Patents

Literature

34results about How to "Easy width adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

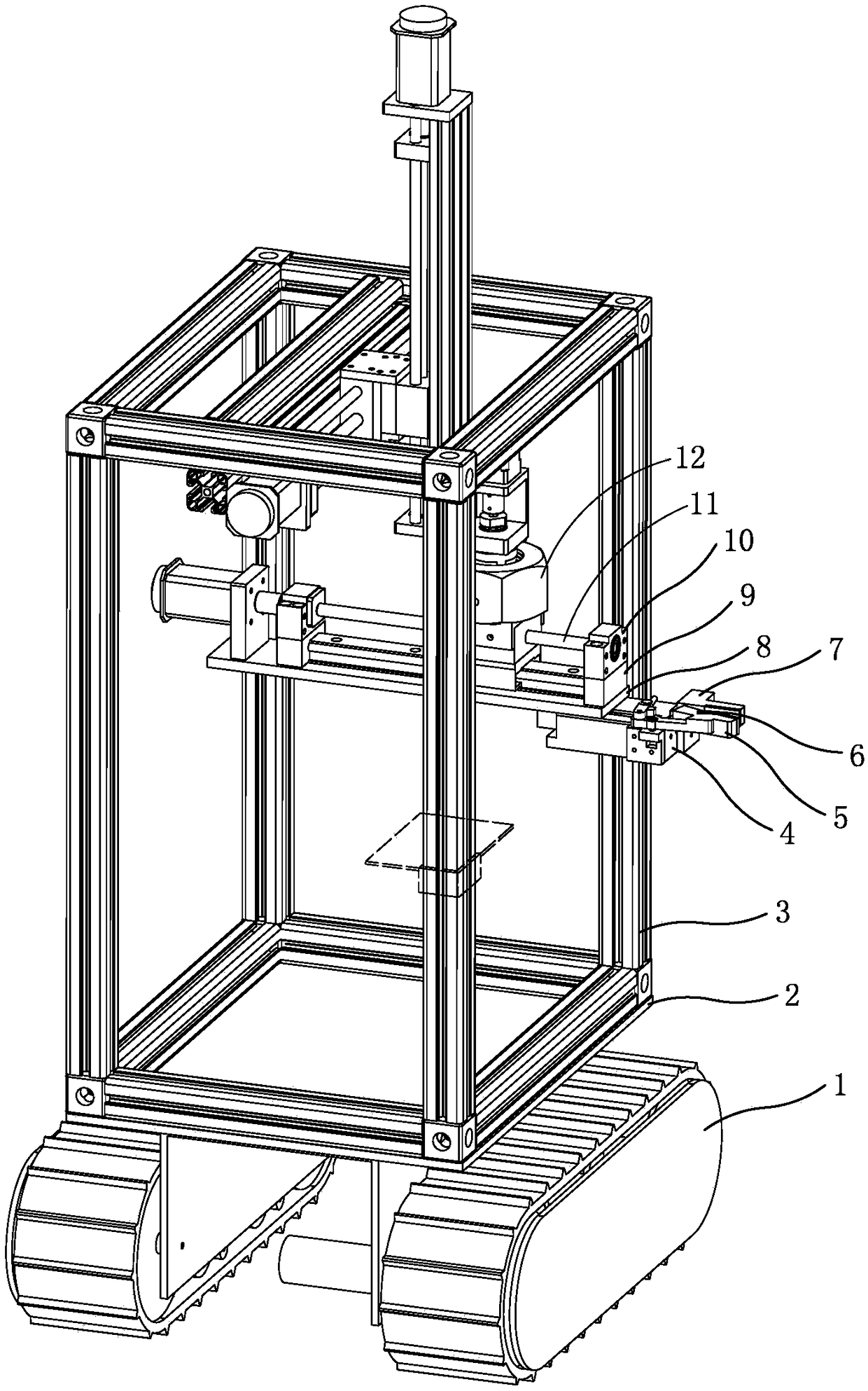

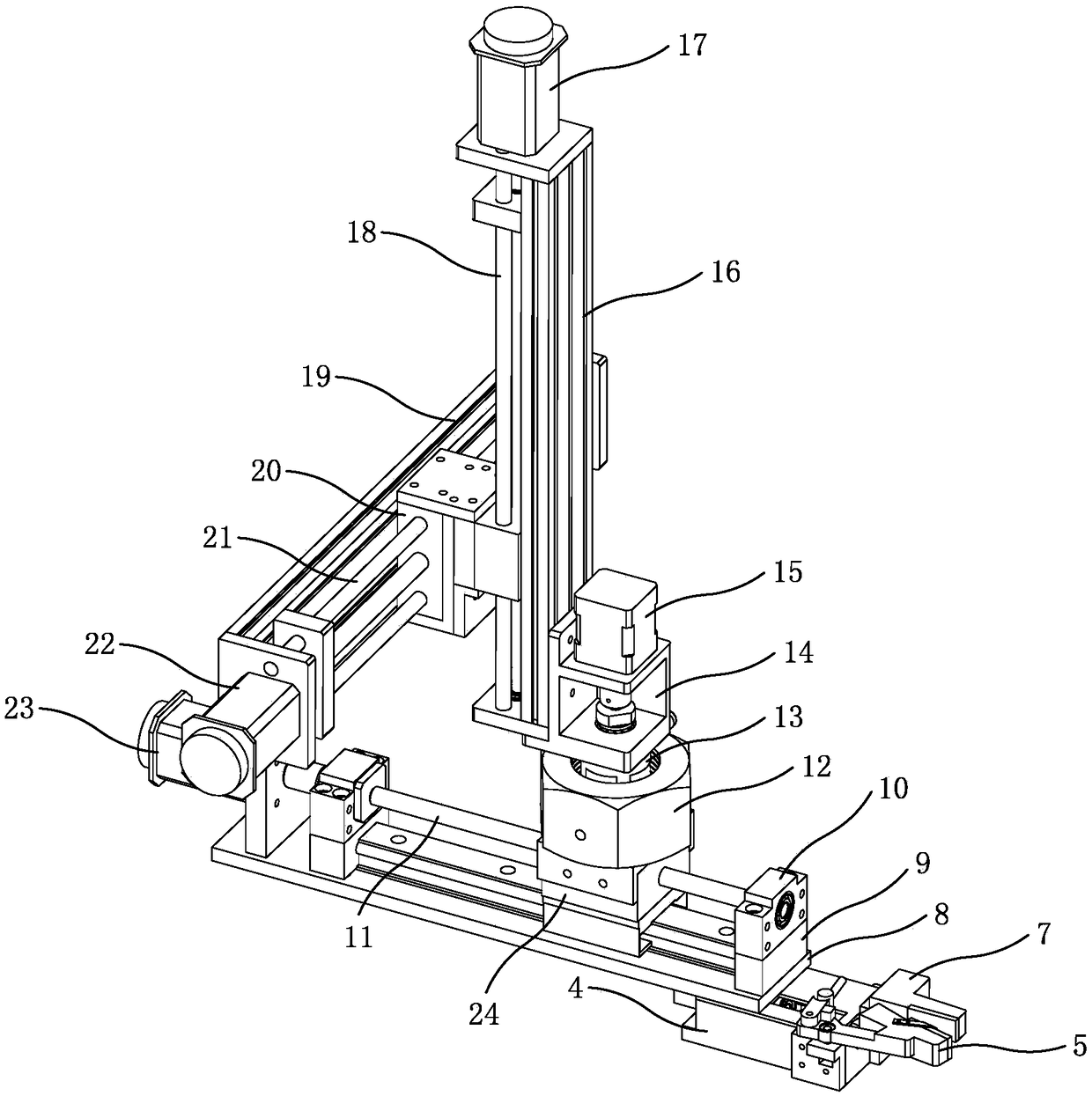

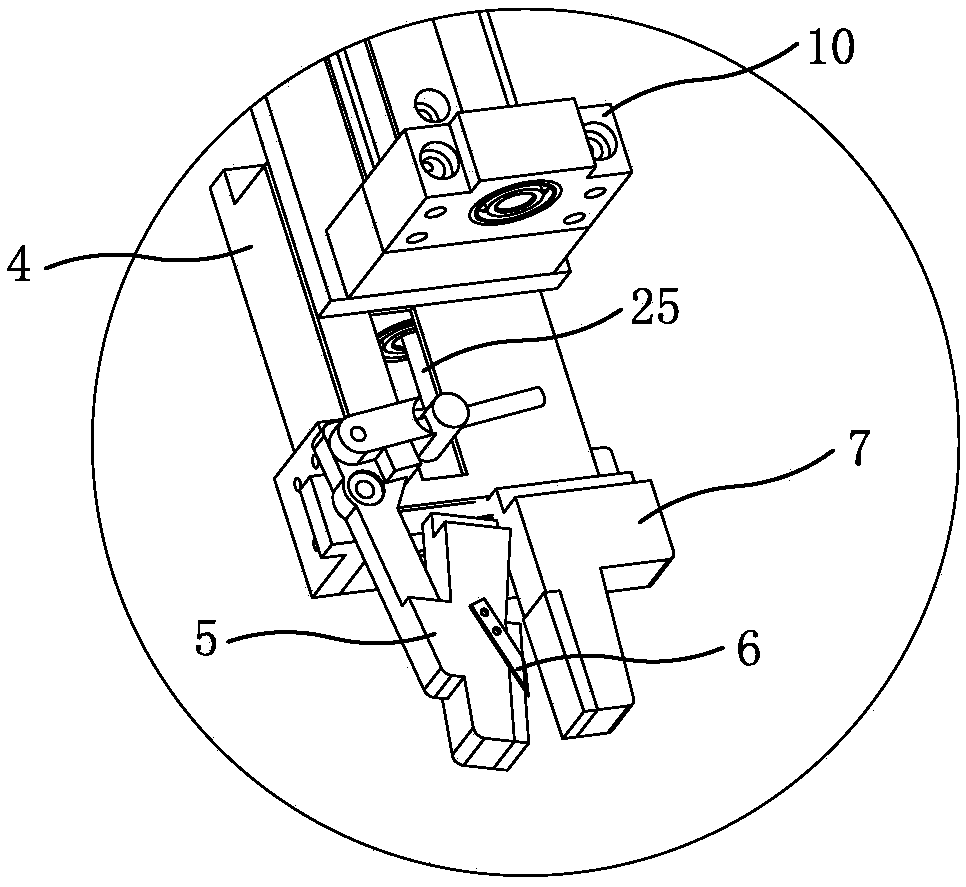

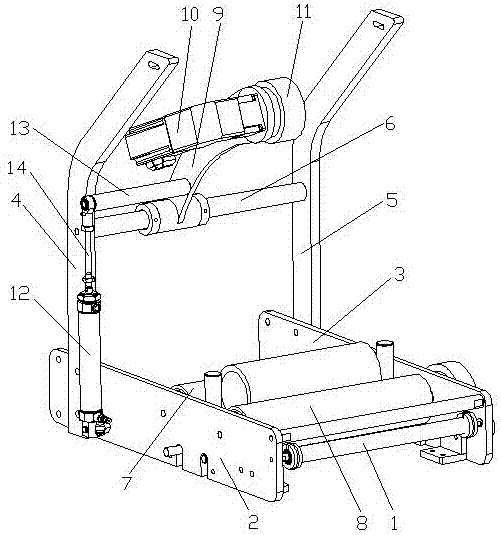

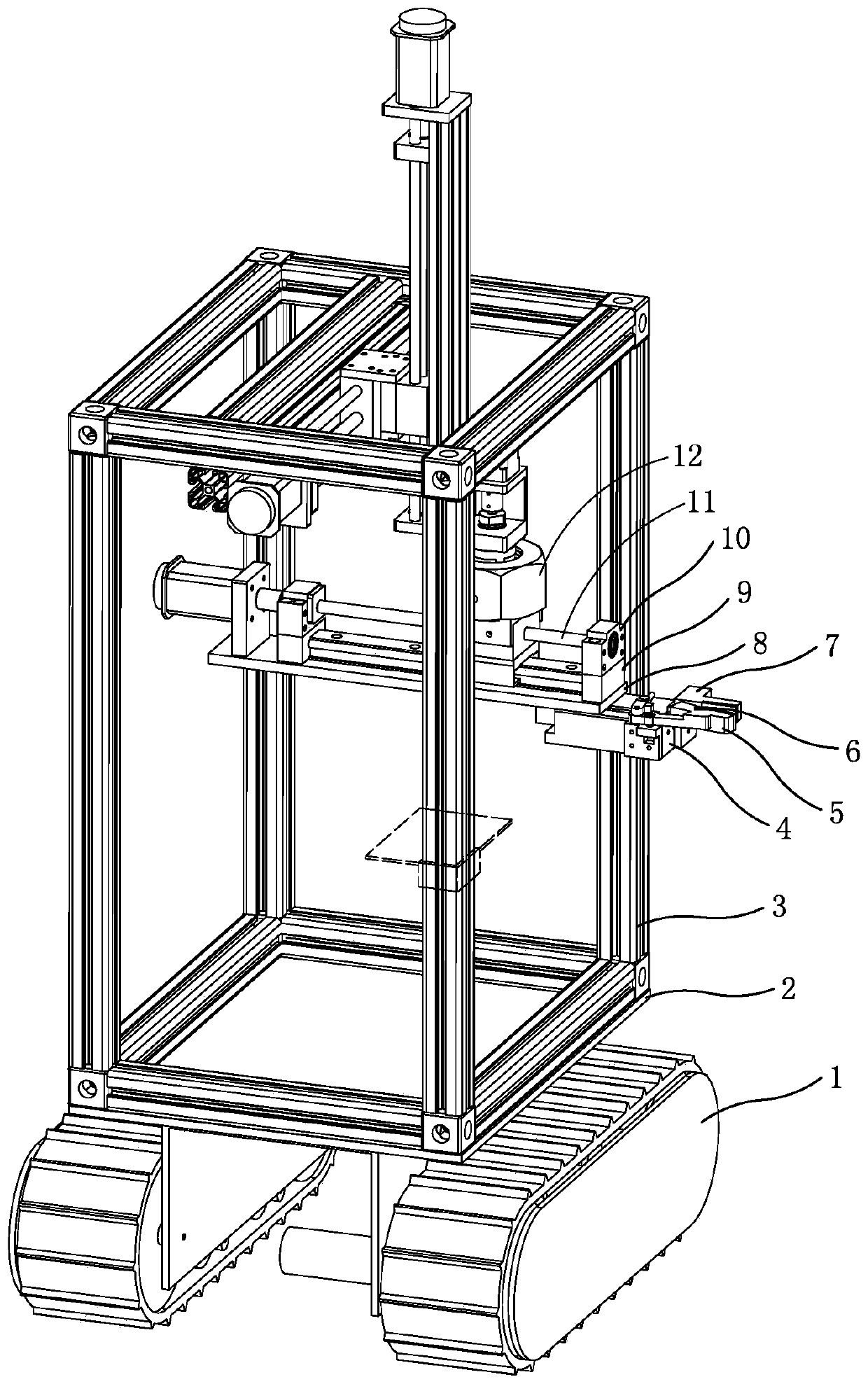

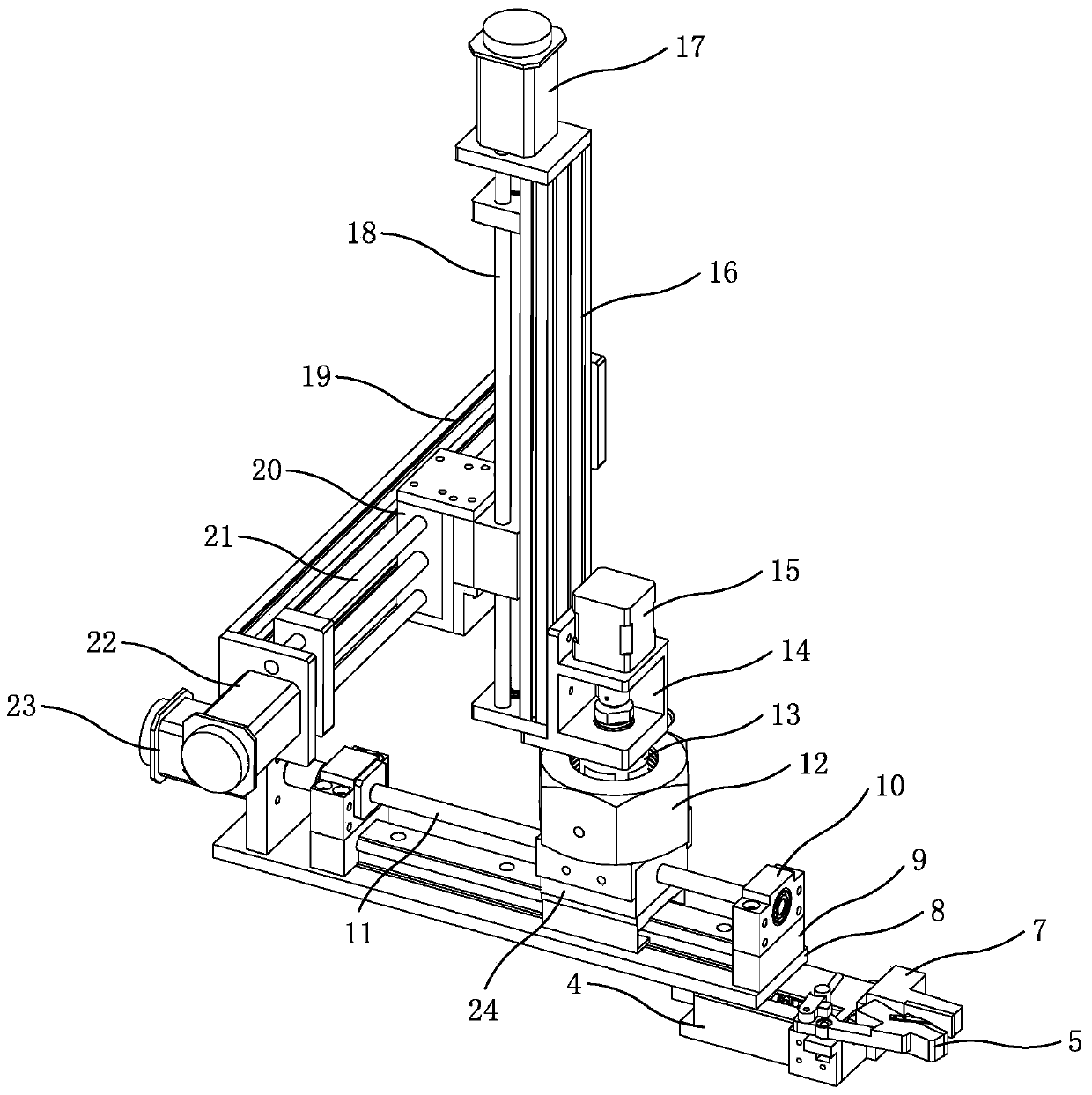

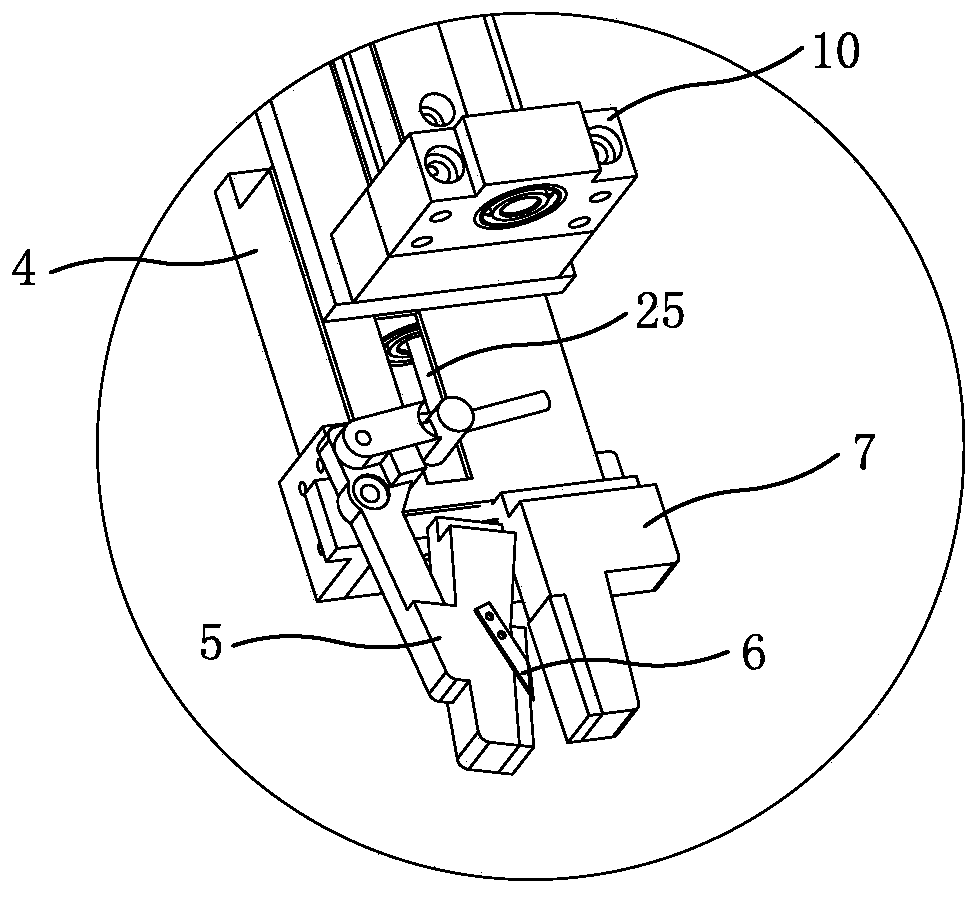

Strawberry picking robot

The invention relates to a strawberry picking robot. The strawberry picking robot is designed for solving the technical problem of the existing like products that grabbing mode structures and structures of machine frames and the like are not good enough in design. A framework of the picking robot is a cubical aluminum-profile framework composed of aluminum profiles, a framework bottom plate of thealuminum-profile framework is provided with a traveling crawler, an actuating mechanism which separately drives three-dimensional traveling through an axial motor is arranged in the aluminum-profileframework, and a mechanical claw is arranged at the tail end of an X-axis direction of the actuating mechanism; a collet supporting seat is arranged at one end of an X-axis bottom plate of the actuating mechanism, a mechanical claw is arranged at the bottom of the collet supporting seat, a cutter blade is arranged at one end of a movable collet of the mechanical claw, the collet supporting seat atthe symmetrical opposite side of the movable collet is provided with a fixed collet, the other end of the movable collet is hinged to the collet supporting seat through a pin shaft and can swing, a camera and a sensor are arranged just above the mechanical claw, a collecting string bag or manipulator collection box is arranged just below the cutter blade of the mechanical claw, and a box groove of the manipulator collection box is driven through a rotating motor to achieve the opening and closing of a hinge mode.

