Patents

Literature

131results about How to "No internal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

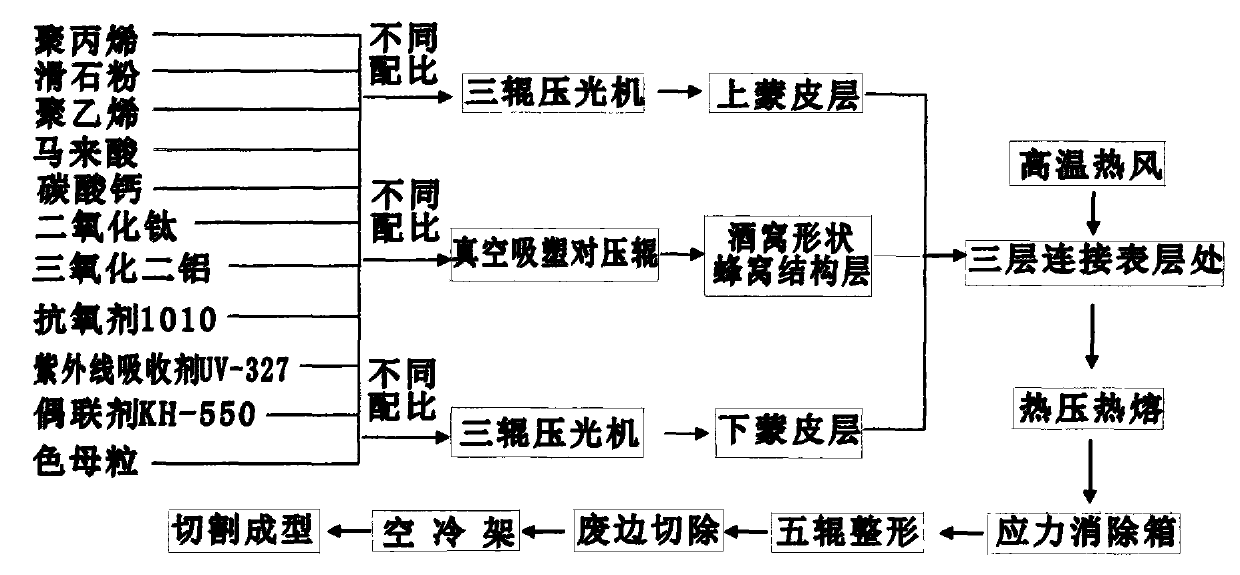

Dimple-shaped honeycomb hollow plate and manufacturing method thereof

InactiveCN104275836AImprove toughnessReduce crystallinityLamination ancillary operationsSynthetic resin layered productsPolypropyleneCHEEK DIMPLES

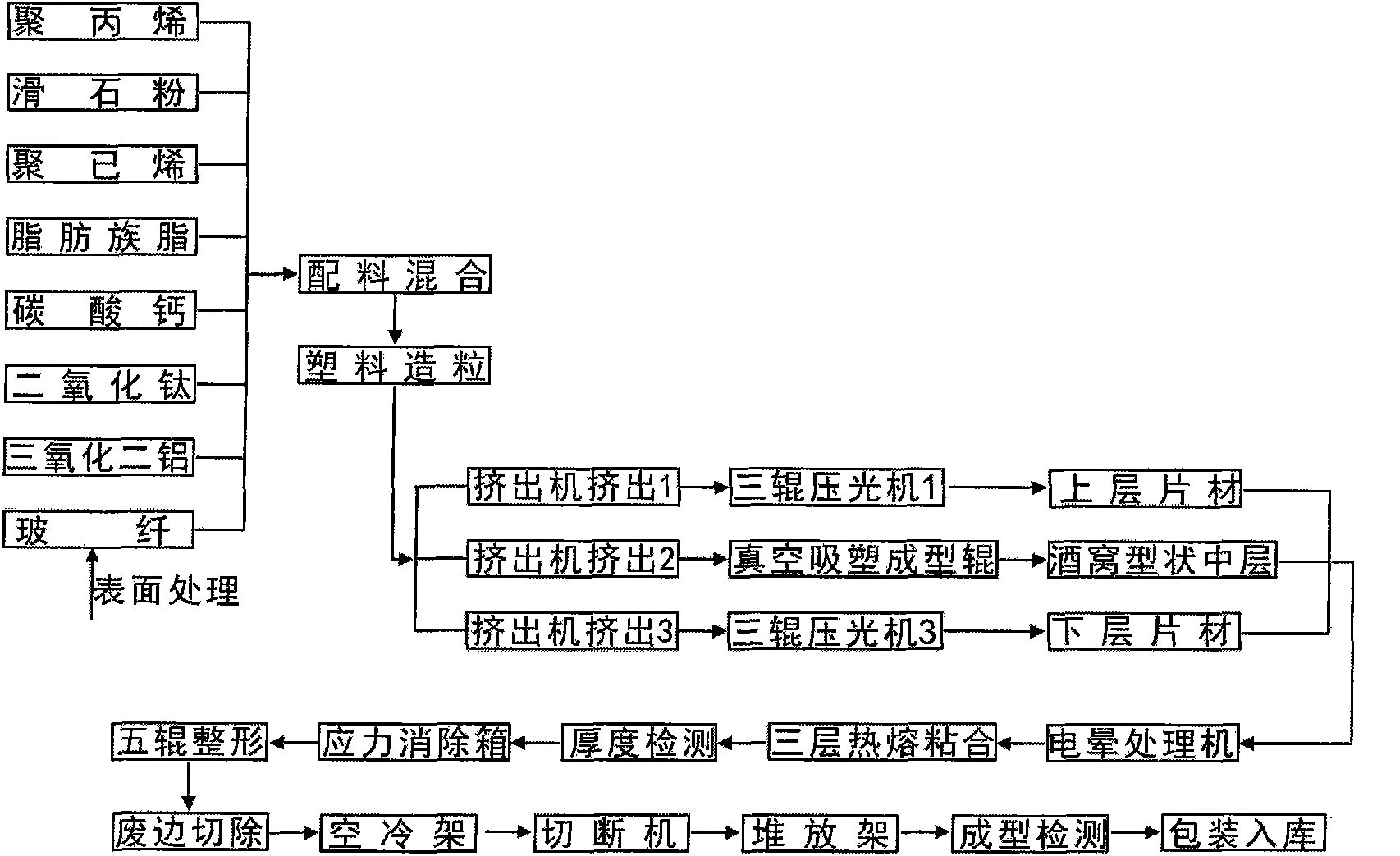

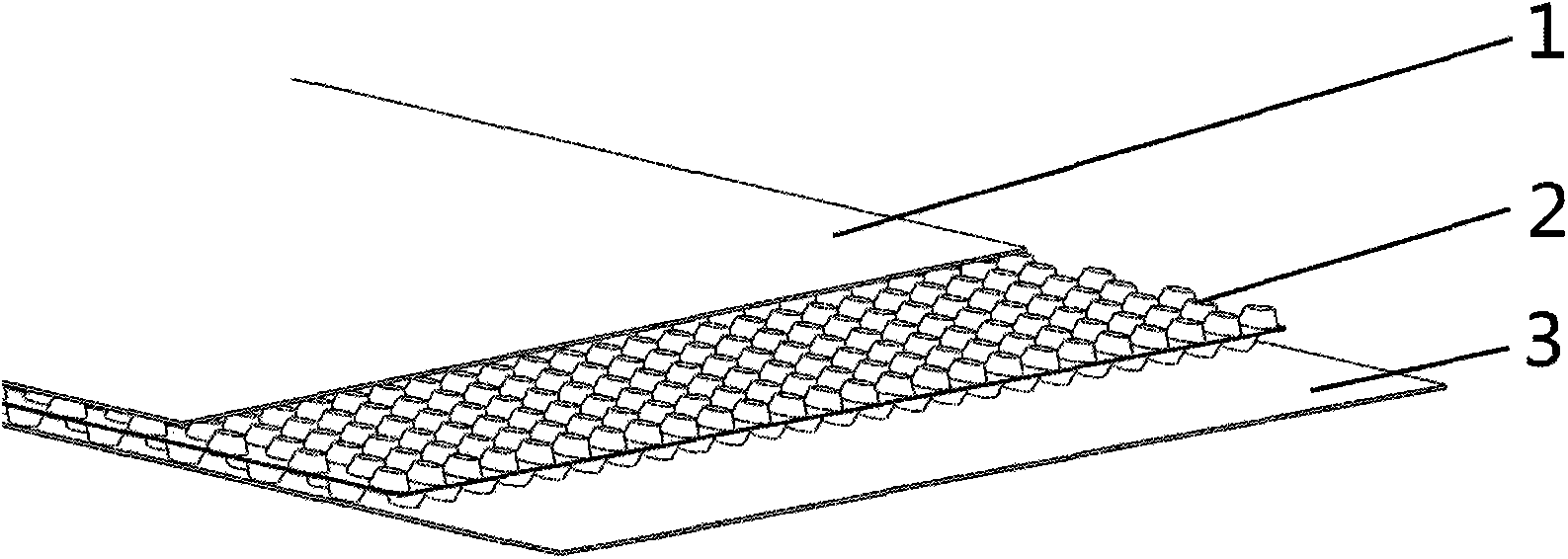

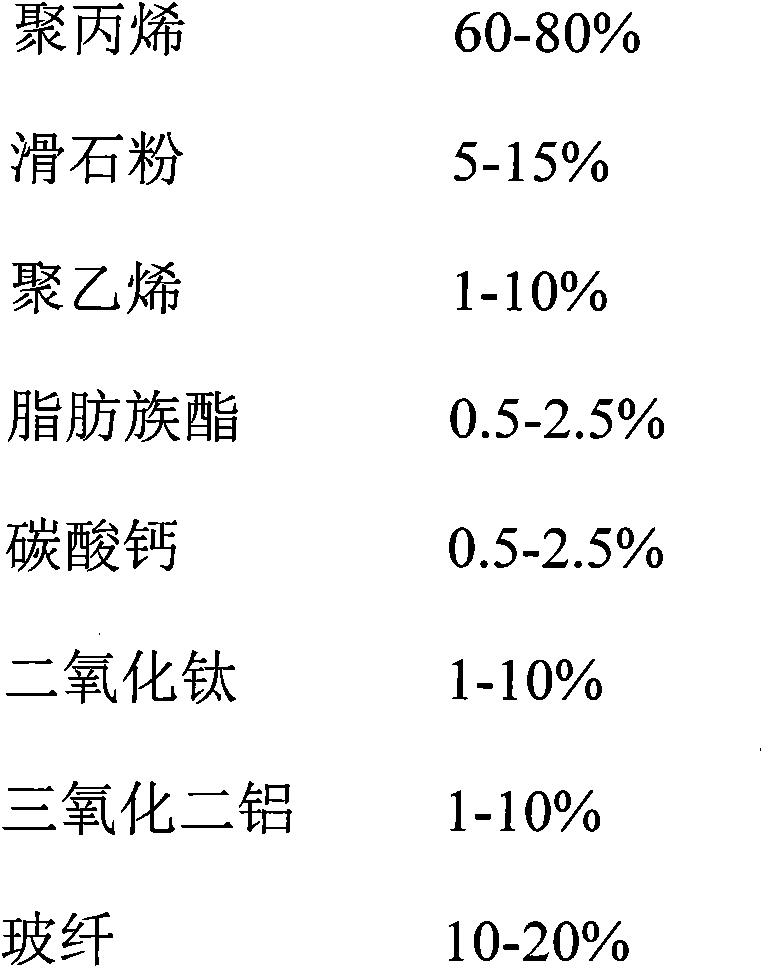

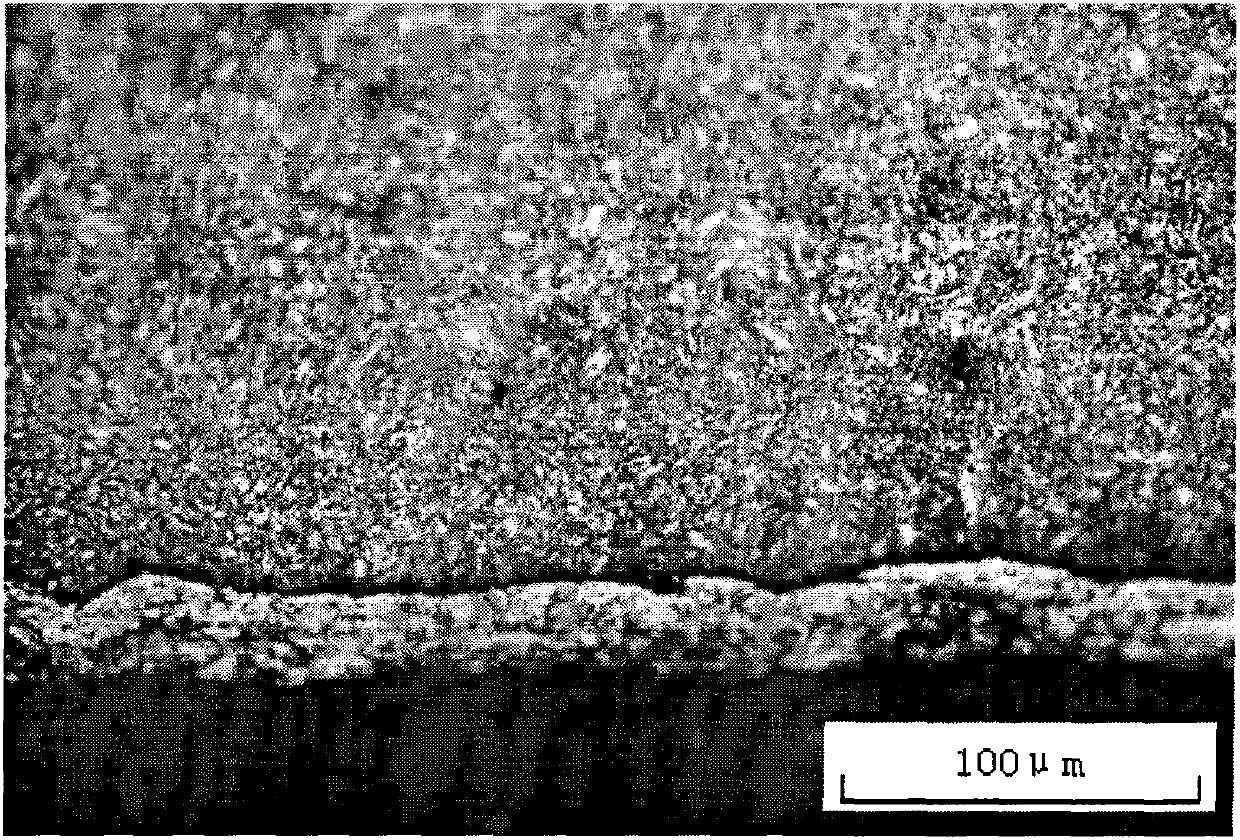

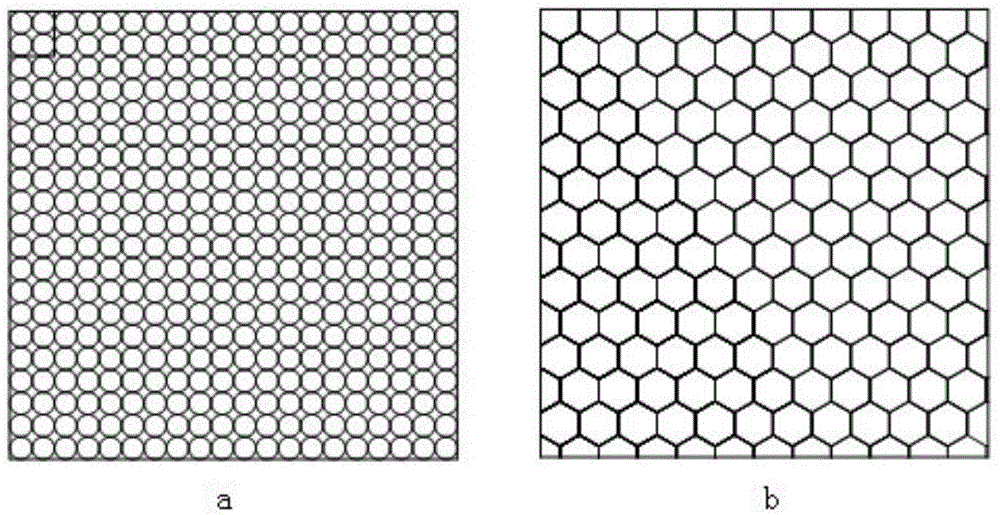

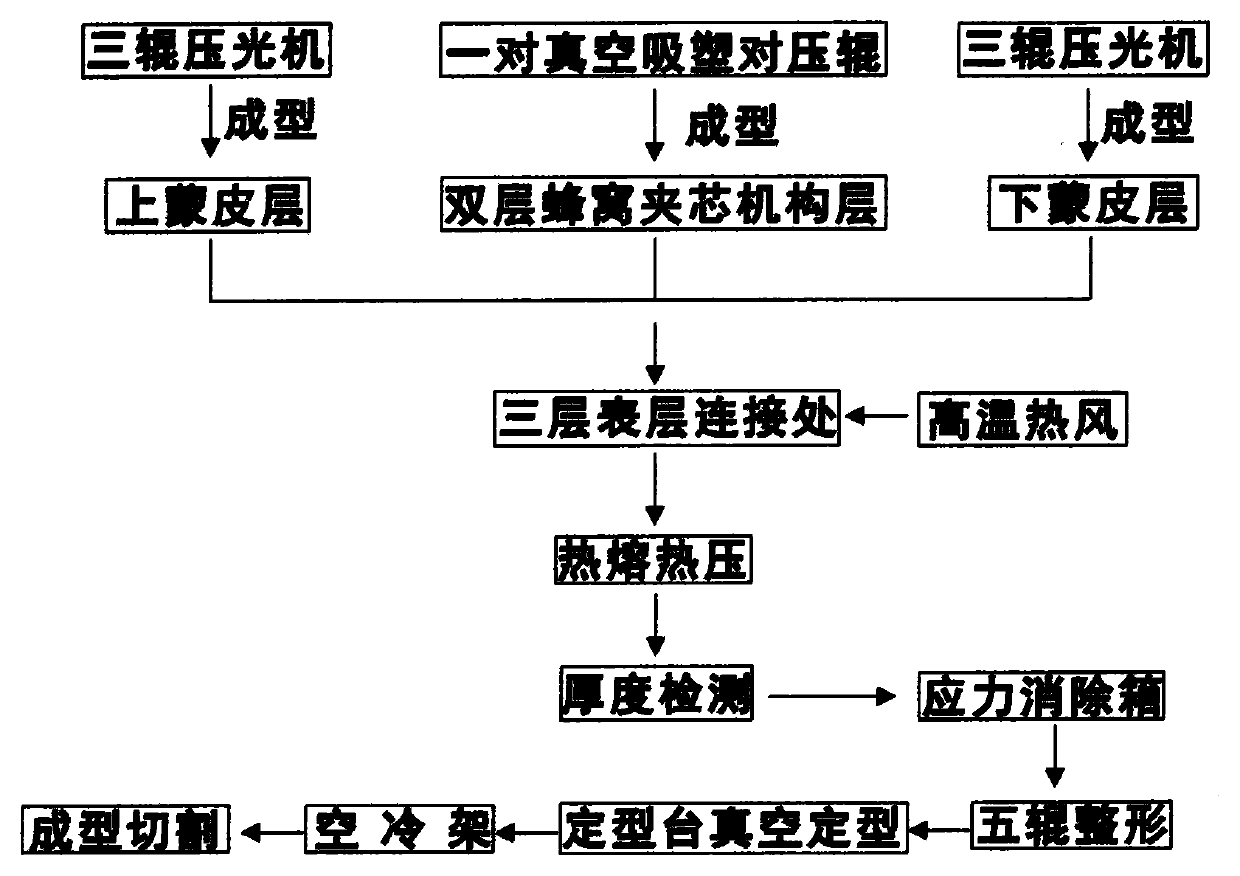

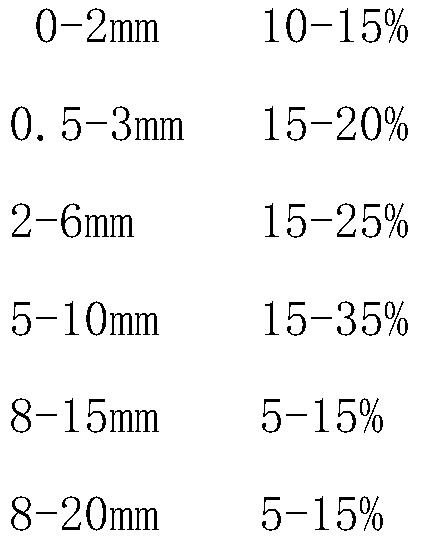

The invention discloses a dimple-shaped honeycomb hollow plate and a manufacturing method thereof, belonging to a manufacturing method of a multiplayer co-extruded molding hollow plate. The dimple-shaped honeycomb hollow plate is characterized in that an internal structure of the dimple-shaped honeycomb hollow plate comprises the following components in percentage by weight: 60-80 percent of polypropylene, 5-15 percent of talcum powder, 1-10 percent of polyethylene, 0.5-2.5 percent of aliphatic ester, 0.5-2.5 percent of calcium carbonate, 1-10 percent of titanium dioxide, 1-10 percent of aluminum oxide and 10-20 percent of glass fiber. The dimple-shaped honeycomb hollow plate is of a sandwich structure and structurally comprises an extrusion molding surface panel at the upper layer, a dimple-shaped honeycomb structure layer as a middle core layer and an extrusion molding surface panel at the lower layer. The manufacturing method of the dimple-shaped honeycomb hollow plate comprises the following steps: proportioning and mixing raw materials; plastifying and pelleting; extruding the extrusion molding surface panels at the upper layer and the lower layer by an extruder, and extruding a dimple-shaped honeycomb structure layer (formed by means of a vacuum plastic suction roller) by the extruder, performing corona treatment, performing hot-press and hot-melting splicing, annealing by a stress removing box, shaping and sizing by five rollers, cooling by an air cooling frame, forming and cutting to manufacture the dimple-shaped honeycomb hollow plate.

