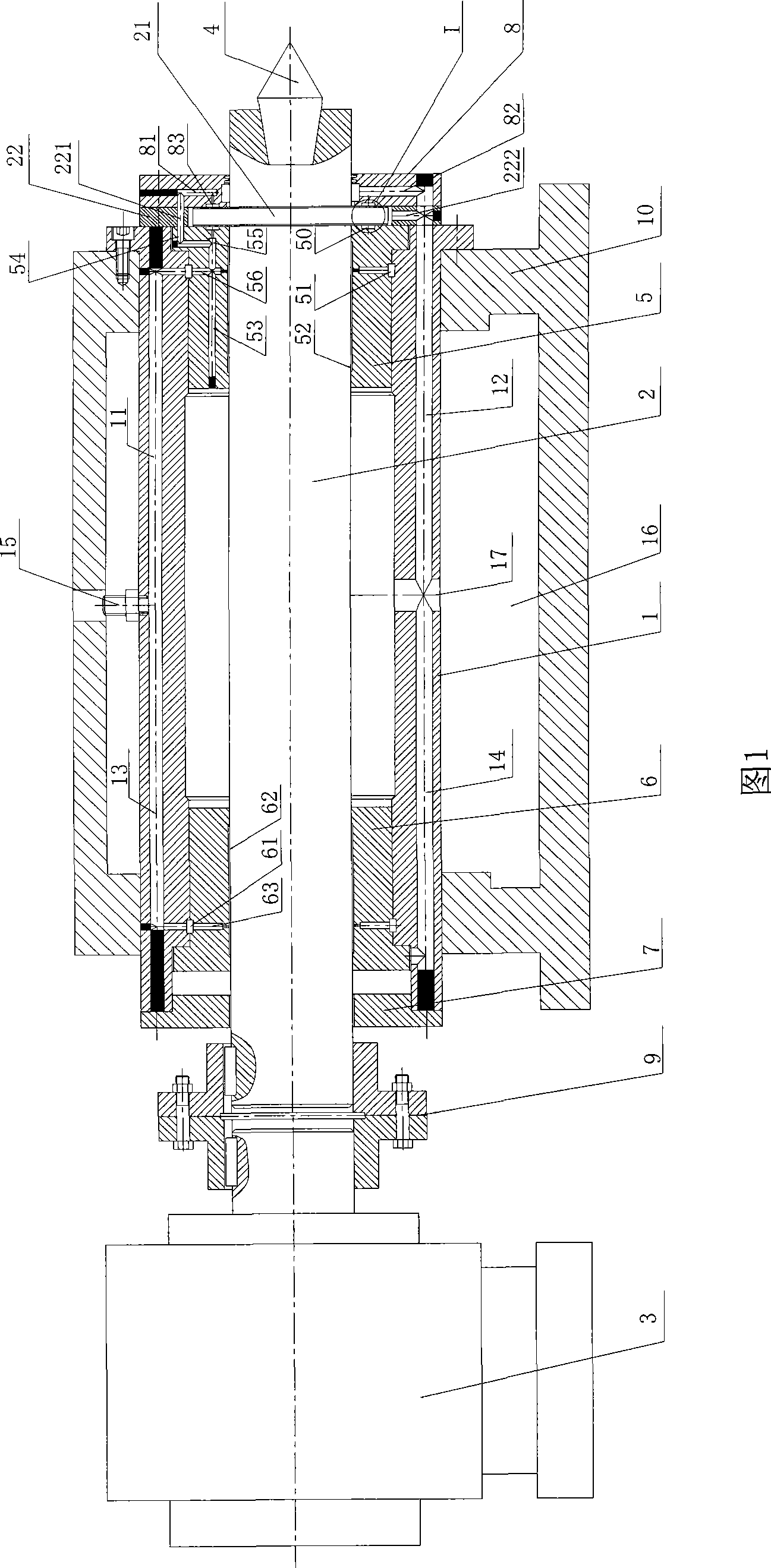

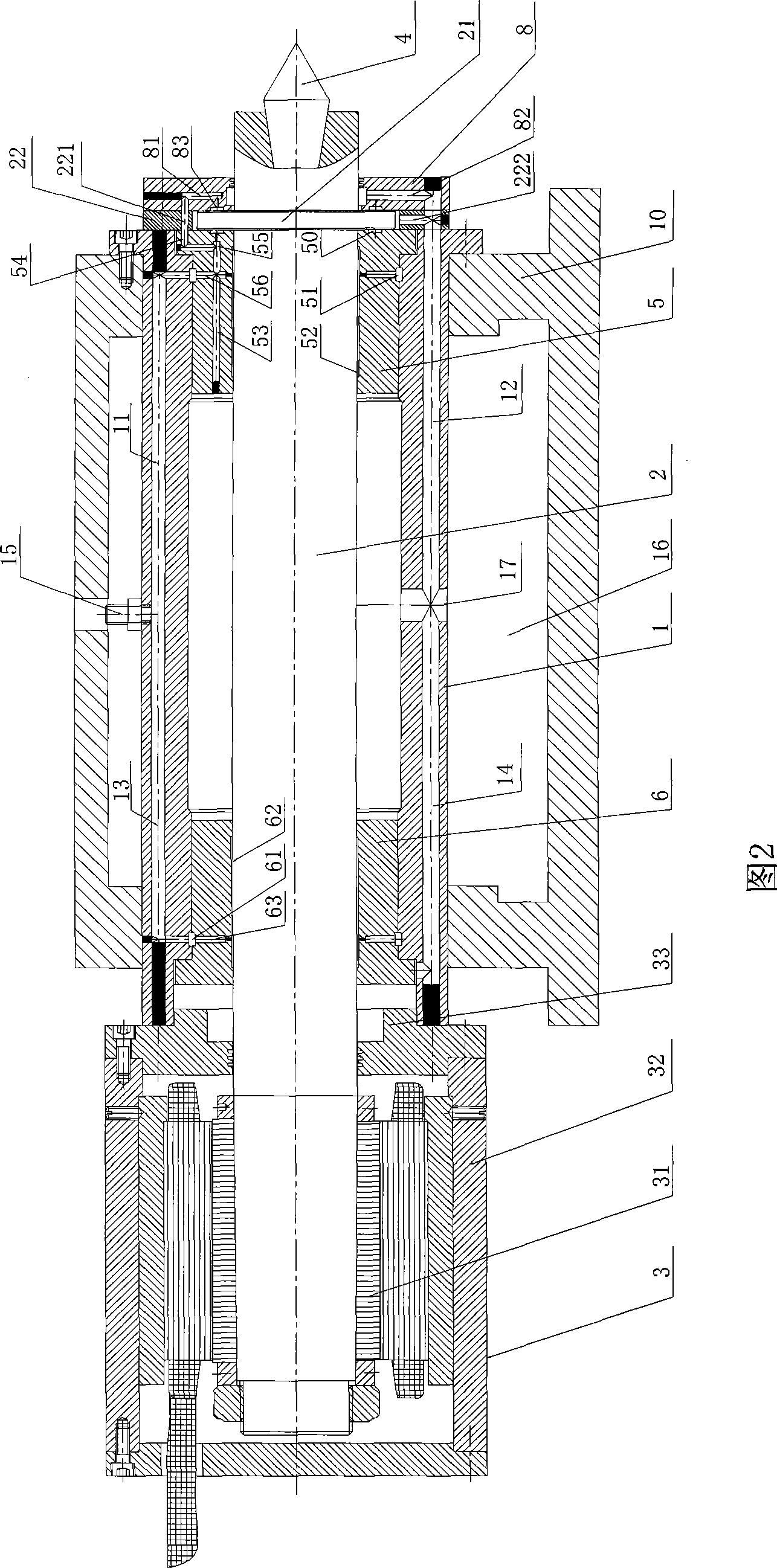

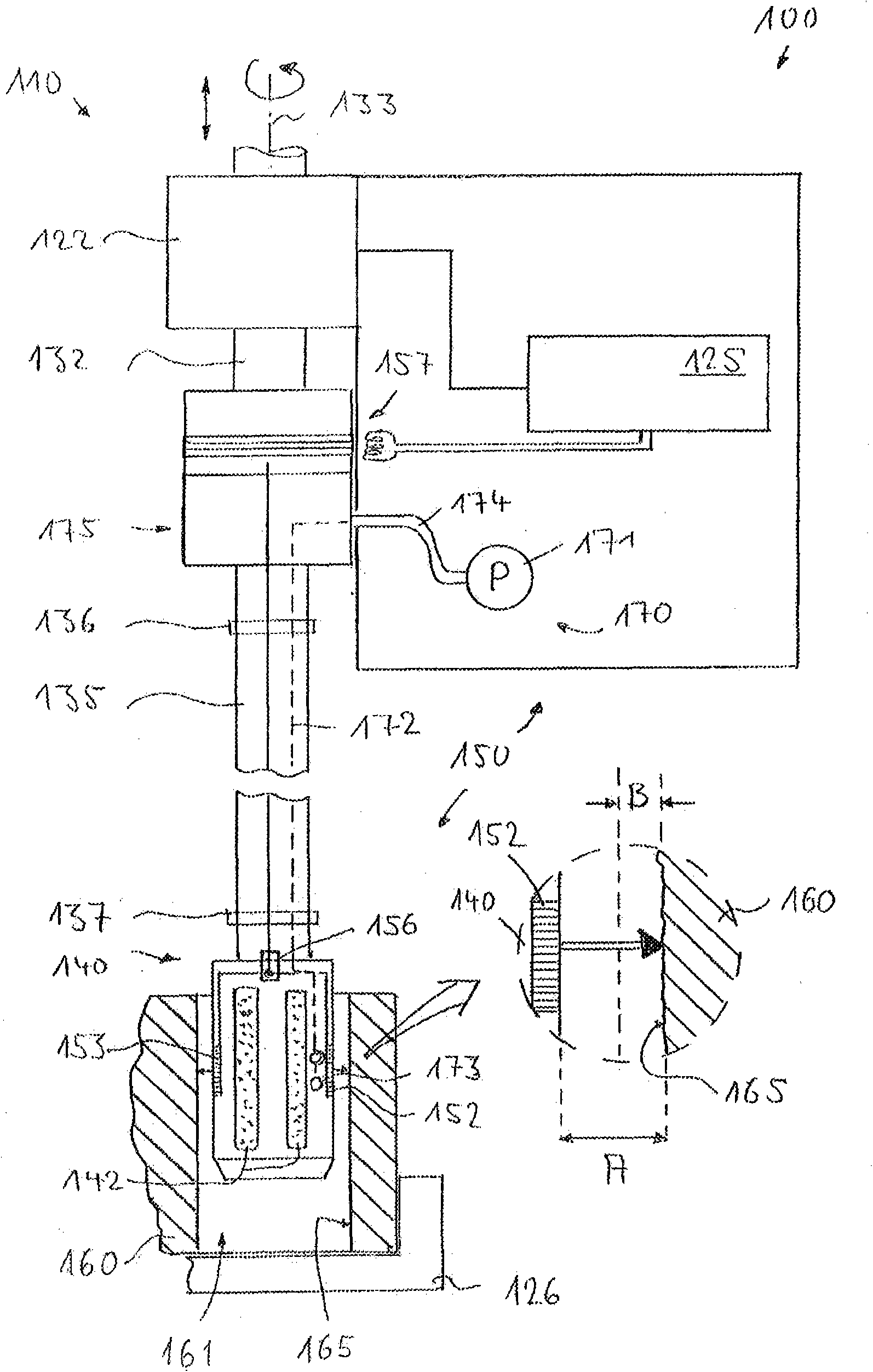

The invention discloses a two-dimensional ultrasonic vibration auxiliary grinding device used for grinding large structural parts. An upper panel and a lower panel are supported and fixed by a landing leg; the two ends of the upper panel are provided with an adjustable pressure pad and a pressure pad; a longitudinal amplitude transformer is fixedly connected with a longitudinal transducer; a coaxial amplitude transformer is fixedly connected with a coaxial transducer; the longitudinal end of the upper panel is fixedly connected with the longitudinal amplitude transformer; the coaxial end of the upper panel is fixedly connected with the coaxial amplitude transformer; the longitudinal transducer is connected with a first ultrasonic generator; the coaxial amplitude transformer is connected with a second ultrasonic generator; the output line of the first ultrasonic generator is connected with a first cymometer; the output line of the second ultrasonic generator is connected with a second cymometer; a processing grinding wheel is arranged on the upper part of the upper panel, thus solving a series of difficulties like low processing efficiency, poor surface quality and high processing cost of a structural ceramic material and realizing the precise processing of a large ceramic flat with high efficiency and quality.

Owner:HENAN POLYTECHNIC UNIV

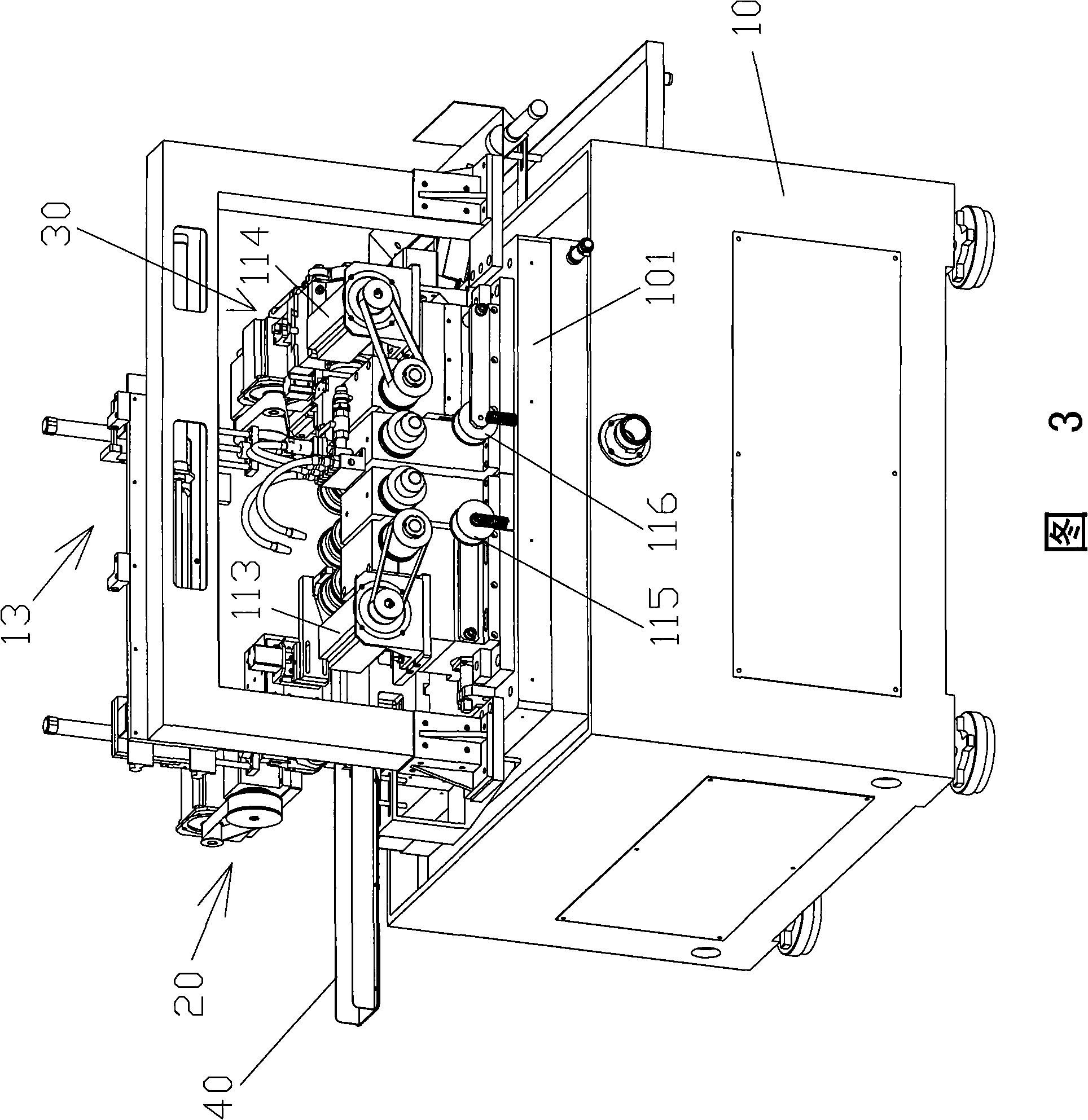

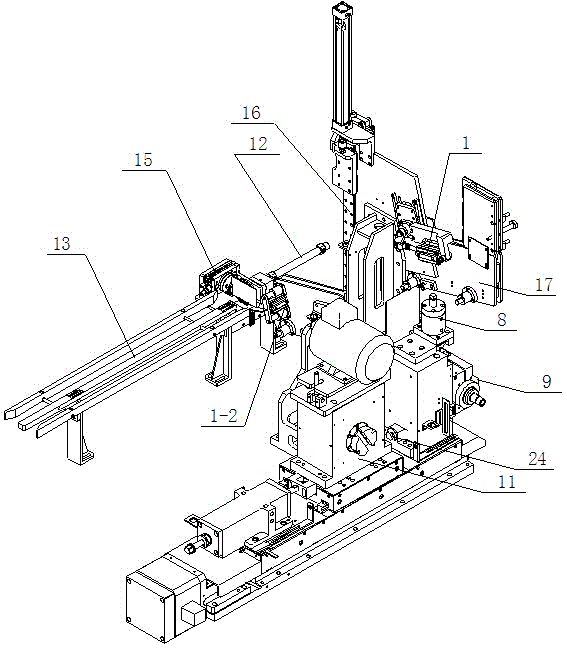

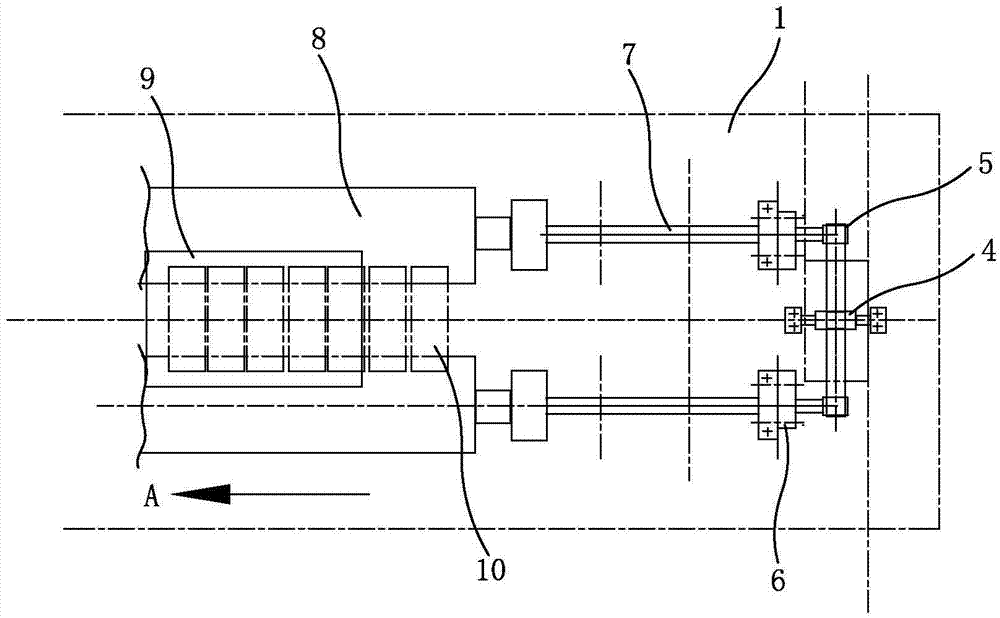

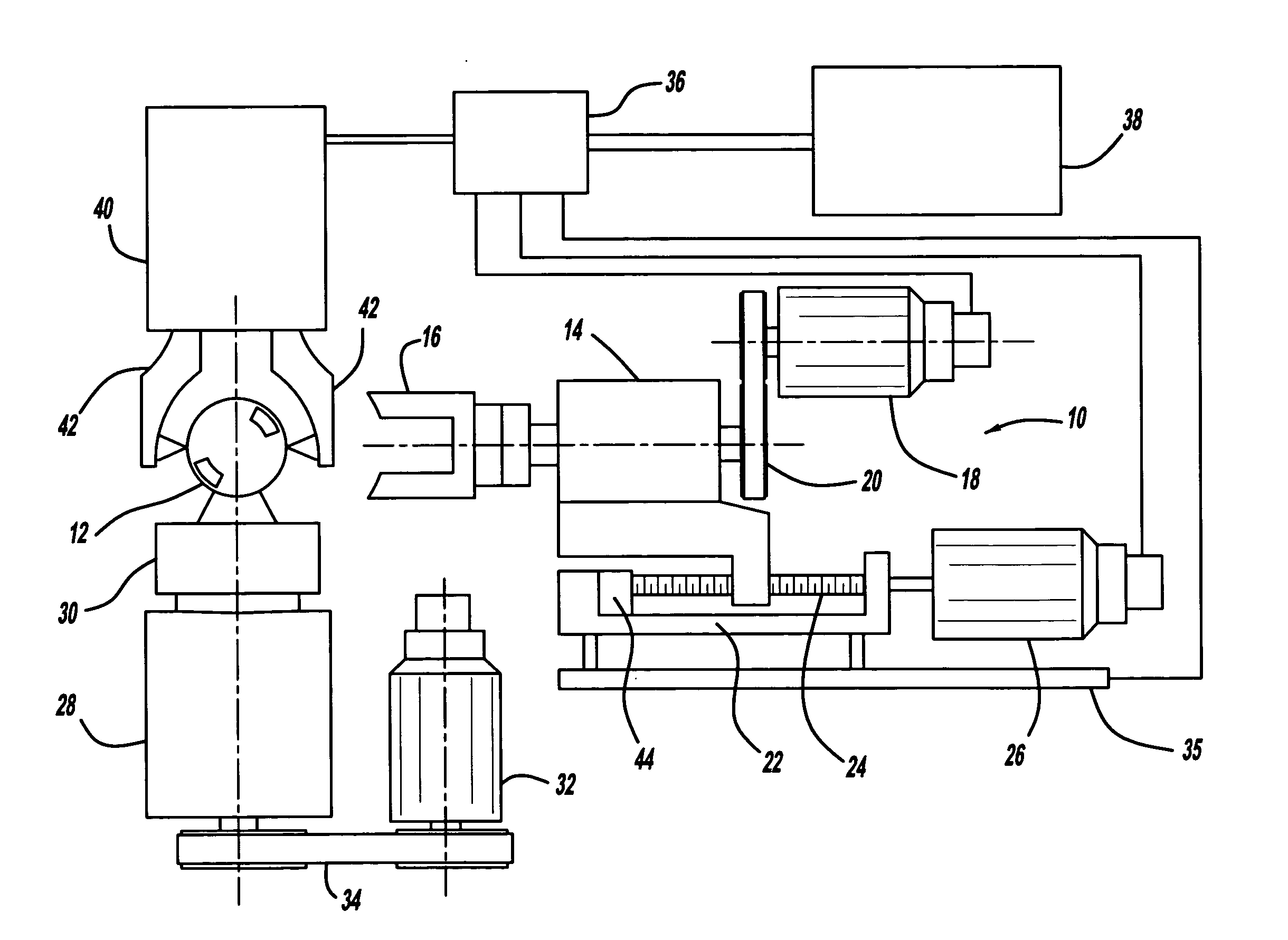

Single groove single race bearing super precise grinding machine

InactiveCN101306513AImprove protection securityReliable actionGrinding machinesSuperfinishing machinesPortal frameManipulator

The invention disclose a single-channel single-race bearing superfine grinding machine including a machine frame with an operating desk, as well as a workpiece seat, a grinding device and a material loading device which are arranged on the operating desk, wherein the workpiece seat includes four rollers which are arranged by groups of two, so as to form a race grinding service position and a channel grinding service position; the grinding device includes a race grinding device which is used for race processing and arranged corresponding to the race grinding service position, and a channel grinding device which is used for channel processing and arranged corresponding to the channel grinding service position; the material loading device includes a portal frame arranged athwart above the workpiece seat, first and second traverse motion mechanisms arranged on the portal frame, as well as first and second manipulators which are respectively connected with the first and the second traverse motion mechanisms, wherein the first manipulator is used for sending a workpiece to the race grinding service position, and the second manipulator is used for sending the workpiece from the race grinding service position to the channel grinding service position. The single-channel single-race bearing superfine grinding machine has the advantages of fully automatic running, precise processing and so on.

Owner:SHANGHAI BENQIU PRECISION MACHINERY

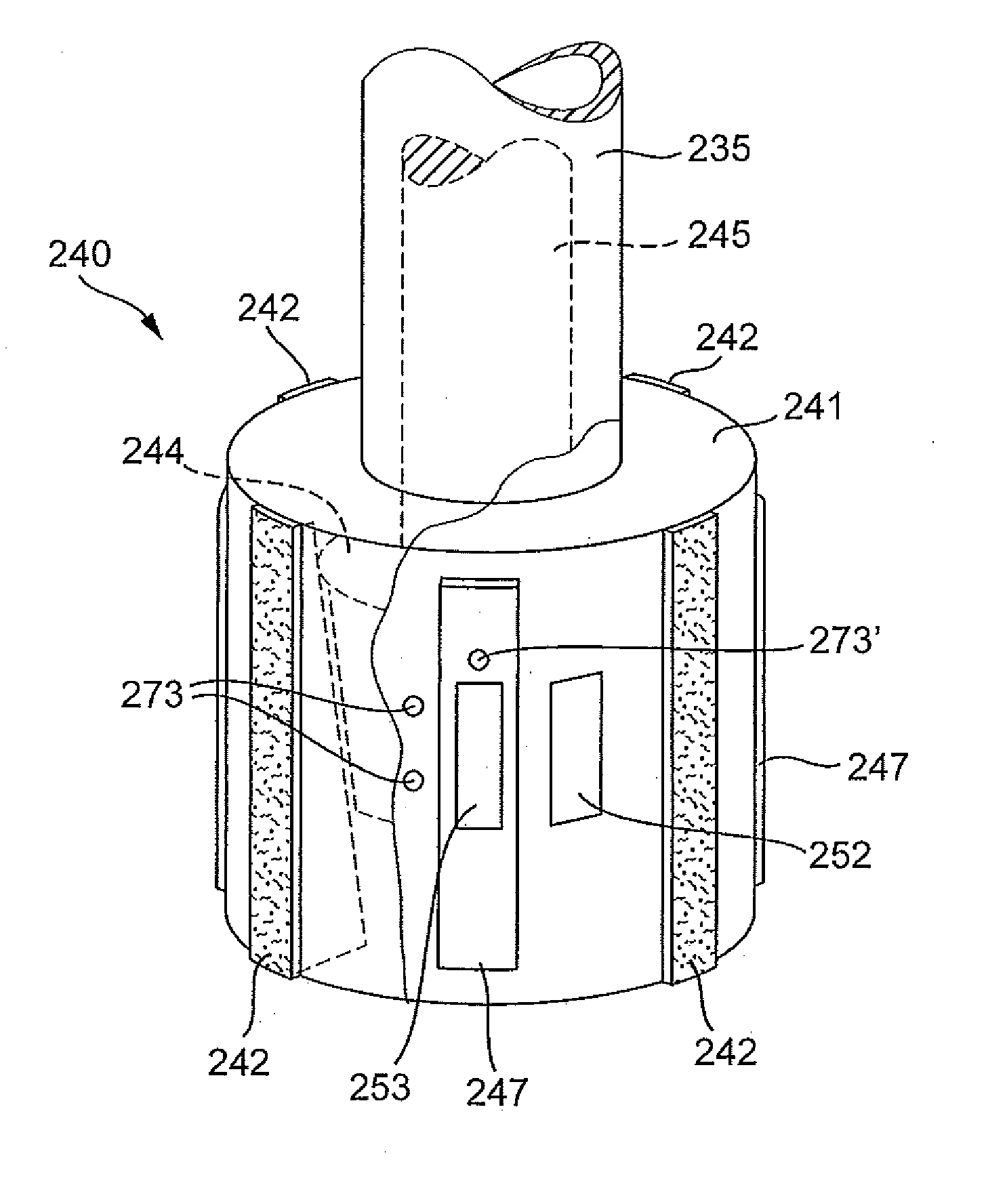

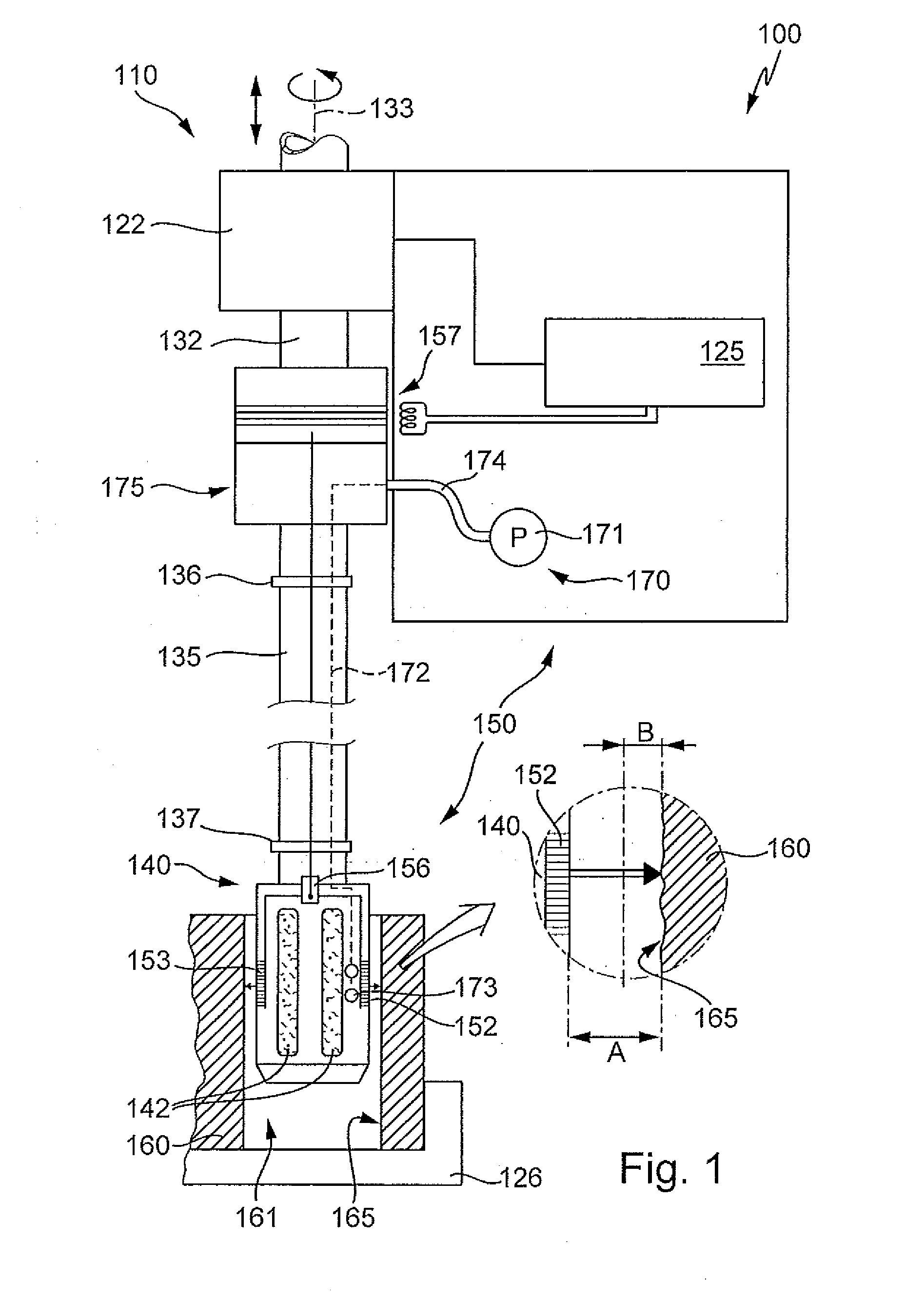

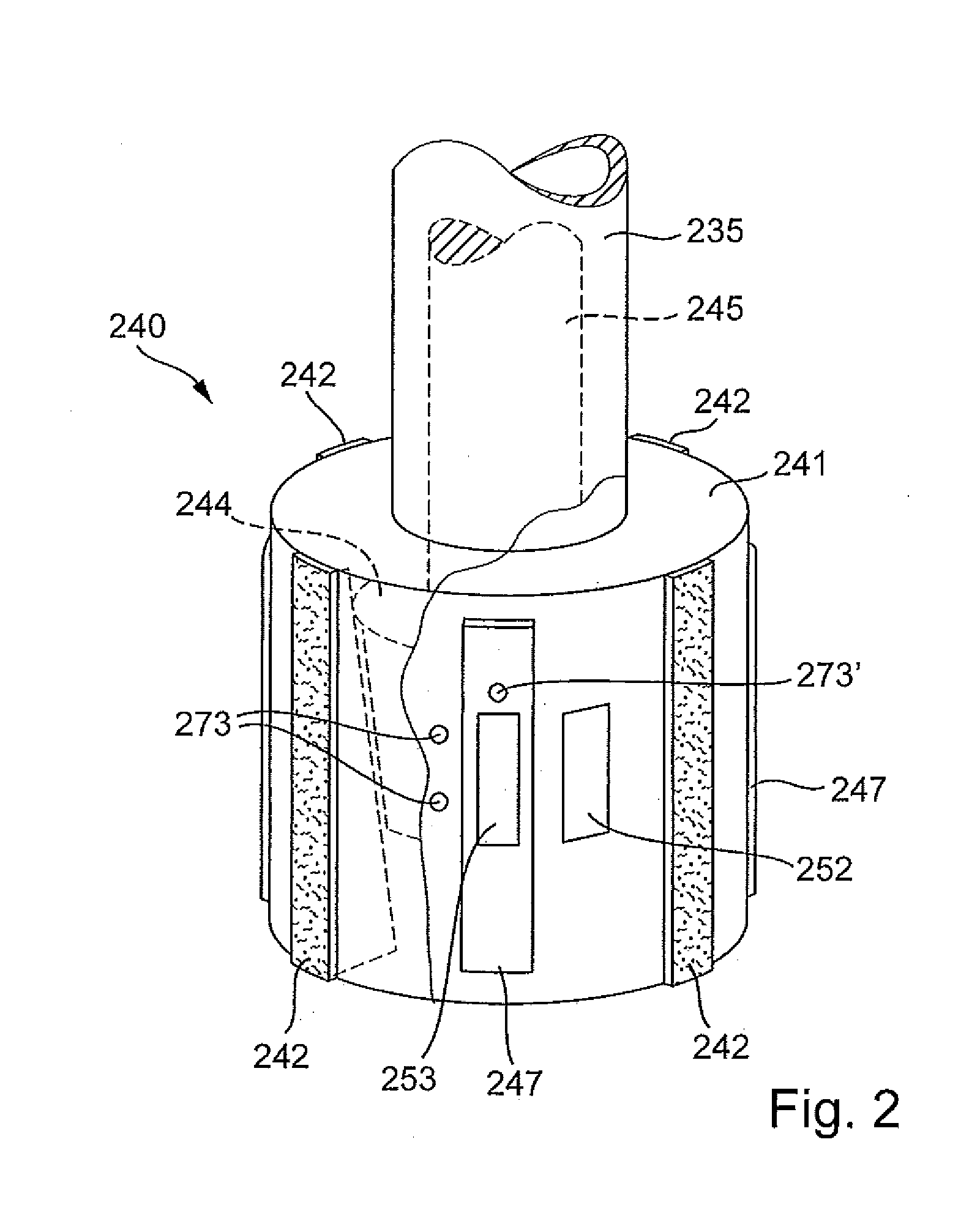

Method and apparatus for the measurement-aided fine machining of workpiece surfaces, and measuring system

InactiveUS20110223833A1Improve accuracyHigh precisionMeasurement/indication equipmentsGrinding feed controlRadar radiationAcoustics

In the case of a method for the material-removing fine machining of a workpiece surface of a workpiece, in particular for the honing or finishing of workpiece portions having substantially rotationally symmetrically curved workpiece surfaces, at least one fine machining tool machines the workpiece surface and, by means of a measuring system, a measurement of the workpiece surface is performed. In this case, at at least one measuring position, radar radiation is directed onto the workpiece surface, and the radar radiation reflected from the workpiece surface is acquired and evaluated for the purpose of determining at least one surface measurement value.

