Two dimensional ultrasonic vibration assistant grinding device for grinding large-sized structural parts

A technology of two-dimensional ultrasonic vibration and large-scale structural parts, which is applied in the direction of ultra-finishing machines, metal processing equipment, manufacturing tools, etc., can solve the problem of destroying the overall performance of grinding machines, achieve high-efficiency and high-quality, improve processing efficiency, and surface The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

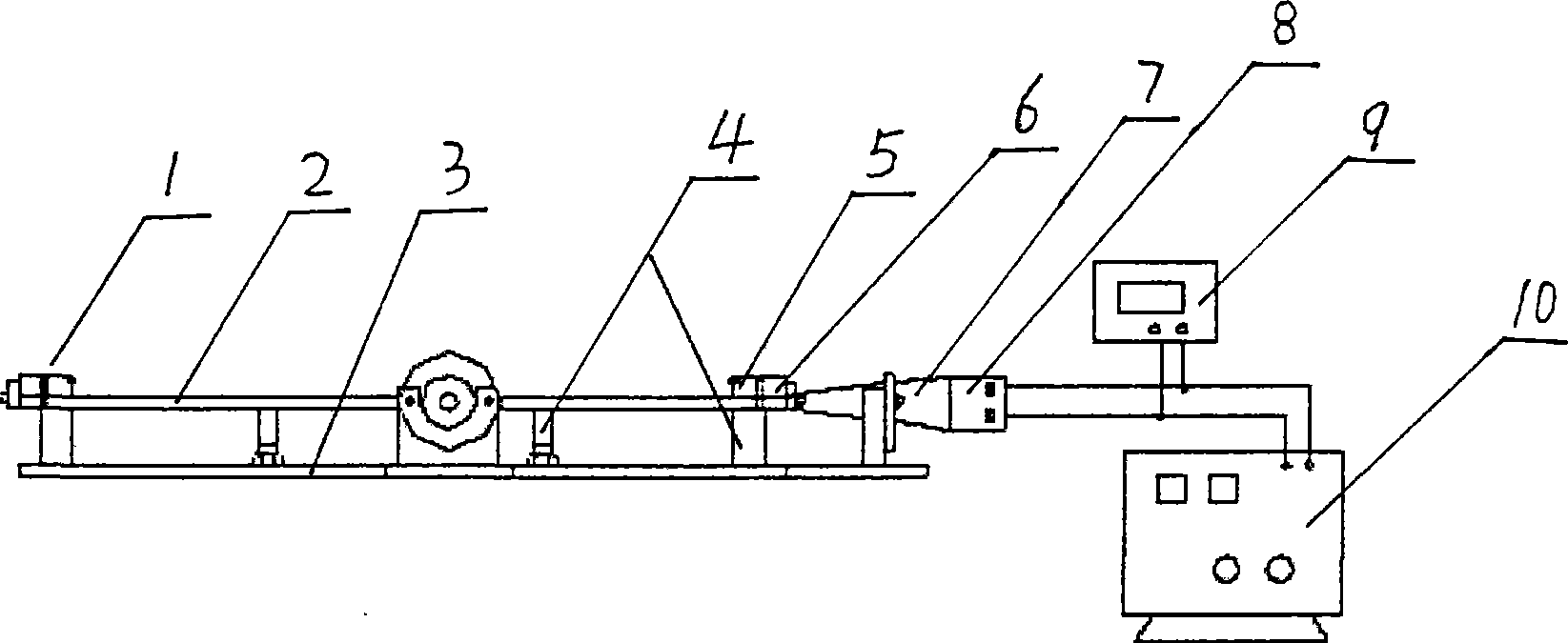

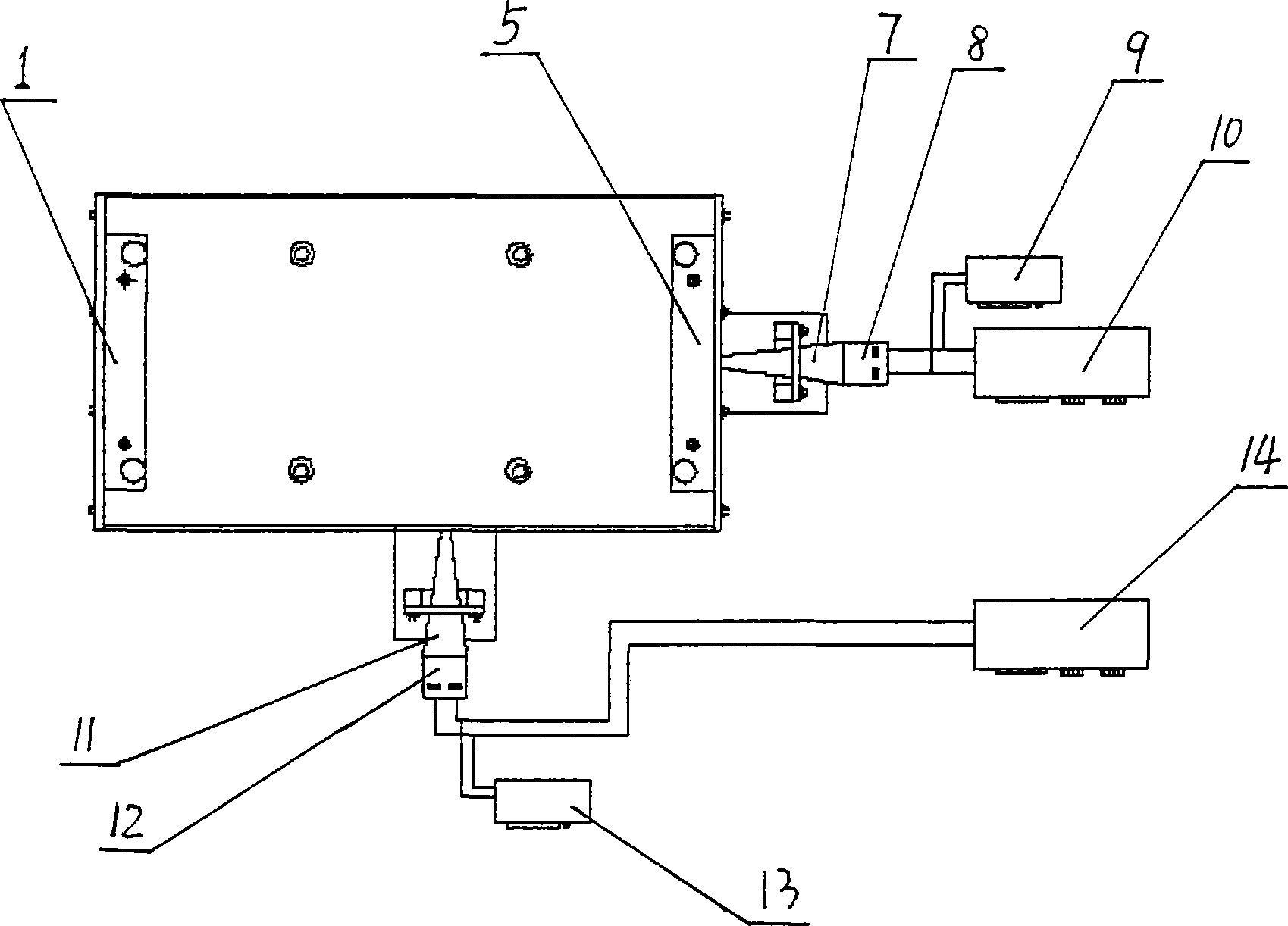

[0009] Depend on figure 1 , figure 2 It can be seen that the present invention includes: upper panel 2, lower panel 3, supporting legs 4, longitudinal horn 7, longitudinal transducer 8, first frequency meter 9, first ultrasonic generator 10, axial horn 11, An axial transducer 12 , a second frequency meter 13 , and a second ultrasonic generator 14 . The upper panel 2 and the lower panel 3 are supported and fixed by the legs 4, and the two ends of the upper panel 2 are provided with an adjustable pressure plate 1 and a pressure plate 5, and the processed parts placed on the upper panel are clamped by the adjustable pressure plate and the pressure plate. Tight, so that the workpiece is integrated with the upper panel, and a baffle 6 is arranged at the right end of the pressure plate to enhance the clamping degree of the pressure plate to the workpiece. The longitudinal horn 7 is fixedly connected to the longitudinal transducer 8, the axial horn 11 is fixedly connected to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com