Owner:周挺

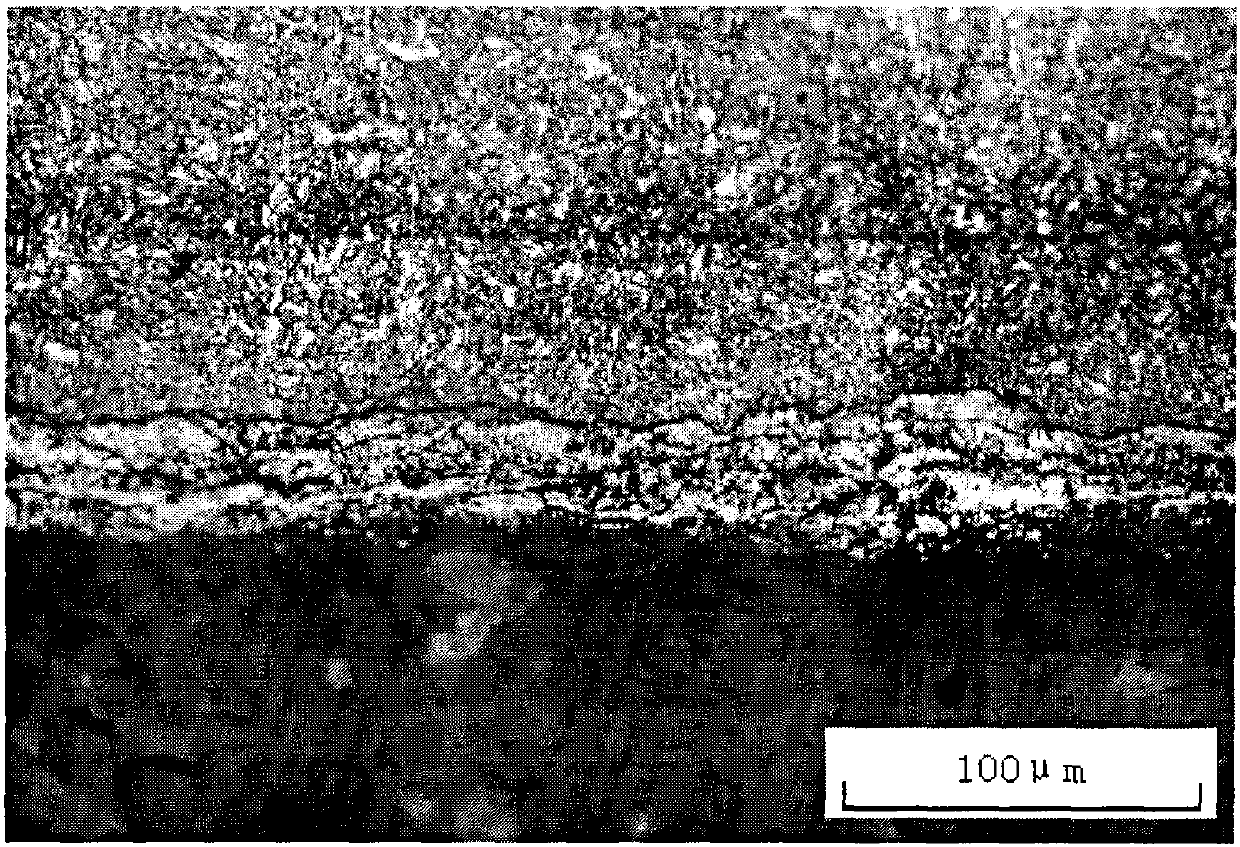

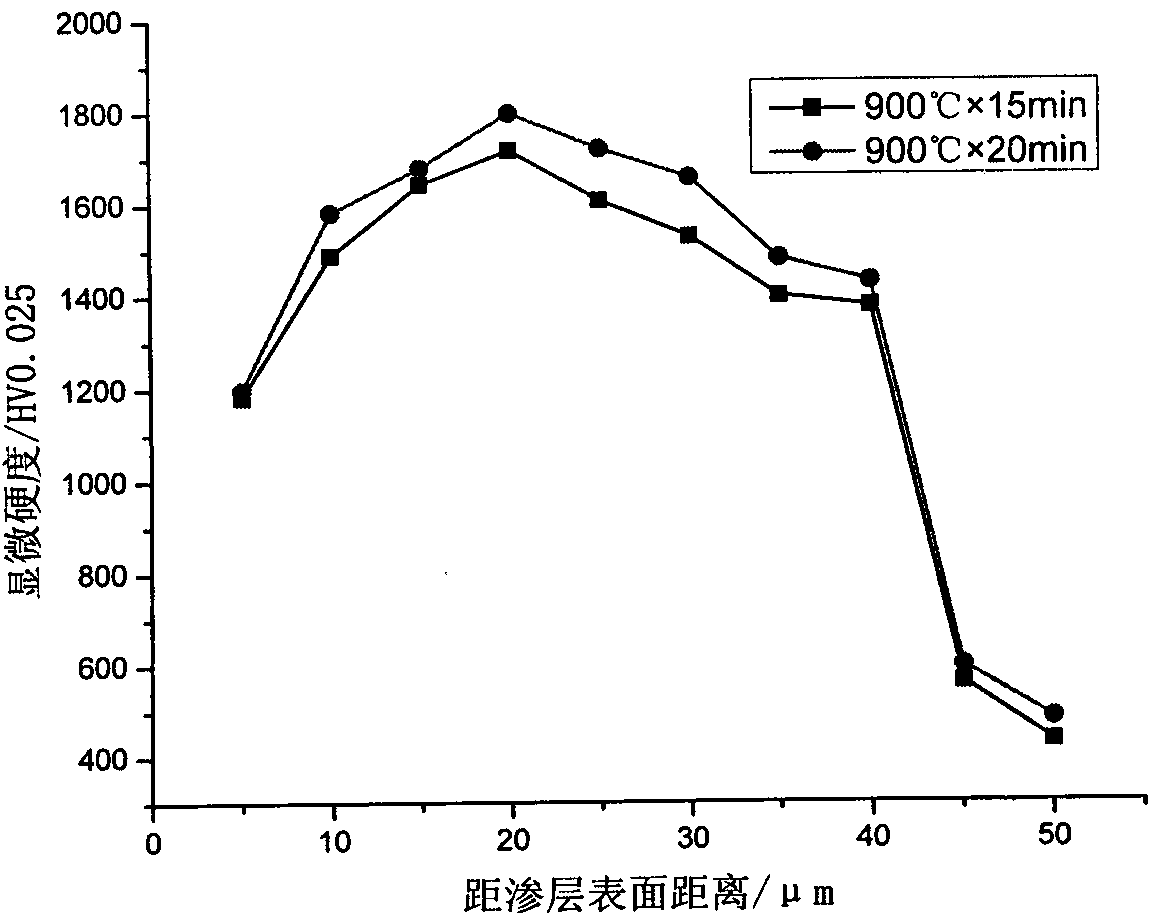

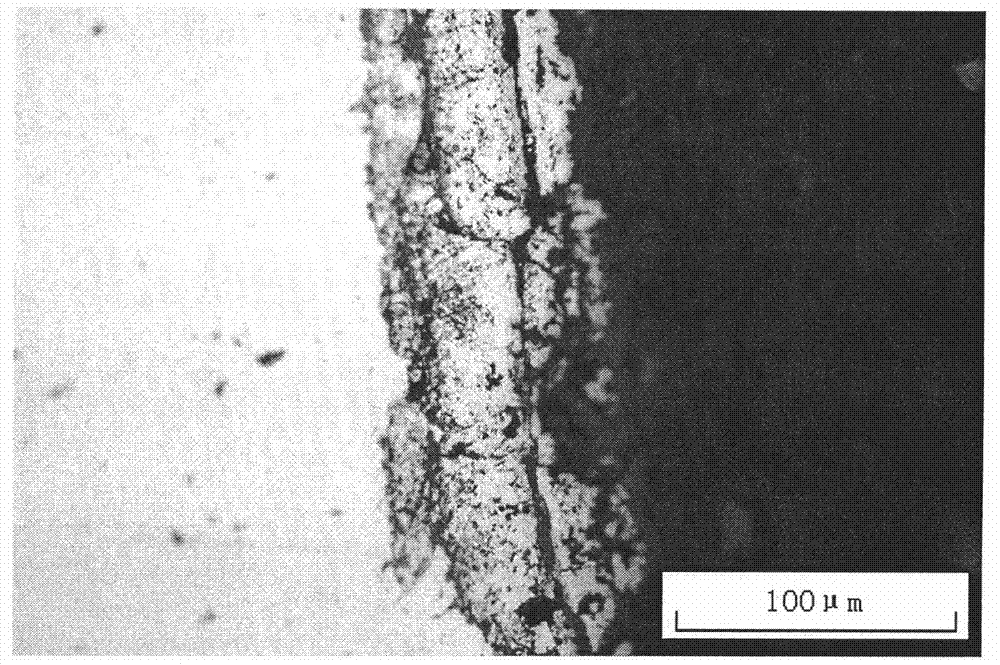

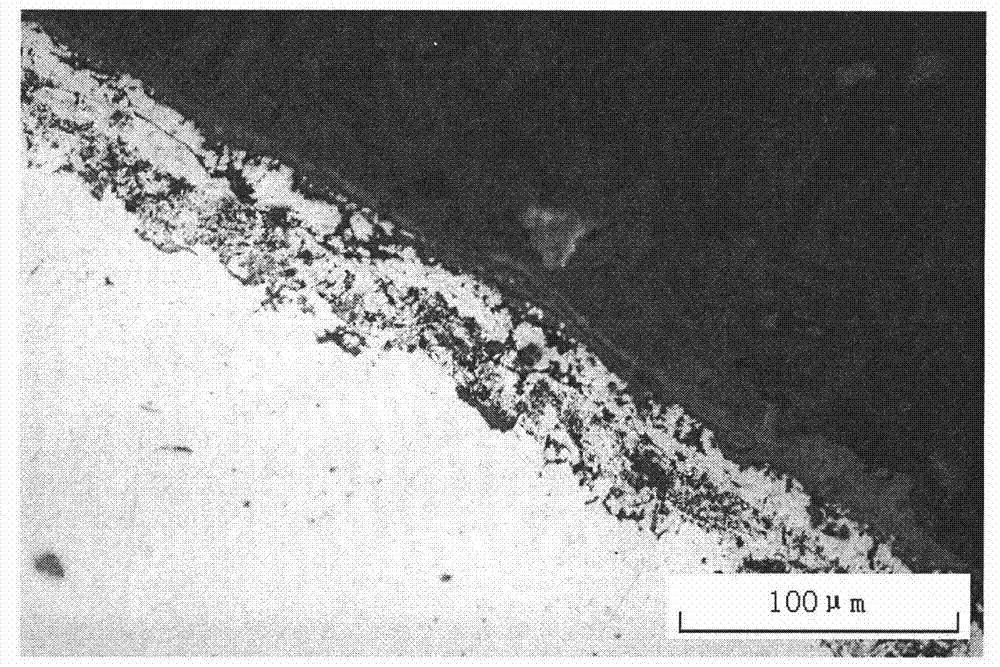

Novel low-temperature rare earth-chromium-boronizing agent

InactiveCN103343314AReduce distortionNo phase changeSolid state diffusion coatingThioureaHigh carbon

The invention discloses a novel low-temperature boron-chromium-rare earth co-permeation agent which comprises the following components in parts by content: 4.8 to 5.0 parts of high-carbon ferrochrome, 3.8 to 4.0 parts of rare earth, 6.8 to 8.4 parts of potassium fluoborate, 21.3 to 24.5 parts of aluminium oxide, 5.9 to 7.6 parts of thiourea and 53.0 to 54.5 parts of ferroboron. The co-permeation agent has the advantages that 1) a workpiece is deformed slightly and cannot generate phase-change and internal stress after being subjected to co-permeation, so that the application of the co-permeation agent on a precise part is promoted greatly; 2) a low-temperature co-permeation layer is thicker and ranges from 30 mu m to 52 mu m or so, so that the application range is wide; and 3) the cost of the low-temperature co-permeation of the boron-chromium-rare earth is lower, so that the good economical effect is obtained.

Owner:SHANDONG JIANZHU UNIV

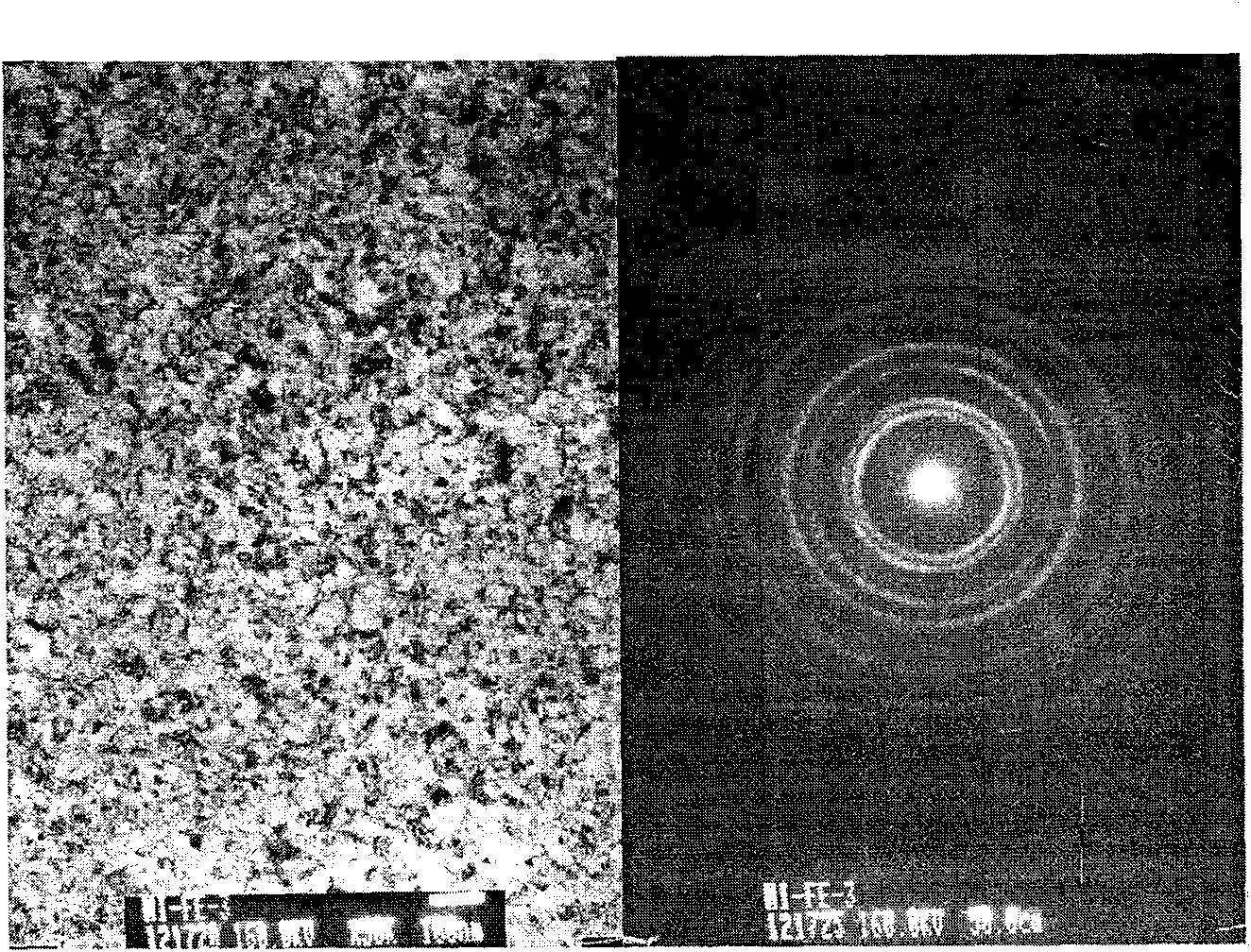

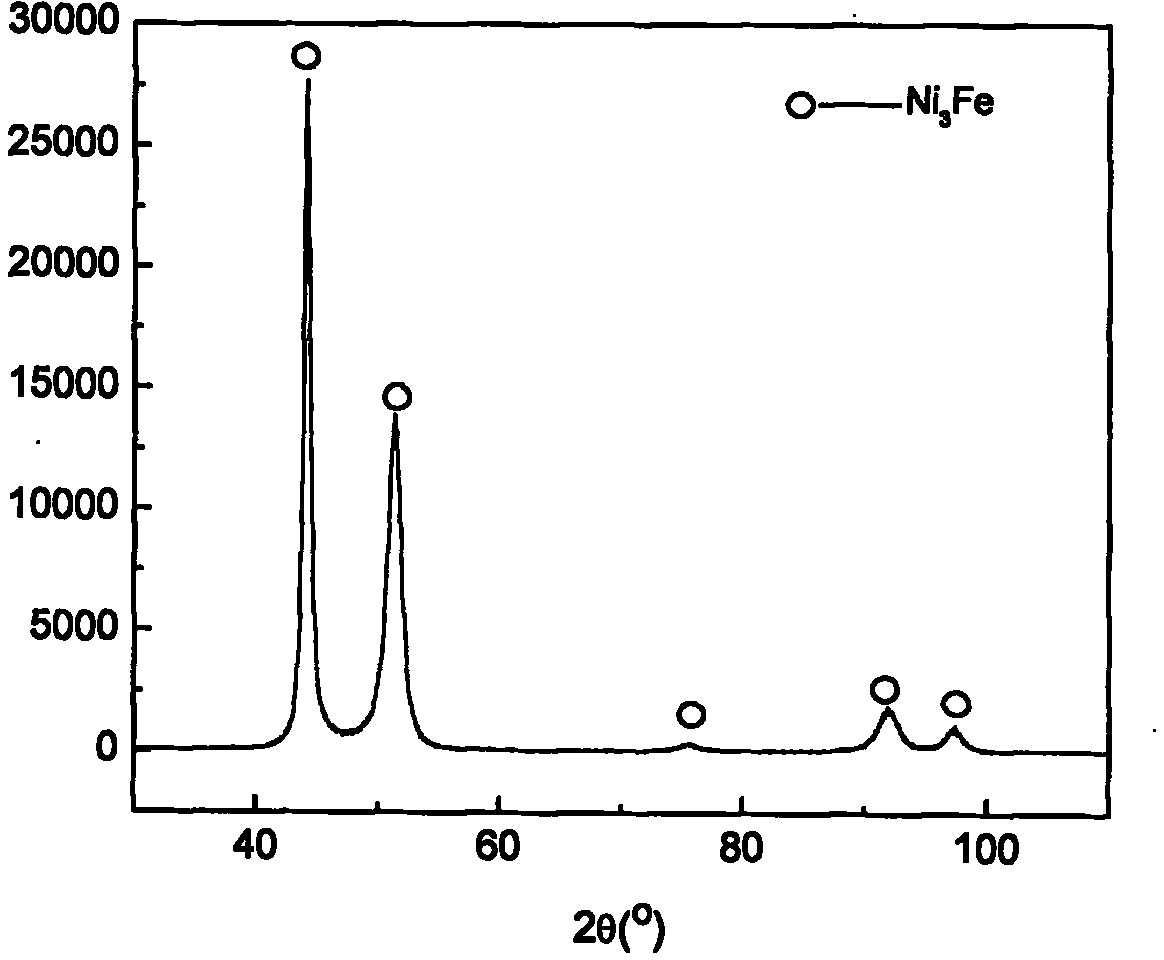

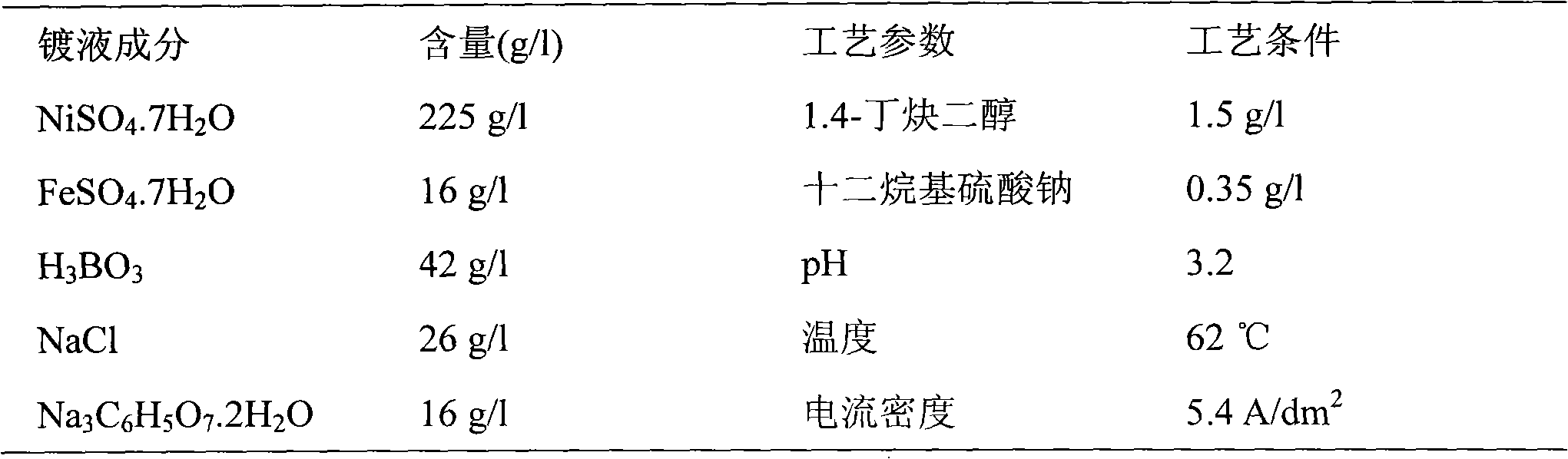

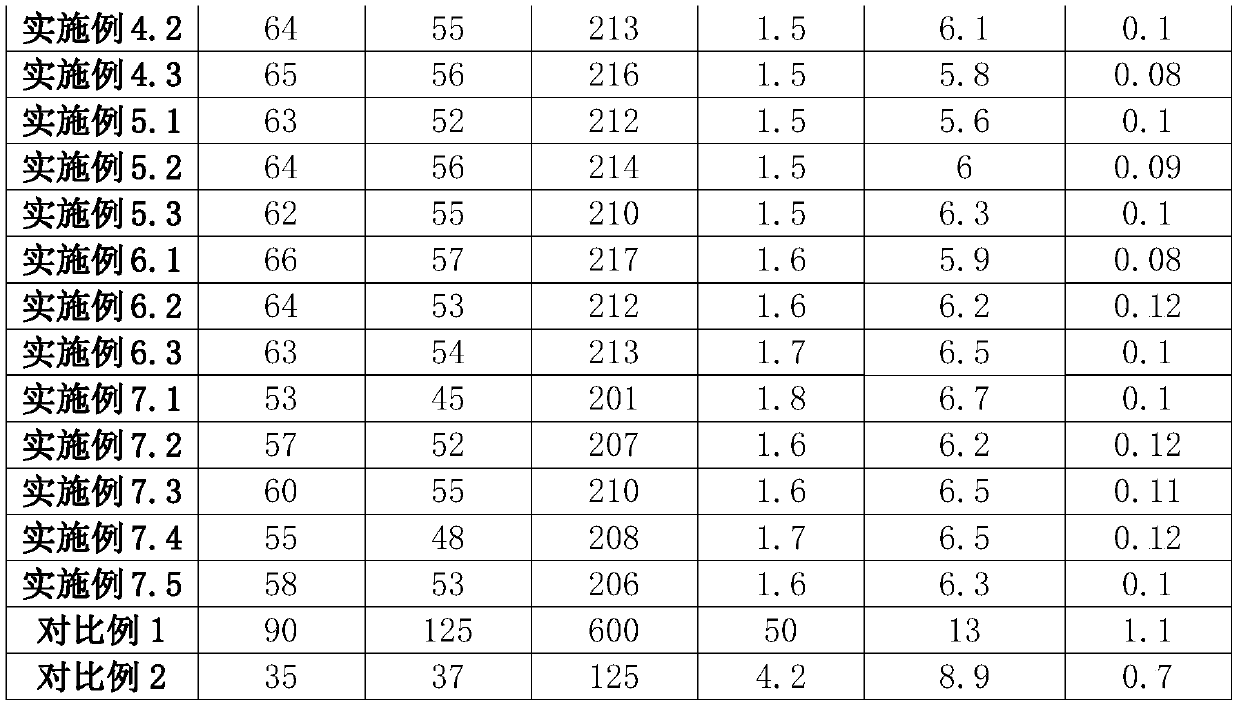

Electro-deposition method for preparing bulk nano ferro-nickel alloy crystalline

InactiveCN102115898ACrystal fine and denseReduce pollutionTemperature controlHydrogen-Ion Concentrations

The invention provides an electro-deposition method for preparing bulk nano-crystalline ferro-nickel alloy. Electro-deposition equipment capable of circularly filtering, stirring, temperature control and cathode movement is adopted; 1g / l to 3g / l of additive A and 0.25g / l to 0.75g / l of additive B are adopted; and the bulk nano ferro nickel alloy is acquired under the technological parameters that the electroplating solution temperature is 55 DEG C to 65 DEG C, the pH (hydrogen ion concentration) value is 3.2 to 3.8, and the cathode current density is 2A / dm2 to 8A / dm2. The invention has the characteristics of simple and easy-to-control technological process, steady product quality, small crystallite dimension, even structure, high purity, little environmental pollution, low production cost, and the like.