Owner:芮杰

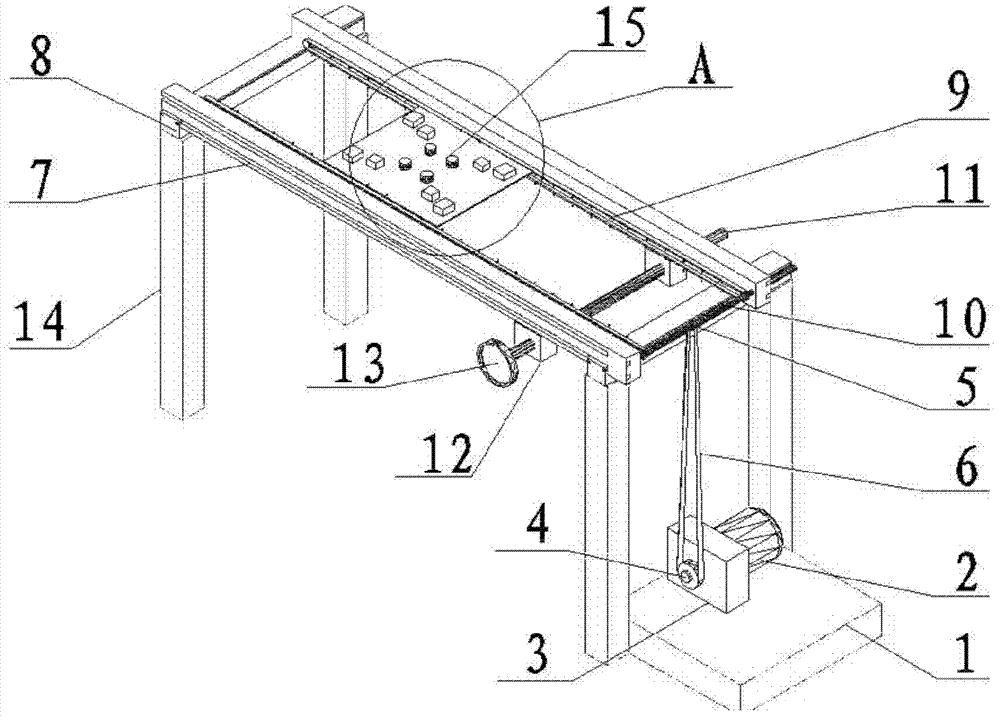

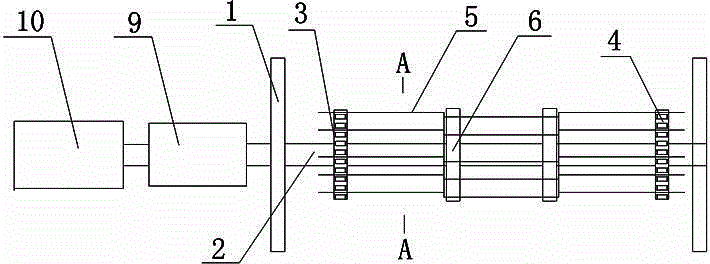

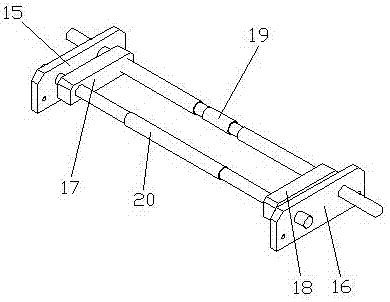

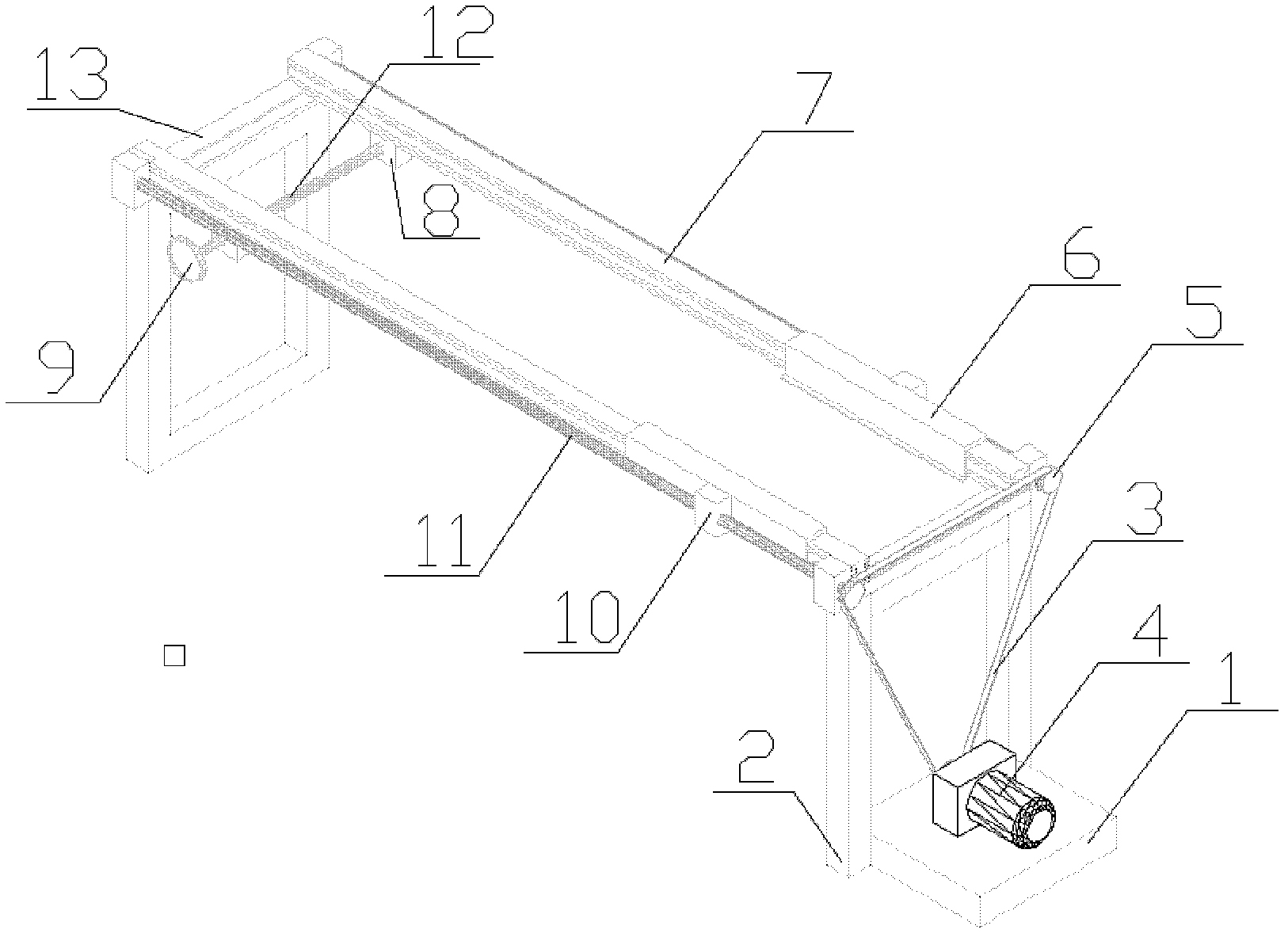

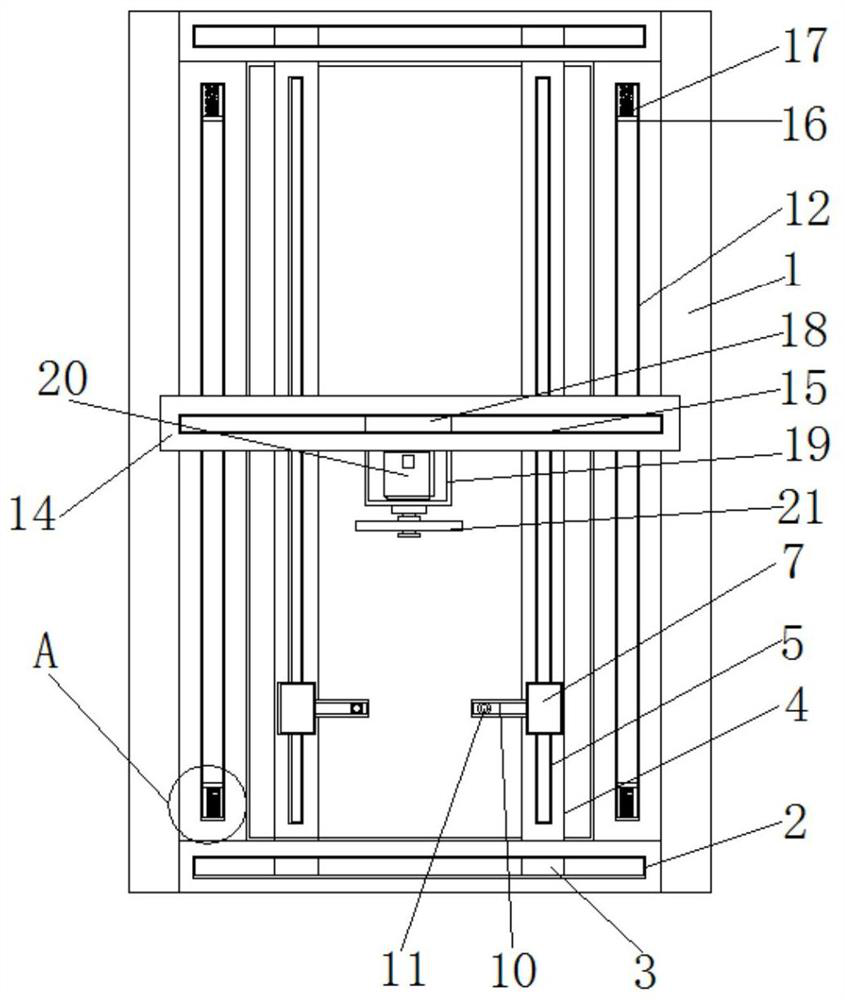

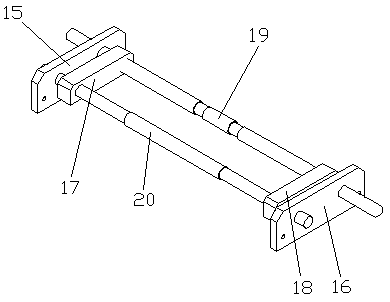

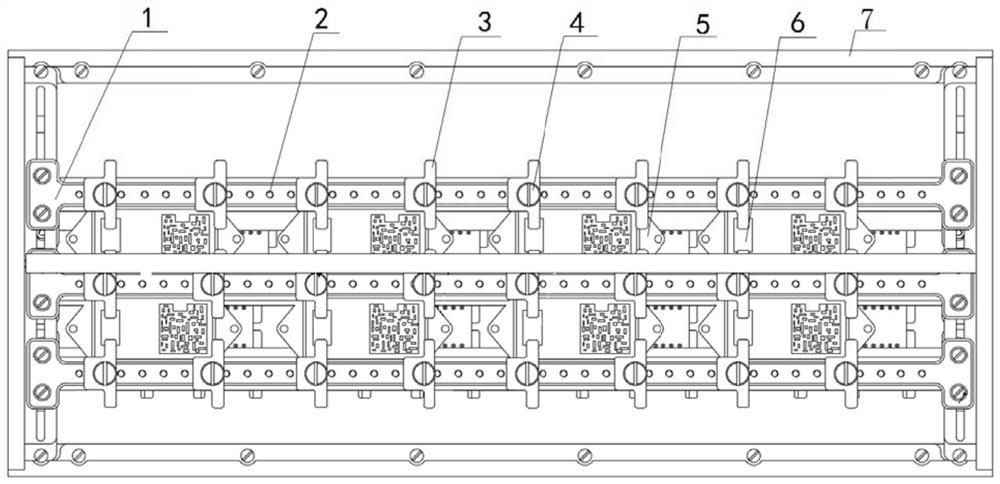

Printed circuit board (PCB) locating device

The invention relates to a printed circuit board (PCB) locating device which comprises a motor. The motor is fixedly installed on a speed reducer, the speed reducer is fixedly installed on a base seat, a big chain wheel is installed on an output shaft of the speed reducer, a small chain wheel is installed on a transmission shaft, the transmission shaft penetrates through conveying chain wheels and is connected with a guide rail, the conveying chain wheels are arranged at two ends of conveying chains, the conveying chain wheels are installed in grooves on the side faces of the guide rail, PCB locating rods and PCB supporting rods are fixedly welded on the side faces of the conveying chains, each set comprises two PCB locating rods, and the PCB supporting rods are welded between every two sets of the PCB locating rods, threads are formed in vertical portions of the PCB locating rods, two sets of holes are formed in two sides of a to-be-welded PCB, the two sets of holes are installed on the PCB locating rods and are fastened by clamp nuts, guide rail sliding blocks are fixed on a support and are connected with the guide rail, a hand wheel is installed on a guide rail lead screw, and the guide rail lead screw penetrates through fixing parts which are welded below the guide rail. The PCB locating device has the advantages of being simple in structure and easy to achieve, and adjusting of width of the PCB locating device is convenient.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

