Ultrasonic vibration auxiliary grinding device for minutely processing surface of micro-structure

An ultrasonic vibration and precision machining technology, applied in the field of ultrasonic vibration-assisted grinding devices, can solve the problems of destroying the surface shape accuracy of the microstructure and the inability to adjust the vibration direction, so as to reduce the crushing phenomenon, expand the plastic processing domain, and improve the normal direction. The effect of grinding stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

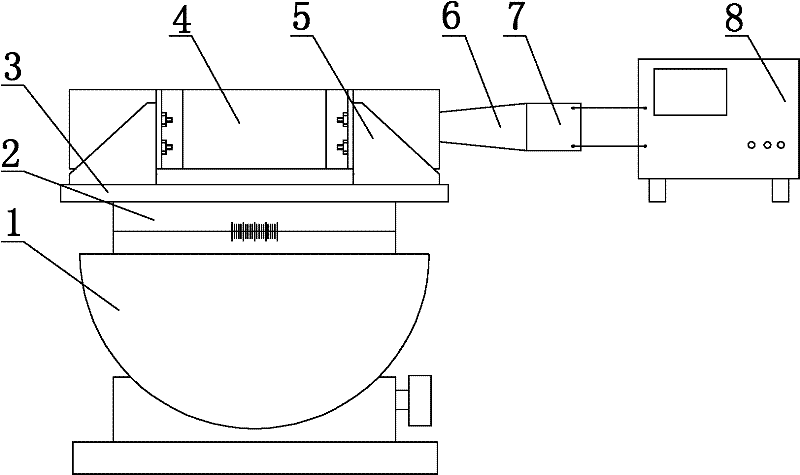

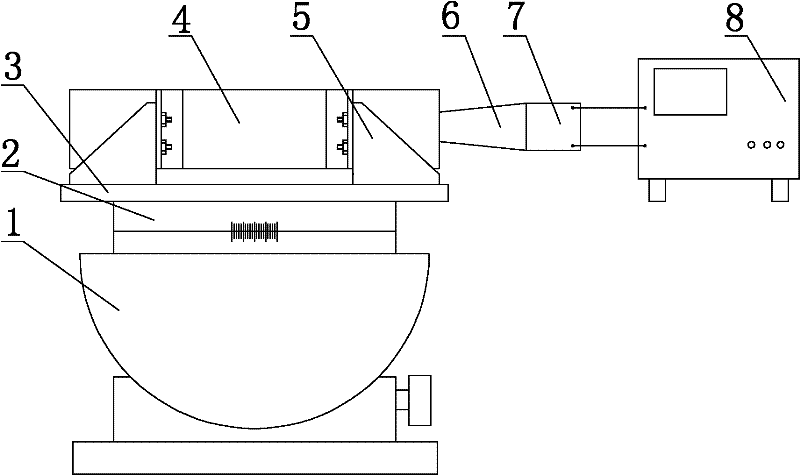

[0010] Specific implementation mode one: combine Figure 1~2 Explain that the ultrasonic vibration-assisted grinding device for microstructure surface precision machining in this embodiment includes a support base plate 3, a vibration table 4, four supports 5, a horn 6, a transducer 7 and an ultrasonic generator 8 , the ultrasonic vibration assisted grinding device also includes a tilting table 1 and a rotary table 2, the lower end surface of the rotary table 2 is fixed on the upper end surface of the tilting table 1, and the support base plate 3 is fixed on the top surface of the rotary table 2 On the upper end face, the vibrating table 4 is fixed above the support base plate 3 through four supports 5, one end of the horn 6 has a small area, and the other end has a large area, and the small area end of the horn 6 is connected to the The side wall of the vibration table 4 is fixedly connected, and the large-area end of the horn 6 is fixedly connected to the transducer 7, and t...

specific Embodiment approach 2

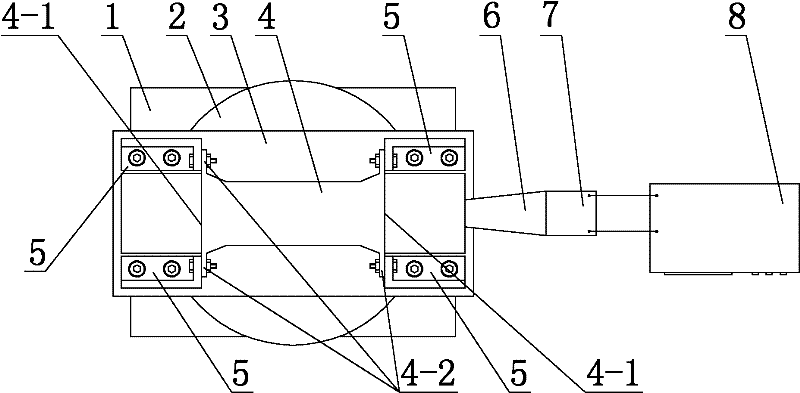

[0012] Specific implementation mode two: combination figure 2 To illustrate, the outline of the vibration table 4 in this embodiment is in the shape of a dumbbell. With such a design, the vibration table 4 can amplify the amplitude of high-frequency mechanical oscillation through its dumbbell-shaped structure. Other compositions and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 2 Note that there are two vibrating nodal surfaces 4-1 with zero amplitude in the longitudinal direction of the vibrating table 4 in this embodiment, and each vibrating nodal surface 4-1 of the vibrating table 4 is provided with two fixed support plates 4-2, and the four fixed support plates 4-2 on the two vibration joint surfaces 4-1 of the vibration table 4 are arranged in one-to-one correspondence, and the four fixed support plates 4-2 on the vibration work table 4 are respectively It is fixedly connected with the corresponding supporting member 5. This design improves the normal machining stiffness during the grinding process and further ensures the surface shape accuracy of the microstructure surface after grinding. Other compositions and connections are the same as those in Embodiment 2.

[0014] working principle:

[0015] Fix the workpiece to be ground at the center of the upper end surface of the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com