Owner:CHANGCHUN UNIV OF TECH

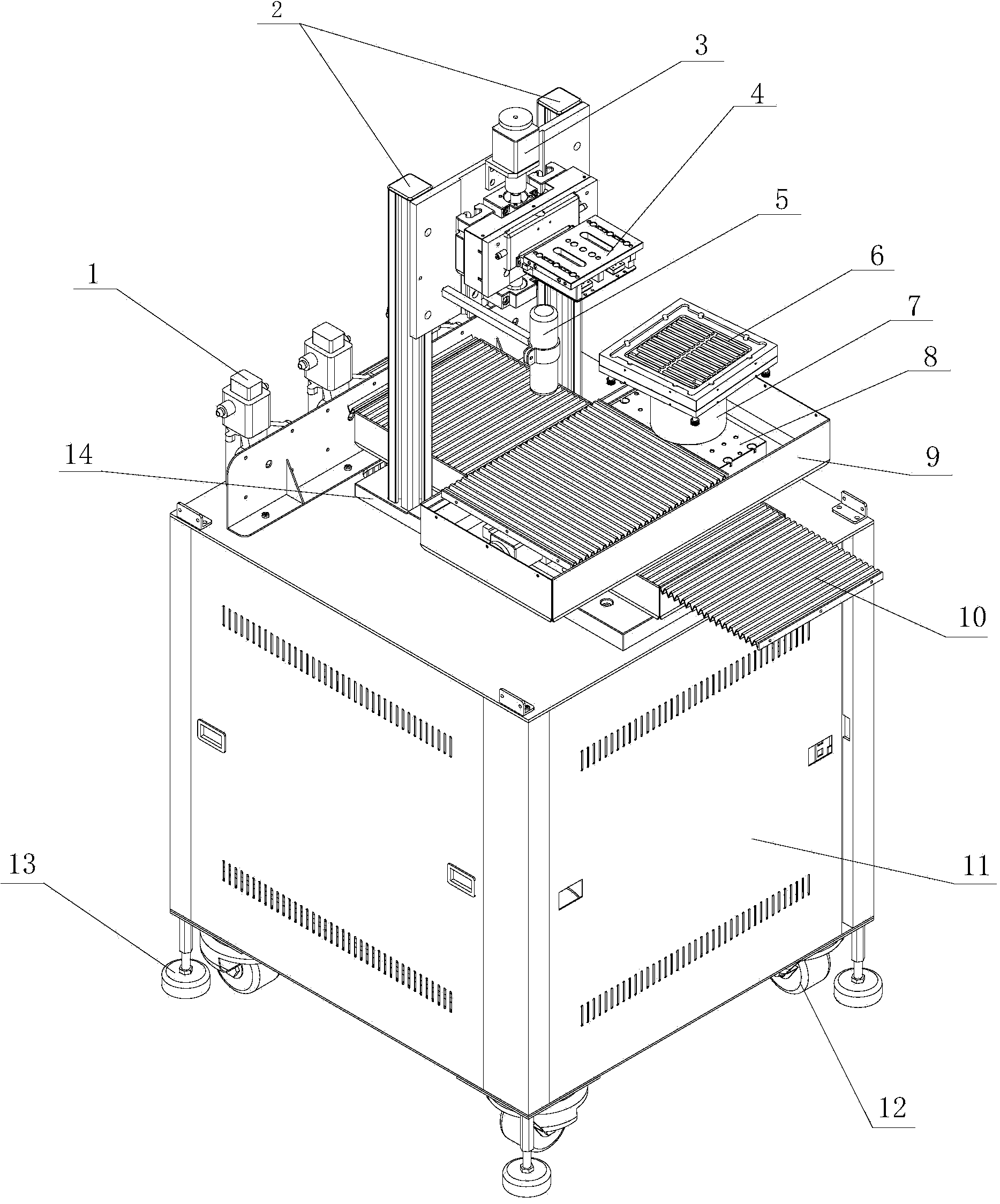

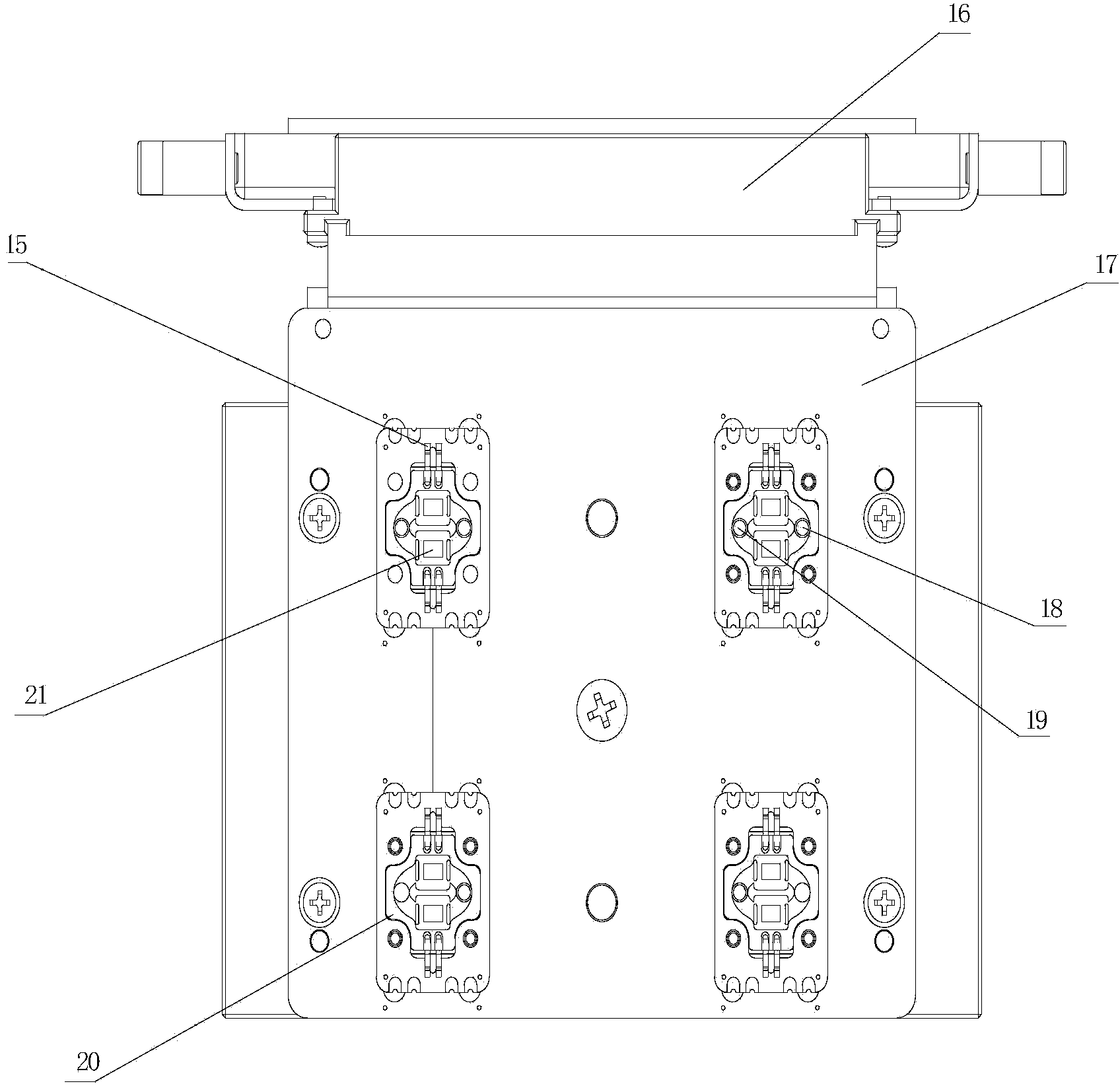

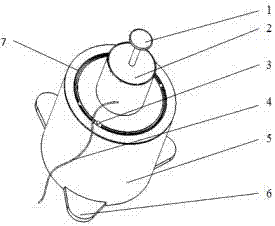

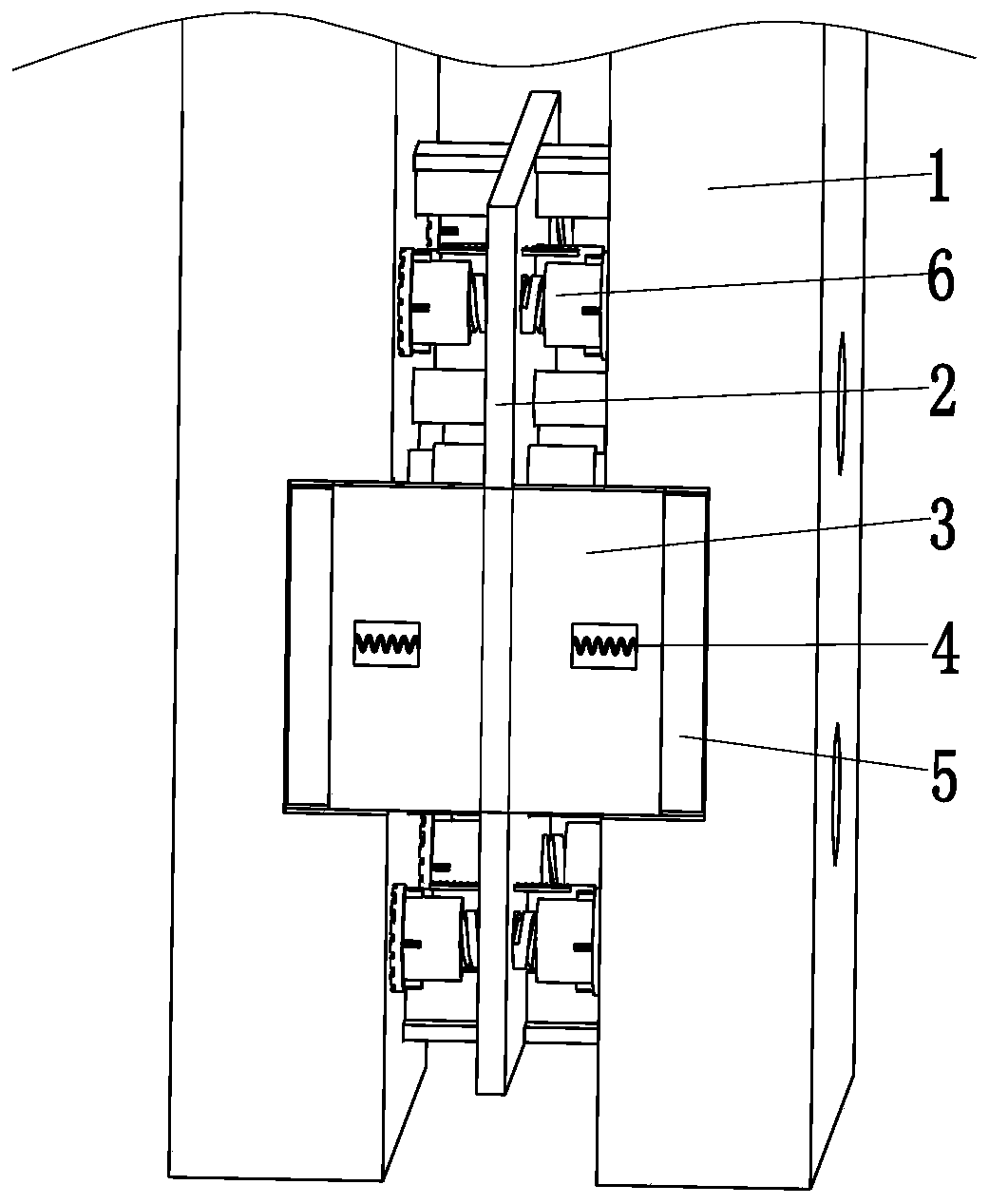

Automatic resistance adjusting device for resistance strain gauge and resistance adjusting method

ActiveCN103668420ARealize automatic resistance adjustment functionHigh control precisionElectrical resistance and conductancePower flow

The invention discloses an automatic resistance adjusting device for a resistance strain gauge and a resistance adjusting method. The device comprises a vertically arranged rack, wherein a Z-axis moving device is mounted on the rack, and a resistance measuring and adjusting device and a CCD (charge coupled device) image acquisition device are fixed on the Z-axis moving device; the automatic resistance adjusting device for the resistance strain gauge further comprises an X-axis moving device, a Y-axis moving device and a gas-liquid combined valve; a product clamping table is mounted on the X-axis moving device; and the resistance measuring and adjusting device is provided with a detecting unit. The adjusting process is controlled by controlling parameters such as current or voltage loaded on the resistance strain gauge, voltage loading time, a resistance adjusting liquid amount and the like, the equipment control accuracy is high, and the operation is easy; the device has a great advantage in the aspects of realizing mass and mechanical operation; and meanwhile, a product whose resistance is adjusted with an electrochemical resistance adjusting method doesn't produce internal stress in a sensitive grid area, so that the stability, the uniformity and the accuracy of the resistance of the product can be improved greatly.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

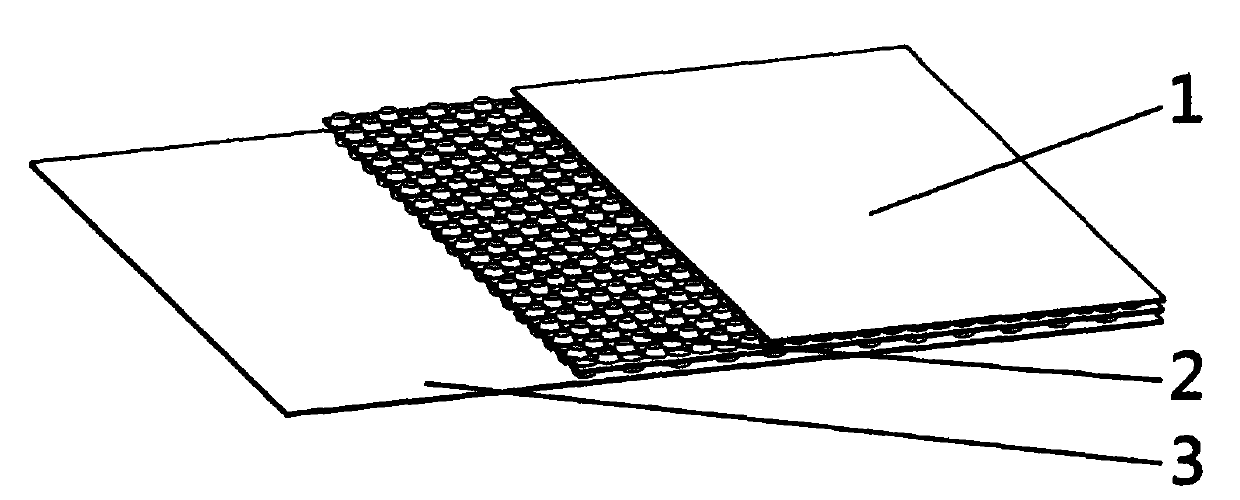

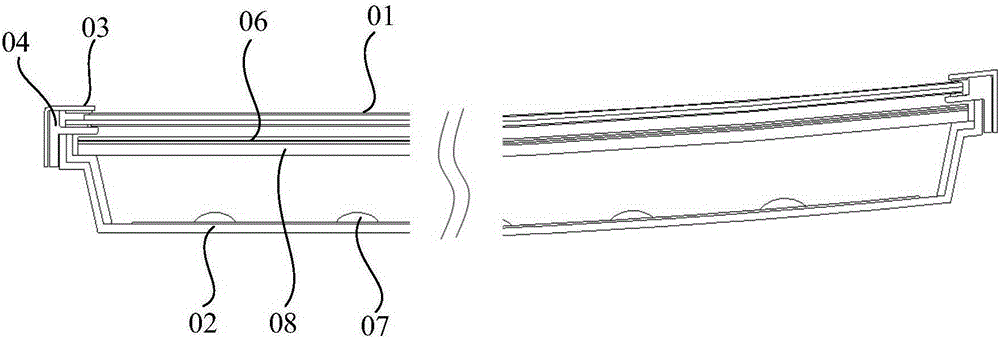

Dimple-shaped honeycomb hollow plate and manufacturing method thereof

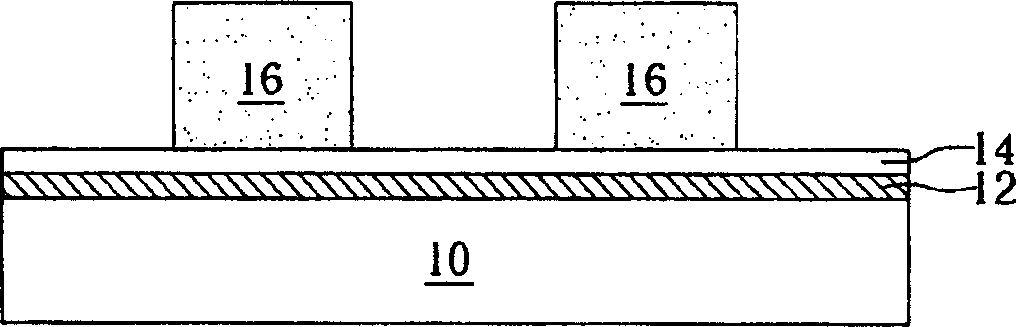

InactiveCN104175613AImprove toughnessReduce crystallinitySynthetic resin layered productsLaminationHoneycomb structureEngineering

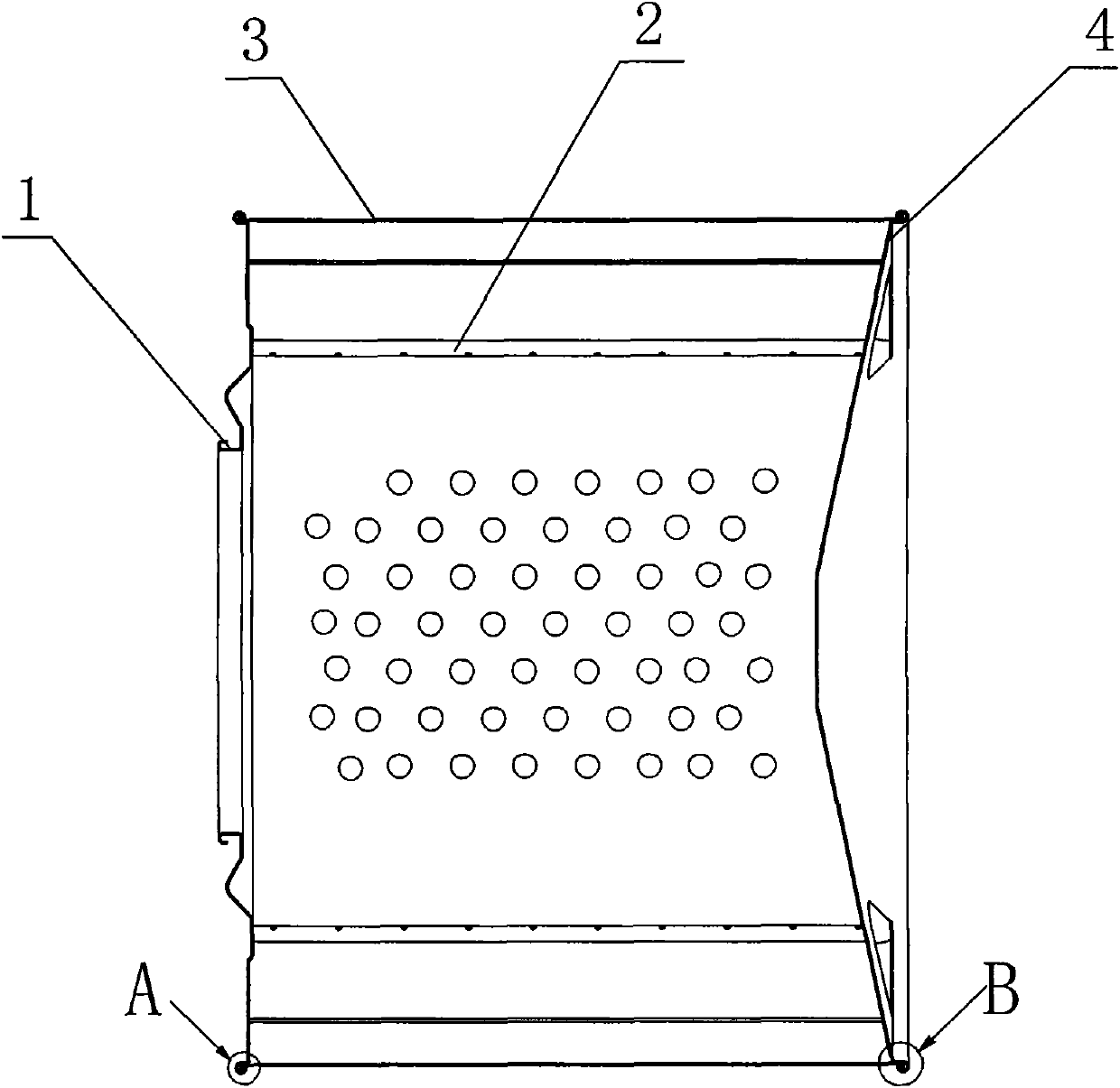

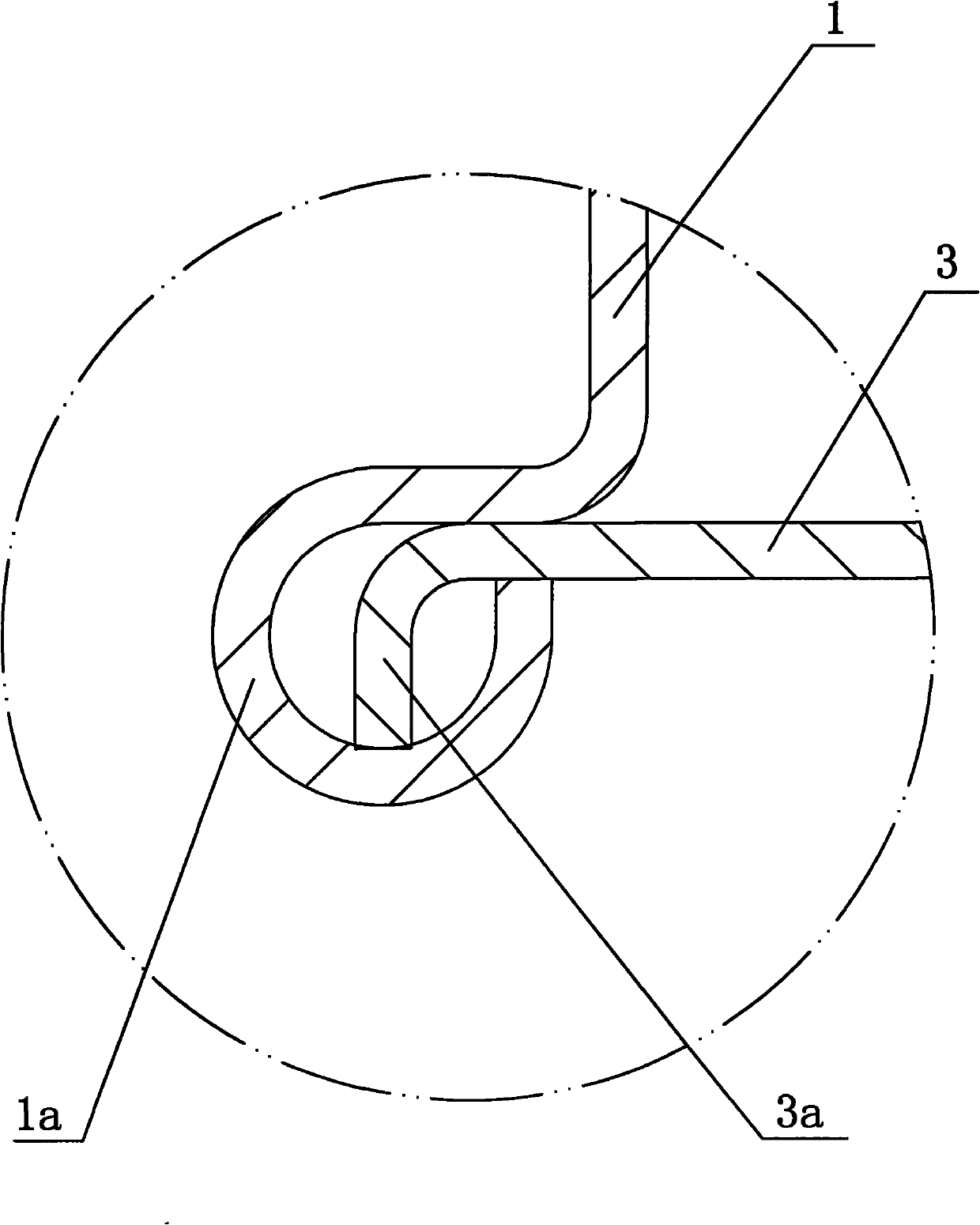

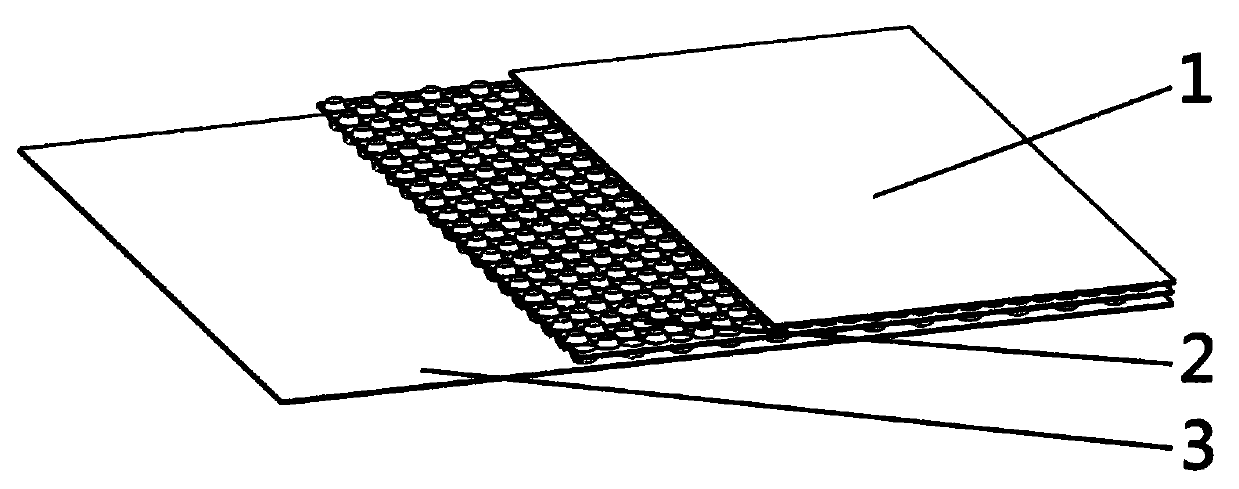

The invention relates to a dimple-shaped honeycomb hollow plate and a manufacturing method thereof, which belong to a manufacturing method of a multilayer co-extrusion molding hollow plate. The dimple-shaped honeycomb hollow plate is characterized in that an internal structure comprises an upper skin layer, a dimple-shaped honeycomb structure layer and a lower skin layer, wherein the dimple-shaped honeycomb structure layer is of an inlaid type sandwich structure in an up-and-down staggered mode. The dimple-shaped honeycomb hollow plate is provided, so as to overcome the defects of poor impact resistant performance, compressive deformation and infirmness of an existing plastic hollow plate, and the dimple-shaped honeycomb hollow plate has good performances of high strength, pressure resistance, wear resistance, heat insulation, impact resistance and breaking resistance, can simultaneously bear transverse section stress, longitudinal section stress and plate positive stress and has the advantages of uniform stress of each side surface, wide application range and good use effect.