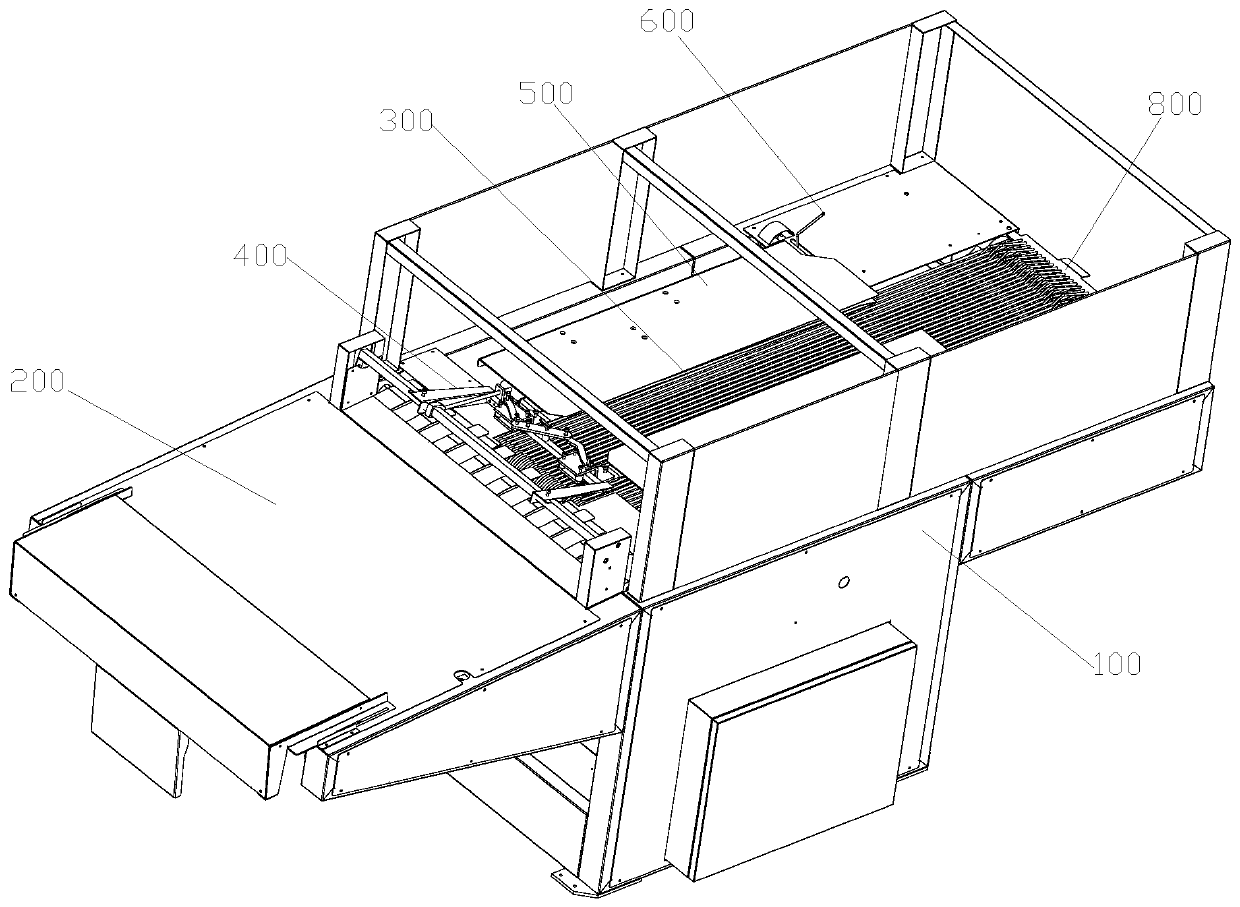

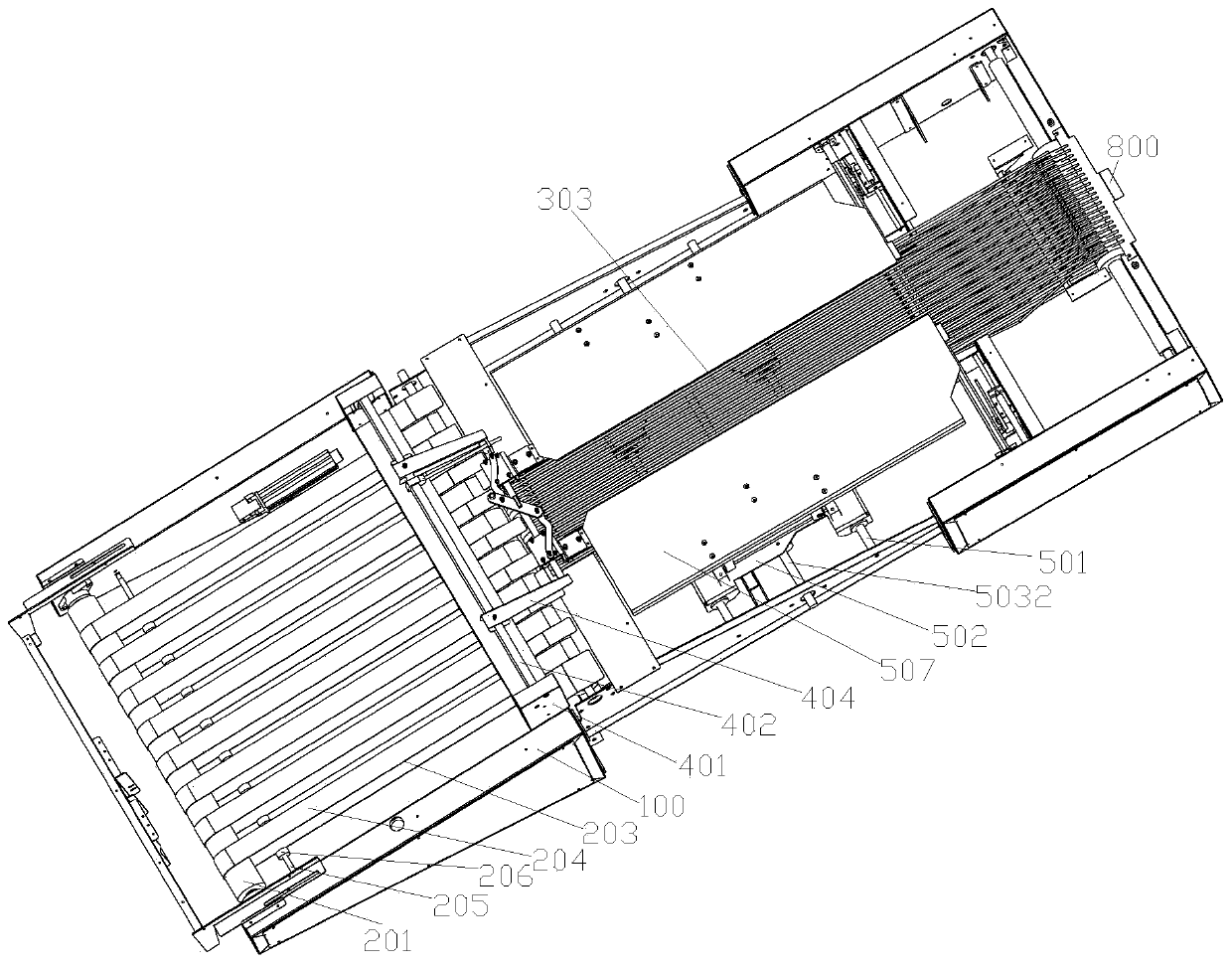

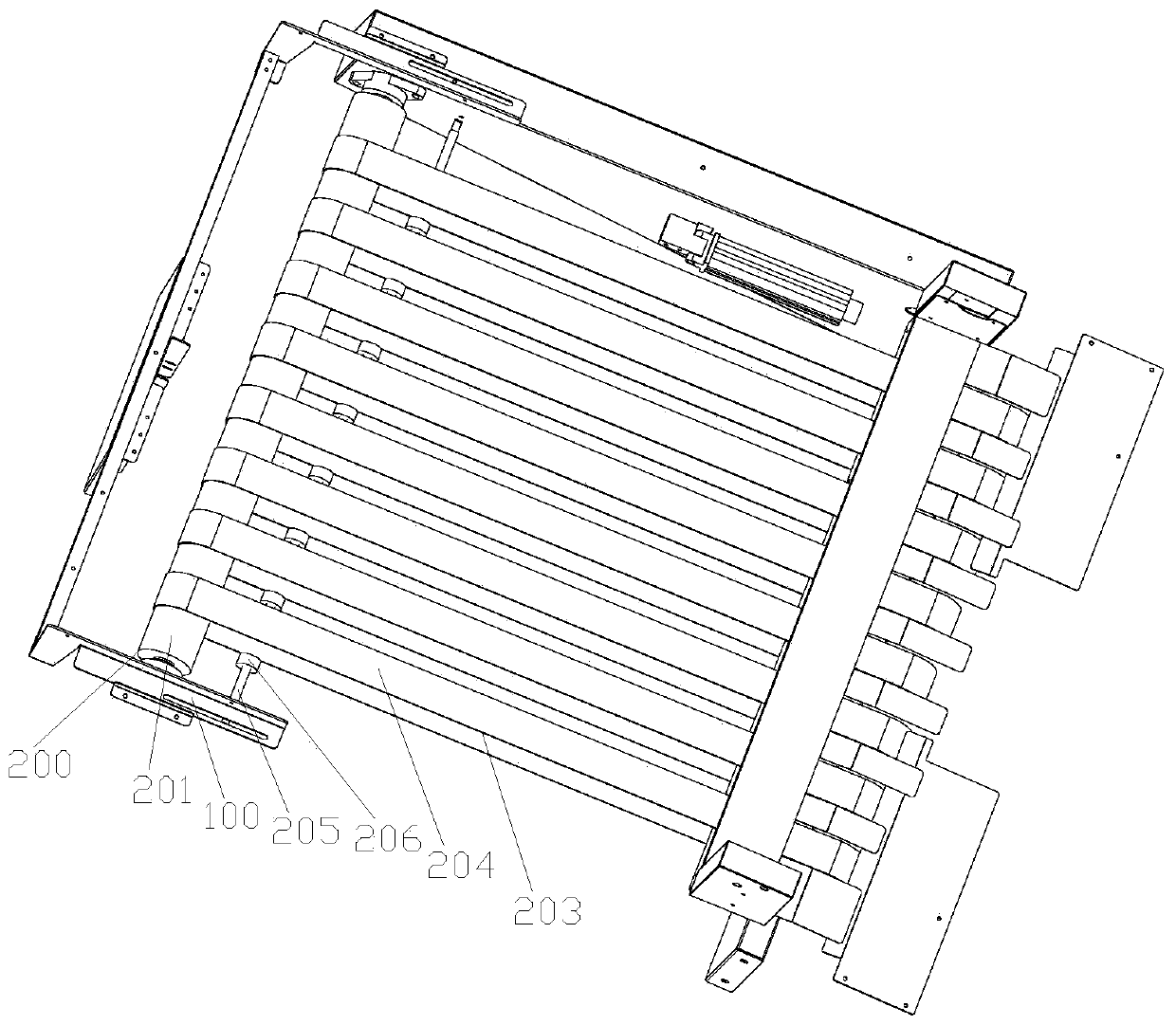

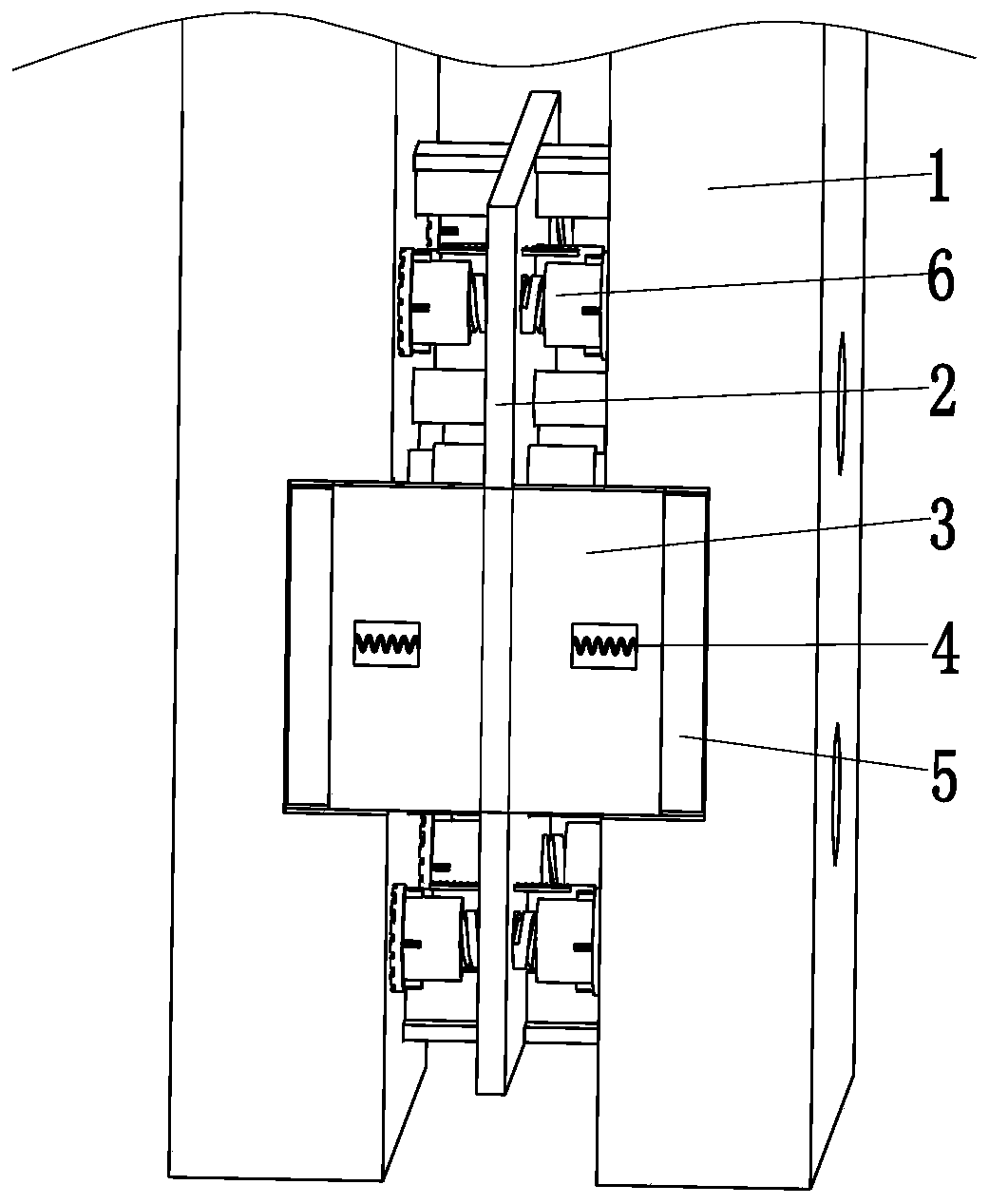

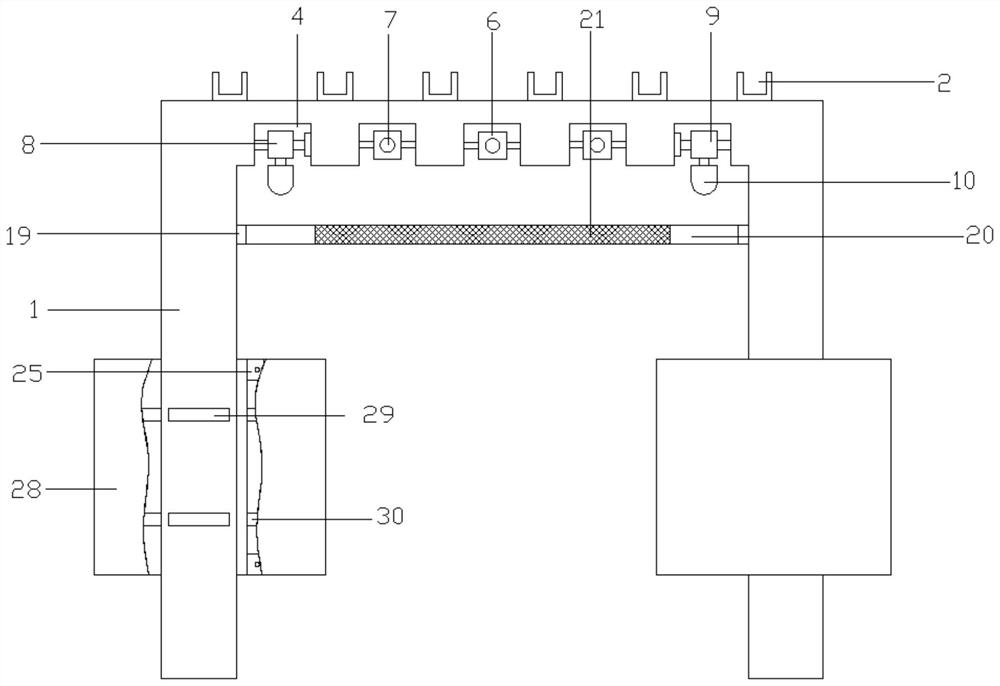

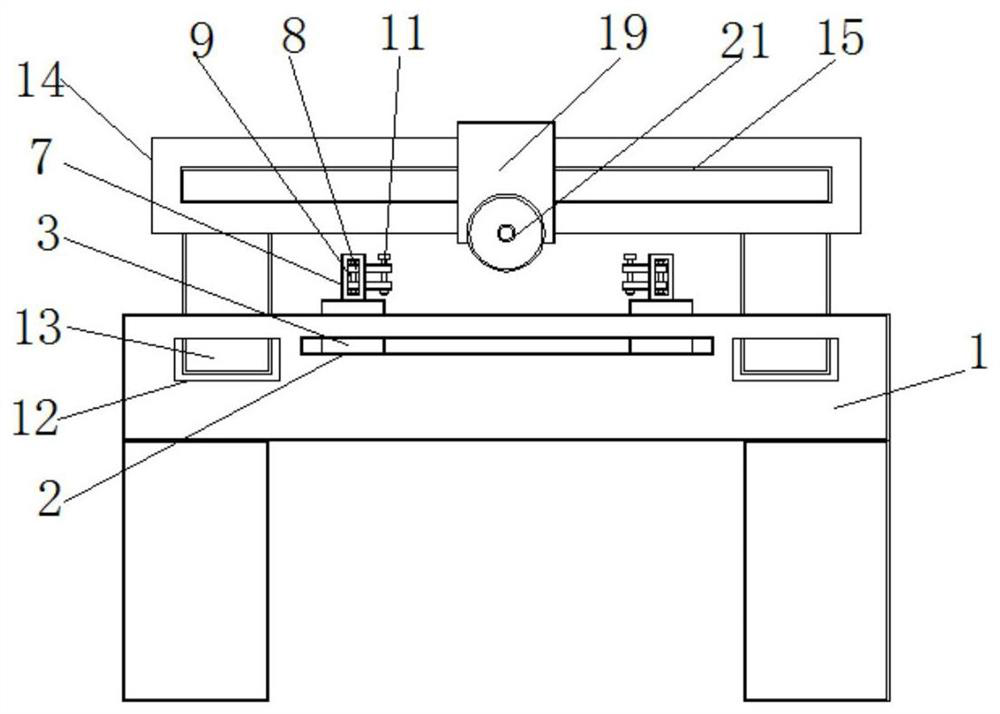

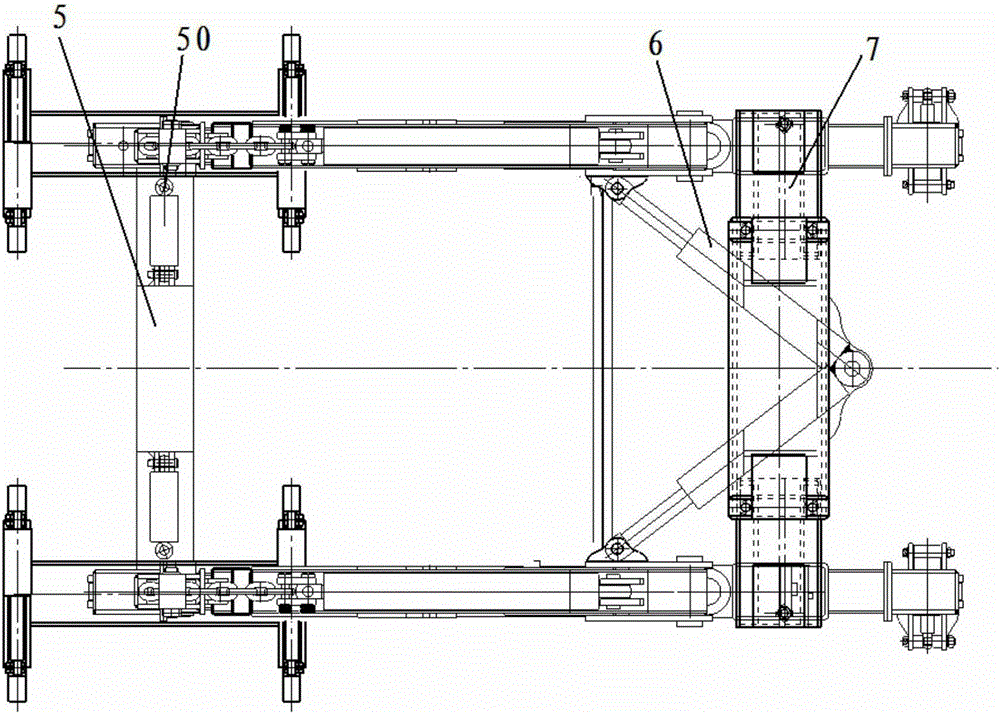

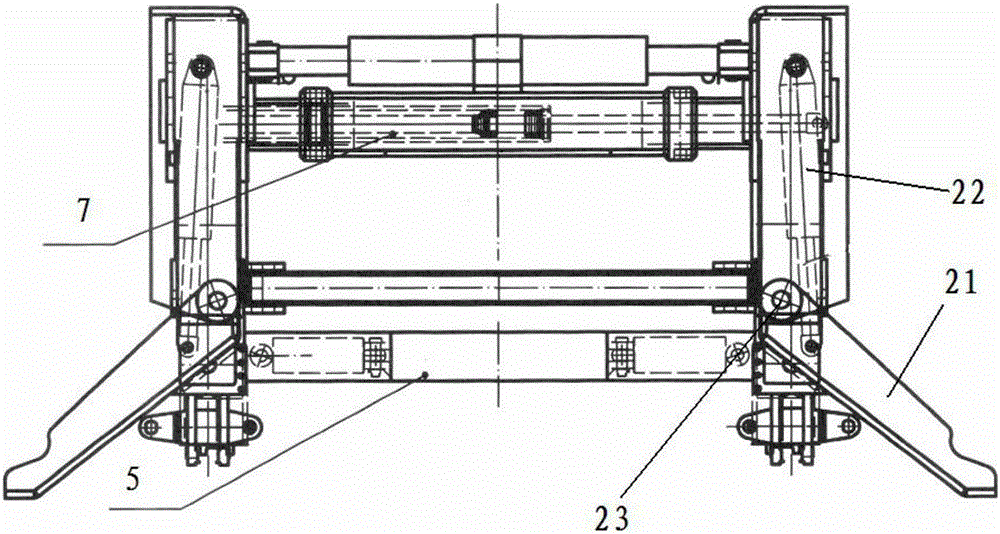

Full-automatic clothes folding machine

InactiveCN110589136AAchieve horizontal foldAchieving Vertical FoldingConveyorsFolding thin materialsEngineeringAutomation

The invention relates to the technical field of clothes packaging, and specifically discloses a full-automatic clothes folding machine. The full-automatic clothes folding machine comprises a machine frame, wherein a first conveying mechanism, a second conveying mechanism, a cloth pressing mechanism, a cloth folding mechanism, a positioning mechanism, a cloth turning mechanism and an output sectionare arranged on the machine frame, the cloth pressing mechanism is positioned above the second conveying mechanism, the position of the cloth folding mechanism on the machine frame corresponds to theposition of the cloth pressing mechanism, the positioning mechanism is located on the machine frame at the position where the clothes are away from the cloth folding mechanism, the cloth turning mechanism is at the position where the machine frame corresponds to the positioning mechanism, and the output section is located at the position where the machine frame is located at the output end of thesecond conveying mechanism. The full-automatic clothes folding machine has the characteristics of no deviation of a conveying strip, good conveying effect, convenient adjustment of the folding width,better adjustment precision, better folding flatness, better folding consistency, better appearance, higher degree of automation, higher production efficiency, low labor intensity and ability of adapting to large-yield demand.

Owner:浙江雅力士自动化设备科技有限公司

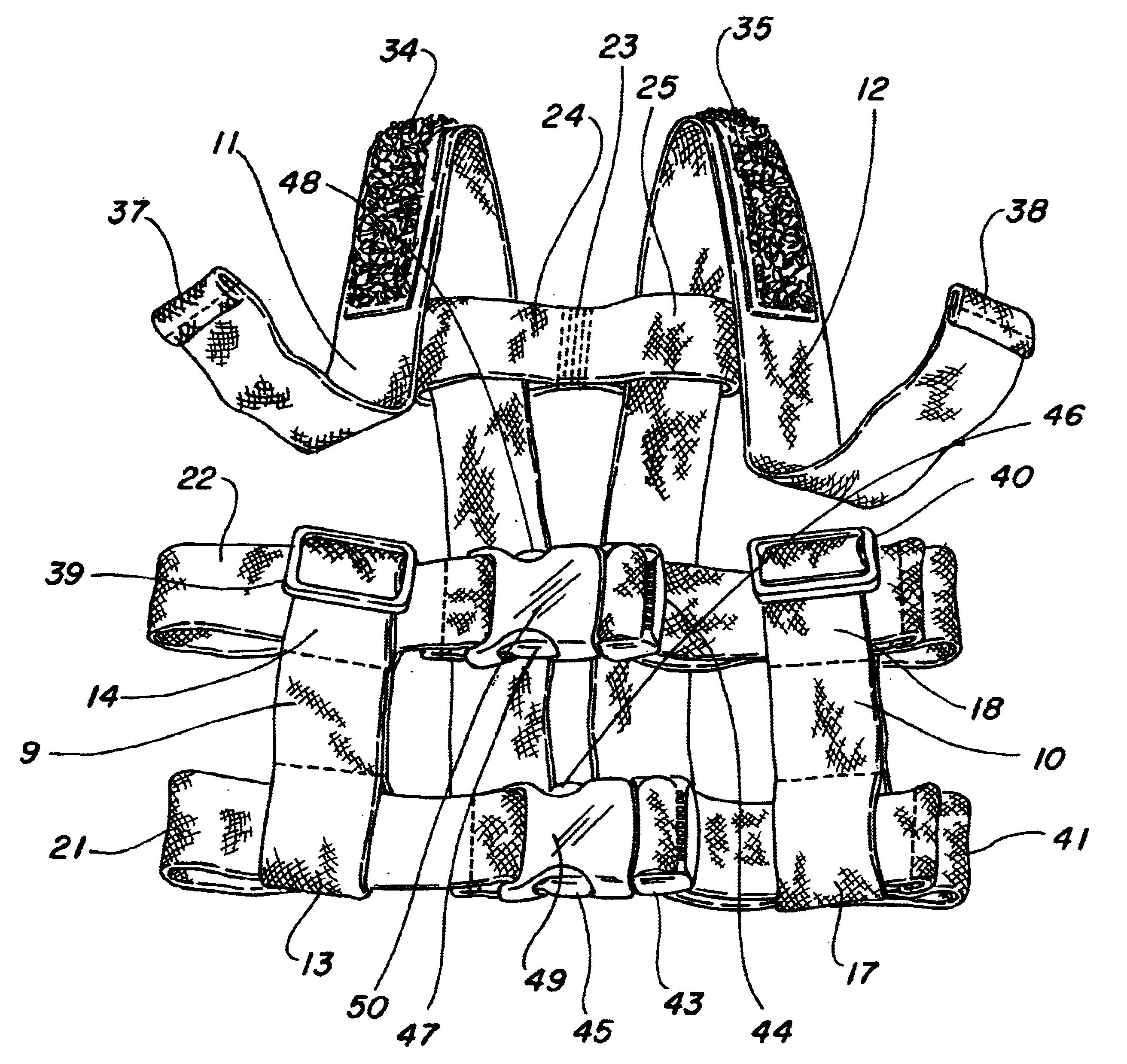

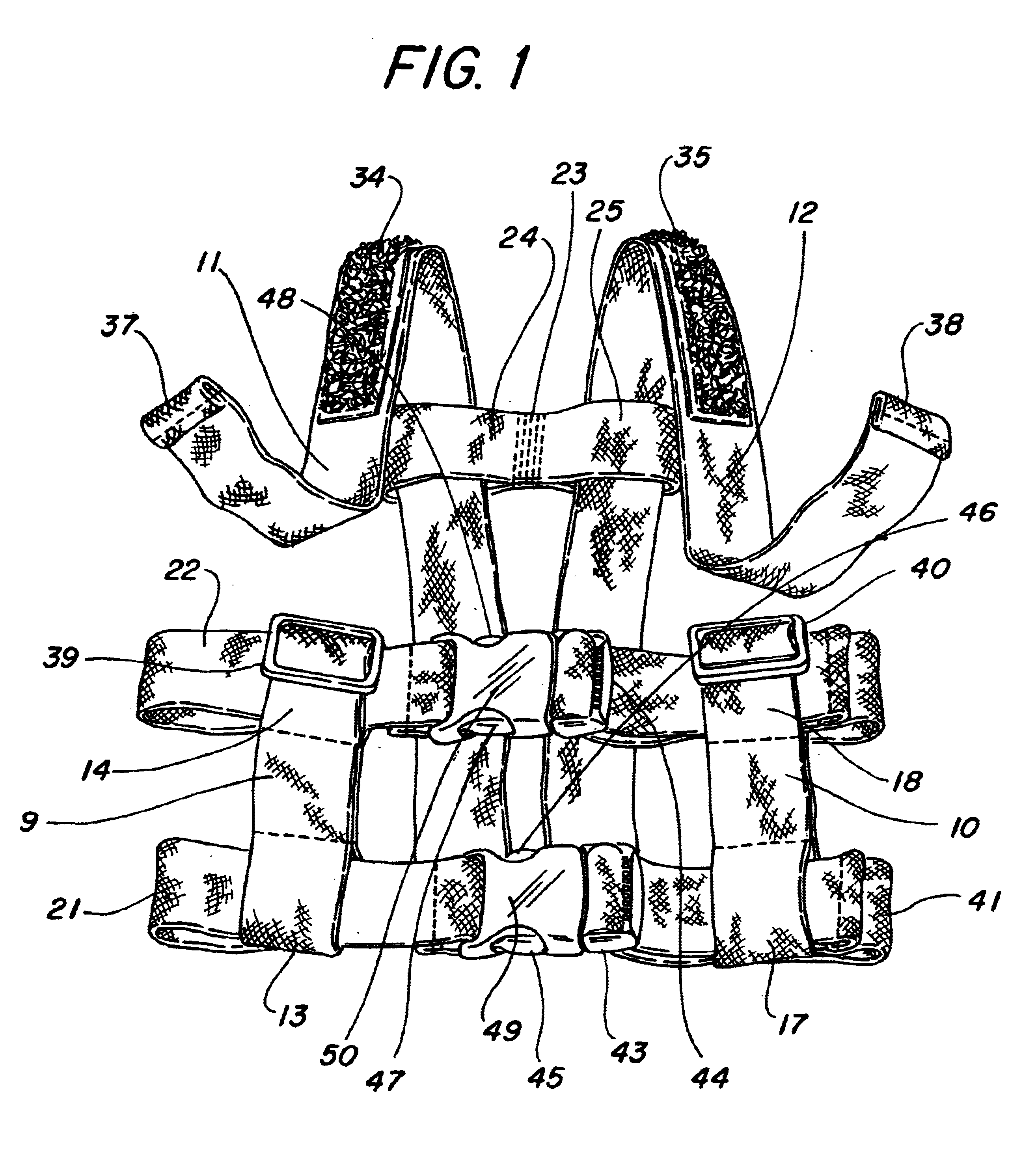

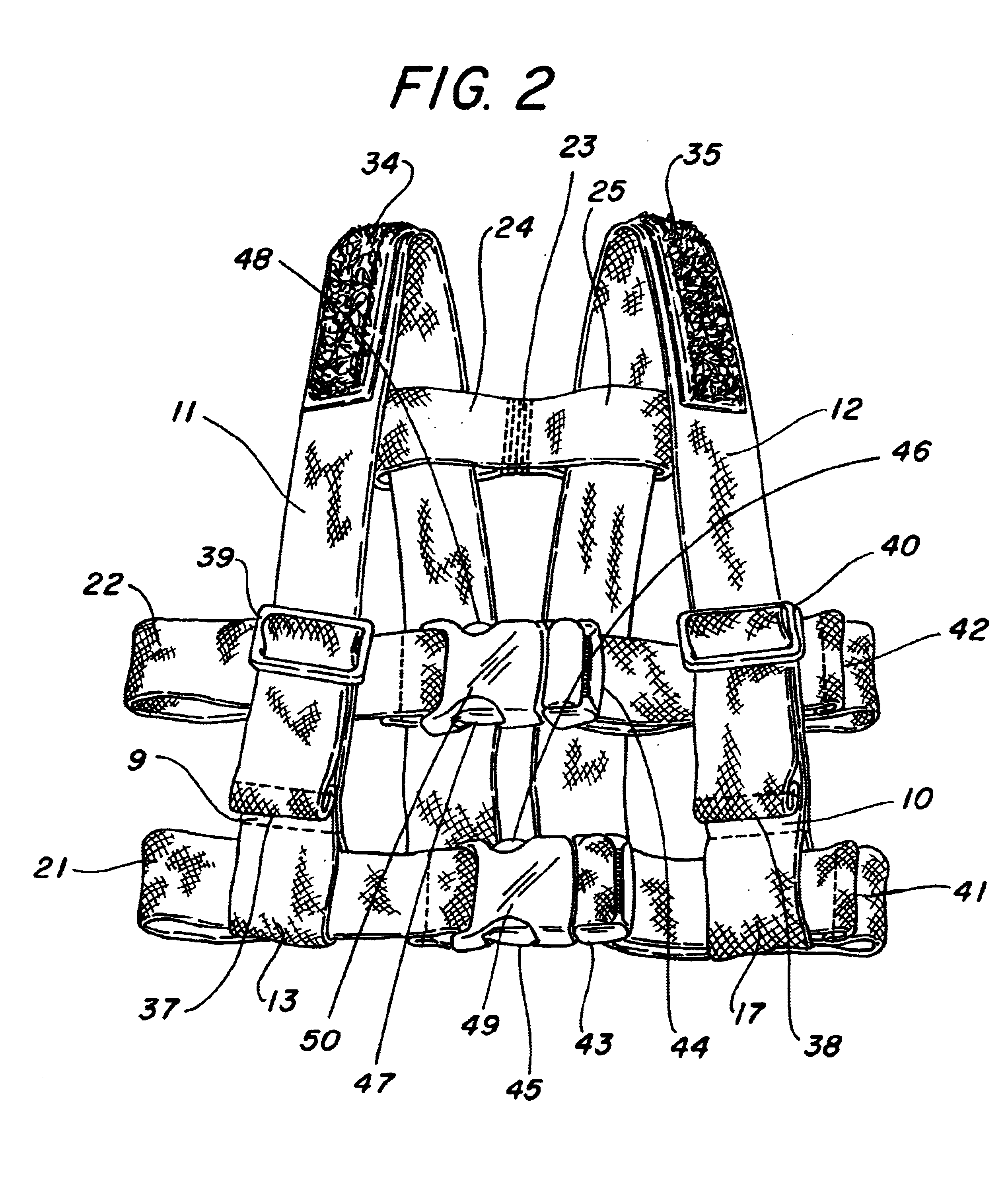

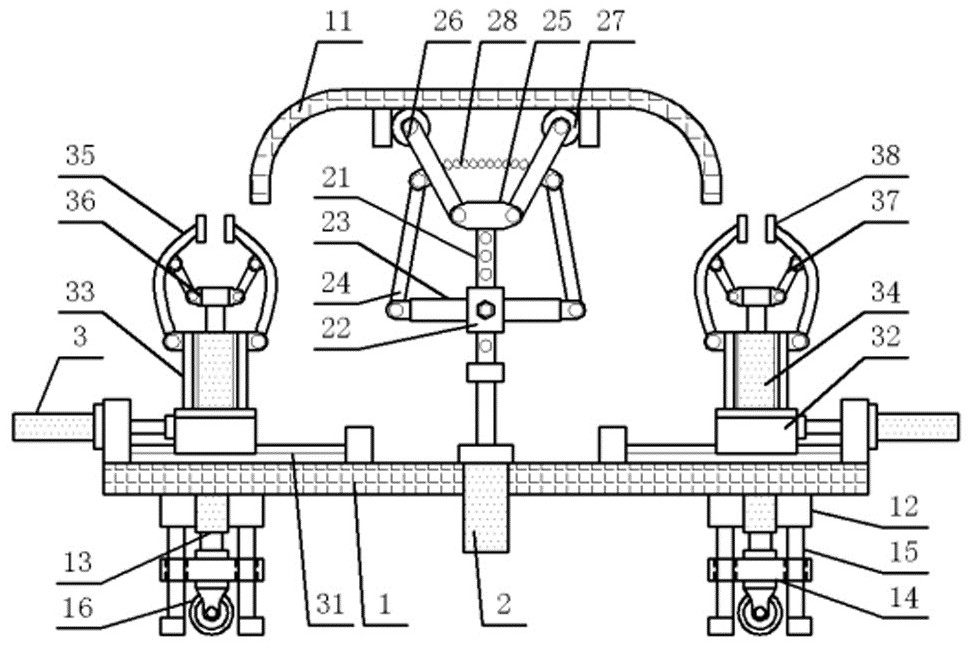

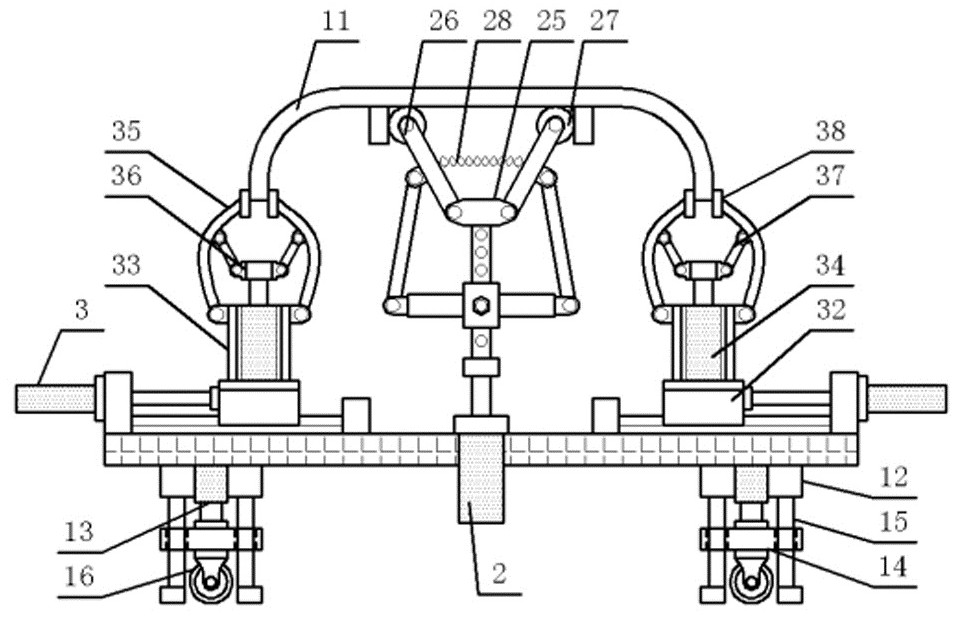

Orthopedic shoulder weight halter

An orthopedic shoulder weight halter and corresponding weight(s) are described which allow one or more weights to be attached to shoulder straps by fastening material strips. Fourteen points of adjustment in the halter allow for a universe of different torso sizes. The harness possesses two shoulder straps, two front support straps, a waist strap, a chest strap, an upper back / chest strap, four double-D rings and two quick release buckles. The harness and the weight(s) can be easily put on or taken off of the wearer.

Owner:HANNERS ERNEST M +1

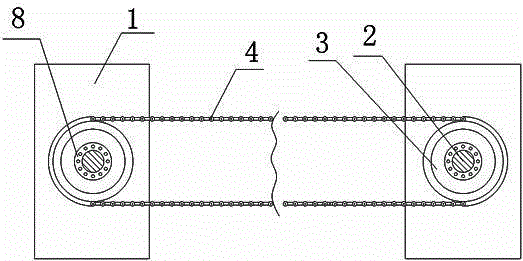

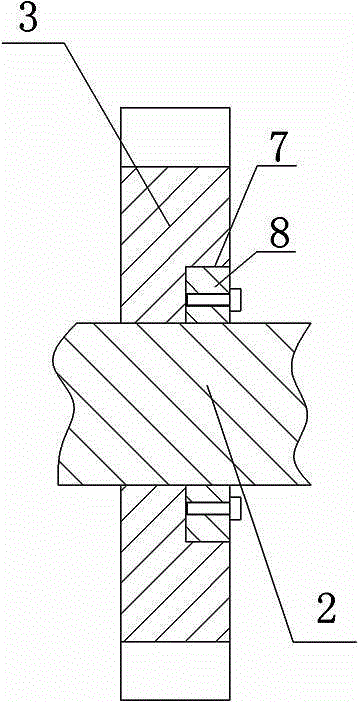

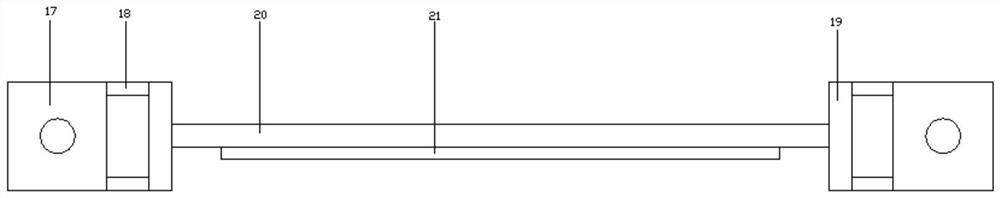

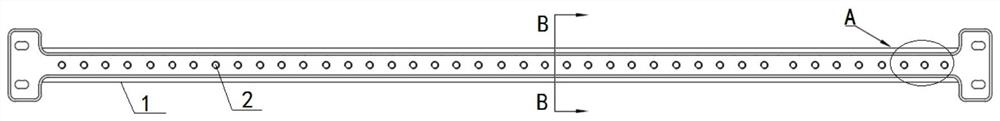

Chain conveying belt

InactiveCN104528418AEasy width adjustmentAdjustable widthConveyorsArticle feedersDrive shaftEngineering

