Ultrasonic pushing device for sectional material

A pushing device, ultrasonic technology, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as vibration, meshing deviation of aluminum profiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings,

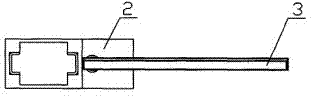

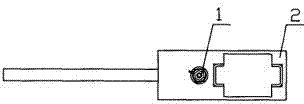

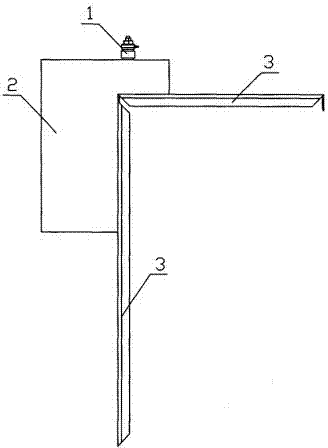

[0012] Such as Figure 1~4 As shown, a profile ultrasonic pushing device includes a pushing module 2 movably installed on the elastic beam of the framing machine. The rear end of the pushing module 2 is equipped with an ultrasonic transducer 1 with an ultrasonic electric energy generating device.

[0013] The working principle of the present invention is as follows:

[0014] When the framing machine is framing, the ultrasonic transducer 1 is powered on, so that the ultrasonic transducer 1 enters the working state, and the extrusion of the aluminum profile 3 is realized with the movement of the pushing module 2 . The ultrasonic transducer 1 cooperates with the pushing module 2 to perform ultrasonic loading on the aluminum profile 3 to reduce m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com