Owner:NINGBO TIANQI HONEYCOMB MATERIALS

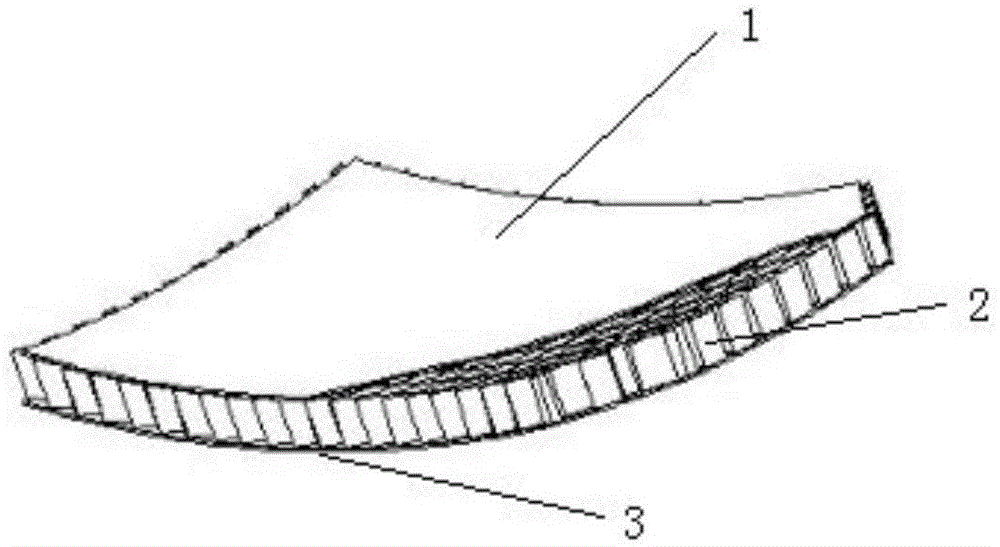

Low-density and high-performance composite sandwich structure and preparation method thereof

InactiveCN105459474AConsistent hygrothermal expansion performanceNo internal stressSynthetic resin layered productsLaminationHoneycombEngineering

The invention discloses a low-density and high-performance composite sandwich structure and a preparation method thereof. The sandwich structure comprises a core sandwich structure, an upper skin layer arranged on the upper bottom surface of the core sandwich structure and a lower skin layer arranged on the lower bottom surface of the core sandwich structure, wherein the core sandwich structure is formed by arranging a plurality of rod parts in parallel; each rod part is made of a fiber-reinforced resin-based composite. The rod parts made of the fiber-reinforced resin-based composites are spliced in a bonding or physical fixing manner to form the core sandwich structure, so that the core material has designability in mechanical property and hydrothermal property and has formability of complicated molded surfaces, and the high-precision, high-stability and complicated honeycomb sandwich structure is manufactured.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

Processing method of silicon micro resonator

InactiveCN103439032ASimple and efficient operationHigh pressure resistance effect and stabilityForce measurement by measuring frquency variationsFluid pressure measurement by electric/magnetic elementsSilicon chipIon

The invention discloses a processing method of a silicon micro resonator, belongs to the field of sensors, and aims at solving the problems in an existing method for manufacturing a resonator. The method provided by the invention comprises the following steps: 1, performing thermal oxidation treatment on an N-type (111) silicon wafer (with the resistivity of 3Omega.cm-10Omega.cm) selected as a to-be-processed silicon wafer so as to obtain a thermal oxidation treatment type silicon wafer; 2, etching a resonance beam structure diagram on the upper surface of the thermal oxidation treatment type silicon wafer by adopting a photoetching technology; removing oxidation layers in areas at two sides of a resonance beam; meanwhile, forming two deep grooves symmetrically in the two sides of the resonance beam by utilizing a deep reaction ion etching technology; 3, covering passivation layers on side walls of the resonance beam; 4, etching passivation layers on the bottoms of the two deep grooves; 5, re-etching the bottoms of the two deep grooves again continuously by a certain depth; 6, corroding the silicon wafer by a TMAH (tetramethylammonium hydroxide) solution, and releasing the resonance beam; communicating the two deep grooves in two sides of the resonance beam to form a vibration chamber, and processing the silicon micro resonator.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP

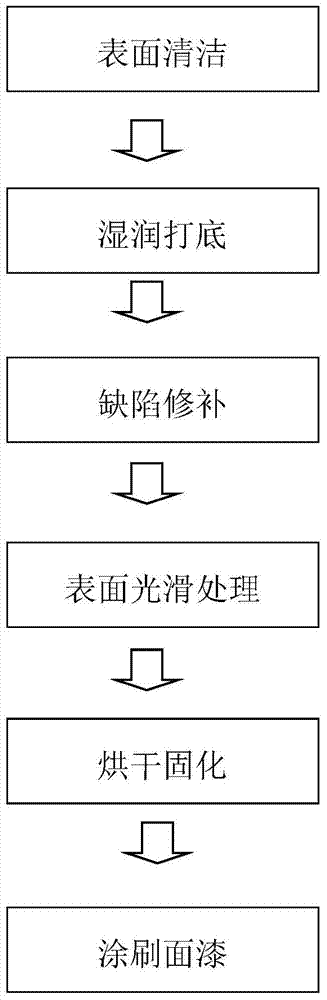

Repairing method of metal workpiece

InactiveCN104841626ALow costLow environmental requirements for operating conditionsPretreated surfacesCoatingsWear resistantCleansing Agents

The invention discloses a repairing method of a metal workpiece. The repairing method includes the steps of cleaning the surface of the metal workpiece, derusting the surface through sandblast so that the roughness degree of the metal surface can reach 6.3, cleaning and drying the surface, comprehensively cleaning up the sandblast workpiece through special cleaning agent so that the cleanliness degree can reach Sa2.5, drying the workpiece, humidifying and bottoming the workpiece, bottoming the cleaned surface through a ceramic fiber coating, repairing defected parts through chromium-molybdenum-contained small-grained wear-resistant healant, conducting drying and solidifying through an iodine-tungsten filament lamp, a warm air machine and other heating devices, conducting heating for 5 hours to 7 hours, coping the surface, cleaning and drying the surface, smearing the surface with finishing coat, and smearing the cleaned and dried workpiece with finishing coat one time to three times through corrosion remover or high-temperature ceramic protective agent. The method is wide in operation and application range, low in working condition requirement, low in cost and good in repairing effect.