Owner:NAGEL MASCHEN UND WERKZEUGFAB

Ultraprecise grinding method for special-shape thin-wall complex-structure workpiece

InactiveCN107253102AAchieve ultra-precision grindingImproving Surface Accuracy of Ultra-precision GrindingSuperfinishing machinesMachined surfaceEngineering

The invention provides an ultraprecise grinding method for a special-shape thin-wall complex-structure workpiece, and relates to a machining technology. According to the ultraprecise grinding method, clamping errors caused by secondary clamping are reduced, the precision of the machined surface shape of the workpiece is guaranteed, and a bulb grinding wheel rod and the workpiece do not interfere with each other. The ultraprecise grinding method includes the steps that the accurate size of the precisely-machined workpiece is obtained, the front end of a workpiece inner rod is clamped, and the clamped portion of the workpiece is subjected to ultraprecise grinding in a mutual-reference mode; a fine-grain metal-based diamond bulb grinding wheel for ultraprecise grinding is installed, and the sphere center of the bulb grinding wheel is adjusted onto the rotating axis of a precise rotating table. The workpiece is installed on a workpiece main shaft through a collet chuck, and it should be guaranteed that the radial play eccentricity of the workpiece is smaller than 5 microns in the installation process. Tool setting for the workpiece is conducted through a CCD tool setting system, and a machining original point is obtained so that the high precision of the surface shape of the machined workpiece can be guaranteed. Ultraprecise grinding of the special-shape thin-wall complex-structure workpiece is achieved by planning the movement track of the bulb grinding wheel.

