Inner ring groove grinding and ultra-fine-processing integral machine for fully automatic bearing ring

A technology for bearing rings and inner ring grooves, which is applied in superfinishing machines, control of workpiece feed movement, grinding machines, etc., and can solve problems such as low detection accuracy, long detection time, and large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

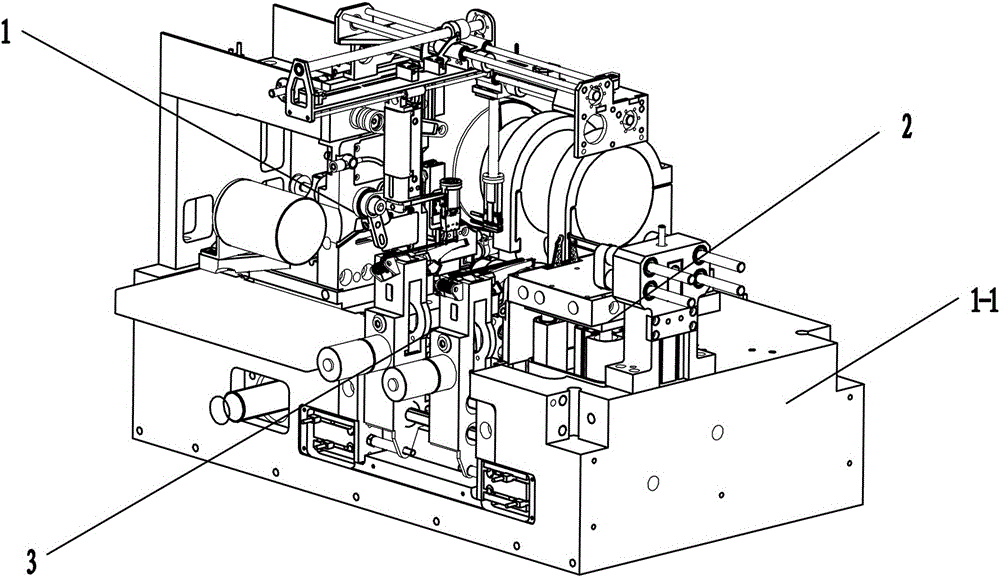

[0065] Such as figure 1 As shown, the fully automatic bearing ring inner ring groove grinding and superintegrating machine provided in this embodiment includes a machine tool 1-1, and a grinding device 1 and a grinding groove detection device 2 are provided on the machine tool 1-1. and a superfinishing device 3 .

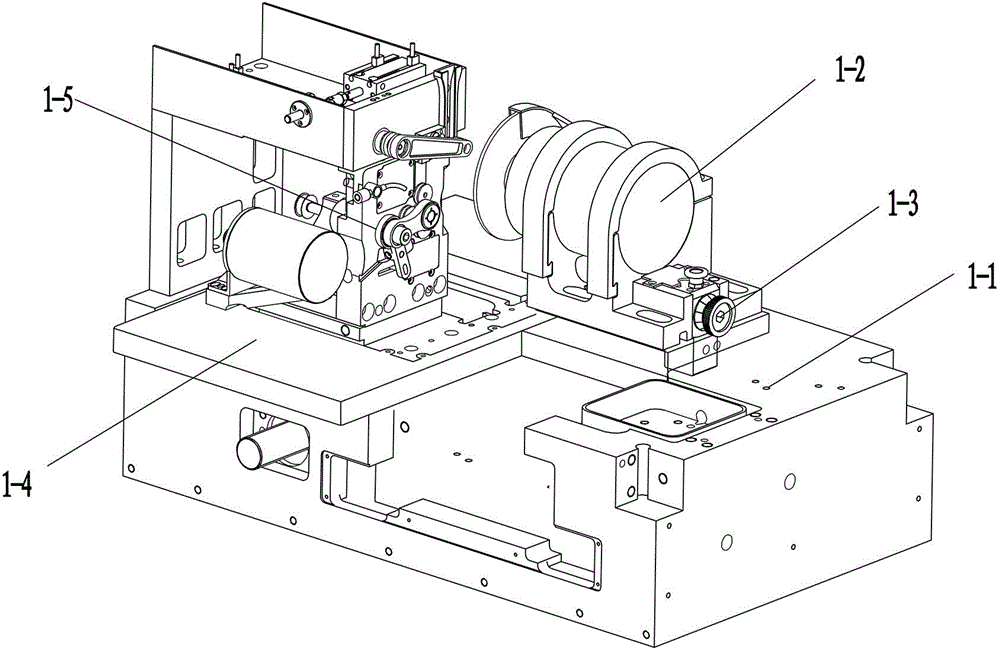

[0066] Such as figure 2 As shown, the grinding device 1 is mainly composed of a grinding wheel assembly and a sliding assembly installed on the machine tool 1-1. The grinding wheel assembly is composed of a grinding wheel 1-2 and a drive motor 1-3 that drives the grinding wheel 1-2 to rotate. The sliding assembly includes a horizontally arranged pallet 1-4 and a vertical panel 1-5 that can reciprocate left and right with the pallet 1-4, and a blanking channel 1-5 is provided on the vertical panel 1-5. 6. Processing positions 1-7 and feeding components for transferring workpieces from blanking chute 1-6 to processing positions 1-7.