Owner:上海易乓乒智能科技股份有限公司

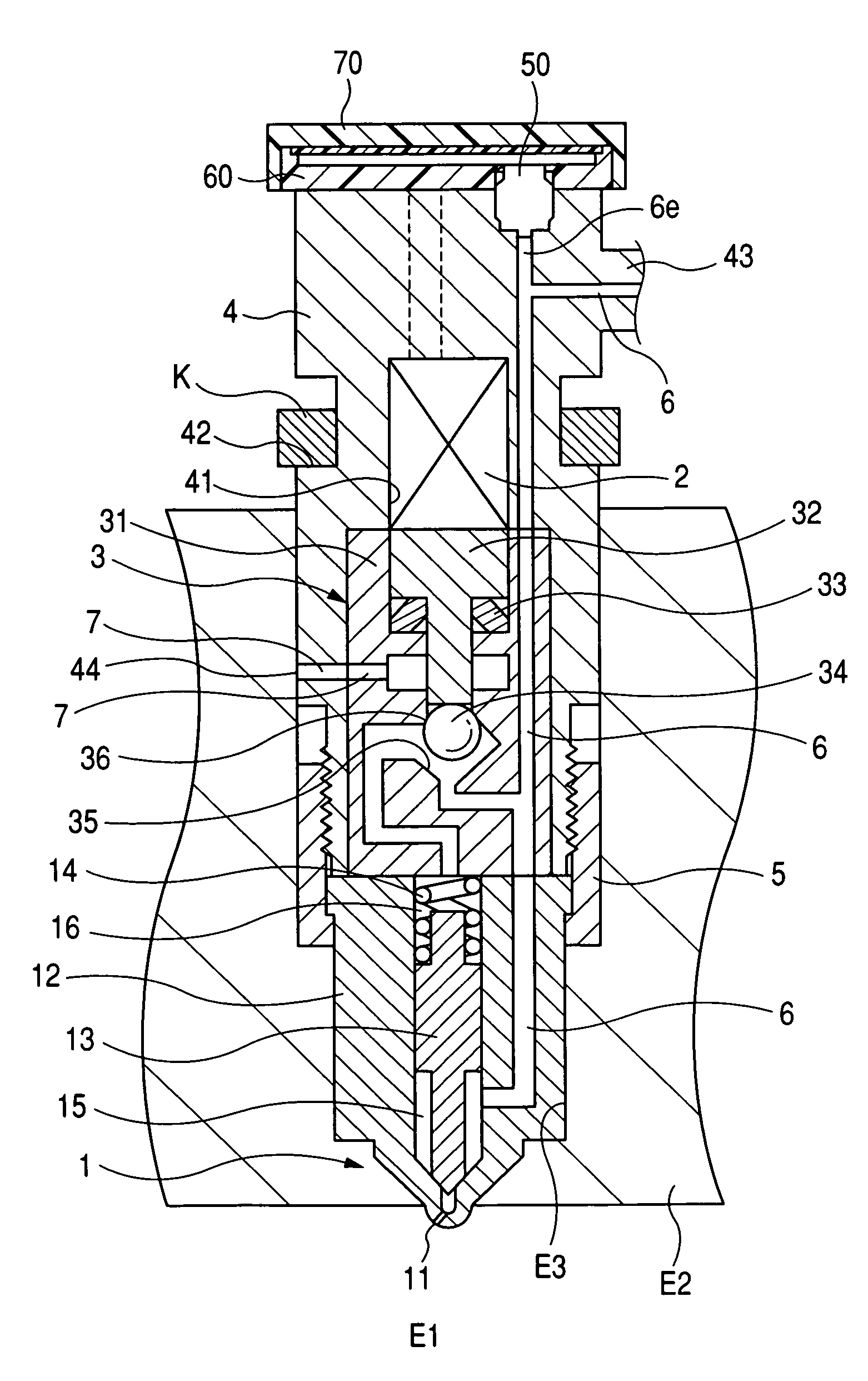

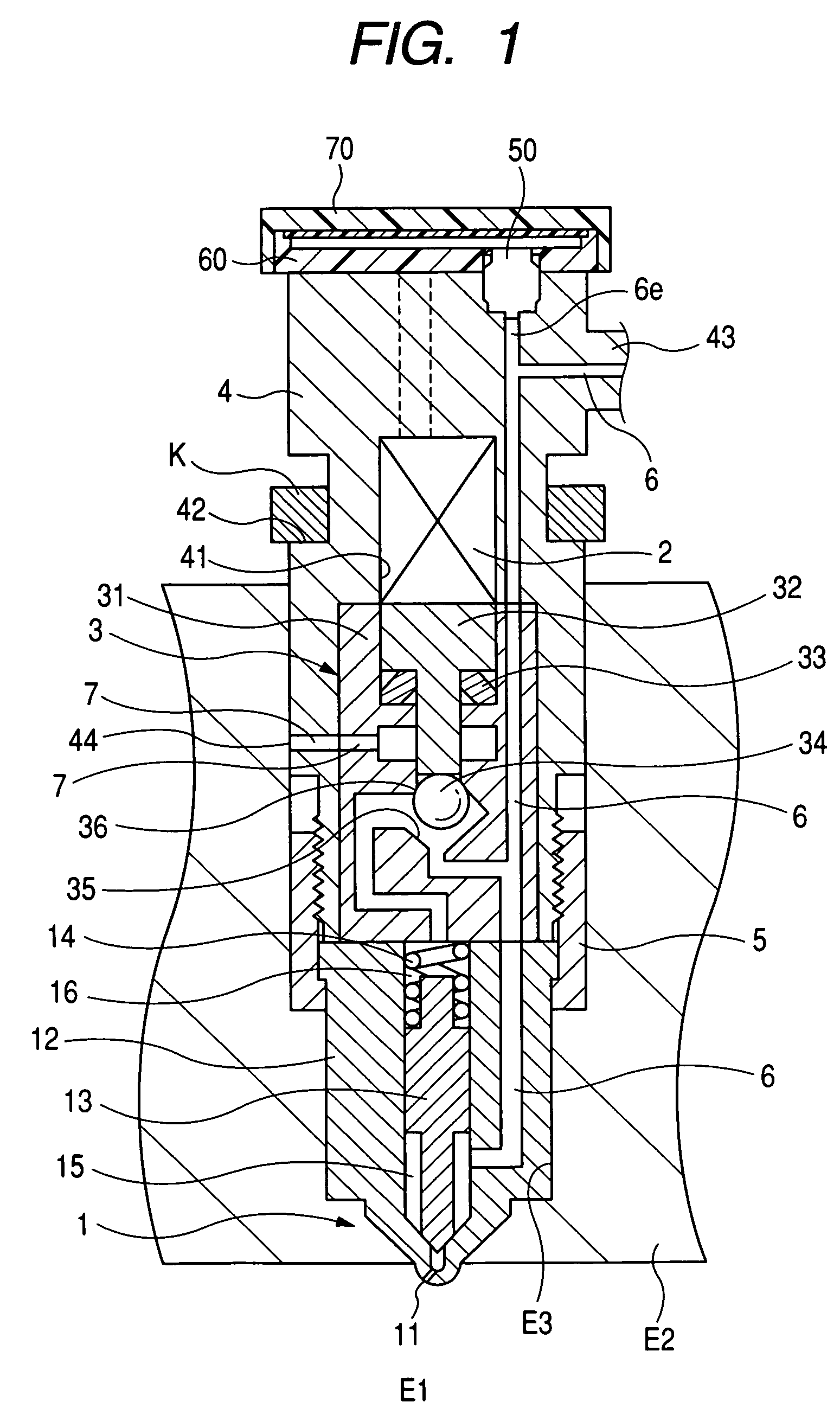

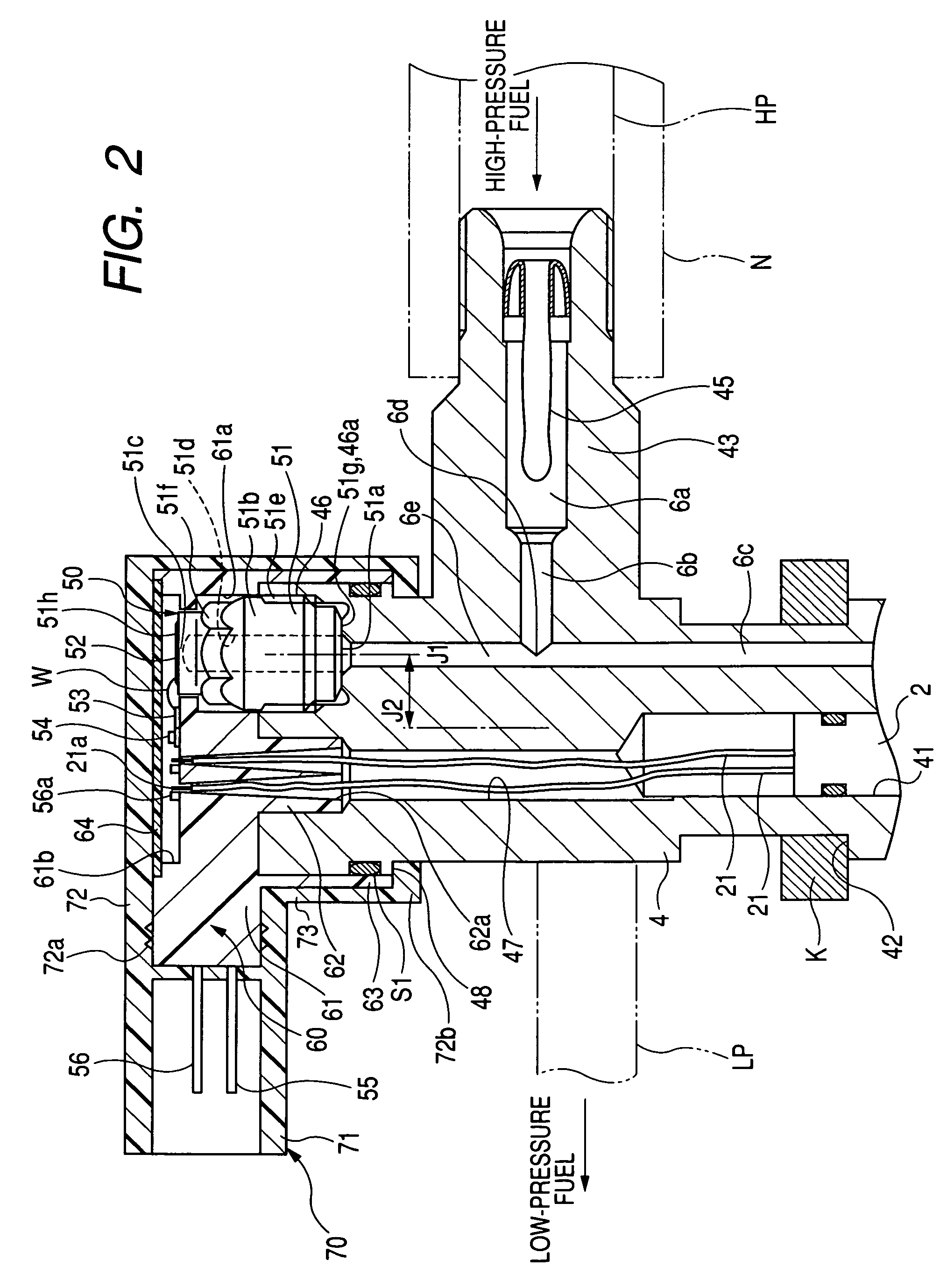

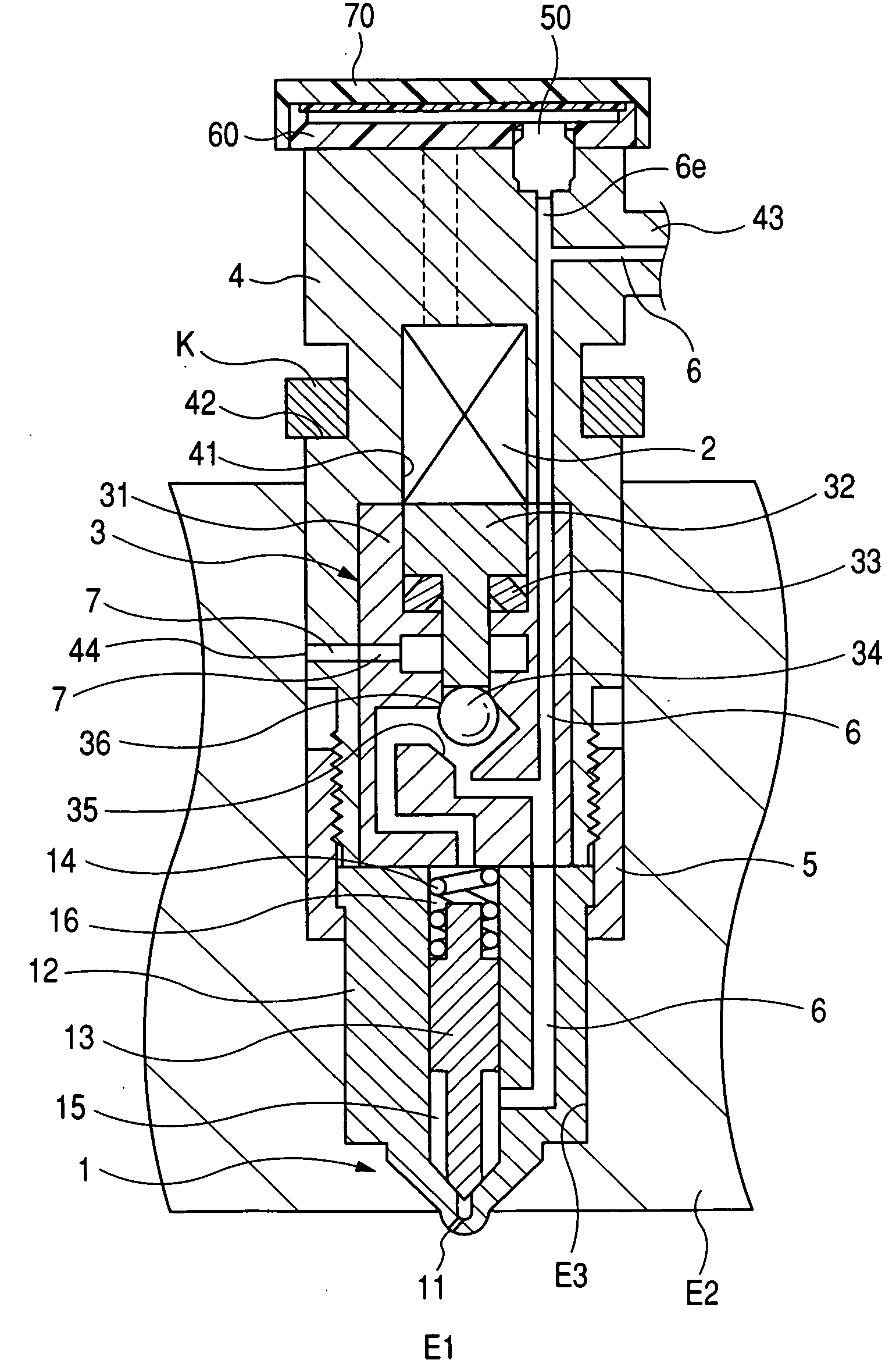

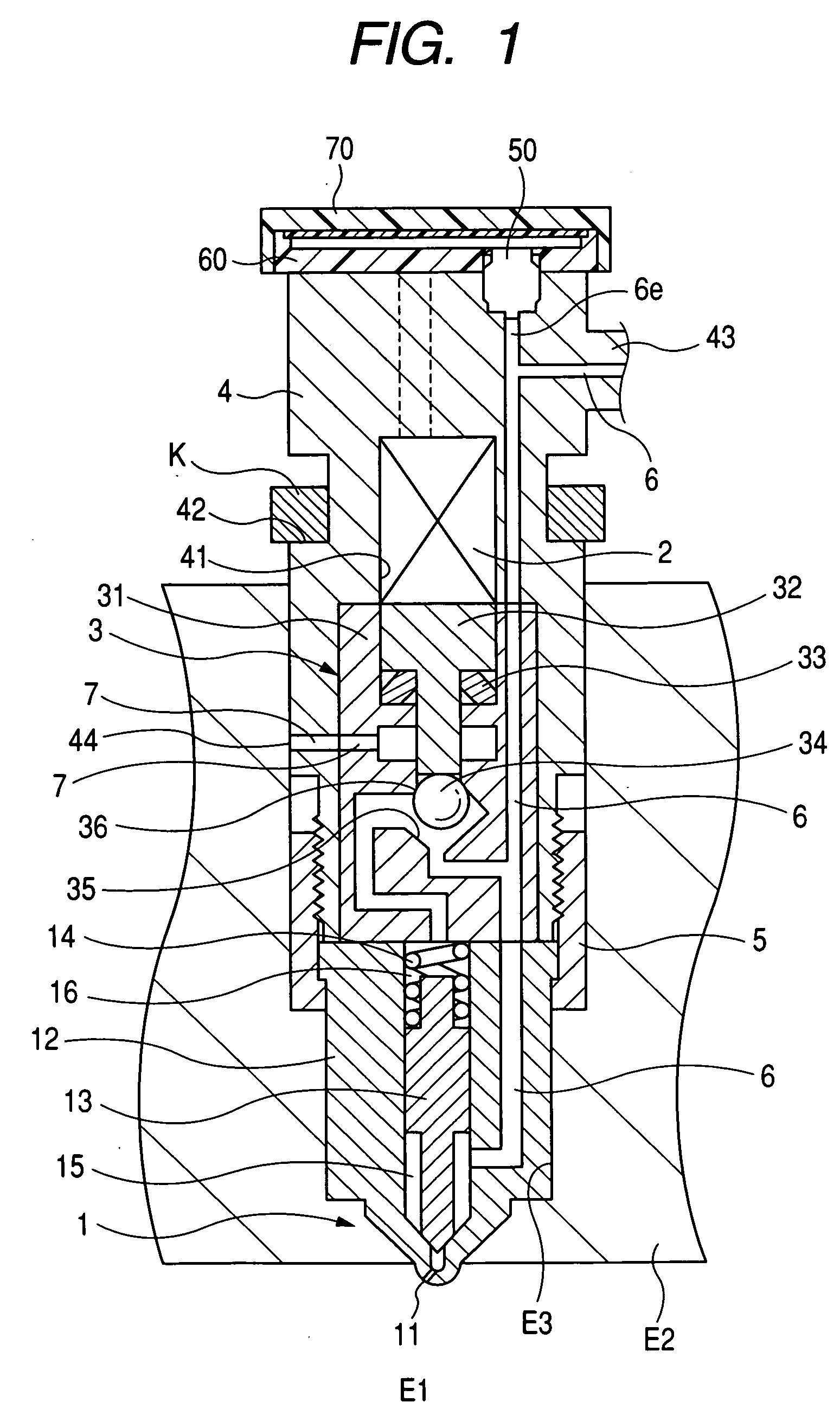

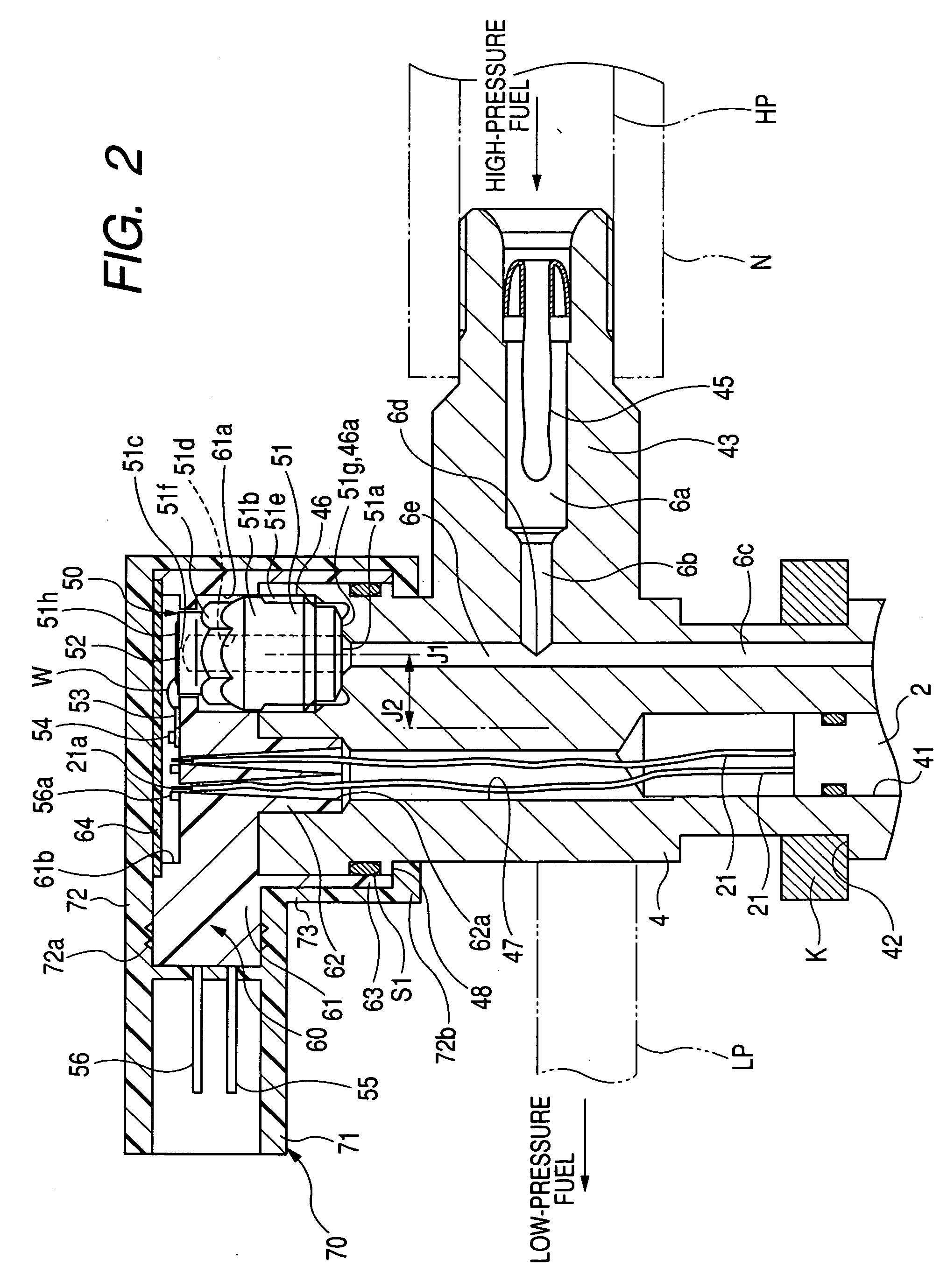

Fuel injector designed to minimize mechanical stress on fuel pressure sensor installed therein

ActiveUS7931009B2Stress minimizationAccuracy in measuring the pressure of fuelDigital data processing detailsSpray nozzlesCylinder headMechanical pressure

Owner:DENSO CORP +1

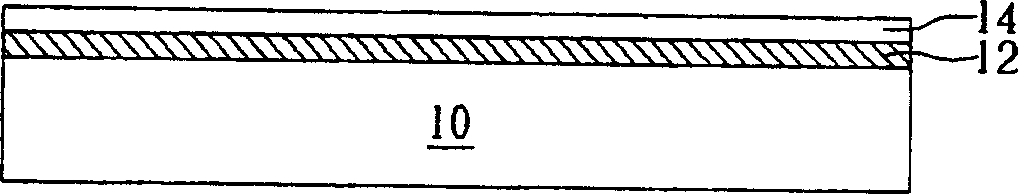

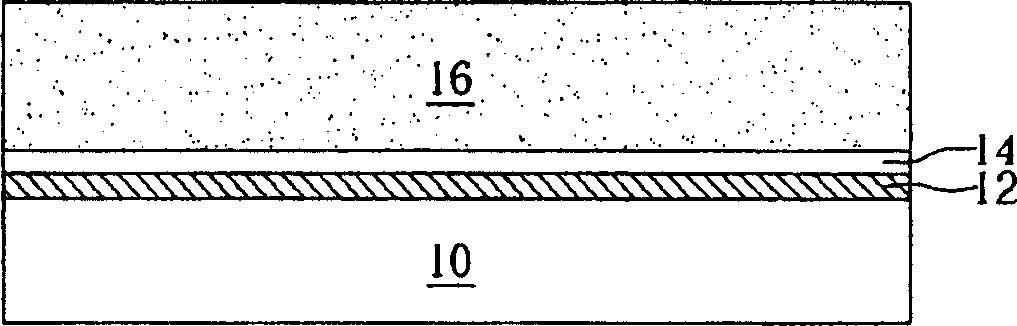

Method for manufacturing metal shield

InactiveCN1658746AHigh resolutionNo internal stressMagnetic/electric field screeningMetal layered productsMetalElectroforming

This invention discloses a method for making the metal shield. Firstly provide a basal board, next form a releasing layer, a electroforming crystal kind layer and a graphical light-obstructing layer. Thereinto the light-obstructing layer is used to limit the graphics of the metal shield, and expose part of the electroforming crystal kind layer. Then do a electroforming procedure to form the metal shield on the exposed electroforming crystal kind layer. Finally do a doffing mould procedure to make the metal shield disengage from the basal board.

Owner:U TECH MEDIA

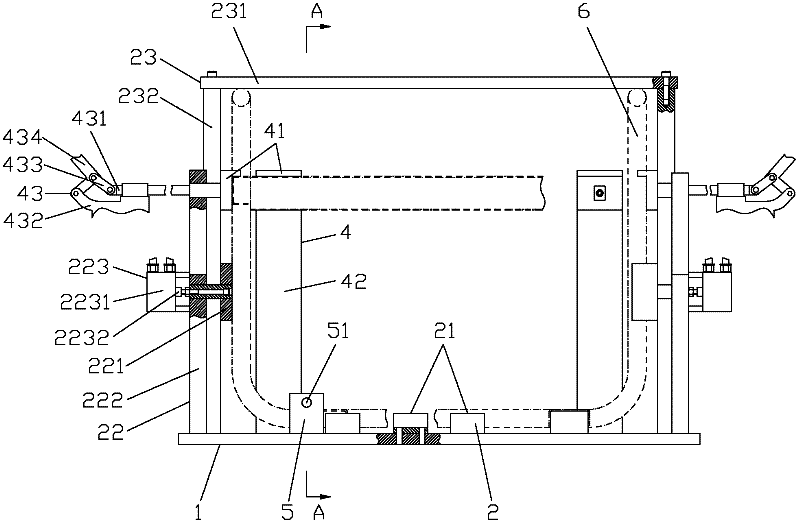

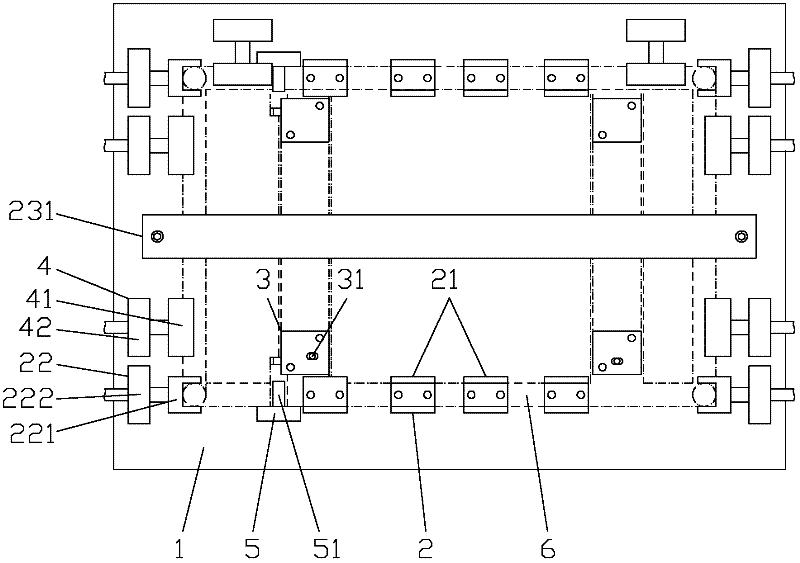

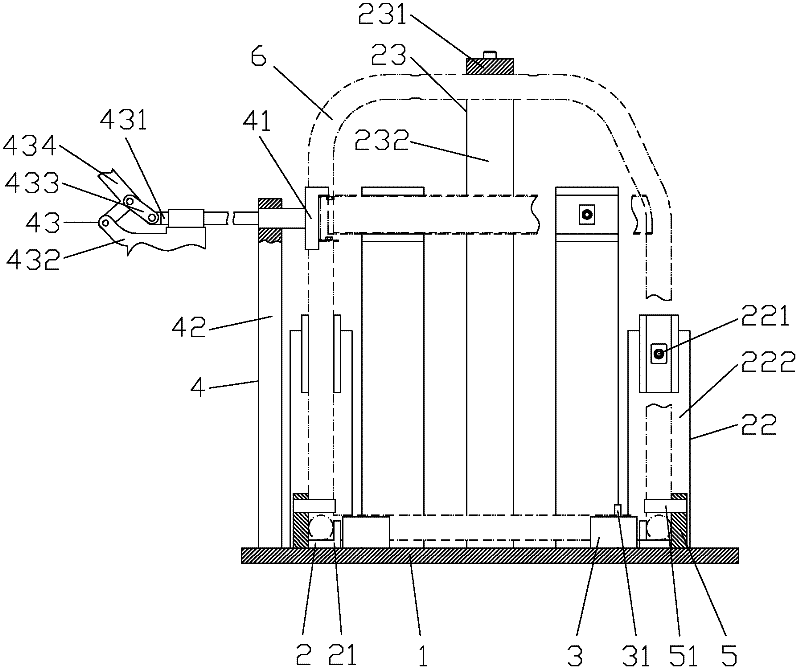

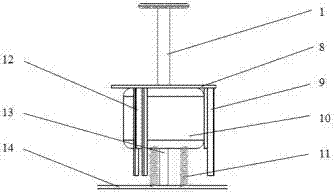

Welding tool for engine frame

InactiveCN102328167AQuality improvementPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringInternal stress

The invention discloses a welding tool for an engine frame. The welding tool comprises a fixed plate, a frame bent pipe positioning component, a bottom plate positioning block, a cross beam positioning block and a wheel shaft seat positioning block, wherein the frame bent pipe positioning component comprises a concave limit sliding block, a lateral positioning block and a compaction device; the cross beam positioning block comprises a positioning sliding block, a supporting plate and a quick clamp; the positioning sliding block is connected to the fixed plate through the supporting plate; and the quick clamp is used for driving the positioning sliding block to slide along the horizontal direction. By the welding tool for the engine frame, a frame bent pipe, and a left bottom plate, a right bottom plate, a left cross beam, a right cross beam, a rear cross beam, a front wheel shaft seat and a rear wheel shaft seat which are required to be welded on the frame bent pipe can be accurately and reliably positioned, and the conditions that the frame cannot generate internal stress after being welded and being provided with other mechanical parts or equipment and cannot deform after being used for a long time are ensured; and a quick clamp structure is used for quick and accurate positioning, so that producing and processing efficiencies can be improved, the improvement on the quality of the processed frame is facilitated, and defective rates are reduced.

Owner:CHONGQING BEIBEI DISTRICT FENGHUO MACHINERY MFG

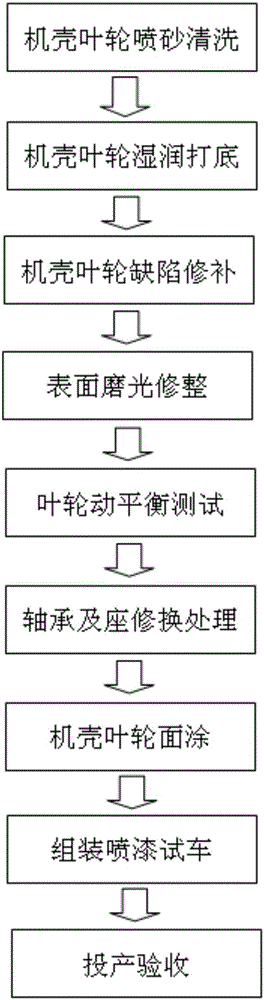

Wear and corrosion resisting repair method for draught fan

The invention discloses a wear and corrosion resisting repair method for a draught fan. The method comprises the process of descaling cleaning, sand blasting or shot blasting, cleaning and drying, wetting bottoming, cleaning and drying, defect repair, wear resisting repair, drying curing, grinding and polishing, impeller dynamic balancing, cleaning and drying, smearing of a first layer of finishing coat, drying curing, smearing of a second layer of finishing coat, drying curing and repair finishing. The wear and corrosion resisting repair method has the beneficial effects that the repair technology is superior to conventional welding repair and machining repair manners, deformation is avoided, no internal stress is generated, the aims of restoring the equipment use function and prolonging the service life are achieved, and the effects of reducing cost and achieving environment friendliness and energy saving are also achieved.

