Method of grinding and processing gear wheel

A processing method and gear grinding technology, applied to hardened tooth surfaces, can solve the problems of restricting the precision of spiral bevel gears, high cost of grinding teeth, and lack of finishing process, so as to reduce the degree of unevenness of roughness and abrasive grain scratches, Effect of increasing cutting length and efficiency and improving surface integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

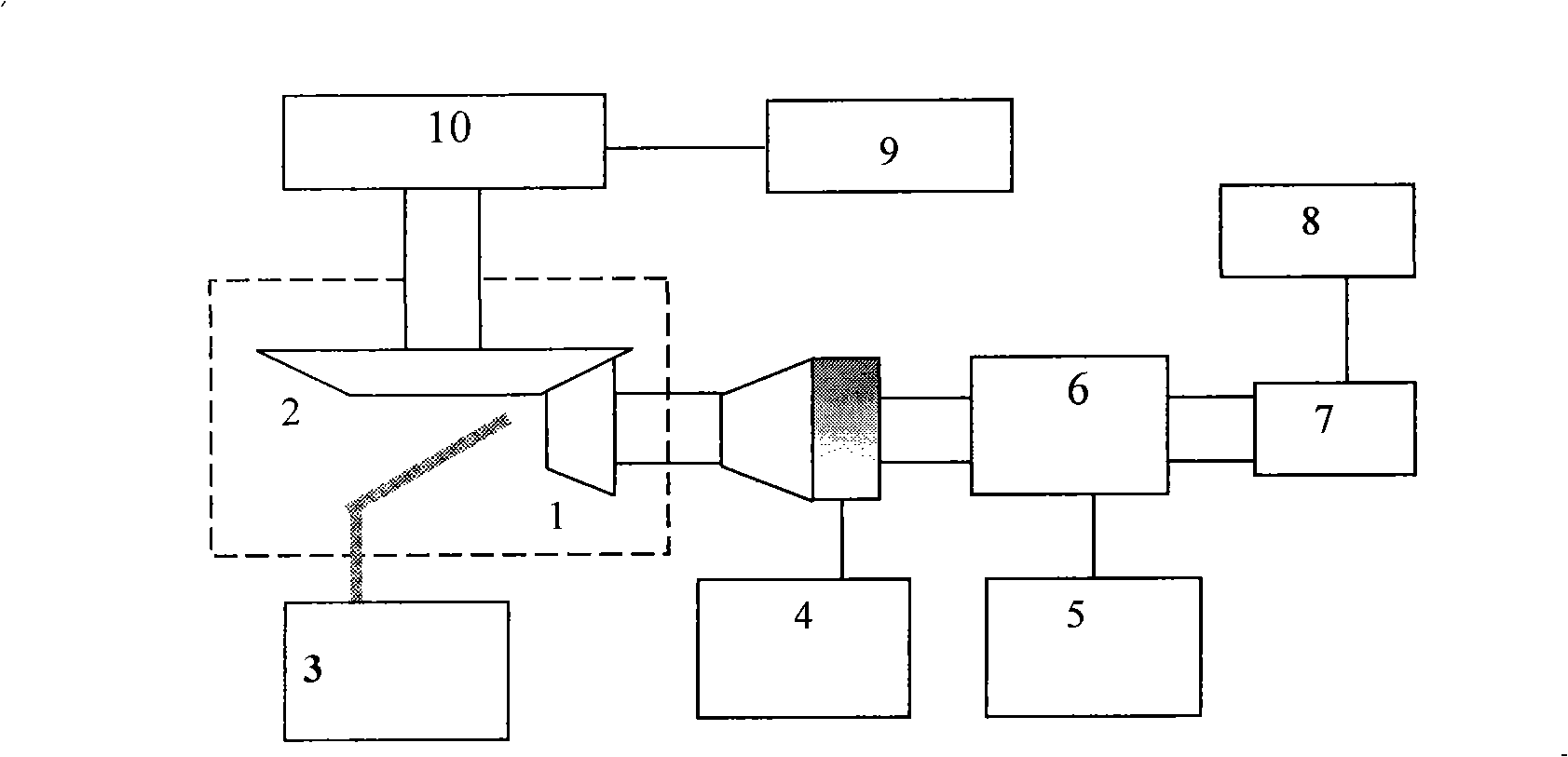

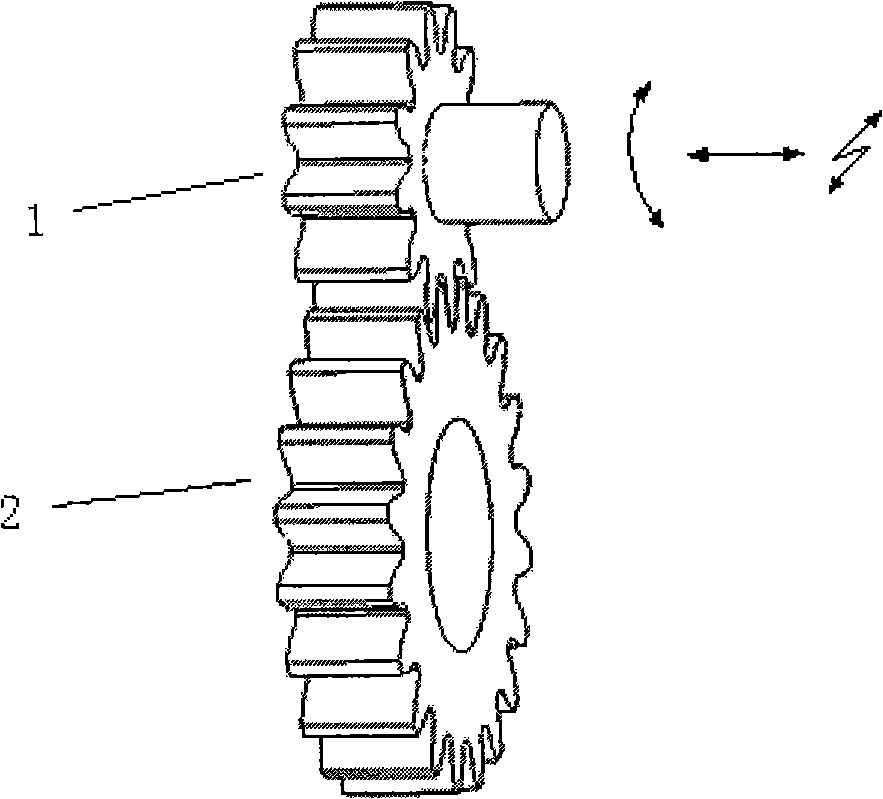

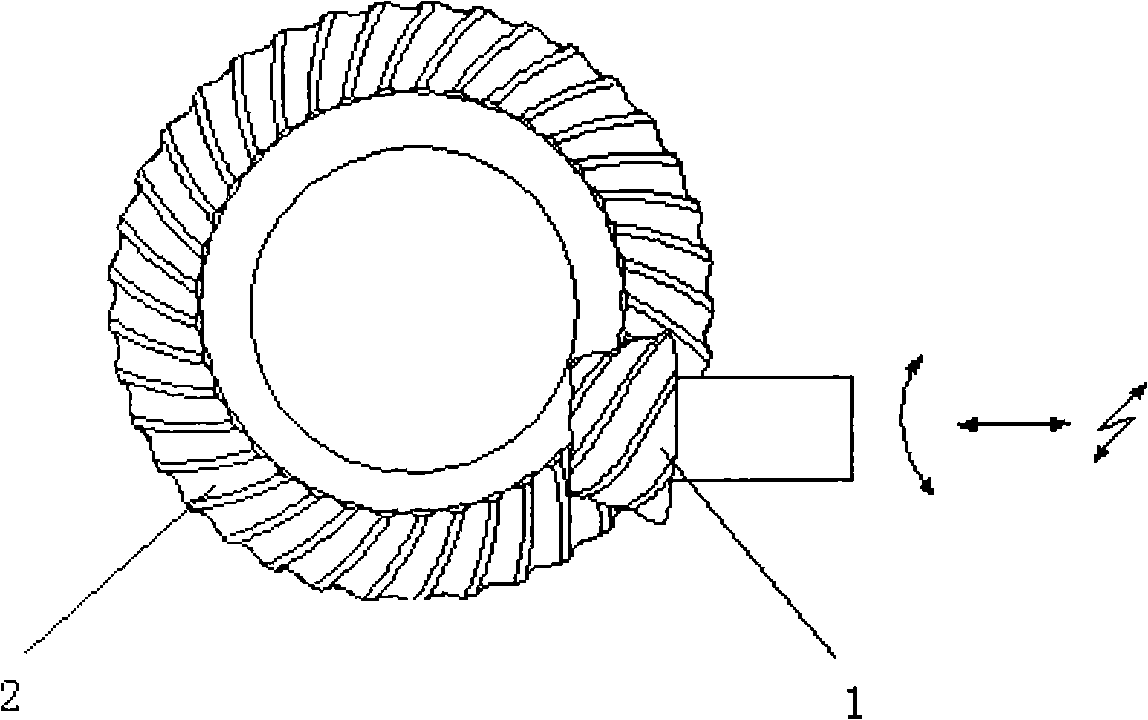

[0037] Example 1: Ultrasonic grinding of spiral bevel gears (1)

[0038] Select two pairs of steel spiral bevel gears, as attached Figure 1 As shown, the modulus is 1.25mm, the gear ratio is 17 / 44, the tooth surface hardness of the large wheel is 48HRc, and that of the small wheel is 50HRc.

[0039] The abrasive is mixed with water and white corundum, the concentration is 25%, and the supply rate is 65.3mL / s. Choose W40# white corundum