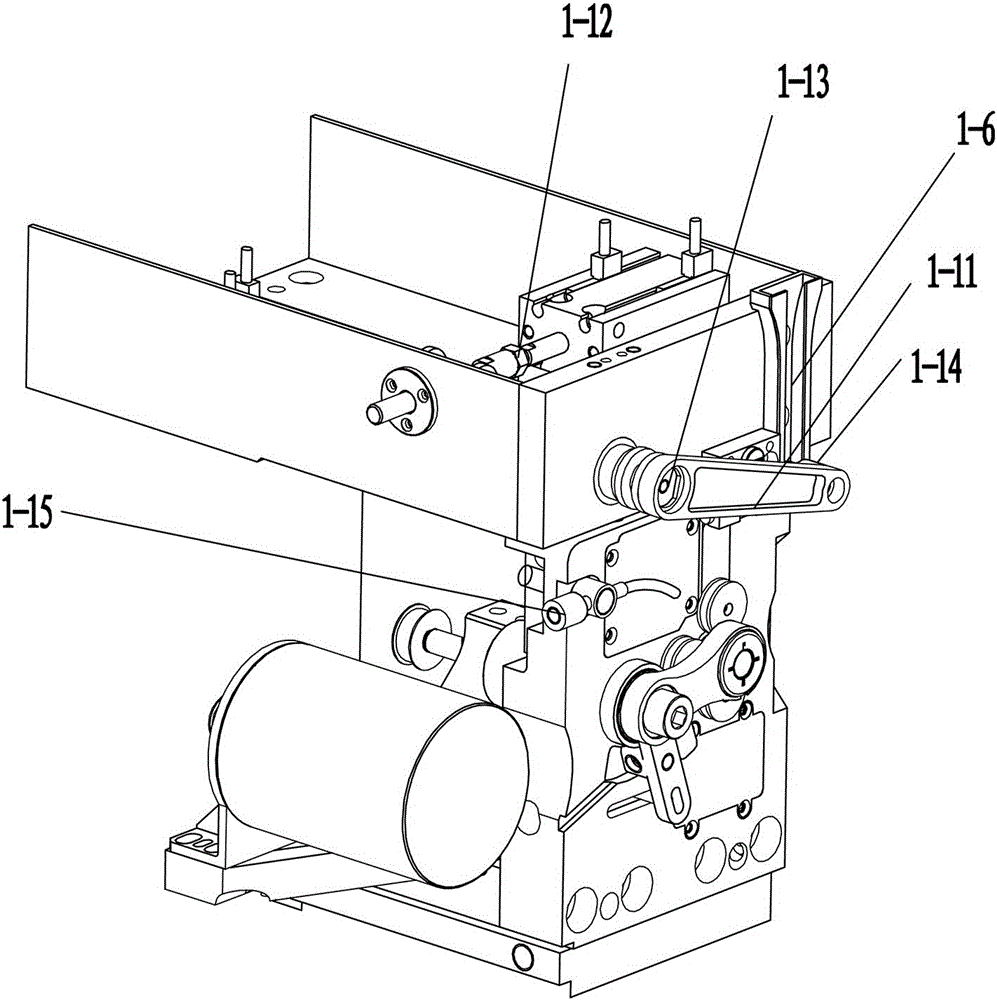

[0067] Such as image 3 As s...

Embodiment 2

[0093] Such as Figure 20 , Figure 21As shown, the fully automatic bearing ring inner ring groove grinding machine provided in this embodiment has the same general structure as that of Embodiment 1, but in the specific use process, in order to improve the grinding machine Accuracy, the machine tool 1-1 is also provided with a grinding wheel dresser 4, the grinding wheel dresser 4 includes a mounting seat 4-2, and a fixed seat 4-3 with an arc-shaped structure is provided on the mounting seat 4-2 , the upper end of the holder 4-3 is provided with a diamond pen 4-4, and the holder 4-3 is also provided with:

[0094] The countersunk bolt 4-5 that cooperates with the external adjustment knob is provided with a circle of positioning ring 4-6 on the outer periphery of the countersunk bolt 4-5 screw rod;

[0095] Lever 4-9, described lever 4-9 is the lever 4-9 that can make the diamond pen 4-4 carry out horizontal movement after the fixed shaft 4-11 on the fixed seat 4-3 is rotated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com