Owner:上海易乓乒智能科技股份有限公司

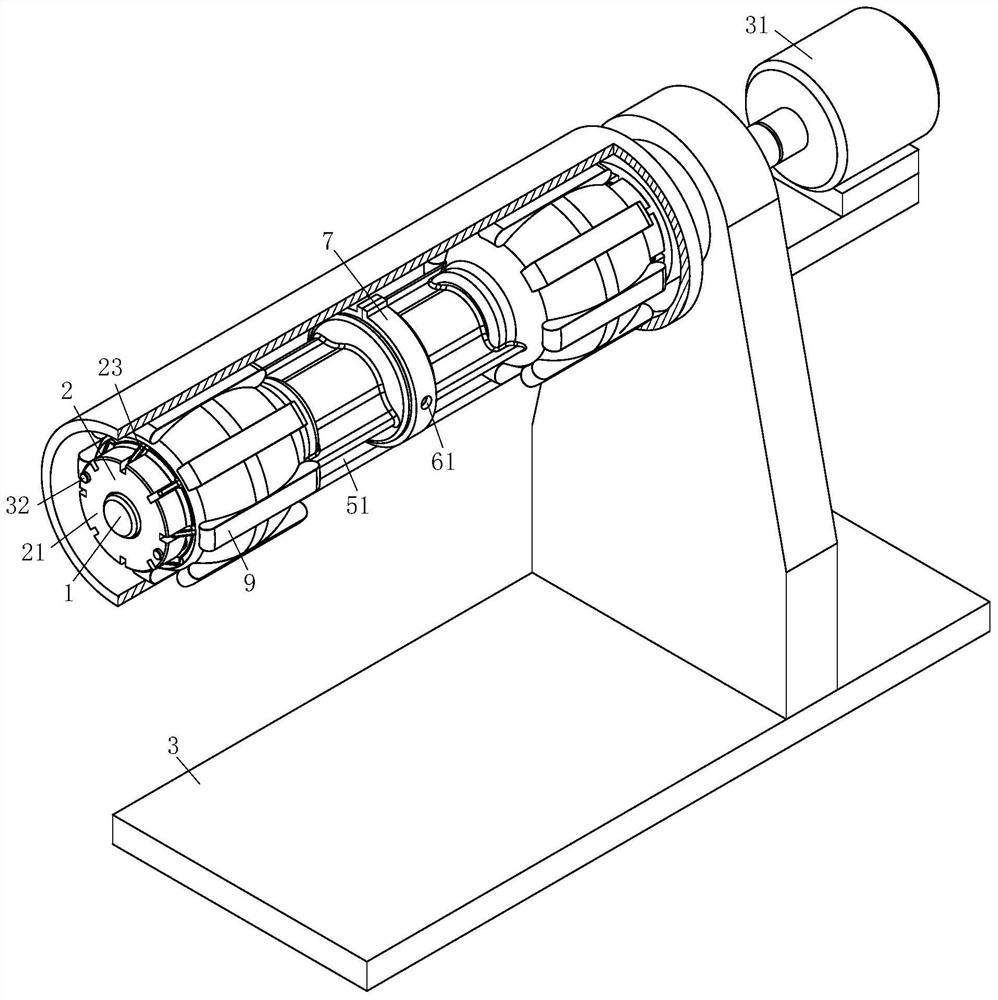

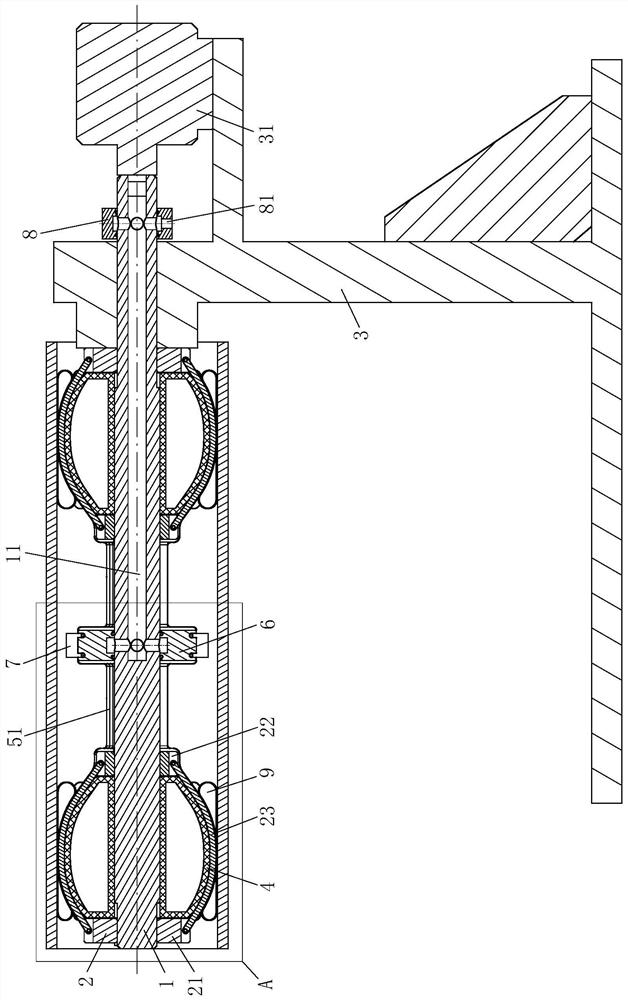

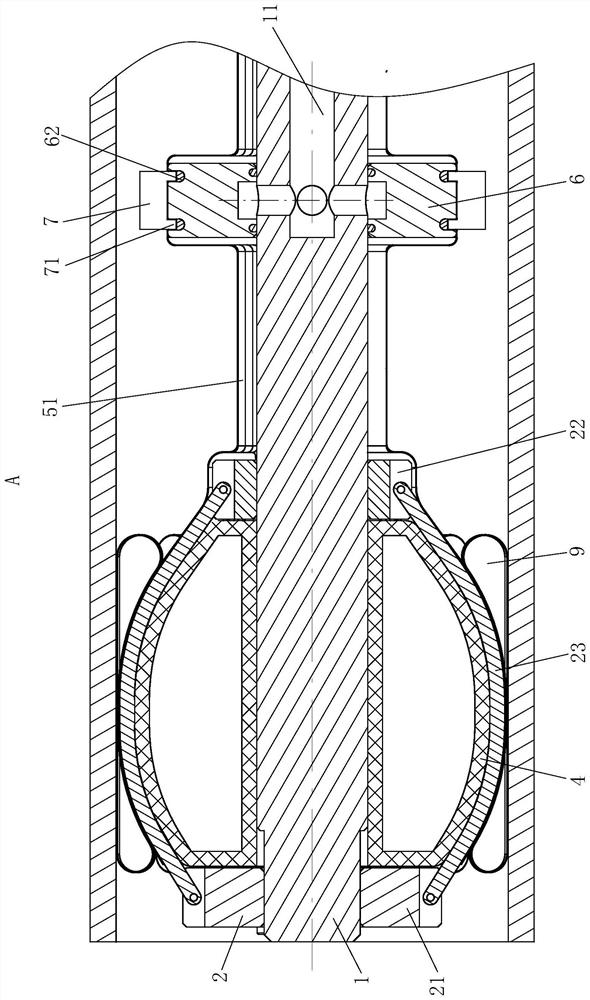

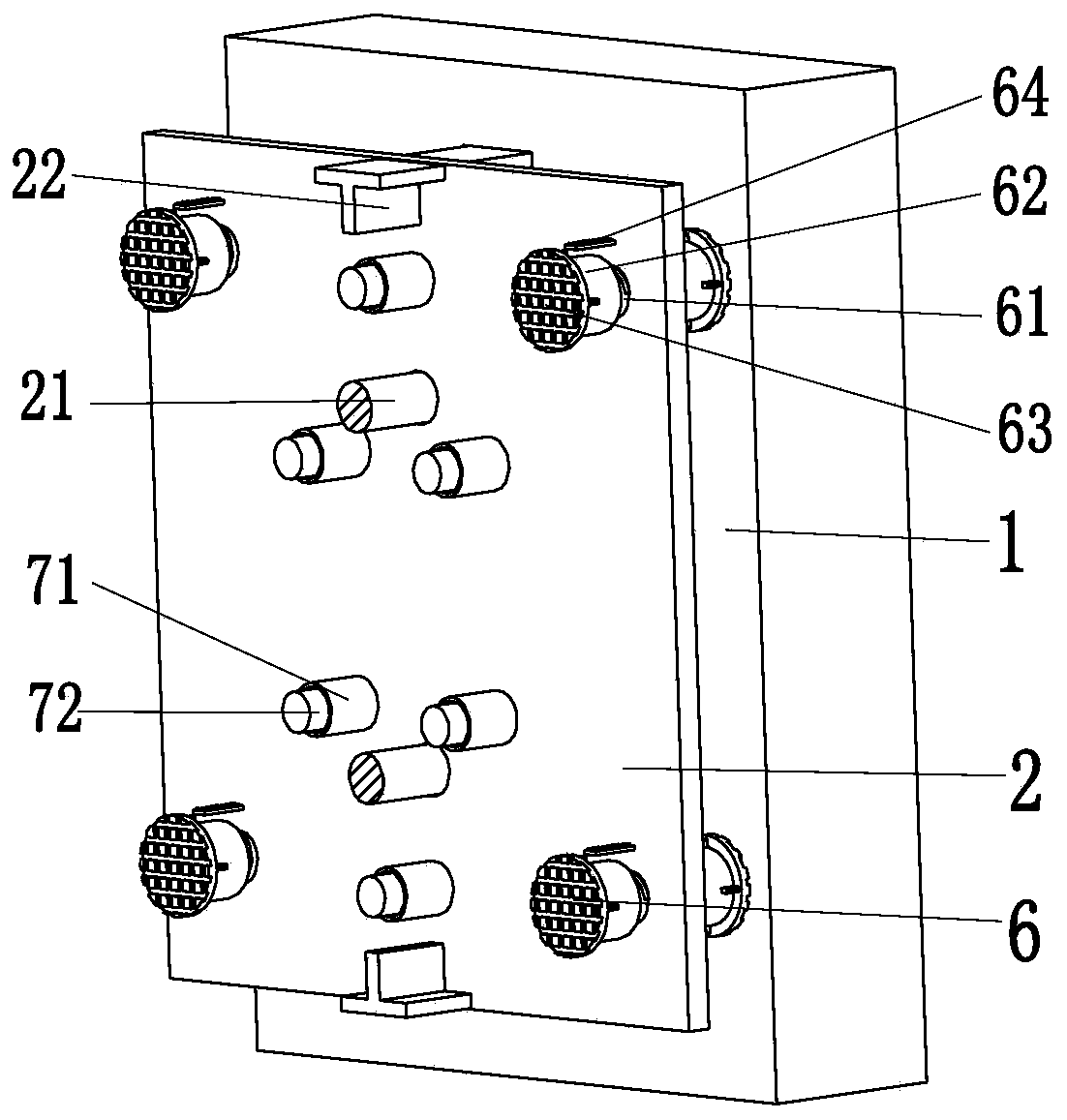

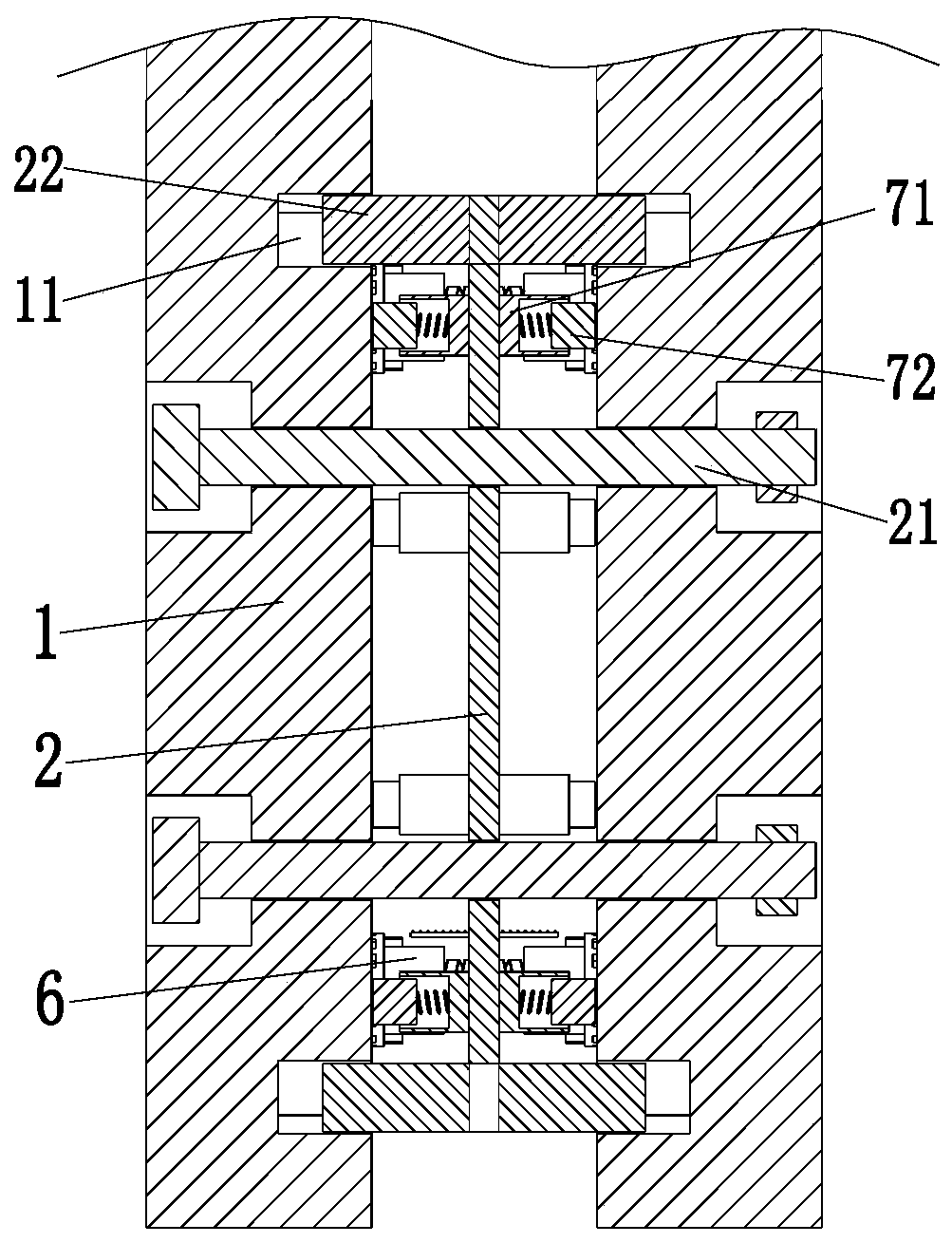

Self-centering clamp for grinding ceramic cylinder sleeve

ActiveCN111660173AGuaranteed stabilityPrevent movementGrinding drivesGrinding machinesElectric machineryComposite material

The invention belongs to the technical field of tool clamps, and particularly relates to a self-centering clamp for grinding a ceramic cylinder sleeve. The self-centering clamp comprises a rotating shaft, a jacking device, a supporting frame, a motor and a connecting rod. According to the self-centering clamp, the motor drives the rotating shaft to rotate, the rotating shaft drives a second rotating disc to move in the axial direction of the rotating shaft through threads, and the threads on the rotating shaft are left-handed thread and right-handed thread respectively, so that the second rotating disc moves to a first rotating disc; in the process, the second rotating disc extrudes elastic spokes, the elastic spokes are bent towards the inner wall of the ceramic cylinder sleeve, the middle portions of the elastic spokes extrude the inner wall of the ceramic cylinder sleeve, and the ceramic cylinder sleeve is clamped; and the elastic spokes are used for clamping the ceramic cylinder sleeve, so that the elastic spokes contact the inner wall of the ceramic cylinder sleeve more closely, the ceramic cylinder sleeve is prevented from being damaged in the clamping process, the elastic spokes are tightly pressed against the inner wall of the ceramic cylinder sleeve, the elastic spokes are integrally elastic, impact force is avoided in the machining process of the ceramic cylinder sleeve, and damage to the ceramic cylinder sleeve is avoided.

Owner:济南宝山石油设备有限公司

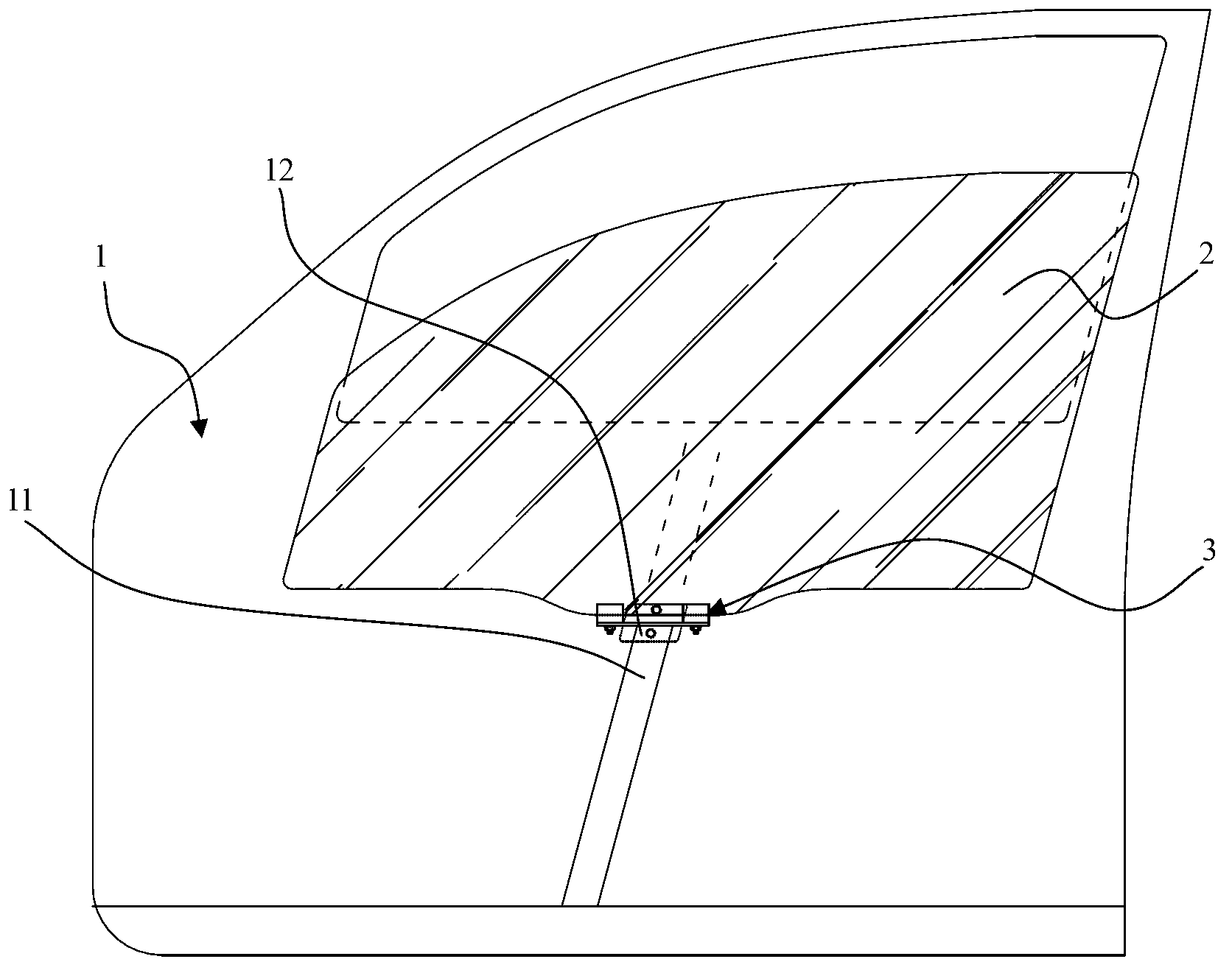

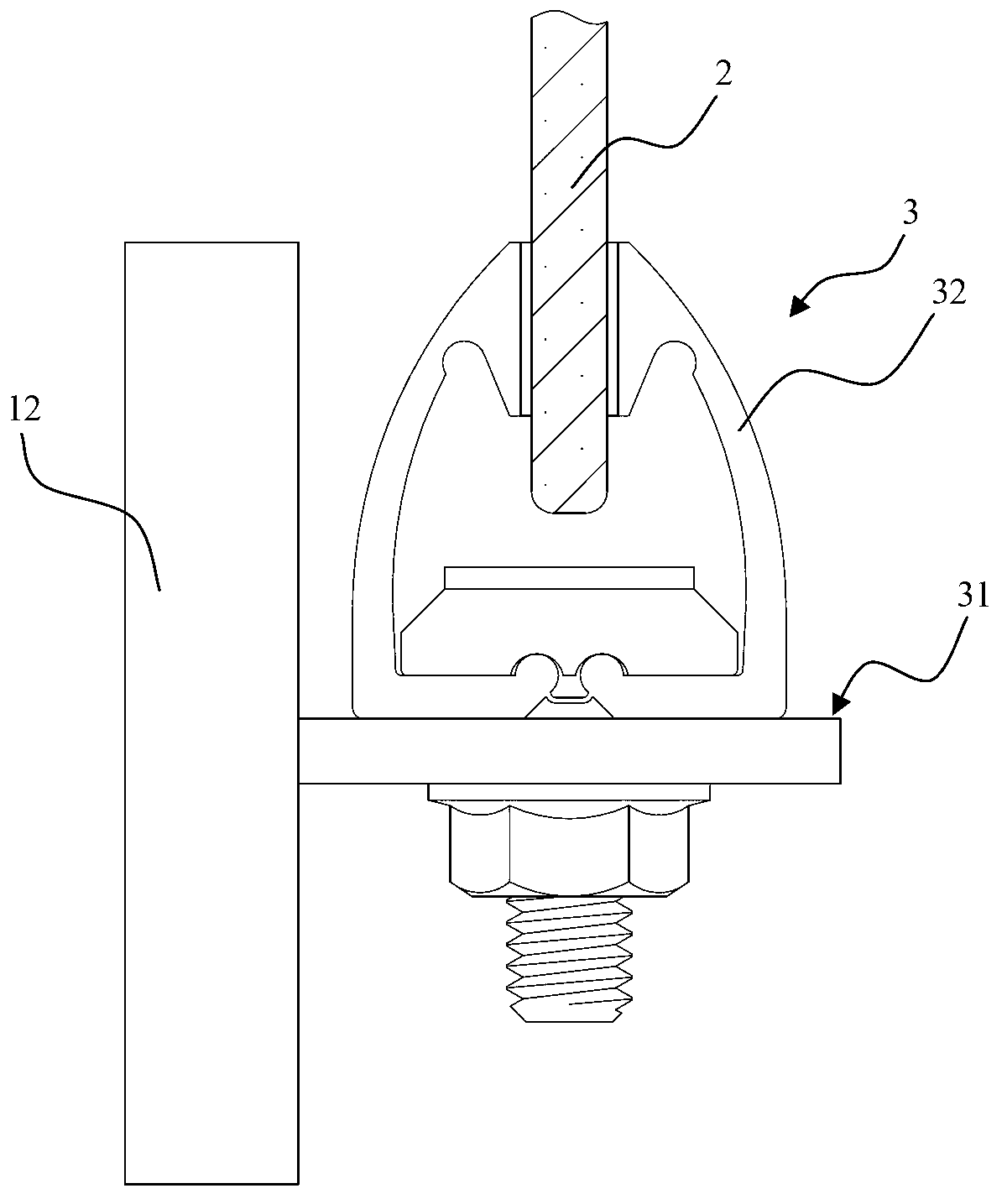

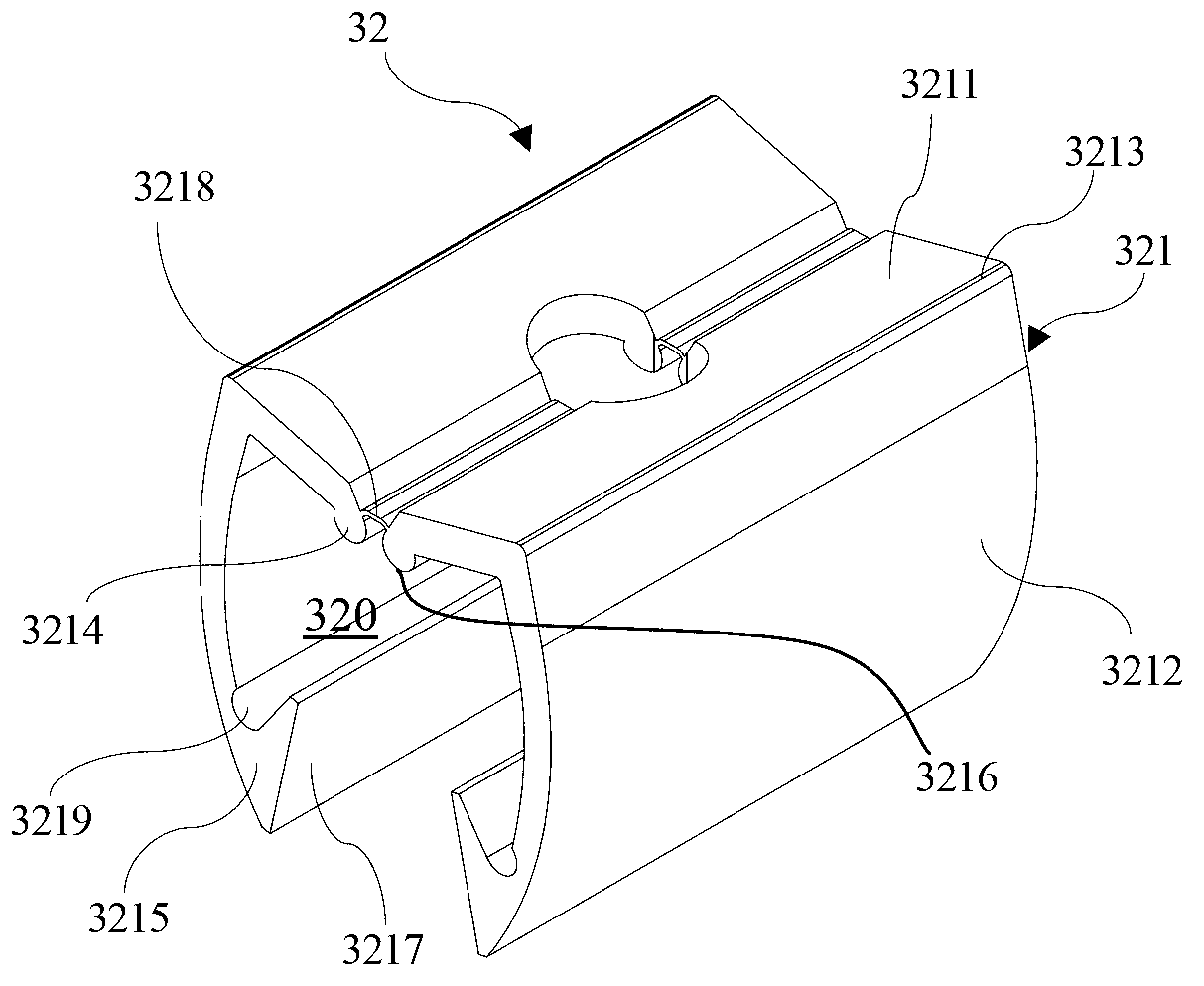

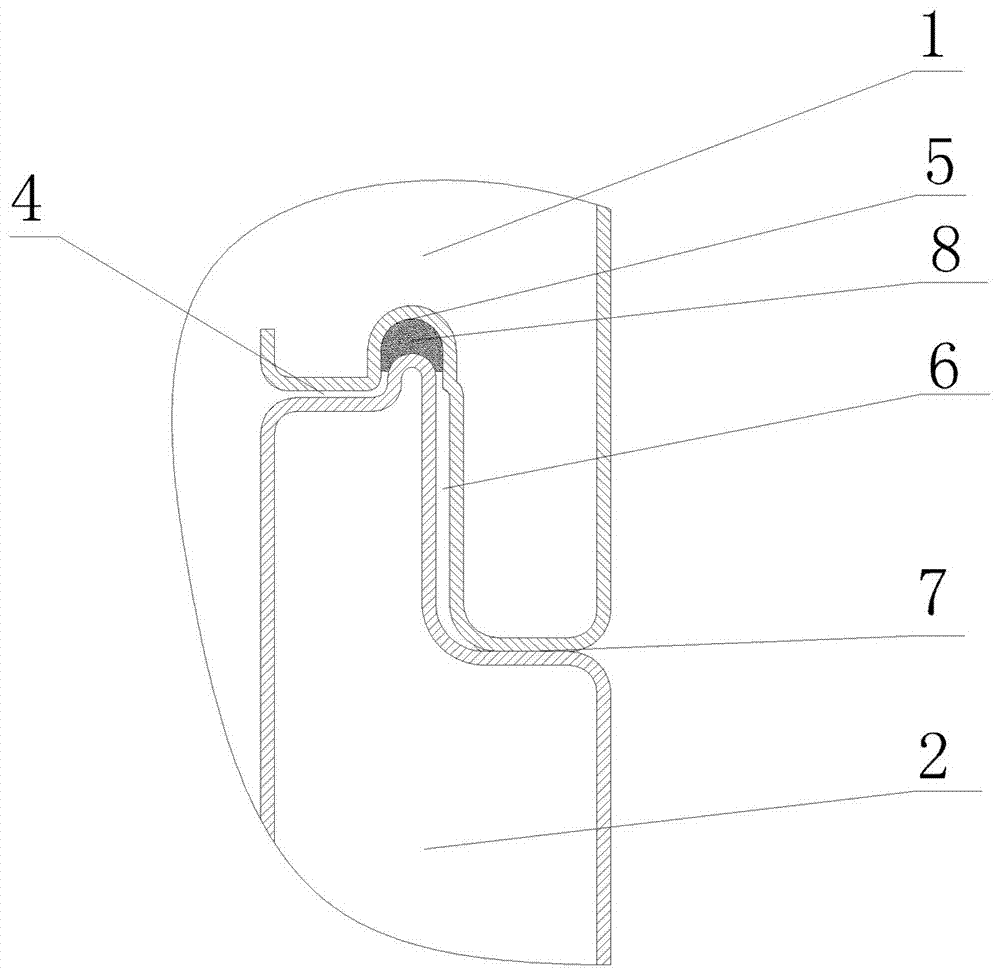

Mounting structure for car door glass tightening and method for mounting car door glass

ActiveCN103303105ATo achieve fastening effectImprove smoothnessWindowsWindscreensPre stressPre stressing

The invention discloses a mounting structure for car door glass tightening, which comprises a car door glass body, wherein the car door glass is movably arranged on a car door through a moving device on a car window track; the car door glass body is fixed on the moving device through a tightening system; the tightening system comprises an oppressing component and a plurality of tightening components; and the tightening components are oppressed through the match of the oppressing component with the car door glass body to generate a pre-stressing force to tighten the car door glass body. In the mounting structure for the car door glass tightening provided by the invention, the tightening components are oppressed through the match of the oppressing component with the car door glass body together to generate the pre-stressing force; the car door glass body becomes a main control element to generate the pre-stressing force; the tightening components are made of elastic materials; and under the action of external forces, a stable pre-stressing force is formed at the inner part of the materials and stored to form a stable pre-stressing force system with the car door glass body and the oppressing component together.

Owner:WM MOTOR TECH GRP CO LTD

Fuel injector designed to minimize mechanical stress on fuel pressure sensor installed therein

ActiveUS20090118983A1Stress minimizationAccuracy in measuring the pressure of fuelElectrical controlDigital data processing detailsCylinder headMechanical pressure

A fuel injector for an internal combustion engine is provided. The fuel injector is to be installed in a cylinder head of the engine and has a fuel pressure sensor working to measure the pressure of fuel within a injector body. The fuel pressure sensor is installed in a portion of the injector body which is to be located away from the cylinder head of the engine across a portion of the injector body on which a mechanical pressure is exerted by an external member such as a fuel supply pipe or a fuel drain pipe, thereby keeping the fuel pressure sensor free from internal stress, as arising from the mechanical pressure exerted on the injector body, to ensure the accuracy in measuring the pressure of the fuel.

