Method and apparatus for the measurement-aided fine machining of workpiece surfaces, and measuring system

一种工件表面、测量系统的技术,应用在测量系统领域,能够解决未详细描述等问题,达到测量次数高、动态测量性能高、优化测量过程的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

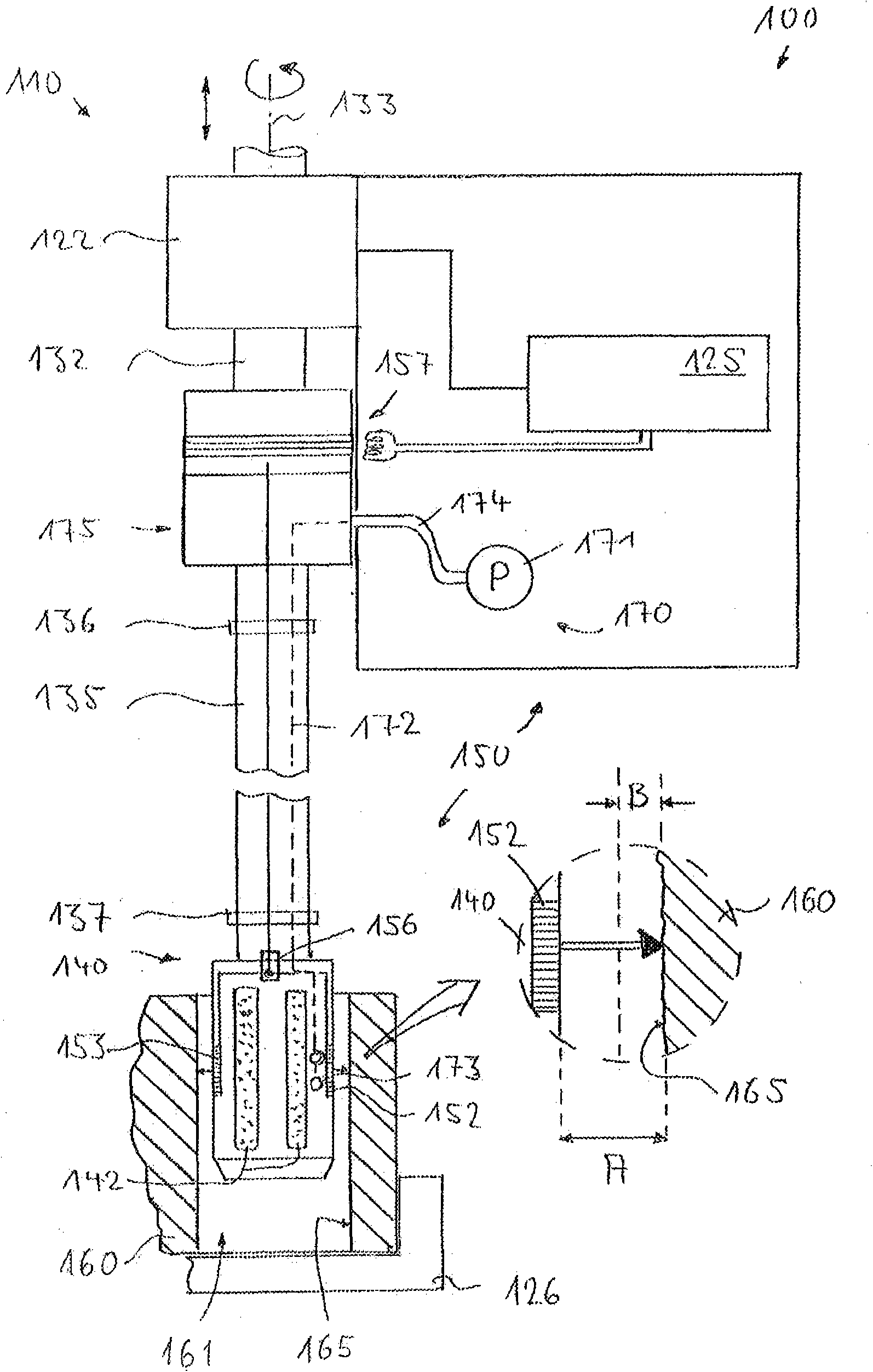

[0042] First, an embodiment of the present invention will be explained by taking the "honing" finishing method as an example.