Owner:ECEC RAKON CRYSTAL CHENGDU

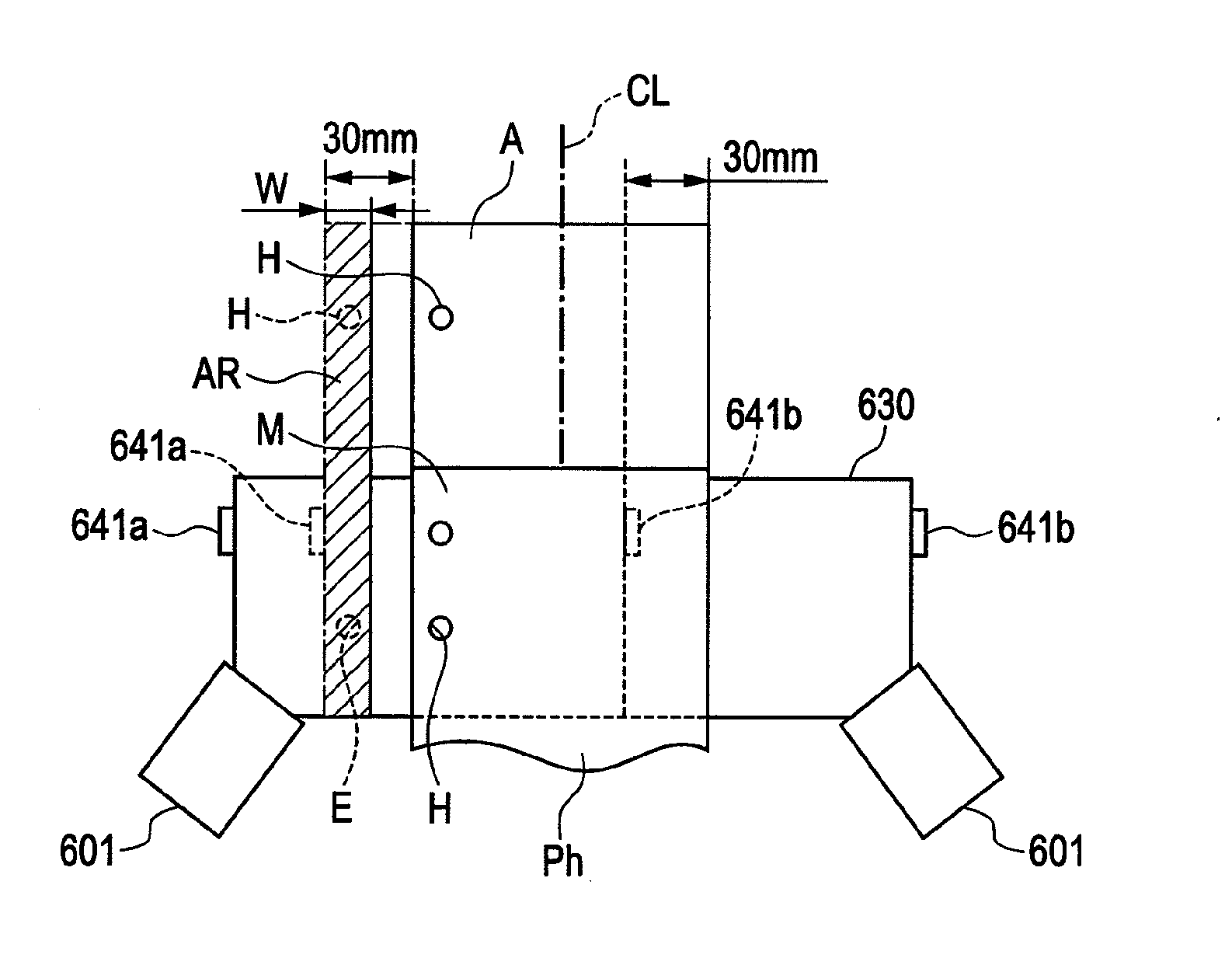

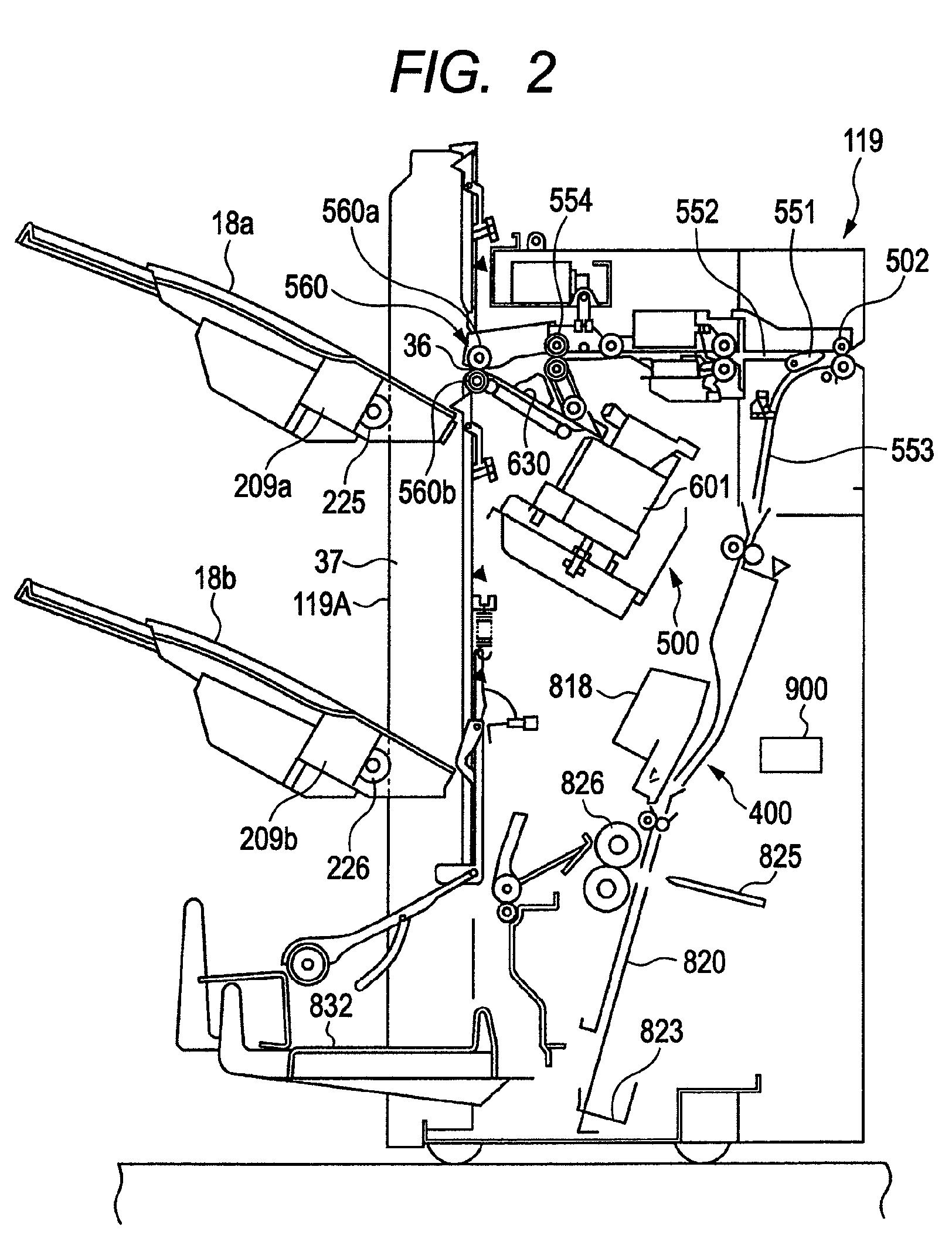

Device for aligning punched sheets

ActiveUS8678367B2Easy width adjustmentRegistering devicesFunction indicatorsEngineeringMechanical engineering

Owner:COPYER

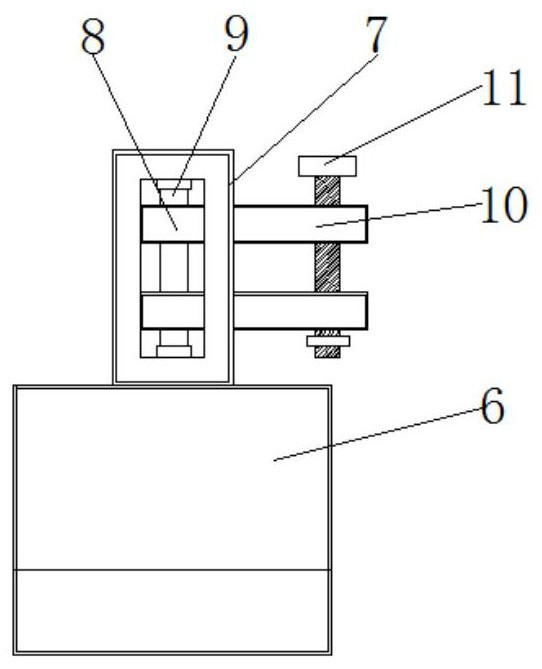

Intelligent tool with multi-point limiting and clamping functions for carbon sliding plate machining and use method of intelligent tool

The invention discloses an intelligent tool with multi-point limiting and clamping functions for carbon sliding plate machining. The intelligent tool comprises a bottom plate. Bases are arranged in the four corners of the bottom face of the bottom plate. A telescopic cylinder of each first telescopic cylinder is movably connected with a roller through a sliding assembly, second connecting blocks are arranged on the end portions of a telescopic cylinder of a second telescopic cylinder, and a second sliding rod is sleeved with a connecting rod mechanism. Rectangular-block-shaped fixed seats arearranged on the two sides of the top face of the bottom plate, a sliding connecting block is arranged on the end portion of a telescopic rod of each sliding telescopic cylinder, the outer side face ofeach sliding connecting block is fixedly connected with a sliding plate on the same side, and a clamping mechanism is arranged on the top face of each sliding plate. The invention further discloses ause method of the intelligent tool with the multi-point limiting and clamping functions for carbon sliding plate machining. As a complete set of tool structure is designed, the tool can meet the requirements of machining carbon sliding plates with different sizes, and is convenient to disassemble and assemble and capable of adapting to structures with different heights, meanwhile, the convenienceof movement of the tool is improved, and the stability and the working efficiency in the using process are improved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

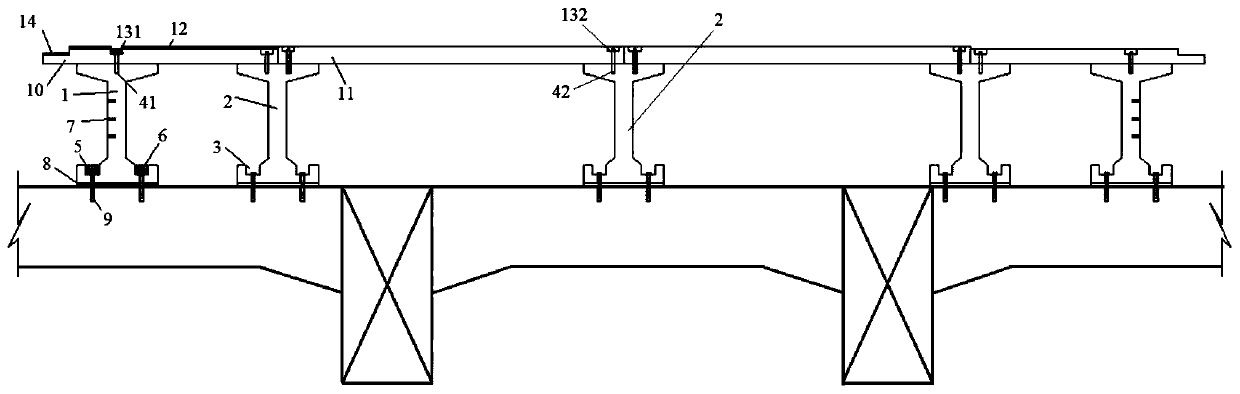

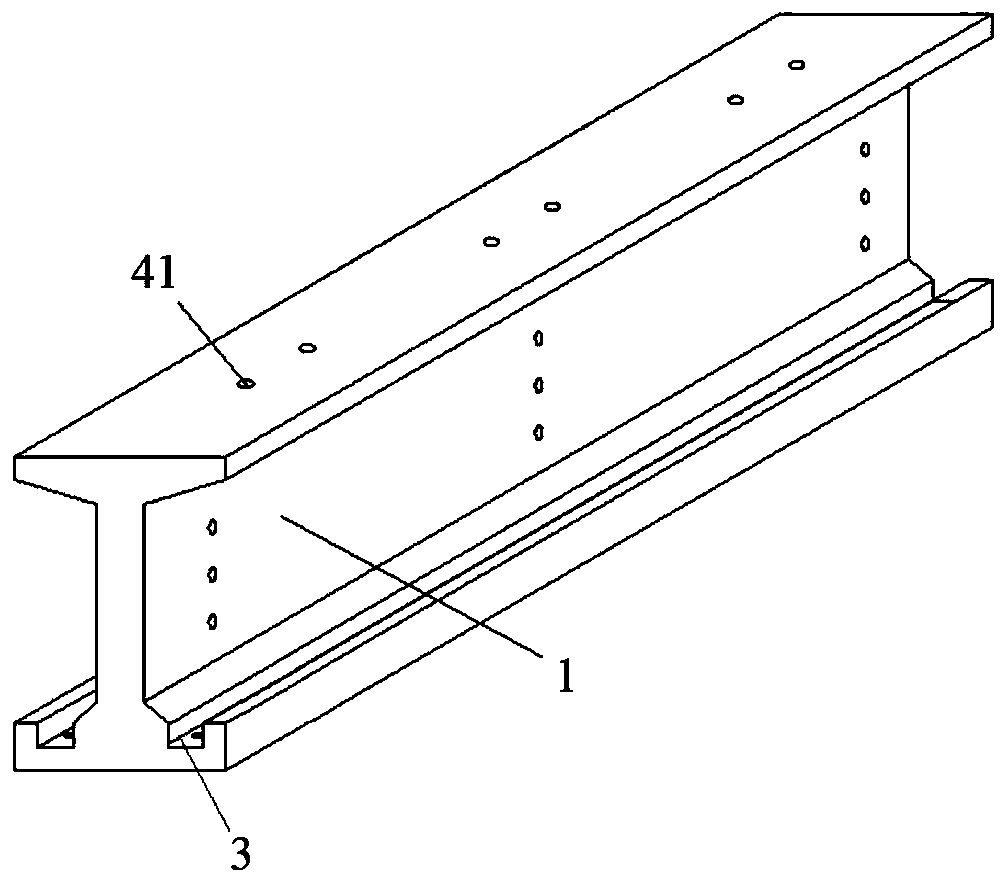

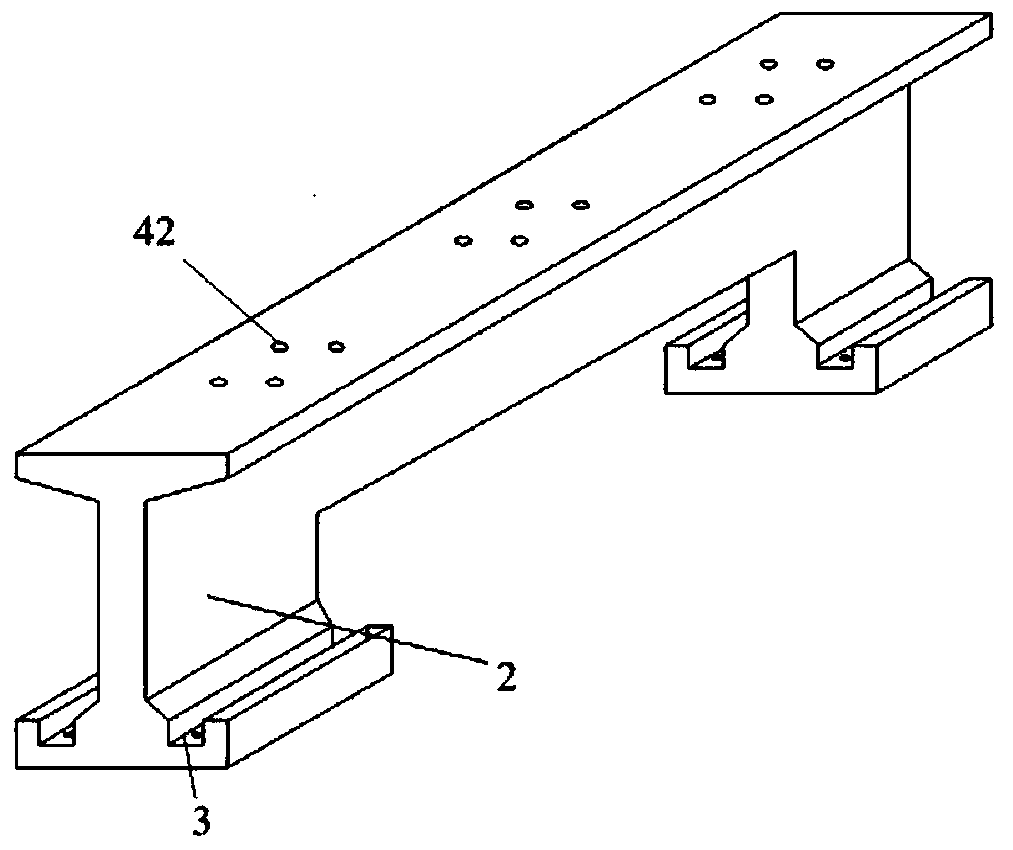

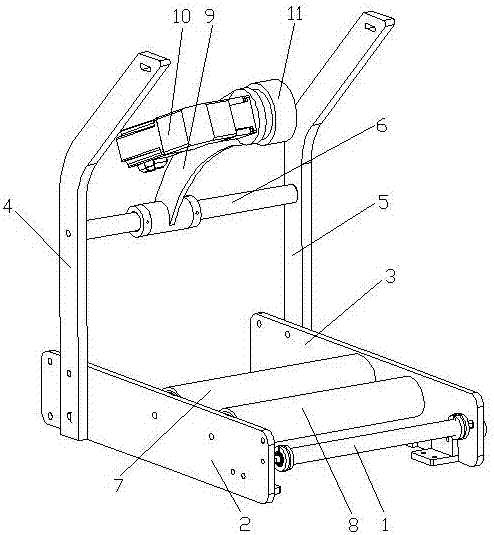

Fabricated subway station platform and construction method thereof

PendingCN111335192AReduce weightSimple structureRefuge islandsRailway componentsArchitectural engineeringJoist

The invention discloses a fabricated subway station platform. The fabricated subway station platform comprises side joists, a middle joist, side platform plates and a middle platform plate. The prefabricated edge joists and the prefabricated middle joist are fixed to the ground through expansion bolts, and the side platform plates and the middle platform plate are fixed to the corresponding side joists or the corresponding middle joist through field drilling and bar planting. The fabricated subway station platform has the following advantages: the structure is simple, the weight of a single piece is light, and transportation and installation are convenient; structural functions are complete, other professional work amount is reduced, and the construction speed can be increased; and a plateand beam fixing device is free of maintenance, durability is improved, all components are modularized, length and width adjustment is facilitated, factory production is facilitated, and the plate andbeam fixing device has high adaptability to different environments.

Owner:CHINA RAILWAY 23RD BUREAU GRP RAILTRANSIT ENG CO LTD +2

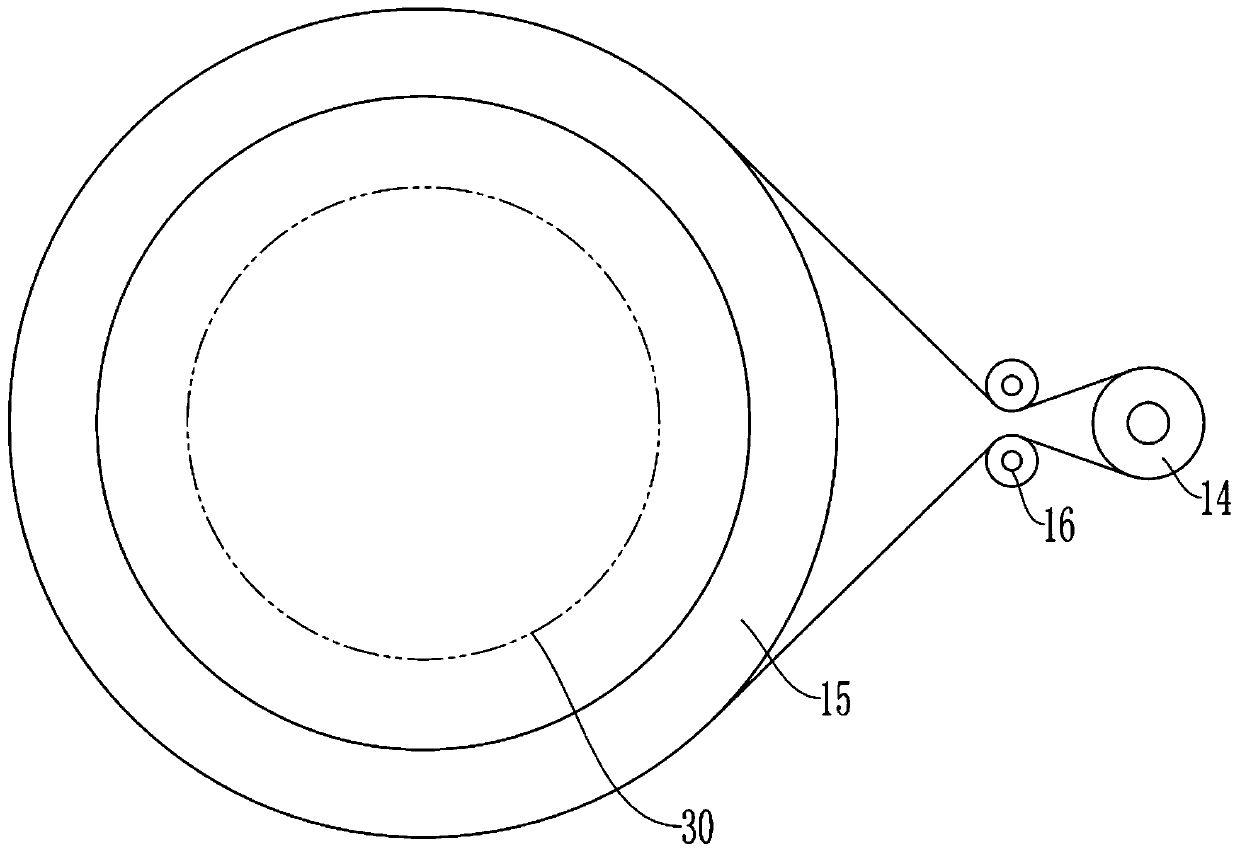

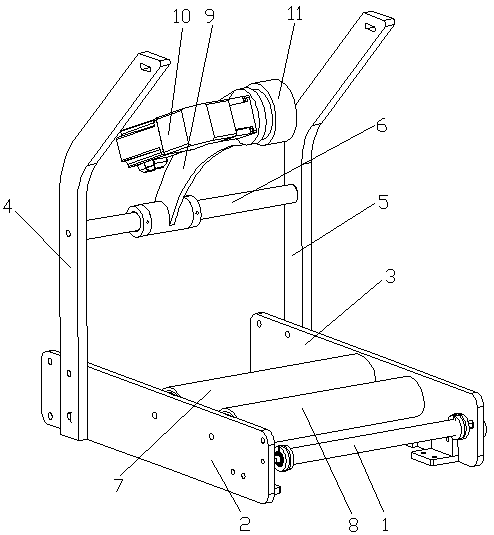

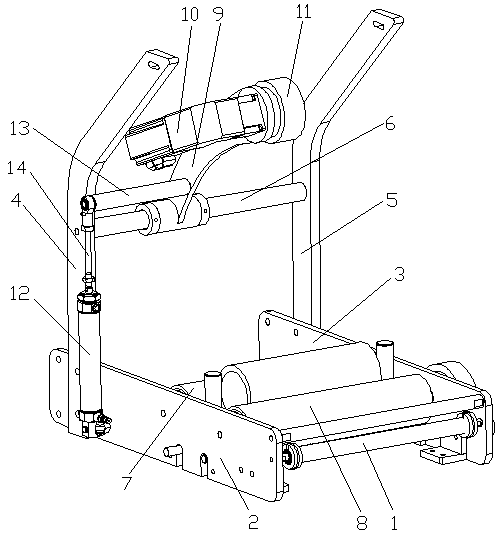

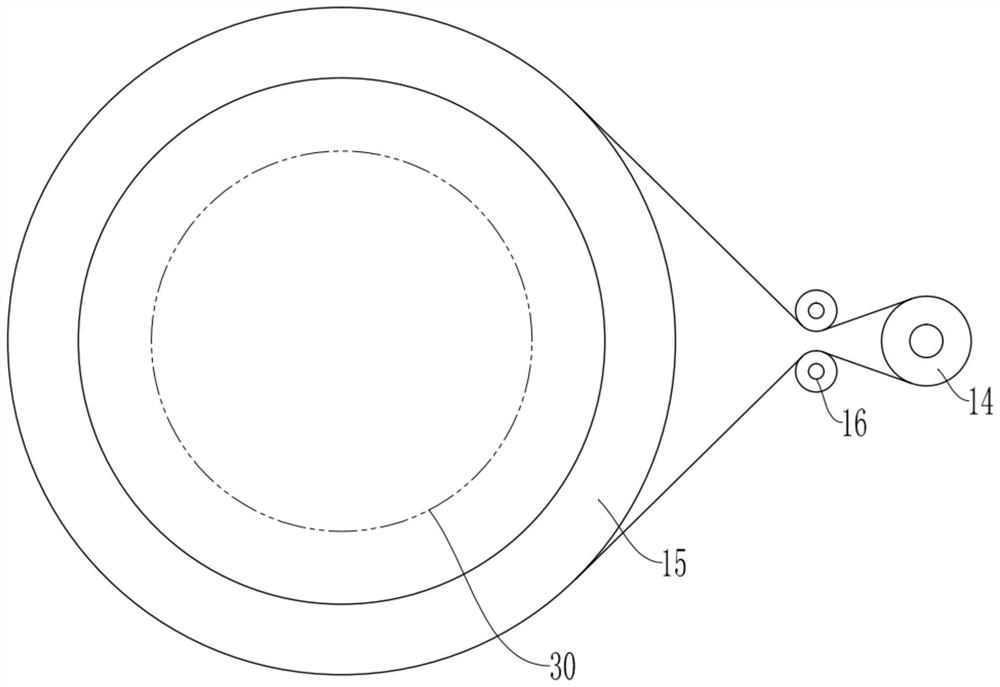

Packaging machine film releasing method

InactiveCN108001749AEasy to replaceLaying film saves time and effortWrapping material feeding apparatusWebs handlingAgricultural engineeringTangential force

The invention discloses a packaging machine film releasing method and belongs to the technical field of packaging. The method is characterized by comprising the following steps that a, a winding drumpackaging film is placed on packaging machine film releasing equipment, and then a part of the winding drum packaging film is pulled out to penetrate a film passing roller on the packaging machine film releasing equipment and is connected with film pulling equipment of the next working procedure; b, a driving rubber coating wheel on the packaging machine film releasing equipment presses the winding drum packaging film; and c, the driving rubber coating wheel is rotated and exerts tangential force on the winding drum packaging film to release the packaging film. According to the method, film releasing saves time and labor, the winding drum packaging film is convenient to replace, moreover, the film releasing stability is good, and the film releasing efficiency and the film releasing qualitycan be improved effectively.

Owner:佛山松瀚智能设备有限公司

Fabricated building wall body

ActiveCN110106995AEasy splicingEasy width adjustmentWallsBuilding material handlingEngineeringBody positioning

The invention relates to a fabricated building wall body. The fabricated building wall body comprises two wallboards, a connecting frame, two side supporting plates, side supporting springs, attachedplates and a limiting mechanism, clamping grooves are formed in the front inner side surfaces and the rear inner side surfaces of the wallboards, and the connecting frame is located between the two wallboards. The two side supporting plates are distributed on the front side surface and the rear side surface of the connecting frame, the side supporting plates are symmetrically installed on the leftside surface and the right side surface of the connecting frame, the outer side surfaces of the side supporting plates and the outer side surfaces of the wallboards are located in a same plane, the side supporting plates are located in the clamping grooves of the wallboards, square grooves are formed in the side surfaces of the side supporting plates, the attached plates are installed in the square grooves of each side supporting plate through the side supporting springs, and four buffering mechanisms are symmetrically installed on the connecting frame. According to the fabricated building wall body, the problem that the splicing size of two current wall bodies cannot be adjusted during splicing is solved; and the wall bodies are positioned through labor using boards during wall body splicing, the positioning mode is poor in precision, the wall body positioning is inaccurate, and the service life of the wall body can be further affected.