Owner:DENSO CORP +1

Nylon fuel tank in use for automobiles and motorcycles, and preparation method

InactiveCN100355809CReduce internal stressNo internal stressUnderstructuresFuel tanksIn vehiclePlasticizer

This invention discloses a process for preparing a nylon fuel tank used in vehicles and motorcycles, which comprises the steps of: molten-mixing 10-49.9 wt.% of epsilon-hexanolactam with the catalyst, plasticizer, antifoamer, antioxygen, light stabilizer and other assistants to obtain component A; molten-mixing the rest of the epsilon-hexanolactam with the catalyst to obtain component B; mixing component A and B, and injecting the mixture into the fuel tank mold to be molded into nylon fuel tanks. The process of this invention achieves plasticizing modification and product molding in a single step with low energy consumption. The nylon fuel tanks have good resisting property, as well as good impact resistance and other mechanical properties at -40DEG C-60 DEG C.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Integration manufacturing method of cantilever beam type dot needle-point based on silicon oxide film

InactiveCN1730378AExcellent mechanical propertiesImprove performanceDecorative surface effectsChemical vapor deposition coatingResistFine structure

A integration Manufacturing method for cantilever beam type spot needlepoint base on silica dioxide film. First growing a layer silica dioxide film by thermal oxidation on the surface of a double-faced mirror polish silicon basal body, then opening a liquid storage groove window on the oxidation film and forming a fluid passage anf forming a fine structure patterns of the cantilever beam and the needle point by two photo resist mask reaction ion etching art work, and then open a window for back etching monocrystalline silicon releasing the cantilever beam on the back side of the silicon in mask chemical etching, using KOH solution aeolotropism masking, getting rid of the silicon basal body under the cantilever beam, releasing the silica dioxide cantilever beam needle point which has been micro machine-shaping. The invention uses thermal oxidation thermal oxidation film replacing general monocrystalline silicon film as constructional material for making cantilever beam type spot needle point, and not only can improve the hydrophilicity of the needle point and the fluid channel, have no inner stress, but also get a convenience and highly effective integration manufacturing process flow.

Owner:SHANGHAI JIAO TONG UNIV

Method for processing integrated reducing multi-way pipe fitting

The present invention relates to a production method of plastic integrated reducing multiway pipe. Said method includes the following several procedures: preparing plastic pipe section; drilling hole and heating; making branch mouth, placing mould core and positioning cover; forming branch mouth; pipe section forming, removing positioning cover and mould core; welding branch mouth so as to form multiway pipe.

Owner:CHINAUST PLASTICS CORP

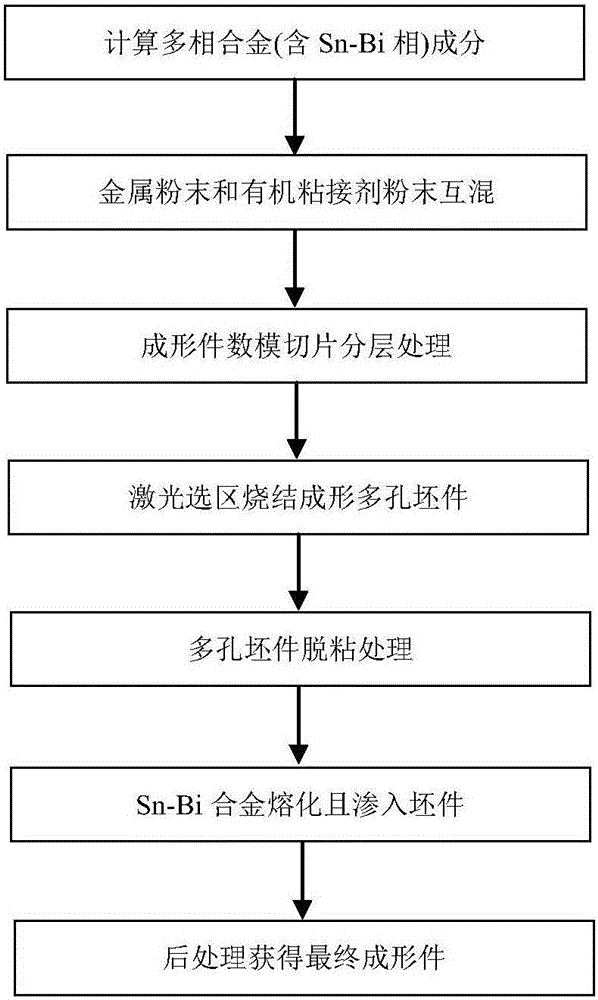

Selective laser sintering method for preparing zero-expansion/shrinkage-rate metal parts

ActiveCN106001572ANo internal stressNo thermal stressAdditive manufacturing apparatusTransportation and packagingSmooth surfaceAfter treatment

The invention relates to a selective laser sintering method for preparing zero-expansion / shrinkage-rate metal parts. The method comprises calculation of multi-phase alloy components, mixing of metal powder and organic adhesive powder, digital-analog slice layering treatment of formed parts, molding of porous blanks through selective laser sintering, debonding treatment of the porous blanks, melting of Sn-Bi alloys and infiltration in the blanks, and obtaining of final formed parts through after-treatment. After two structures with zero expansion rate and zero shrinkage rate are mixed, the metal parts with zero expansion rate and zero shrinkage rate can be obtained by an added material manufacturing forming technology and a diffusion metalizing method. The preparation method has advantages such as convenient operation, reliable performance, low comprehensive cost, light weight of the metal formed parts, smooth surface and capability of satisfying the use requirements and prolonging the service life, and can be widely popularized and applied.

Owner:四川三阳激光增材制造技术有限公司

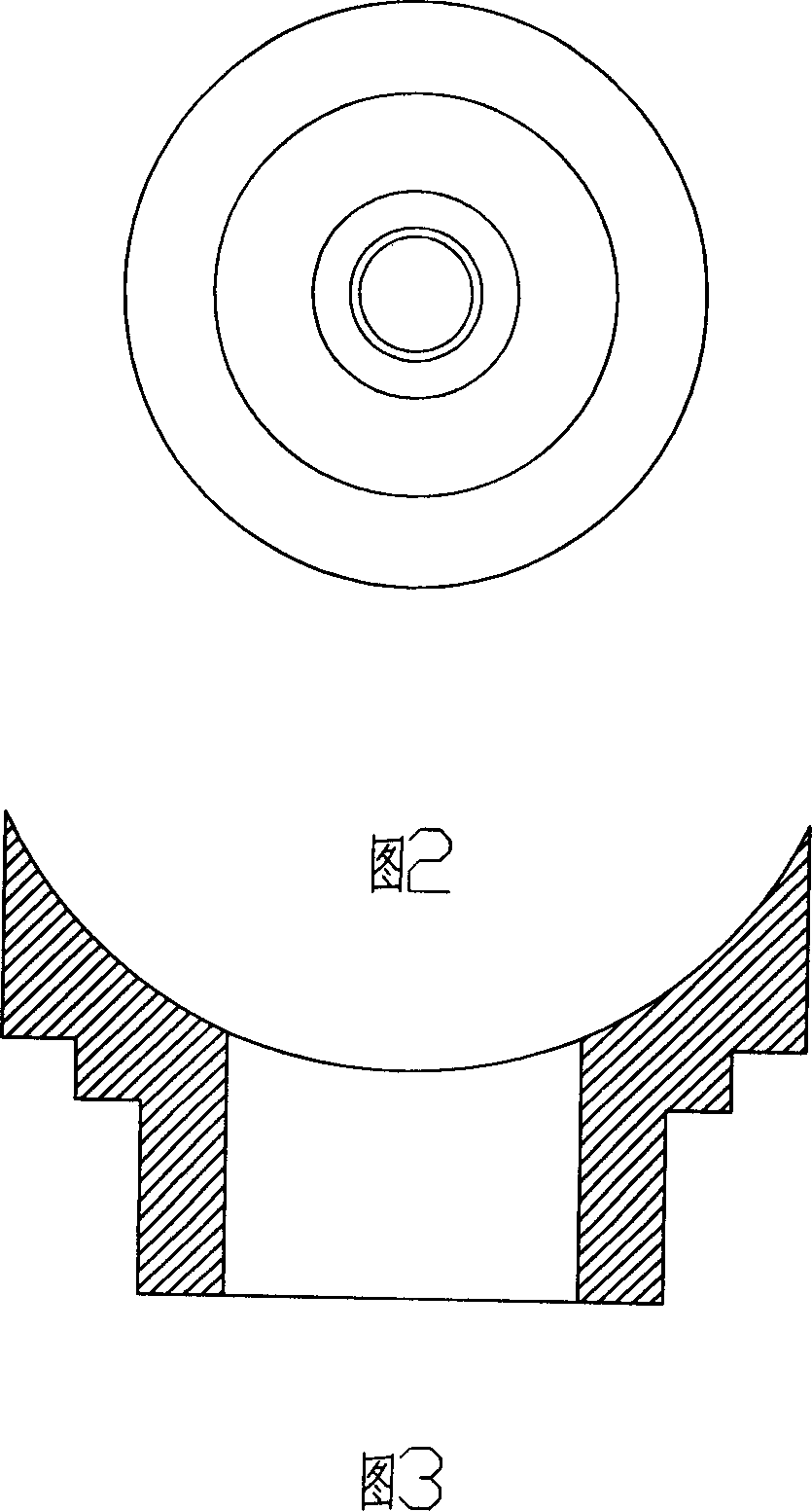

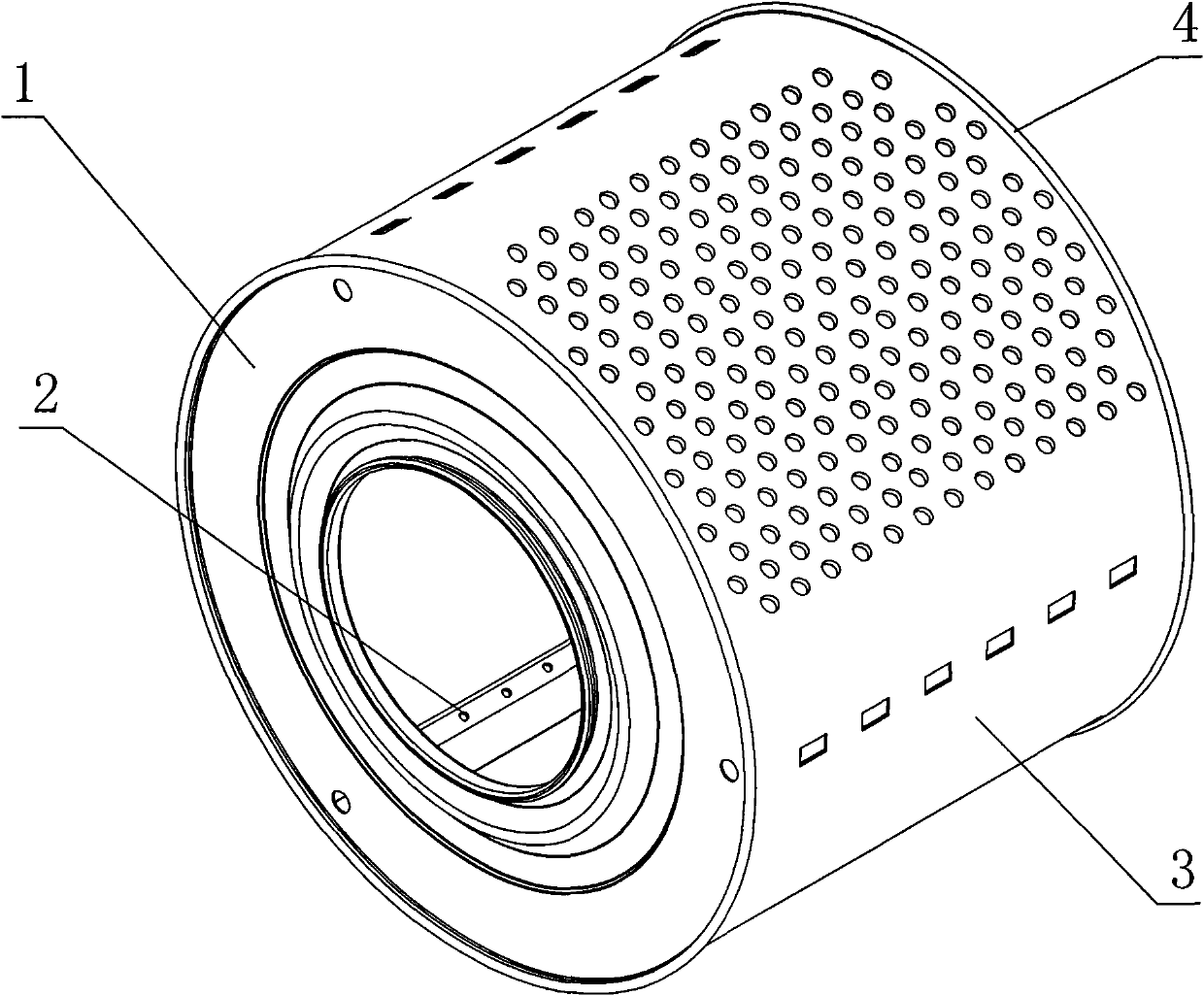

Industrial washing machine washing internal cylinder with non-welded structure and manufacturing method thereof

InactiveCN101994231ANo internal stressReduce distortionOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention discloses an industrial washing machine washing internal cylinder with a non-welded structure and a manufacturing method thereof. Assemblies of the washing internal cylinder comprise a machined cylindrical net sheet, wherein meshes are formed on the net sheet uniformly; a front end cover and a rear end cover of the internal cylinder are fixedly connected with both ends of the cylindrical net sheet; a plurality of lifting tendons are arranged on the inner wall of the net sheet at intervals; flangings overturning outwards are arranged on edges at front and rear ends of the net sheet; hemmings overturning outwards are arranged on edges of the front and the rear end covers; the lifting tendons are attached to the inner wall of the net sheet closely, and both ends of the lifting tendons are clamped between the front and the rear end covers closely; and the hemmings on the front and the rear end covers are mutually meshed with the flangings on the net sheet. In the washing internal cylinder, the net sheet, the lifting tendons and the front and the rear end covers are integrated by a stamping connection forming method; and the assemblies of the integral internal cylinder avoid welding and internal stress at joints, so that the internal cylinder has small deformation, good quality and long service life, and does not damage linen.

Owner:上海川岛艾美机械设备有限公司

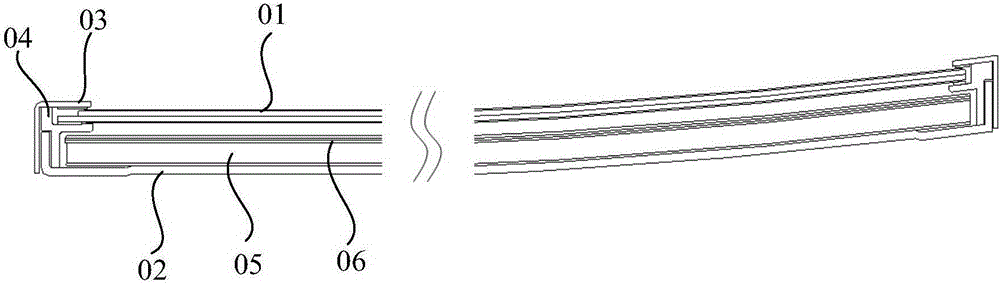

Light hard double-layer honeycomb polypropylene hollow plate

InactiveCN104175614AImprove carrying capacityNo internal stressSynthetic resin layered productsLaminationHoneycombCo extrusion

The invention relates to a light hard double-layer honeycomb polypropylene hollow plate, which belongs to a manufacturing method of a multilayer co-extrusion molding hollow plate. The light hard double-layer honeycomb polypropylene hollow plate is characterized in that an internal structure comprises an upper skin layer, a double-layer honeycomb sandwich structure layer and a lower skin layer, wherein the double-layer honeycomb sandwich structure layer is extruded by a plastic extruder and formed by virtue of a pair of vacuum plastic suction pressing rollers, the double-layer honeycomb sandwich structure layer is of a sandwich type structure and is provided with an upper layer and a lower layer which form a staggered honeycomb shape, the upper layer and the lower layer are mutually supported and connected by flaky plates, and the material formulas of the upper skin layer, the double-layer honeycomb sandwich structure layer and the lower skin layer are consistent. The light hard double-layer honeycomb polypropylene hollow plate is provided, so as to overcome the defects of poor impact resistant performance, compressive deformation and infirmness of an existing plastic hollow plate, and the light hard double-layer honeycomb polypropylene hollow plate can simultaneously bear transverse section stress, longitudinal section stress and plate positive stress and has the advantages of uniform stress of each side surface, wide application range and good use effect.

Owner:NINGBO TIANQI HONEYCOMB MATERIALS

Water expansion forming process for vehicle universal joints

ActiveCN108838270AImprove surface appearance qualityIncrease productivityUniversal jointPore water pressure

The invention discloses a water expansion forming process for vehicle universal joints. The process is characterized by comprising the following steps: (1) raw materials-carbon steel pipes are cut asneeded sizes; and burrs at two ends are removed; (2) the carbon steel pipes are annealed at a temperature of 450-600 DEG C to reach the surface hardness HRB of 30-40; (3) the carbon steel pipes are put in a water expansion mold; the mold is tightly pressed by a water expansion machine; meanwhile, booster cylinders at two ends are pushed into punches; saponification liquid with pressure of 16 MPa is injected for primary water expansion formation; the water expansion forming parameters are as follows: the water expansion machine applies the pressure of 120 tonnages to a main cylinder; the pressure is lower than 24 MPa; the output pressure is higher than 18 MPa; the output water pressure of left and right side cylinders is 20-28 MPa; the displacements of the left and right punches are 43 mm;the water cylinder capacity is higher than 1.5 L; and the water supply pressure is lower than 4 MPa; and (4) semi-finished products are annealed again after water expansion by the procedures; the annealing temperature is 450-600 DEG C; and the hardness HRB is 34-36.

Owner:广东思豪内高压科技有限公司

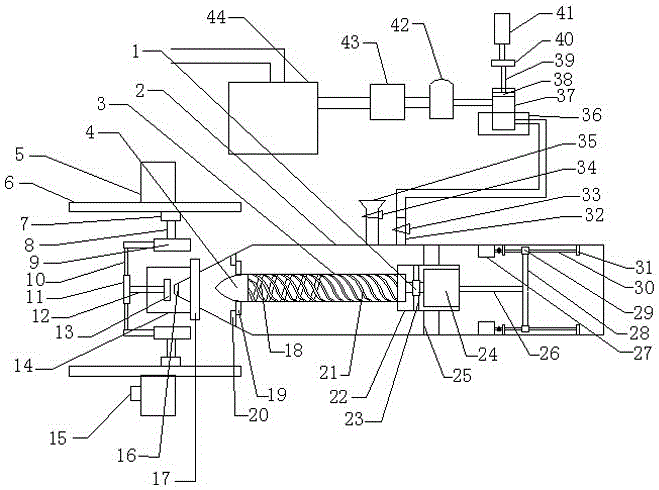

Injection micro-foaming device

The invention discloses an injection micro-foaming device, and belongs to the technical field of machine equipment. The injection micro-foaming device comprises a bearing, a material barrel, a screw, a screw head, a frame, a linear motor, a movable block, a first supporting rod, a first air cylinder, a second supporting rod, a first push plate, a first push rod, a first press plate, a housing body, a controller, a spraying nozzle, a rubber ring, a leftward-thread lead section, a non-return valve, a gasket, a rightward-thread lead section, a machine shell, an anti-leaking ring, a first motor, a flow stop ring, a connecting rod, a second motor, a support, a nut, a lead screw, a bearing frame, an air inlet pipe, an air inlet valve, a feeding valve, a feeding inlet, a condensate water device, a compression tank, a second press plate, a second push rod, a second push plate, a second air cylinder, a desulfurizer, a dehydration device and an air storage tank. The air storage tank is connected with a smoke exhausting system of a factory through a pipeline and connected with the dehydration device through a pipeline. The injection micro-foaming device has the advantages of achieving efficient mixing, eliminating internal stress of injection products and preventing products from being prone to deformation.

Owner:ZHEJIANG JIACHENG MACHINERY

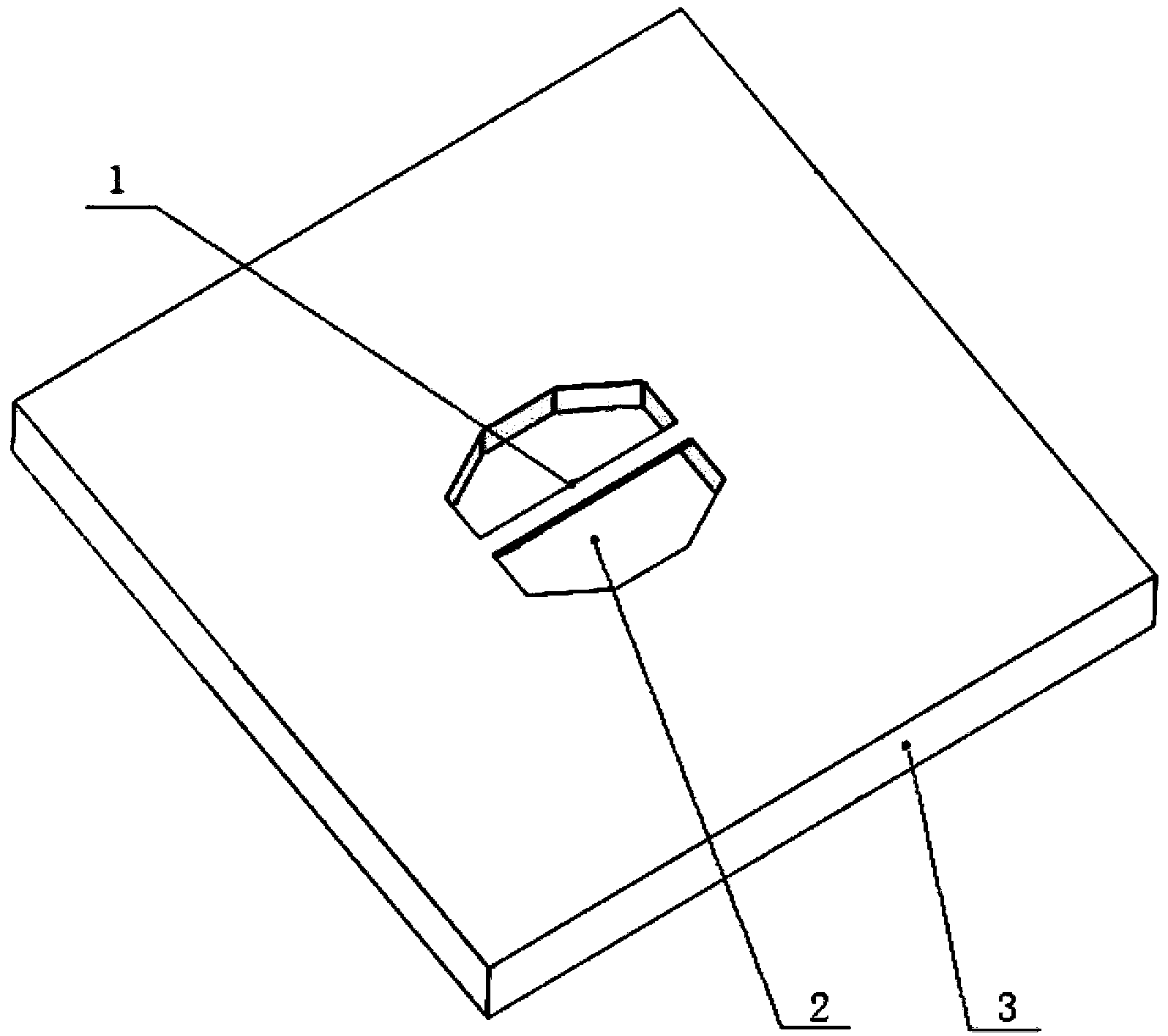

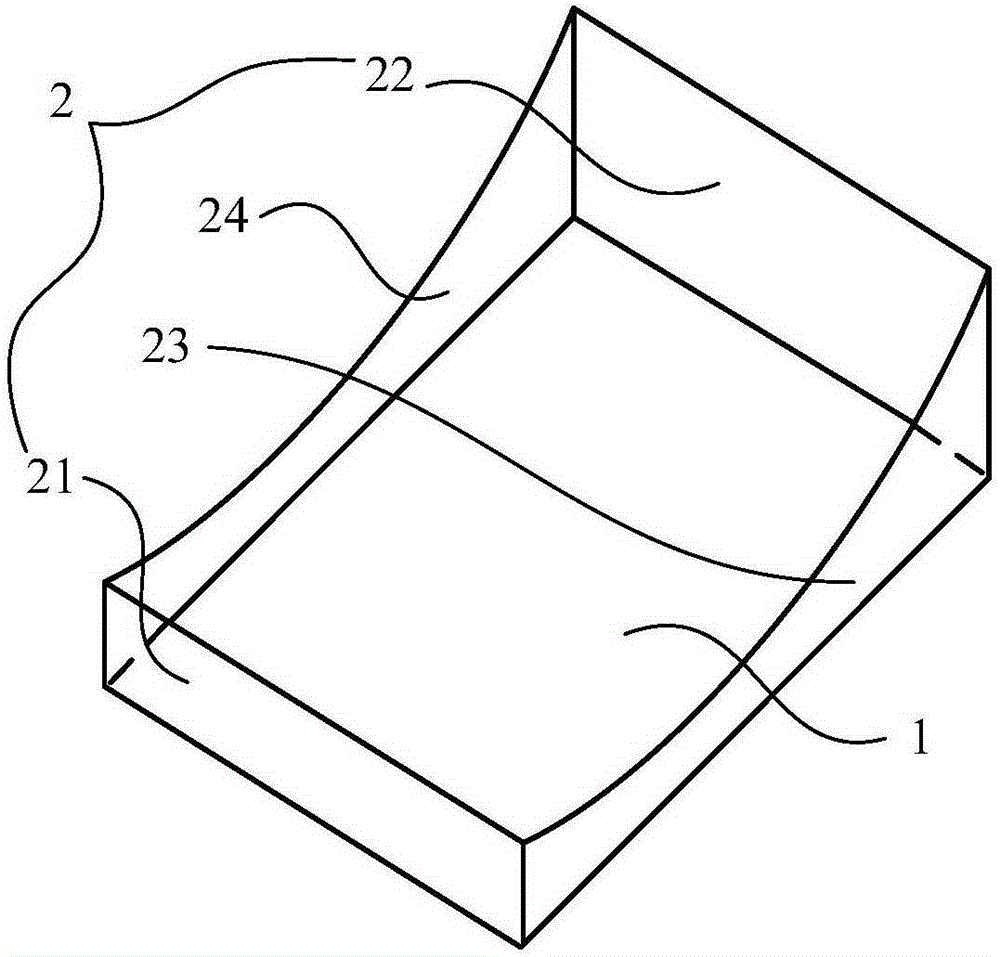

Backboard and curved-surface display device

InactiveCN105261298AAvoid springback deformationCurvature stableIdentification meansBackplaneEngineering

The embodiment of the invention provides a backboard and a curved-surface display device, relating to the technical field of display devices, and aiming to solve the problems that a backboard structure in the prior art easily generates rebound deformation and is high in processing cost. The backboard comprises a base plate and a side wall surrounding the edge of the base plate for a circle, wherein the base plate is a flat plate, and the upper edge of the side wall forms a curved-surface box structure used for limiting the curvature of a display panel in the curved-surface display device. The backboard can be used in the curved-surface display device.