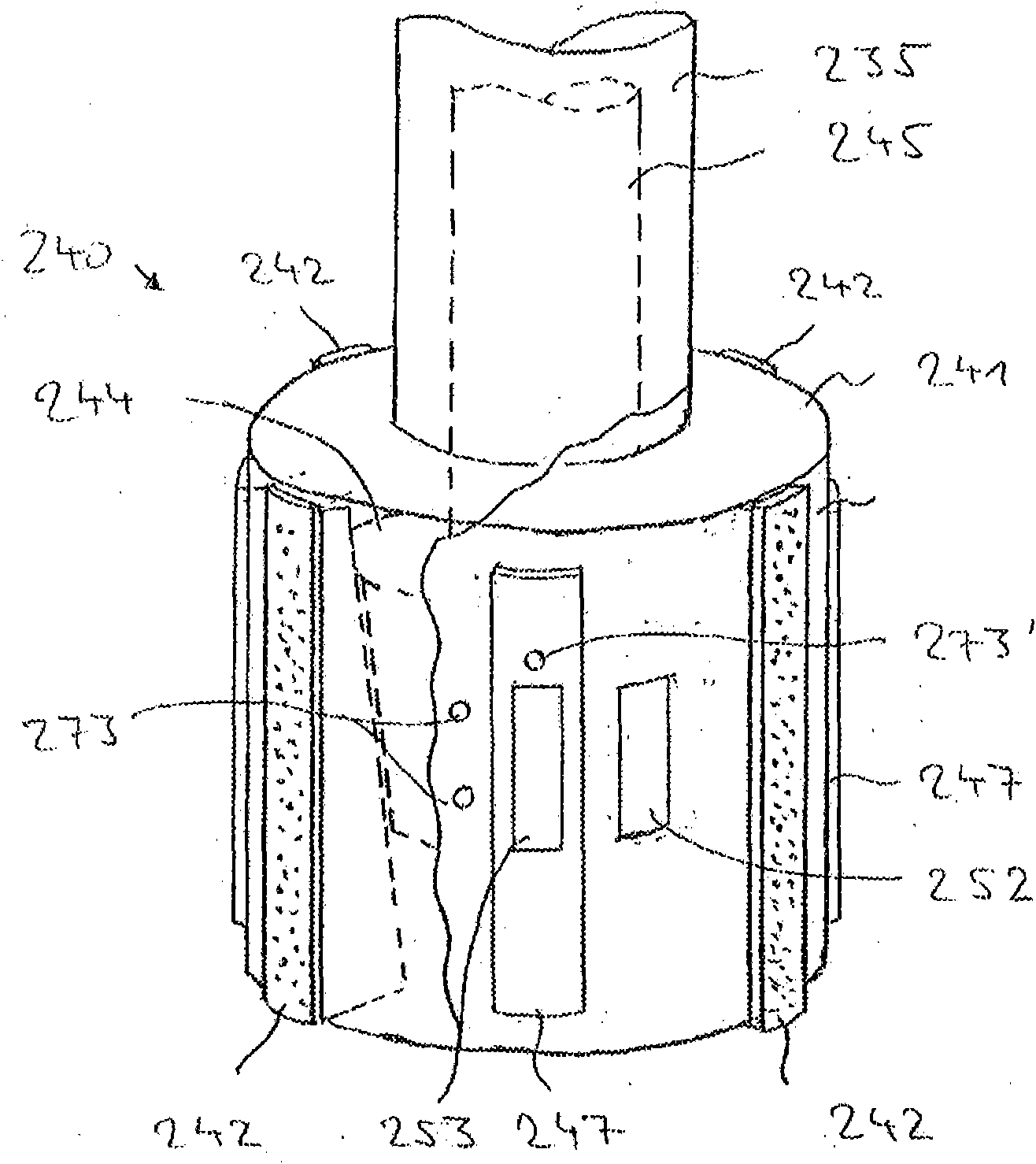

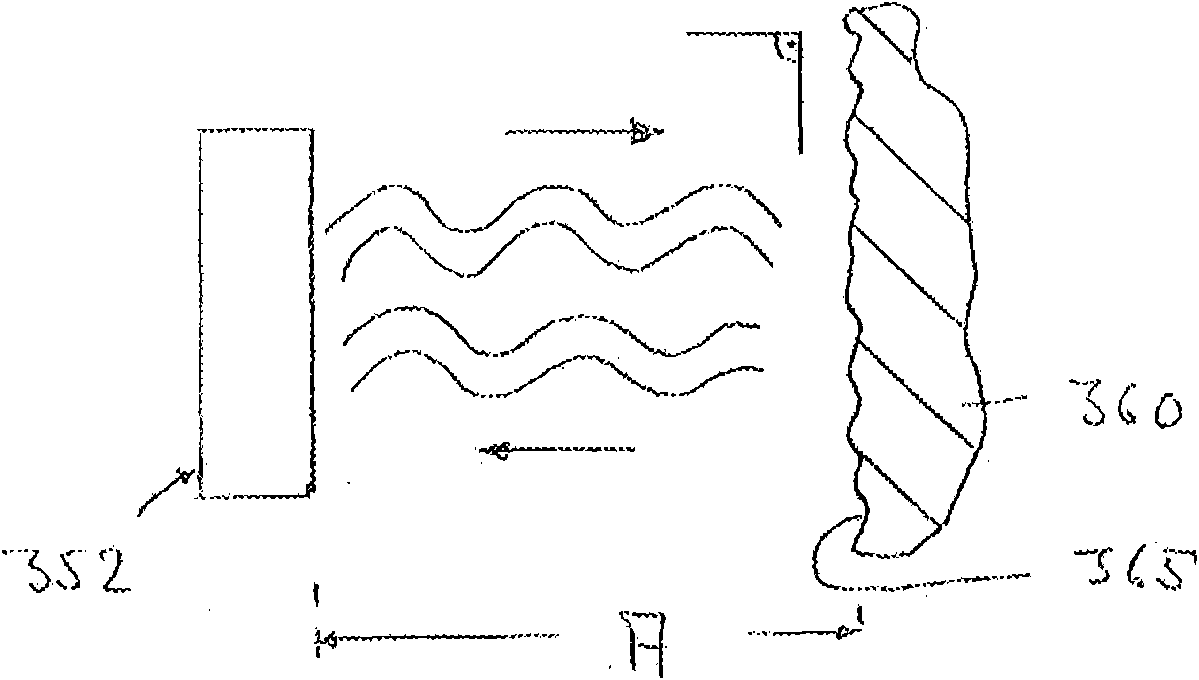

[0043] attached figure 1 Shown is a schematic view of an embodiment of a honing machine 100 designed as a vertical honing machine, which can be used, for example, for honing the inner surfaces of substantially cylindrical bores in workpieces for the production of engines. The multi-axis honing machine 100 has a plurality of honing units, with figure 1 Only one of the honing units 110 is depicted in . The honing unit 110 includes a fixed member and a member movable relative to the fixed member. The movable component comprises a honing spindle 132 mounted with a vertically extending spindle axis 133 and a transmission rod 135 connected to the free lower end of the honing spindle 132 with a spindle-side joint 136 . The honing tool 140 is connected to the free lower end of the transmission rod by means of a polyaxial joint 137 so that it can be moved t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com