Owner:HARBIN INST OF TECH

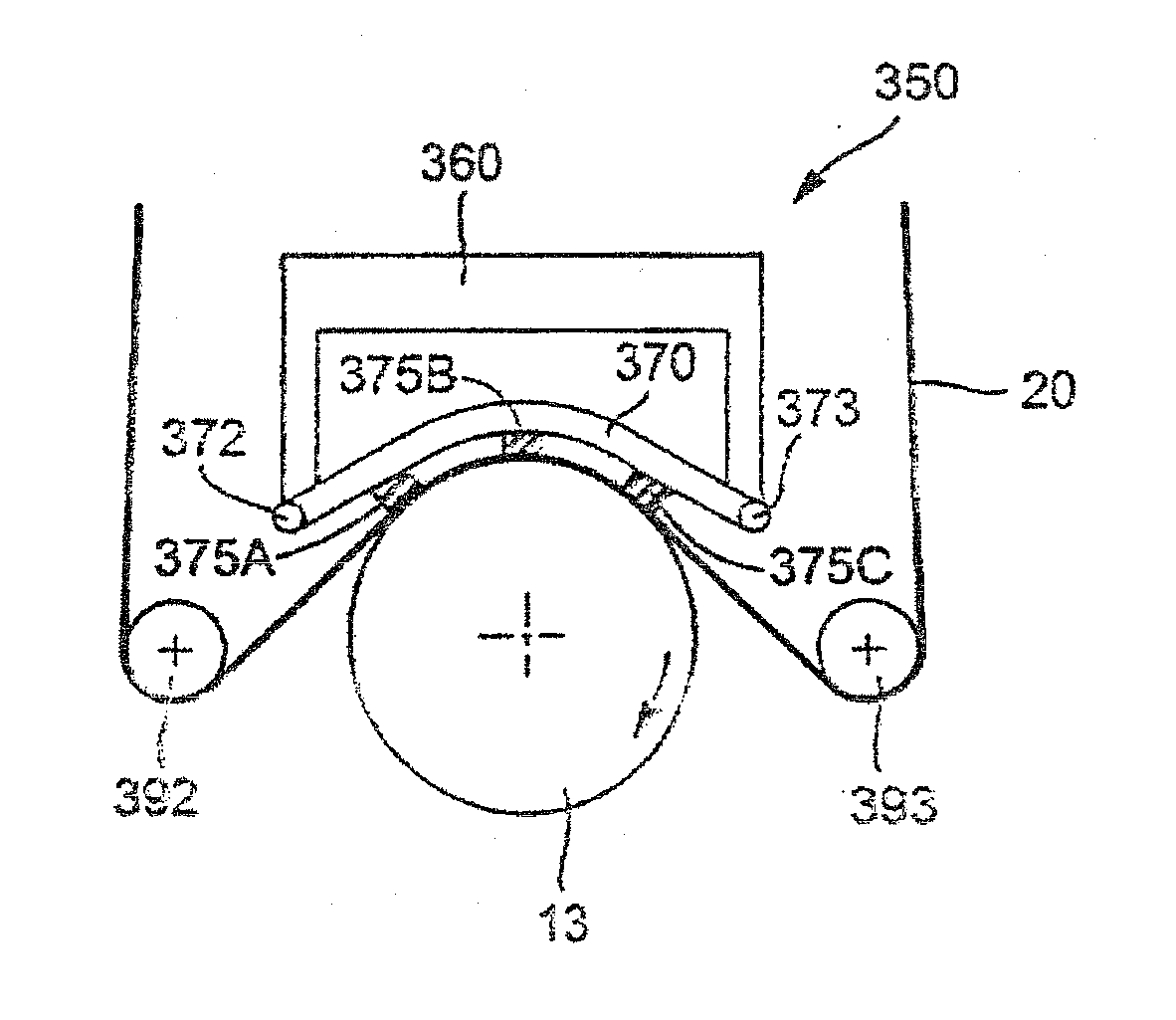

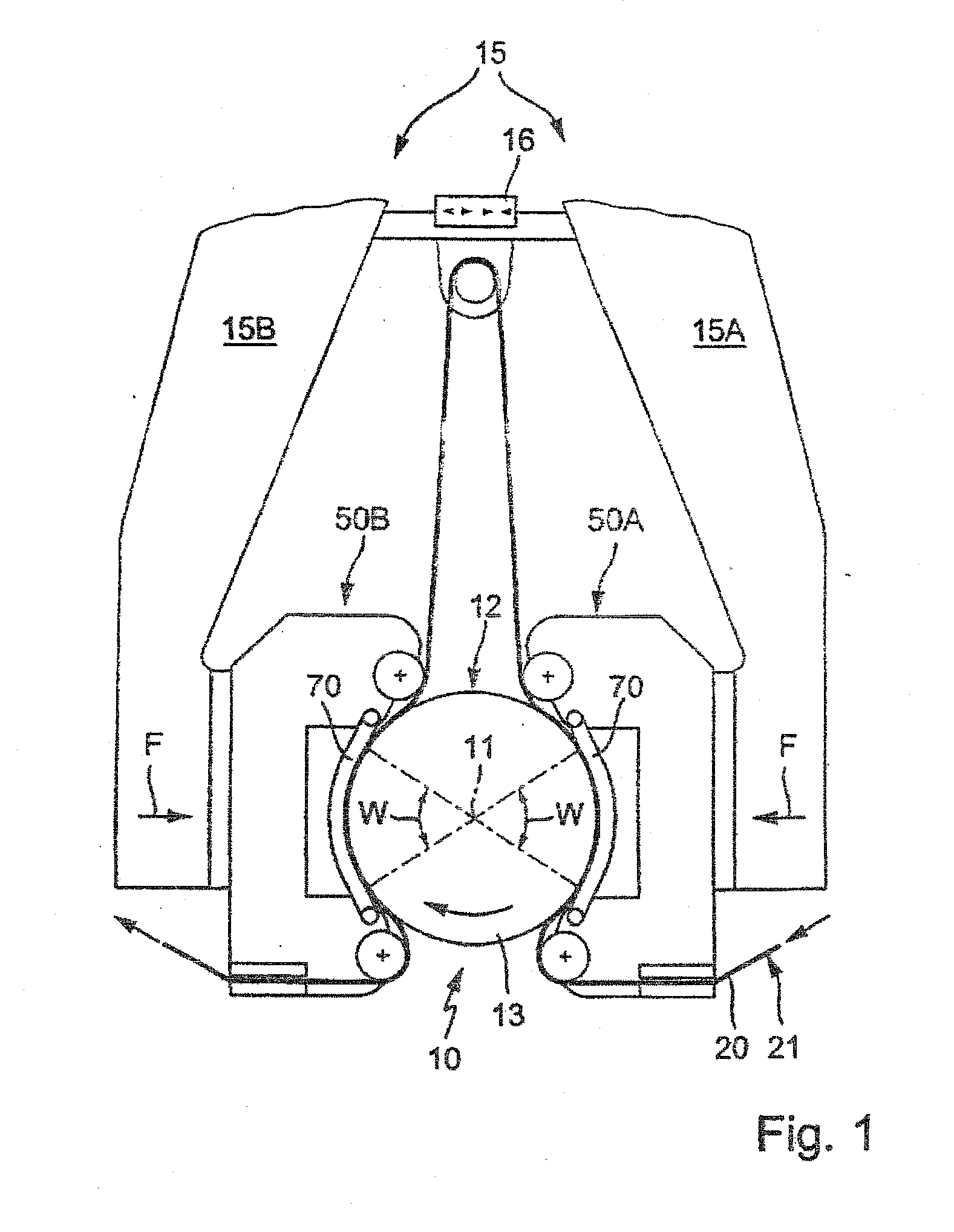

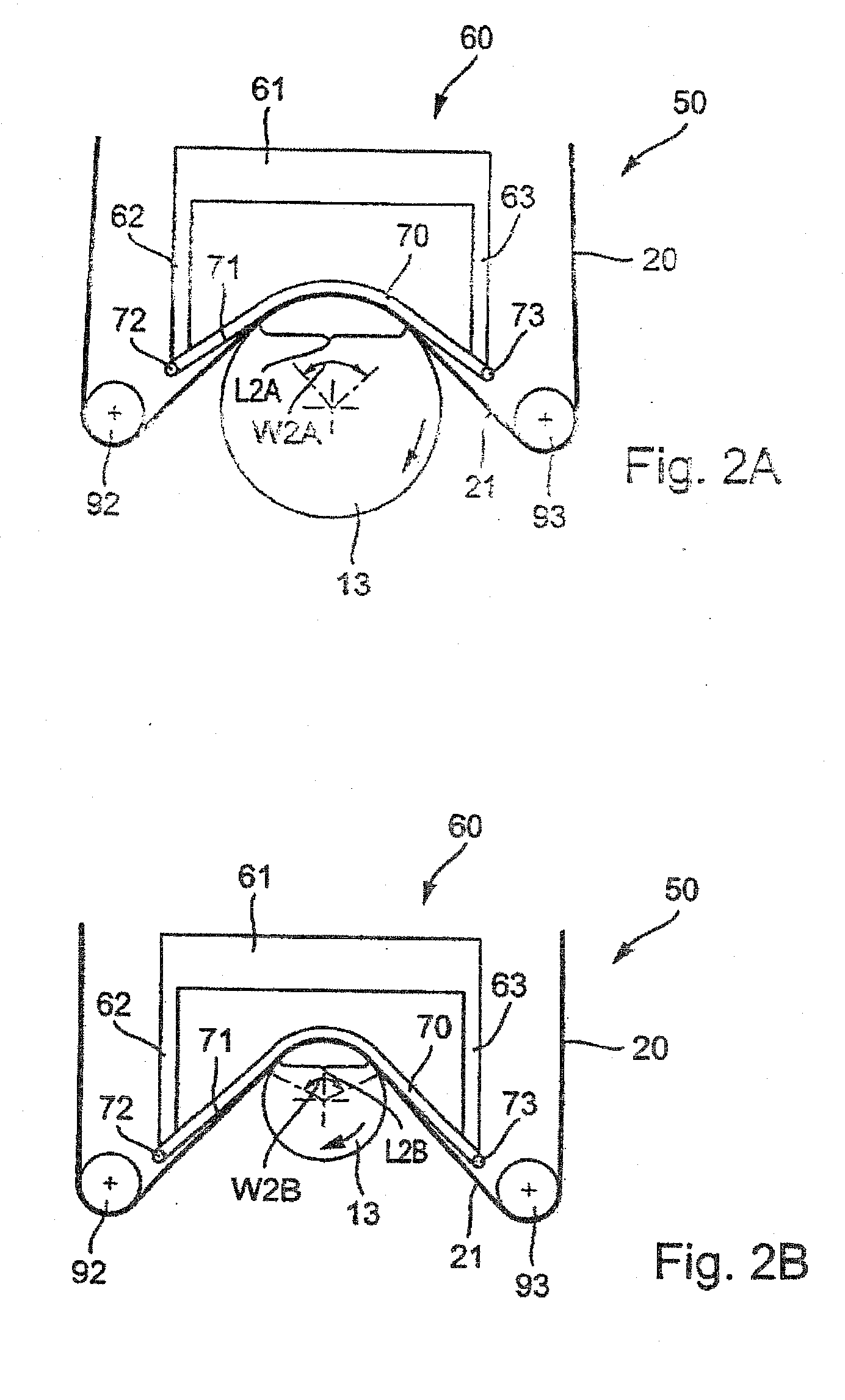

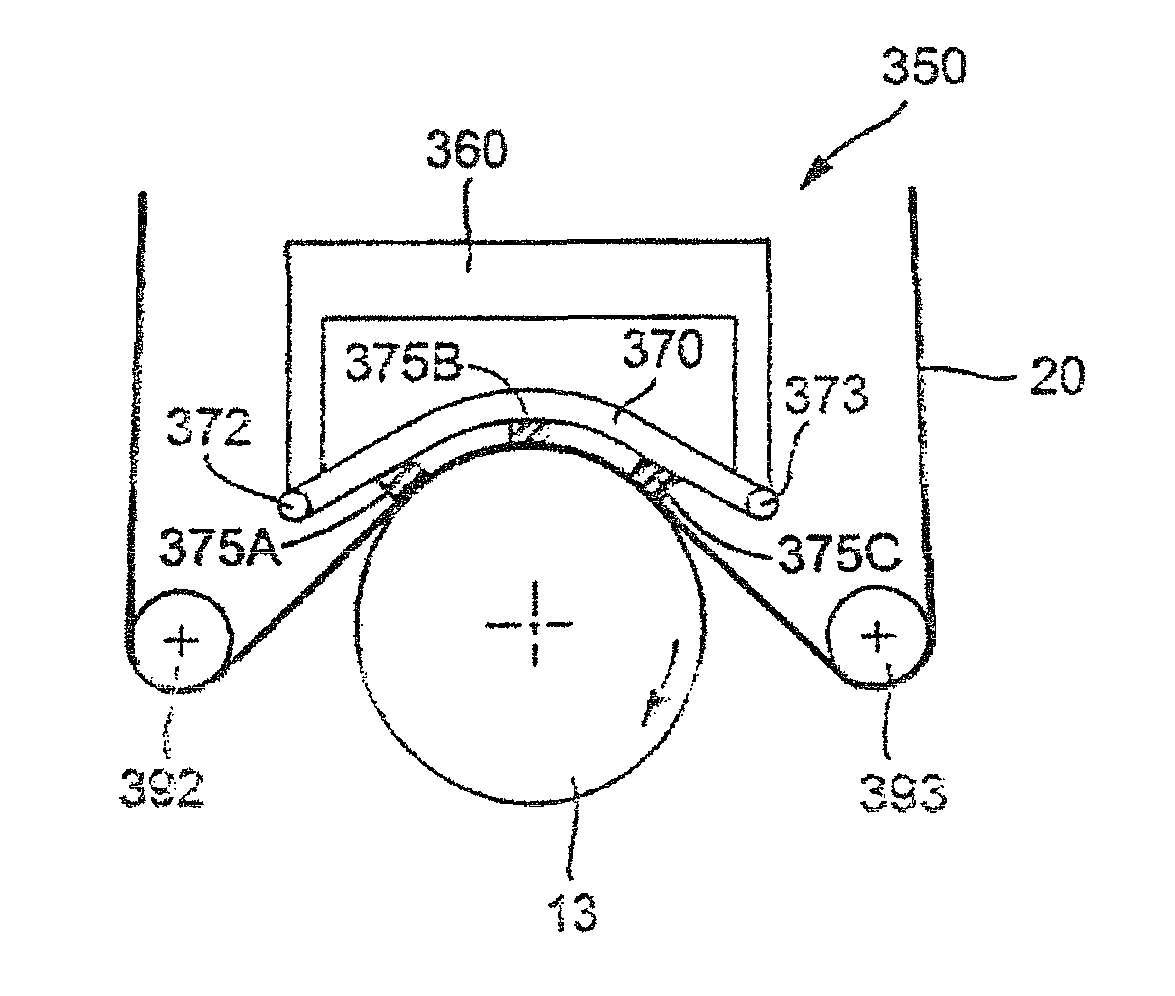

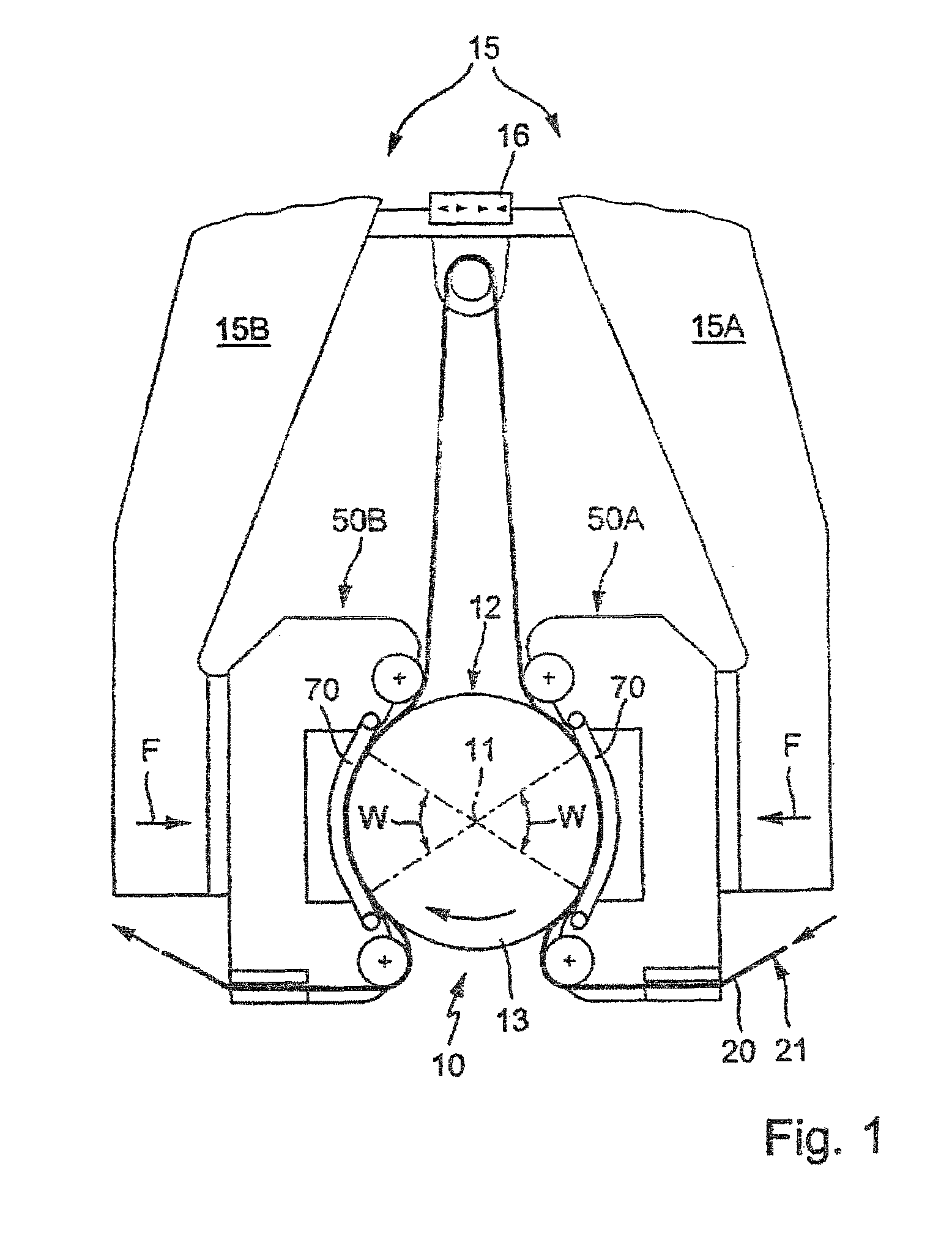

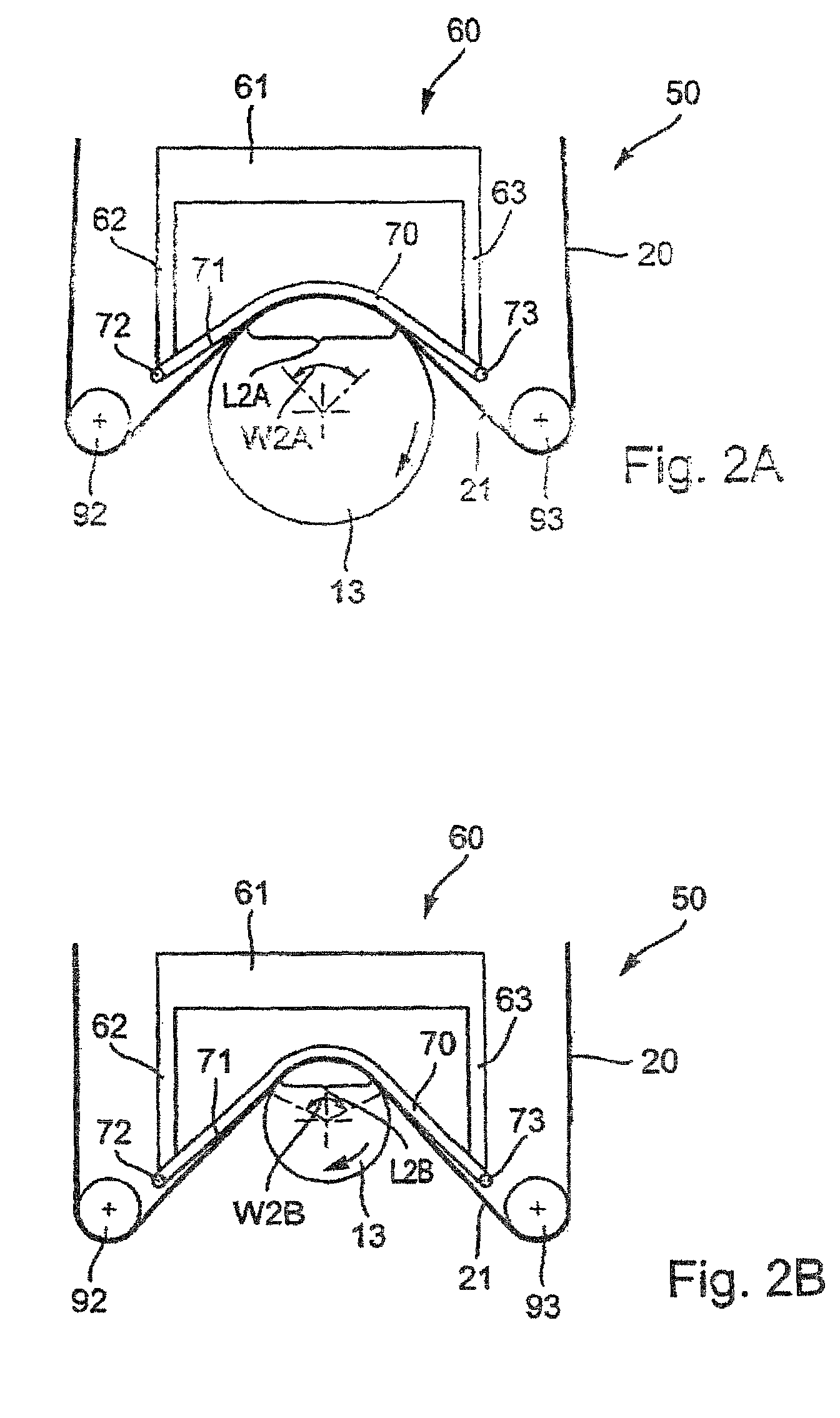

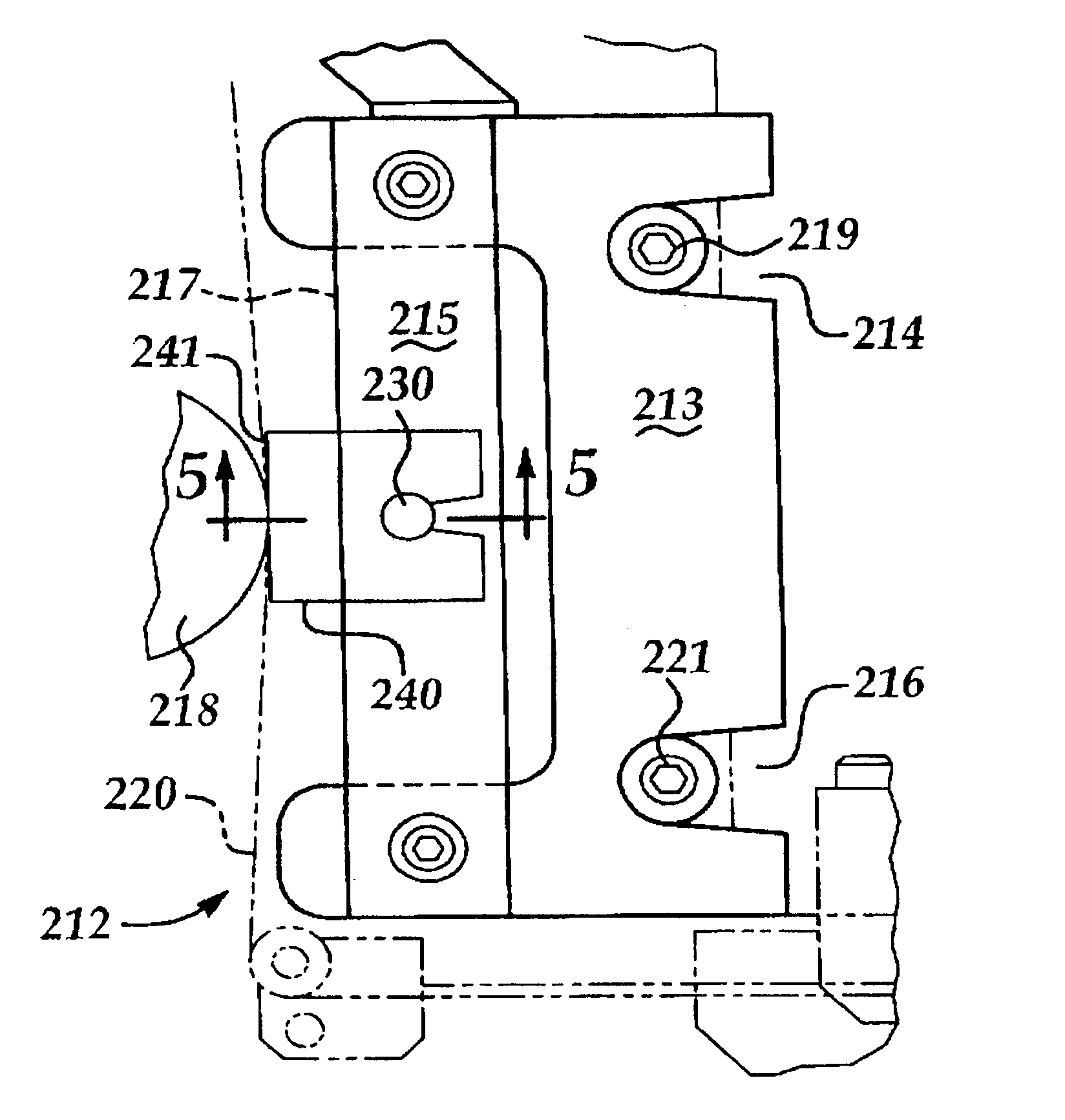

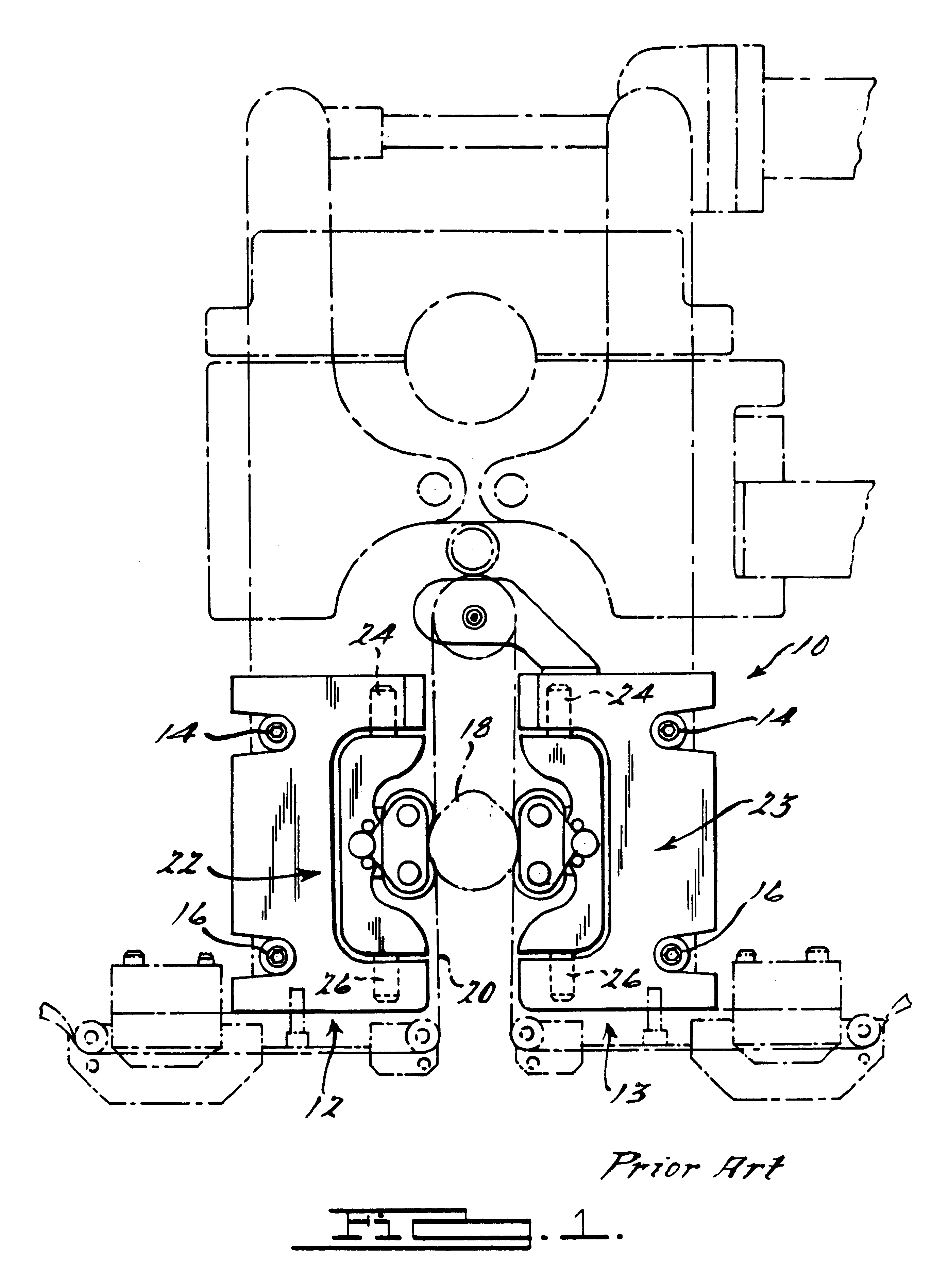

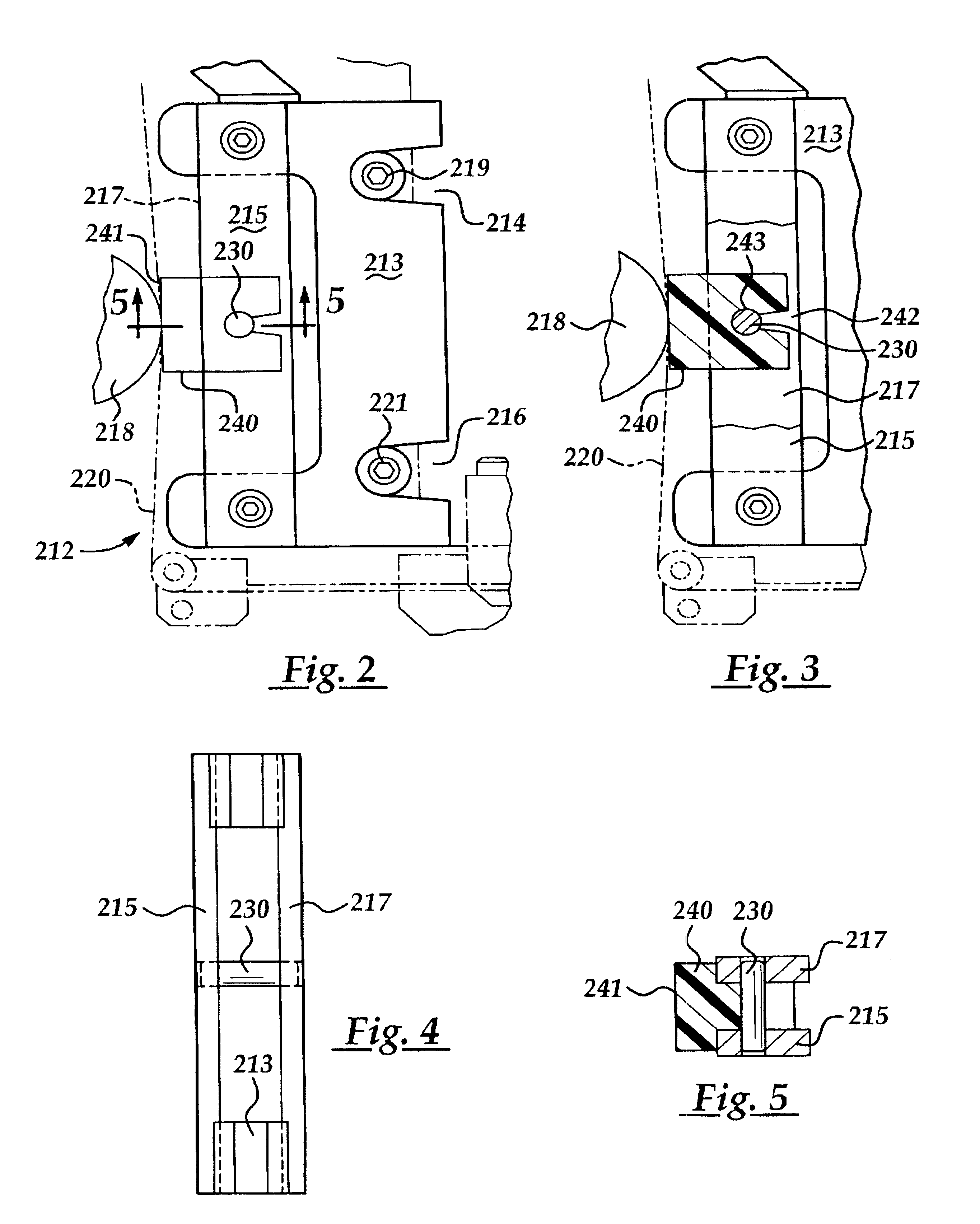

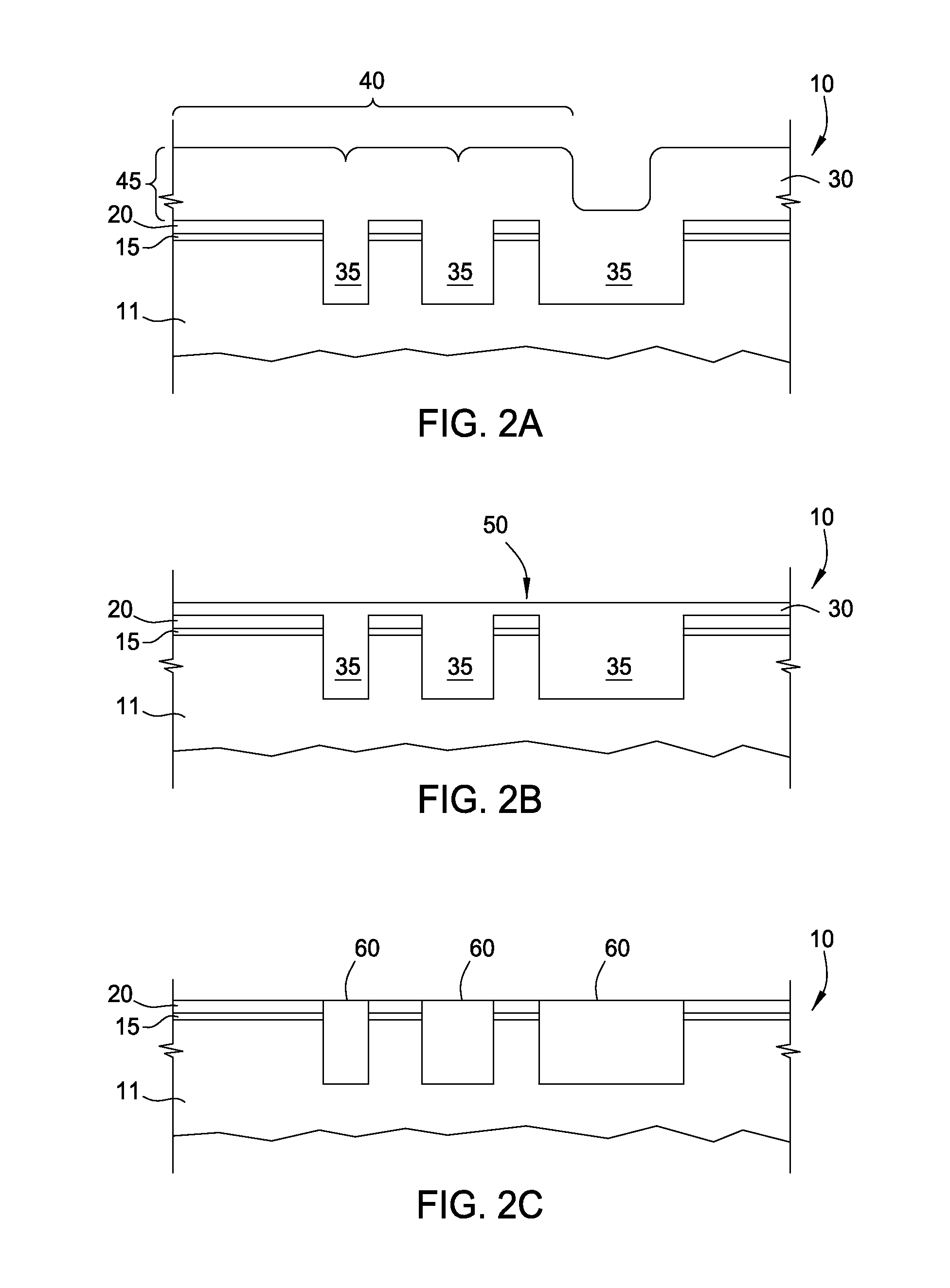

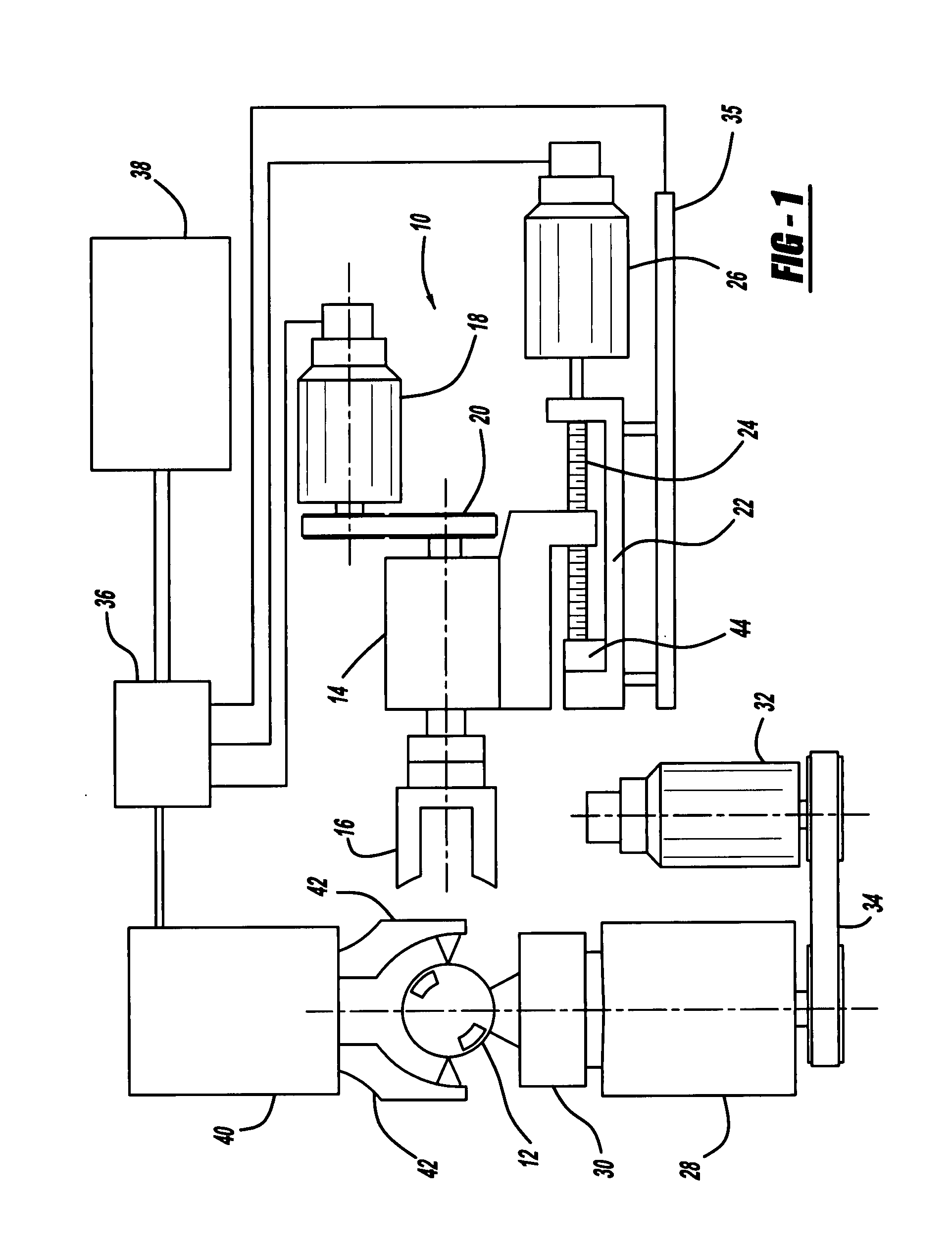

Pressing device for cutting means and apparatus and method for finishing circumferential surfaces on cylindrical parts of a workpiece

InactiveUS20100236314A1Improve surface qualityRevolution surface grinding machinesMetal-working feeding devicesEngineeringMechanical engineering

A pressing device (50) for pressing cutting means onto circumferential surfaces (12) of substantially cylindrical workpiece portions (13) during a finishing operation is provided for pressing the cutting means onto a circumferential surface with a pressing force over a contact angle. The pressing device is steplessly adaptable for the machining of workpiece portions of differing diameters that have a diameter difference of at least 0.1 mm.

Owner:NAGEL MASCHEN UND WERKZEUGFAB

Grinding-bed static head rack capable of realizing accurate ultra micro-finishing

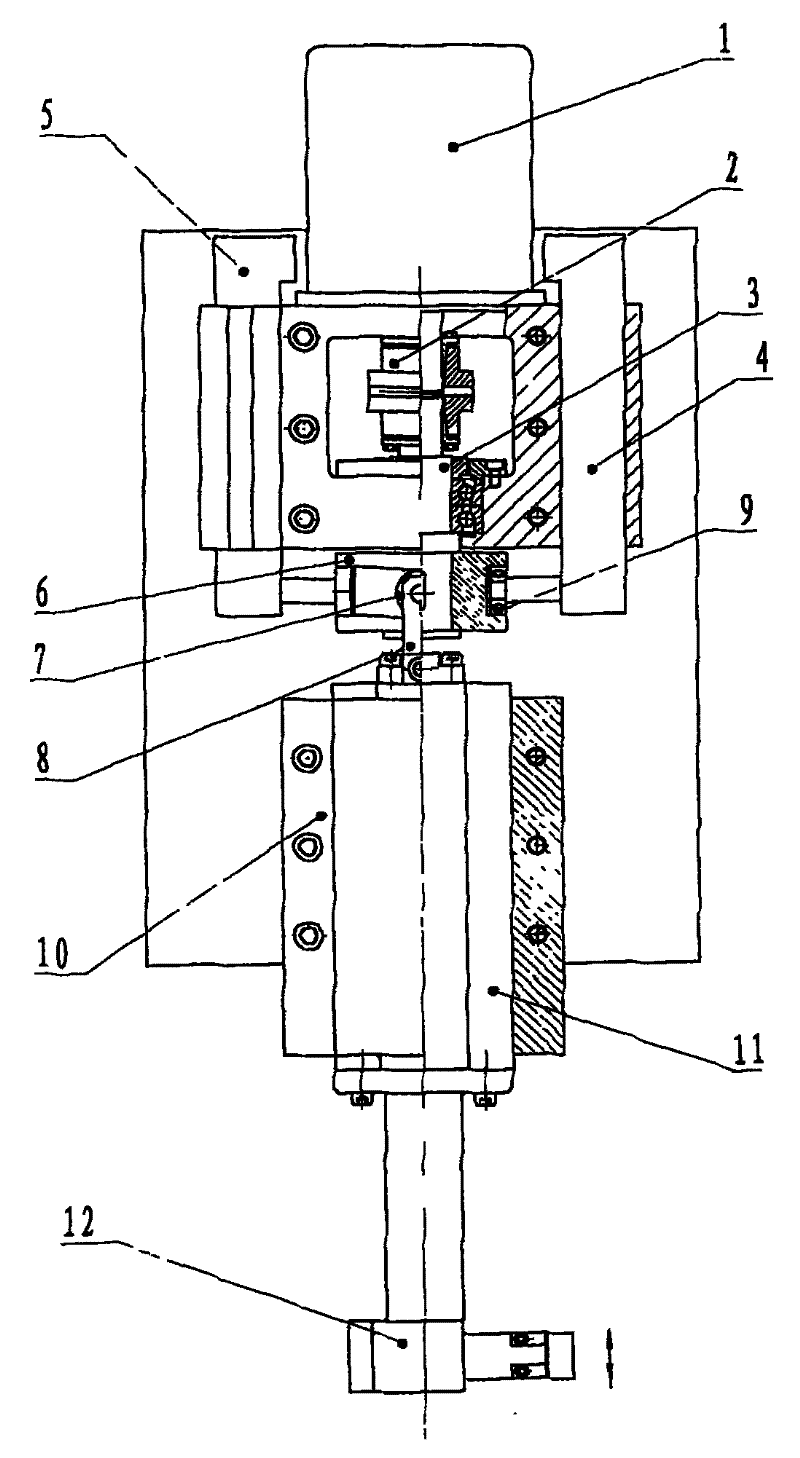

InactiveCN101417410AEasy to debugEasy maintenanceGrinding machine componentsSuperfinishing machinesEngineeringGasket

The invention relates to a static head frame of a grinding machine, which can realize precise and super-precise grinding, comprising a sleeve, a head frame spindle, a support box body, a head frame tip which is arranged on the front end of the head frame spindle and a head frame motor which is connected with the back end of the head frame spindle; wherein, the sleeve is positioned on the support box body; a front end cover is arranged at the front end of the sleeve; the front end and the back end of the head frame spindle are respectively supported on the sleeve through a front liquid hydrostatic bearing and a back liquid hydrostatic bearing; liquid medium is filled between the head frame spindle and both the front liquid hydrostatic bearing and the back liquid hydrostatic bearing; a thrust shaft shoulder is arranged on the head frame spindle and sleeved with a circle of gasket; the thrust shaft shoulder and the gasket are both positioned between the front liquid hydrostatic bearing and the front end cover; a front end gap exists between the front end of the thrust shaft shoulder and the front end cover and a back end gap exists between the back end of the thrust shaft shoulder and the front liquid hydrostatic bearing; and liquid medium is filled in the front end gap and the back end gap to form a liquid hydrostatic thrust bearing. The head frame has the advantages of good rigidity, high rotation accuracy, good vibration reducing performance and long precision life.

Owner:HUNAN UNIV

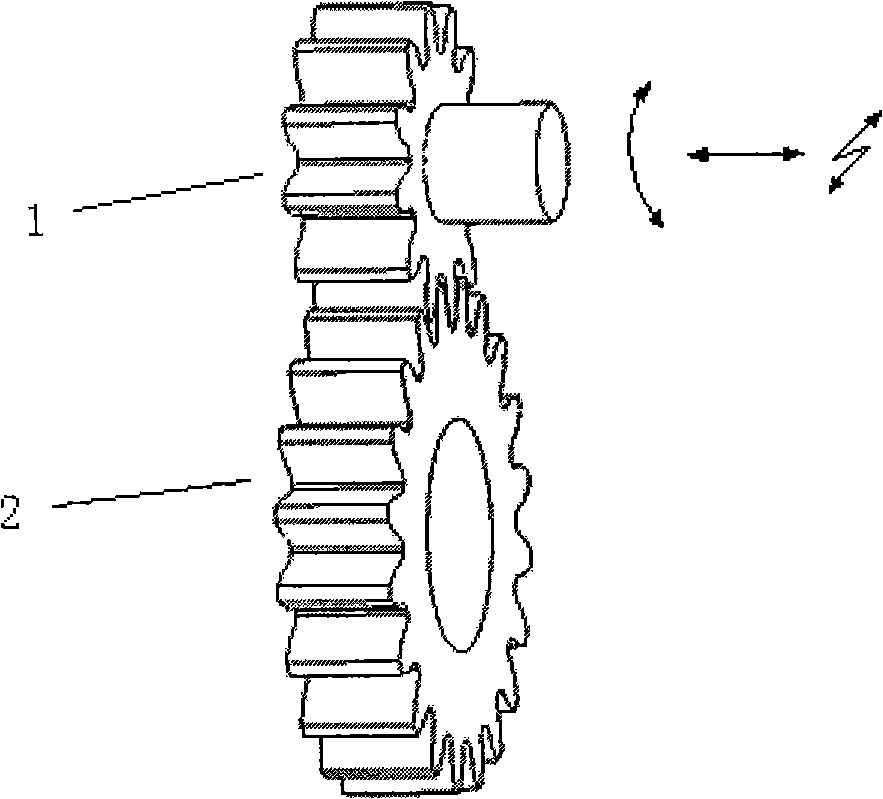

Point superabrasive machining of nickel alloys

ActiveUS7144307B2Edge grinding machinesRevolution surface grinding machinesNickel alloyPoint contact

A process for point superabrasive machining of a nickel based material comprising the steps of providing a tool having a grinding surface coated with a superabrasive material, orienting the tool relative to a surface of the nickel based material to be machined so that there is point contact between the surface to be machined and the grinding surface, and forming a part by removing material at the point contract by rotating the tool. The tool comprises an enlarged portion, a tip portion, and a first shaft portion extending from the enlarged portion to the tip portion, the first shaft portion and the tip portion being coated with an abrasive material, and the first shaft portion having a constant diameter.

Owner:RAYTHEON TECH CORP

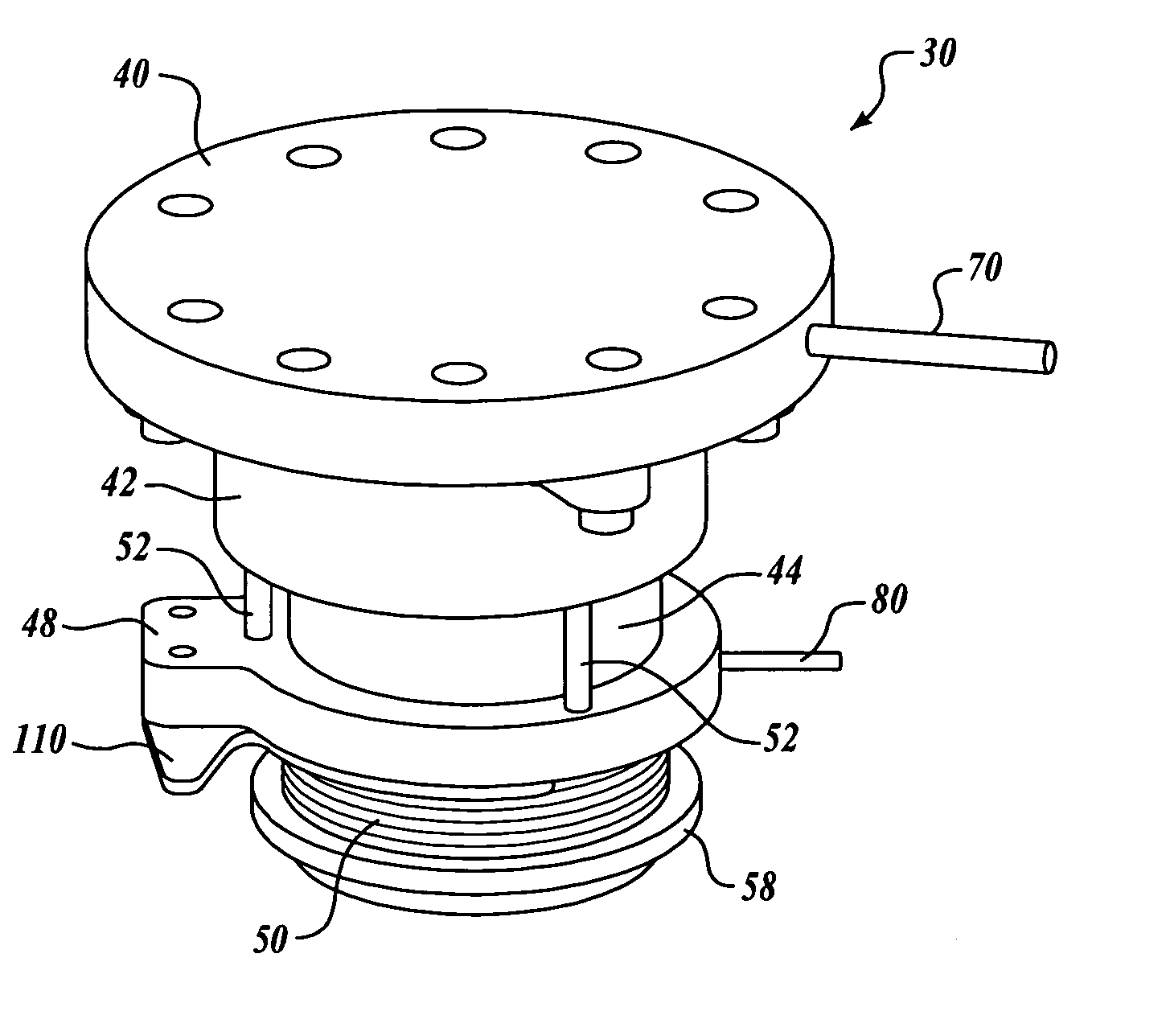

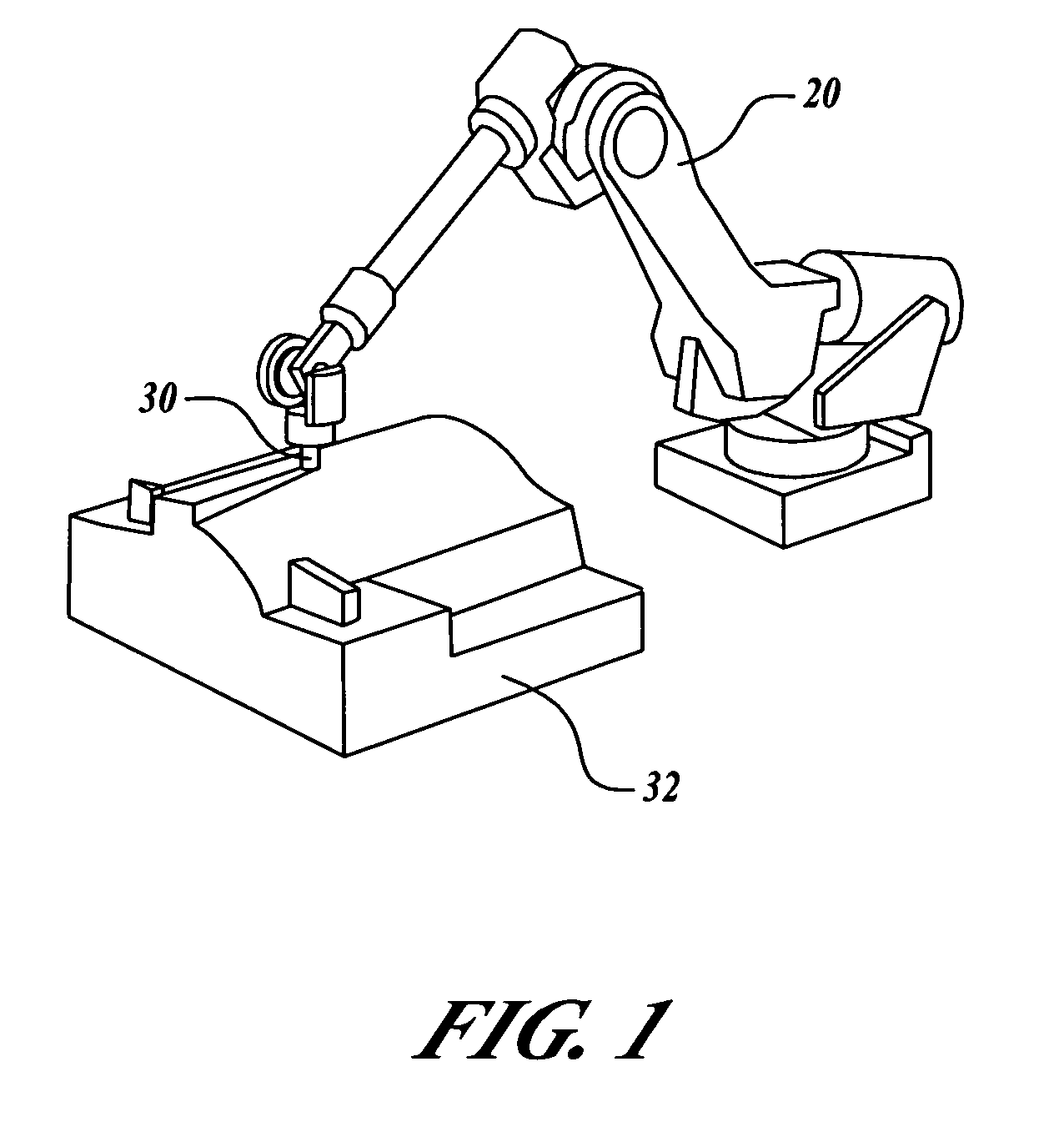

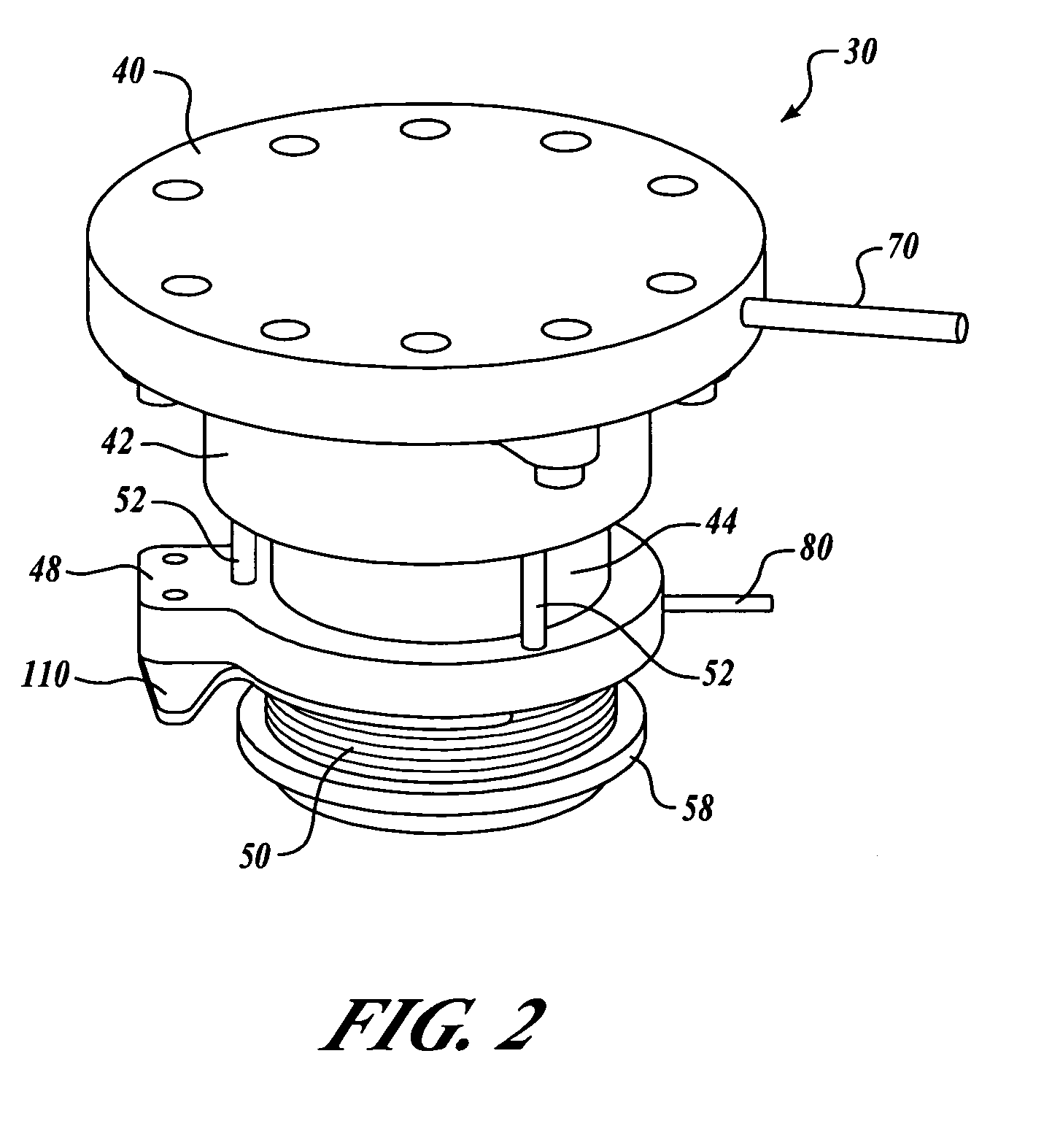

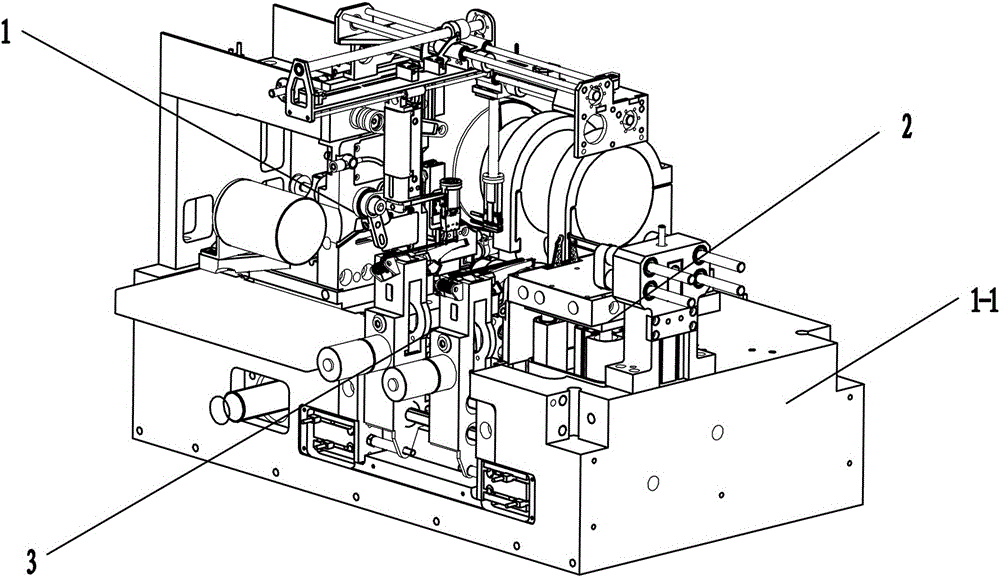

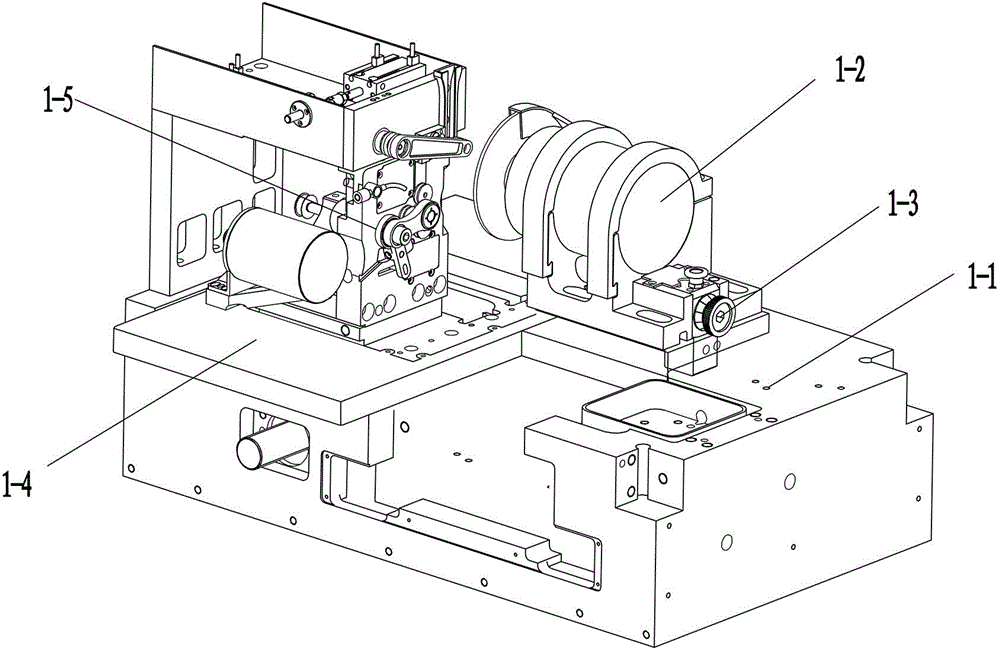

Pneumatically actuated flexible coupling end effectors for lapping/polishing

Methods and apparatus for end effectors for performing surface lapping using a robotic system are provided. In one embodiment, a lapping system includes a robotic arm and a pneumatic end effector unit. The pneumatic end effector unit includes a first base attached to the robotic arm, a second base, a lapping pad attachable to the second base, and a pneumatic piston system coupled between the first and second bases. An abrasive pad is attached to the lapping pad with a layer of pitch. The pneumatic piston system includes a piston chamber, a piston being slideably received within the piston chamber, and a component for controlling air pressure within the piston chamber. A slurry system introduces a slurry compound into one of the second base or the lapping pad.

