Ultra-precision grinding machine for ball track

A bearing raceway and fine grinding technology, which is applied in the direction of superfinishing machines, metal processing equipment, manufacturing tools, etc., can solve the problems of rough bearing raceway, low quality, and insufficient safety, so as to improve roundness and increase production Efficiency, vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

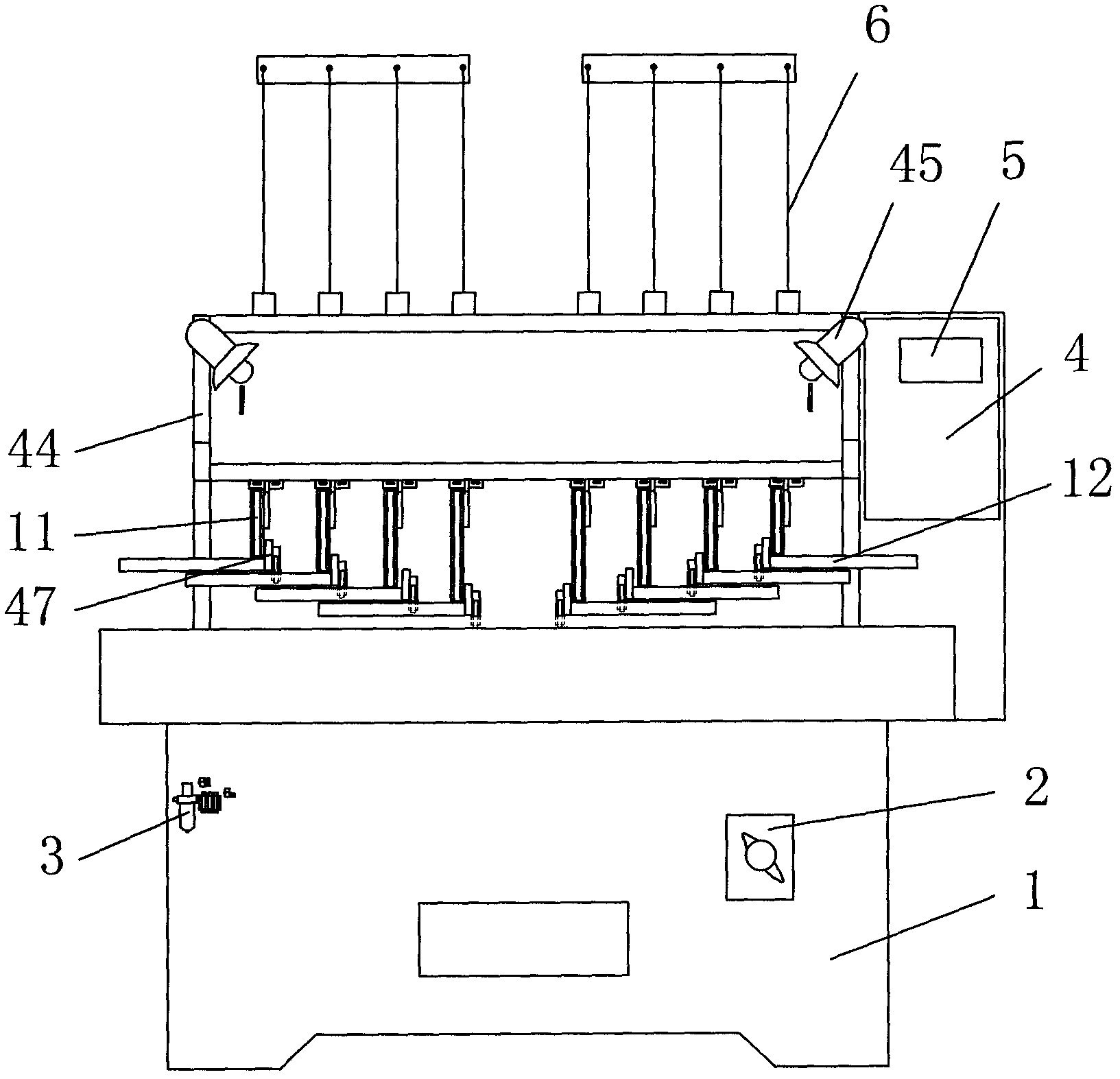