Owner:江西天岩建设工程有限公司

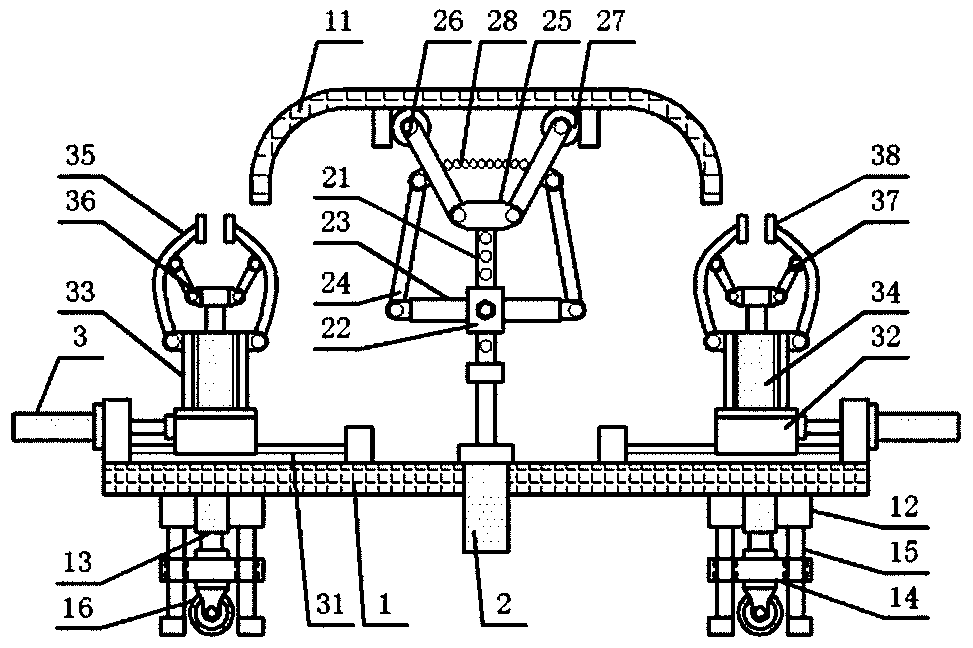

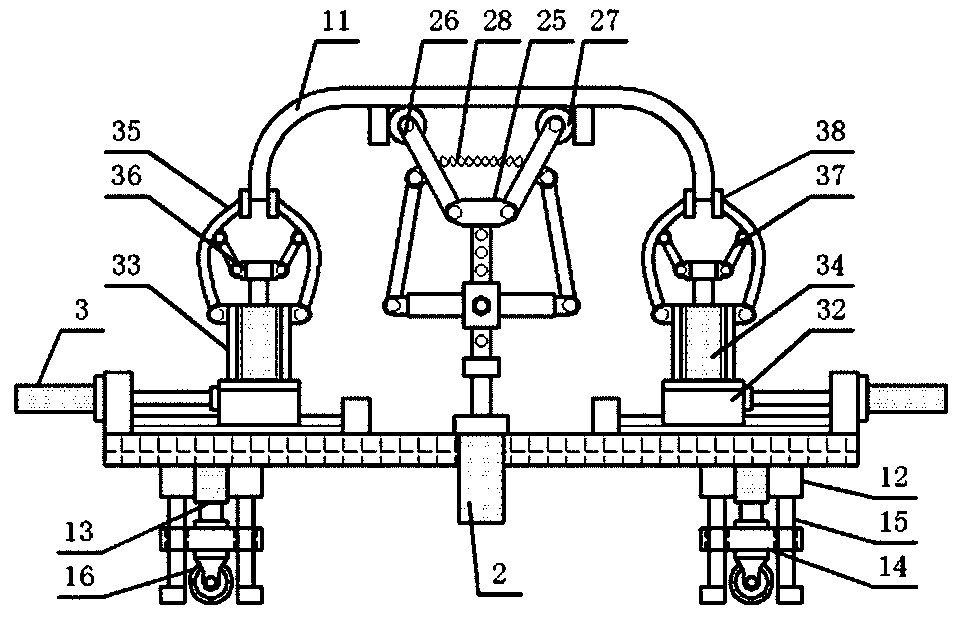

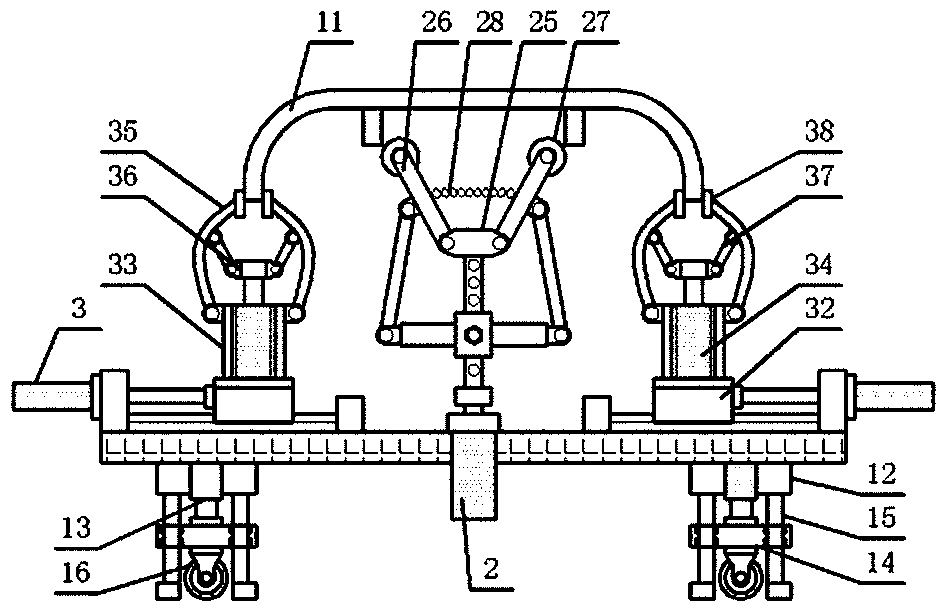

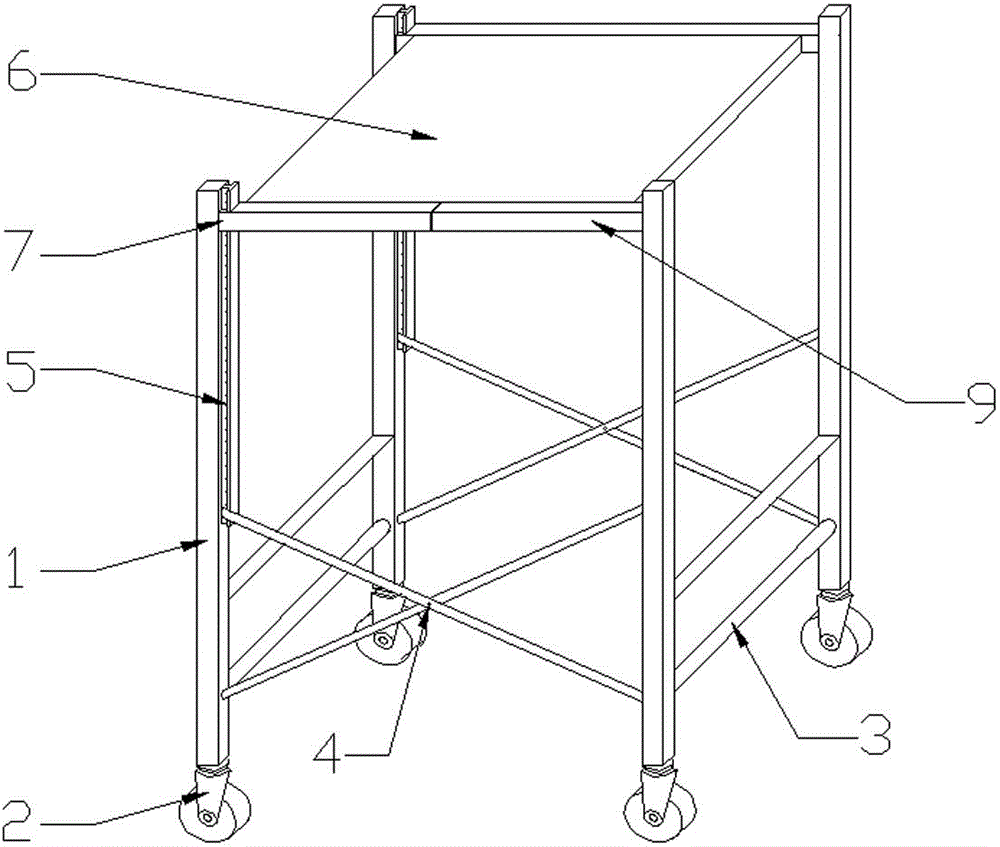

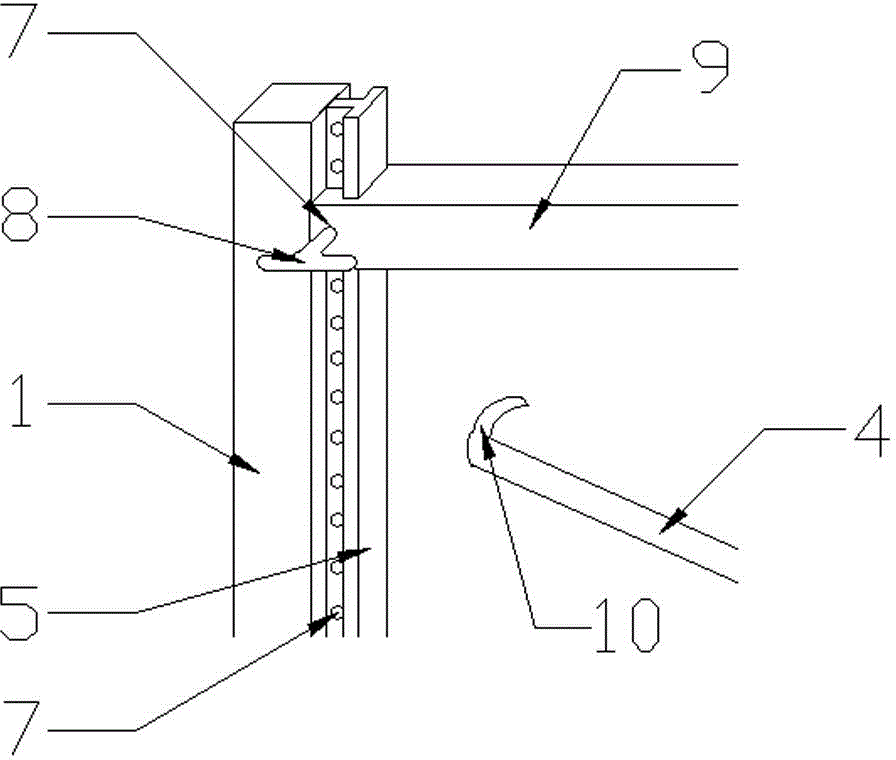

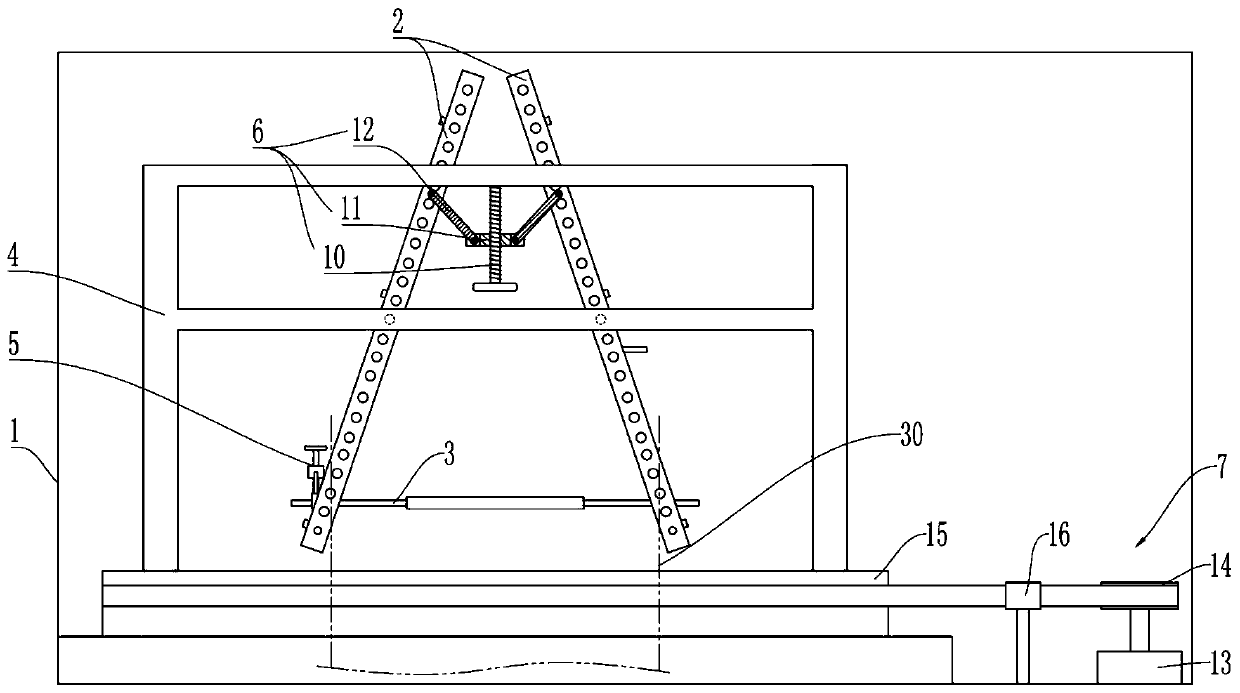

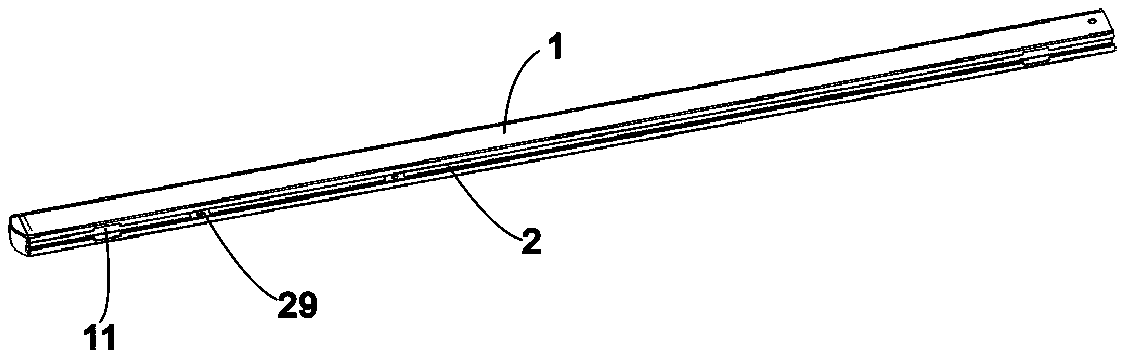

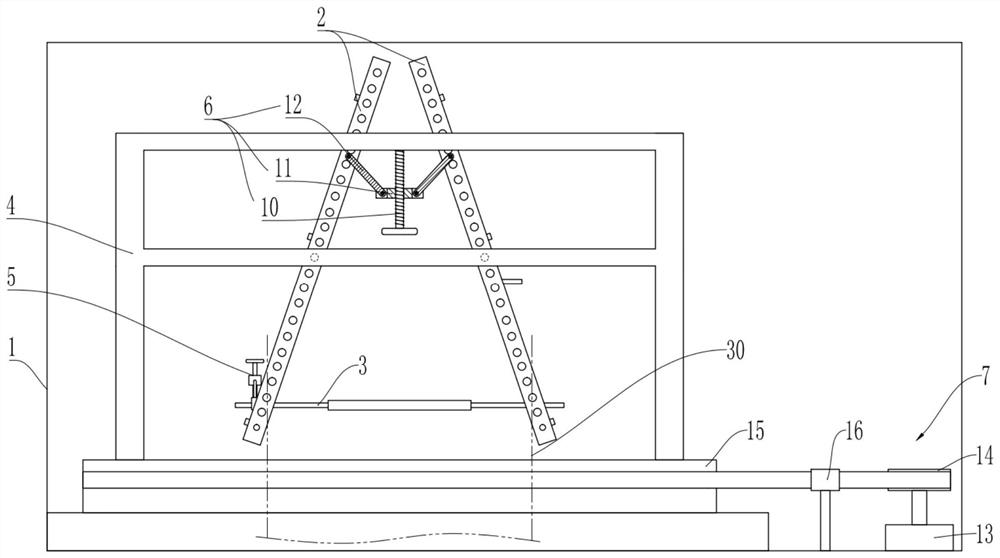

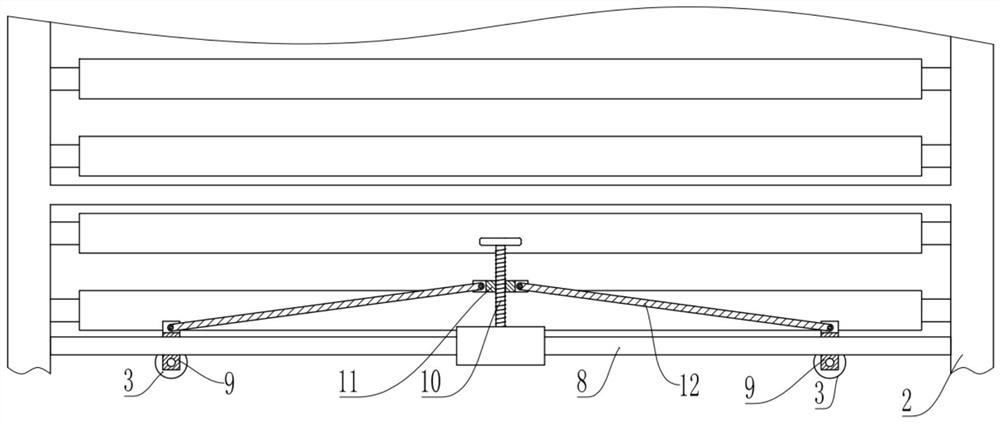

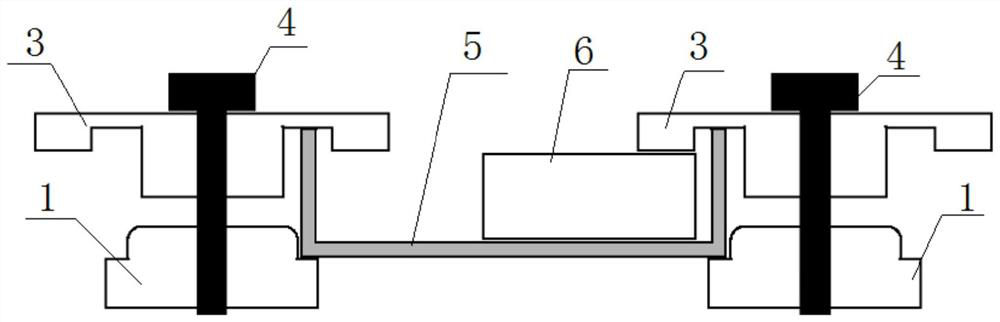

Width-adjustable decorating scaffold

The invention provides a width-adjustable decorating scaffold. The scaffold comprises upright posts (1), a pulley (2) and a supporting frame (3), and is characterized in that a fixing part (5) with a T-shaped cross section is arranged at the upper part of each upright post; T-shaped grooves are formed in the two ends of a supporting crossbeam (9) used for supporting a movable cushion board (6); the T-shaped grooves are slidably connected with the fixing parts (5); each upright post (1) is provided with an obliquely-pulling connecting part (4); one end of the obliquely-pulling connecting part (4) is fixedly hinged on the upright post (1), and the other end is movably connected with each fixing part (5). The invention provides the width-adjustable decorating scaffold which can be used for conveniently adjusting the width and freely adjusting the movable cushion board supported by the scaffold up and down, and is applicable to various types of indoor and outdoor decoration engineering under complex and special environments.

Owner:韩翼

Road traffic width and height limiting device

InactiveCN112240010AEasy to limit handlingEasy to monitor and handleTraffic restrictionsBraced frameElectric machinery

The invention relates to the field of traffic, in particular to a road traffic width and height limiting device which comprises a supporting frame, a connecting groove is formed in the supporting frame, sliding grooves are formed in the two ends of the supporting frame, second motors are installed at the bottoms of the sliding grooves, threaded rods are installed on the upper sides of the second motors, partition plates are arranged at the upper ends of the sliding grooves, and first sliding blocks are in threaded connection with the threaded rods. The inner sides of the first sliding blocks are connected with first mounting plates, a height limiting rod is mounted between the first mounting plates, an electronic display screen is mounted on the front side of the height limiting rod, second sliding blocks are arranged at the upper end and the lower end of the threaded rod located on the lower side of the partition plate, and the inner sides of the second sliding blocks are connected with second mounting plates through second connecting blocks; first mounting bases are mounted at the front end and the rear end of the second mounting plate and connected with connecting rods through connecting shafts, and the inner sides of the connecting rods are connected with the second mounting bases through connecting shafts. According to the device, stable width-limiting and height-limitingtreatment can be effectively and conveniently carried out on the equipment, and the equipment is convenient to use.