Owner:THE BOEING CO

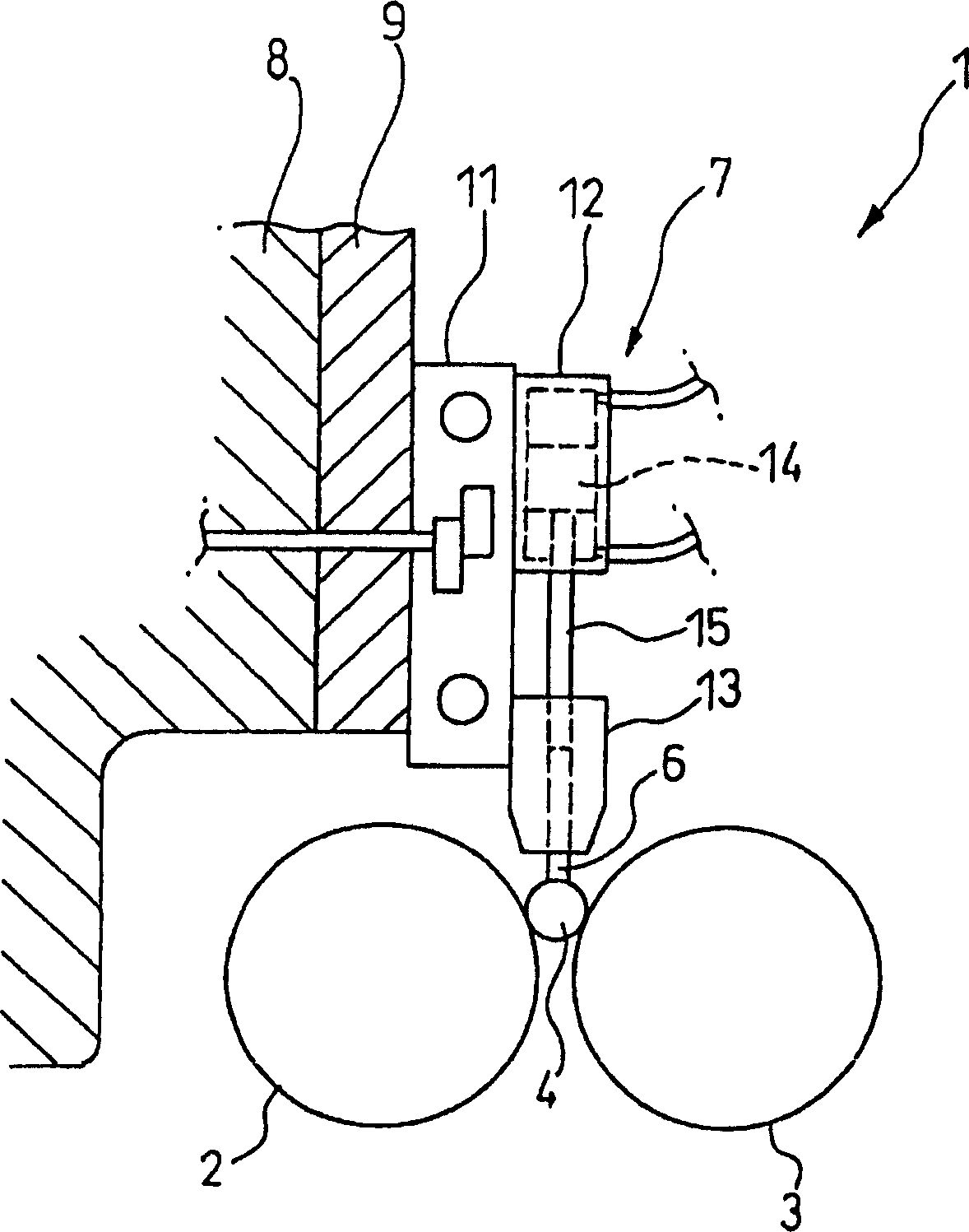

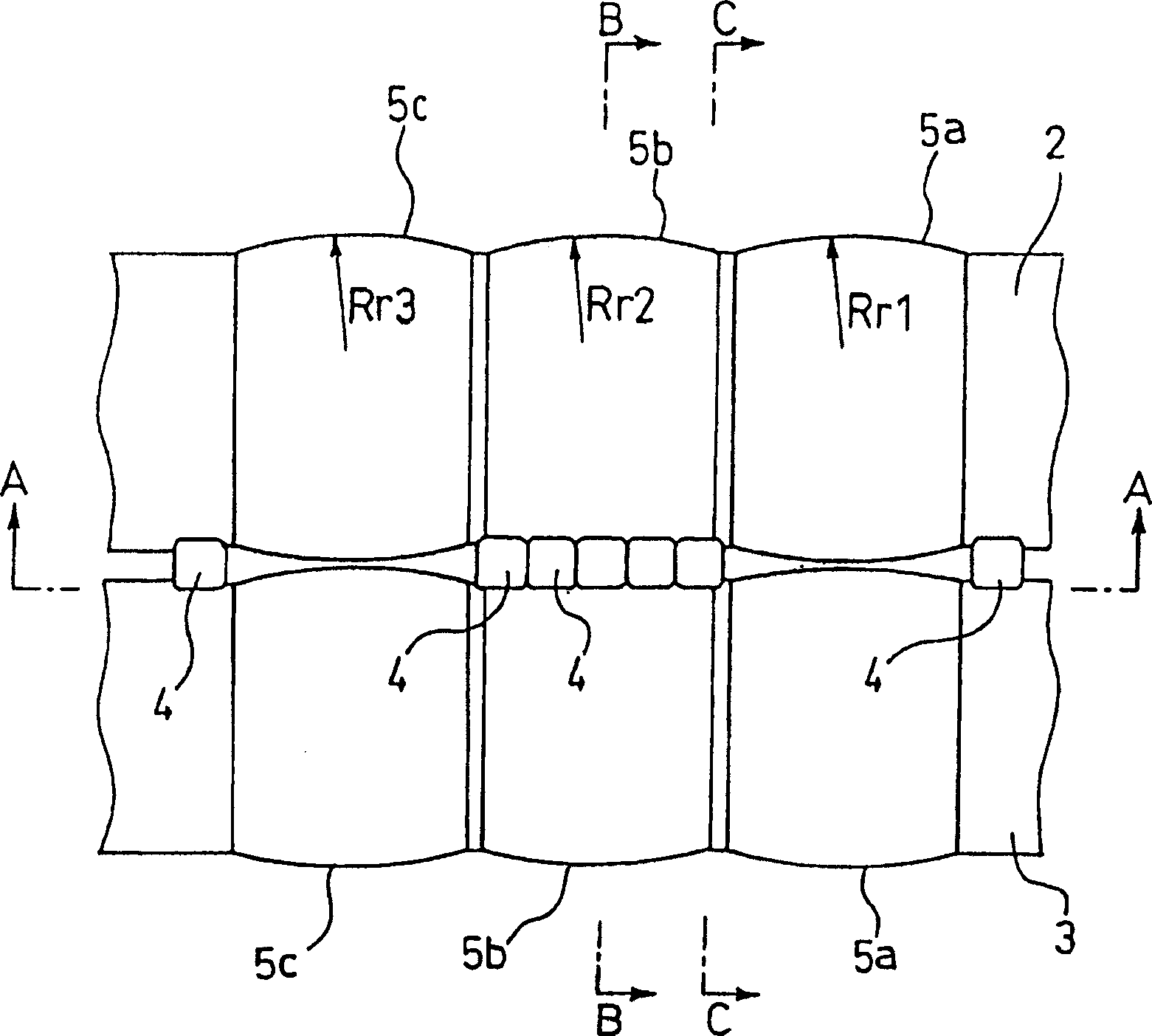

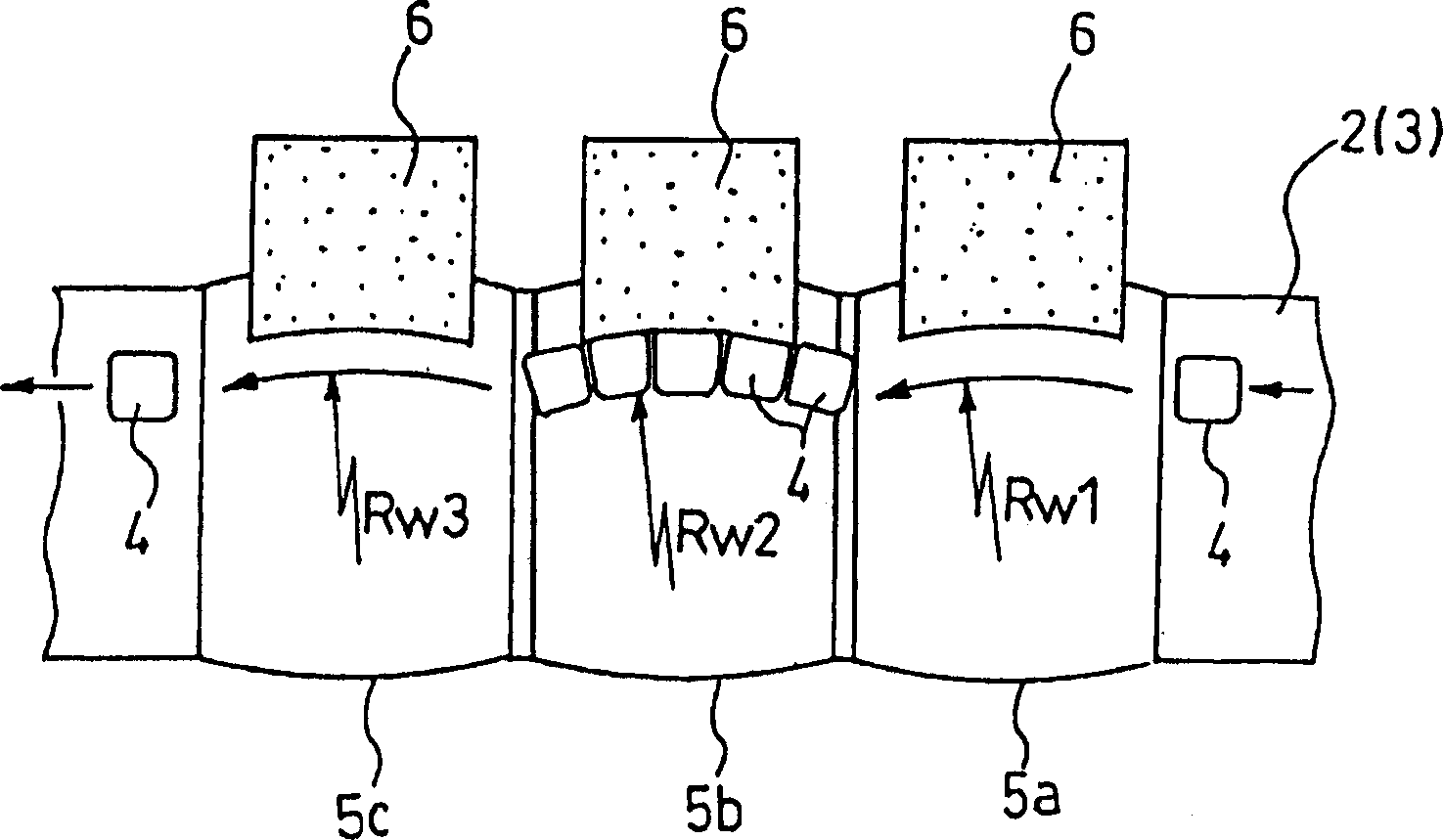

Super grinding machine, super grinding method rolling piece and rolling bearing

InactiveCN1535795ARoller bearingsRevolution surface grinding machinesEngineeringMechanical engineering

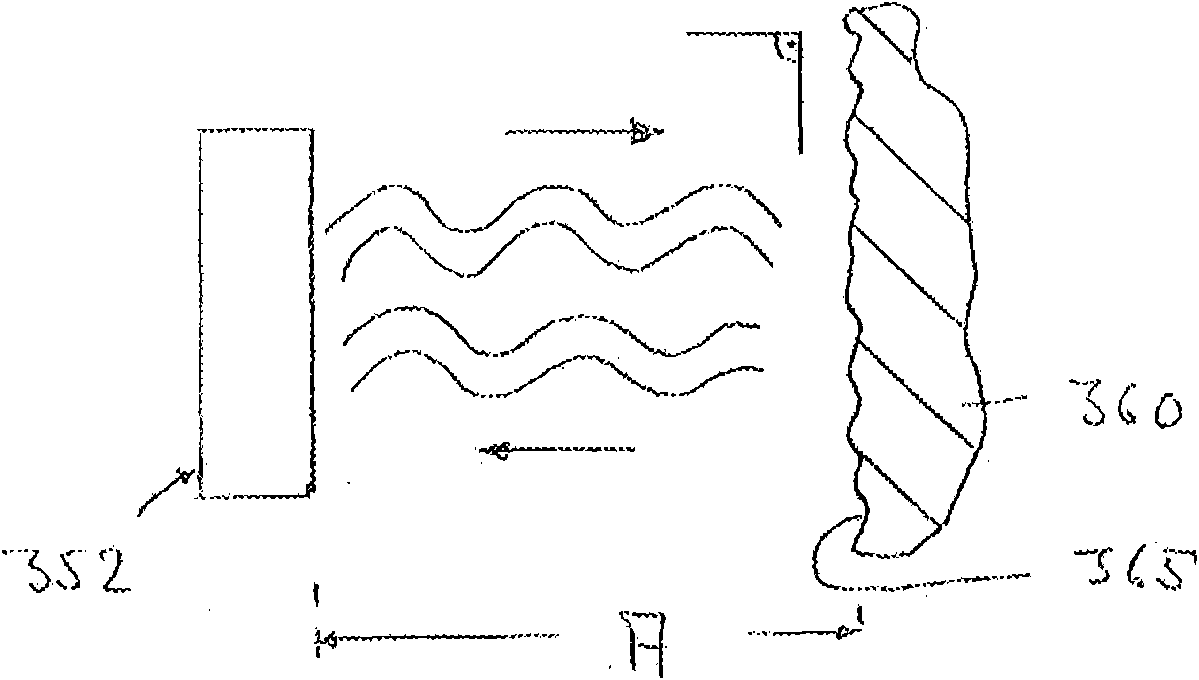

Driving rollers 2, 3 which rotate in the same direction are arranged in parallel to each other. A plurality of convex portions 5a, 5b, 5c having different radii of curvature Rr1, Rr2 and Rr3 are formed along the axial direction at opposing positions on the driving rollers 2, 3. A rolling element 4 which is fed into the gap between the driving rollers 2, 3 and rotated is moved along tracks having different radii of curvature Rw1, Rw2 and Rw3 in the axial direction. There is provided a superfinishing grindstone 6 which is pressed on the rolling surface of the rolling element 4 moving on tracks having different radii of curvature to superfinish the rolling surface of the rolling element 4.

Owner:NSK LTD

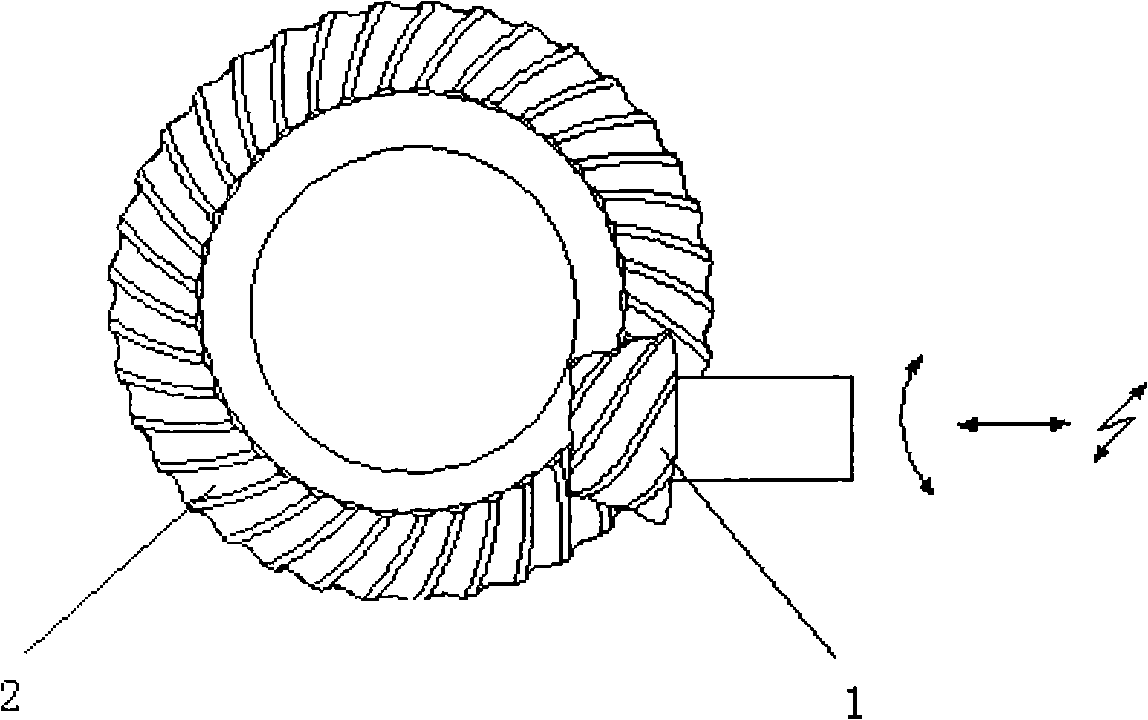

Method of grinding and processing gear wheel

InactiveCN101274379AReduce meshing vibrationImprove surface integrityOther chemical processesSuperfinishing machinesBrake torqueEngineering

Owner:HENAN UNIV OF SCI & TECH

Pressing device for cutting means and apparatus and method for finishing circumferential surfaces on cylindrical parts of a workpiece

InactiveUS8517804B2Improve surface qualityEdge grinding machinesPolishing machinesMachiningContact angle

A pressing device (50) for pressing cutting means onto circumferential surfaces (12) of substantially cylindrical workpiece portions (13) during a finishing operation is provided for pressing the cutting means onto a circumferential surface with a pressing force over a contact angle. The pressing device is steplessly adaptable for the machining of workpiece portions of differing diameters that have a diameter difference of at least 0.1 mm.

Owner:NAGEL MASCHEN UND WERKZEUGFAB

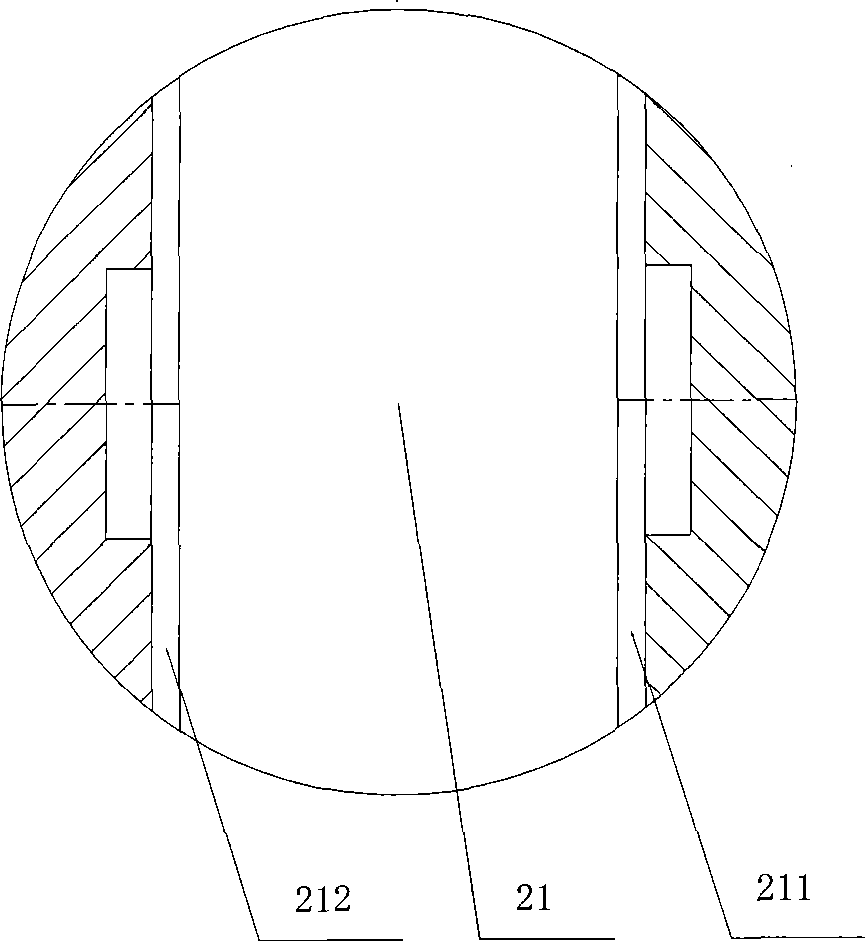

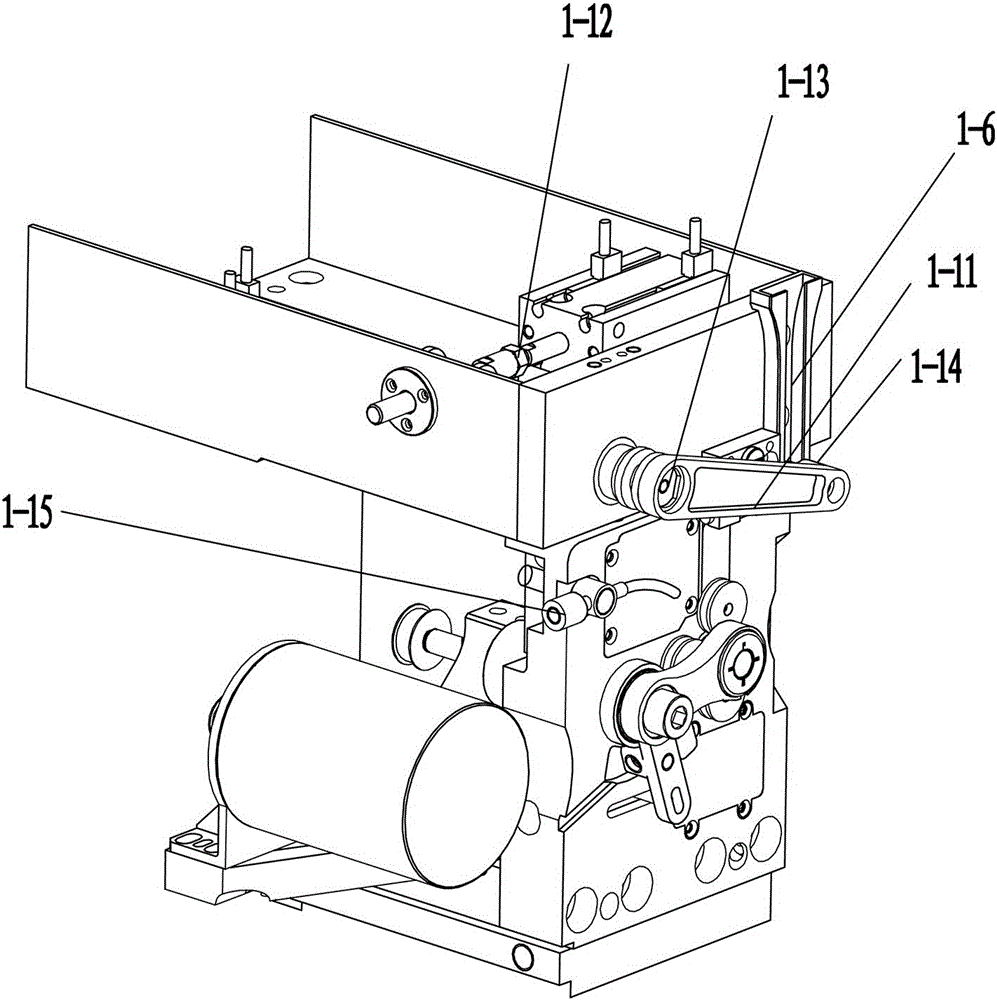

Outer-ring superfinishing machine for four-point contact bearings

InactiveCN104149018AEasy to replaceImprove machining accuracyGrinding feedersSuperfinishing machinesMachine partsSuperfinishing

Owner:WUXI LANMA MACHINERY MFR

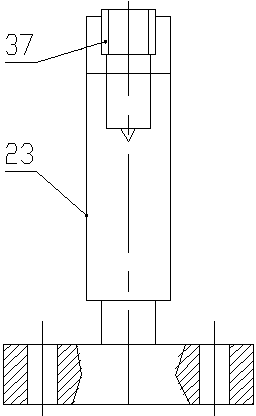

Superfine grinding oscillation mechanism

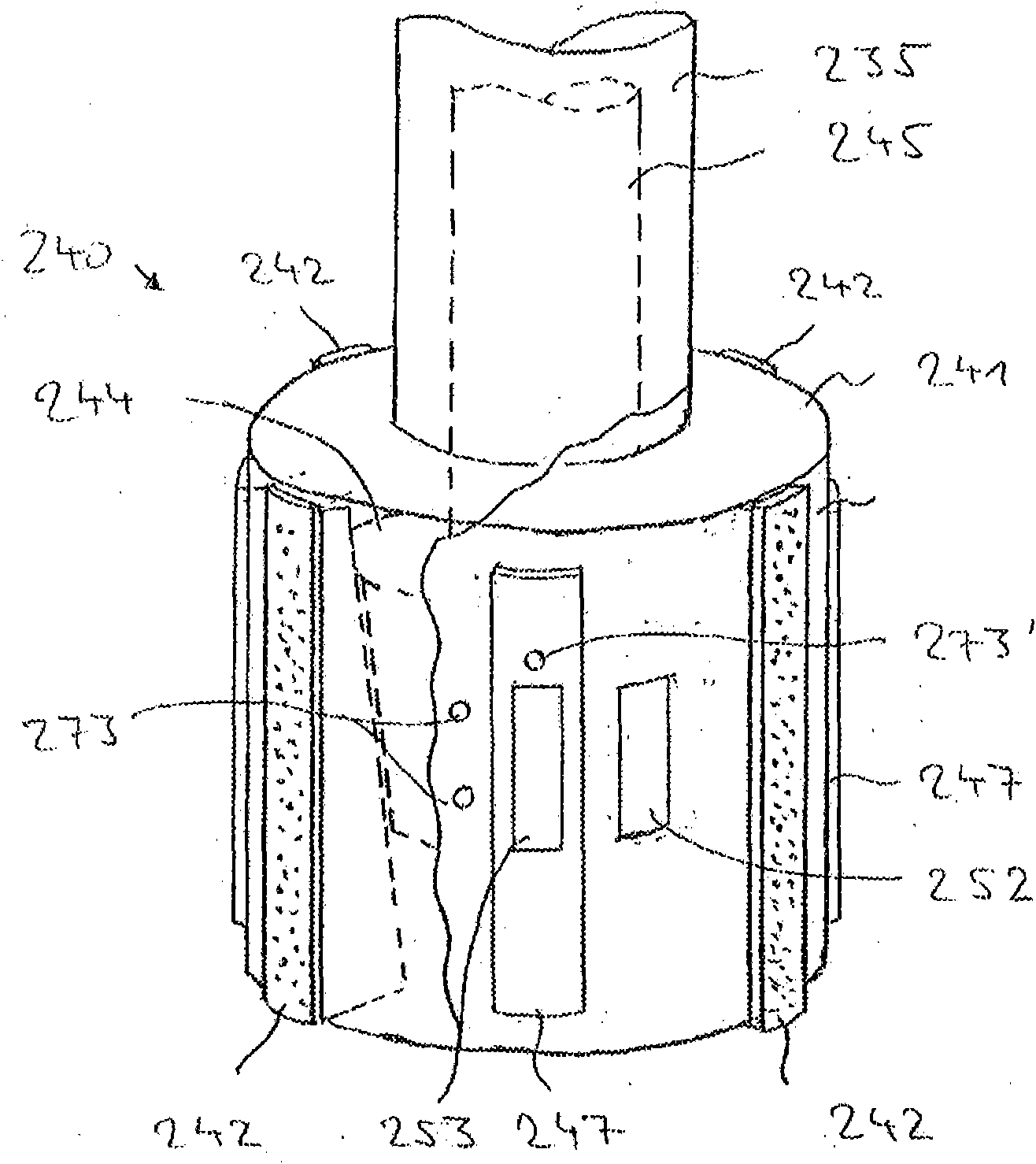

ActiveCN102328268AIncrease the oscillation frequencyReduce impactSuperfinishing machinesRotational axisDrive wheel

The invention discloses a superfine grinding oscillation mechanism which comprises an oscillation mechanism on a superfine grinding machine. Two balance wheels between left and right balance blocks are rotatably connected with a Geneva wheel together; the Geneva wheel is composed of two symmetric parts which are fixed on rotation shafts by bolts respectively; a drive wheel is mounted on the rotation shafts on the two sides of the Geneva wheel in a manner symmetrically protruding out of a shaft surface; and a transmission plate is coupled between the drive wheel and a ram. Through the invention, the oscillation frequency can be improved by more than one time, the oscillation conversion is smooth, the impact is obviously reduced, and the superfine grinding oscillation mechanism is favorable for improving the processing efficiency as well as surface accuracy and quality of products.