[0040] The frequency f=19kHz of the ultrasonic tooth grinding, because the gear to be ground is relatively small, the amplitude of the small end face of the small wheel is adjusted to A1=8μm.

[0041] The rotational speed of the driving gear during processing is 600r / min, the braking torque applied to the driven gear is 0.2Nm, and the grinding time is 2min. According to the weight loss of the gears before and after grinding, the material removal rate was measured to be 87.3mg / min.

Embodiment 2

[0042] Example 2: Ultrasonic grinding of spiral bevel gears (2)

[0043] Select two pairs of steel spiral bevel gears, and the gear parameters are the same as in Example 1.

[0044] The abrasive is mixed with water and white corundum, the concentration is 20%, and the supply rate is 65.3mL / s. Choose W40# white corundum.

[0045] The frequency f=19kHz for ultrasonic tooth grinding, and the amplitude of the small end face of the small wheel is adjusted to A1=8μm.

[0046] The rotational speed of the driving gear during processing is 200r / min, the braking torque applied to the driven gear is 0.12Nm, and the grinding time is 2min. According to the weight loss of the gears before and after grinding, the material removal rate was measured to be 132.0mg / min.

Embodiment 3

[0047] Example 3: Ultrasonic Grinding of Spiral Bevel Gears (3)

[0048] Select two pairs of steel spiral bevel gears, and the gear parameters are the same as in Example 1.

[0049] The abrasive is made by mixing water and W40# white corundum, the concentration is 20%, and the supply rate is 65.3mL / s.

[0050] The frequency f=19kHz for ultrasonic tooth grinding, and the amplitude of the small end face of the small wheel is adjusted to A1=8μm.

[0051]The rotational speed of the driving gear during processing is 400r / min, the braking torque applied to the driven gear is 2.0Nm, and the grinding time is 3min. According to the weight loss of the gears before and after grinding, the material removal rate was measured to be 65.0mg / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com