Owner:钱幼华

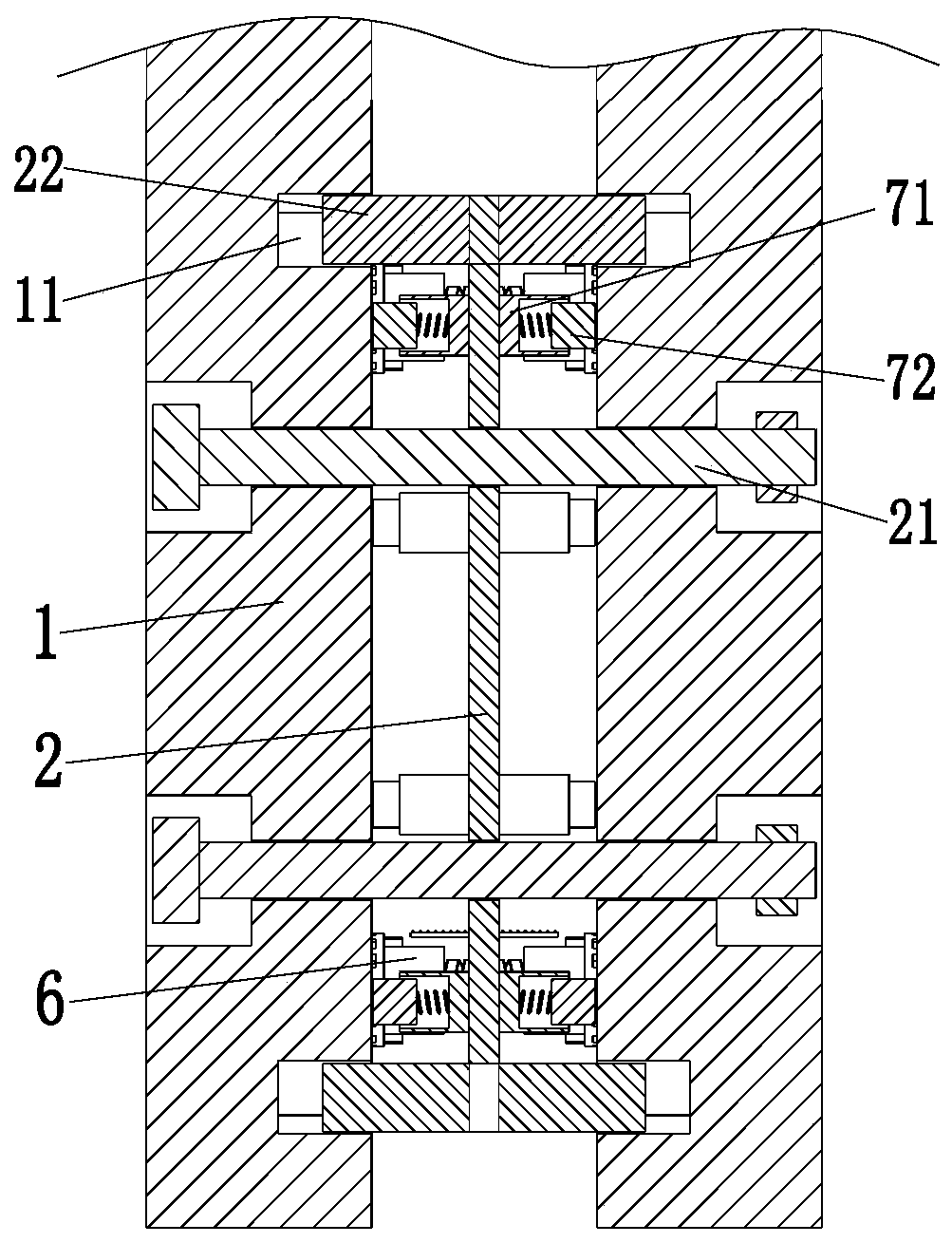

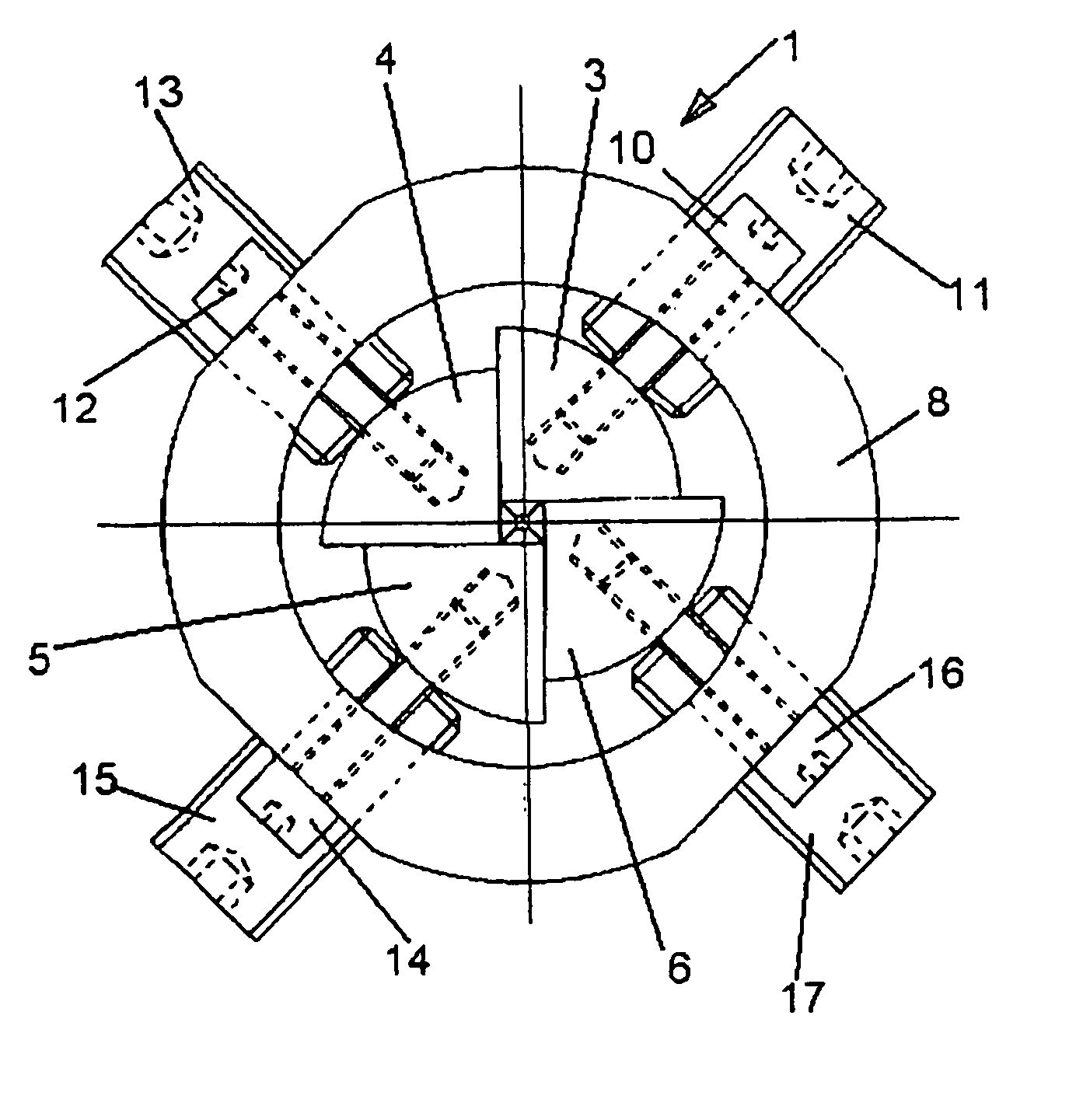

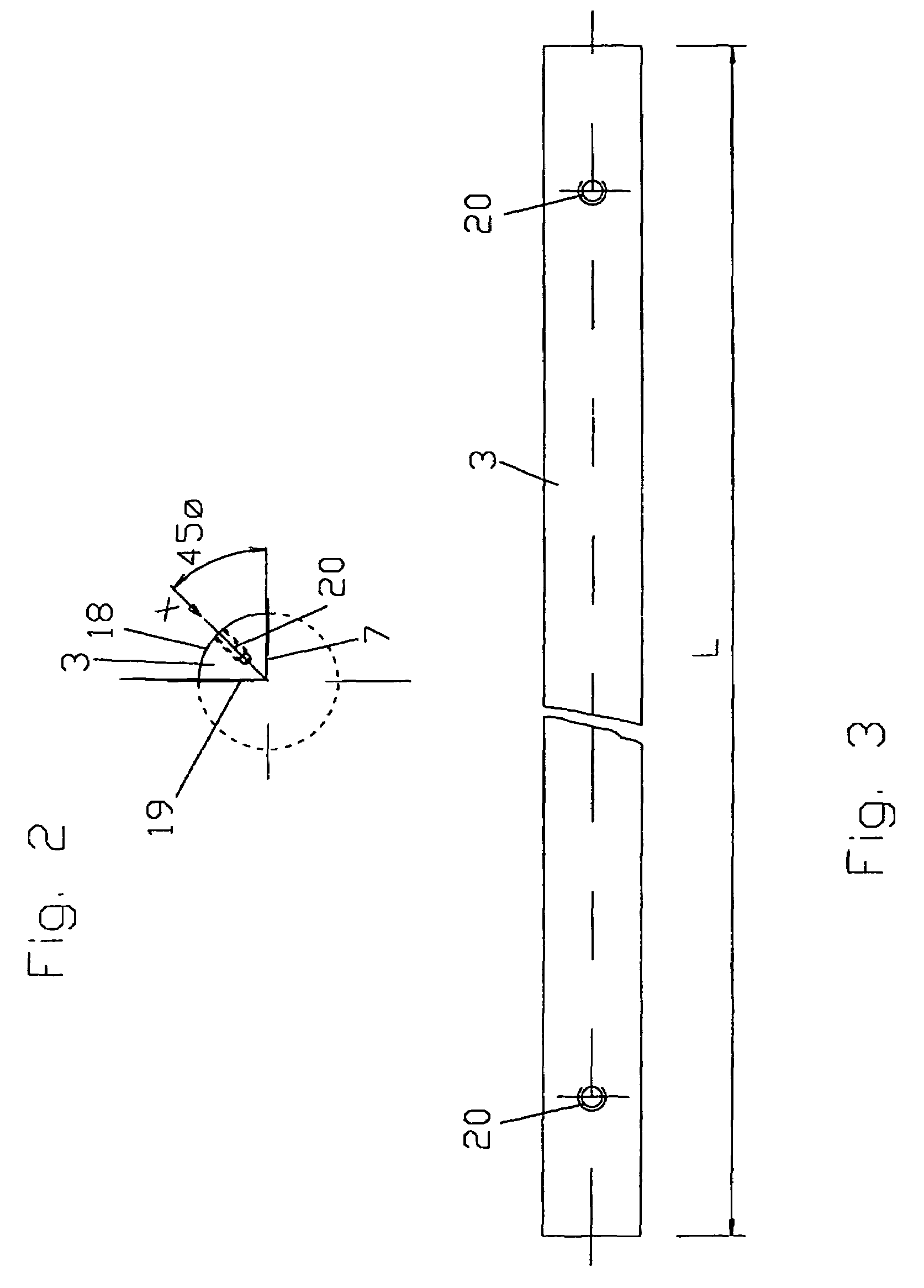

Micro beam collimator having an iris like capillary for compressing beams

InactiveUS7109506B2Easy to adjustAdjustable lengthLaser detailsElectrode and associated part arrangementsLight beamBeam collimation

“A micro beam collimator for compressing beams is described, where the collimator has channel means for providing a channel having a cross section and guiding the beams from an entrance end to an exit end of the channel. The invention provides a micro beam collimator for compressing beams which allows easy adjustment of the width of the cross section of the beams while making it possible at the same time to adjust the length of the cross section of the beams. The invention forms the channel means by at least three rod members each of which having at least one bordering surface for bordering the cross section, wherein the rod members are moveable against each other along the bordering surfaces so that the geometry of the cross action is variable.”

Owner:EURATOM

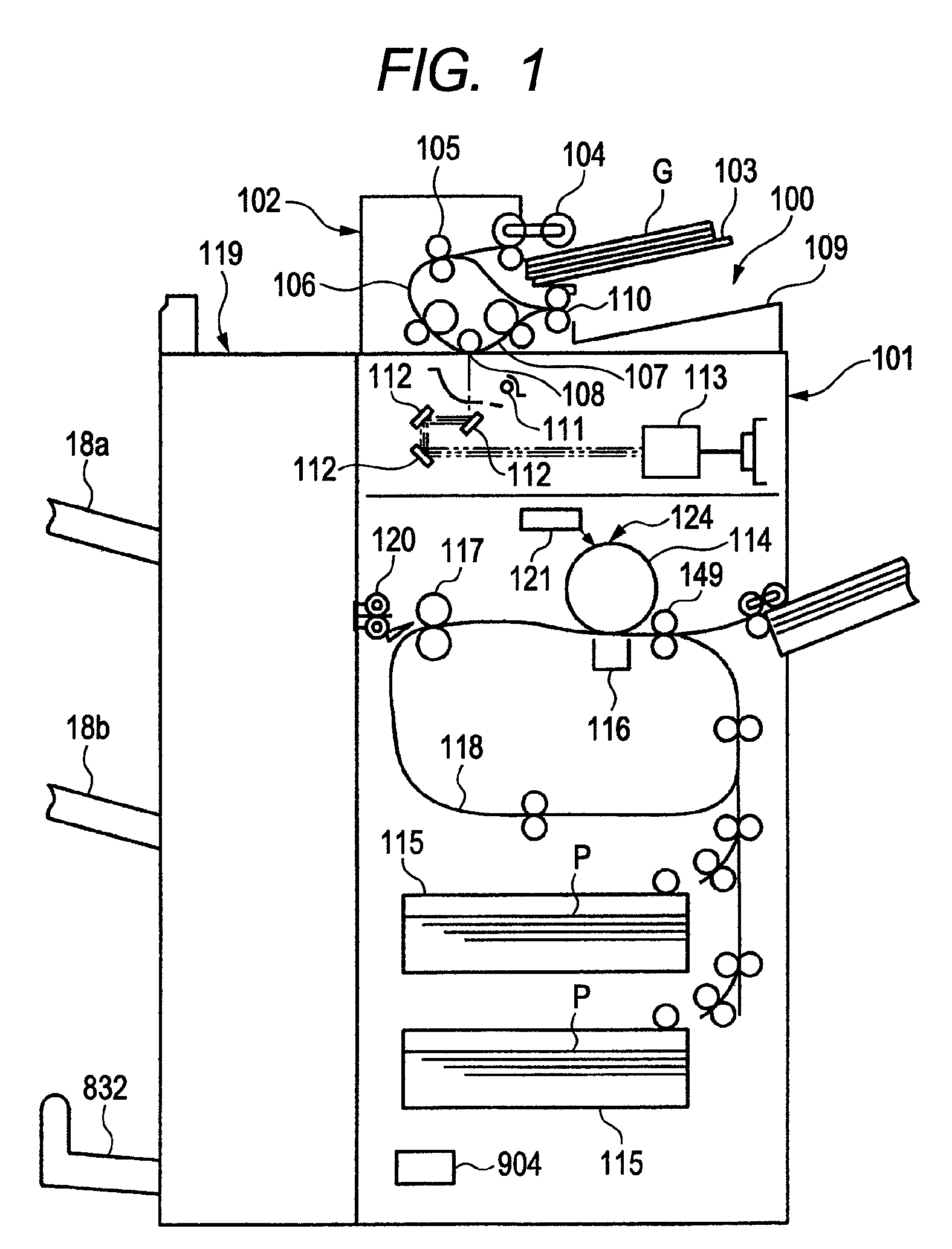

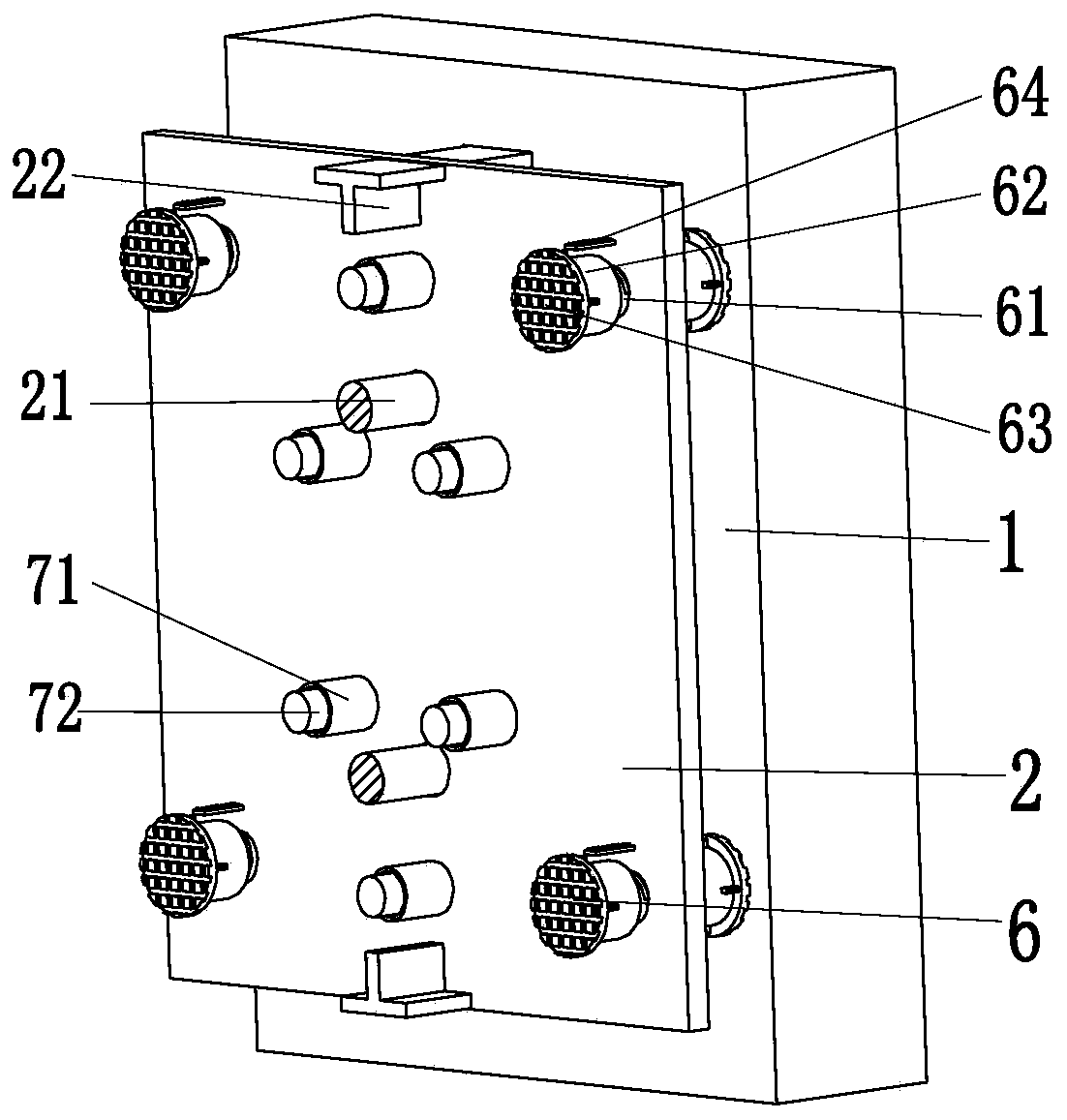

Printed circuit board (PCB) transmission system of selective crest welder capable of steadily transmitting

InactiveCN103100781ASmooth transmissionEasy width adjustmentPrinted circuit assemblingSoldering auxillary devicesEngineeringSprocket

Provided is a printed circuit board (PCB) transmission system of a selective crest welder capable of steadily transmitting. The PCB transmission system comprises a pair of supports with equal height, and a pair of slide rails which are placed in a parallel mode and fixed on the supports. Both ends of the pair of transmission guide rails are respectively arranged on a pair of slide rails through a sliding groove. One ends of the pair of transmission guide rails are fixed on the slide rails; the other ends of the transmission guide rails are capable of sliding on the slide rails. A transmission bracket is arranged on the transmission rails, transmission screw rods are respectively arranged at the outer ends of the pair of the transmission rails, and both ends of the pair of the transmission screw rods are fixedly arranged on a bearing of the transmission rails. Two guide rail screw rod fixing parts are arranged on the lower portion of a fixing end next to the pair of transmission rails. A transmission screw nut is sleeved on the transmission screw rods and is fixedly assembled with the transmission bracket. A chain wheel is arranged at a shaft end of the pair of the transmission screw rods next to a slidable end of the pair of transmission rails. The guide rail screw rods penetrate through the two guide rail screw rod fixing parts. The hand wheel is arranged at one end of each guide rail screw rod. The transmission system has the advantages of being simple in structure and steady in transmission, and the width is convenient to adjust.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

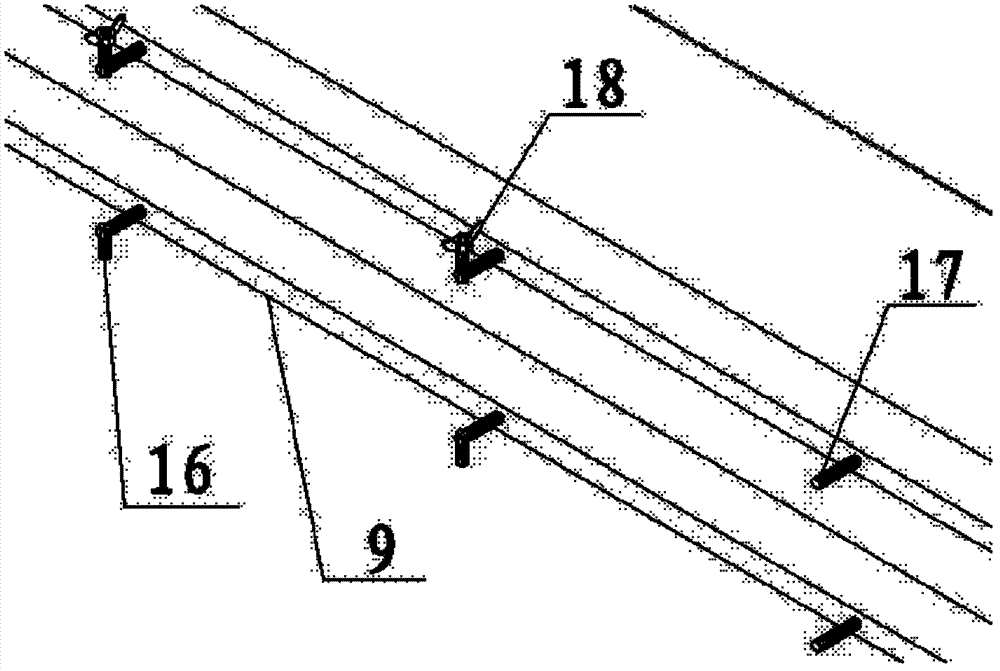

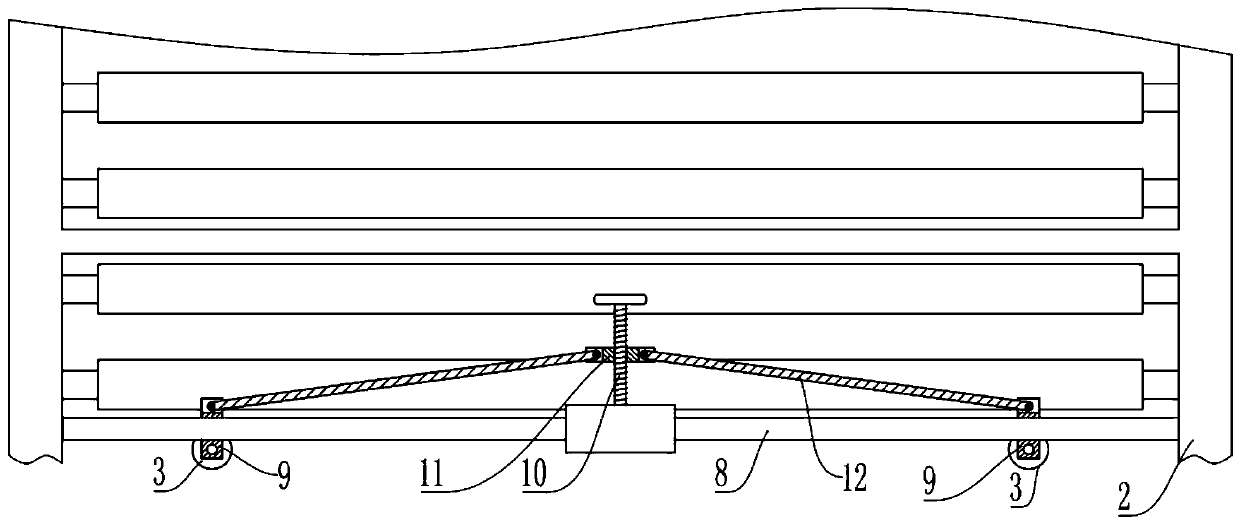

Inclination frame adjusting mechanism

The invention relates to the technical field of plastic thin film production, and particularly discloses an inclination frame adjusting mechanism. The mechanism comprises a rack and a herringbone plate, the herringbone plate comprises two opposite inclination frames, limiting rollers, a supporting frame, a width adjusting assembly and a driving assembly located on the rack are further included, the limiting rollers are located between the two inclination frames, sliding rods are arranged on the two inclination frames, the two ends of the limiting rollers are in sliding connection to the sliding rods on the two inclination frames, the two inclination frames are connected to the supporting frame, the driving assembly is used for driving the supporting frame to rotate, the width adjusting assembly is located between the two limiting rollers, the width adjusting assembly comprises a guide rod, a sliding base and two push rods, the guide rod is rotatably connected to one sliding rod, the sliding base is in sliding connection to the guide rod, one ends of the two push rods are rotatably connected to the sliding base, and the other ends of the two push rods are rotatably connected to thetwo limiting rollers. Through the scheme, the problem that in the prior art, bubbles are easily extruded to form by the herringbone plate, and the bubble thickness is not uniform is solved.

Owner:CHONGQING RUITING PLASTIC

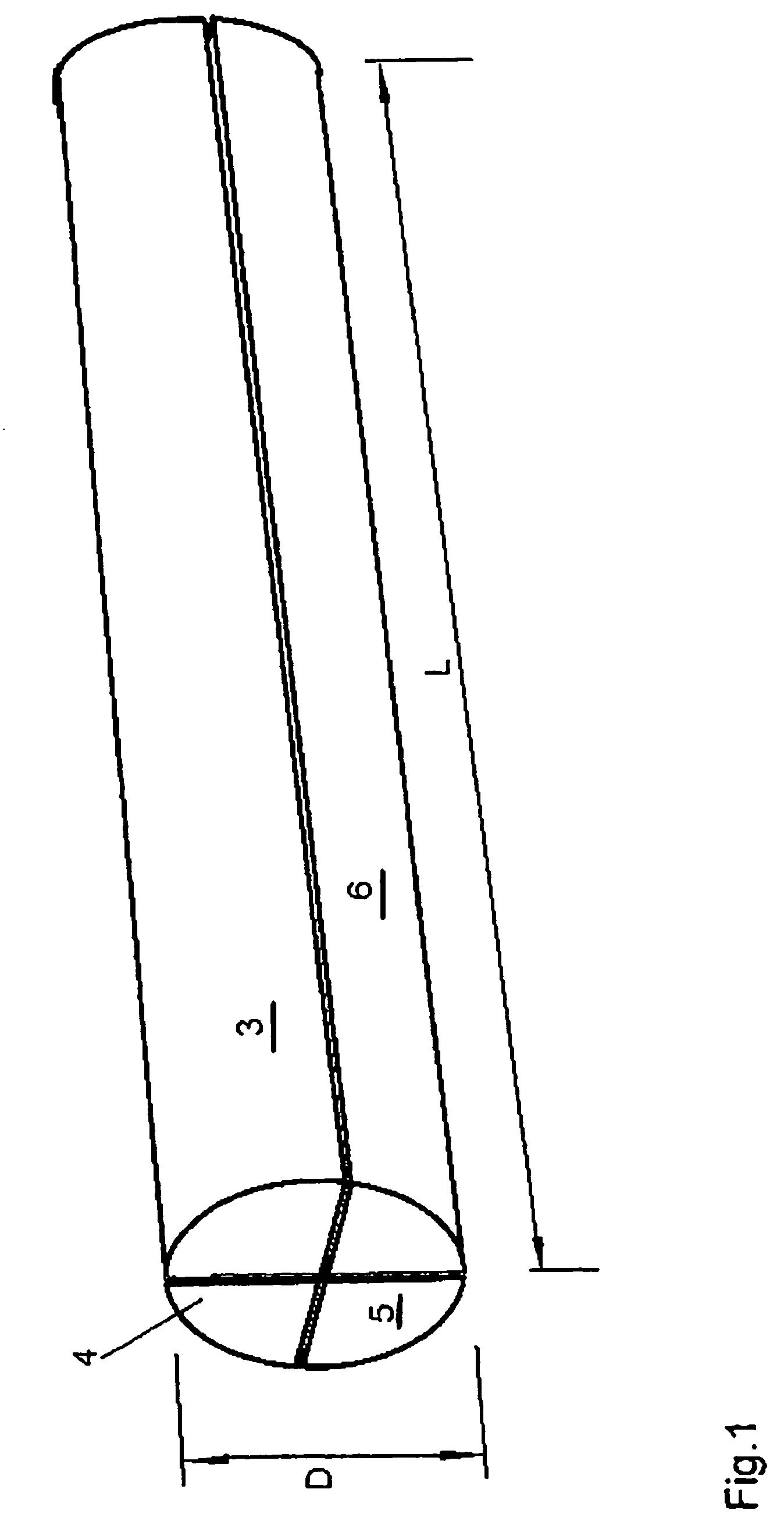

Low-cost and high-quality warp-knitted unidirectional fabric and production process thereof

ActiveCN107099927ACumulative error ensuresCumulative errors ensure that noWarp knittingPulp and paper industryWeft yarn

The invention discloses a low-cost and high-quality warp-knitted unidirectional fabric and a production process thereof. A multiaxial warp knitting machine is adopted. The production process comprises the following steps that 1, weft yarns are laid, wherein the weft yarns are laid in a weft yarn laying zone of the multiaxial warp knitting machine, and it is ensured that the separation distances of the weft yarns are equal; 2, weft insertion and binding are performed, wherein the laid weft yarns are conveyed to a warp knitting machine head of the multiaxial warp knitting machine, are compounded with 0-degree warp yarns and then are bound by binding yarns, it is limited that one weft yarn is inserted every one rotating circle of the machine head and is bound. By adopting the process, the weft yarns equal in separating distance can be produced, the unidirectional fabric with the independently bound weft yarns has a flat cloth cover and is flat and straight, the weft yarns can be rough yarns of 200 tex and 300 tex, the raw materials are relatively lower in price, and the fabric cost is lower. In addition, fabric width adjustment is more convenient, waste is relatively little, the cost can be also controlled through device change, and the process is smooth and stable in operation.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

Cutting machine for production of fabricated villa materials

The invention discloses a cutting machine for production of fabricated villa materials. The cutting machine comprises a cutting plate and a cutting rotary knife, width adjusting grooves are formed inthe end faces of the two sides of the cutting plate, and width adjusting sliding blocks are connected to the interiors of the width adjusting groove. Blade adjusting sliding grooves are formed in theouter sides of supporting frames. Blade adjusting sliding blocks are connected to the interiors of the blade adjusting sliding grooves, and a cutting support is connected to the end faces of one sidesof the blade adjusting sliding blocks. Limiting plates are arranged on the end faces of the two sides of the blade adjusting sliding grooves, limiting springs are connected to the inner surfaces of the limiting plates, and cutting sliding blocks are connected to the interiors of cutting sliding grooves. And a motor frame is fixed to the end faces of one sides of the cutting sliding blocks, a cutting motor is installed in the motor frame, and the cutting rotary knife is located on the end face of one side of the cutting motor. According to the cutting machine for production of the villa materials, the cutting rotary knife connected with the sliding motor frame can effectively move through the sliding motor frame, so that stable cutting is conducted, and the cutting precision is improved.