Owner:XINXIANG SUNRISE CNC BEARING EQUIP

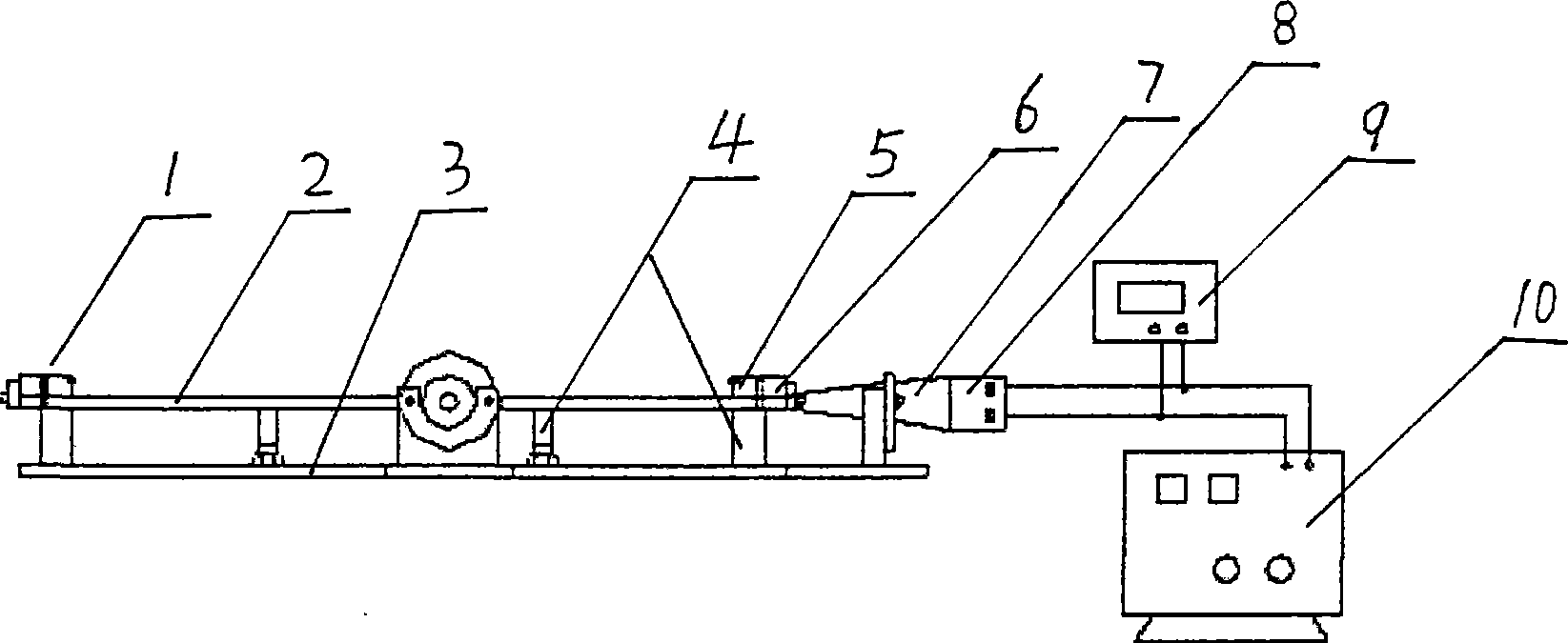

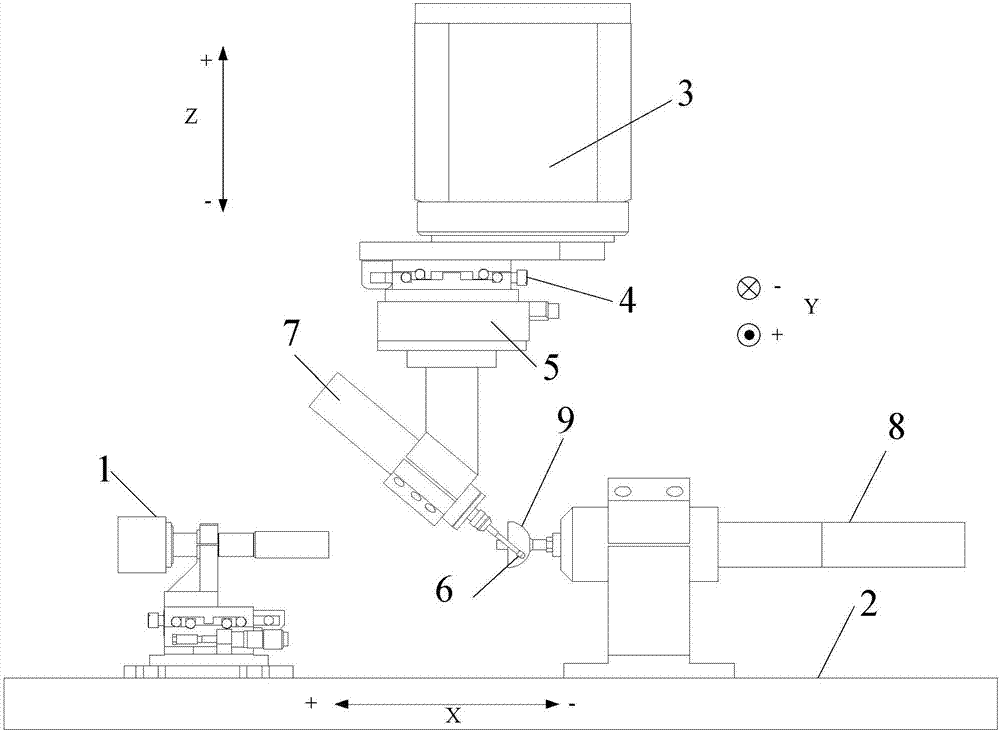

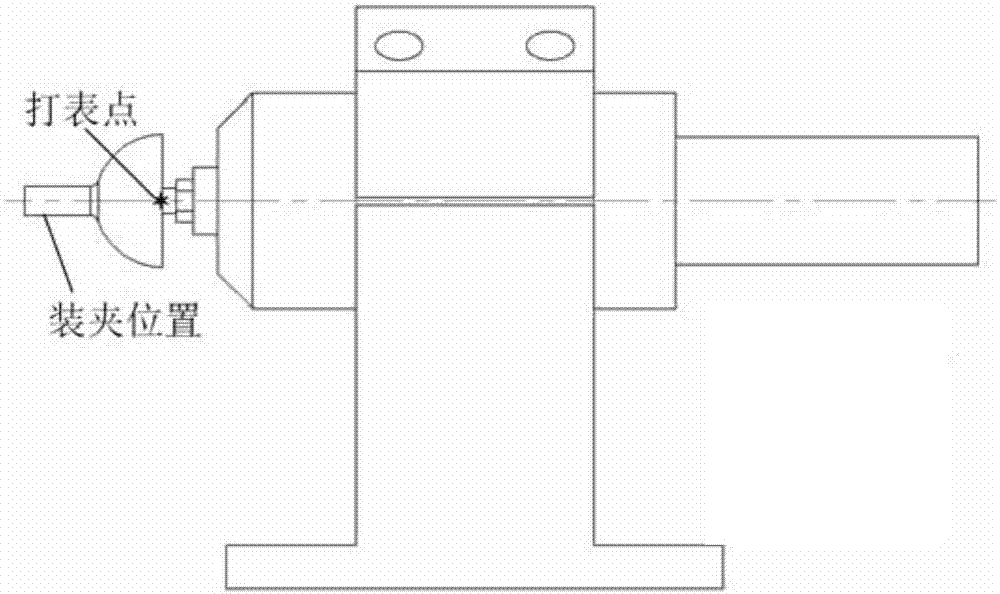

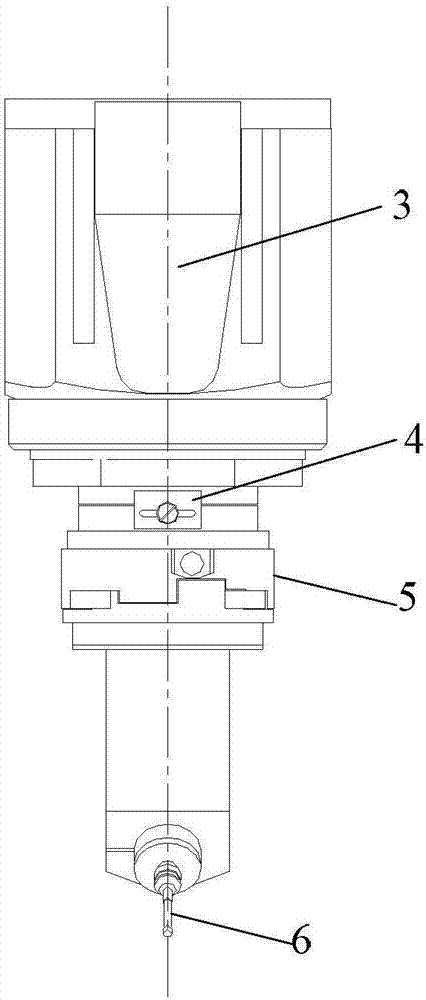

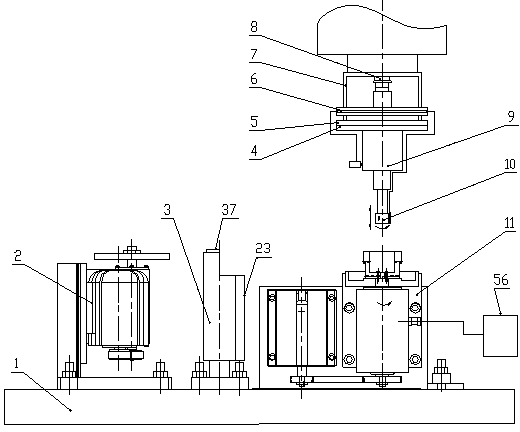

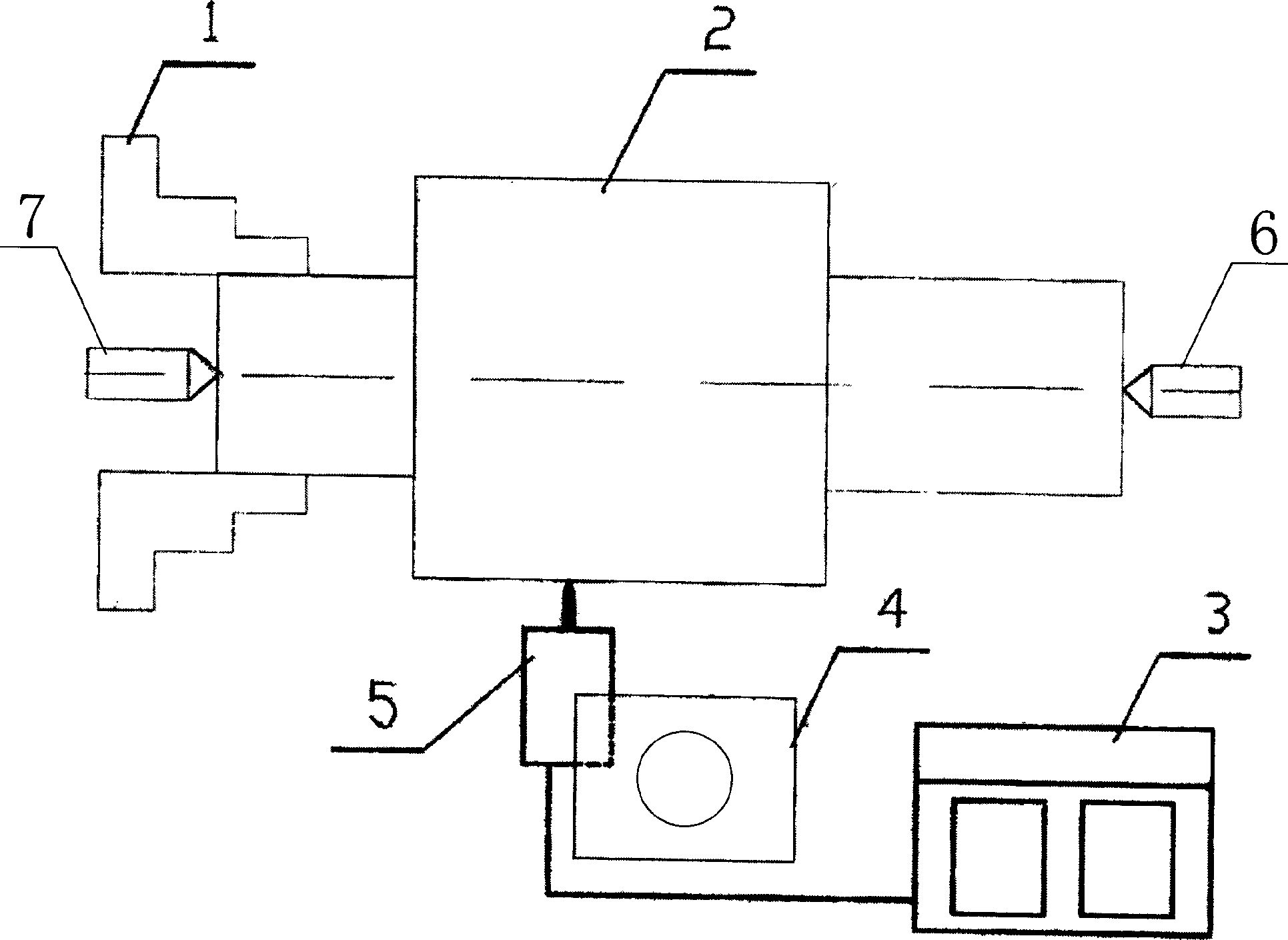

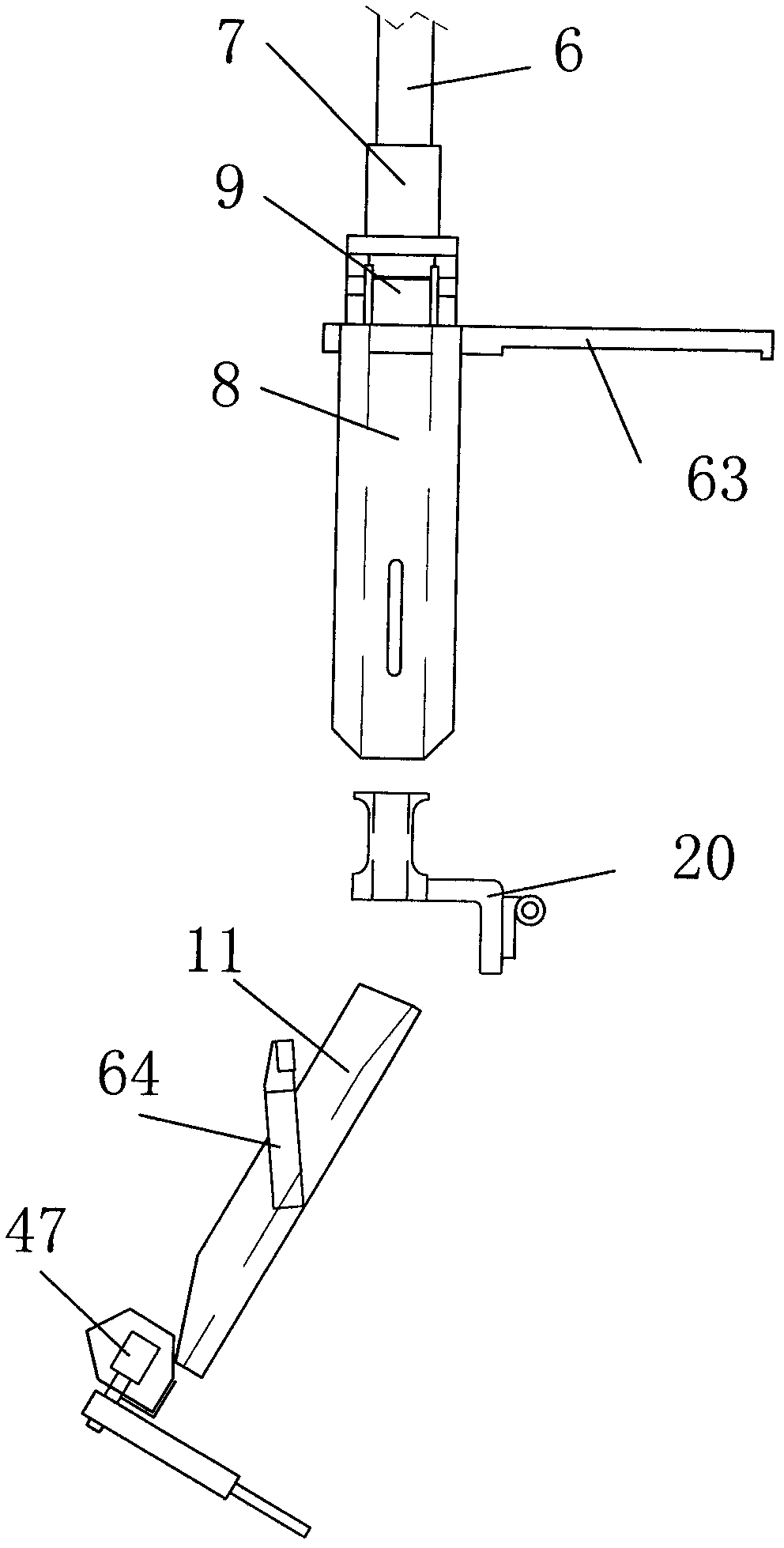

Online abrasive wheel dressing experiment system suitable for ultrasonic composite grinding of small hole inner circle

ActiveCN104191372AAbrasive surface conditioning devicesSuperfinishing machinesFixed frameEngineering

An online abrasive wheel dressing experiment system suitable for ultrasonic composite grinding of a small hole inner circle comprises a machine tool workbench, a machine tool main shaft and a precise filtering oil mist lubrication device arranged on the side face of a machine tool. The machine tool main shaft is vertically arranged above the machine tool workbench. The machine tool workbench is provided with a frequency-variable speed-adjustable abrasive wheel dressing device, an abrasive wheel electrolytic in-process dressing (ELID) rough dressing sharpening device and a workpiece clamping and rotating device. The machine tool main shaft is provided with an ultrasonic vibration cutter device. A fixing frame capable of synchronously moving up and down with the machine tool main shaft is arranged outside the machine tool main shaft, an online ELID dressing sharpening device is arranged outside the middle of the fixing frame, and an upper induction disc and a lower induction disc are arranged outside the lower portion of the fixing frame. Online abrasive wheel dressing is carried out while the ultrasonic vibration grinding is achieved, a multi-technology combined efficient mirror finishing technology is realized, the technology support is provided for the application of efficient ultra-smooth surface machining of hard and brittle materials in the high technology fields such as national defense and aerospace, and the online abrasive wheel dressing experiment system has high theoretical value and practical value.

Owner:CONPROFE TECH GRP CO LTD +1

Method and apparatus for the measurement-aided fine machining of workpiece surfaces, and measuring system

Owner:NAGEL MASCHEN UND WERKZEUGFAB

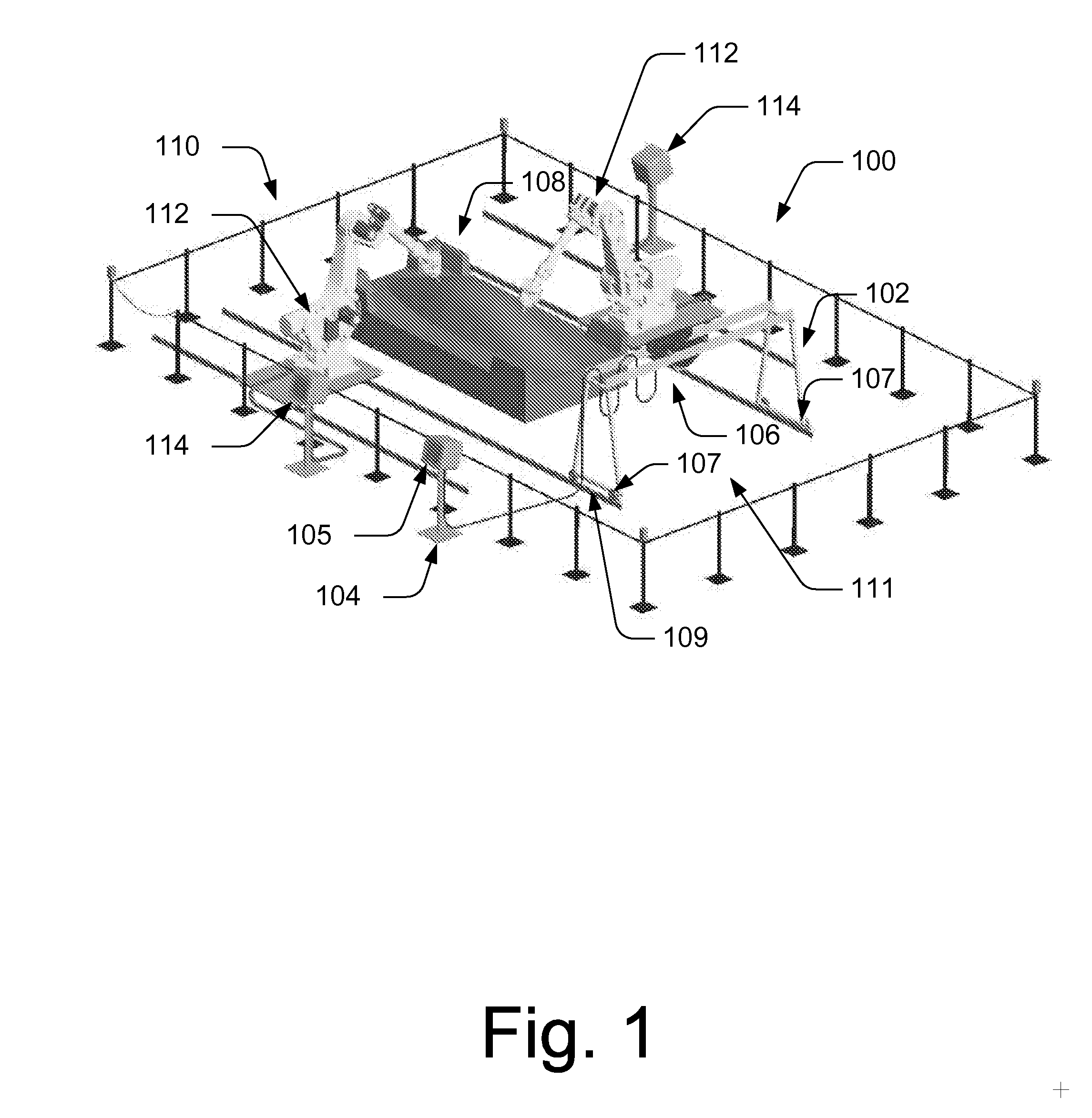

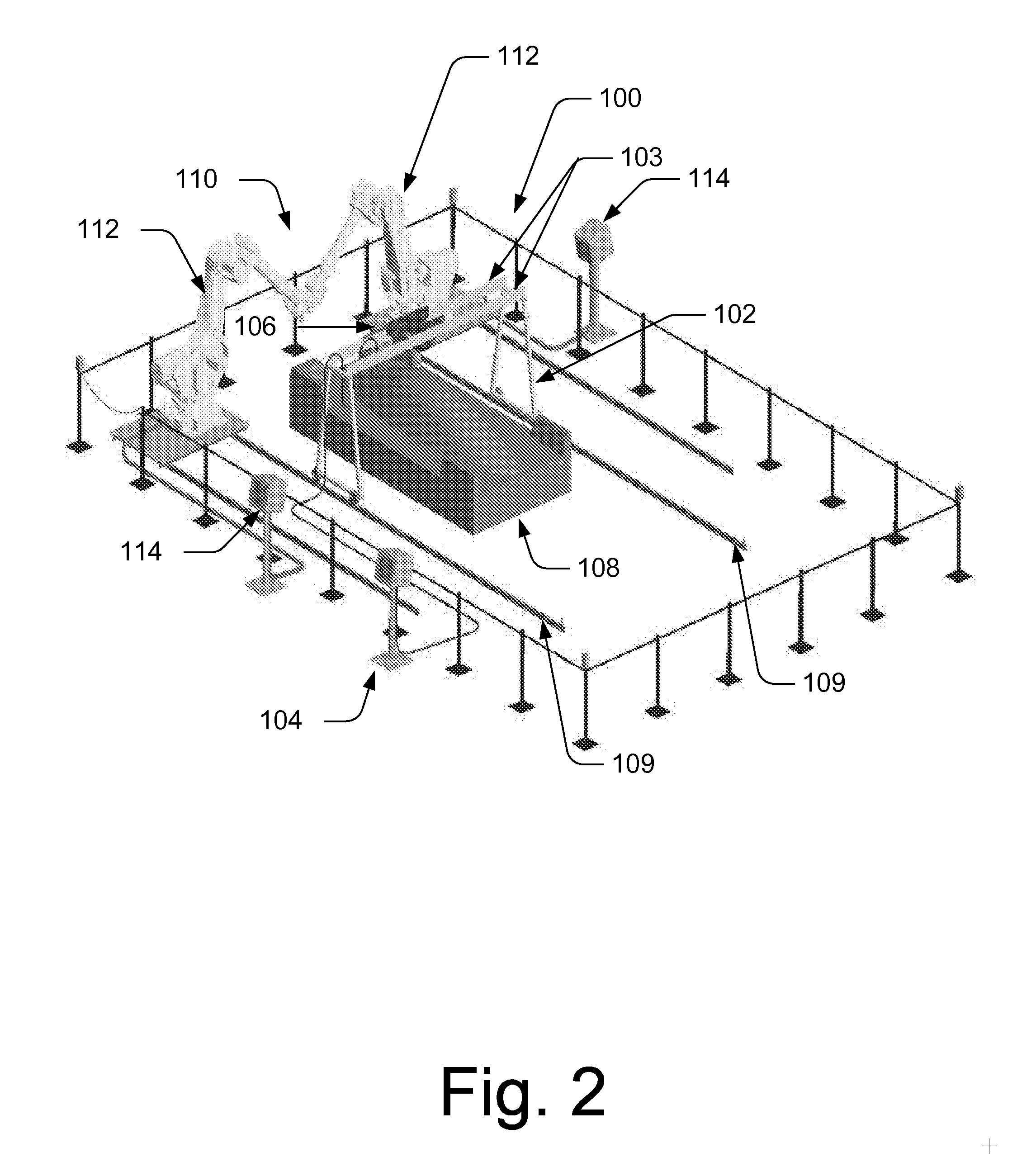

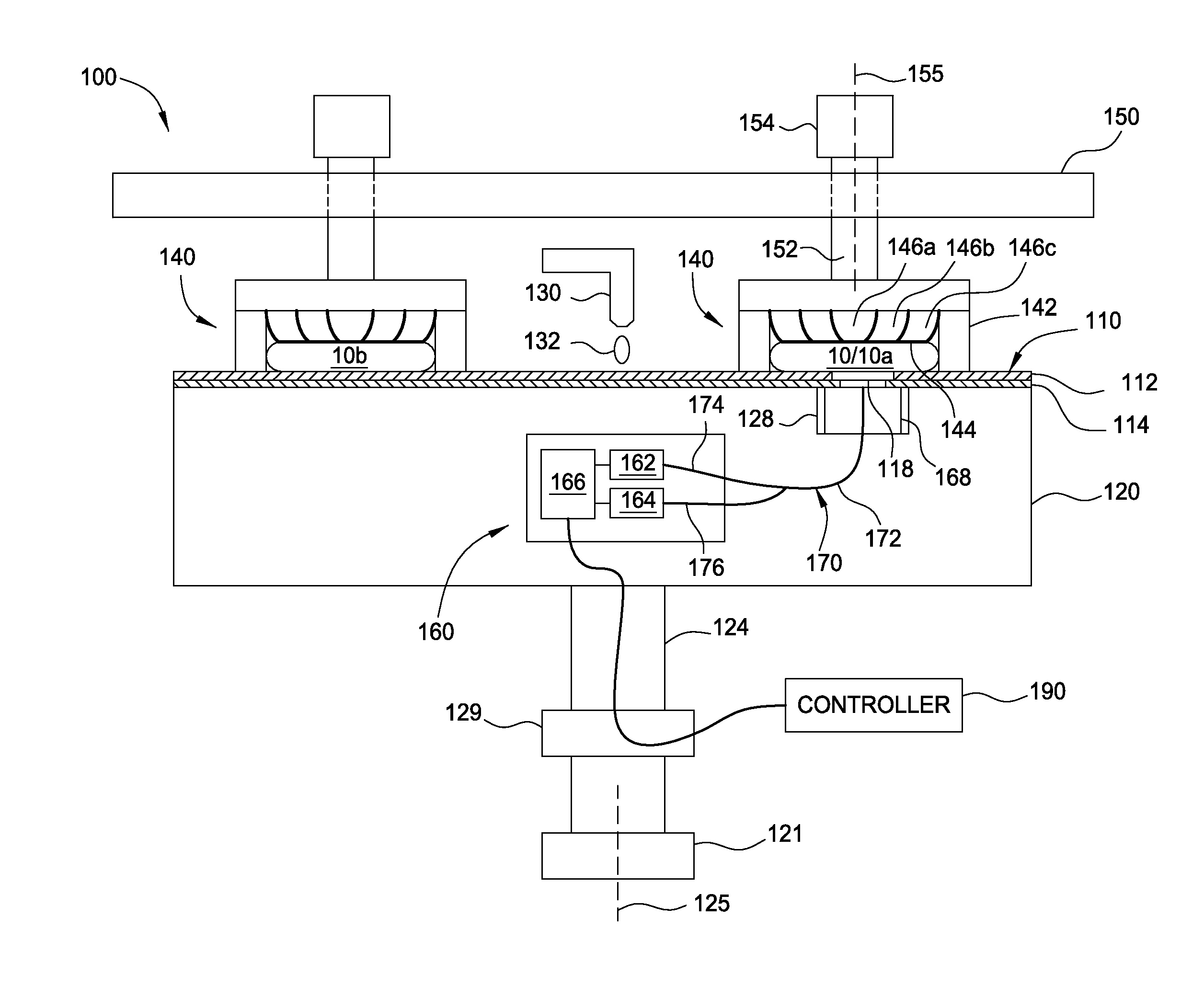

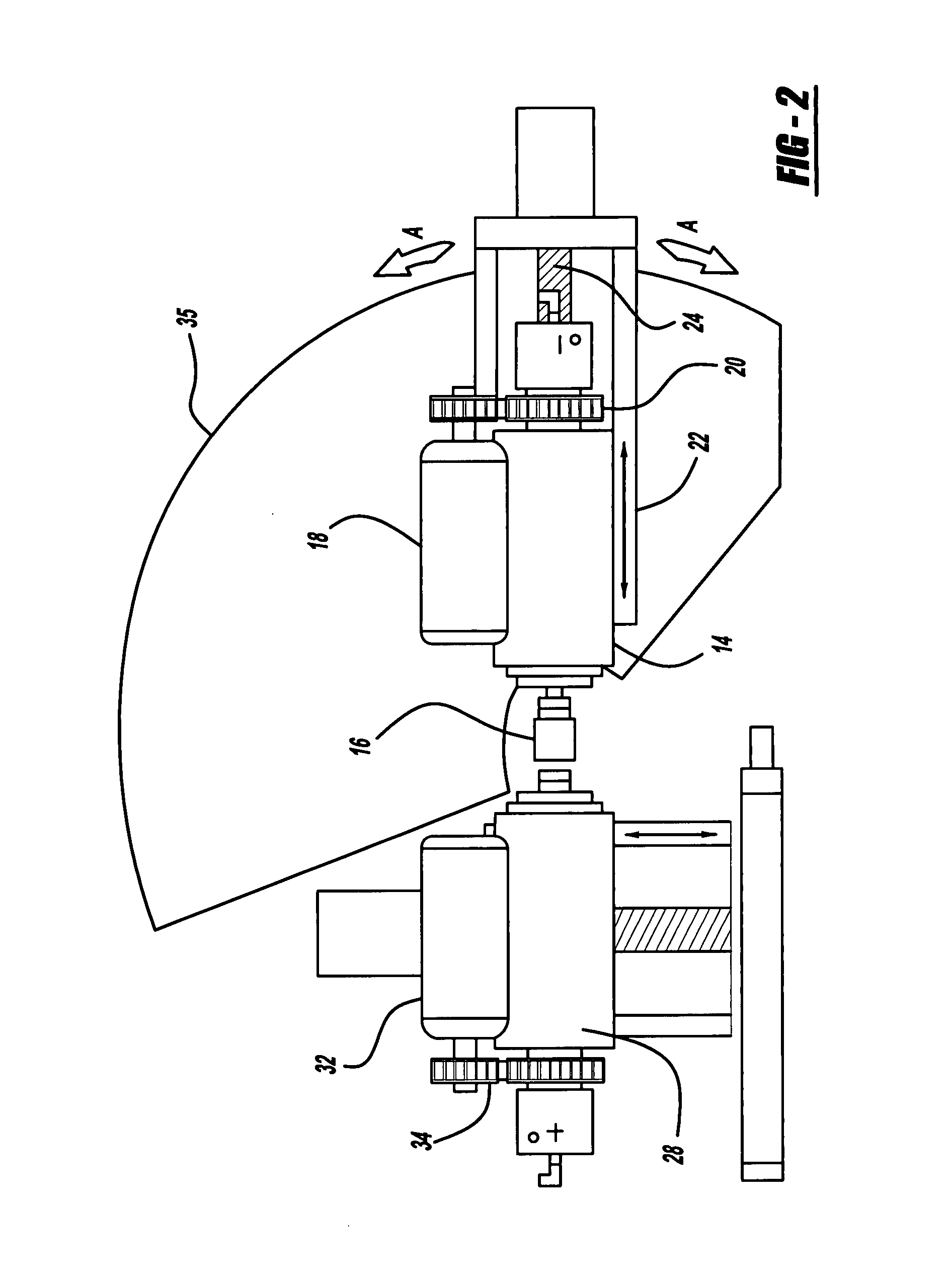

In-Process Non-Contact Measuring Systems and Methods for Automated Lapping Systems

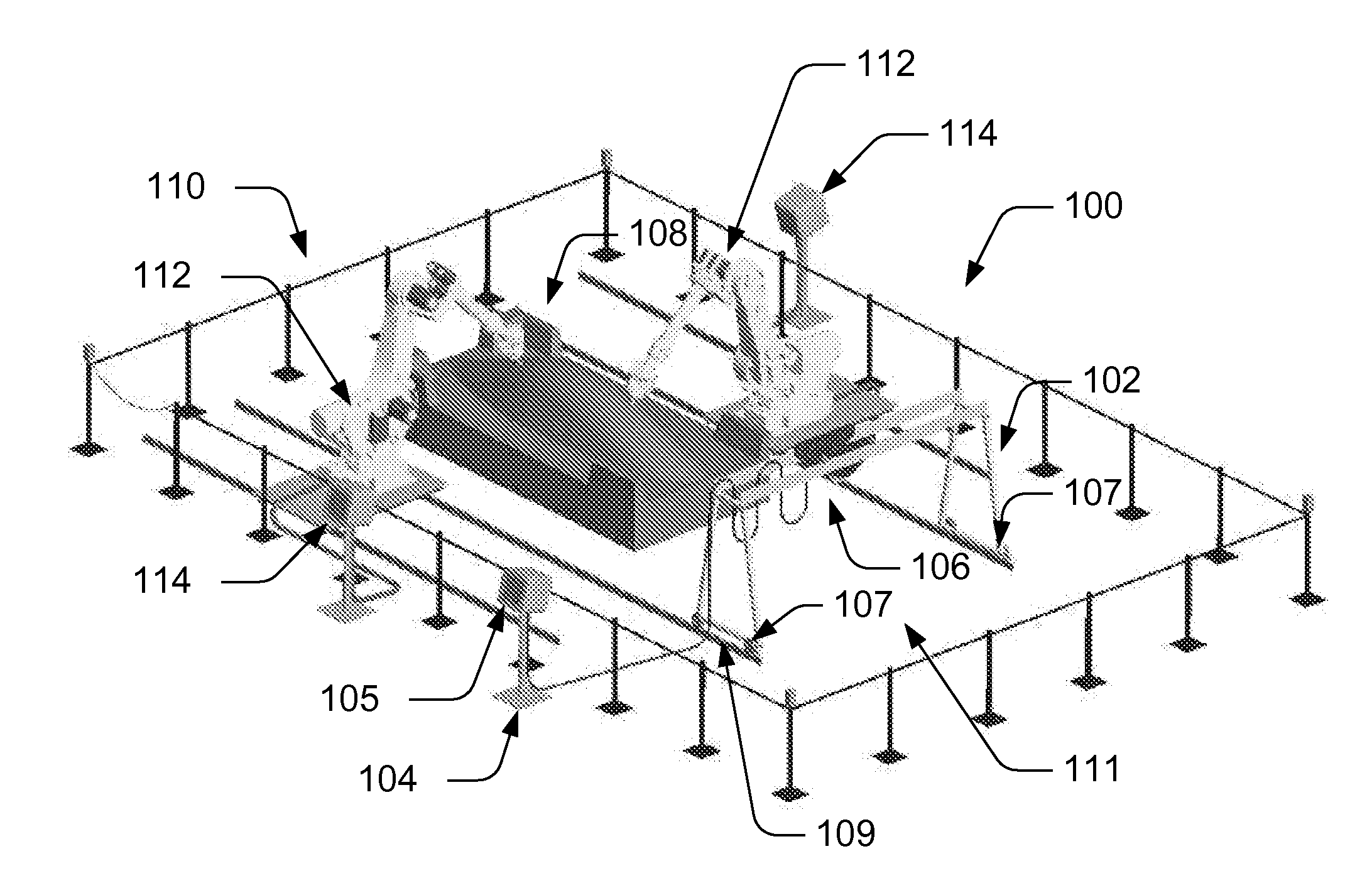

InactiveUS20080216336A1Mitigate undesirable characteristicQuality improvementComputer controlSimulator controlControl signalEngineering

In-process non-contact measurement systems and methods for automated lapping systems are disclosed. In an embodiment, a moveable frame can be controllably positioned proximate to a lapped work product. A control component can provide first control signals to control a movement of the moveable frame relative to the lapped work product. A non-contact measuring device can be coupled to the moveable frame measures a surface of the lapped work product and can transmit measurement data of the surface of the lapped work product to the control component. The control component can further provide second control signals to control a movement of the non-contact measuring device relative to the moveable frame.

Owner:THE BOEING CO

Inner ring groove grinding and ultra-fine-processing integral machine for fully automatic bearing ring

ActiveCN105751037ASimple structureImprove inner ring processing efficiencyGrinding feed controlGrinding machinesSuperfinishingEngineering

The invention discloses an inner ring groove grinding and ultra-fine-processing integral machine for a fully automatic bearing ring. The inner ring groove grinding and ultra-fine-processing integral machine comprises a machine tool, wherein a grinding device, a groove grinding detection device and an ultra-fine-processing device are arranged on the machine tool. The problem of low efficiency of the existing inner ring groove forming is solved. The grinding device, the groove grinding detection device and the ultra-fine-processing device are installed together; the inner ring processing efficiency of the bearing ring is improved; meanwhile, the processing precision stability is high. A grinding wheel trimmer is added, so that the service life of the grinding and ultra-fine-processing integral machine is higher, and the precision is higher.

Owner:NINGBO MINGRUN MACHINERY MFG

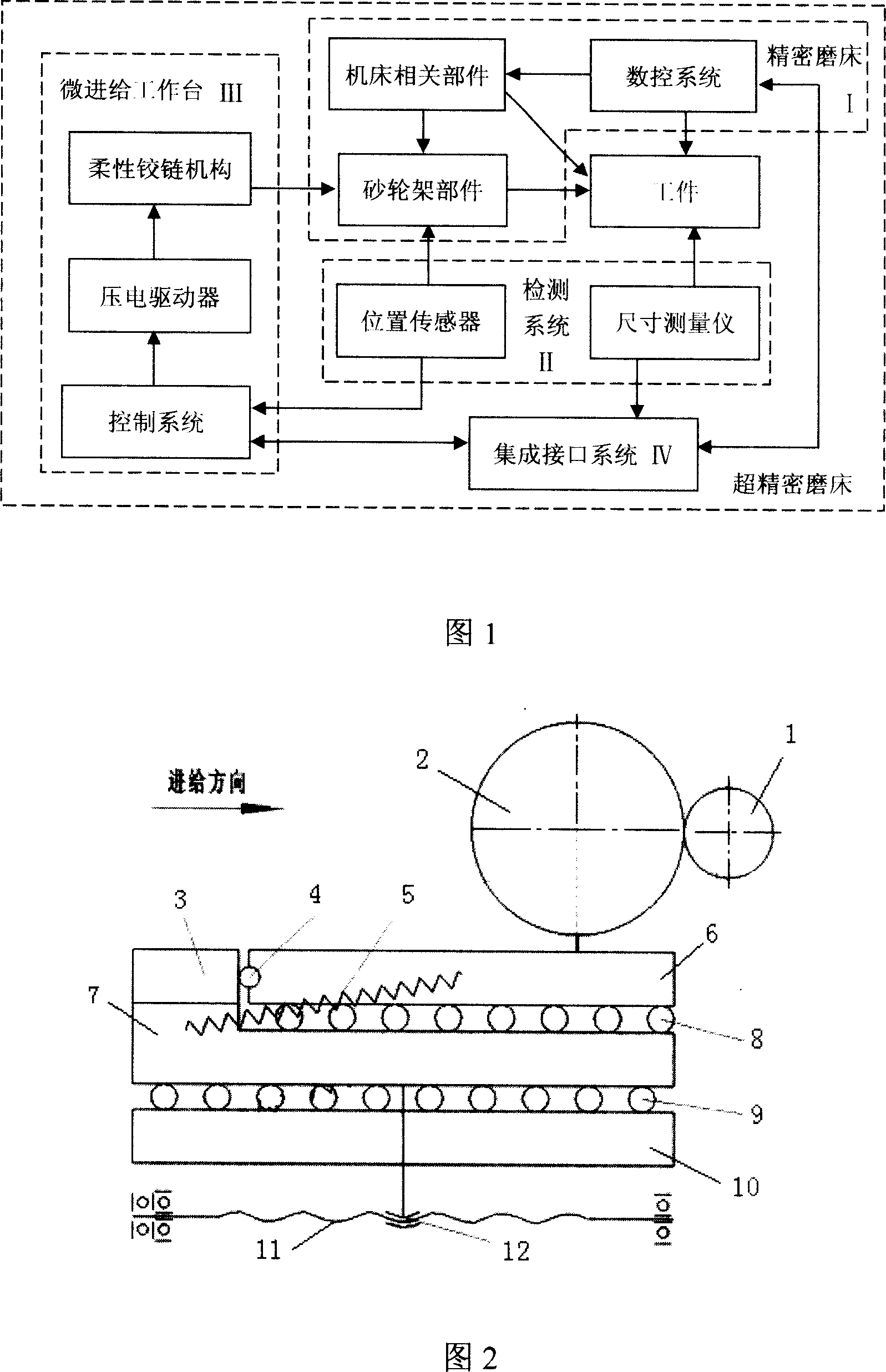

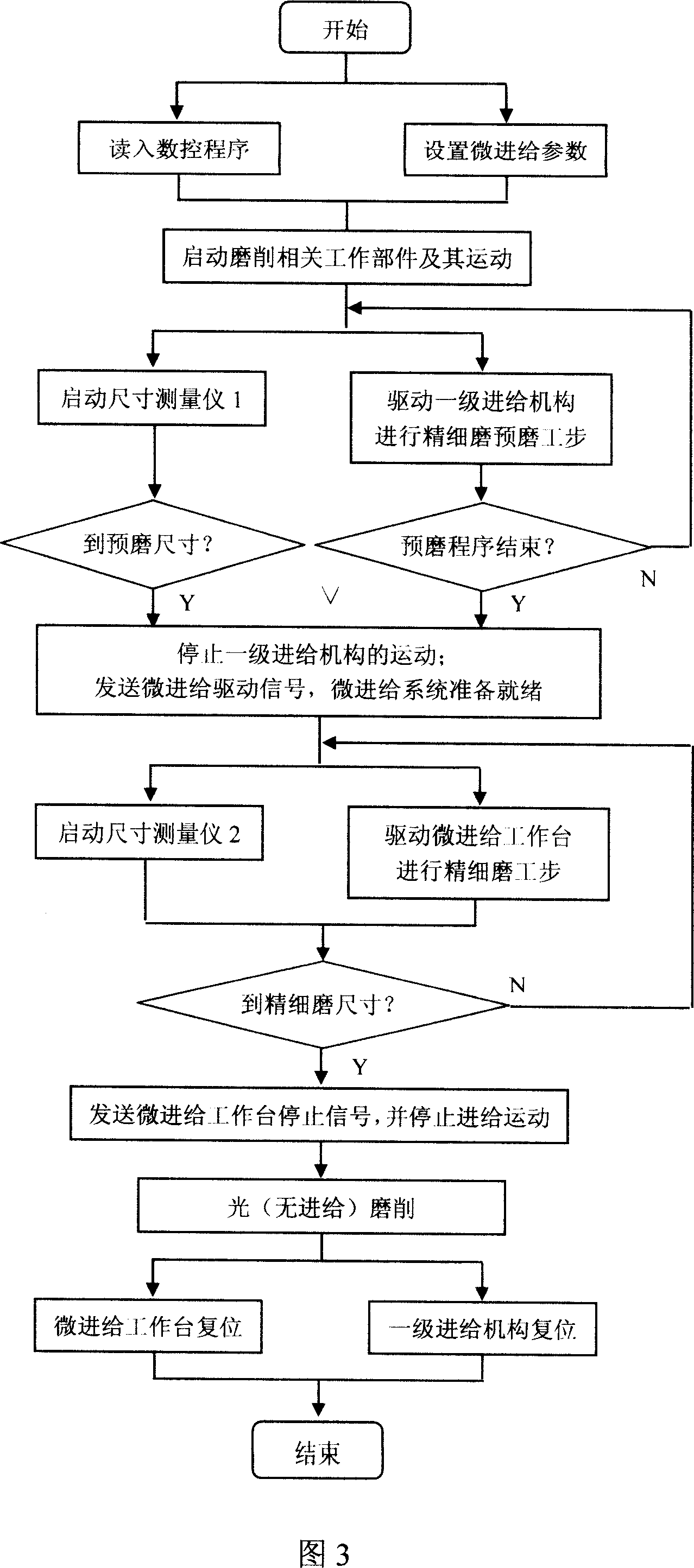

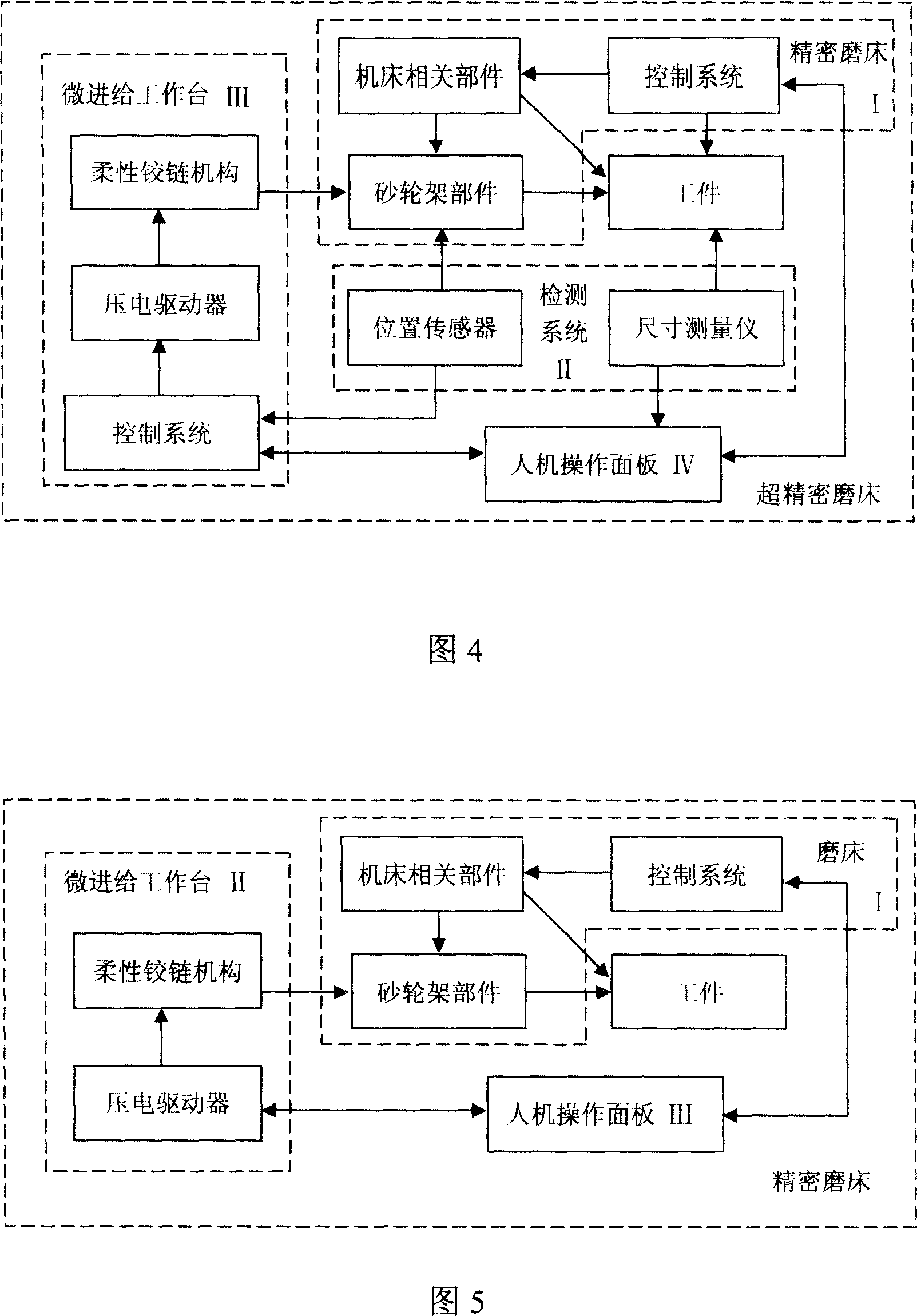

Ultraprecise grinder with two stages of feeding mechanism and its control method

InactiveCN1986156AMeet the needs of ultra-precision grindingIncreased R&D success rateGrinding drivesGrinding feed controlSize measurementControl system

The present invention relates to ultra precise numerically controlled grinder with two stages of feeding mechanism and its control method. The grinder includes an ultra precise numerically controlled grinder; a micro feeding bench comprising a piezoelectric driver, a flexible hinge mechanism and a control system; a detection system comprising a position sensor and a size measurer; and an integrated interface system for transmitting the pulse signals to realize the integrated control of the grinder. The grinder has numerically controlling system, and increased micro feeding bench control system, monitoring system and integrated interface system. The present invention is for completing the coarse, semi-precise and precise grinding of high precision parts of optical glass, ceramic and other hard and fragile material.