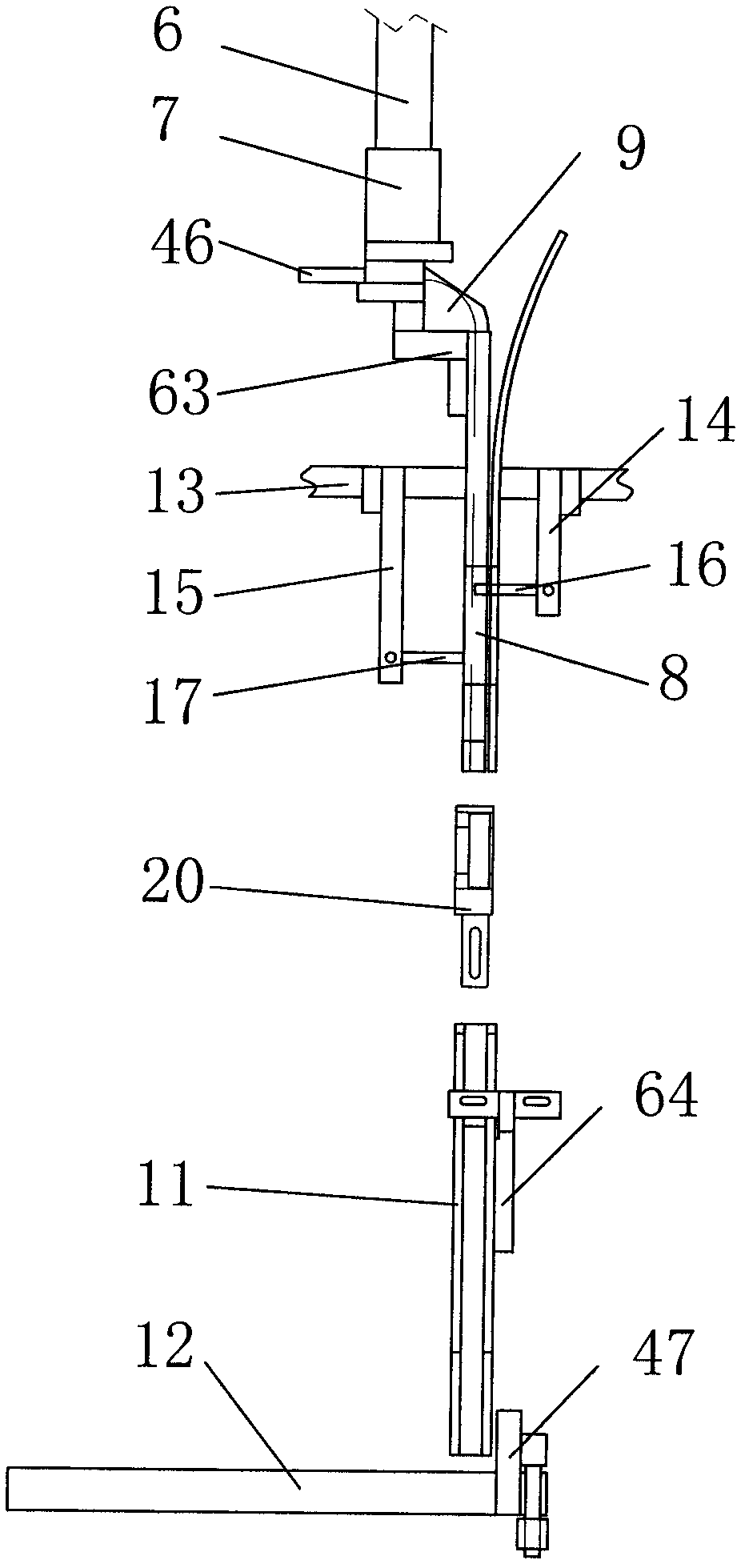

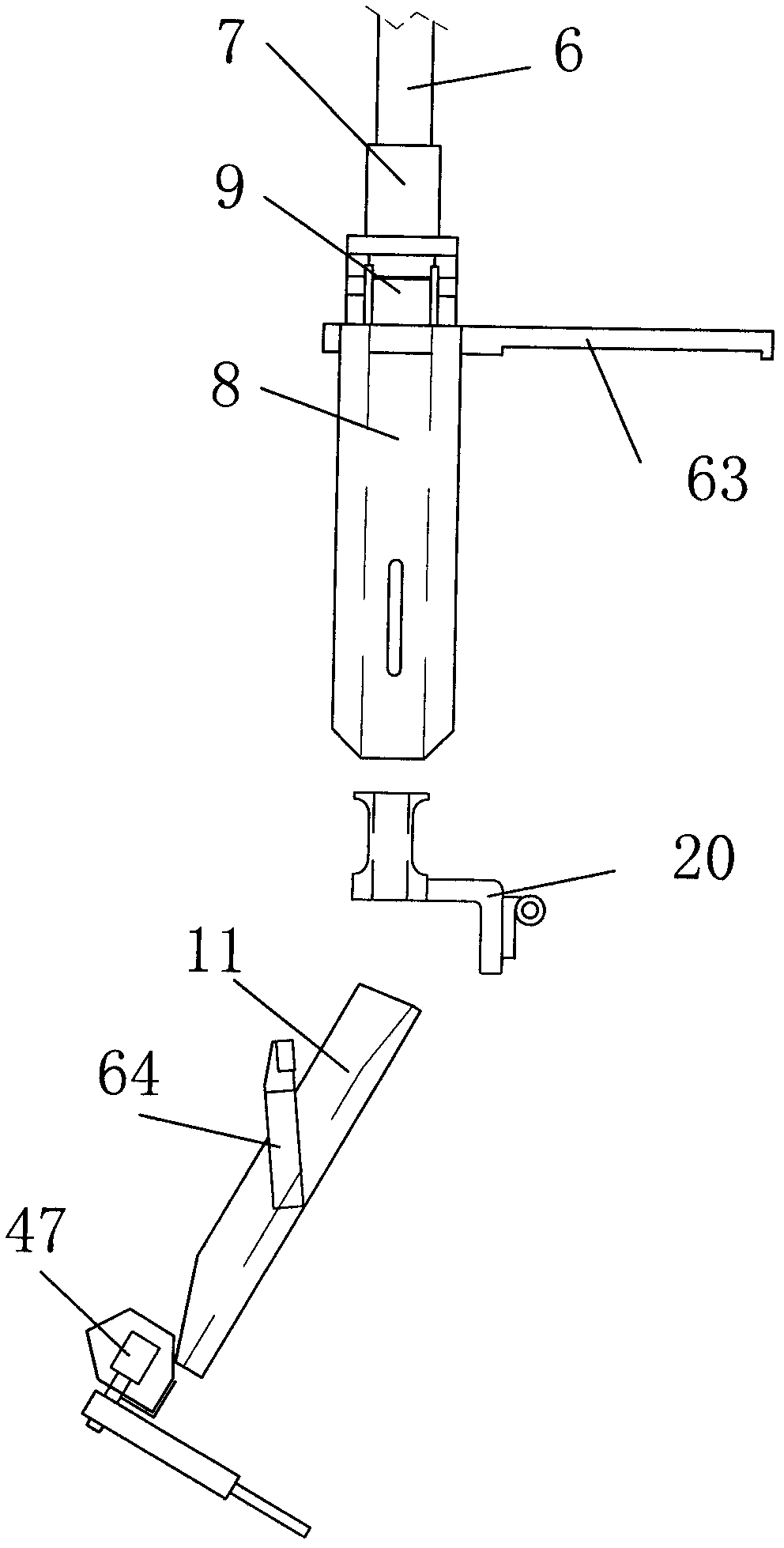

[0047] refer to Figure 1 to Figure 10 , a bearing raceway ultra-fine grinding machine, including a machine base 1, the front of the machine base 1 is provided with a main power switch 2 and a pneumatic device 3, the machine base 1 is provided with a control panel 4, and the control panel 4 is provided with a display 5. It adopts a computer-type human-machine interface input control system, which is easy to operate. At least one set of feeding components is provided on the machine base 1, and the feeding components include a connecting sleeve 7 with a vertical feeding channel. The feeding The channel is provided with a material hanging rod 6 protruding upwards outside the connecting sleeve 7, and the lower part of the connecting sleeve 7 is provided with a blanking guide sleeve 8 with a vertical feeding chute, and the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com