Owner:BOE TECH GRP CO LTD +1

Novel mineral material and preparation method and application thereof

The invention provides a novel mineral material. The novel mineral material is prepared from the following raw materials in percentage by weight: 65-90% of stone, 0-5% of carbon fibers, 5-10% of ash powder and 5-20% of epoxy resin and a curing agent. The invention further provides a preparation method and application of the novel mineral material. The mineral material provided by the invention isgood in shock absorption, and particularly 10 times better than cast iron, and brings optimal vibration damping and noise reduction effects. The thermal stability is good, and the influence of temperature change on the dimensional precision of the machine tool hardly exists when the material is used for the numerical control machine tool, precision is high, a casting temperature is low, internal stress is avoided, the precision can be guaranteed, the integration is good, the novel mineral material can be directly injected into a pipeline, a cable, a sensor and the like, the corrosion resistance is good, good corrosion resistance is achieved on oil, cooling liquid and other corrosive liquid, energy is saved, environment is protected, energy consumption is low and is reduced by 80% comparedwith cast iron, and the material can be used as a regenerated material for secondary utilization.

Owner:杭州太普机械科技有限公司

Mechanical cutting device for aircraft skin

The invention provides a mechanical cutting device for an aircraft skin, and relates to the field of repairing of the aircraft skin. The mechanical cutting device for the aircraft skin comprises a scale handle, a power device and a cutting tool. The mechanical cutting device for the aircraft skin is characterized in that the device is positioned on a fixed skin during use; the scale handle slides to indicate the radius of the skin needing to be cut; an operating handle is downwards pressed, and then the power device downwards moves; a bevel tooth sleeve and a bevel gear are separated; a power wire is connected to switch on a power supply; the cutting tool is driven by the power device to cut the skin; the skin cutting intensity is determined by controlling the downward pressing force of the operating handle; after the skin is cut, the power supply is switched off; the pressure on the operating handle is released while the rotating speed is turned into low speed; the power device is rebound through an elastic device; and the bevel gear and the bevel tooth sleeve are engaged to lock the rotating of a driving shaft. With the adoption of the device, aircraft crews can quickly cut the skin without influencing the skin material performances.

Owner:嘉善县泰佳包装材料有限公司

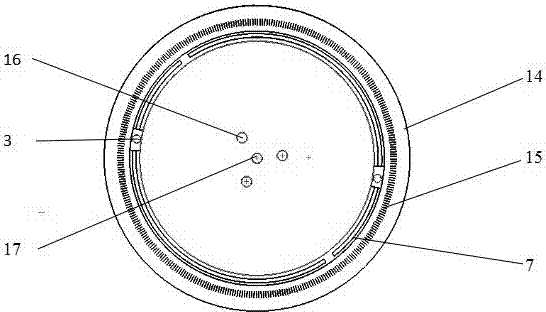

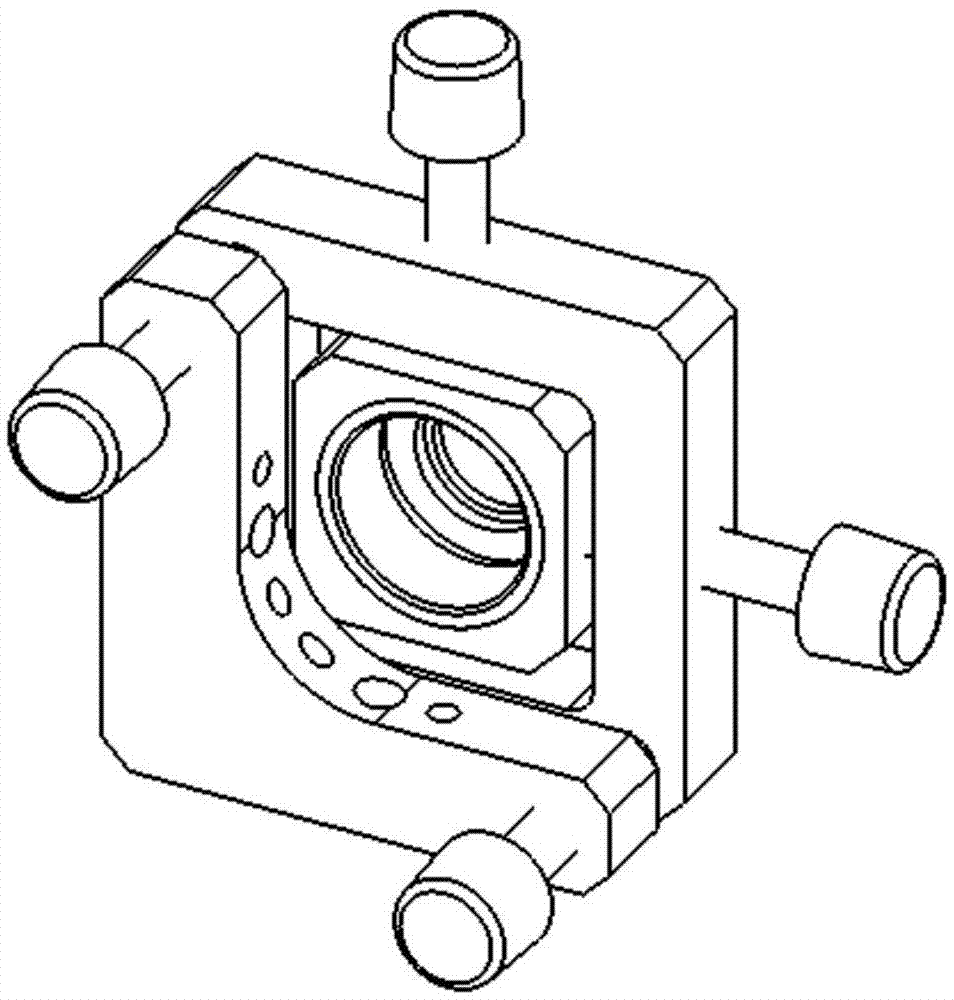

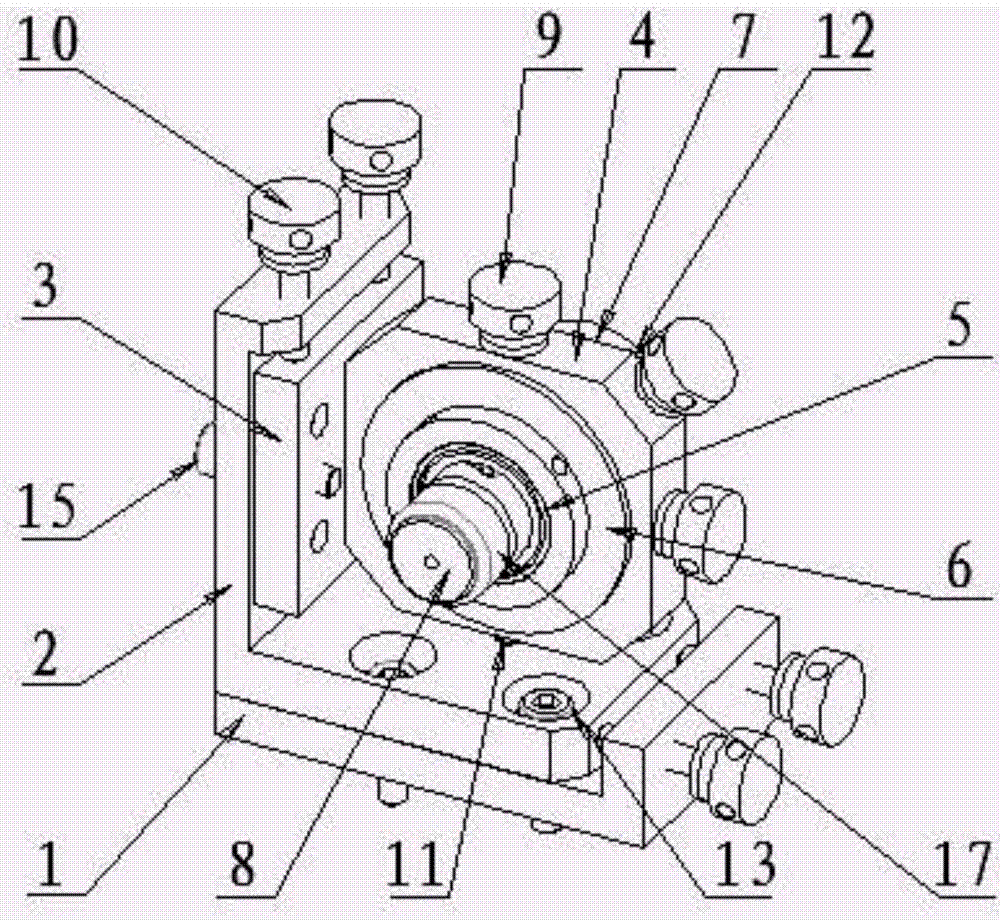

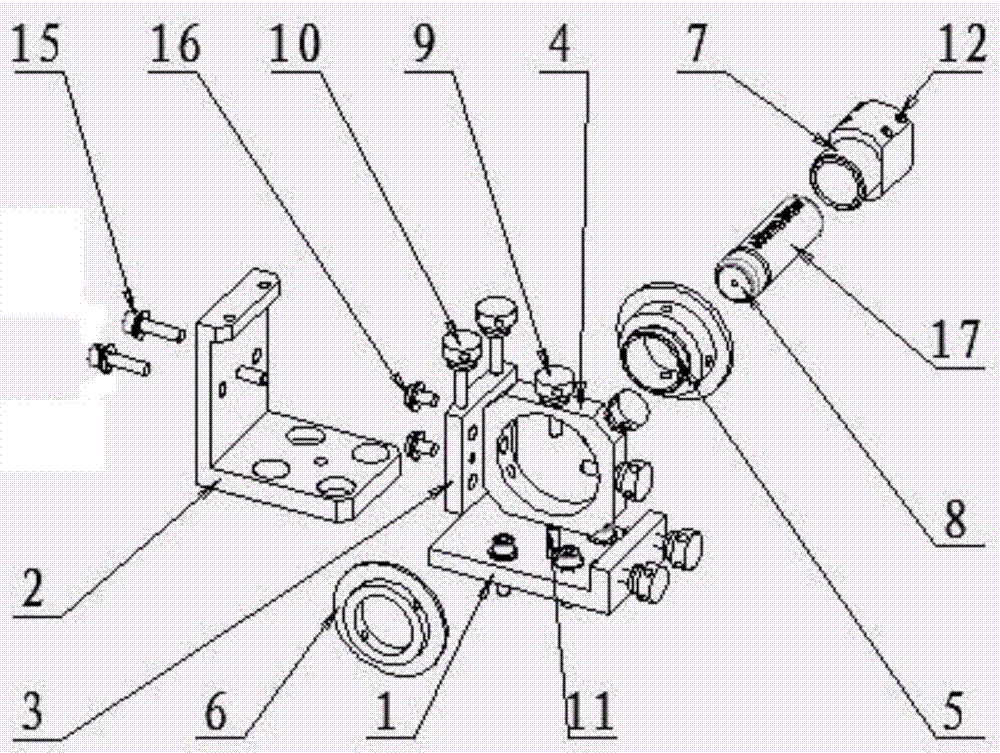

Semiconductor laser light source regulation device applied to laser light path system

ActiveCN106936067ANo internal stressStable outputSemiconductor laser structural detailsSet screwLight spot

The invention relates to a semiconductor laser light source regulation device applied to a laser light path system, which comprises a semiconductor laser light source, a first regulation plate, a second regulation plate, a third regulation plate, a fourth regulation plate, a regulation ring, a locking ring, a nylon sleeve and an indicator light spot sleeve, wherein the semiconductor laser light source is fixed in the nylon sleeve through four set screws; the end surface of the semiconductor laser light source is provided with the indicator light spot sleeve; the nylon sleeve is arranged in the regulation ring and is then fixed on the fourth regulation plate by the locking ring; the fourth regulation plate is fixed on the third regulation plate through two first screws; the third regulation plate is positioned on the second regulation plate through a cylindrical pin and is then locked by two screws; the second regulation plate is positioned on the first regulation plate through a cylindrical pin and is then locked on the first regulation plate by two screws; and the first regulation plate is fixed on a laser base through two second screws. During the laser light path matching, mounting, positioning and regulation processes, the precision is high, the stability is good, the cost is low, and the application is wide.

Owner:WUHAN MIRACLE LASER SYST

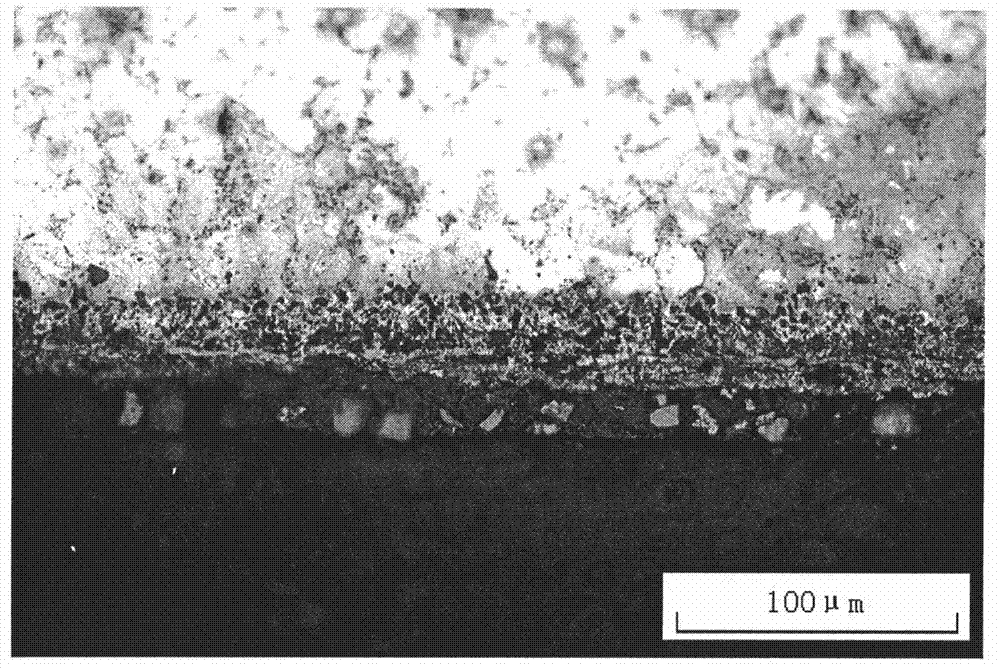

Novel low-temperature solid boronizing activator

InactiveCN103938150AWorkpiece deformation is smallWide range of applicationsSolid state diffusion coatingBoron atomUrea

The invention discloses a novel low-temperature solid boronizing activator. The novel low-temperature solid boronizing activator consists of the following components in parts by mass: 12.6-17.2 parts of potassium fluoborate, 35.8-40.4 parts of cryolite (Na5AlF6), 23.0-27.6 parts of calcium fluoride (CaF2) and 14.8-19.4 parts of urea. The novel low-temperature solid boronizing activator has the following advantages that 1, after boronization, a workpiece slightly deforms and generates neither phase change nor internal stress, and the application of the workpiece on a precise part is promoted greatly; 2, a low-temperature boronizing layer is very thick, the thickness is about 24-46 micrometers and the application field is very wide; 3, the boron atoms in low-temperature solid boronizing have enhanced activity and enhanced diffusion rate and is good in economy.

Owner:SHANDONG JIANZHU UNIV

Fabricated building wall body

ActiveCN110106995AEasy splicingEasy width adjustmentWallsBuilding material handlingEngineeringBody positioning

The invention relates to a fabricated building wall body. The fabricated building wall body comprises two wallboards, a connecting frame, two side supporting plates, side supporting springs, attachedplates and a limiting mechanism, clamping grooves are formed in the front inner side surfaces and the rear inner side surfaces of the wallboards, and the connecting frame is located between the two wallboards. The two side supporting plates are distributed on the front side surface and the rear side surface of the connecting frame, the side supporting plates are symmetrically installed on the leftside surface and the right side surface of the connecting frame, the outer side surfaces of the side supporting plates and the outer side surfaces of the wallboards are located in a same plane, the side supporting plates are located in the clamping grooves of the wallboards, square grooves are formed in the side surfaces of the side supporting plates, the attached plates are installed in the square grooves of each side supporting plate through the side supporting springs, and four buffering mechanisms are symmetrically installed on the connecting frame. According to the fabricated building wall body, the problem that the splicing size of two current wall bodies cannot be adjusted during splicing is solved; and the wall bodies are positioned through labor using boards during wall body splicing, the positioning mode is poor in precision, the wall body positioning is inaccurate, and the service life of the wall body can be further affected.

Owner:江西天岩建设工程有限公司

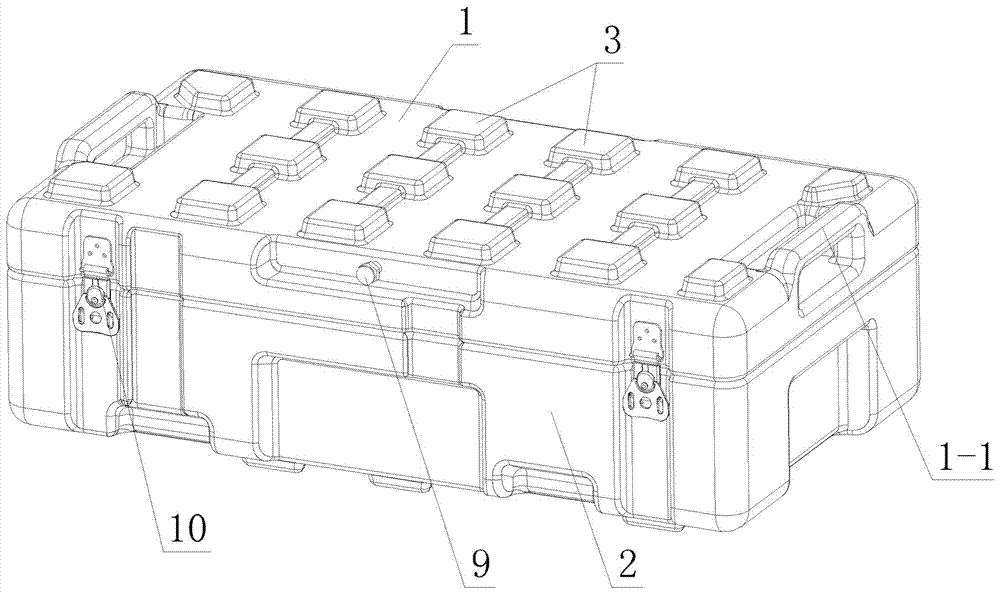

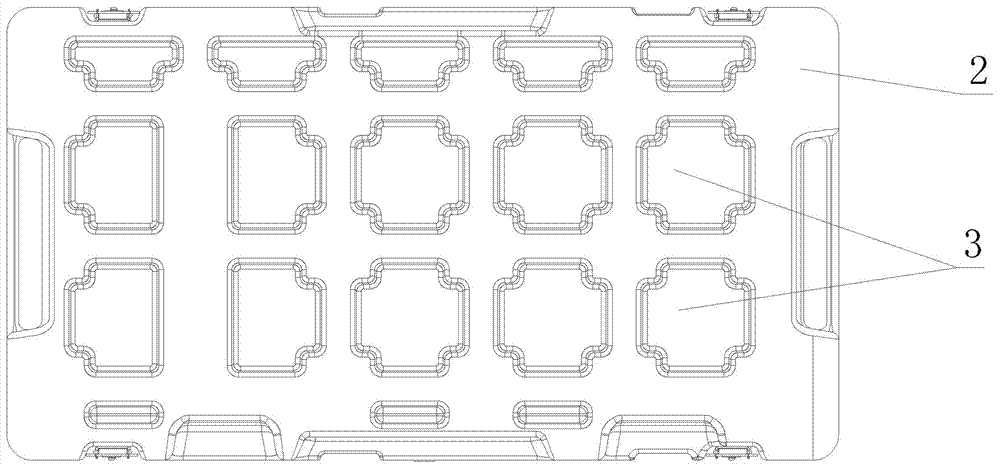

Air-drop type storage-transportation packaging box convenient to stack and preparation method of packaging box

ActiveCN107383579ANot easy to damageImprove toughnessCoatingsRigid containersLinear low-density polyethyleneLow-density polyethylene

The invention relates to an air-drop type storage-transportation packaging box convenient to stack and a preparation method of the packaging box, belonging to the package and transportation fields. The packaging box comprises a box body and a box cover which are mutually buckled, wherein the box body and the box cover are prepared from the following raw materials in parts by weight through rotational molding: 50-70 parts of linear low density polyethylene, 50-70 parts of low density polyethylene, 40-80 parts of high density polyethylene, 10-30 parts of medium density metallocene polyethylene and 1-6 parts of a coupling agent; and rig grids are arrayed at the bottom of the box body or the top of the box body or the box cover in a matrix manner, the rig grids at the top of the box body or the box cover are mutually seamed and clamped with the rig grids at the bottom of the box body on an upper layer so as to form embedding and splicing type anti-dislocation stacking structure. The packaging box is produced from the polyethylene materials with different densities through mixing and rotational molding, and modularized rid grid structures are arranged at the top and the bottom of the packaging box, so that the strength, impact resistance and packaging efficiency of the packaging box are improved, and the mutual stable stacking of different specifications of packaging boxes is realized.

Owner:河北金后盾塑胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com