Owner:DONGHUA UNIV +1

Cam micro-finishing tool

InactiveUS6309287B2Inhibit wearEasy to replaceRevolution surface grinding machinesBelt grinding machinesMechanical engineeringEngineering

Owner:FORD GLOBAL TECH LLC

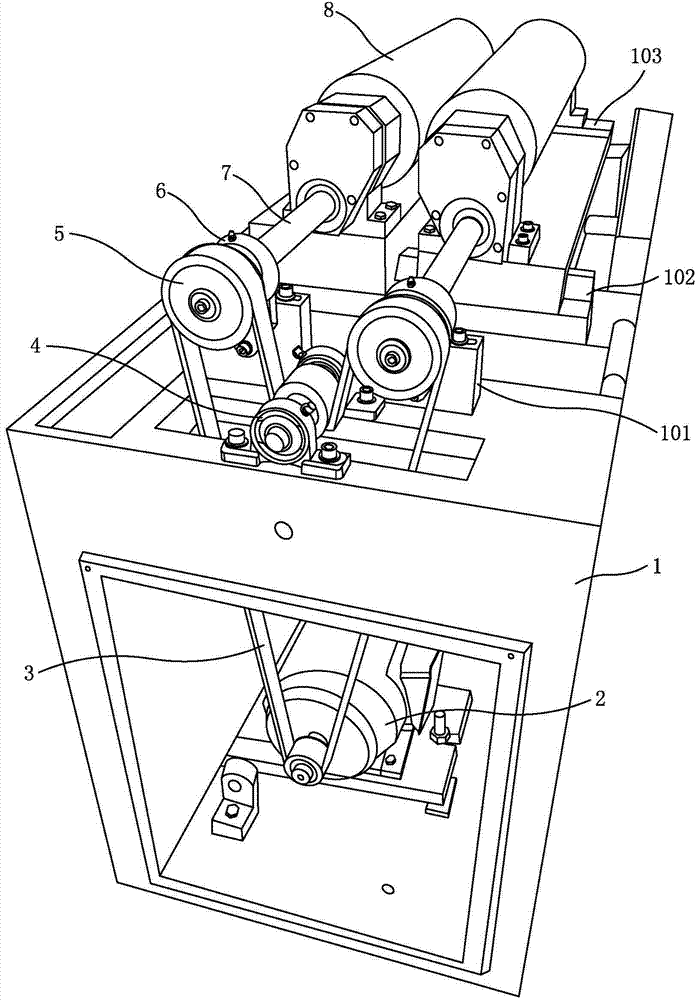

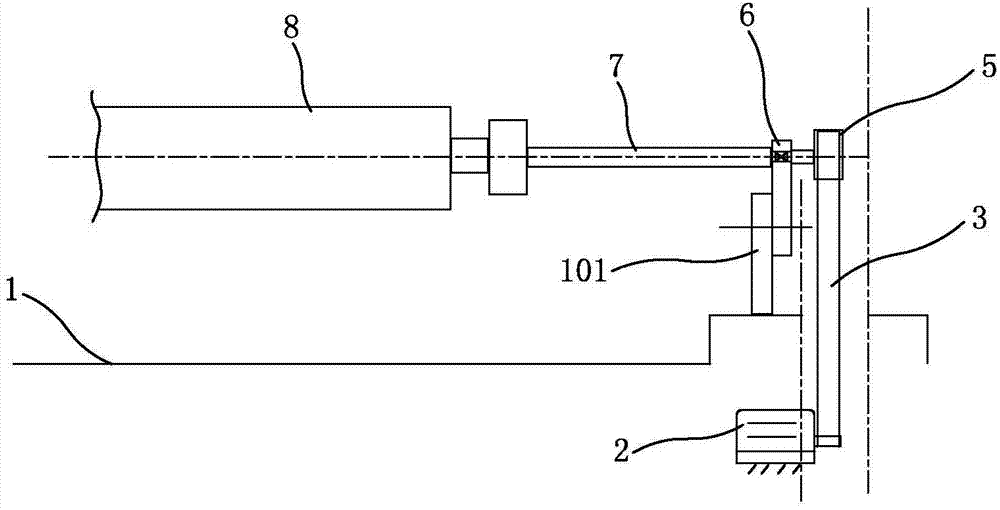

Bearing ring super lapping machine and using method thereof

ActiveCN104742004AReasonable structural designEasy to useGrinding drivesSuperfinishing machinesDrive shaftEngineering

The invention relates to a bearing ring super lapping machine and a using method thereof. The bearing ring super lapping machine and the using method thereof are designed aiming at the technical problems that the service life is comparatively short, the precision is not good, and the production cost is high of an existing like product. An electromotor and rolling shafts are arranged on a rack of the super lapping machine, the electromotor is arranged on an electromotor seat board below a rack workbench, and a ring is arranged between the symmetrically-arranged rolling shafts. The super lapping machine is characterized in that one ends of the rolling shafts are connected with an adaptor composed of a transmission shaft, a bearing component and a belt pulley, the belt pulley comprises a first belt pulley and a second belt pulley, a pinch wheel is arranged between the belt pulleys, and the belt pulleys sequentially winds a V-shaped transmission mechanism composed of the electromotor, the first belt pulley, the pressing wheel and the second belt pulley; the ends of the rolling shafts are connected with an adaptor composed of a cardan joint and a gearbox. The design of the structure of the super lapping machine is reasonable, operation and use are convenient, the using method is practicable and simple, the precision of lapping machining is high, the stability is good, and the super lapping machine is applied to the supper lapping machining of the outer diameter of the bearing ring.

Owner:NINGBO DAER MACHINERY TECH CO LTD

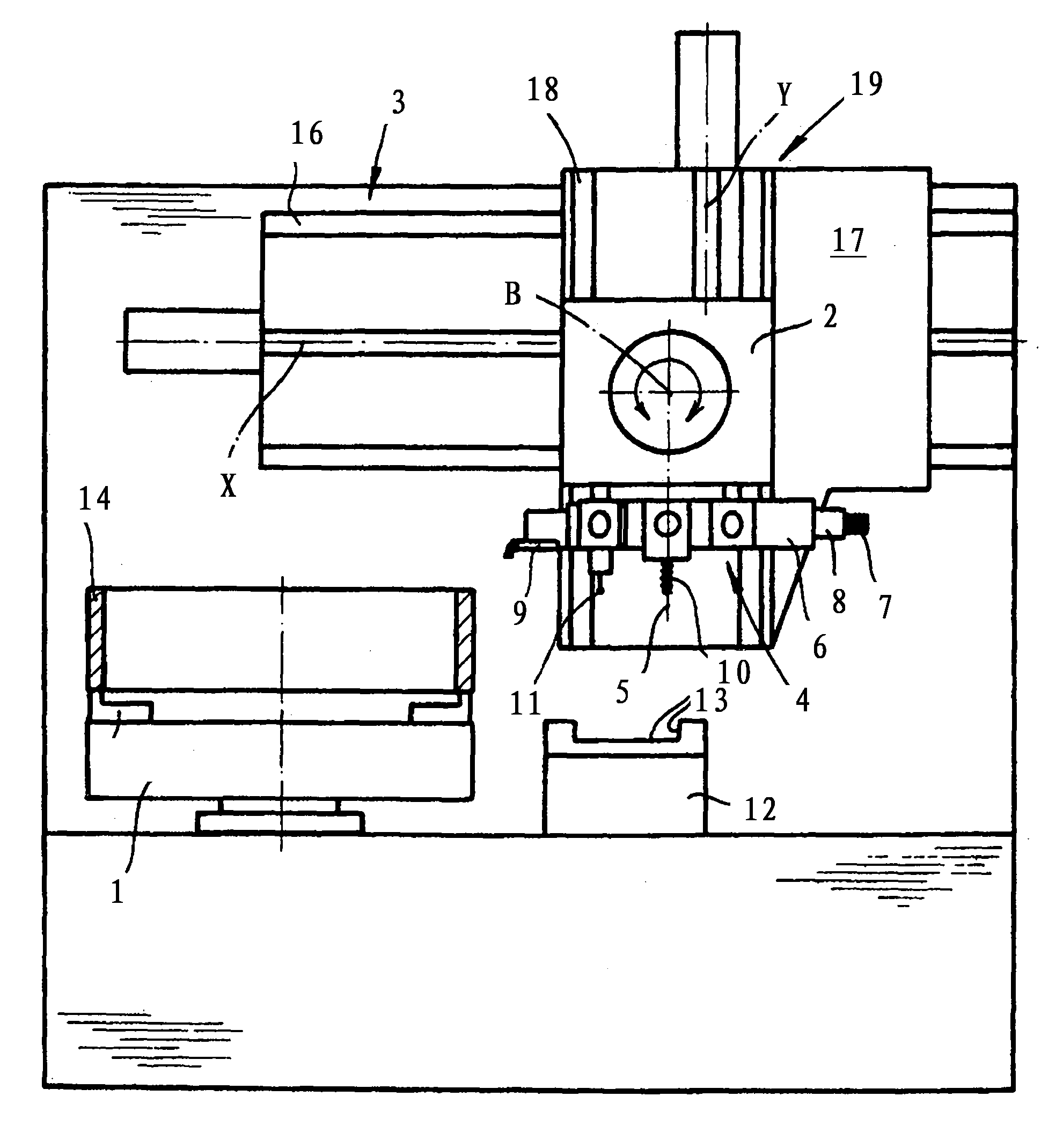

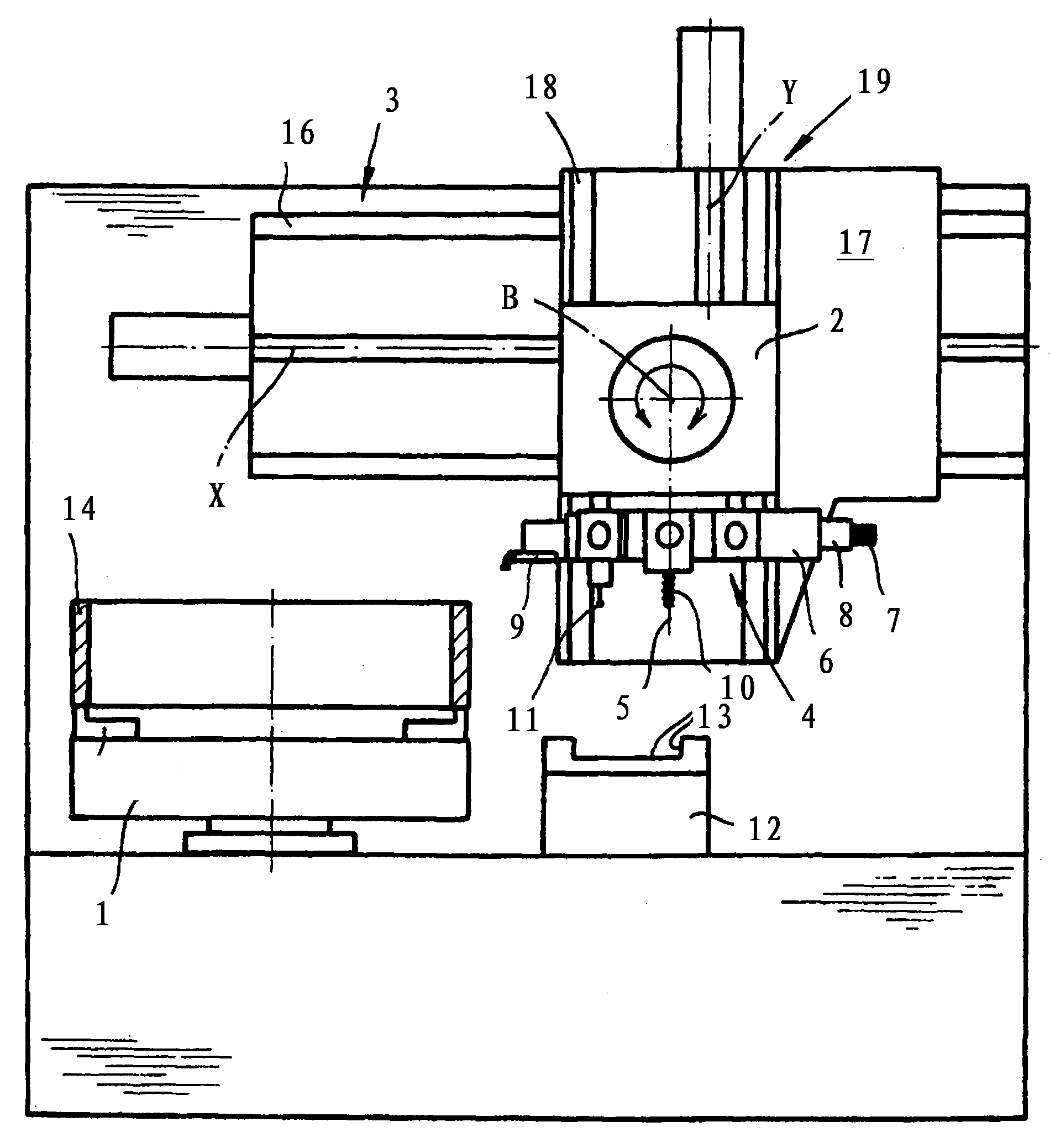

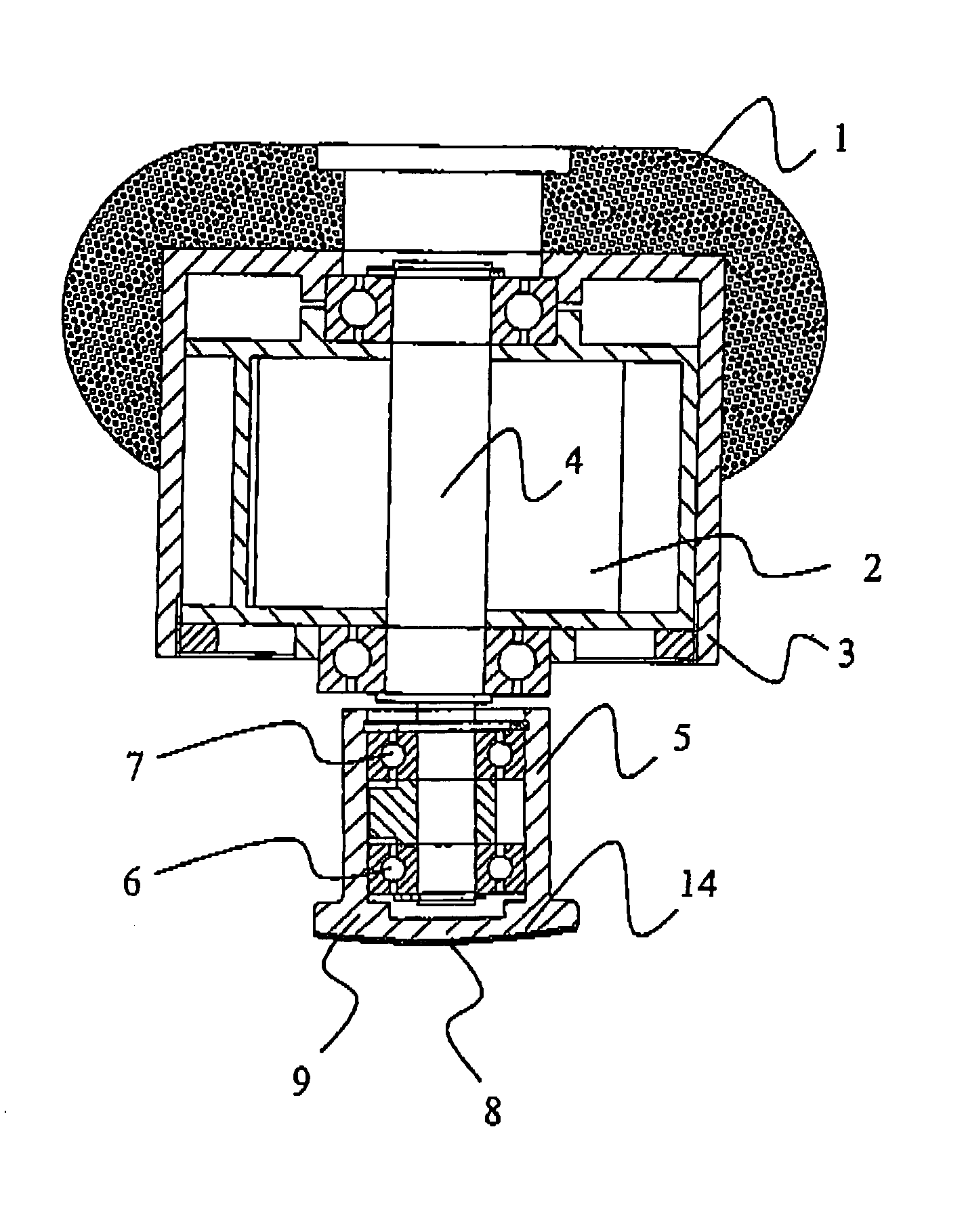

Device for performing fine machining on annular workpiece

InactiveCN102009346ASmall fluctuationHigh shape accuracyOther manufacturing equipments/toolsGrinding machinesHorizontal axisEngineering

The present invention relates to a device for performing fine machining on an annular workpiece, which comprises the following components: a workpiece bracket (1) which drives rotatably; a double-axis base machine tool (3) which comprises a rotating unit (2), wherein the base machine tool allows linear feeding movement of the rotating unit along a horizontal axis (X) and a vertical axis (Y); and a cutter tower (4) which is connected with the rotating unit and comprises a rotation axis (5) and a plurality of cutter carriers that are circumferentially arranged in the rotation axis. The rotating unit comprises a rotation axis (B) which is vertical to the two linear axes. The rotation axis of the cutter tower is aligned to vertical with the rotation axis of the rotating unit so that the cutter tower performs rotation movement in the rotation axis in a period when the rotating unit is activated. At least one cutter carrier of the cutter tower comprises a device (6) which is used for short-stroke honing and comprises an oscillation driving member that generates the oscillation movement of a honing millstone carrier (8). At least one another cutter carrier of the cutter tower is equipped for receiving a material cutter such as a hard turning tool (9).

Owner:ERNST THIELENHAUS GMBH & CO KG

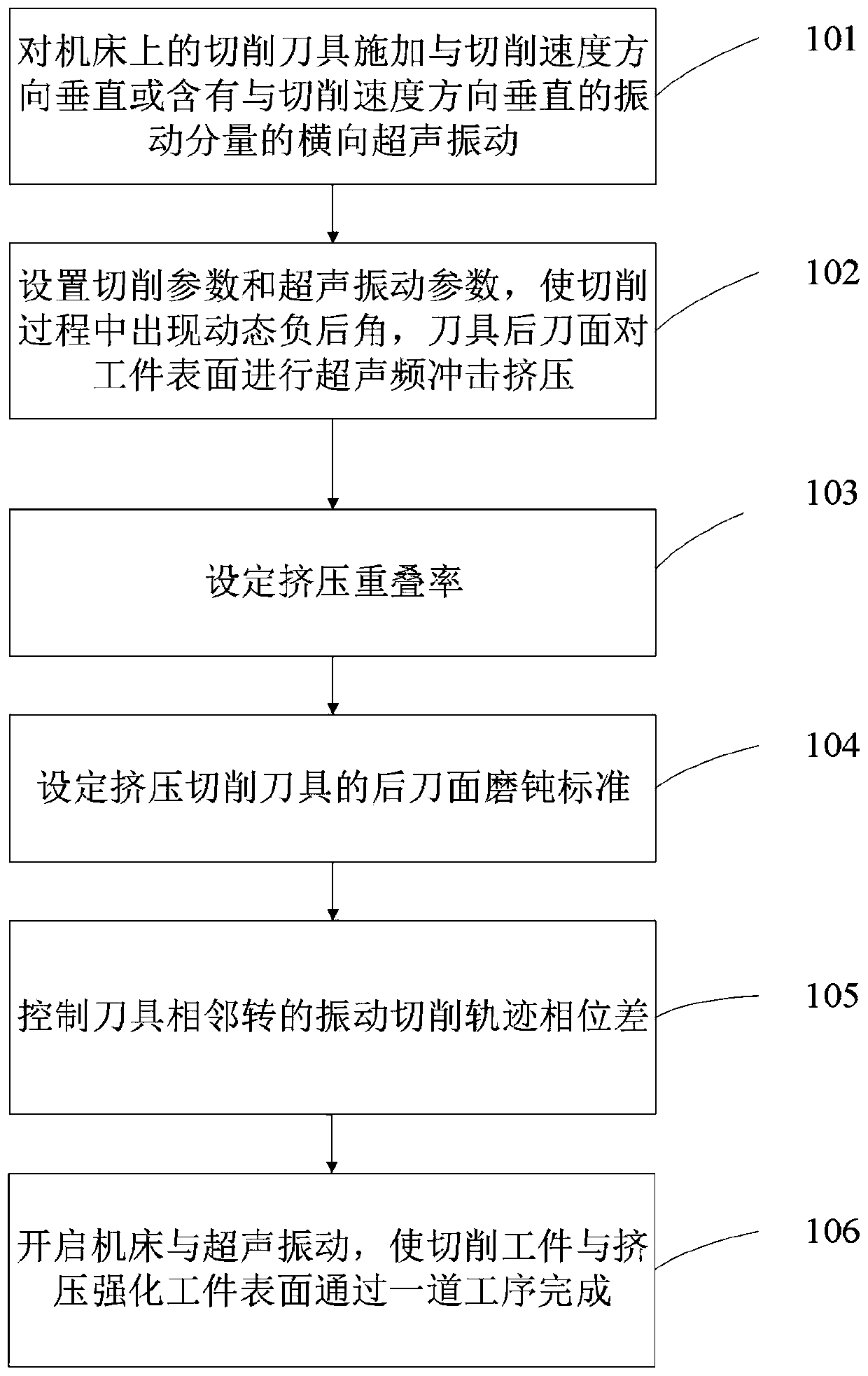

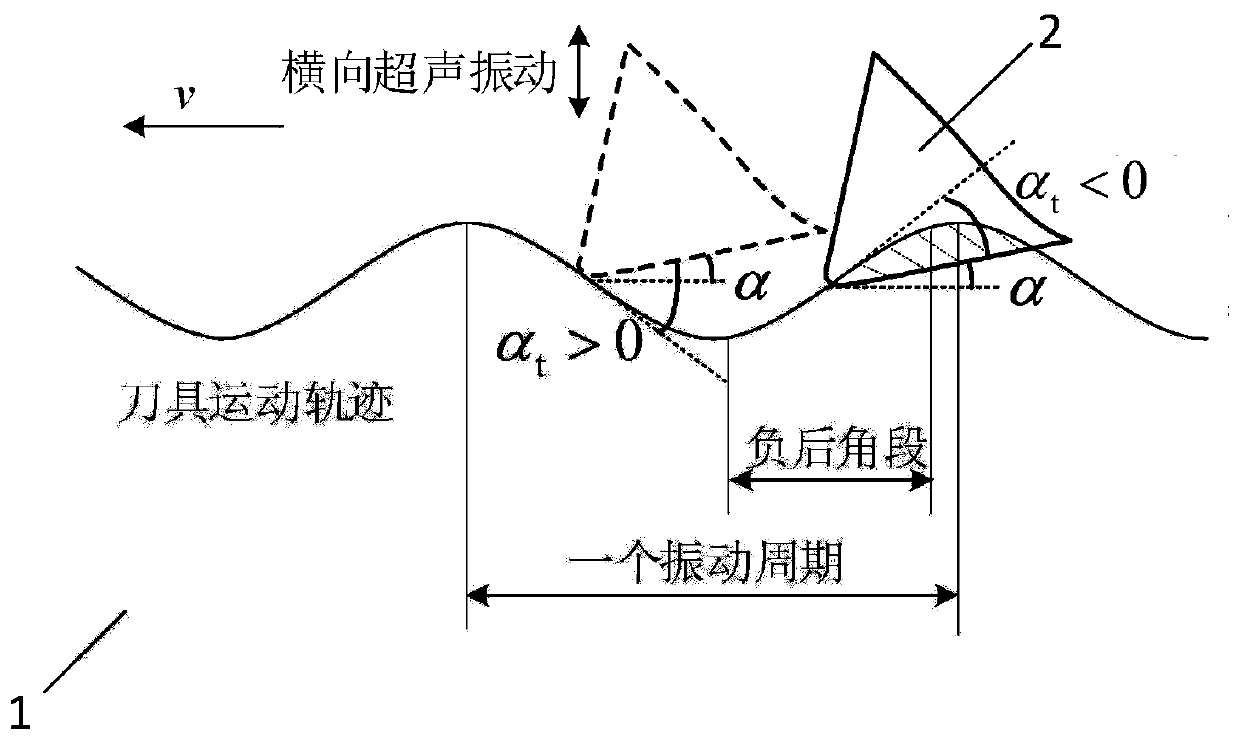

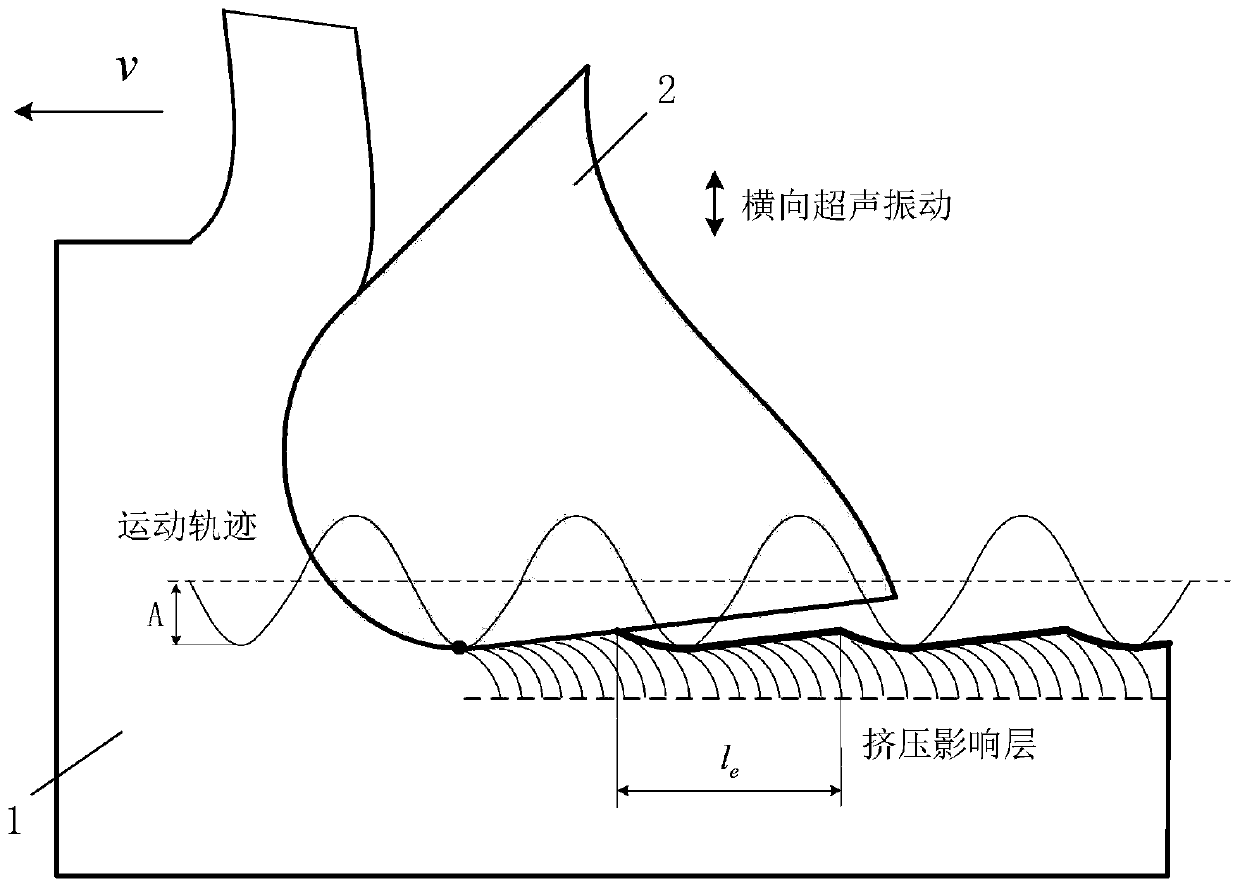

Ultrasonic stamping type cutting and extruding integrated machining method

ActiveCN110076350AImprove fatigue lifeIncreased surface microhardnessTurning machine accessoriesBurnishing machinesPhase differenceUltrasonic vibration

The invention discloses an ultrasonic stamping type cutting and extruding integrated machining method. The ultrasonic stamping type cutting and extruding integrated machining method comprises the following steps that transverse ultrasonic vibration which is perpendicular to the cutting speed direction or contains a vibration component perpendicular to the cutting speed direction is applied to a cutting tool on a machine tool; cutting parameters and ultrasonic vibration parameters are set, so that a dynamic negative rear angle is generated in the cutting process, and ultrasonic-frequency impactextrusion is performed on the surface of a workpiece by a rear tool face of the tool; the extrusion overlap ratio is set; a grinding dulling standard of a rear tool face of an extruding and cutting tool is set; the vibrating and cutting track phase difference of adjacent rotation of the tool is controlled; the machine tool and ultrasonic vibration are started, so that workpiece cutting and extrusion reinforcement of the surface of the workpiece are completed through one working procedure. According to the ultrasonic stamping type cutting and extruding integrated machining method, a reinforcing working procedure is not needed to be additionally provided, and the surface of the workpiece can undergo extrusion reinforcement while the workpiece is cut.