Owner:湖南吉人住宅工业股份有限公司

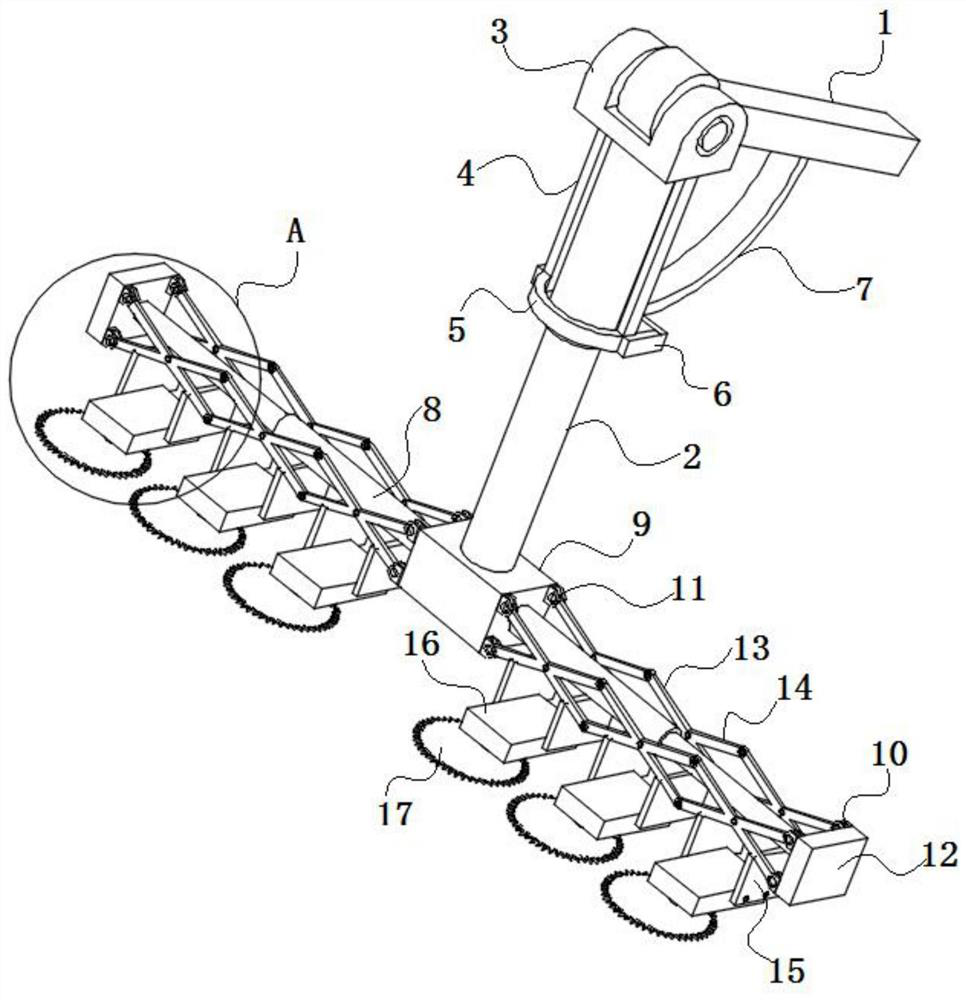

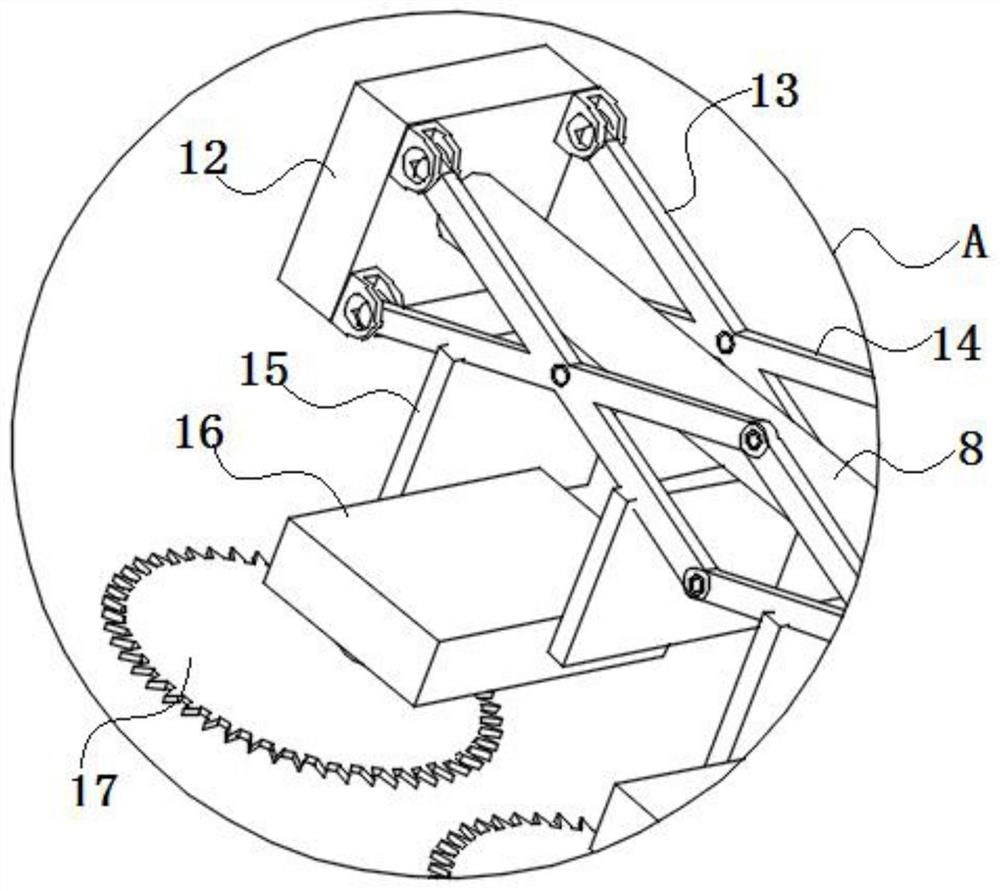

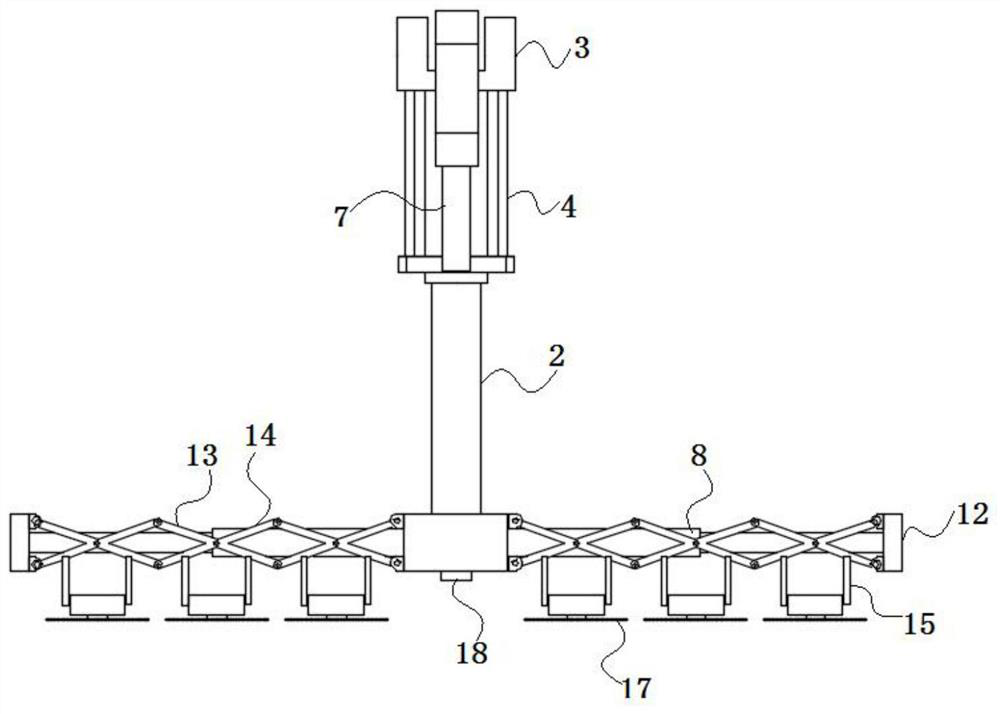

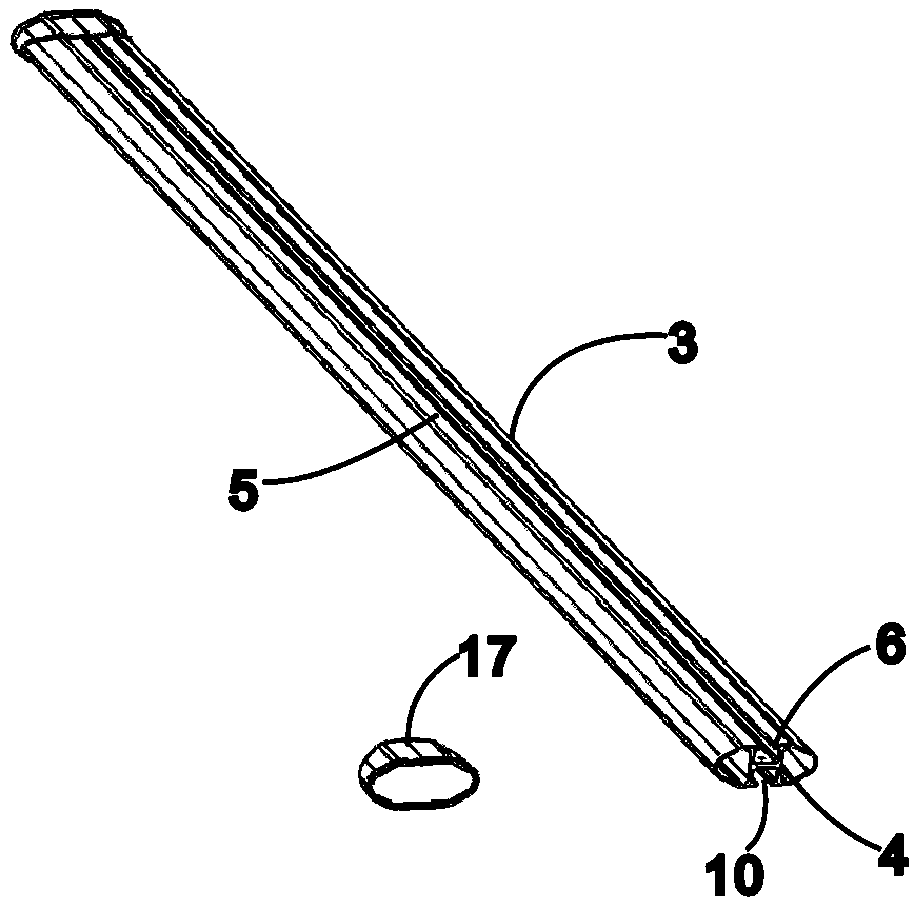

Floating root cutter assembly used on mint harvester

InactiveCN112425359AImprove adaptabilityEasy width adjustmentMowersAgricultural engineeringKnife blades

The invention discloses a floating root cutter assembly used on a mint harvester, and relates to the technical field of cutters. The floating root cutter assembly comprises a first connecting rod, a first connecting block, a first telescopic rod, a second connecting block, a second telescopic rod, a contraction mechanism, a cutting device and a distance measuring device; one end of the first telescopic rod is fixedly connected with the first connecting block; the other end of the first telescopic rod is fixedly connected with the first connecting block; and the cutting device comprises a horizontal plate and a cutting blade. By arranging the first connecting rod, the first connecting block and the first telescopic rod, the height of the cutting device of the harvester is more convenient toadjust, and mint roots are prevented from being damaged during cutting; and the second connecting block, the second telescopic rod, the contraction mechanism and the cutting device are arranged, so that the width of the cutting device is adjusted more flexibly, the cutting device can adapt to harvesting operation in different planting areas, and the adaptability of the harvester is improved.

Owner:界首市永银种植专业合作社

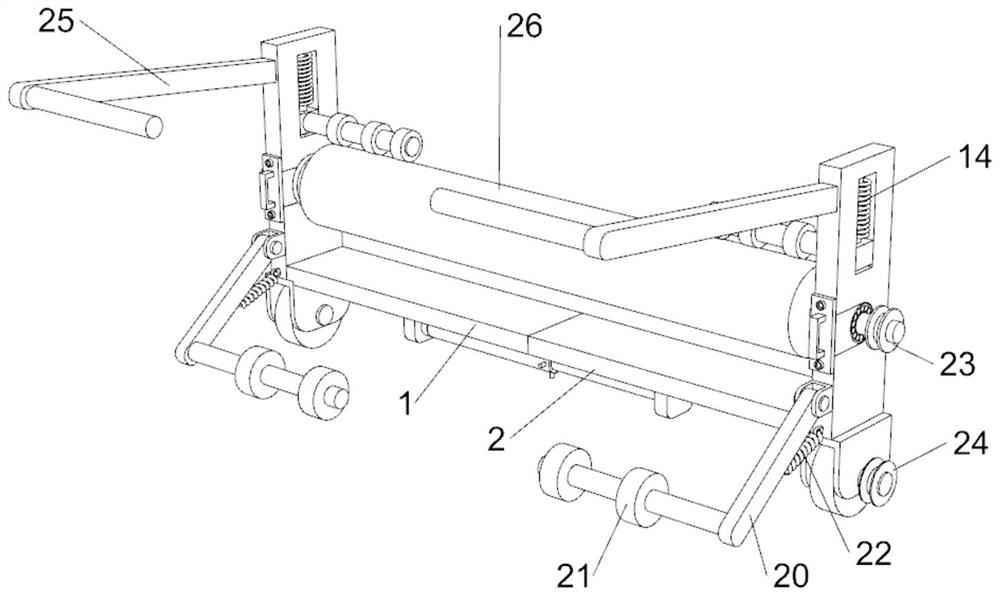

Concrete curing device of double-layer water retention system and construction method

PendingCN114232436AEasy to layEasy to operateRoads maintainenceArchitectural engineeringSupport plane

The invention discloses a concrete curing device of a double-layer water retention system and a construction method.The concrete curing device comprises a first supporting frame and a second supporting frame, the second supporting frame is installed on the first supporting frame in an inserted mode, width adjusting assemblies are installed at the bottoms of the first supporting frame and the second supporting frame, and installation grooves are formed in the first supporting frame and the second supporting frame; a first supporting shaft rod and a second supporting shaft rod are arranged on the first supporting frame and the second supporting frame, the first supporting shaft rod and the second supporting shaft rod are installed in an inserted mode, bearings are installed at the ends of the first supporting shaft rod and the second supporting shaft rod, and the bearings are installed in the installation grooves and fixed through fixing plates. The first supporting shaft rod and the second supporting shaft rod are arranged on the first supporting frame and the second supporting frame, the film barrel is installed on the first supporting shaft rod and the second supporting shaft rod, a film is conveniently laid on the concrete ground, operation is convenient and easy, the traditional mode that a user spreads the film with hands is replaced, and the laying efficiency is improved.

Owner:CHINA CONSTR EIGHTH ENG DIV

Packing machine membrane arrangement equipment

InactiveCN107813998AGuaranteed continuityImprove film release efficiencyWrapping material feeding apparatusSupport pointIndustrial engineering

The invention discloses packing machine membrane arrangement equipment and belongs to the technical field of packing equipment. The packing machine membrane arrangement equipment comprises a support and a membrane passing roller. The packing machine membrane arrangement equipment is characterized in that the support comprises a first seat plate, a second seat plate, a first supporting plate, a second supporting plate and a supporting point shaft connected between the first supporting plate and the second supporting plate; the first supporting plate is fixed to the first seat plate, and the second supporting plate is fixed to the second seat plate; one end of the membrane passing roller is connected with the first seat plate, and the other end of the membrane passing roller is connected with the second seat plate; a first carrier roller and a second carrier roller are arranged between the first seat plate and the second seat plate side by side; and the supporting point shaft is providedwith a swing arm, the swing arm is fixedly provided with a servo motor, and the servo motor is connected with an active glue wrapping wheel. By means of the packing machine membrane arrangement equipment, a winding drum package membrane is quite convenient to replace, time and labor are saved, membrane arrangement stability is good, and membrane arrangement efficiency and quality can be effectively improved.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

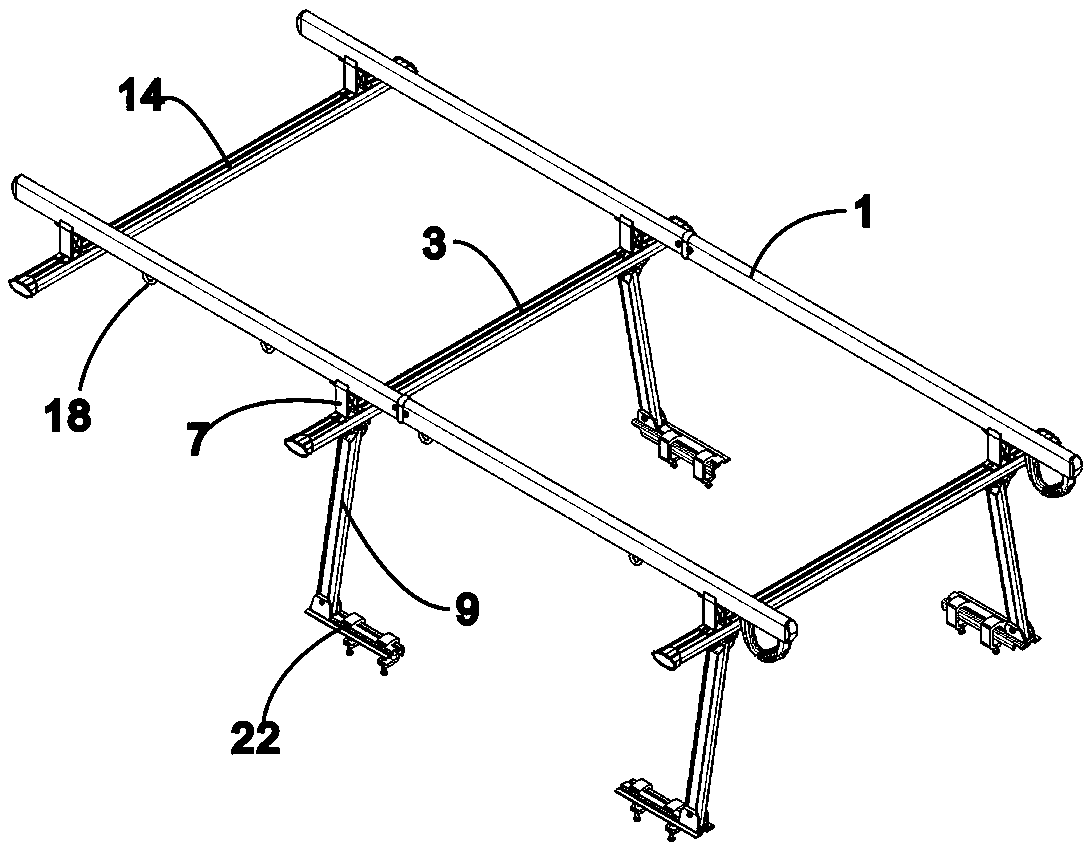

Vehicle shelf

PendingCN110171491AEasy width adjustmentEasy to adjustLoad securingTransportation itemsStructural engineeringEngineering

The invention provides a vehicle shelf. The vehicle shelf comprises beams, fixing rods, moving frames, supporting frames, fixing seats, rope fixing buckles and connecting seats, wherein the beams andthe fixing rods are two, the two beams are oppositely placed, and meanwhile, the two fixing rods which are located at the bottom of the two beams and the beams are arranged in a cross mode. The connecting seats are used for connecting the beams and the fixing rods, through the cooperation of bolts, bolt connecting parts and clamping plates, the connecting seats can move along sliding grooves of the beams and upper sliding grooves I of the fixing rods, the connecting seats can further be fixed at the same time; the two supporting frames are further fixed to the bottom of each of the fixing rods, the tops of the supporting frames can move along lower sliding grooves I of the fixing rods by the cooperation of the bolts, the bolt connecting parts and the clamping plates and can further be fixed at the same time; the bottoms of the supporting frames are supplied for fixing the fixing seats; and the moving frames are fixed to the two beams, the moving frames can move back and forth along thebeams and can further be fixed at the same time. Of course, the rope fixing buckles can further move along the sliding grooves at the bottoms of the beams and can be fixed.

