Single groove single race bearing super precise grinding machine

A grinding machine and raceway technology, which is applied in the field of bearing grinding machines, can solve problems such as low quality, low roundness of the groove, and low efficiency, and achieve the effects of stable and reliable action, improved protection safety, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

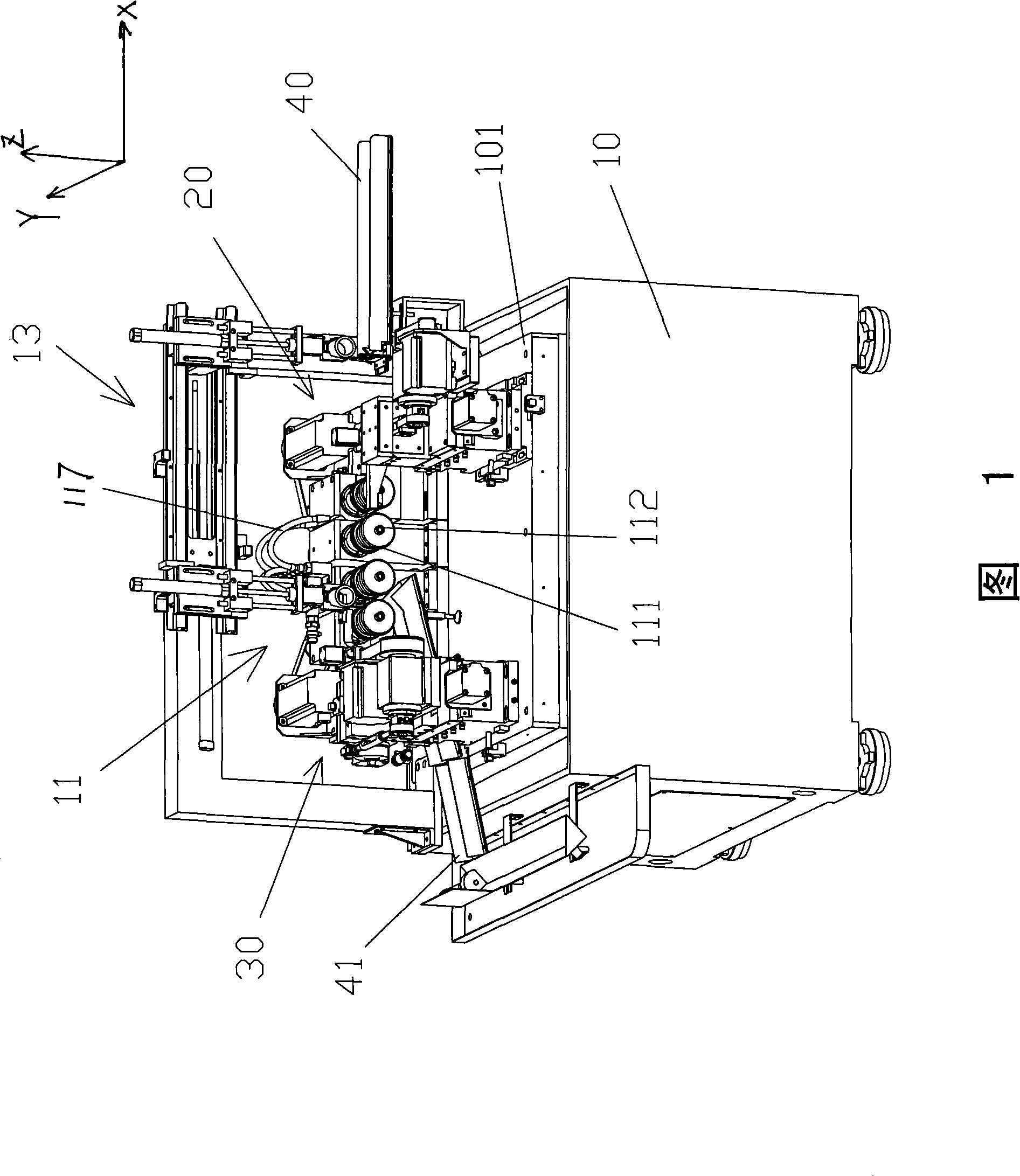

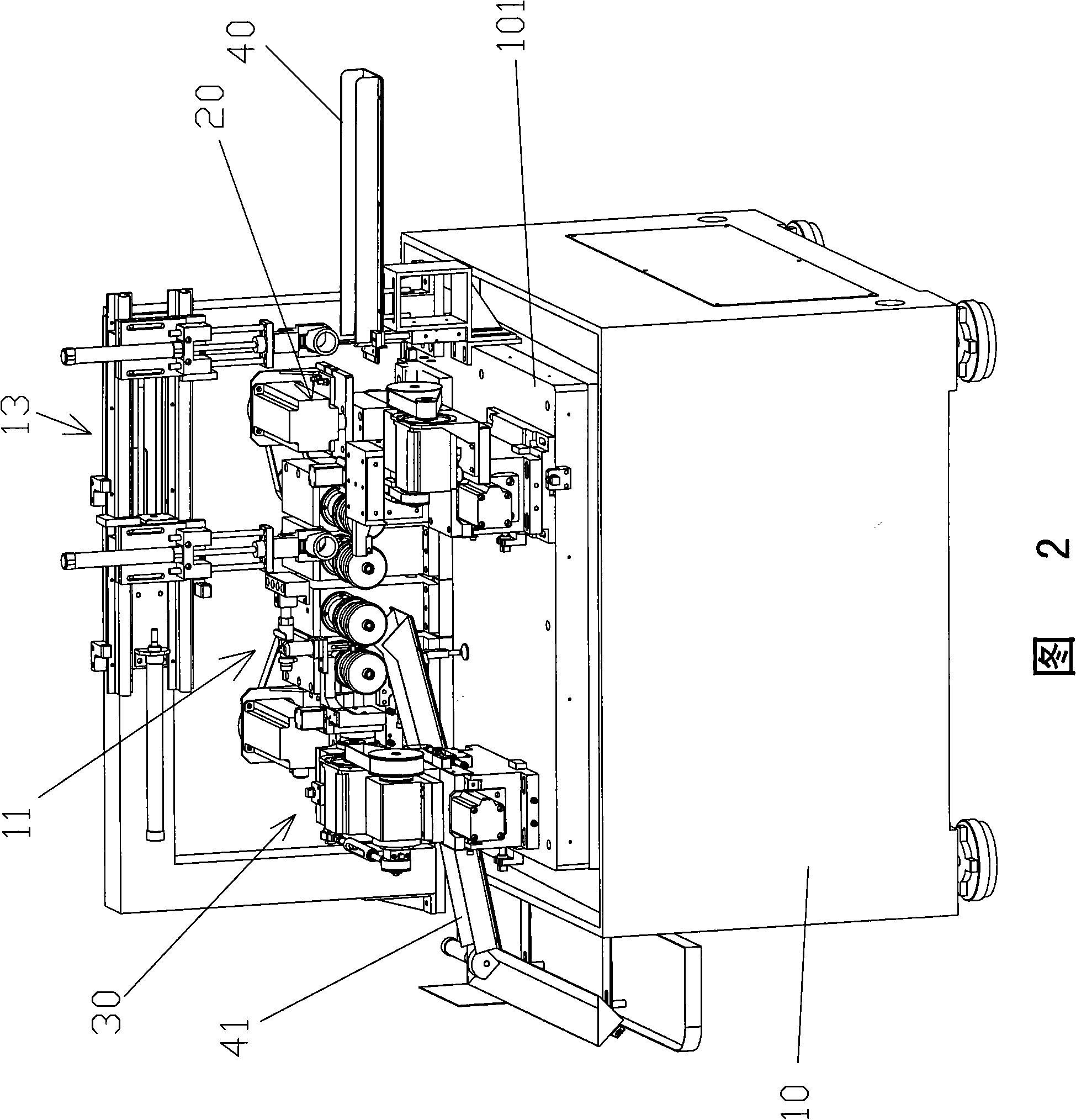

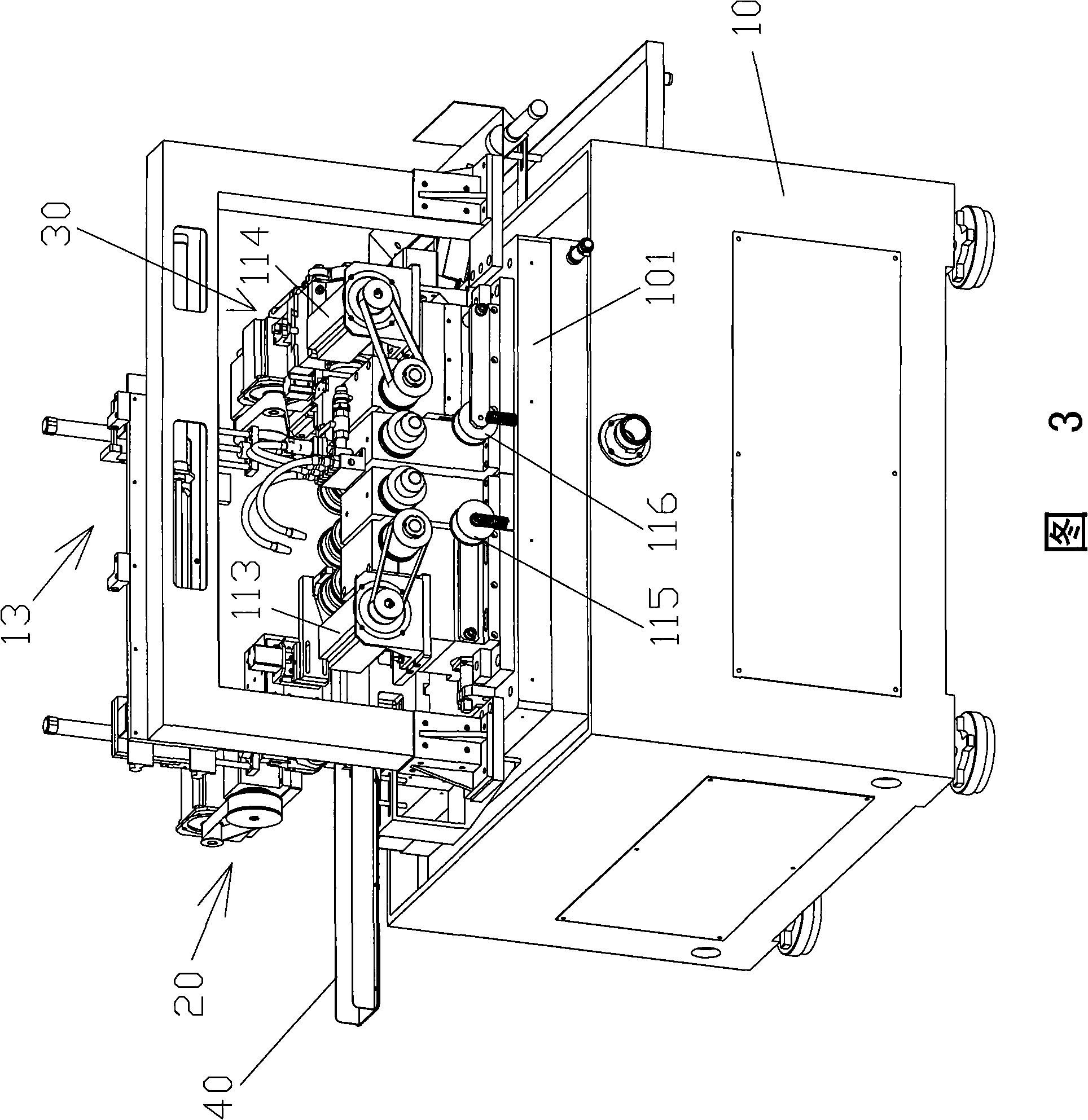

[0029] Referring to FIGS. 1 to 3 , the superfinishing machine for single-channel and single-raceway bearings of the present invention includes: a frame 10 , a workpiece seat 11 , a grinding device, and a feeding device 13 . The bed of the machine frame adopts a welded structure and is tempered at low temperature. A cast iron plate 101 with a large thickness is placed on the bed. The relative position is fixed. At the same time, a fully enclosed cover (not shown) can be installed on the bed to prevent splashing of the cooling oil mist used to cool the workpiece (ie the bearing) during processing.

[0030] The workpiece seat 11 is located at the center of the rear side of the frame 10, and it has four cylinders 111 arranged in parallel, which are respectively arranged on four workpiece spindles 112, wherein two cylinders are used as a group, and workpieces to be processed can be placed therebetween. A raceway grinding station and a channel grinding station are formed respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com