Owner:BEIHANG UNIV

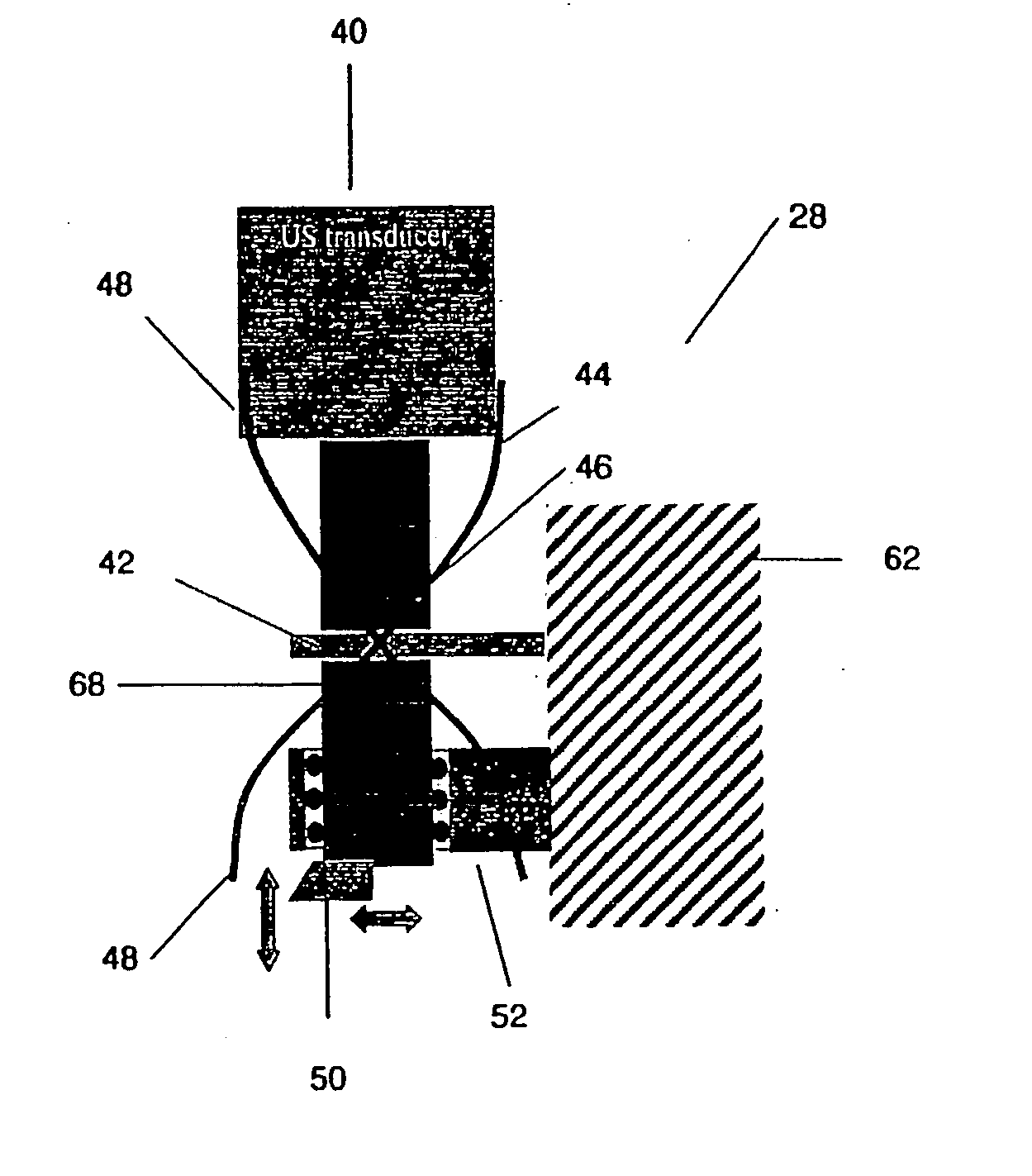

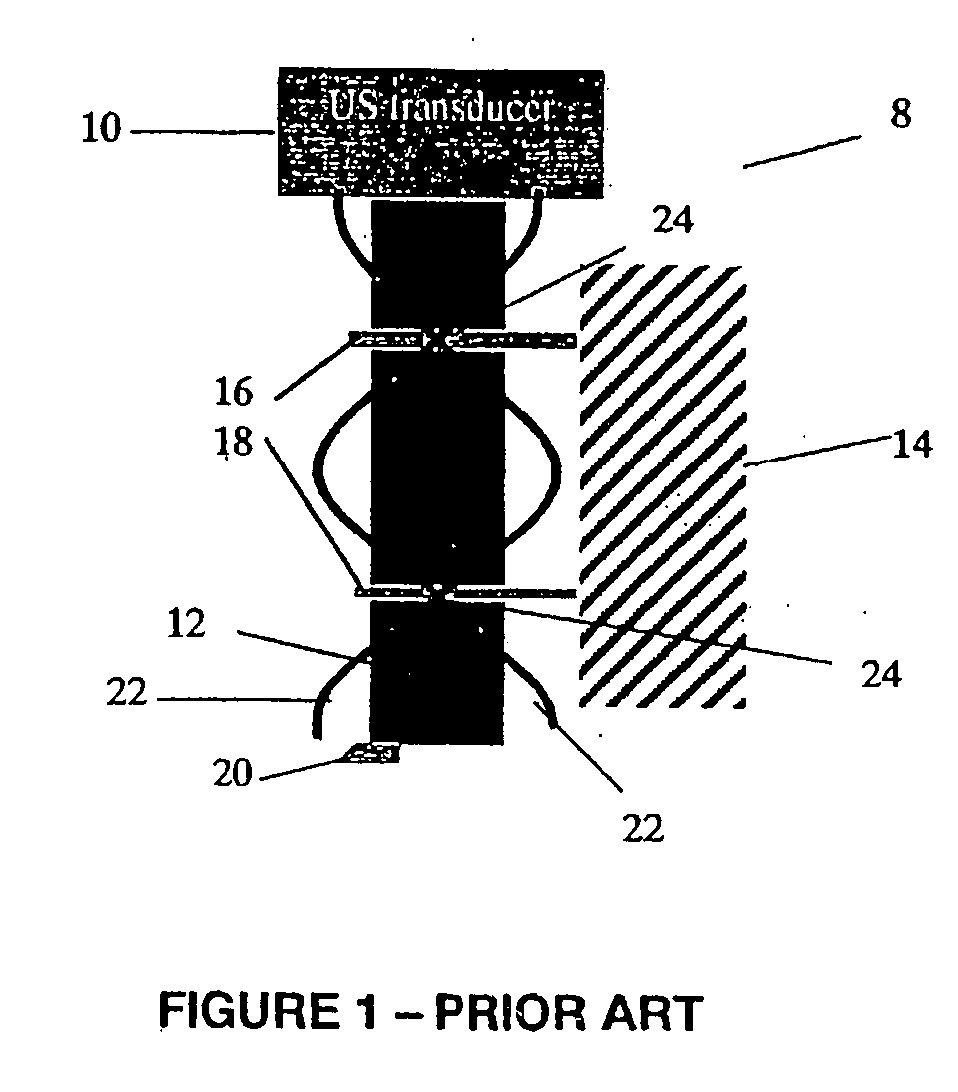

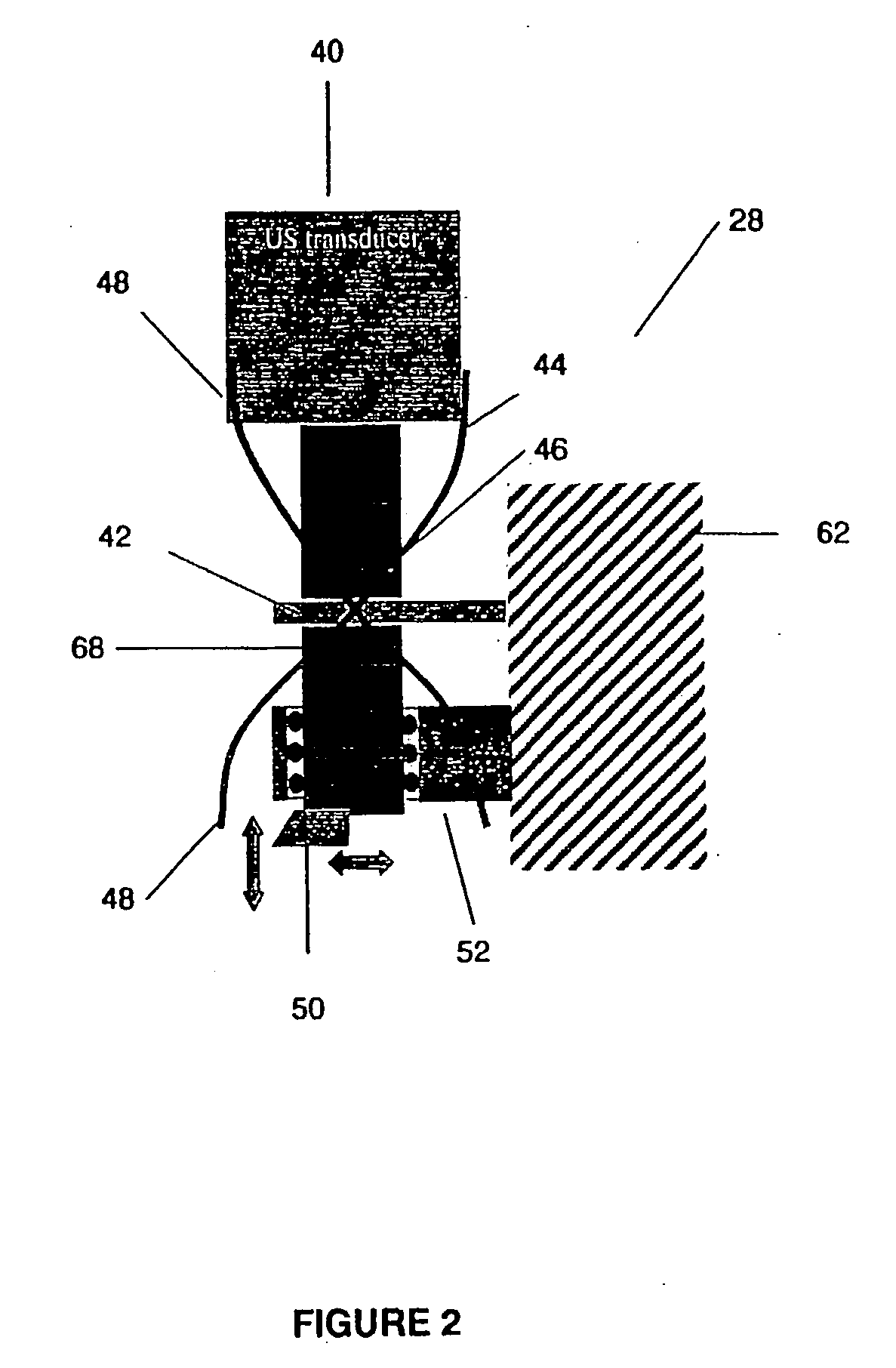

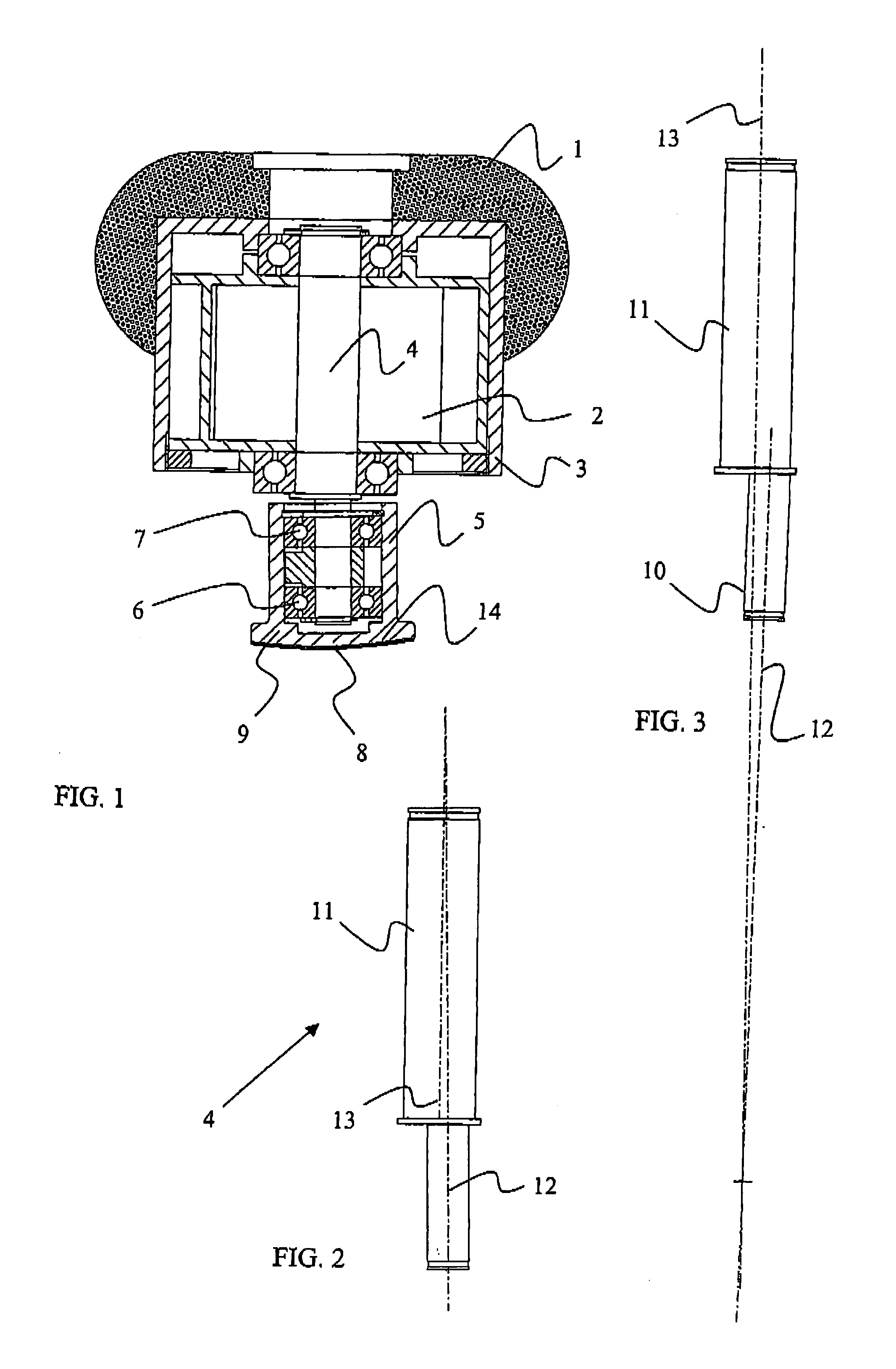

Apparatus For Ultrasonic Vibration-Assisted Machining

InactiveUS20070257579A1Reduce vibrationOptical surface grinding machinesPiezoelectric/electrostriction/magnetostriction machinesEngineeringUltrasonic vibration

Apparatus for ultrasonic vibration-assisted machining, the apparatus comprising an ultrasonic transducer for generating ultrasonic waves in a vibration horn; first clamp on the vibration horn at a static node of the ultrasonic waves; and a second clamp between the first clamp and a lowermost end of the vibration horn. The second clamp comprises a linear bearing for reducing vibration of the vibration horn in a direction laterally of the vibration horn, and allowing vibration of the vibration horn in the direction of a longitudinal axial of the vibration horn.

Owner:AGENCY FOR SCI TECH & RES

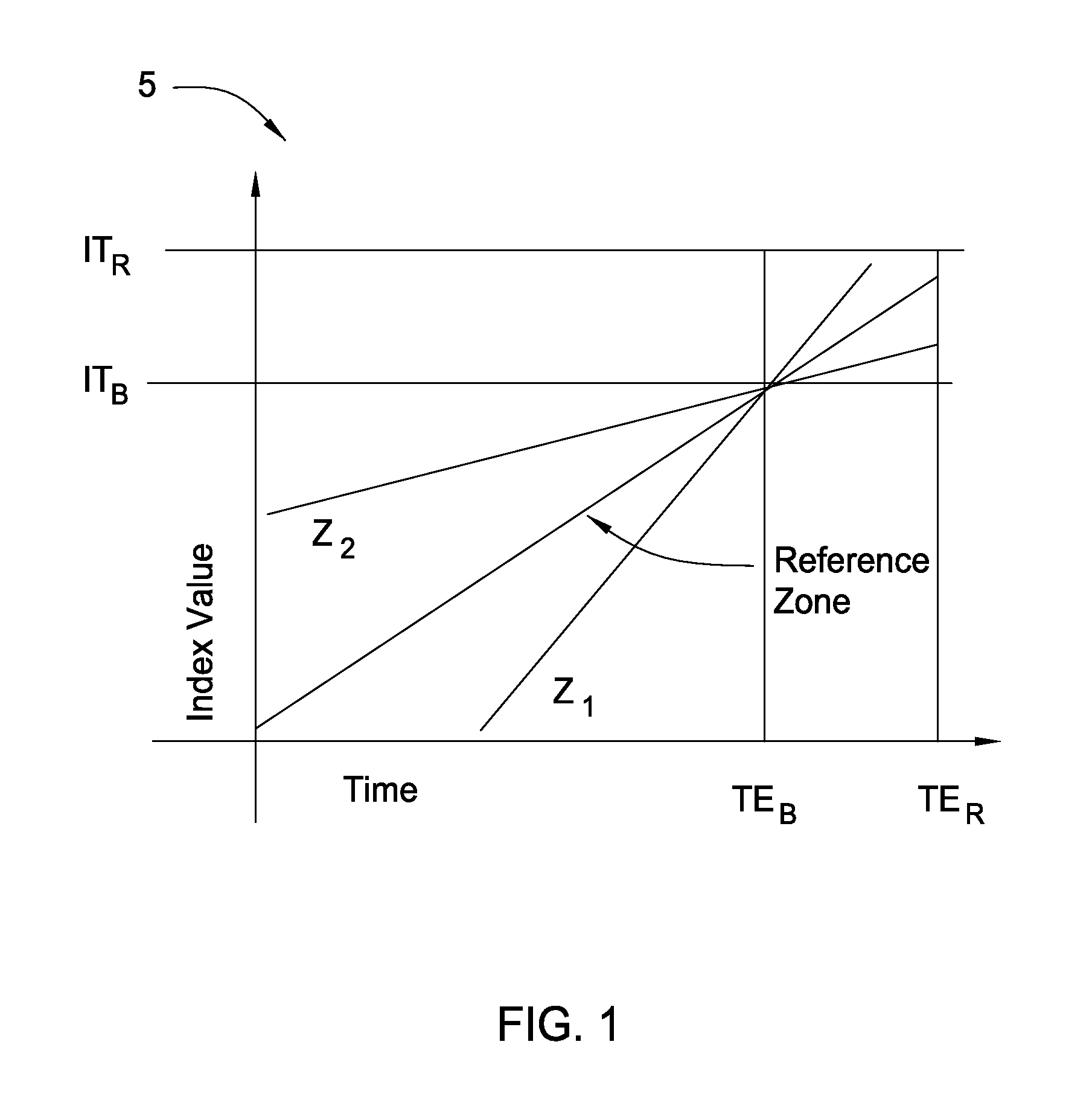

Dynamic residue clearing control with in-situ profile control (ISPC)

A method for controlling the residue clearing process of a chemical mechanical polishing (“CMP”) process is provided. Dynamic in-situ profile control (“ISPC”) is used to control polishing before residue clearing starts, and then a new polishing recipe is dynamically calculated for the clearing process. Several different methods are disclosed for calculating the clearing recipe. First, in certain implementations when feedback at T0 or T1 methods are used, a post polishing profile and feedback offsets are generated in ISPC software. Based on the polishing profile and feedback generated from ISPC before the start of the clearing process, a flat post profile after clearing is targeted. The estimated time for the clearing step may be based on the previously processed wafers (for example, a moving average of the previous endpoint times). The calculated pressures may be scaled to a lower (or higher) baseline pressure for a more uniform clearing.

Owner:APPLIED MATERIALS INC

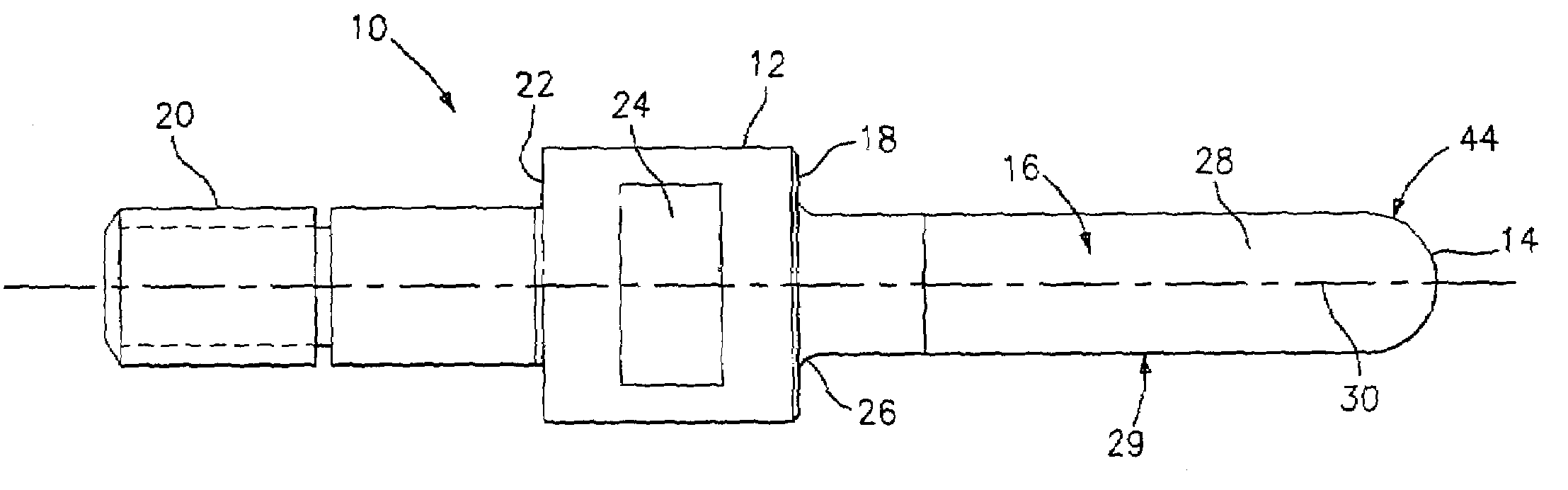

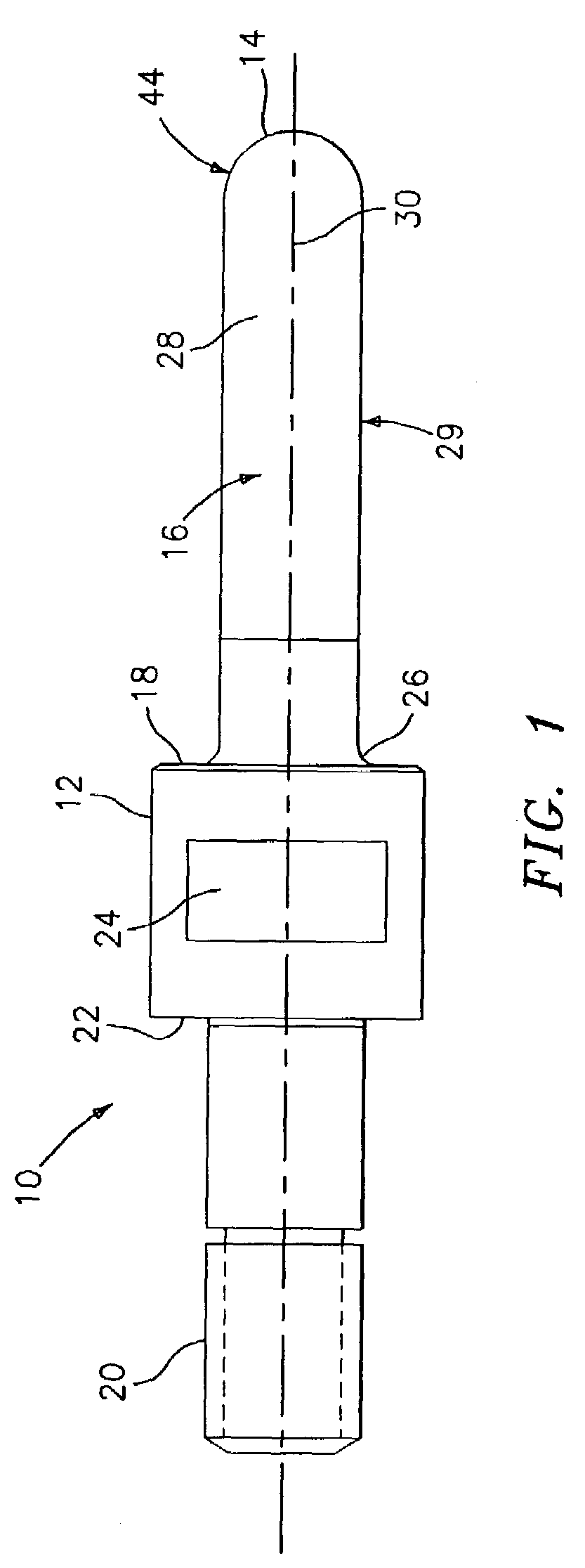

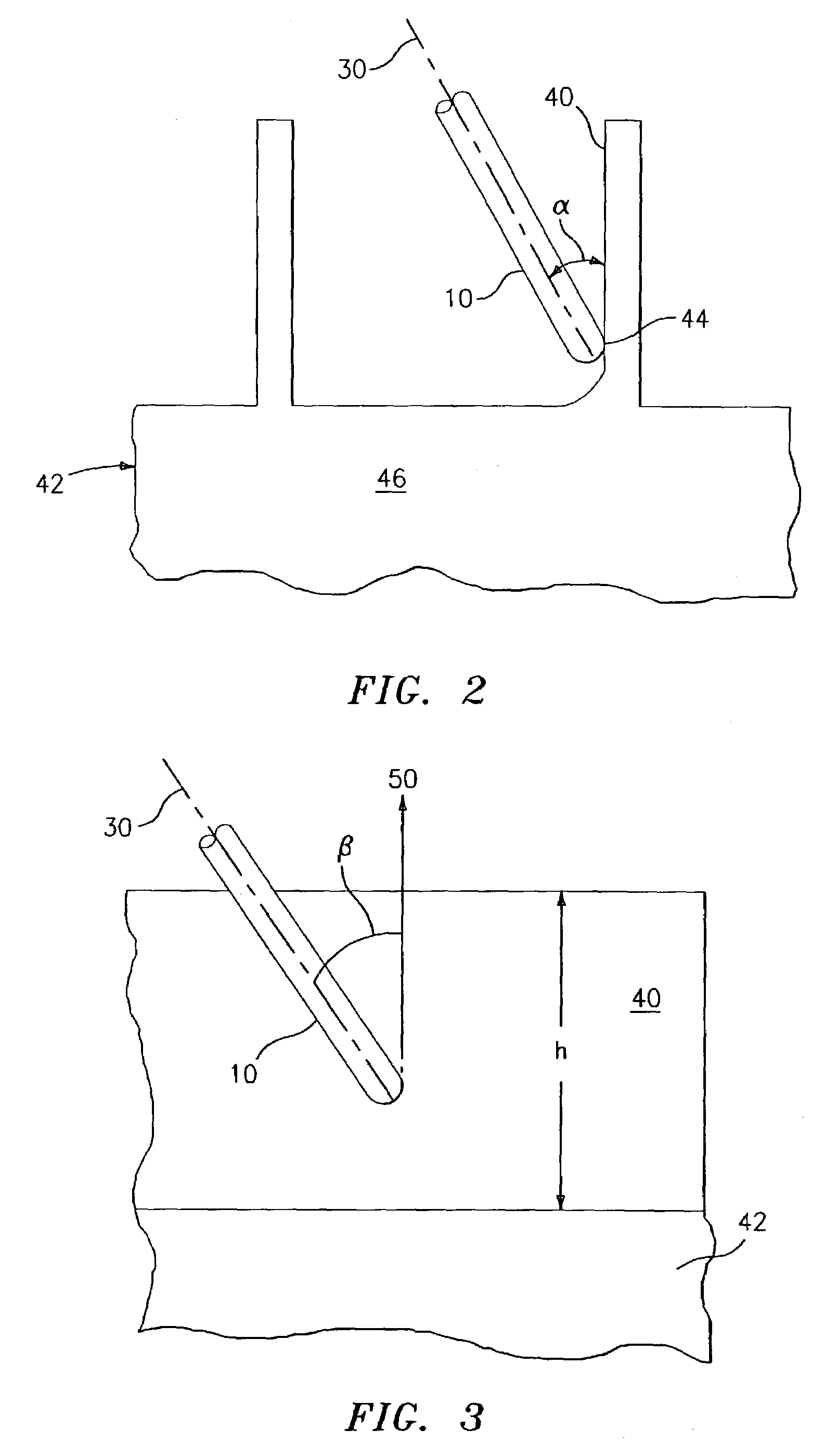

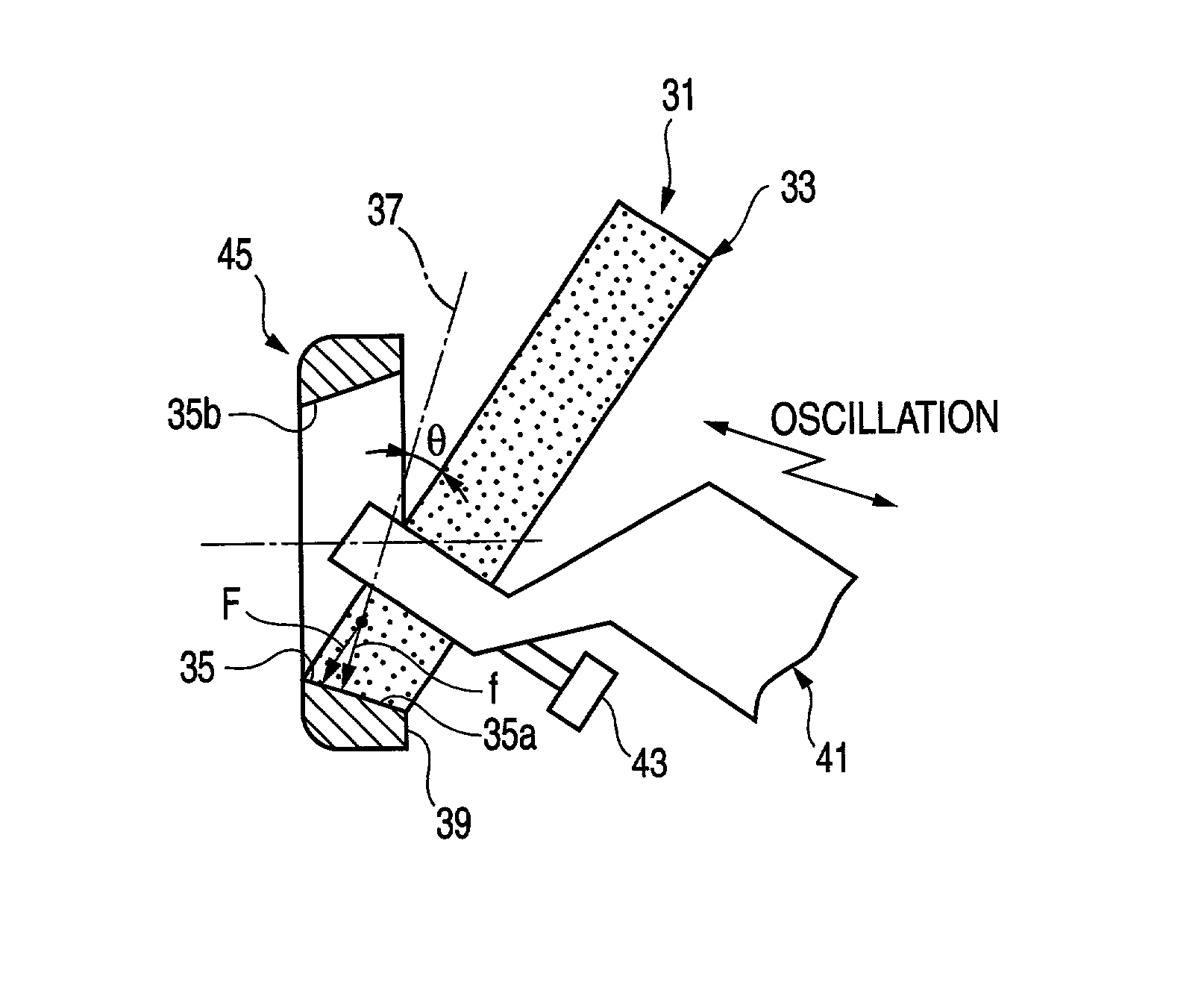

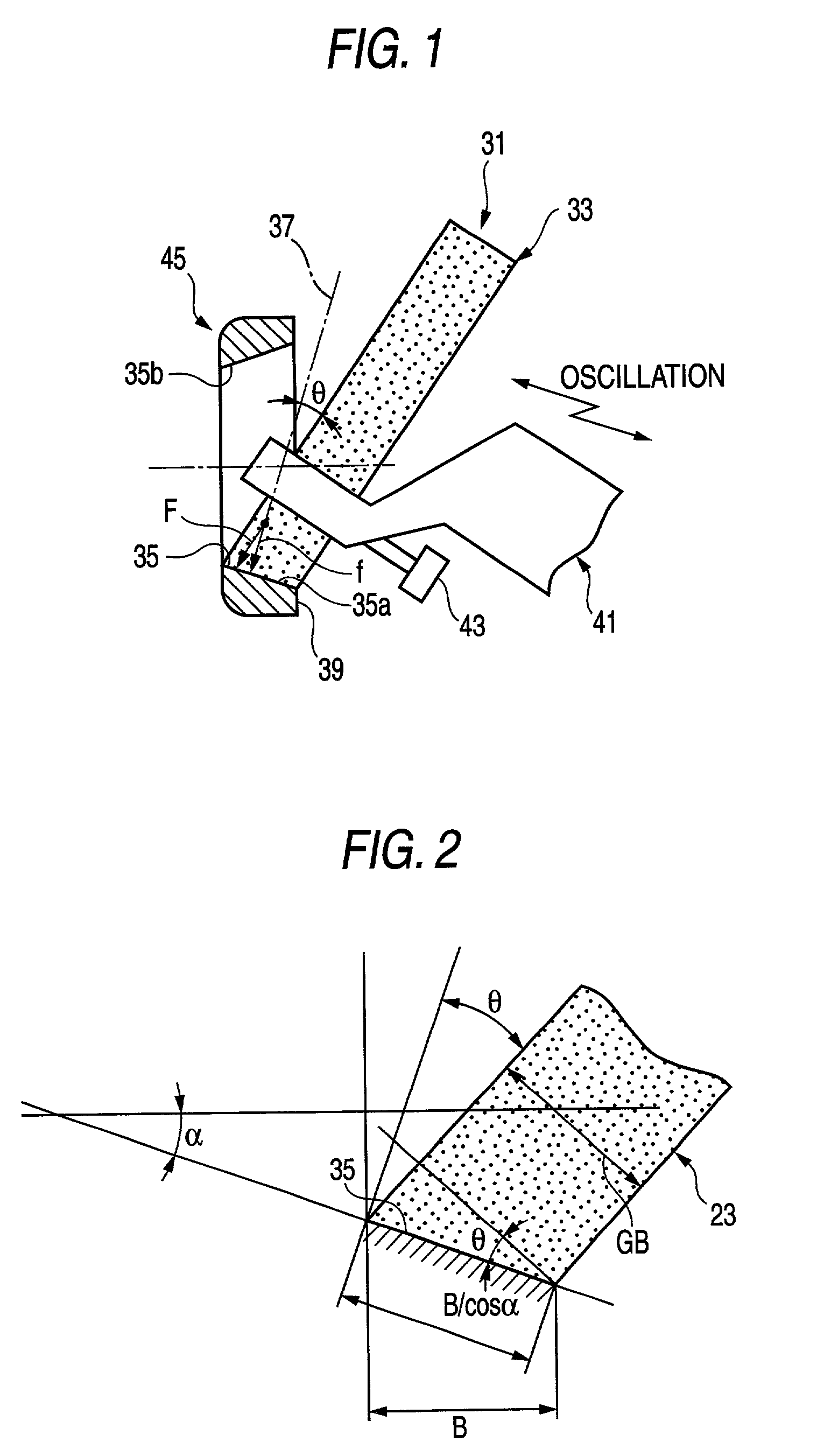

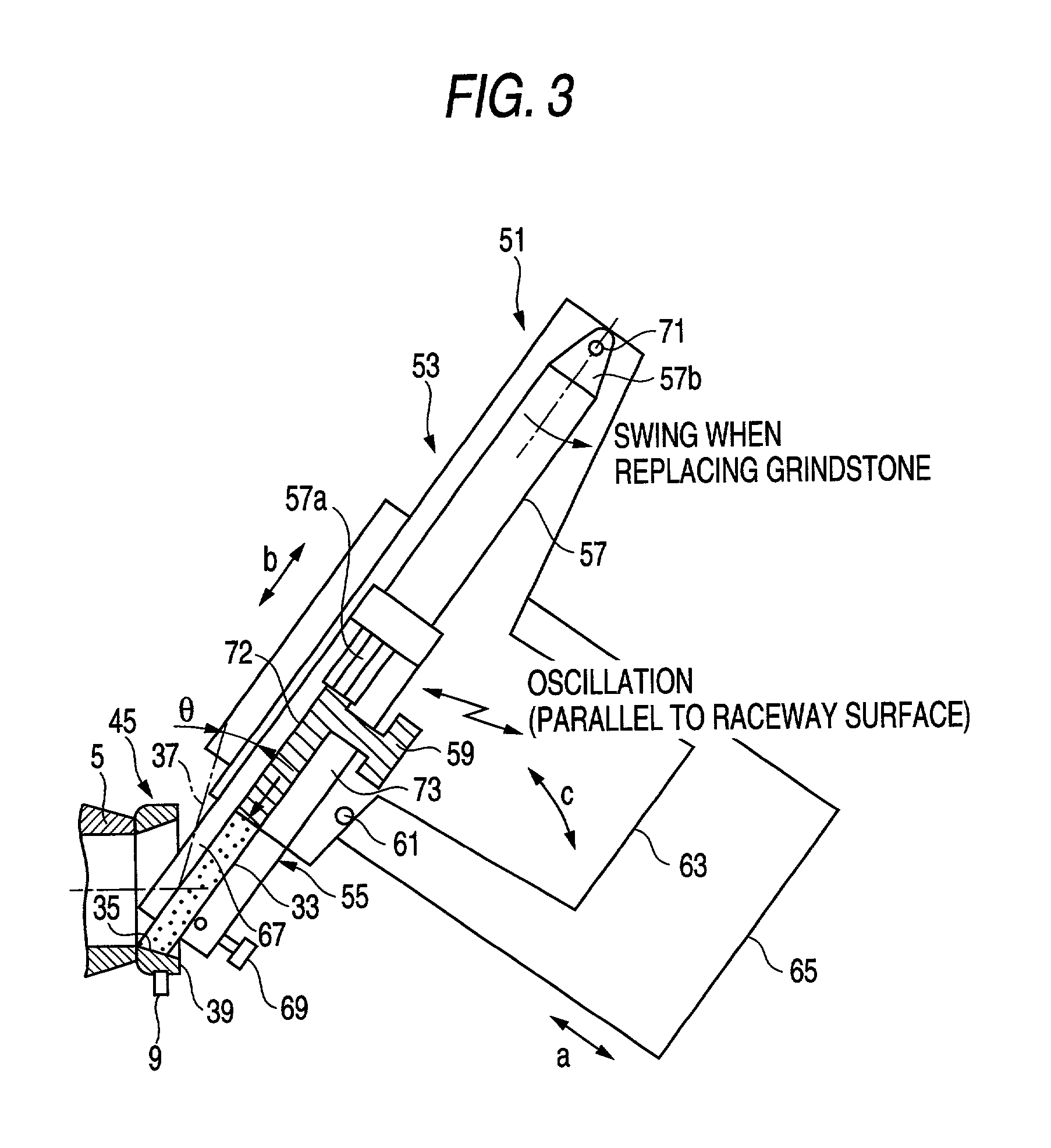

Method and apparatus for superfinishing tapered roller bearing

InactiveUS20020152616A1Edge grinding machinesRoller bearingsMechanical engineeringTapered roller bearing

A superfinishing method of a tapered roller bearing, including the steps of: rotating an outer ring of the tapered roller bearing about a center axis thereof; inserting a straight-shaped superfinishing stone from a front face of outer ring; and slidingly contacting a leading end face of the superfinishing stone with a taper-shaped raceway surface formed in an inner peripheral surface of the outer ring to thereby superfinish the raceway surface. The superfinishing stone is inclined outwardly of the front face of outer ring with respect to a vertical line of the raceway surface.