Owner:FORCOME ZHEJIANG CO LTD

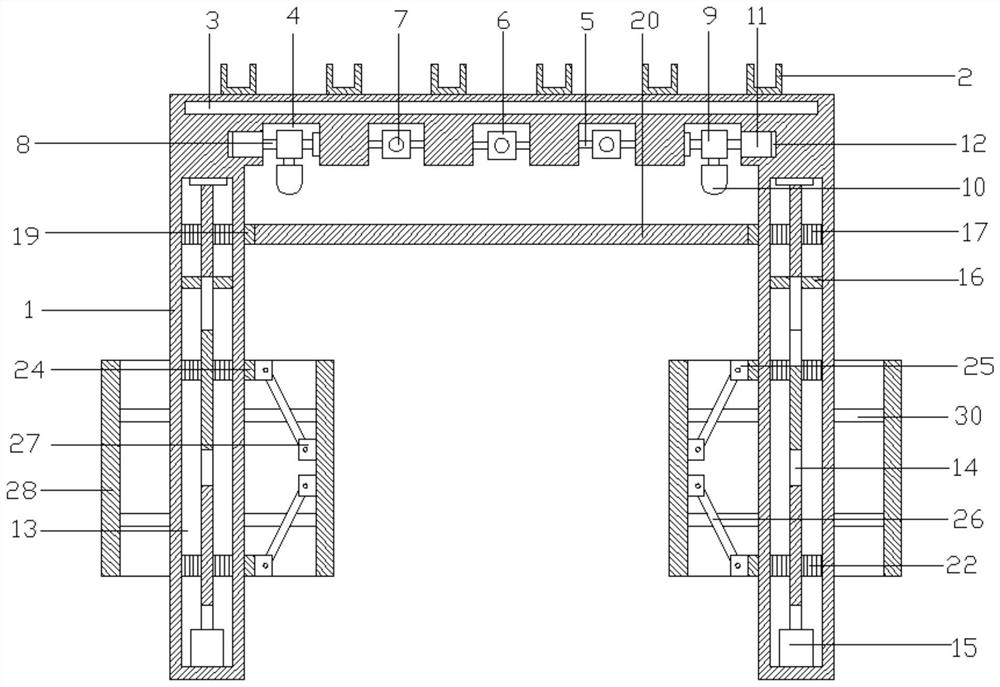

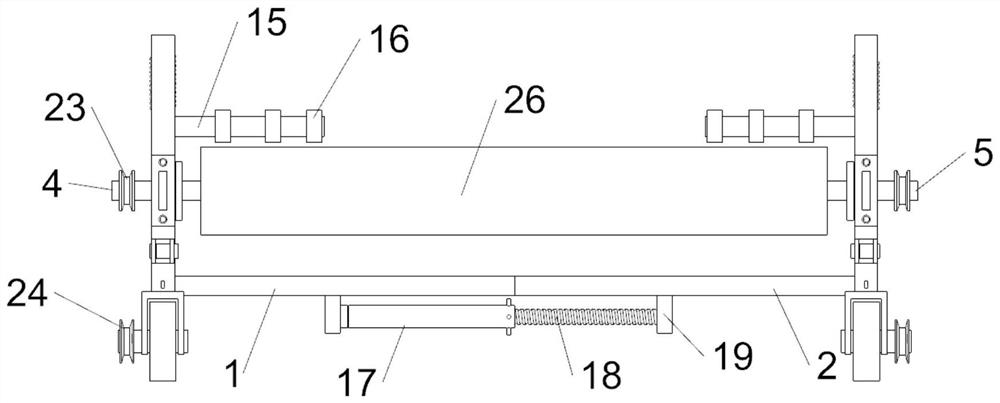

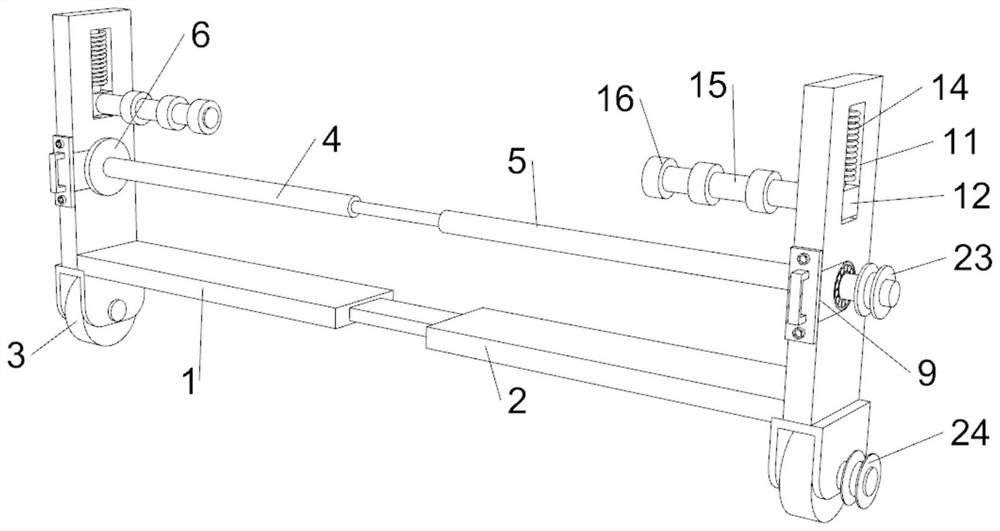

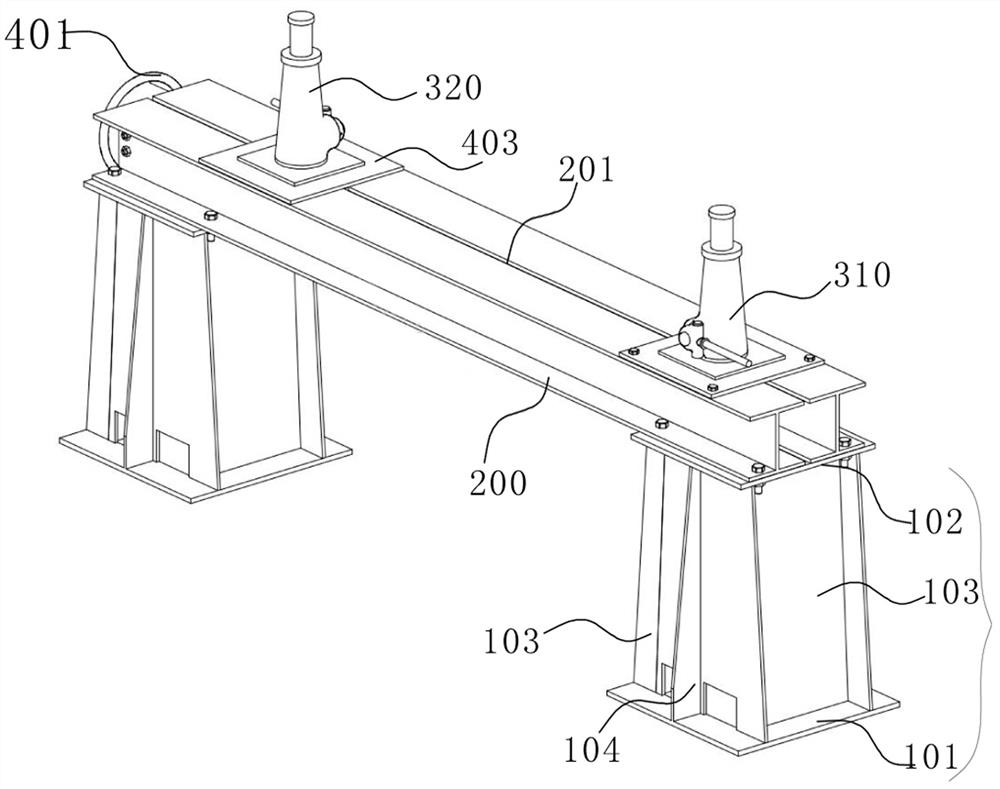

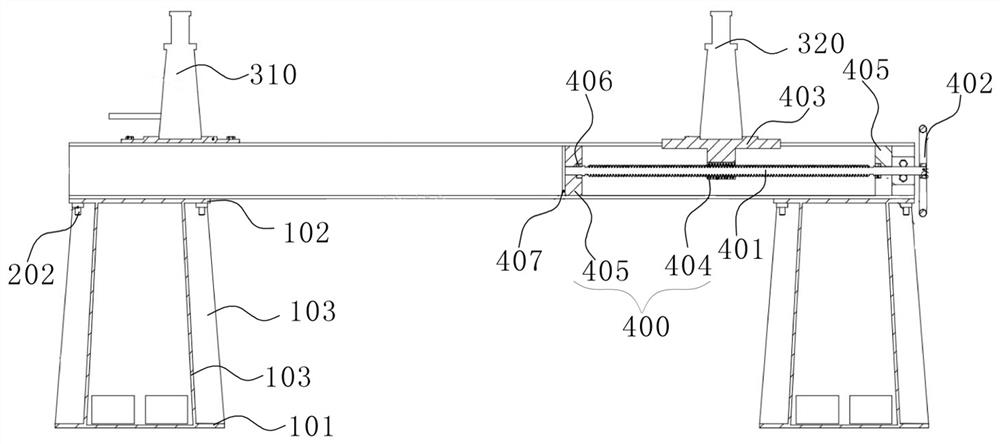

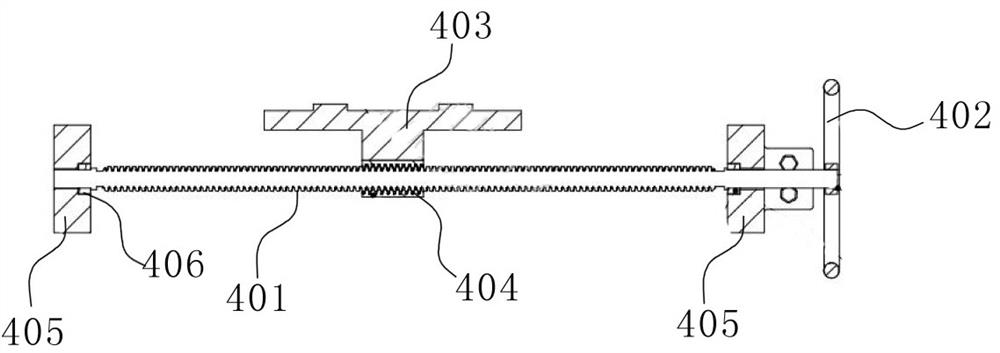

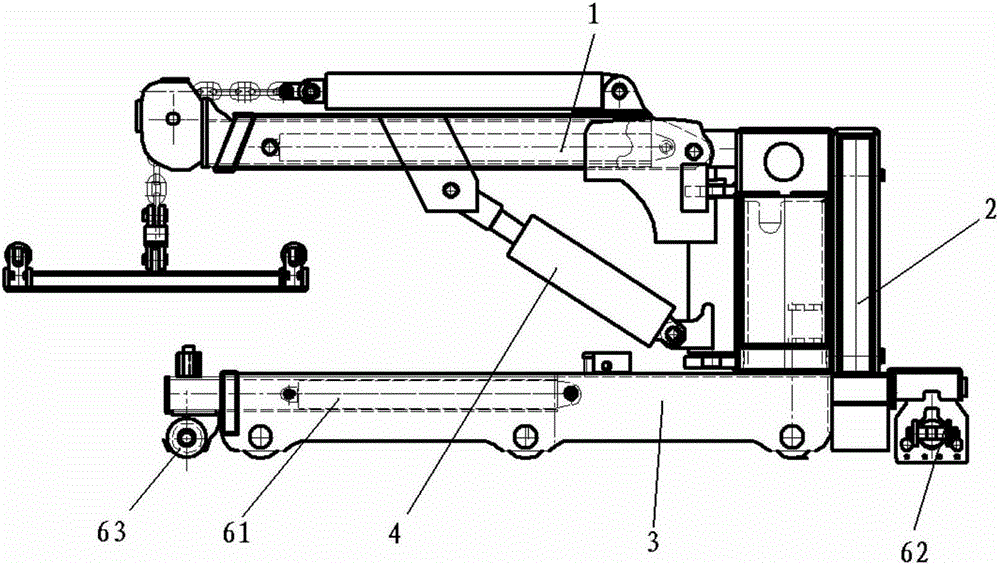

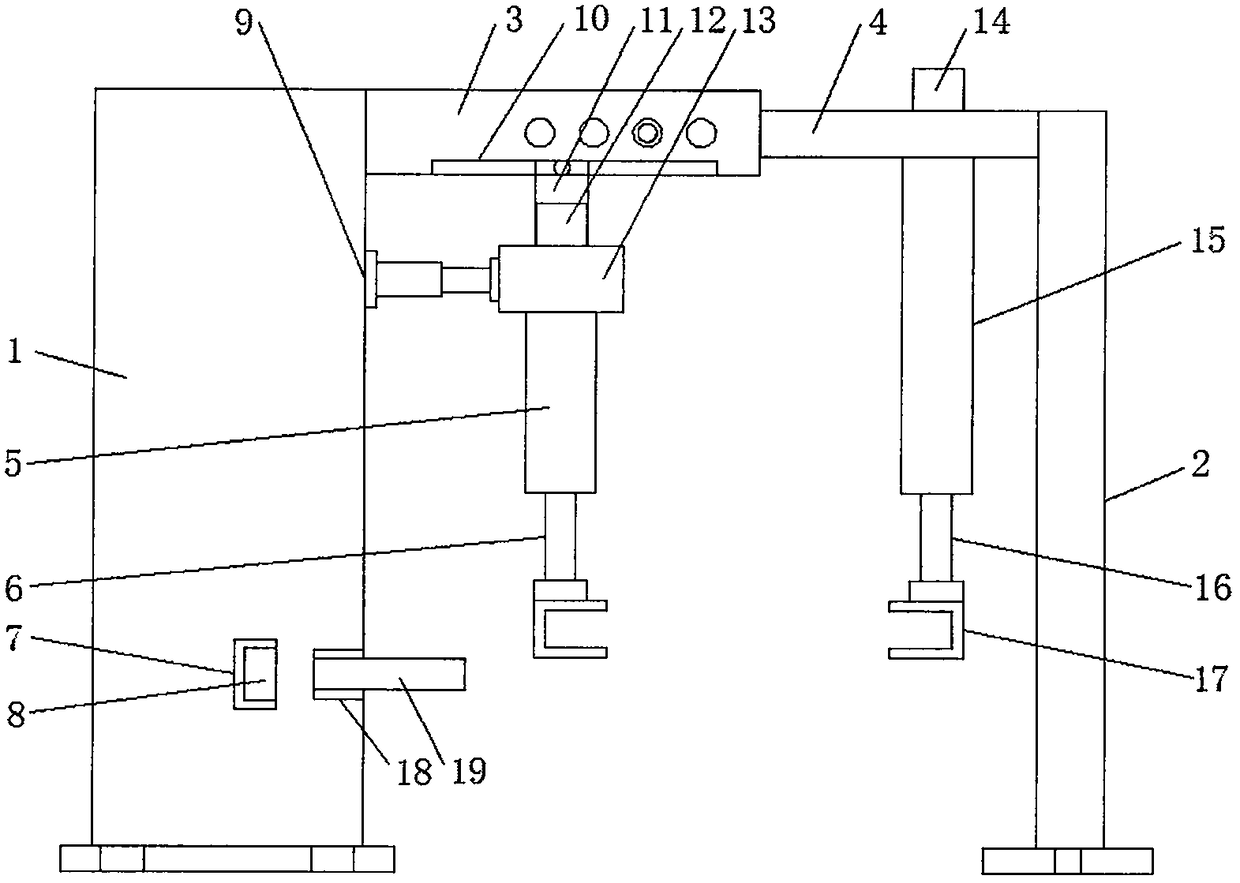

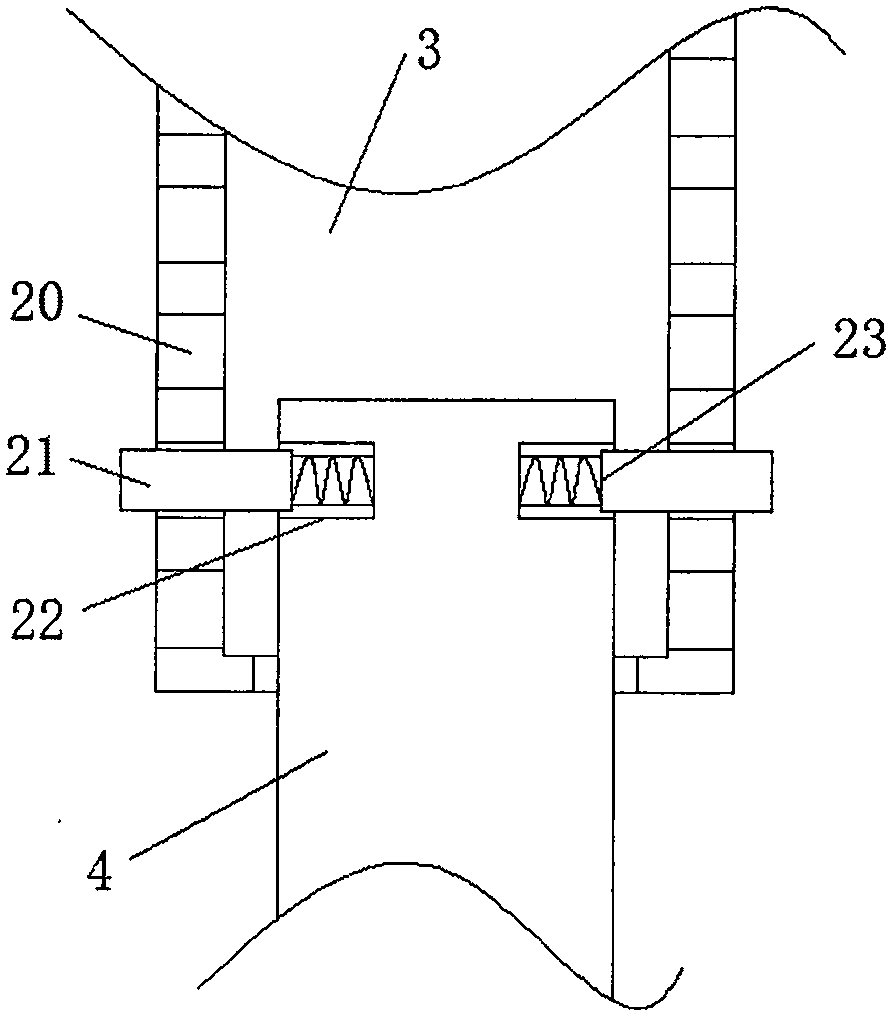

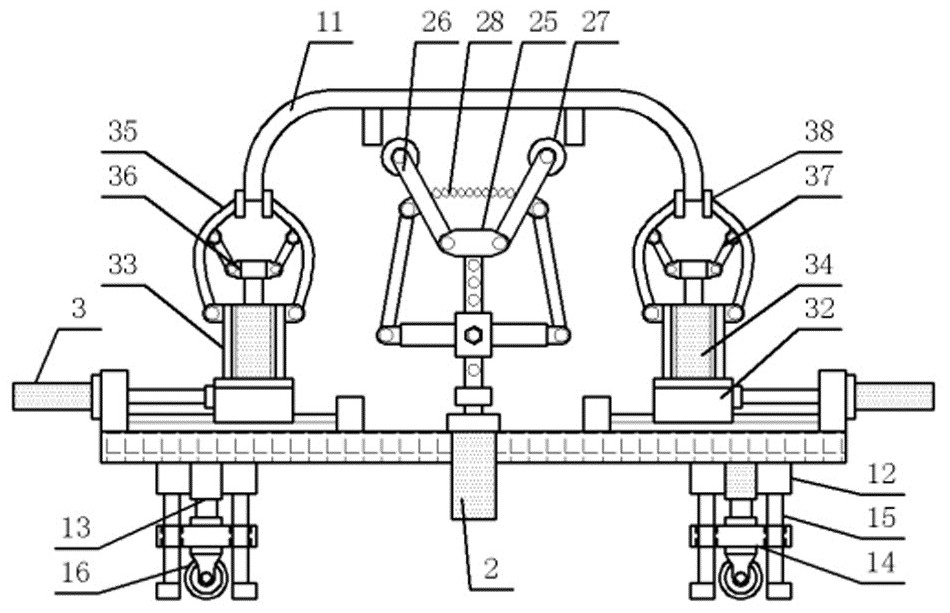

Width-adjustable rail engineering truck body unwheeling platform

The invention belongs to the technical field of rail engineering truck body steel structure unwheeling. The width-adjustable rail engineering truck body unwheeling platform comprises two unwheeling piers, a cross beam, a first hydraulic jack, a second hydraulic jack and a transverse movement adjusting unit, wherein the two unwheeling piers are correspondingly arranged left and right. The two ends of the cross beam are fixedly arranged on the two unwheeling piers respectively. The first hydraulic jack is arranged at the first end part of the cross beam. The second hydraulic jack is arranged at the second end part of the cross beam. The transverse movement adjusting unit is arranged between at least one of the first hydraulic jack and the second hydraulic jack and the cross beam, and the transverse movement adjusting unit adjusts the position of the first hydraulic jack or / and the second hydraulic jack on the cross beam. The overall structural design is reasonable, the structural stability is high, the width adjustment is made more convenient, the practicability is high in the operations of rail engineering trucks and the adjustment is made convenient.

Owner:CRRC LUOYANG CO LTD

Strawberry Picking Robot

The invention relates to a strawberry picking robot. The strawberry picking robot is designed for solving the technical problem of the existing like products that grabbing mode structures and structures of machine frames and the like are not good enough in design. A framework of the picking robot is a cubical aluminum-profile framework composed of aluminum profiles, a framework bottom plate of thealuminum-profile framework is provided with a traveling crawler, an actuating mechanism which separately drives three-dimensional traveling through an axial motor is arranged in the aluminum-profileframework, and a mechanical claw is arranged at the tail end of an X-axis direction of the actuating mechanism; a collet supporting seat is arranged at one end of an X-axis bottom plate of the actuating mechanism, a mechanical claw is arranged at the bottom of the collet supporting seat, a cutter blade is arranged at one end of a movable collet of the mechanical claw, the collet supporting seat atthe symmetrical opposite side of the movable collet is provided with a fixed collet, the other end of the movable collet is hinged to the collet supporting seat through a pin shaft and can swing, a camera and a sensor are arranged just above the mechanical claw, a collecting string bag or manipulator collection box is arranged just below the cutter blade of the mechanical claw, and a box groove of the manipulator collection box is driven through a rotating motor to achieve the opening and closing of a hinge mode.

Owner:芮杰

Tilt frame adjustment mechanism

The invention relates to the technical field of plastic film production, and specifically discloses a tilting frame adjustment mechanism, including a frame and a herringbone board. The drive assembly on the frame, the limit roller is located between two inclined frames, and the two inclined frames are equipped with slide bars, and the two ends of the limit roller are respectively slidably connected to the slide bars of the two inclined frames; the two inclined The frames are all connected to the support frame, and the drive assembly is used to drive the support frame to rotate; the width adjustment assembly is located between the two limit rollers, and the width adjustment assembly includes a guide rod, a sliding seat and two push rods, and the guide rod is rotatably connected to it On one slide bar, the slide seat is slidably connected to the guide rod, one ends of the two push rods are both rotatably connected to the slide seat, and the other ends of the two push rods are respectively rotatably connected to the two limit rollers. This solution is used to solve the problems in the prior art that the bubbles are easily squeezed and deformed by the herringbone plate and the thickness of the bubbles is not uniform.

Owner:CHONGQING RUITING PLASTIC

Warp-knitted unidirectional fabric and its production process

The invention discloses a low-cost and high-quality warp-knitted unidirectional fabric and a production process thereof. A multiaxial warp knitting machine is adopted. The production process comprises the following steps that 1, weft yarns are laid, wherein the weft yarns are laid in a weft yarn laying zone of the multiaxial warp knitting machine, and it is ensured that the separation distances of the weft yarns are equal; 2, weft insertion and binding are performed, wherein the laid weft yarns are conveyed to a warp knitting machine head of the multiaxial warp knitting machine, are compounded with 0-degree warp yarns and then are bound by binding yarns, it is limited that one weft yarn is inserted every one rotating circle of the machine head and is bound. By adopting the process, the weft yarns equal in separating distance can be produced, the unidirectional fabric with the independently bound weft yarns has a flat cloth cover and is flat and straight, the weft yarns can be rough yarns of 200 tex and 300 tex, the raw materials are relatively lower in price, and the fabric cost is lower. In addition, fabric width adjustment is more convenient, waste is relatively little, the cost can be also controlled through device change, and the process is smooth and stable in operation.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

A middle tank hydraulic crane

ActiveCN103588105BEasy width adjustmentReduce horizontal sizeCranesPulp and paper industryTelescopic cylinder

The invention discloses a hydraulic crane for a middle trough. The hydraulic crane comprises frames, a crane jib, a crane jib liftingoil cylinder, a crane jib rotating oil cylinder and the like, wherein a supporting device is arranged on the two sides of each frame, a telescopic device is arranged between the frames on the two sides and comprises a frame telescopic cylinder at the bottom of the frame and a telescopic beam at the upper part of the frame. The hydraulic crane for the middle trough has the advantages that the horizontal size of the hydraulic crane for the middle trough is greatly reduced, so that the hydraulic crane for the middle trough can be conveniently transported on the ground and underground, the dismounting procedure is canceled, and the production efficiency is greatly improved. As a supporting structure is added, the stability of the crane is guaranteed when the middle trough is lifted; in addition, as the frame telescopic cylinder is connected with the frames through pin shafts, the frame telescopic cylinder is conveniently dismounted when the crane works, so that the workload is greatly reduced, and the efficiency is improved by several times.

Owner:LIAONING XINFENG MINE IND GRP CO LTD

A plate loading and unloading device for a plasma cutting machine

InactiveCN106925873BIncrease productivityEasy to adjustPlasma welding apparatusEngineeringPlasma cutting

The invention discloses a panel loading and unloading device for a plasma cutting machine. The panel loading and unloading device comprises a device body and an adjusting seat arranged on one side of the device body. The device body and the adjusting seat are mounted on the two sides of the top of the plasma cutting machine through screws correspondingly. The tops of the sides, close to each other, of the device body and the adjusting seat are connected with a supporting plate and an adjusting plate correspondingly. The supporting plate is of a cavity structure. The two sides of the supporting plate are provided with adjusting holes arranged linearly. The two sides, close to the supporting plate, of the adjusting plate are both provided with fixing grooves. The inner walls of the fixing grooves are fixedly connected with spring pillars. The ends, far from the adjusting plate, of the spring pillars are connected with adjusting levers. The bottom end of the supporting plate is provided with a sliding groove. A sliding rod is connected into the sliding groove in a sliding mode. The bottom end of the sliding rod is provided with a fixed plate. The panel loading and unloading device is reasonable in design and facilitates loading and unloading. The width of the whole device can be adjusted conveniently according to the width of a working table of the plasma cutting machine. The manual operation cost is reduced. The production efficiency of panels is effectively improved.

Owner:ZHEJIANG JINYUAN IND CO LTD

Tooling for processing intelligent carbon skateboard with multi-point limit clamping and its application method

The invention discloses a tooling for processing intelligent carbon skateboards with multi-point limit clamping, including a bottom plate, four corners of the bottom surface of the bottom plate are provided with bases, and the telescopic cylinders of each first telescopic cylinder are movably connected with rollers through sliding components; The ends of the telescopic cylinders of the two telescopic cylinders are equipped with a second connecting rod, and a connecting rod mechanism is set on the second sliding rod; rectangular block-shaped fixing seats are arranged on both sides of the top surface of the bottom plate, and the telescopic movement of each sliding telescopic cylinder The ends of the rods are all provided with sliding connecting blocks, and the outer surface of each sliding connecting block is fixedly connected with the sliding plate on the same side, and the top surface of each sliding plate is provided with a clamping mechanism. The invention also discloses the use method of the tooling for intelligent carbon skateboard processing with multi-point limit clamping; the invention designs a complete set of tooling structure so that it can meet the processing requirements of carbon skateboards with different sizes, is convenient for disassembly and assembly, and can adapt to The structure of different heights increases the convenience of tooling movement, improves the stability and work efficiency during use.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

A hybrid integrated circuit fixed structure for rotary vacuum vapor phase cleaning

ActiveCN112911827BEasy to placeImprove stabilityPrinted circuit assemblingConductive pattern polishing/cleaningHemt circuitsVapor phase

The invention provides a hybrid integrated circuit fixing structure for rotary vacuum vapor phase cleaning. Several beams are fixedly arranged on the frame body. The two sides are placed on the beam wall of the adjacent beam, and the inside of the circuit shell is exposed to the outside, which is convenient for vacuum vapor phase cleaning in the circuit shell. On both sides of the top of the circuit housing, the stability of the circuit housing on the beam is improved, effectively avoiding the problem of circuit fixing during vacuum vapor phase cleaning, and ensuring the stability of the hybrid integrated circuit when rotating during vacuum vapor phase cleaning sex.

Owner:XIAN MICROELECTRONICS TECH INST

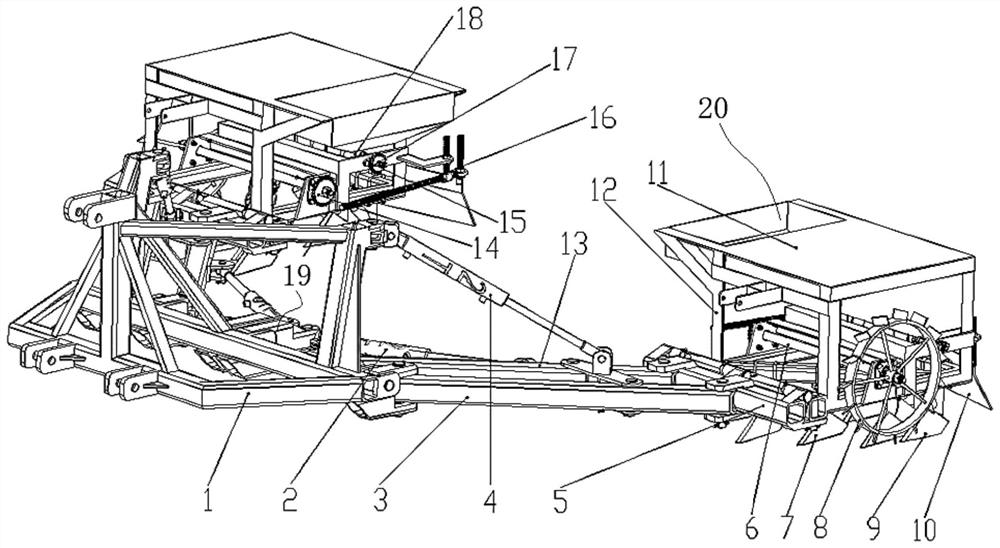

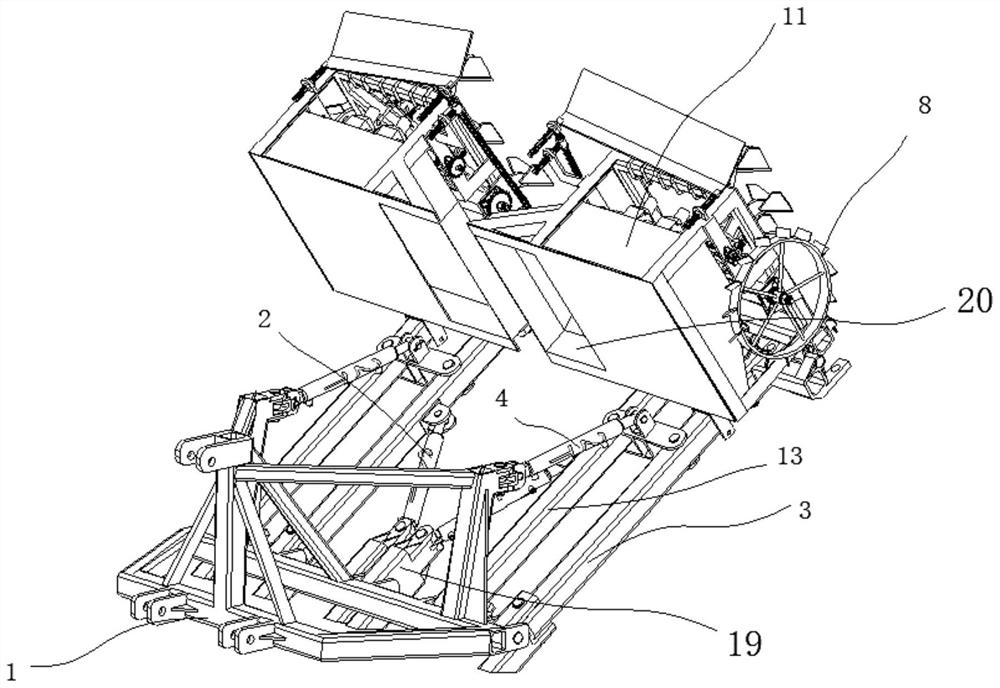

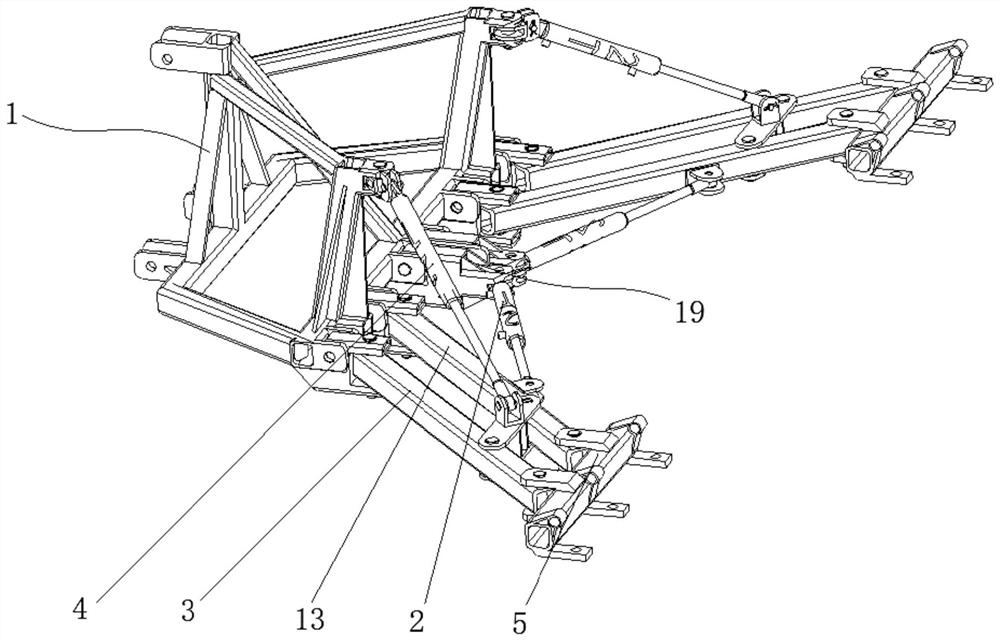

Hydraulic contraction type orchard fertilizer applicator

PendingCN114097383AHigh structural reliabilityImprove fertilization efficiencySpadesFertiliser distributersFruit treeHydraulic cylinder

The invention relates to the field of agricultural machinery, and provides a hydraulic retractable orchard fertilizer applicator, the left end and the right end of a front suspension main body rack are respectively provided with a fertilizer application assembly, the two fertilizer application assemblies can fertilize multiple rows of fruit trees at a time, and the width of the two fertilizer application assemblies is respectively adjusted through a width adjusting hydraulic cylinder; the front suspension main body rack is provided with a hydraulic fixing seat, one ends of two width adjusting hydraulic cylinders are hinged to the hydraulic fixing seat, and the other ends of the two width adjusting hydraulic cylinders are assembled on the two fertilizing assemblies respectively; the fruit tree fertilizing device is simple in structure and convenient to operate, effectively integrates traditional fertilizing procedures, has a width adjusting function, is simple in structure, can be used for fertilizing two rows of fruit trees at a time, is suitable for orchards with various line spacings, and greatly improves the fertilizing efficiency.

Owner:EASTERN GANSU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com