Bearing ring super lapping machine and using method thereof

A bearing ring and super-finishing technology, which is applied in the field of lapping machines, can solve problems such as poor precision, short service life of accessories, and high production costs, and achieve high precision lapping, good stability, and convenient operation and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

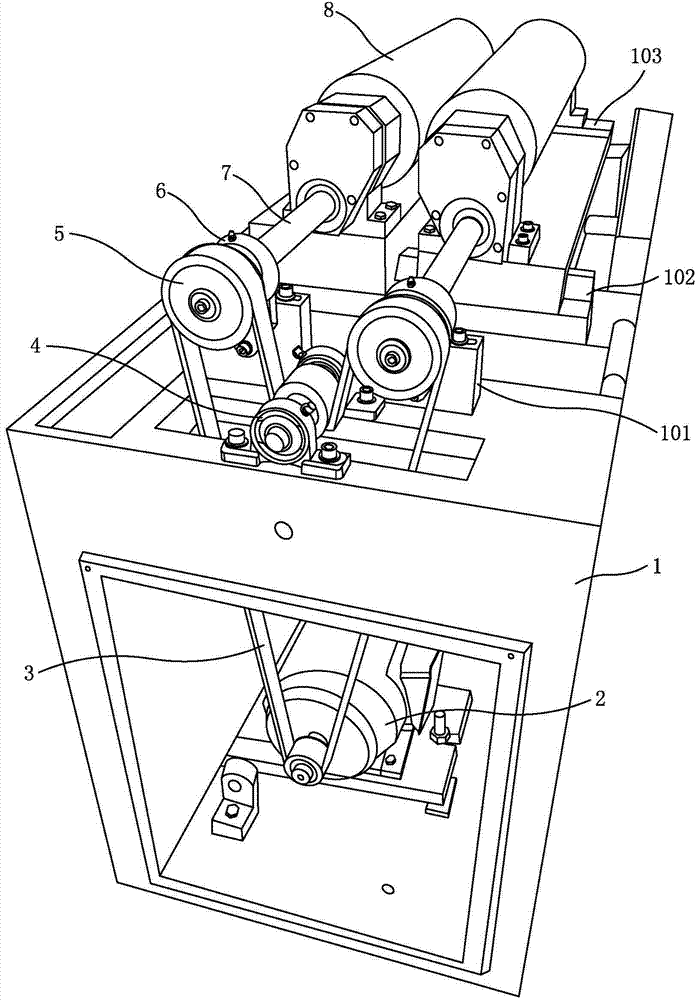

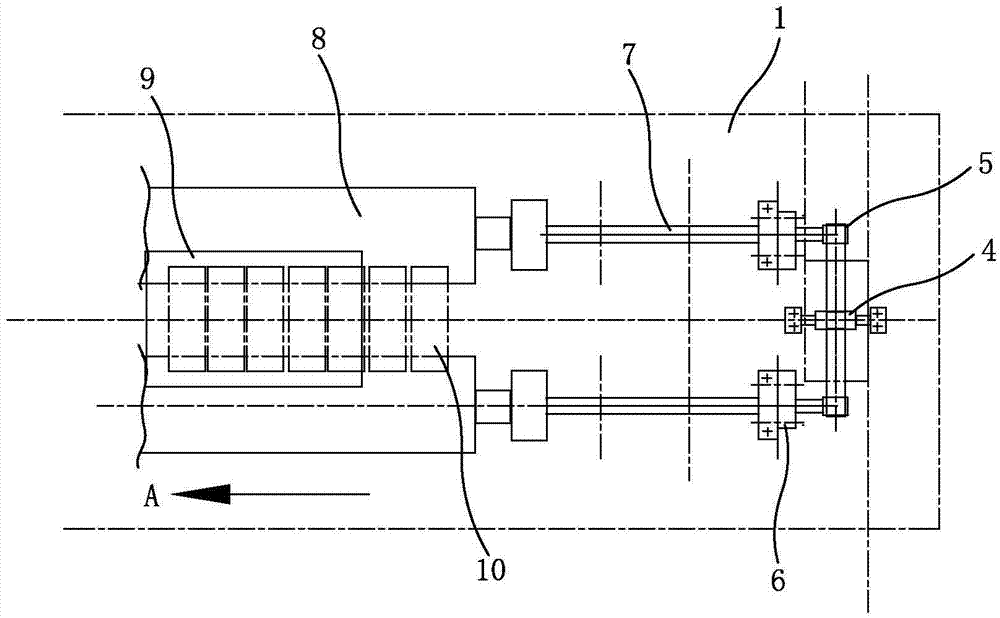

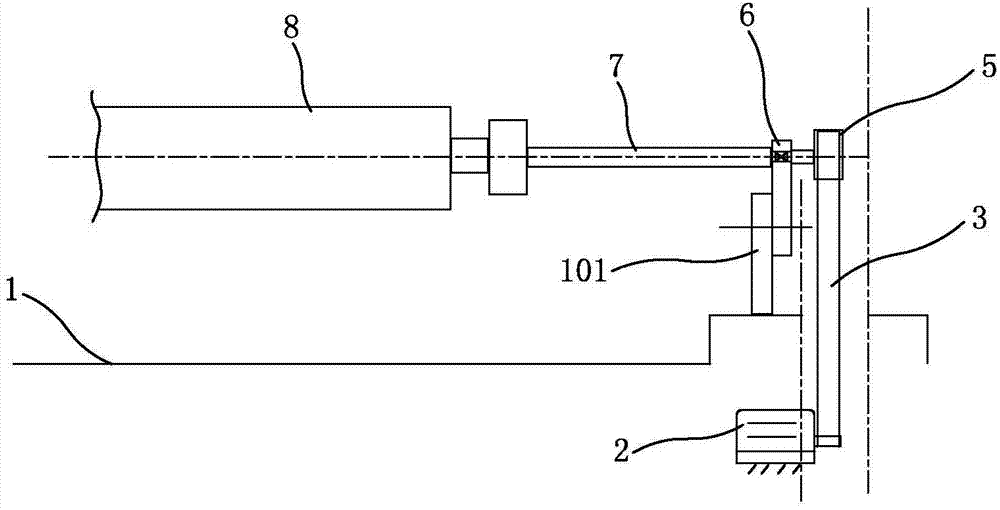

[0022] Now in conjunction with the accompanying drawings, the structure and use of the present invention will be further described. Such as Figure 1 ~ Figure 4 Shown embodiment one, this ultrafinishing machine comprises frame 1, motor 2, belt 3, pinch pulley 4, belt pulley 5, bearing assembly 6, drive shaft 7, roller 8, and frame is provided with motor, roller, The pressing wheel, the motor is arranged on the motor seat plate under the workbench of the frame, and the motor seat plate is provided with an adjustment side groove; the roller is arranged on the roller seat 103, and the roller seat is arranged on the track seat 102 of the frame work surface, and the track The screw mandrel of the seat is connected with the hand wheel on one side of the frame; a ferrule 10 is arranged between the symmetrically arranged rollers, and a whetstone 9 is arranged on the outer diameter of the rollers. One end of the roller shaft is provided with a transmission shaft respectively, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com