Owner:NSK LTD

Method and apparatus for finishing a workpiece

InactiveUS20090104855A1High cutting rateReduce potential loss of processing tool efficiencyGrinding feed controlAutomatic grinding controlContact pressureMaterial removal

A method for abrasive material removal that includes the steps of establishing an optimum force profile relating to the force or contact pressure applied by a processing tool on a workpiece. The actual force generated during the metal removal operation is monitored and compared to the optimum force profile. Based on the comparison of the actual force with the optimum force profile machine parameters are adjusted such that the actual force generated follows the established optimum force profile.

Owner:THIELENHAUS MICROFINISH

Oscillating grinding machine

ActiveUS20070224924A1Easy to operateBig advantageEdge grinding machinesSpherical surface grinding machinesDrive shaftDrive motor

The present invention relates particularly to an oscillating grinding machine. The grinding machine comprises a driving motor (3) surrounded by a body (3), and a drive shaft (4) cooperating with the driving motor. The drive shaft comprises a grinding head (5) that constitutes a support for a grinding product (8). The drive shaft (4) is arranged in two pieces and comprises a main shaft (11) and an eccentric shaft (10) arranged rigidly thereto. The eccentric shaft comprises a centre line (12) that assumes an angle (α) against a corresponding centre line (13) of the main shaft, and thus the grinding head (5) will assume an eccentric placement in relation to the main shaft (11). Thus, the grinding head is arranged to oscillate in a substantially spherical plane provided by the rotation of the main shaft and the eccentricity and inclination of the eccentric shaft in relation to the main shaft.

Owner:KWH MIRKA

High small ultrasonic polishing, collating equipment in use for parts of axes, and processing method

InactiveCN1915592AChange performanceHigh strengthSuperfinishing machinesBiomedical engineeringUltrasonic generator

An efficient ultrasonic polishing apparatus for the axle-type parts is composed of a HF (200000-300000 H2) ultrasonic generator and a grinding head, and is installed to the cutting-tool carrier. Its polishing method features that the part to be polished is fixed to a lathe.

Owner:CITIC HEAVY INDUSTRIES CO LTD

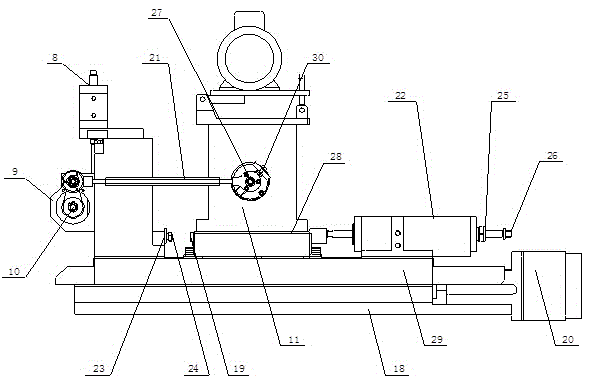

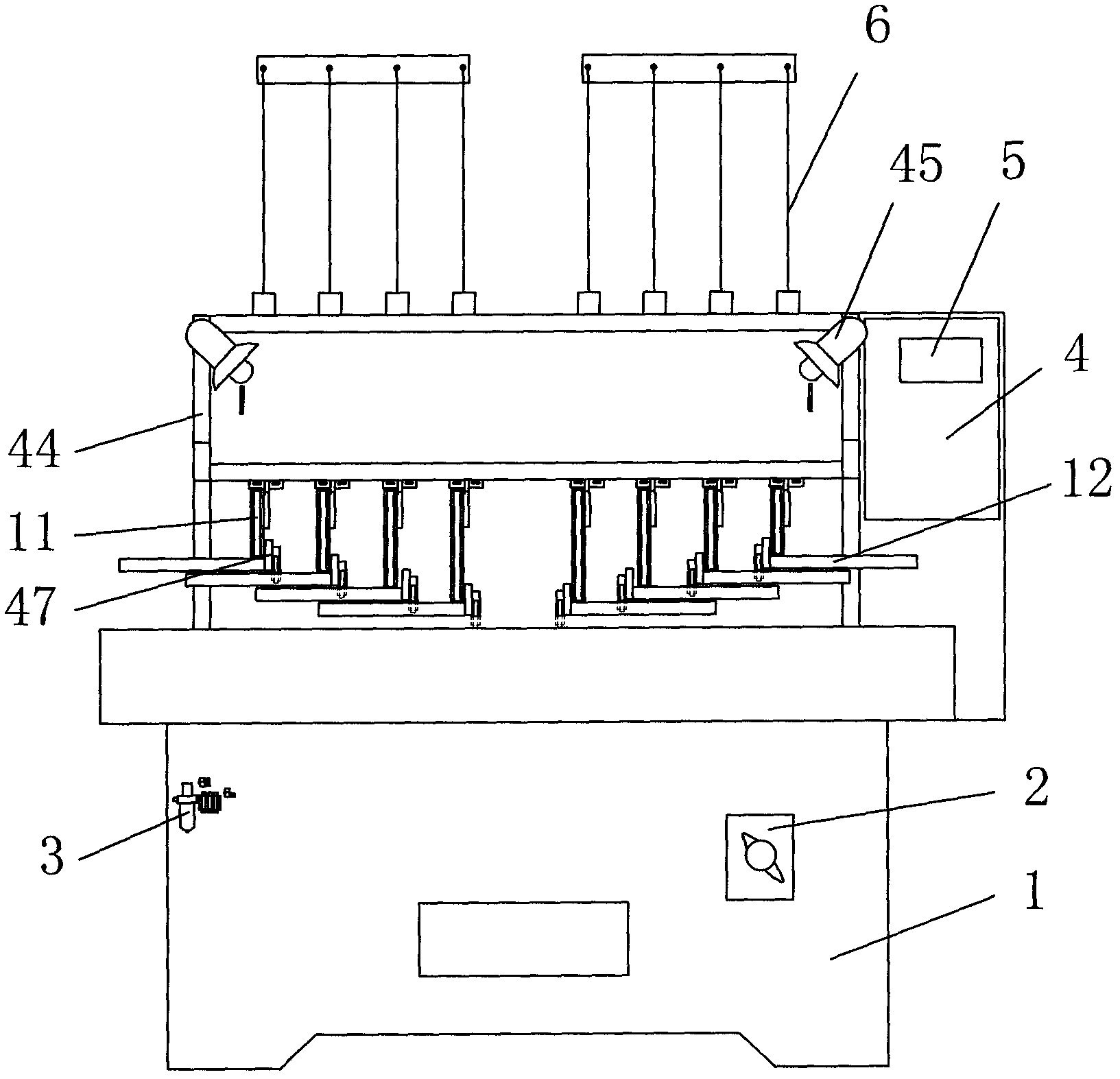

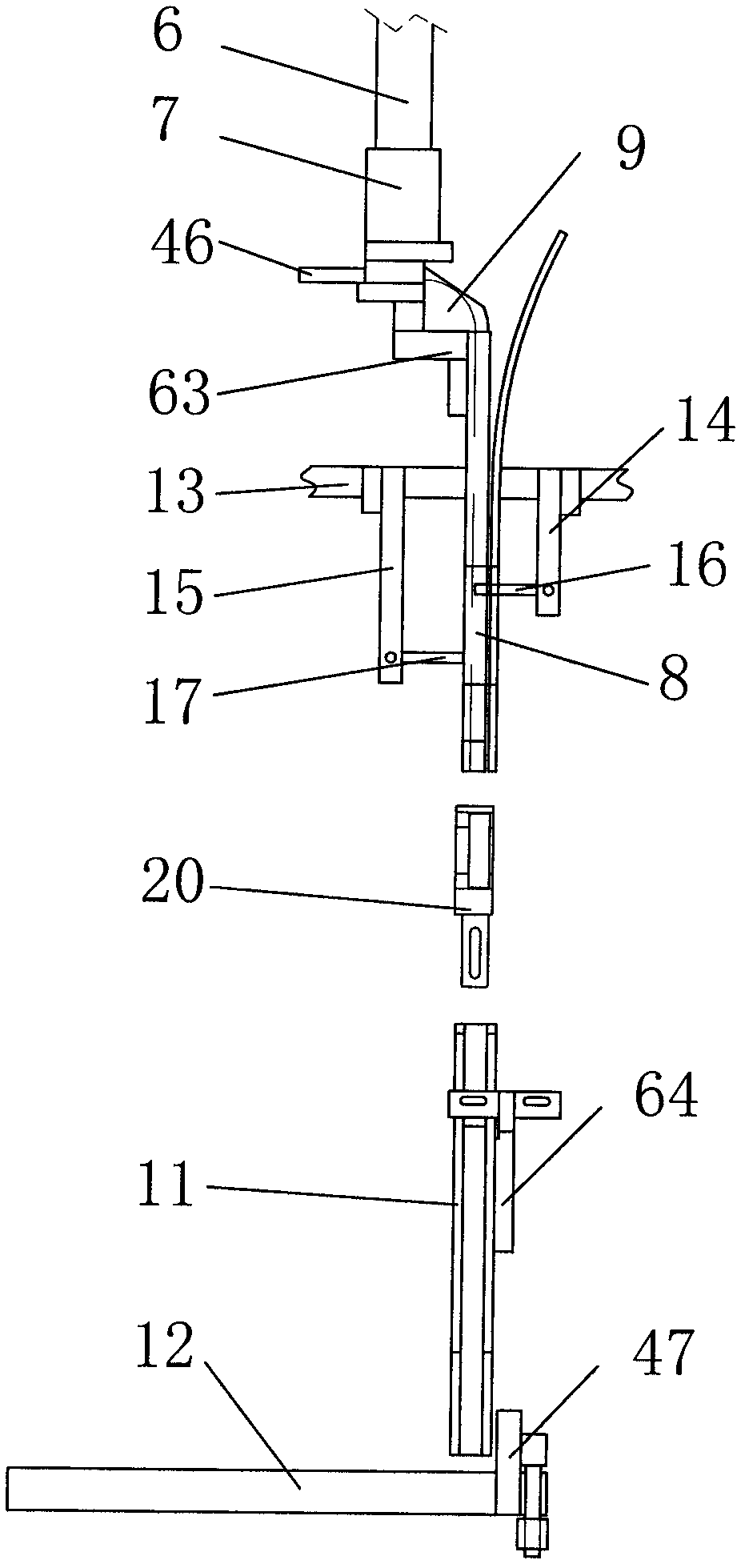

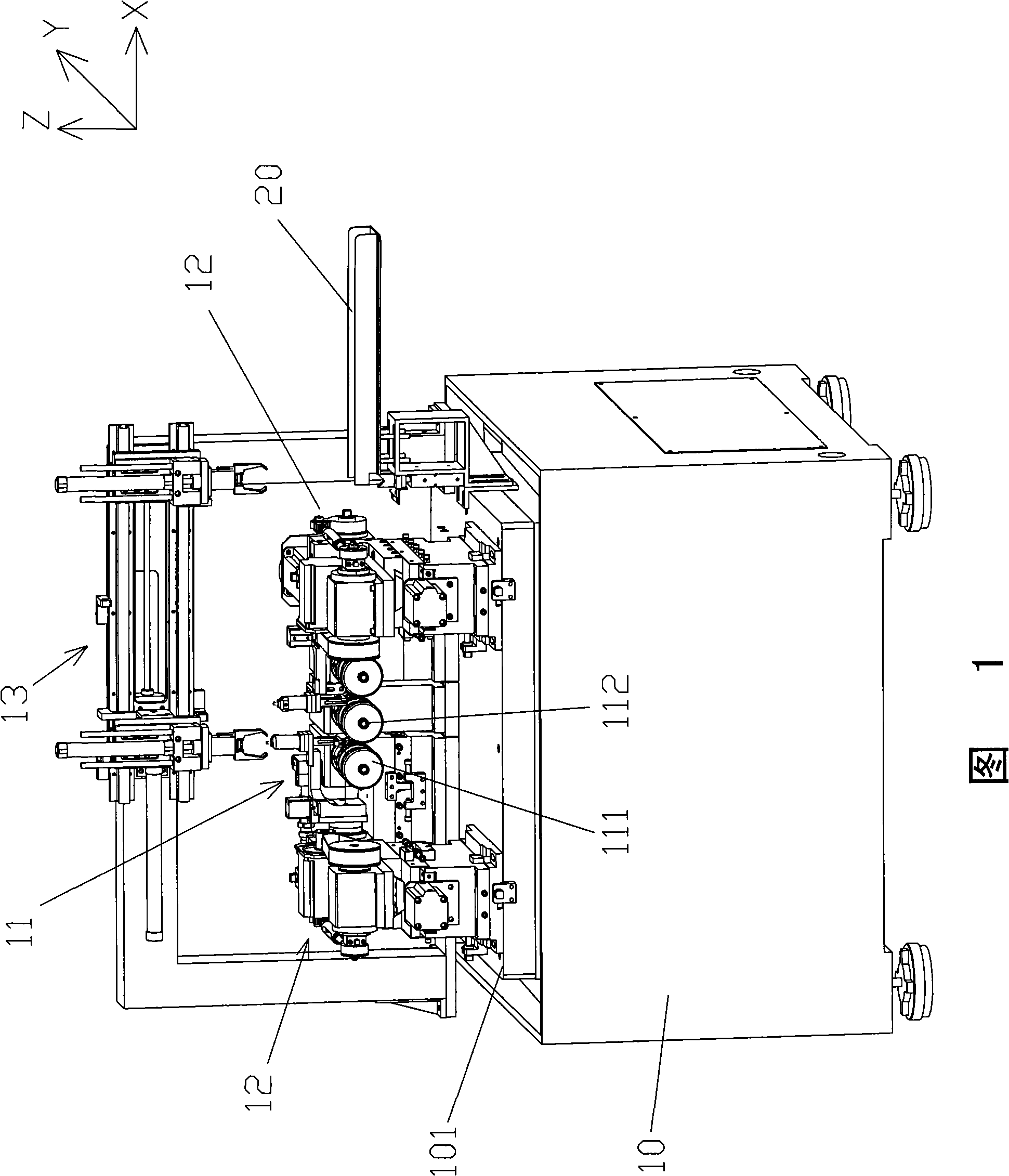

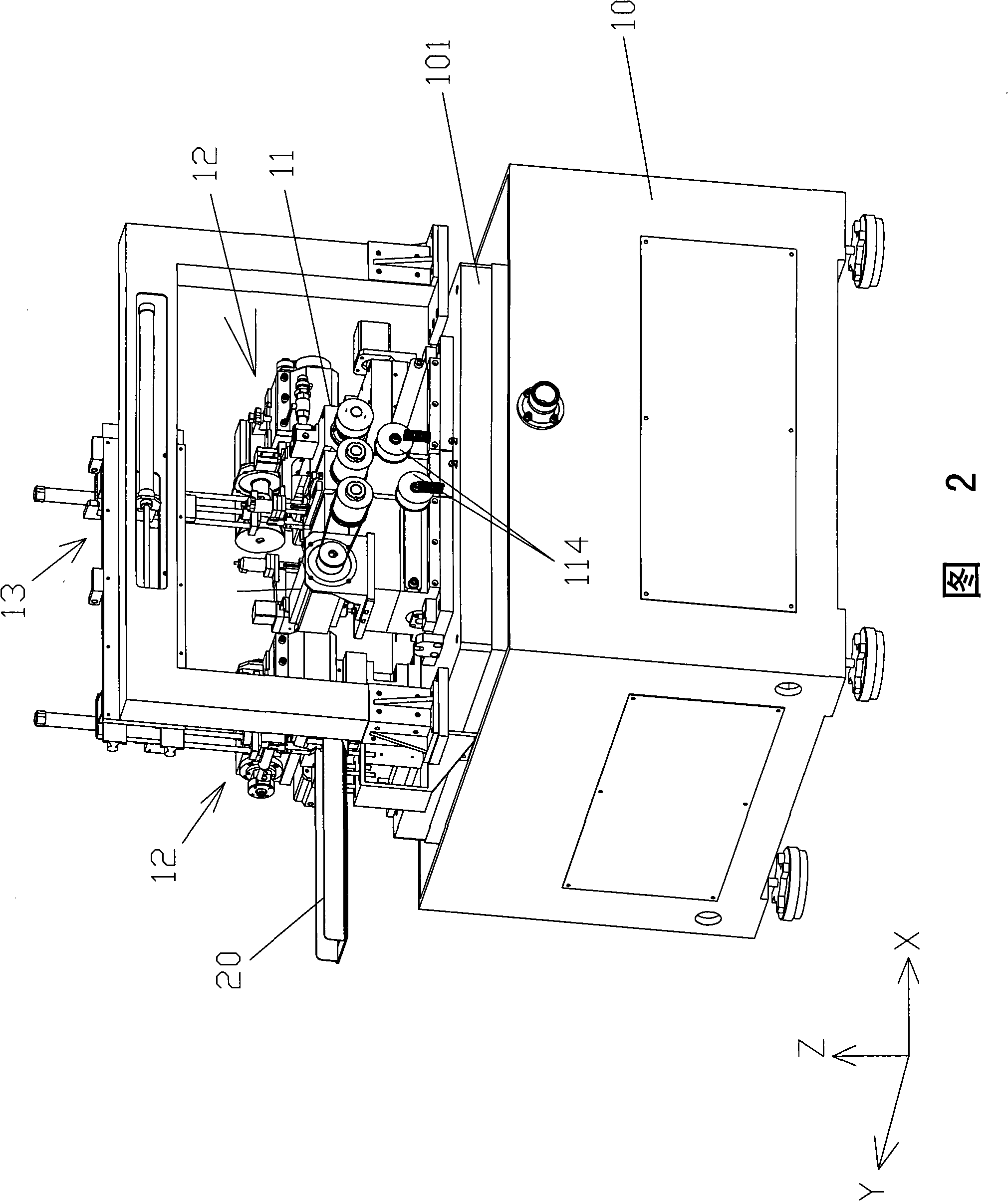

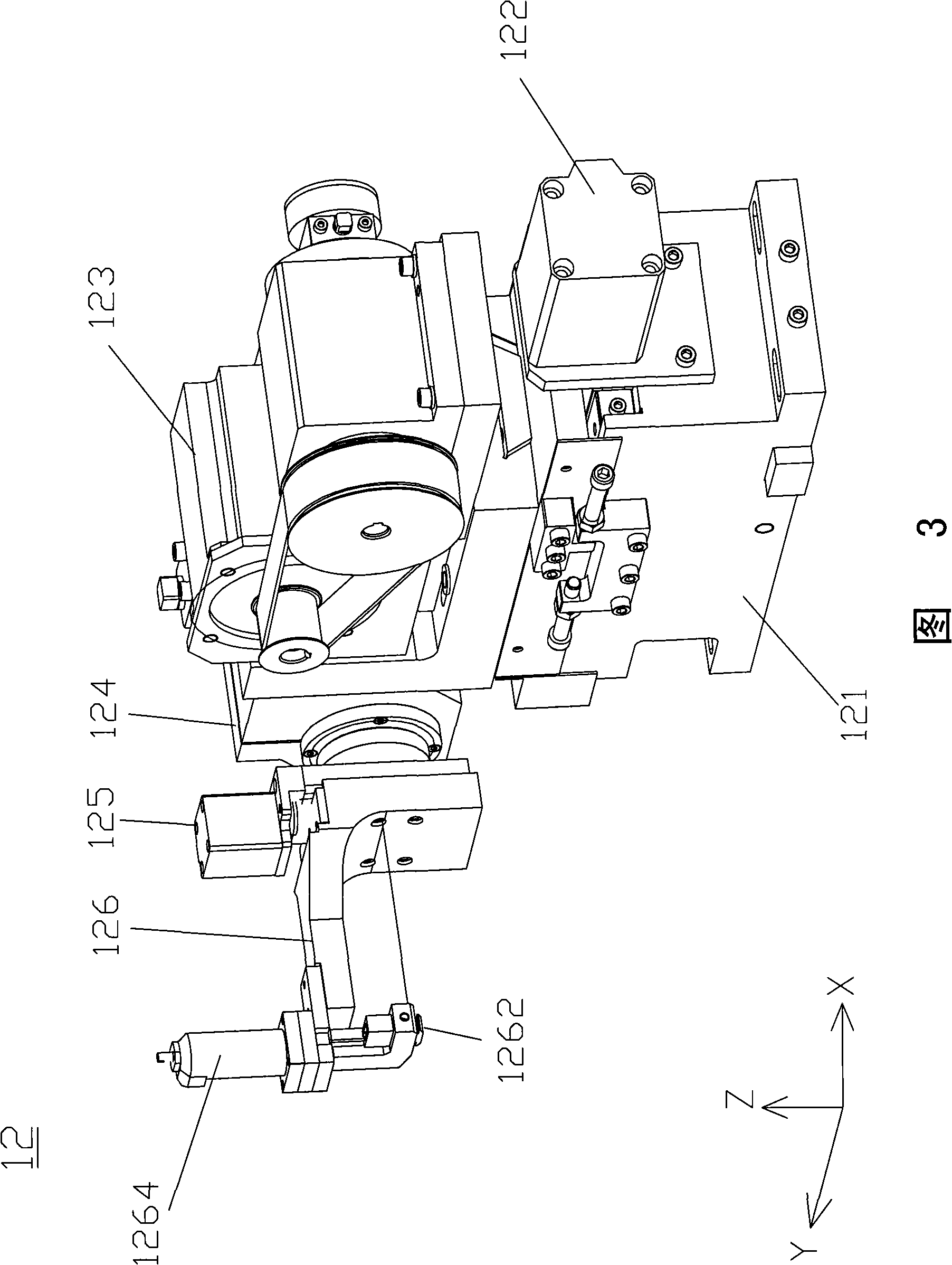

Ultra-precision grinding machine for ball track

The invention discloses an ultra-precision grinding machine for a ball track. The grinding machine comprises a base, a camshaft, an emptying swing arm and a material receiving swing arm, wherein feeding components consisting of material hanging rods, feeding guide sleeves, emptying mechanisms, mechanical hands, blanking frames and bearing brackets are arranged on the base; emptying mechanisms are fixed on an emptying shaft; the mechanical hands are fixed on a material receiving shaft; two sides of the mechanical hands are provided with rolling rod mechanisms; grinding heads which swing in a reciprocating mode are arranged above the mechanical hands; ejector rod tools are arranged below the grinding heads; radial cams, a material receiving surface cam and an emptying surface cam are arranged on the camshaft; the ejector rod tools are driven by the radial cams to vertically move; the material receiving surface cam makes the material receiving shaft move transversely through the material receiving swing arm; and the emptying surface cam makes the emptying shaft move transversely through the emptying swing arm. Due to the structure, the ball track can be fully automatically machined, rough ultra-precision machining and finish ultra-precision machining can be performed on the same machine tool, and the quality and machining efficiency of the product are improved; meanwhile, the grinding machine is simple and compact in structure and convenient to operate, and the protection safety is improved.

Owner:慈溪大旗机械科技有限公司

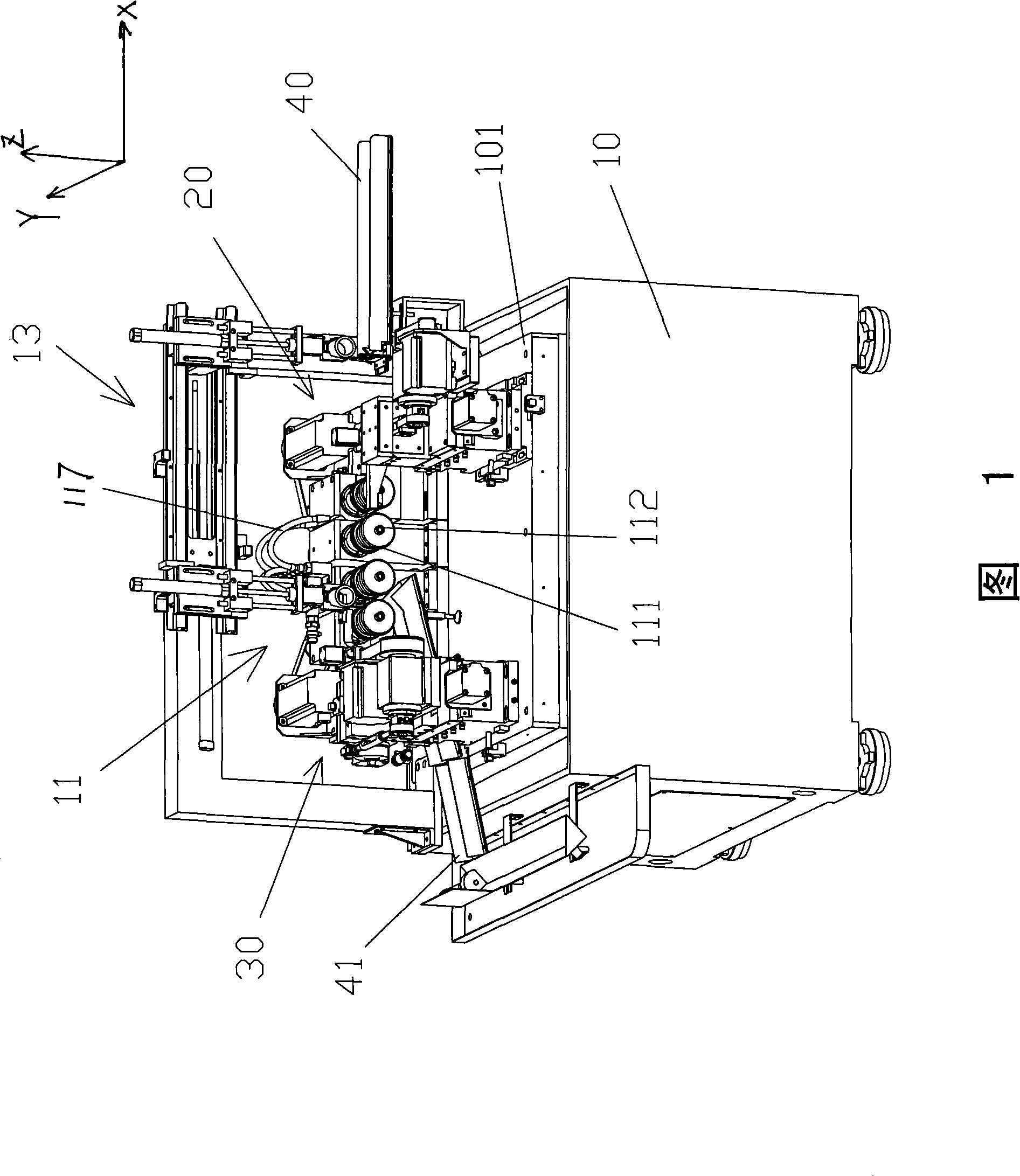

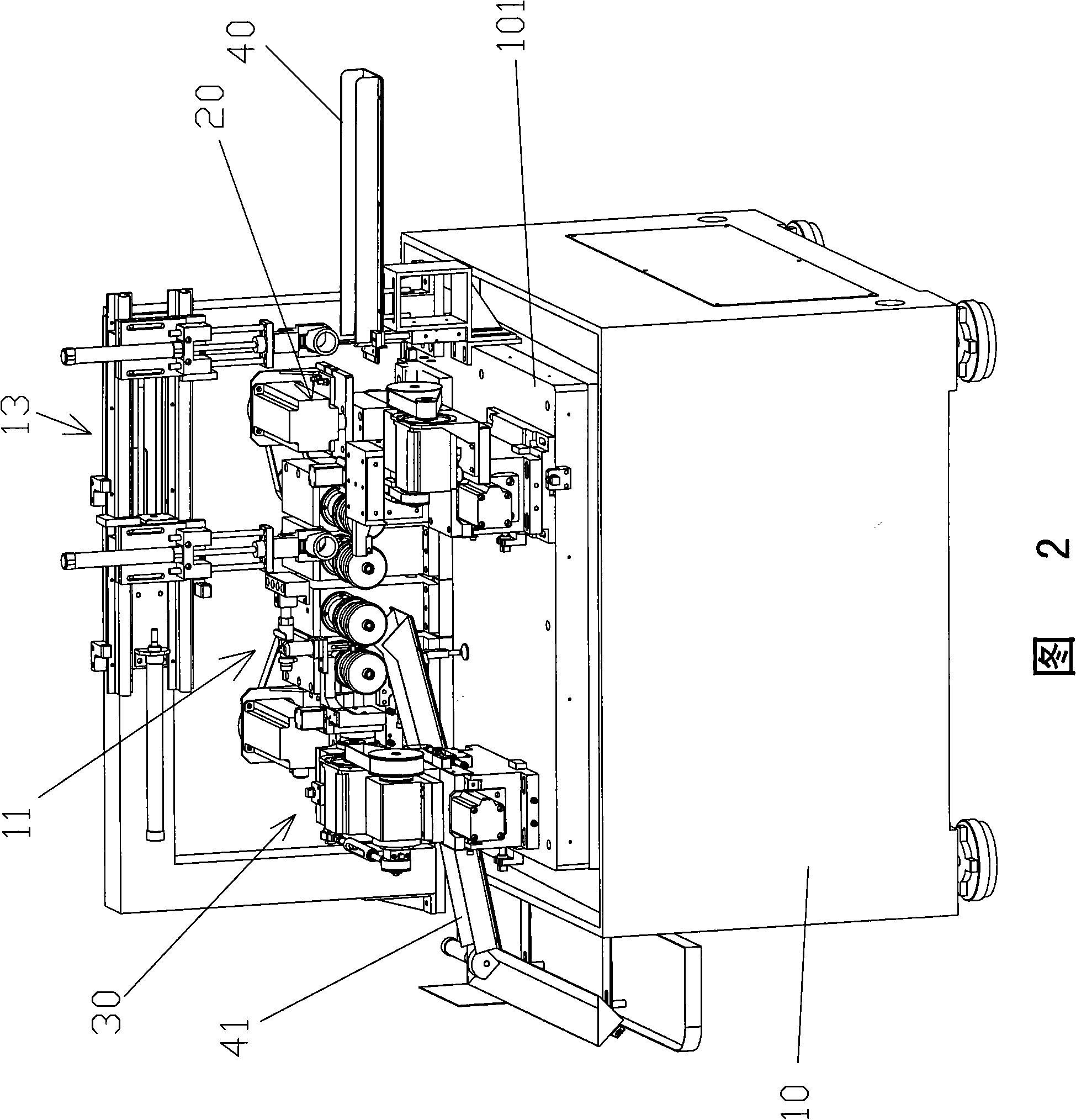

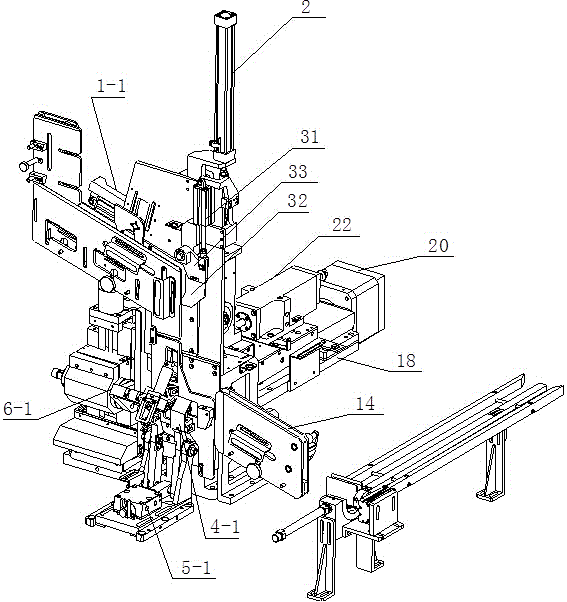

Double-groove bearing super precise grinding machine

InactiveCN101306515AImprove protection securityReliable actionGrinding machinesSuperfinishing machinesManipulatorPortal frame

The invention disclose a double-channel bearing superfine grinding machine including a machine frame with an operating desk, as well as a workpiece seat, a grinding device and a material loading device which are arranged on the operating desk, wherein the workpiece seat includes three rollers which are arranged in parallel, every two adjacent rollers form a grinding service position; the grinding device includes two channel grinding devices respectively corresponding to the two grinding service positions, so as to process channels on the workpieces in the grinding service positions; the material loading device includes a portal frame arranged above the workpiece seat, first and second traverse motion mechanisms arranged on the portal frame, as well as first and second manipulators which are respectively connected with the first and the second traverse motion mechanisms, wherein the first manipulator is used for sending one workpiece to one of the channel grinding service positions, and the second manipulator is used for sending the workpiece from one of the channel grinding service positions to the other channel grinding service position. The double-channel bearing superfine grinding machine has the advantages of fully automatic running, precise processing and so on.

Owner:SHANGHAI BENQIU PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com